Rockwell Automation 25-COMM-D User Manual

User Manual

PowerFlex 525 DeviceNet Adapter

Catalog Number: 25-COMM-D

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/) describes some important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Automation, Rockwell Software, PowerFlex, Studio 5000 and Connected Components Workbench are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

|

Table of Contents |

|

|

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

Preface |

|

Overview |

Recommended Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

Chapter 1 |

|

Getting Started |

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

Understanding Parameter Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

Compatible Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

Chapter 2 |

|

Installing the Adapter |

Preparing for an Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

Commissioning the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

Connecting the Adapter to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

Connecting the Adapter to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

Chapter 3 |

|

Configuring the Adapter |

Configuration Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

Using the Drive Keypad Interface to Access Parameters . . . . . . . . . . . . . |

23 |

|

Using the PowerFlex 4-Class HIM to Access Parameters. . . . . . . . . . . . . |

25 |

|

Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

Setting the Data Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

Setting the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

Using Master-Slave Hierarchy (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

Selecting COS, Cyclic, or Polled I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

Setting a Fault Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

Resetting the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

Restoring Adapter Parameters to Factory Defaults . . . . . . . . . . . . . . . . . . |

30 |

|

Viewing the Adapter Status Using Parameters . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Updating the Adapter Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Chapter 4 |

|

Configuring the I/O |

Using RSLinx Classic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

CompactLogix Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

Chapter 5 |

|

Using the I/O |

About I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

3 |

Table of Contents |

|

|

|

Understanding the I/O Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

Using Logic Command/Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

Using Reference/Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

Using Datalinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

Example Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

CompactLogix Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Chapter 6 |

|

Using Explicit Messaging |

About Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

|

Performing Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

CompactLogix Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

Chapter 7 |

|

Using Multi-Drive Mode |

Single-Drive Mode vs. Multi-Drive Mode . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Understanding the I/O Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Configuring the RS-485 Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

|

Multi-Drive Ladder Logic Program Example . . . . . . . . . . . . . . . . . . . . . . . |

73 |

|

CompactLogix Example Using Generic Profile . . . . . . . . . . . . . . . . . . . . . |

74 |

|

Multi-Drive Mode Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

|

Chapter 8 |

|

Troubleshooting |

Understanding the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

|

PORT Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

MOD Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

NET A Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Viewing Adapter Diagnostic Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Viewing and Clearing Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Appendix A |

|

Specifications |

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

Appendix B |

|

Adapter Parameters |

Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

|

Appendix C |

|

DeviceNet Objects |

Supported Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

Identity Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

|

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

100 |

4 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

|

|

Table of Contents |

|

Connection Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 101 |

|

Register Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 103 |

|

Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 106 |

|

Parameter Group Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 109 |

|

PCCC Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 111 |

|

DPI Device Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 114 |

|

DPI Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 117 |

|

DPI Fault Object. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 123 |

|

DPI Diagnostic Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 125 |

|

Appendix D |

|

Logic Command/Status Words: |

Logic Command Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 127 |

PowerFlex 525 Drives |

Logic Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 128 |

|

Glossary |

|

Index |

|

|

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

5 |

Table of Contents

Notes:

6 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Preface

Recommended

Documentation

Overview

For information on… |

See page… |

Recommended Documentation |

7 |

|

|

Manual Conventions |

7 |

|

|

All the recommended documentation listed in this section is available online at http://www.rockwellautomation.com/literature.

The following publications provide additional information:

For... |

See... |

Publication |

|

|

|

DeviceNet |

DeviceNet Network Configuration User Manual |

DNET-UM004 |

|

|

|

|

DeviceNet Media Design Installation Guide |

DNET-UM072 |

|

|

|

|

DeviceNet Starter Kit User Manual |

DNET-UM003 |

|

|

|

PowerFlex®520-Series Drives |

PowerFlex 525 Adjustable Frequency AC Drive User Manual |

520-UM001 |

|

|

|

RSLinx® Classic |

RSLinx Classic Getting Results Guide |

LINX-GR001 |

|

|

|

RSNetWorx for DeviceNet |

Getting Results with RSNetWorx for DeviceNet |

DNET-GR001 |

|

|

|

RSLogix™ 5000 |

RSLogix 5000 online help(1) |

– |

CompactLogix™ 5370 |

CompactLogix 5370 Controllers User Manual (1769-L36ERM) |

1769-UM021 |

|

|

|

MicroLogix™ 1100 |

MicroLogix 1100 Programmable Controllers User Manual |

1763-UM001 |

|

|

|

MicroLogix™ 1400 |

MicroLogix 1400 Programmable Controllers User Manual |

1766-UM001 |

|

|

|

Connected Components |

Website containing information on the Connected Components |

http:// |

Workbench |

Workbench software tool, and includes a link for free software |

www.ab.com/ |

|

download. |

support/ |

|

|

abdrives/ |

|

|

webupdate/ |

|

|

software.html |

|

Connected Components Workbench online help(2) |

– |

(1) The online help is installed with the software.

Manual Conventions

This manual provides information about the DeviceNet adapter and using it with PowerFlex 525 drives for network communication.

The following conventions are used throughout this manual:

•Parameter names are shown in the format axxx [*]. The a represents the parameter group. The xxx represents the parameter number. The * represents the parameter name— for example C175 [DSI I/O Cfg].

•Menu commands are shown in bold type face and follow the format Menu > Command. For example, if you read “Select File > Open,” you should click the File menu and then click the Open command.

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

7 |

Preface Overview

•RSLinx Classic (version 2.51), RSNetWorx for DeviceNet (version 21), and RSLogix 5000 (version 20) were used for the screen captures in this manual. Different versions of the software may differ in appearance and procedures.

•The Studio 5000™ Engineering and Design Environment combines engineering and design elements into a common environment. The first element in the Studio 5000 environment is the Logix Designer application. The Logix Designer application is the rebranding of RSLogix 5000 software and will continue to be the product to program Logix 5000 controllers for discrete, process, batch, motion, safety, and drive-based solutions. The Studio 5000 environment is the foundation for the future of Rockwell Automation engineering design tools and capabilities. It is the one place for design engineers to develop all the elements of their control system.

8 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Chapter 1

Getting Started

Components

The DeviceNet adapter is a communication option intended for installation into a PowerFlex 525 drive. The Multi-Drive feature (Chapter 7) also provides a means for other supported PowerFlex drives and DSI Hosts to connect to a DeviceNet network.

