Rockwell Automation 1797-IRT8 User Manual

FLEX Ex

Thermocouple/

RTD/mV Input

Module

Cat. No. 1797-IRT8

User Manual

Important User Information Because of the variety of uses for the products described in this publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some important differences between solid-state equipment and electromechanical devices that should be taken into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION |

Identifies information about practices or |

|

circumstances that can lead to personal injury or |

||

|

||

|

death, property damage or economic loss |

!

Attention statements help you to:

∙identify a hazard

∙avoid a hazard

∙recognize the consequences

IMPORTANT |

Identifies information that is critical for successful |

|

application and understanding of the product. |

||

|

||

|

||

|

|

Allen-Bradley, FLEX Ex, FLEX I/O, and ControlNet Ex are trademarks of Rockwell Automation

ControlNet is a trademark of ControlNet International

Preface

Using This Manual

Why Read this Manual

Who Should Read this Manual

About the Vocabulary

What this Manual Contains

This manual shows you how to use your FLEX Ex™ thermocouple/ RTD/mV module with the ControlNet Ex™ products and ControlNet network. The manual helps you install, program, and troubleshoot your module.

You must be able to program and operate a ControlNet Ex product and ControlNet™ network to make efficient use of a FLEX Ex module.

In this manual, we refer to the:

∙ 1797-IRT8 as the “input module”. or “module.”

The following chart lists each chapter with its corresponding title and a brief overview of the topics covered in that chapter.

Chapter |

Title |

Contents |

|

|

|

1 |

About the FLEX Ex Analog Modules |

Describes features, capabilities, |

|

|

and hardware components |

|

|

|

2 |

Understanding Configurable FLEX Ex |

Describes configurable features of |

|

thermocouple/RTD/mV Input Module |

the input module |

|

Features |

|

|

|

|

3 |

How to Install Your Thermocouple/ |

How to install and wire the module |

|

RTD/mV Module |

|

|

|

|

4 |

Input, Output and Configuration Files |

Describes communication over the |

|

for the hermocouple/RTD/mV Module |

I/O backplane between the module |

|

on the ControlNet network |

and the adapter, and how data is |

|

|

mapped into the image table |

|

|

|

5 |

Calibrating Your Module |

Lists the tools needed, and the |

|

|

methods used to calibrate the |

|

|

module |

|

|

|

6 |

Applying FLEX Ex Analog Modules |

Learn how to evaluate, define, |

|

|

select, match and optimize your |

|

|

system. |

|

|

|

7 |

Troubleshooting Your Module |

How to use the indicators to |

|

|

troubleshoot your module |

|

|

|

Appendix |

Title |

Contents |

|

|

|

A |

Specifications |

Outlines module specifications and |

|

|

accuracy |

|

|

|

B |

Programming the FLEX Ex Analog |

Shows ladder diagramming for |

|

Module using RIO |

programming. |

|

|

|

Publication 1797-6.5.2 - February 2001

Using This Manual |

4 |

|

|

For Additional

Information

In Summary

For additional information on FLEX Ex systems and modules, refer to the following documents,