Topic |

Page |

|

|

Components |

9 |

|

|

Features |

10 |

|

|

Understanding Parameter Types |

10 |

|

|

Compatible Products |

11 |

|

|

Required Equipment |

11 |

|

|

Safety Precautions |

12 |

|

|

Quick Start |

13 |

|

|

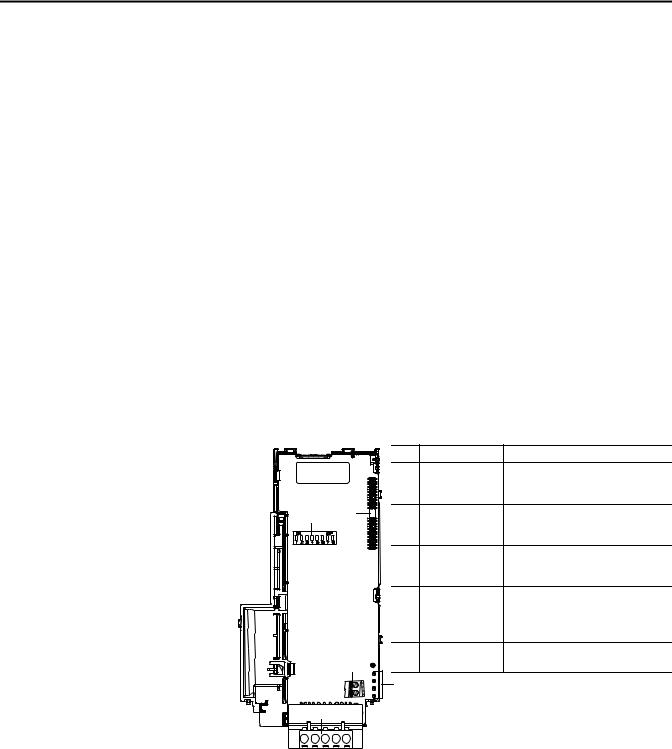

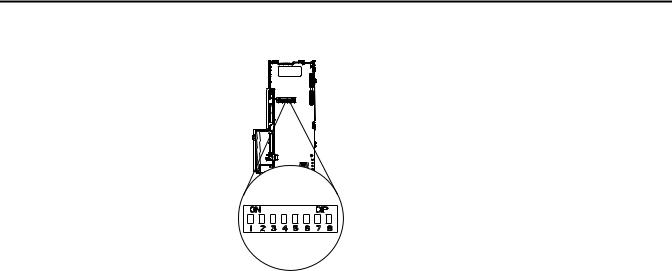

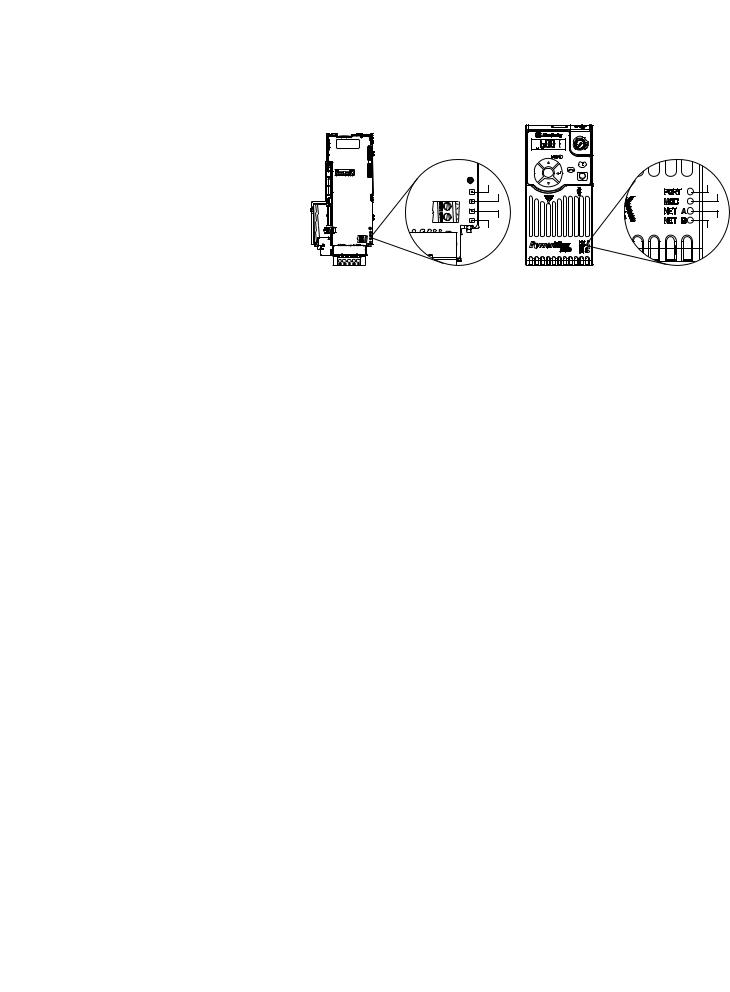

Components of the DeviceNet Adapter

25-COMM-D |

|

|

|

|

|

|

Item |

Part |

Description |

|

|

|

Node Address/Rate |

Switches for setting the node address and |

|

|

|

switches |

network data rate. Chapter 2, Installing the |

|

|

|

|

Adapter. |

|

|

|

Communication card- |

A 40-pin, double-row shrouded female |

|

|

Drive header |

header. An interface connector is used to |

|

|

|

|

|

connect this header to a header on the drive. |

|

|

|

Status indicators |

Three LEDs that indicate the status of the |

|

|

|

|

connected drive, adapter and network. See |

|

|

|

|

Chapter 8, Troubleshooting |

|

|

|

CS1/CS2 terminals |

Provides a clean ground for the |

|

|

|

|

communication bus cable shields. |

|

|

|

|

CS1 or CS2 should be connected to a clean |

|

|

|

|

ground or PE ground on the drive. |

|

|

|

DeviceNet connector |

A 5-pin connector to which a 5-pin linear |

|

|

|

|

plug can be connected. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

9 |

Chapter 1 |

Getting Started |

|

|

Features

Understanding Parameter

Types

The features of the DeviceNet adapter include:

•Mounting onto a PowerFlex 525 Control Module back cover for installation into the drive. It receives the required power from the drive and from the DeviceNet network.

•Switches to set a node address and network data rate before applying power to the PowerFlex drive. Alternatively, you can disable the switches and use parameters to configure these functions.

•Compatibility with various configuration tools to configure the DeviceNet adapter and host drive. The tools include network software such as RSNetWorx for DeviceNet, and drive-configuration software such as RSLogix 5000 (version 17 or greater), Logix Designer (version 21 or greater), and Connected Components Workbench (version 3 or greater).

•Status indicators that report the status of the DeviceNet adapter and network communications.

•Parameter-configured 16-bit Datalinks in the I/O to meet application requirements (four Datalinks to write data from the network to the drive, and four Datalinks to read data to the network from the drive).

•Explicit Messaging and UCMM (Unconnected Message Manager) support.

•Master-Slave hierarchy that can be configured to transmit data to and from a controller on the network.

•Multi-drive mode which allows up to five drives to share a single DeviceNet address node.

•User-defined fault actions to determine how the DeviceNet adapter and its host PowerFlex 525 drive respond to:

–I/O messaging communication disruptions (Comm Flt Action)

–Controllers in idle mode (Idle Flt Action)

•Multiple data exchange methods, including Polled, Cyclic, and Change of State (COS), can be used to transmit data between the network and adapter.

•Faulted node recovery is supported. You can configure a device even when it is faulted on the network if you have a configuration tool that uses faulted node recovery and have properly set the adapter node address switches and data rate switches.

This manual references two types of parameters:

•Device parameters are used to configure the adapter to operate on the network. These parameters reside on the adapter.

•Host parameters are used to configure the drive, including the datalink configuration for the datalinks used by the adapter. These parameters reside on the drive.

10 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Getting Started |

Chapter 1 |

|

|

Compatible Products

You can view adapter Device parameters and Host parameters with any of the following drive configuration tools:

•PowerFlex 4-class HIM (22-HIM-A3 or 22-HIM-C2S)

•Connected Components Workbench software – click the tab for the adapter at the bottom of the window, and click the Parameters icon in the tool bar.

At the time of publication, the DeviceNet adapter is compatible with AllenBradley PowerFlex 525 drives.

Required Equipment |

Equipment Shipped with the Drive |

When you unpack the adapter, verify that the package includes:

One PowerFlex 520-series DeviceNet communications adapter (25-COMM-D) (installed in a PowerFlex 520-series drive control module back cover)

One 5-pin inline DeviceNet plug (connected to the DeviceNet connector on the adapter)

Two interface connectors (for connecting the Communication card-Drive header to the header on the drive)

Installation leaflet (publication 520COM-IN001)

User-Supplied Equipment

The adapter parameters can be configured using the drive keypad interface (see Using the Drive Keypad Interface to Access Parameters on page 23). In addition, you must supply:

DeviceNet cable (thin cable with an outside diameter of 6.9 mm (0.27 in.) is recommended)

Controller configuration software, such as:

–RSNetWorx for DeviceNet

–RSLogix 5000 or Logix Designer

–Connected Components Workbench (version 3 or greater)

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

11 |

Chapter 1 |

Getting Started |

|

|

Safety Precautions

Please read the following safety precautions carefully.

ATTENTION: Risk of injury or death exists. The PowerFlex drive may contain high voltages that can cause injury or death. Remove all power from the PowerFlex drive, and then verify power has been removed before installing or removing an adapter.

ATTENTION: Risk of injury or equipment damage exists. Only personnel familiar with drive and power products and the associated machinery should plan or implement the installation, start up, configuration, and subsequent maintenance of the drive using this DeviceNet adapter. Failure to comply may result in injury and/or equipment damage.

ATTENTION: Risk of equipment damage exists. The adapter contains ESD (Electrostatic Discharge) sensitive parts that can be damaged if you do not follow ESD control procedures. Static control precautions are required when handling the adapter. If you are unfamiliar with static control procedures, see Guarding Against Electrostatic Damage (publication 8000-4.5.2)

ATTENTION: Risk of injury or equipment damage exists. If the adapter is transmitting control I/O to the drive, the drive may fault when you reset the adapter. Determine how your drive will respond before resetting the adapter.

ATTENTION: Risk of injury or equipment damage exists. Device parameters 15 [Comm Flt Actn] and 16 [Idle Flt Actn] let you determine the action of the adapter and drive if I/O communication is disrupted, the controller is idle, or explicit messaging for drive control is disrupted. By default, these parameters fault the drive. You may configure these parameters so that the drive continues to run, however, precautions should be taken to ensure that the settings of these parameters do not create a risk of injury or equipment damage. When commissioning the drive, verify that your system responds correctly to various situations (for example, a disconnected cable or a controller in idle state).

ATTENTION: Risk of injury or equipment damage exists. When a system is configured for the first time, there may be unintended or incorrect machine motion. Disconnect the motor from the machine or process during initial system testing.

ATTENTION: Risk of injury or equipment damage exists. The examples in this publication are intended solely for purposes of example. There are many variables and requirements with any application. Rockwell Automation, Inc. does not assume responsibility or liability (to include intellectual property liability) for actual use of the examples shown in this publication.

12 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Getting Started |

Chapter 1 |

|

|

Quick Start

This section is provided to help experienced users quickly start using the DeviceNet adapter. If you are unsure how to complete a step, refer to the referenced chapter.

Step |

Action |

See... |

|

|

|

1 |

Review the safety precautions for the adapter. |

Throughout this manual |

|

|

|

2 |

Verify that the PowerFlex drive is properly installed. |

PowerFlex 525 |

|

|

Adjustable Frequency AC |

|

|

Drive User Manual |

|

|

(publication 520-UM001) |

3 |

Commission the adapter. |

Chapter 2, |

|

Set a unique node address and the appropriate data rate using the switches on the |

Installing the Adapter |

|

adapter. If desired, you can disable the switches and use parameter settings instead. |

|

4 |

Install the adapter. |

|

|

Verify that the PowerFlex drive is not powered. Then, connect the adapter to the drive |

|

|

using the interface connector (included with adapter). |

|

5 |

Connect the drive to the DeviceNet network. |

|

|

Verify that the DeviceNet network is not powered. Then, connect the DeviceNet |

|

|

adapter to the network using a DeviceNet cable. |

|

6 |

Apply power to the drive and to the network. |

|

|

The adapter receives power from the drive and network. |

|

|

a. The status indicators should be green. If they flash red, there is a problem. See |

|

|

Chapter 8, Troubleshooting. |

|

|

b. Configure/verify key drive parameters. |

|

7 |

Configure the adapter for your application. |

Chapter 3, |

|

Set DeviceNet adapter parameters for the following functions as required by your |

Configuring the Adapter |

|

application: |

|

|

– Node address |

|

|

– Data rate |

|

|

– I/O configuration |

|

|

– Change of State, Cyclic, or polled I/O data exchange |

|

|

– Fault actions |

|

8 |

Apply power to the DeviceNet master and other devices on the network. |

DeviceNet Planning and |

|

Verify that the master and network are installed and functioning in accordance with |

Installation Manual |

|

DeviceNet standards, and then apply power to them. |

(ODVA pub 27) |

|

|

|

9 |

Configure the scanner to communicate with the adapter. |

Chapter 4, |

|

Use a network tool such as RSNetWorx for DeviceNet to configure the scanner on the |

Configuring the I/O |

|

network. Make sure to: |

|

|

– Set up the scan list. |

|

|

– Map the adapter data to the scan list. |

|

|

– Save your DeviceNet configuration to the scanner and a file. |

|

10 |

Create a ladder logic program. |

Chapter 5, |

|

Use a controller configuration tool such as RSLogix 5000/Logix Designer to create a |

Using the I/O |

|

ladder logic program that enables you to: |

Chapter 6, |

|

– Control the adapter and drive using I/O. |

Using Explicit Messaging |

|

– Monitor or configure the drive using Explicit messages. |

|

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

13 |

Chapter 1 |

Getting Started |

|

|

Notes:

14 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Chapter 2

Installing the Adapter

Chapter 2 provides instructions for installing the DeviceNet adapter in a PowerFlex 525 drive.

Topic |

Page |

|

|

Preparing for an Installation |

15 |

|

|

Commissioning the Adapter |

15 |

|

|

Connecting the Adapter to the Drive |

17 |

|

|

Connecting the Adapter to the Network |

19 |

|

|

Applying Power |

20 |

|

|

Preparing for an Installation

Commissioning the Adapter

Before installing the adapter, do the following:

•Read the DeviceNet Media Design and Installation Guide, publication DNET-UM072.

•Read the DeviceNet Starter Kit User Manual, publication DNETUM003.

•Verify that you have all required equipment. See Chapter 1, Getting Started.

To commission the adapter, you must set a unique node address and the data rate that is used by the network. (See the Glossary for details about data rates and node addresses.).

There are two methods for configuring the adapter’s Node address and data rate:

•Using the onboard DIP Switches;

•Using adapter parameters – Use adapter parameters when you want more flexibility in setting up the node address. To set the Node address using adapter parameters, see Setting the Node Address on page 25.

IMPORTANT Regardless of the method used to set the adapter’s node address, each node on the network must have a unique node address. To change a node address, you must set the new value and then cycle drive power.