Catalog |

|

Publications |

||

Description |

|

|

||

Number |

Installation |

User |

||

|

||||

|

|

Instructions |

Manual |

|

1797 Series |

FLEX Ex Product Data |

1797-2.1 |

|

|

|

|

(Product data) |

|

|

|

|

|

|

|

1797 Series |

FLEX Ex System Overview |

1797-2.2 |

|

|

|

|

(System |

|

|

|

|

overview) |

|

|

|

|

|

|

|

1797 Series |

ControlNet Ex System Cable Guide |

1797-6.2.1 |

|

|

|

|

(System guide) |

|

|

|

|

|

|

|

1797 Series |

FLEX Ex System Certification |

1797-6.2.6 |

|

|

|

Reference Manual |

|

|

|

|

|

|

|

|

1797-TB3 |

FLEX Ex Terminal Base |

1797-5.1 |

|

|

|

|

|

|

|

1797-TB3S |

FLEX Ex Spring Clamp Terminal Base |

1797-5.2 |

|

|

|

|

|

|

|

1797-OE8 |

FLEX Ex 8 Output Analog Module |

1797-5.3 |

1797-6.5.1 |

|

|

|

|

|

|

1797-IRT8 |

FLEX Ex RTD/Thermocouple/mV |

1797-5.4 |

1797-6.5.2 |

|

|

Module |

|

|

|

|

|

|

|

|

1797-IE8 |

FLEX Ex 8 Input Analog Module |

1797-5.5 |

1797-6.5.1 |

|

|

|

|

|

|

1797-IE8NF |

FLEX Ex 8 Input Analog Module w/ |

1797-5.31 |

1797-6.5.1 |

|

|

Noise Filter |

|

|

|

|

|

|

|

|

1797-OB4D |

4 Output Module |

1797-5.6 |

|

|

|

|

|

|

|

1797-IBN16 |

FLEX Ex NAMUR Digital Input Module |

1797-5.7 |

|

|

|

|

|

|

|

1797-IJ2 |

2 Frequency Input Module |

1797-5.9 |

1797-6.5.4 |

|

|

|

|

|

|

1797-PS2N |

FLEX Ex Power Supplies |

1797-5.12 |

|

|

1797-PS2E |

|

|

|

|

|

|

|

|

|

1797-ACNR15 |

ControlNetEx Adapter |

1797-5.14 |

1797-6.2.1 |

|

|

|

|

|

|

1797-RPA, -RPFM |

Fiber Hub |

1797-5.15 |

1797-6.2.1 |

|

|

|

|

|

|

1797-BIC |

Bus Isolator |

1797-5.13 |

|

|

|

|

|

|

|

1797-TPR, |

FLEX Ex Taps |

1797-5.18 |

1797-6.2.1 |

|

- TPRS, -TPYR, |

|

|

|

|

-TPYS |

|

|

|

|

|

|

|

|

|

1797-CE1S, |

Interconnect Cables |

1797-5.20 |

|

|

-CE3S, -CEFTN, |

|

|

|

|

-CEFTE |

|

|

|

|

|

|

|

|

|

1797-EXMK |

Marker Kit |

1797-5.23 |

|

|

|

|

|

|

|

1797 |

FLEX Ex System Certification |

|

1797-6.5.6 |

|

|

|

|

|

|

This preface gave you information on how to use this manual efficiently. The next chapter introduces you to the 1797-IRT8 Thermocouple/RTD/mV Input module.

Publication 1797-6.5.2 - February 2001

Table of Contents

Preface

Using This Manual

Table of Contents

About the FLEX Ex Thermocouple/

RTD/mV Input Module

Understanding Configurable FLEX

Ex Thermocouple/RTD/mV Input

Module Features

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Why Read this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Who Should Read this Manual . . . . . . . . . . . . . . . . . . . . . . . . 3 About the Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 What this Manual Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 3 For Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . 4 In Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 1

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 1-1 What the FLEX Ex Thermocouple/RTD/mV Modules Do. . . 1-1 How FLEX Ex Thermocouple/RTD/mV Modules

Communicate with Programmable Controllers . . . . . . . . . . 1-2 Events following Power-Up . . . . . . . . . . . . . . . . . . . . . 1-2 Features of Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 Using Alarms on the 1797-IRT8 Module . . . . . . . . . . . . . . . 1-3 Data Format Alarm Example. . . . . . . . . . . . . . . . . . . . . 1-4

Overrange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Underrange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Open Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Cold Junction Compensation Alarm . . . . . . . . . . . . . . . . . . . . 1-4

Data Formats and Fault Modes . . . . . . . . . . . . . . . . . . . 1-5 Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Setting a FLEX Ex Thermocouple/RTD Module’s Operating Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Input Type Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 Sensor Type Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 Input Filter Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 Sensor Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 Preset Temperature Select . . . . . . . . . . . . . . . . . . . . . . 2-5 RTD Loop Resistance Offset Select . . . . . . . . . . . . . . . . 2-6 Fault Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 Using Module Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 Overrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7 Underrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8 Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9 Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Publication 1797-6.5.2 - February 2001

Table of Contents |

ii |

|

|

How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Input, Status, Output and Configuration Files for the Thermocouple/RTD/mV Module on the ControlNet Network

Chapter 3

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Before You Install Your Analog Module. . . . . . . . . . . . . . . 3-1 Compliance to European Union Directives . . . . . . . . . . . . . 3-2 EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Ex Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Installation in Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Electrostatic Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removal and Insertion

Under Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Installing the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Mounting on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Panel/Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Mounting the 1797-IRT8 Module on the Terminal

Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 Wiring the Terminal Base Units . . . . . . . . . . . . . . . . . . . . . 3-9 Connecting Wiring to the

FLEX Ex Thermocouple/RTD/mV Module . . . . . . . . . . . . . 3-10 Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10 Wiring connections for the 1797-IRT8 Module . . . . . . . . 3-11 Grounding the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Chapter 4

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Using Programming Software in Your FLEX Ex Application. 4-2 About the ControlNet Ex Adapter. . . . . . . . . . . . . . . . . . . . 4-2 Communication Over the FLEX Ex Backplane . . . . . . . . . . 4-2 Scheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . 4-3 Unscheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . 4-3 Module I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 I/O Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 Adapter Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 Fault State Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 Device Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 Communication Fault Behavior. . . . . . . . . . . . . . . . . . . 4-6 Idle State Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7 Input Data Behavior upon Module Removal . . . . . . . . . 4-7

Thermocouple/RTD/mV Input Module (1797-IRT8) Image Table Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8 Bit/Word Description for the Thermocouple/RTD/mV Input Module (1797-IRT8) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Publication 1797-6.5.2 - February 2001

Table of Contents |

iii |

|

|

Calibrating Your Module

Applying FLEX Ex Thermocouple/

RTD/mV Input Modules

Troubleshooting the FLEX Ex

Thermocouple/RTD/mV Input

Module

Specifications

Chapter 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 5-1 When and How to Calibrate Your FLEX Ex Thermocouple/RTD/mV Input Module. . . . . . . . . . . . . . . . 5-1 Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Calibration Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chapter 6

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 6-1 Evaluate the Application . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 Define the Area Classification . . . . . . . . . . . . . . . . . . . . . . 6-2 Decide Classification Method . . . . . . . . . . . . . . . . . . . . 6-2 Determine Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 Determine Temperature Rating . . . . . . . . . . . . . . . . . . . 6-2 Select Protection Method(s) . . . . . . . . . . . . . . . . . . . . . . . . 6-3 Match Field Devices and I/O Modules . . . . . . . . . . . . . . . . 6-3

1797-IRT8 and Thermocouple and RTD Functional and IS Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 Using the Entity Method. . . . . . . . . . . . . . . . . . . . . . . . 6-5 Entity Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6 General Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Interconnect Wiring 6-7

I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8 Optimize Power Distribution . . . . . . . . . . . . . . . . . . . . . . . 6-8 Assigning Power Supplies . . . . . . . . . . . . . . . . . . . . . . 6-8 Power Supply Considerations . . . . . . . . . . . . . . . . . . . . 6-9 Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Chapter 7

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

CE/CENELEC I/O Entity Parameters . . . . . . . . . . . . . . . . . . A-2

UL, C-UL I/O Entity Parameters . . . . . . . . . . . . . . . . . . . . . A-3

Table 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

FM I/O Entity Parameters . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Wiring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Table 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Publication 1797-6.5.2 - February 2001

Table of Contents |

iv |

|

|

Programming the FLEX Ex I/O

Modules

Using RIO

Index

Back Cover

Appendix B

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . B-1 Enter Block Transfer

Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 Using the PLC-5C Processor. . . . . . . . . . . . . . . . . . . . . . . . B-2

Publication 1797-6.5.2 - February 2001

Chapter 1

About the FLEX Ex Thermocouple/RTD/mV

Input Module

What this Chapter Contains

What the FLEX Ex

Thermocouple/RTD/mV

Modules Do

Read this chapter to familiarize yourself with the 1797-IRT8 input module.

For information on: |

See page: |

|

|

What the FLEX Ex Thermocouple/ |

1-1 |

RTD/mV Modules Do |

|

|

|

How FLEX Ex Thermocouple/RTD/mV |

1-2 |

Modules Communicate with |

|

Programmable Controllers |

|

|

|

Features of Your Module |

1-2 |

|

|

Chapter Summary |

1-5 |

|

|

The 1797-IRT8 module accepts up to 8 thermocouple, RTD or mV inputs. The inputs are nonisolated and are selected with analog multiplexers which have a common-mode input range of -0.5 to +3.6 volts. The inputs will accept a millivolt or resistive input. Default input spans are –40.00mV to +100.00mV or 0.00 to 500.00 ohms. Fault Indicators are located on the field side.

No switches or jumpers are used on the thermocouple/RTD/mV input module. The Inputs have both fixed hardware filters and selectable firmware digital filters.

This module offers:

∙local microprocessor intelligence for advanced features

∙full functionality without switches or jumpers

∙multiple data ranges that can be independently programmed in channel groups

∙lead breakage detection

∙overrange/underrange alarms

as well as a host of other module features.

Publication 1797-6.5.2 - February 2001

1-2 About the FLEX Ex Thermocouple/RTD/mV Input Module

How FLEX Ex Thermocouple/RTD/mV Modules Communicate with Programmable Controllers

FLEX Ex thermocouple/RTD/mV modules provide best utility when used with ControlNet Ex products on the ControlNet network. Data connections are established between the I/O module and an Allen-Bradley programmable controller to transfer information between the two at a scheduled rate.

Input module information is then automatically made available in the PLC data table.

When the data connection is established, configuration information for the module is automatically transferred to it via the network.

Events following Power-Up

You must apply intrinsically safe +/-V power to your FLEX Ex I/O modules. The following sequence of events occurs after power has initially been applied to your module:

1.The module begins an interal diagnostic check. The channel 0 LED indicator turns ON to indicate the check has begun. The indicator turns OFF when the check is finished.

2.After the diagnostic check, module configuration information, selected by the user and downloaded over the network, is applied by the module.

For more information on configuration options, see Chapter 2.

3.Following the module configuration download for the 1797-IRT8 module, the module begins producing runtime data for the PLC.

4.If any diagnostics or alarms are generated during normal module operation, the data is returned to the PLC.