ATTENTION: Risk of equipment damage exists. The adapter contains ESD (Electrostatic Discharge) sensitive parts that can be damaged if you do not follow ESD control procedures. Static control precautions are required when handling the adapter. If you are unfamiliar with static control procedures, see Guarding Against Electrostatic Damage (publication 8000-4.5.2)

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

15 |

Chapter 2 Installing the Adapter

Setting the Node Address and Data Rate Using the DIP Switches

Switch |

Description |

Default |

|

|

|

|

|

SW1 |

Least Significant Bit (LSB) of Node Address |

1 |

Node 63 |

|

|

|

|

SW2 |

Bit 1 of Node Address |

1 |

|

|

|

|

|

SW3 |

Bit 2 of Node Address |

1 |

|

|

|

|

|

SW4 |

Bit 3 of Node Address |

1 |

|

|

|

|

|

SW5 |

Bit 4 of Node Address |

1 |

|

|

|

|

|

SW6 |

Most Significant Bit (MSB) of Node Address |

1 |

|

|

|

|

|

SW7 |

Least Significant Bit (LSB) of Data Rate |

1 |

Autobaud |

|

|

|

|

SW8 |

Most Significant Bit (MSB) of Data Rate |

1 |

|

Node Address Switch Settings (UP = ON = 1)

Switch Setting |

|

|

|

Node |

||

|

|

|

|

|

|

Address |

SW 1 |

SW 2 |

SW 3 |

SW 4 |

SW 5 |

SW 6 |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

0 |

0 |

1 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

0 |

0 |

2 |

|

|

|

|

|

|

|

1 |

1 |

0 |

0 |

0 |

0 |

3 |

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

0 |

0 |

4 |

|

|

|

|

|

|

|

1 |

0 |

1 |

0 |

0 |

0 |

5 |

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

0 |

0 |

6 |

|

|

|

|

|

|

|

1 |

1 |

1 |

0 |

0 |

0 |

7 |

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

0 |

0 |

8 |

|

|

|

|

|

|

|

1 |

0 |

0 |

1 |

0 |

0 |

9 |

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

0 |

0 |

10 |

|

|

|

|

|

|

|

1 |

1 |

0 |

1 |

0 |

0 |

11 |

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

0 |

0 |

12 |

|

|

|

|

|

|

|

1 |

0 |

1 |

1 |

0 |

0 |

13 |

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

0 |

0 |

14 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

0 |

0 |

15 |

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

1 |

0 |

16 |

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

1 |

0 |

17 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

1 |

0 |

18 |

|

|

|

|

|

|

|

1 |

1 |

0 |

0 |

1 |

0 |

19 |

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

1 |

0 |

20 |

|

|

|

|

|

|

|

1 |

0 |

1 |

0 |

1 |

0 |

21 |

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

1 |

0 |

22 |

|

|

|

|

|

|

|

1 |

1 |

1 |

0 |

1 |

0 |

23 |

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

1 |

0 |

24 |

|

|

|

|

|

|

|

1 |

0 |

0 |

1 |

1 |

0 |

25 |

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

1 |

0 |

26 |

|

|

|

|

|

|

|

1 |

1 |

0 |

1 |

1 |

0 |

27 |

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

1 |

0 |

28 |

|

|

|

|

|

|

|

1 |

0 |

1 |

1 |

1 |

0 |

29 |

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

1 |

0 |

30 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

0 |

31 |

|

|

|

|

|

|

|

Switch Setting |

|

|

|

Node |

||

|

|

|

|

|

|

Address |

SW 1 |

SW 2 |

SW 3 |

SW 4 |

SW 5 |

SW 6 |

|

0 |

0 |

0 |

0 |

0 |

1 |

32 |

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

0 |

1 |

33 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

0 |

1 |

34 |

|

|

|

|

|

|

|

1 |

1 |

0 |

0 |

0 |

1 |

35 |

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

0 |

1 |

36 |

|

|

|

|

|

|

|

1 |

0 |

1 |

0 |

0 |

1 |

37 |

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

0 |

1 |

38 |

|

|

|

|

|

|

|

1 |

1 |

1 |

0 |

0 |

1 |

39 |

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

0 |

1 |

40 |

|

|

|

|

|

|

|

1 |

0 |

0 |

1 |

0 |

1 |

41 |

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

0 |

1 |

42 |

|

|

|

|

|

|

|

1 |

1 |

0 |

1 |

0 |

1 |

43 |

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

0 |

1 |

44 |

|

|

|

|

|

|

|

1 |

0 |

1 |

1 |

0 |

1 |

45 |

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

0 |

1 |

46 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

0 |

1 |

47 |

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

1 |

1 |

48 |

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

1 |

1 |

49 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

1 |

1 |

50 |

|

|

|

|

|

|

|

1 |

1 |

0 |

0 |

1 |

1 |

51 |

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

1 |

1 |

52 |

|

|

|

|

|

|

|

1 |

0 |

1 |

0 |

1 |

1 |

53 |

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

1 |

1 |

54 |

|

|

|

|

|

|

|

1 |

1 |

1 |

0 |

1 |

1 |

55 |

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

1 |

1 |

56 |

|

|

|

|

|

|

|

1 |

0 |

0 |

1 |

1 |

1 |

57 |

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

1 |

1 |

58 |

|

|

|

|

|

|

|

1 |

1 |

0 |

1 |

1 |

1 |

59 |

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

1 |

1 |

60 |

|

|

|

|

|

|

|

1 |

0 |

1 |

1 |

1 |

1 |

61 |

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

1 |

1 |

62 |

|

|

|

|

|

|

|

1 |

1 |

1 |

1 |

1 |

1 |

63 |

|

|

|

|

|

|

|

16 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Installing the Adapter |

Chapter 2 |

|

|

Connecting the Adapter to the Drive

Data Rate Switch Settings (UP = ON = 1)

Switch Setting |

Data Rate |

|

|

|

|

SW 7 |

SW 8 |

|

0 |

0 |

125 kbps |

|

|

|

1 |

0 |

250 kbps |

|

|

|

0 |

1 |

500 kbps |

|

|

|

1 |

1 |

Autobaud |

|

|

|

IMPORTANT If all switches are in the OFF position (all 0’s), then the Node Address and Data Rate are determined by parameter settings (Device parameters 07 [Net Addr Cfg] and 09 [Net Rate Cfg]).

Setting Single-Drive or Multi-Drive Mode

To select between Single-Drive or Multi-Drive mode, see Parameter Configuration for Multi-Drive Mode on page 73.

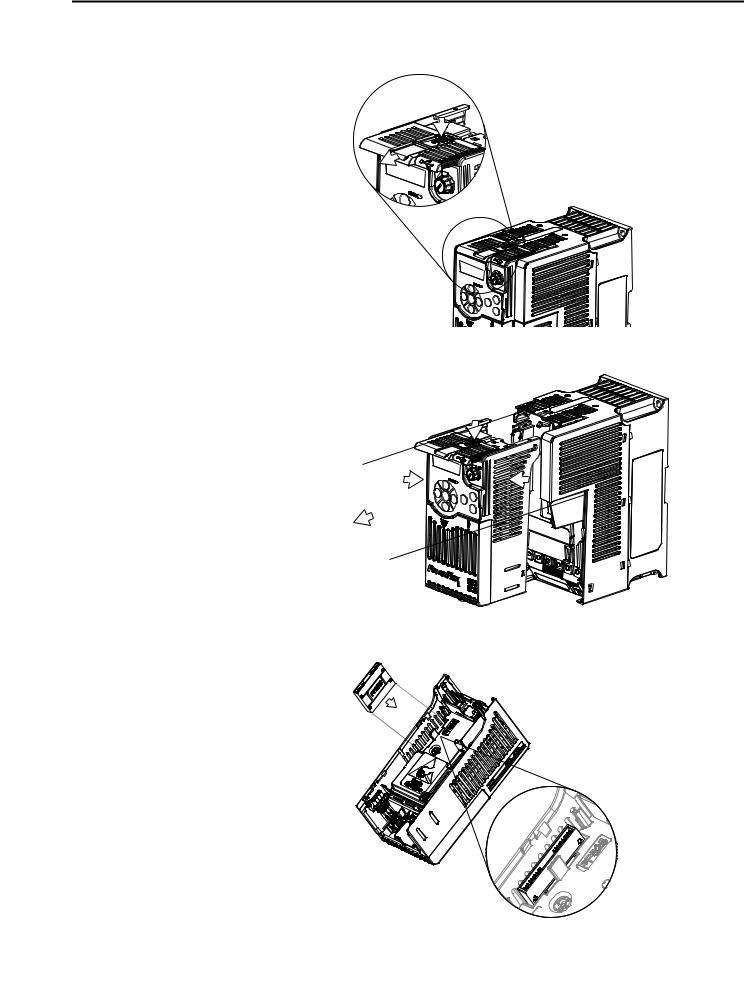

ATTENTION: Risk of injury or death exists. The PowerFlex drive may contain high voltages that can cause injury or death. Remove power from the drive, and then verify power has been discharged before connecting the DeviceNet adapter to the network.

1.Remove power from the drive.

2.Use static control precautions.

3.Separate the drive’s control module from the power module.

a.Press and hold down the catch on both sides of the frame cover, then pullout and swing upwards to remove (Frames B...E only).

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

17 |

Chapter 2 Installing the Adapter

b.Press down and slide out the top cover of the control module to unlock it from the power module.

c.Hold the sides and top of the control module firmly, then pull out to separate it from the power module.

4.Insert the interface connector for the adapter into the header located at the back of the control module.

18 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Installing the Adapter |

Chapter 2 |

|

|

5.Align the Communication card-Drive header on the adapter with the interface connector. Then, press down firmly around the adapter. The adapter snaps into the back of the control module.

Connecting the Adapter to the Network

IMPORTANT The CS1/CS2 terminals on the adapter provide a clean ground for the communication bus cable shields. You should connect the CS1 or CS2 terminal to a clean ground or PE ground on the drive.

6. Attach the control module to the power module.

ATTENTION: Risk of injury or death exists. The PowerFlex drive may contain high voltages that can cause injury or death. Remove power from the drive, and then verify power has been discharged before connecting the embedded EtherNet/IP adapter to the network.

1.Remove power from the network.

2.Use static control precautions.

3.Connect a DeviceNet cable to the network. A DeviceNet thin cable with an outside diameter of 6.9 mm (0.29 in.) is recommended.

IMPORTANT Maximum cable length depends on data rate. See the Glossary for Data Rate.

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

19 |

Chapter 2 Installing the Adapter

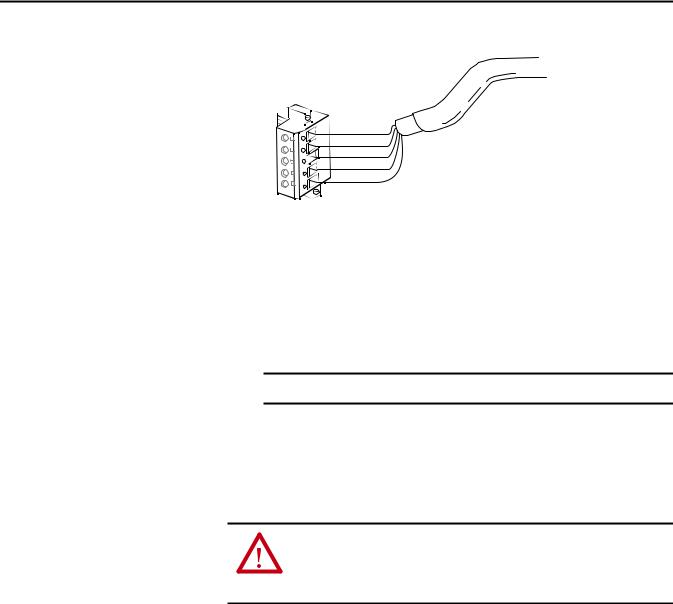

4. Connect the 5-pin linear plug to the DeviceNet cable.

5 |

Red |

|

White |

||

4 |

||

Bare |

||

3 |

||

Blue |

||

2 |

||

Black |

||

1 |

||

|

Terminal |

|

Color |

Signal |

Function |

|

5 |

|

Red |

V+ |

Power Supply |

|

|

|

|

|

|

|

4 |

|

White |

CAN_H |

Signal High |

|

|

|

|

|

|

|

3 |

|

Bare |

SHIELD |

Shield |

|

|

|

|

|

|

|

2 |

|

Blue |

CAN_L |

Signal Low |

|

|

|

|

|

|

|

1 |

|

Black |

V- |

Common |

|

|

|

|

|

|

|

TIP |

A 5-pin linear plug is shipped with the adapter. If a replacement plug is |

||||

|

needed, the replacement plug part number is 1799-DNETSCON. |

||||

Applying Power

IMPORTANT A 10-pin linear plug is not supported.

5.Insert the 5-pin linear plug into the mating socket on the adapter and secure it with the two screws. Verify that the colors of the wires on the plug match up with the color codes on the socket.

ATTENTION: Risk of equipment damage, injury, or death exists. Unpredictable operation may occur if you fail to verify that parameter settings are compatible with your application. Verify that settings are compatible with your application before applying power to the drive.

1.Make sure that the adapter will have a unique address on the network and is set at the correct data rate or to autobaud. If a new data rate or address is needed, reset its switches (see Commissioning the Adapter on page 15).

2.Apply power to the drive. The adapter receives its power from the connected drive and network.

3.If the parameter settings for the data rate and node address are to be used, a configuration tool such as Connected Components Workbench (version 3 or greater) can be used to adjust the respective parameters in the adapter.

See Chapter 3, Configuring the Adapter.

Start-Up Status Indication

After power has been applied, the status indicators can be viewed on the front of the drive. When you apply power to the product and network for the first time,

20 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Installing the Adapter |

Chapter 2 |

|

|

the status indicators should be green after an initialization. If the status indicators go red, there is a problem. See Chapter 8, Troubleshooting.

Drive and Adapter Status Indicators

25-COMM-D |

PowerFlex 525 Frame A shown |

FWD |

|

ENET LINK |

|

EtherNet/IP |

|

Esc |

Sel |

|

|

|

Item |

Status Indicator |

Status(1) |

Description |

|

PORT |

Green |

Normal operation. The adapter is properly |

|

|

|

connected and is communicating with the |

|

|

|

drive. |

|

|

Flashing green |

The adapter is in the process of establishing a |

|

|

|

connection to the drive. This status indicator |

|

|

|

will turn solid green or red. |

|

MOD |

Green |

Normal operation. The adapter is operational |

|

|

|

and is transferring I/O data. |

|

|

Flashing green |

Normal operation. The adapter is operational |

|

|

|

but is not transferring I/O data. |

|

NET A |

Green |

Normal operation. The adapter is properly |

|

|

|

connected and communicating on the |

|

|

|

network. |

|

|

Flashing green |

The adapter is properly connected but is not |

|

|

|

communicating with any devices on the |

|

|

|

network. |

|

NET B |

Off |

Not used for DeviceNet. |

|

|

|

|

(1) If all status indicators are off, the adapter is not receiving power. If any other conditions occur, see Chapter 8, Troubleshooting.