Features of Your Module The module label identifies the keyswitch position, wiring and module type. Use the removable label to note individual designations

per your application.

Publication 1797-6.5.2 - February 2001

About the FLEX Ex Thermocouple/RTD/mV Input Module |

1-3 |

|

|

Using Alarms on the 1797-IRT8 Module

Indicators

Indicators are provided to identify input or output fault conditions, and to show when power is applied to the module.

1797-IRT8

Module Type

Removable Label

Ex

Ex

1797-IRT8

Keyswitch Position

Indicator (#2)

PWR Power On Indicator

Power On Indicator

Input Designators |

|

40070 |

|

The 1797-IRT8 FLEX Ex module is capable of generating four alarms:

∙Underrange

∙Overrange

∙Fault (open wire)

∙Cold junction compensation Fault

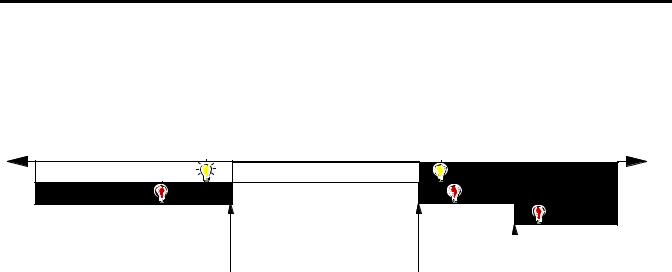

These alarm conditions are described in general terms and as they relate to bits on the FLEX Ex I/O module on the following pages. The graphic below shows at what values these alarms are generated for Data Format 4.

Publication 1797-6.5.2 - February 2001

1-4 About the FLEX Ex Thermocouple/RTD/mV Input Module

|

Data Format Alarm Example |

|

|

In this example, the normal active data range is 4-20mA. The alarms |

|

|

are generated in three overlapping bands. |

|

|

PHYSICAL INPUT SIGNAL RANGE |

|

underrange |

normal signal range |

overrange |

CJC fault |

|

CJC fault |

|

|

open wire fault |

Minumum |

Maximum |

|

|

|

|

Maximum |

Channel Data |

||||

Value for |

Value for |

Measureable |

Forced to |

||

Sensor |

Sensor |

Value |

Maximum for Type |

||

Type |

Type |

||||

|

|

|

|||

|

|

|

|||

Overrange

If the input is greater than the maximum temperature of the thermocouple or RTD range, millivolt (+100mV), or resistance (500W) the overrange bit for that channel will be set.

Underrange

If the input is less than the minimum temperature of the thermocouple or RTD range, millivolt (-40mV), or resistance (0W) the underrange bit for that channel will be set.

Open Wire

Individual channel fault alarm for broken wire. If a broken wire/ detached lead is detected, the data value is forced to maximum. In RTD/W mode, input levels above 540W will set this bit; in thermocouple/mV mode, input levels above 210mV will set this bit.

Cold Junction Compensation Alarm

Broken or detached lead or shorted lead detection is included for CJCs. This detection is only available when the input type selected is thermocouple and sensor mode is set to CJC compensation.

When either CJC fails its fault is reported. Both CJCs ae normally used in compensation calculations. If one CJC fails, calculations use the remaining good device. If both fail, calculations use the last good value.

Publication 1797-6.5.2 - February 2001

About the FLEX Ex Thermocouple/RTD/mV Input Module |

1-5 |

|

|

Chapter Summary

Data Formats and Fault Modes

The tables below shows the bit settings for the data formats and fault modes for your FLEX Ex thermocouple/RTD/mV module.

Data Formats

Bit |

11 |

10 |

09 |

08 |

Data type for channels 0 thru 7 |

|

0 |

0 |

0 |

0 |

oC (see note) |

|

0 |

0 |

0 |

1 |

oF (see note) |

|

0 |

0 |

1 |

0 |

oK (see note) |

|

0 |

0 |

1 |

1 |

-32767 to +32767 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

0 to 65535 |

|

|

|

|

|

|

|

0101 thru 1111 not used |

||||

|

|

|

|

|

|

Note: Module defaults to -4000 to 10,000 in millivolt mode, and 0 to 5000 in ohms mode

Fault Mode

Bit |

06 |

Fault enable for channels 0-3 |

|

|

07 |

Fault enable for channels 4-7 |

|

|

|

|

|

|

|

0 |

= disabled |

|

|

1 |

= enable wire-off detection |

|

|

|

|

In this chapter, we told you about the FLEX Ex system and the thermocouple/RTD/mV module, and how it communicates with programmable controllers.

Publication 1797-6.5.2 - February 2001

1-6 About the FLEX Ex Thermocouple/RTD/mV Input Module

Publication 1797-6.5.2 - February 2001

Chapter 2

What this Chapter Contains

Understanding Configurable FLEX Ex

Thermocouple/RTD/mV Input

Module Features

Read this chapter to familiarize yourself with configurable features on the 1797-IRT8 module.