Configuring/Verifying Key Drive Parameters

The PowerFlex 525 drive can be separately configured for the control and Reference functions in various combinations. For example, you could set the drive to have its control come from a peripheral or terminal block with the Reference coming from the network. Or you could set the drive to have its control come from the network with the Reference coming from another peripheral or terminal block. Or you could set the drive to have both its control and Reference come from the network.

Configuring the Host parameters can be done using the drive’s keypad, a HIM, Logix Designer or Connected Components Workbench. In the following example, the drive will receive the Logic Command and Reference from the network.

1.Set the value of Host parameter P046 [Start Source 1] to 4“Network Opt”.

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

21 |

Chapter 2 Installing the Adapter

2.Set the value of Host parameter P047 [Speed Reference1] to 4 “Network Opt”.

TIP |

The PowerFlex 525 drive supports up to three control functions and |

|

three Reference functions. |

For more information on how to set different combinations of the control and Reference functions, see the PowerFlex 525 drive user manual,

publication 520-UM001.

22 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Chapter 3

Configuration Tools

Using the Drive Keypad Interface to Access Parameters

Configuring the Adapter

Chapter 3 provides instructions and information for setting the parameters to configure the DeviceNet adapter.

Topic |

Page |

|

|

Configuration Tools |

23 |

|

|

Using the Drive Keypad Interface to Access Parameters |

23 |

|

|

Using the PowerFlex 4-Class HIM to Access Parameters |

25 |

|

|

Setting the Node Address |

25 |

|

|

Setting the Data Rate |

26 |

|

|

Setting the I/O Configuration |

26 |

|

|

Using Master-Slave Hierarchy (Optional) |

26 |

|

|

Selecting COS, Cyclic, or Polled I/O |

28 |

|

|

Setting a Fault Action |

29 |

|

|

Resetting the Adapter |

30 |

|

|

Restoring Adapter Parameters to Factory Defaults |

30 |

|

|

Viewing the Adapter Status Using Parameters |

31 |

|

|

Updating the Adapter Firmware |

31 |

|

|

For a list of parameters, see Appendix B, Adapter Parameters. For definitions of terms in this chapter, see the Glossary.

The adapter parameters can be configured using the drive keypad interface (see page 23) or a PowerFlex 4-class HIM (Human Interface Module, see page 25).

RSLogix 5000/Logix Designer, Connected Components Workbench (version 3 or greater), and RSNetWorx for DeviceNet (version 21 or greater) can also be used to access the adapter parameters.

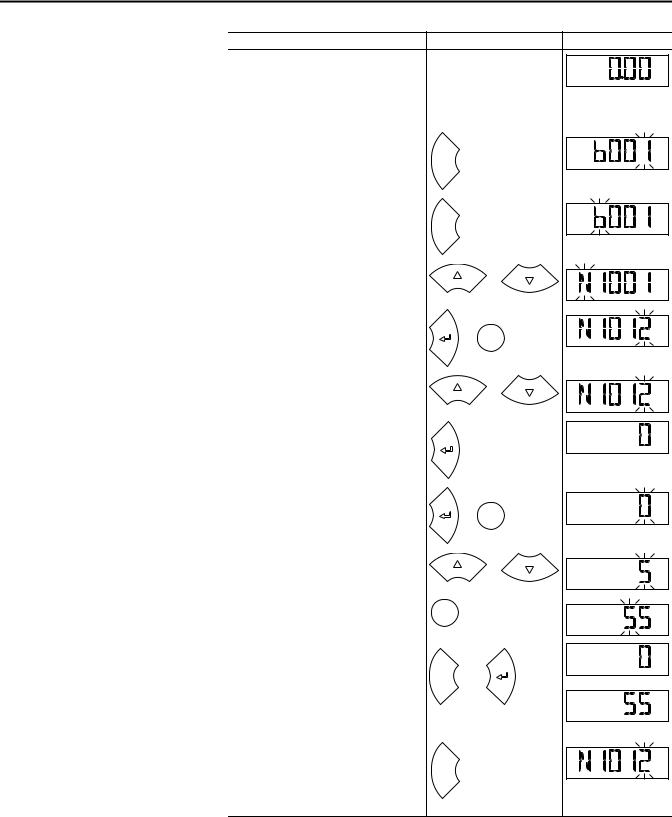

The following is an example of basic integral keypad and display functions. This example provides basic navigation instructions and illustrates how to program a parameter.

IMPORTANT The DeviceNet adapter Device parameters can be accessed on the drive keypad via the “N” (Network) group. Note that the parameters in the “N” group will appear offset from the Device parameter numbers referenced in this manual by 1000 (decimal) on the LCD display.

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

23 |

Chapter 3 Configuring the Adapter

Step |

Key(s) |

Example Display |

|

1. |

When power is applied, the last user-selected |

|

|

|

Basic Display Group parameter number is briefly |

|

FWD |

|

|

|

|

|

displayed with flashing characters. The display |

|

HERTZ |

|

|

|

|

|

then defaults to that parameter’s current value. |

|

|

|

(Example shows the value of b001 [Output |

|

|

|

Freq] with the drive stopped.) |

|

|

2. |

Press Esc to display the Basic Display Group |

|

|

|

parameter number shown on power-up. The |

|

FWD |

|

parameter number will flash. |

Esc |

|

3. |

Press Esc to enter the parameter group list. The |

|

|

|

parameter group letter will flash. |

|

FWD |

|

|

Esc |

|

4. |

Press the Up Arrow or Down Arrow to scroll |

|

or |

|

through the group list (b, P, t, C, L, d, A, f, N, M, |

|

|

|

|

FWD |

|

|

and Gx). |

|

|

5. |

Press Enter or Sel to enter a group. The right |

|

|

|

digit of the last viewed parameter in that group |

or |

FWD |

|

will flash. |

Sel |

|

6. |

Press the Up Arrow or Down Arrow to scroll |

|

or |

|

through the parameter list. |

|

|

|

|

FWD |

|

7. Press Enter to view the value of the parameter.

Or |

FWD |

|

Press Esc to return to the parameter list.

8. |

Press Enter or Sel to enter Program Mode and |

|

|

|

|

edit the value. The right digit will flash and the |

|

or Sel |

FWD |

|

word Program on the LCD display will light up. |

|

PROGRAM |

|

9. |

Press the Up Arrow or Down Arrow to change |

|

or |

|

|

the parameter value. |

|

FWD |

|

|

|

|

||

|

|

|

|

PROGRAM |

10. If desired, press Sel to move from digit to digit |

|

|

|

|

|

or bit to bit. The digit or bit that you can change |

Sel |

|

FWD |

|

will flash. |

|

|

PROGRAM |

11. Press Esc to cancel a change and exit Program |

|

|

|

|

|

Mode. |

|

|

FWD |

|

|

|

|

|

|

Or |

Esc |

or |

or |

|

Press Enter to save a change and exit Program |

|

|

|

|

|

|

|

|

|

Mode. |

|

|

FWD |

|

The digit will stop flashing and the word |

|

|

|

|

Program on the LCD display will turn off. |

|

|

|

12. |

Press Esc to return to the parameter list. |

|

|

|

|

Continue to press Esc to back out of the |

|

|

FWD |

|

programming menu. |

Esc |

|

|

|

If pressing Esc does not change the display, then |

|

|

|

|

b001 [Output Freq] is displayed. Press Enter or |

|

|

|

|

Sel to enter the group list again. |

|

|

|

24 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Configuring the Adapter |

Chapter 3 |

|

|

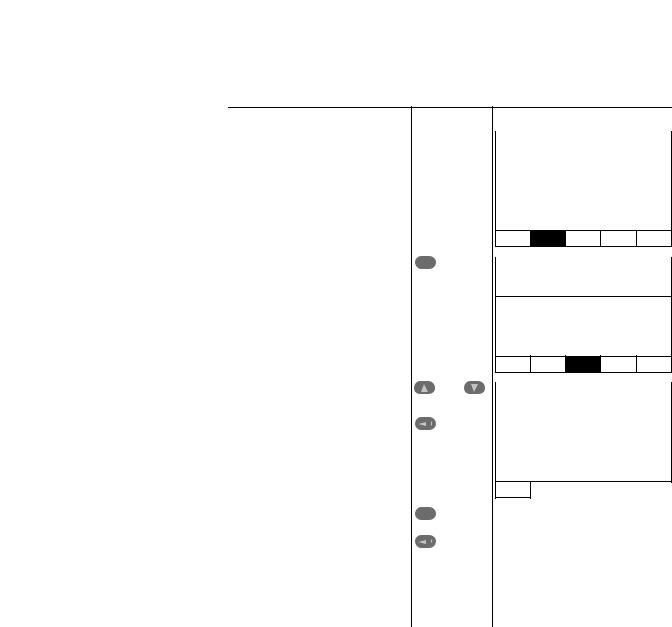

Using the PowerFlex 4-Class HIM to Access Parameters

The PowerFlex 4-class HIM can be used to access parameters in the adapter (see basic steps shown below). It is recommended that you read through the steps for your HIM before performing the sequence. For additional HIM information, refer to the HIM Quick Reference card, publication 22HIM-QR001.

Step |

Key(s) |

Example Display |

|

1. |

Power up the drive. Then connect the HIM |

|

|

Parameters |

|

||

|

|||

|

to the DSI port of the drive. The Parameters |

|

|

|

tab for the drive will be displayed. |

|

|

|

Groups |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Linear List |

|

|

|

Changed Params |

|

DIAG PARAM DSEL MEM SEL

2. Press Sel until the DSEL tab is selected. |

|

|

|

|

Sel |

Device Select |

|||

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

DSI Devices |

|

|

|

|

|

|

DIAG PARAM DSEL MEM SEL

3. Select DSI Device in the DSEL tab if it is not |

|

|

|

|

|

and |

DSI Devices |

||

already selected using the Up Arrow or |

|

|||

Down Arrow. |

|

|

|

|

|

|

|

PowerFlex 525 |

|

Press Enter to select DSI Device. |

|

|

|

|

|

|

|

25-COMM-D |

|

|

|

|

||

|

|

|

|

|

4. Press the Up Arrow or Down Arrow to scroll |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Sel |

DSI Devices |

||||||

to 25-COMM. |

|||||||

|

|

|

|

|

|

||

Press Enter to reload the HIM to browse |

|

|

|

|

|

||

|

|

|

|

PowerFlex 525 |

|||

only the Communication Adapter (25- |

|

|

|

|

|

|

|

|

|

|

|

25-COMM-D |

|||

COMM-D) parameters. |

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To display the Host parameters, repeat steps 1 through 3 and select “PowerFlex |

|

525” at step 3. |

Setting the Node Address |

The value of Device parameter 07 [Net Addr Cfg] determines the node address if |

|

all the adapter DIP switches are in the OFF position (all 0’s). We recommend |

|

that you do not use node address 63 because all new devices use it as the default |

|

address. Address 63 is also used for Automatic Device Recovery (ADR). |

|

1. Set the value of Device parameter 07 [Net Addr Cfg] to a unique node |

|

address. |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

25 |

Chapter 3 Configuring the Adapter

2. Reset the adapter by power cycling the drive.

TIP |

If you are using RSNetWorx for DeviceNet, select Network > Single Browse |

|

Path to see the new address; then delete the old address. |

Setting the Data Rate

The value of Device parameter 09 [Net Rate Cfg] determines the DeviceNet data rate if all of the adapter DIP switches are in the OFF position (all 0’s). The Autobaud setting will detect the data rate used on the network if another device is setting the data rate. Your application may require a different setting.

1.Set the value of Device parameter 09 [Net Rate Cfg] to the data rate at which your network is operating.

Options |

0 |

“125kbps” (Default) |

|

1 |

“250kbps” |

|

|

|

|

2 |

“500kbps” |

|

|

|

|

3 |

“Autobaud” |

|

|

|

2. Reset the adapter by power cycling the drive.

Setting the I/O Configuration The value of Host parameter C175 [DSI I/O Cfg] determines the number of drives that will be represented on the network as one node by the adapter. Up to

five drives can be represented as one node by the adapter.

1.Set the value of Host parameter C175 [DSI I/O Cfg] to the number of drives you want to be represented as one node.

Options |

0 |

“Drive 0” (Default) |

|

1 |

“Drive 0-1” |

|

|

|

|

2 |

“Drive 0-2” |

|

|

|

|

3 |

“Drive 0-3” |

|

|

|

|

4 |

“Drive 0-4” |

|

|

|

Using Master-Slave Hierarchy (Optional)

Drive 0 is the PowerFlex 525 with the 25-COMM-D adapter installed. Drive 1 through 4 are other PowerFlex drives that daisy-chain to the RJ45 (RS-485) port on Drive 0. See Chapter 7, Using Multi-Drive Mode for further instructions.

2. Reset the adapter by power cycling the drive.

A hierarchy determines the type of device with which the adapter exchanges data. In a Master-Slave hierarchy, the adapter exchanges data with a master, such as a scanner (1769-SDN, 1756-DNB, 1771-SDN, 1747-SDN, and so forth).

26 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Configuring the Adapter |

Chapter 3 |

|

|

Configuring a Master-Slave Hierarchy

The controller I/O image can have anywhere from zero to eight (four In and four Out) additional 16-bit parameters called Datalinks. They are configured using

Host parameters C161 [Opt Data In 1] through C164 [Opt Data In 4], and C165 [Opt Data Out 1] through C168 [Opt Data Out 4]. The number of Datalinks actively used is controlled by the connection size in the controller and the in/out parameters. See the respective controller example sections in Chapter 4 for more information on setting the connection size.

When using a ControlLogix or CompactLogix controller and the Generic Profile, or a MicroLogix 1100/1400 controller, configure the Datalink parameters now as described in this section.

Enabling Datalinks To Write Data

IMPORTANT Always use the Datalink parameters in consecutive numerical order, starting with the first parameter. For example, use Host parameters C161, C162, and C163 to configure three Datalinks to write data. Otherwise, the network I/O connection will be larger than necessary, which needlessly increases controller response time and memory usage.

Host parameters C161 [Opt Data In 1] through C164 [Opt Data In 4] control which parameters in the drive receive values from the network. To configure these parameters, set them to the drive parameter number you want to write them to.