For information on: |

See page: |

|

|

Setting a FLEX Ex Thermocouple/RTD |

2-2 |

Module’s Operating Status |

|

|

|

Input Type Select |

2-2 |

|

|

Sensor Type Select |

2-2 |

|

|

Data Format |

2-4 |

|

|

Preset Temperature Select |

2-5 |

|

|

RTD Loop Resistance Offset Select |

2-6 |

|

|

Fault Mode Select |

2-7 |

|

|

Using Module Alarms |

2-7 |

|

|

Overrange Alarm |

2-7 |

|

|

Underrange Alarm |

2-8 |

|

|

Fault Alarm |

2-9 |

|

|

Chapter Summary |

2-9 |

|

|

This chapter describes the following features:

∙Input type

∙Sensor type

∙Data formats

∙Preset temperature selection

∙RTD loop resistance offset selections

∙Fault mode

∙Overrange Alarms

∙Underrange alarms

∙Fault alarms

Important:You must use your programming software to configure these features. A brief description of each module feature is provided in this chapter, but you must use the online help included with your programming software to perform specific configuration.

Publication 1797-6.5.2 - February 2001

2-2 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

Setting a FLEX Ex

Thermocouple/RTD

Module’s Operating

Status

Input Type Select

Select the thermocouple or RTD mode for input channel groups 0-3 and 4-7. If 2 is selected, the module defaults to thermocouple. If 3 is selected, the module defaults to RTD.

Range: 0 = thermocouple, 1 = RTD, 2 and 3 not used

Bits 06-07 |

Input Type Select |

|

||

|

|

|

|

|

|

Bit |

07 |

06 |

Input type selection for channels 0-3 |

|

|

|

|

|

|

|

0 |

0 |

Thermocouple |

|

|

|

|

|

|

|

0 |

1 |

RTD |

|

|

|

|

|

|

|

1 |

0 |

Not used |

|

|

|

|

|

|

|

1 |

1 |

|

|

|

|

||

|

|

|

|

|

Input type select for channels 4 through 7 use bits in word 1.

Sensor Type Select

Select the type of sensor for input channel groups 0-3 and 4-7.

Thermocouple mode 0 = mV, 1 = B, 2 = E, 3 = J, 4 = K, 5 = TXK/ XK(L), 6 = N, 7 = R, 8 = S, 9 = T, 10-15 not used.

RTD mode: 0 = W, 1 = Pt100 IEC 751 Amendment 2, 2 = Pt200 IEC 751 Amendment 2, 3 = Pt100 JIS C1604-1989, 4 = Pt200 JIS C1604-1989, 5 = Ni100 DIN 43760-1987, 6 = Ni200 DIN 43760-1987, 7 = Ni120 Minco, 8 = Cu10 Minco, 9-15 not used.

If unused settings are chosen, diagnostic status “2 = configuration failure” will be set, and the last valid configuration will be used. The default = 0.

Publication 1797-6.5.2 - February 2001

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features |

2-3 |

|

|

Bits 00-03 Sensor Type (Thermocouple or RTD)

RTD Type

|

Bit |

03 |

02 |

01 |

00 |

Sensor type for channels 0 through 3 |

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

Resistance (default) |

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

100 ohm Pt α = 0.00385 Euro (–200 to +870°C) |

|

|

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

200 ohm Pt α = 0.00385 Euro (–200 to +400°C) |

|

|

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

100 ohm Pt α = 0.003916 U.S. (–200 to +630°C) |

|

|

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

200 ohm Pt α = 0.003916 U.S. (–200 to +400°C) |

|

|

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

100 ohm Nickel (–60 to +250°C) |

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

200 ohm Nickel (–60 to +200°C) |

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

120 ohm Nickel (–80 to +320°C) |

|

|

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

10 ohm Copper (–200 to +260°C) |

|

|

|

|

|

|

|

|

|

1001 through 1111 not used |

|

|||

|

|

|

|

|

|

|

Bits 00-03 Thermocouple Type

|

Bit |

03 |

02 |

01 |

00 |

Sensor type for channels 0 through 3 |

||

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

mV (default) |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

B |

300 to 1800°C |

(572 to 3272°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

E |

–250 to 1000°C |

(–418 to 1832°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

J |

–210 to 1200°C |

(–346 to 2192°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

K |

–250 to 1372°C |

(–418 to 2502°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

0 |

1 |

L |

–200 to 800°C |

(–328 to 1472°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

0 |

N |

–250 to 1300°C |

(–418 to 2372°F) |

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

R |

–0 to 1768°C |

(32 to 3214°F) |

|

|

|

|

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

S |

–0 to 1768°C |

(32 to 3214°F) |

|

|

|

|

|

|

|

|

|

|

|

1 |

0 |

0 |

1 |

T |

–250 to 400°C |

(–418 to 752°F) |

|

|

|

|

|

|

|

|

|

|

|

1010 through 1111 not used |

|

|

|

|||

|

|

|

|

|

|

|

|

|

Input Filter Cutoff

A series of eight available input filters – filters are hardware and software – allow you to choose the best rolloff frequency for input channels on your I/O module. When choosing a filter, remember that time frequency rolloff may affect your input signal’s accuracy.