The following steps are required to enable Datalinks to write data:

1.Set the values of only the required number of contiguous controller-to- drive Datalinks needed to write data to the drive and that are to be included in the network I/O connection.

2.Reset the adapter by power cycling the drive.

After the above steps are complete, the adapter is ready to receive input data and transfer status data to the master (controller). Next, configure the controller to recognize and transmit I/O to the adapter. See Chapter 4, Configuring the I/O.

Enabling Datalinks To Read Data

IMPORTANT Always use the Datalink parameters in consecutive numerical order, starting with the first parameter. For example, use Host parameters C165, C166, and C167 to configure three Datalinks to read data. Otherwise, the network I/O connection will be larger than necessary, which needlessly increases controller response time and memory usage.

Host parameters C165 [Opt Data Out 1] through C168 [Opt Data Out 4] configure which parameters in the drive, adapter, or any other connected

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

27 |

Chapter 3 Configuring the Adapter

Selecting COS, Cyclic, or Polled I/O

peripheral send values to the network. To configure these parameters, set them to the parameter number you wish to read over the network.

The following steps are required to enable Datalinks to read data:

1.Set the values of only the required number of contiguous drive-to- controller Datalinks needed to read data from the drive and that are to be included in the network I/O connection.

2.Reset the adapter by power cycling the drive.

After the above steps are complete, the adapter is ready to send output data to the master (controller). Next, configure the controller to recognize and transmit I/O to the adapter. See Chapter 4, Configuring the I/O.

The data exchange (sometimes called allocation) is the method that the adapter uses to exchange data on the DeviceNet network. The adapter can be configured to use one of the following data exchanges:

• |

COS (Change of State) |

• |

Polled and COS |

• |

Cyclic |

• |

Polled and Cyclic |

• |

Polled |

|

|

If “Polled and COS” or “Polled and Cyclic” is used, the adapter receives the I/O from the polled messages. It transmit its Logic Status and Feedback in COS or Cyclic messages. Other data is transmitted in Polled messages.

Cyclic and Polled data exchanges are configured in the scanner, so you only need to set the I/O configuration in the adapter. COS data exchange must be configured in both the adapter and the scanner. You need to set the I/O configuration and COS parameters in the adapter.

Using COS (Change of State) Data Exchange (Optional)

Set Device parameter 11 [COS Status Mask] for the bits in the Logic Status word that should be checked for changes. For the Logic Status bit definitions, see Appendix D or the drive documentation.

1. Edit any of the bits as required.

Value |

Description |

|

|

0 |

Ignore this logic bit (Default) |

|

|

1 |

Use the logic bit. |

2.Set Device parameter 12 [COS Fdbk Change] for the amount of change to the Feedback that is required to trigger a Change of State message.

The adapter is now configured for COS data exchange. You must configure the scanner to allocate it using COS. See Chapter 4, Configuring the I/O.

28 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Configuring the Adapter |

Chapter 3 |

|

|

Setting a Fault Action

By default, when communications are disrupted (the network cable is disconnected) and/or the scanner is idle, the drive responds by faulting if it is using I/O from the network. You can configure a different response to:

•Disrupted I/O communication by using Device parameter

15 [Comm Flt Actn].

•An idle scanner by using Device parameter 16 [Idle Flt Actn].

ATTENTION: Risk of injury or equipment damage exists. Device parameters 15 [Comm Flt Actn] and 16 [Idle Flt Actn] respectively let you determine the action of the adapter and drive if communications are disrupted or the controller is idle. By default, these parameters fault the drive. You may configure these parameters so that the drive continues to run, however, precautions should be taken to ensure that the settings of these parameters do not create a risk of injury or equipment damage. When commissioning the drive, verify that your system responds correctly to various situations (a disconnected network cable or a controller in idle state).

Changing the Fault Action

Set the values of Device parameters 15 [Comm Flt Actn] and 16 [Idle Flt Actn] to the desired responses:

Value |

Action |

Description |

|

|

|

0 |

Fault |

The drive is faulted and stopped. Datalink data is no longer sent to the drive. (Default) |

|

|

|

1 |

Stop |

The drive is stopped as per Host parameter P045 [Stop Mode] setting. Datalink data sent to |

|

|

the drive remains unchanged. |

2 |

Zero Data |

The drive is sent “0” values for all Reference and Datalink data. This does not command a stop. |

|

|

|

3 |

Hold Last |

The drive continues in its present state. |

|

|

|

4 |

Send Flt Cfg |

The drive is sent the Reference and Datalink data that you set in the fault configuration |

|

|

parameters (Device parameters 17 [Flt Cfg Logic], 18 [Flt Cfg Ref], and 19 [Flt Cfg DL 1] |

|

|

through 22 [Flt Cfg DL 4]). |

Changes to these parameters take effect immediately. A reset is not required.

If Multi-Drive mode is used, the same fault action is used by the adapter for all of the drives it controls (Drive 0...4).

Setting the Fault Configuration Parameters

When setting Device parameters 15 [Comm Flt Actn] and 16 [Idle Flt Actn] to 4 “Send Flt Cfg,” the values in the following parameters are sent to the drive after a communications fault and/or idle fault for drive control fault occurs. You must set these parameters to values required by your application.

Device Parameter |

Description |

|

17 |

[Flt Cfg Logic] |

A 16-bit integer value sent to the drive for Logic Command. |

|

|

|

18 |

[Flt Cfg Ref] |

A 16-bit integer value sent to the drive for Reference. |

|

|

|

19 |

[Flt Cfg DL 1] through |

A 16-bit integer value sent to the drive for a Datalink. |

22 |

[Flt Cfg DL 4] |

|

Changes to these parameters take effect immediately. A reset is not required.

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

29 |

Chapter 3 Configuring the Adapter

Resetting the Adapter

Restoring Adapter Parameters to Factory Defaults

Changes to switch settings on some adapter parameters require that you reset the

adapter before the new settings take effect. You can reset the adapter by cycling power to the drive or by using Device parameter 14 [Reset Module].

ATTENTION: Risk of injury or equipment damage exists. If the adapter is transmitting control I/O to the drive, the drive may fault when you reset the adapter. Determine how your drive will respond before resetting the adapter.

Set Device parameter 14 [Reset Module] to 1 “Reset Module”.

Value |

Description |

|

|

0 |

Ready (Default) |

|

|

1 |

Reset Module |

|

|

2 |

Set Defaults |

|

|

When you enter 1 “Reset Module”, the adapter will be immediately reset. An alternate method to reset the adapter is by power cycling the drive.

Set Device parameter 14 [Reset Module] to 2 “Set Defaults”.

Value |

Description |

|

|

0 |

Ready (Default) |

|

|

1 |

Reset Module |

|

|

2 |

Set Defaults |

|

|

When you enter 2 “Set Defaults”, the adapter will set all of its parameters to their factory default values.

IMPORTANT When performing a Set Defaults action, the drive may detect a conflict and then not allow this function to occur. If this happens, first resolve the conflict and then repeat a Set Defaults action. Common reasons for a conflict include the drive running or a controller in Run mode.

After performing a Set Defaults action, you must enter 1 “Reset Module” or power cycle the drive so that the new values take effect. Thereafter, this parameter will be restored to a value of 0 “Ready”.

30 |

Rockwell Automation Publication 520COM-UM002A-EN-E - April 2013 |

Loading...

Loading...