For example, in configuration word 0, if you choose the fastest time frequency of 600Hz (hardware filter only), little noise is added, but the slowest frequency of 0.2Hz will provide the most accurate process noise filtering. See below to decide which input filter to use in your application:

Publication 1797-6.5.2 - February 2001

2-4 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

Input Filter Cutoff bits

Bit |

02 |

01 |

00 |

Definition |

|

|

|

|

|

|

|

|

0 |

0 |

0 |

Hardware filtering only (default filtering) 600Hz (1.7ms) |

|

|

|

|

|

|

|

|

0 |

0 |

1 |

40Hz |

(25ms) |

|

|

|

|

|

|

|

0 |

1 |

0 |

10Hz |

(100ms) |

|

|

|

|

|

|

|

0 |

1 |

1 |

4Hz |

(250ms) |

|

|

|

|

|

|

|

1 |

0 |

0 |

2Hz |

(500ms) |

|

|

|

|

|

|

|

1 |

0 |

1 |

1Hz |

(1s) |

|

|

|

|

|

|

|

1 |

1 |

0 |

0.5Hz |

(2s) |

|

|

|

|

|

|

|

1 |

1 |

1 |

0.2Hz |

(5s) |

|

|

|

|

|

|

Choose the best input filter cutoff in your programming software.

Data Format

You must choose a module data format in your user program. Select the format by setting bits as shown below. Note that this parameter affects channel accuracy.

Data format – module defaults to –4000 to 10000 in millivolt mode, and 0 to 5000 in ohms mode

Bit |

11 |

10 |

09 |

08 |

Data type for channels 0-7 |

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

°C |

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

°F |

|

|

|

|

|

|

|

0 |

0 |

1 |

0 |

×K |

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

–32767 to +32767 |

|

|

|

|

|

|

|

0 |

1 |

0 |

0 |

0 to 65535 |

|

|

|

|

|

|

|

0101 through 1111 not used |

|

|||

|

|

|

|

|

|

oC, oF and oK will have formats appropriate to the selected thermocouple or RTD range (e.g. -xxxx to +xxxx with 1 decimal place implied - 3500 = 350.0). For Cu10 RTD, 2 decimal points are implied.

If using mV, data format defaults to -4000 to +10000 (2 decimal points implied (e.g. -40 to 100.00). If using W mode selection, data format defaults to 0 to 5000 (1 decimal point implied, e.g. 0.- to 500.0).

In the thermocouple and RTD modes, if unused data formats are chosen, the module will default to oC.

Publication 1797-6.5.2 - February 2001

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features |

2-5 |

|

|

Sensor Mode Select

Selects the sensor mode for input channels 0-3 and 4-7.

If using cold junction compensation, both CJCs must be installed. The difference between the CJCs will be linearly apportioned to each thermocouple channel based on its position across the base. If one CJC is broken or missing, the remaining CJC is used to compensate all channels. The appropriate CJC alarm will be set in this case. If the second CJC fails, the last valid reading is frozen for compensation use. The second CJC alarm will also be set.

When using only channels 0-3 for thermocouples, connect the CJCs to terminals 5 and 12. If only using channels 4-7, connect the CJCs to terminals 22 and 29. If all channels are configured for thermocouples, connect the CJCs to terminals 5 and 29.

When CJC thermistor temperature compensation is selected for one channel group, all channels configured for thermocouple inputs will use the CJC compensation.

Bit |

05 |

04 |

Sensor mode for channels 0 thru 3 |

|

13 |

12 |

Sensor mode for channels 4 thru 7 |

||

|

||||

|

|

|

Thermocouple Mode |

|

|

0 |

0 |

External compensation - uses cold junction sensors |

|

|

0 |

1 |

Internal compensation - Uses the value selected for reference junction |

|

|

1 |

0 |

No compensation (Data is referenced to 0oC) |

|

|

1 |

1 |

Differential measurement between 2 channels |

|

|

|

|

RTD Mode |

|

|

0 |

0 |

2-wire RTD - no compensation |

|

|

0 |

1 |

2-wire RTD with user compensation |

|

|

1 |

0 |

3-wire RTD |

|

|

1 |

1 |

4-wire RTD |

Preset Temperature Select

This parameter is used if Input Type Select is set to thermocouple and Sensor Mode Select is set to fixed compensation. This parameter then sets a fixed reference temperature used to compensate all thermocouple channels.

The default = 0.

Publication 1797-6.5.2 - February 2001

2-6 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

Bits 03-05 Reference Junction – used when input type is set to thermocouple and sensor mode is set to fixed compensation. Sets a fixed reference junction to compensate all thermocouple channels.

|

Bit |

05 |

04 |

03 |

Reference Junction |

|

|

|

|

|

|

|

|

0 |

0 |

0 |

0°C |

|

|

|

|

|

|

|

|

0 |

0 |

1 |

20°C |

|

|

|

|

|

|

|

|

0 |

1 |

0 |

25°C |

|

|

|

|

|

|

|

|

0 |

1 |

1 |

30°C |

|

|

|

|

|

|

|

|

1 |

0 |

0 |

40°C |

|

|

|

|

|

|

|

|

1 |

0 |

1 |

50°C |

|

|

|

|

|

|

|

|

1 |

1 |

0 |

60°C |

|

|

|

|

|

|

|

|

1 |

1 |

1 |

70°C |

|

|

|

|

|

|

RTD Loop Resistance Offset Select

This parameter is used if Input Type Select is set to RTD and Sensor Mode Select is set to 2-wire with loop resistance compensation. This parameter then sets total RTD loop resistance compensation for each RTD channel. Either the value stored for each channel during calibration is used to compensate the module RTD channels, or one of 3 fixed values is used to compensate module RTD channels.

This parameter is disabled for Cu10 RTDs.

00-15 (00-17) RTD loop resistance offset select bits – used input type is set to RTD and sensor mode select is set to 2-wire with loop resistance compensation. Allows you to set the type of RTD loop resistance compensation used for all RTDs or one of three fixed values for all channels. NOTE: Not applicable to 10W copper RTD, which defaults to 0W.

|

Bit |

01 |

00 |

RTD channel 0 |

|

|

|

|

|

|

Bit |

03 |

02 |

RTD channel 1 |

|

|

|

|

|

|

Bit |

05 |

04 |

RTD channel 2 |

|

|

|

|

|

|

Bit |

07 |

06 |

RTD channel 3 |

|

|

|

|

|

|

Bit |

09 |

08 |

RTD channel 4 |

|

|

|

|

|

|

Bit |

11 |

10 |

RTD channel 5 |

|

|

|

|

|

|

Bit |

13 |

12 |

RTD channel 6 |

|

|

|

|

|

|

Bit |

15 |

14 |

RTD channel 7 |

|

|

|

|

|

|

|

0 |

0 |

Use channel loop compensation value stored during |

|

|

|

|

calibration procedure for 2-wire RTD (default = 0W) |

|

|

|

|

|

|

|

0 |

1 |

5W |

|

|

|

|

|

|

|

1 |

0 |

10W |

|

|

|

|

|

|

|

1 |

1 |

15W |

|

|

|

|

|

Range: 0 = use channel loop compensation value determined and

stored during calibration procedure for 2-wire RTD, 1 = 5Ω, 2 = 10Ω, 3 = 15Ω. Default = 0.

Publication 1797-6.5.2 - February 2001

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features |

2-7 |

|

|

Fault Mode Select

Select whether the channel fault detection is enabled or disabled for channels 0-3 and 4-7.

Range: 0 = disable, 1 = fault detection enabled (wire off, mV overvoltage, RTD open). Default = 0.

Bits 06-07 Fault Mode bits – when a bit is set (1), fault mode is enabled for that channel. Bit 06 corresponds to channels 0-3; bit 07 corresponds to channels 4-7.

0 = disabled

1 = enable wire-off detection

Using Module Alarms |

FLEX Ex I/O modules are capable of generating four alarms: |

|

|

∙ |

Overrange |

|

∙ |

Underrange |

|

∙ |

Fault |

∙ Cold Junction Compensation (CJC) Fault

These alarm conditions are described in general terms and as they relate to bits on the FLEX Ex I/O module on the following pages.

Overrange Alarm

The channel overrange alarm is set if the input is greater than the maximum temperature (thermocouple or RTD range dependent), millivolt (+100mV) or resistance (500Ω) range value.

Range: 0 = normal, 1 = input overrange. Default = 0.

This alarm stays active at any value above 100% of range and is always enabled by the module. Refer to the figure below for the sensor dependent signal which causes this alarm to be generated.

Publication 1797-6.5.2 - February 2001

2-8 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

IRT8 Specific alarming performance |

||

|

PHYSICAL INPUT SIGNAL RANGE |

|

underrange |

normal signal range |

overrange |

CJC fault |

|

CJC fault |

|

|

open wire fault |

Sensor Type

IEC PT100 |

-200C |

+870C |

IEC PT200 |

-200C |

+400C |

JIS PT100 |

-200C |

+630C |

JIS PT200 |

-200C |

+400C |

DIN Ni100 |

-60C |

+250C |

DIN Ni200 |

-60C |

+200C |

Minco Ni120 |

-80C |

+320C |

Minco Cu10 |

-200C |

+260C |

0-500 Resistance |

0ohm |

500ohm |

millivolt |

-40mV |

+100mV |

B |

300C |

+1800C |

E |

-250C |

+1000C |

J |

-210C |

+1200C |

K |

-250C |

+1372C |

TXK/XK(L) |

-200C |

+800C |

N |

-250C |

+1300C |

R |

0C |

+1768C |

S |

0C |

+1768C |

T |

-250C |

+400C |

Cold Junction Compensation |

-20C |

100C |

~ 520ohm equivalent |

|

~ 520ohm equivalent |

|

~ 520ohm equivalent |

|

~ 520ohm equivalent |

|

~ 520ohm equivalent |

|

~ 520ohm equivalent |

|

~ 520ohm equivalent |

Channel |

~ 520ohm equivalent |

Data |

~ 520ohm |

Forced |

~ 210mV |

to |

~ 210mV equivalent |

Maximum |

~ 210mV equivalent |

for Type |

|

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

~ 210mV equivalent |

|

Underrange Alarm

The channel underrange alarm is set if the input is less than the minimum temperature (thermocouple or RTD range dependent), millivolt (-40mV) or resistance (0Ω) range value.

Range: 0 = normal, 1 = input overrange. Default = 0.

This alarm stays active at any value below 0% of range and is always enabled by the module.

Range: 0 = normal, 1 = input overrange. Default = 0.

Publication 1797-6.5.2 - February 2001

Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features |

2-9 |

|

|

Chapter Summary

Fault Alarm

The module has individual channel fault alarms for a broken or detached wire. In any mode, if a broken/detached lead is detected, the data value is forced to maximum. Once the alarm is issued, it remains active as long as the input signal is faulted.

In mV mode, for input levels above 210mV, this bit is set.

In RTD mode, an open input will set this bit.

Range: 0 = normal,1 = wire off, excessive input fault detected.

Default = 0.

In this chapter, we told you about the FLEX Ex system and the analog I/O modules, and how they communicate with programmable controllers.

Publication 1797-6.5.2 - February 2001

2-10 Understanding Configurable FLEX Ex Thermocouple/RTD/mV Input Module Features

Publication 1797-6.5.2 - February 2001

Chapter 3

How to Install Your FLEX Ex Thermocouple/ RTD/mV Module

What this Chapter Contains

Before You Install Your

Analog Module

Read this chapter to install the 1797-IRT8 thermocouple/RTD/mV module.

For information on: |

See page: |

|

|

Before You Install Your Analog |

3-1 |

Module |

|

|

|

Compliance to European Union |

3-2 |

Directives |

|

|

|

Installation in Zone 1 |

3-2 |

|

|

Removal and Insertion Under Power |

3-3 |

|

|

Installing the Module |

3-3 |

|

|

Connecting Wiring to the FLEX Ex |

3-10 |

Thermocouple/RTD/mV Module |

|

|

|

Grounding the Module |

3-13 |

|

|

Chapter Summary |

3-13 |

|

|

Before installing your FLEX Ex analog module:

You need to: |

As described under: |

|

|

|

|

Verify that the module will be installed in a |

Installation in Zone 1, page 3-2 |

|

suitable metal enclosure |

|

|

|

|

|

Position the keyswitch on the |

Installing the Module, page 3-8 |

|

terminal base |

|

|

|

|

|

|

|

|

ATTENTION |

These modules do not receive primary operational |

|

power from the backplane. +/-V dc power must be |

||

|

||

|

applied to your module before installation. If power |

!is not applied, the module position will appear to the adapter as an empty slot in your chassis.

Publication 1797-6.5.2 - February 2001

3-2 How to Install Your FLEX Ex Thermocouple/RTD/mV Module

Compliance to European Union Directives

If this product has the CE mark, it is approved for installation within the European and EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic Compatibility (EMC) by applying the following standards, in whole or in part, documented in a technical construction file:

∙EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial Environment

∙EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Ex Directive

Installation in Zone 1

This product is tested to meet the Council Directive 94/9/EC (ATEX 100a) Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres by applying the following standards:

∙EN50014:1992, Electrical Apparatus for Potentially Explosive Atmospheres

∙EN50020:1994, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsic Safety “i”

∙prEN50284:1997, Special requirements for construction, test and marking of electrical apparatus of equipment group II, category 1G

This module must not be exposed to the environment. Provide a suitable metal enclosure.

ATTENTION

!

This module cannot be used in an intrinsically safe environment after it has been exposed to non-intrinsically safe signals.

Publication 1797-6.5.2 - February 2001

Loading...

Loading...