Rockwell Automation 2098-IPD-xxx User Manual

Ultra5000 Intelligent

Positioning Drives

(Catalog Numbers 2098-IPD-005, -005-DN 2098-IPD-010, -010-DN 2098-IPD-020, -020-DN

2098-IPD-030, -030-DN, -HV030, -HV030-DN 2098-IPD-HV050, -HV050-DN 2098-IPD-075, -075-DN,

2098-IPD-HV100, -HV100-DN 2098-IPD-150, -150-DN, -HV150, -HV150-DN 2098-IPD-HV220, -HV220-DN

Installation Manual

Important User Information |

Because of the variety of uses for the products described in this |

|

|

publication, those responsible for the application and use of this |

|

|

control equipment must satisfy themselves that all necessary |

|

|

steps have been taken to assure that each application and use |

|

|

meets all performance and safety requirements, including any |

|

|

applicable laws, regulations, codes and standards. |

|

|

The illustrations, charts, sample programs and layout examples |

|

|

shown in this guide are intended solely for purposes of example. |

|

|

Since there are many variables and requirements associated with |

|

|

any particular installation, Allen-Bradley® does not assume |

|

|

responsibility or liability (to include intellectual property liability) |

|

|

for actual use based upon the examples shown in this |

|

|

publication. |

|

|

Allen-Bradley publication SGI-1.1, Safety Guidelines for the |

|

|

Application, Installation and Maintenance of Solid-State Control |

|

|

(available from your local Allen-Bradley office), describes some |

|

|

important differences between solid-state equipment and |

|

|

electromechanical devices that should be taken into |

|

|

consideration when applying products such as those described |

|

|

in this publication. |

|

|

Reproduction of the contents of this copyrighted publication, in |

|

|

whole or part, without written permission of Rockwell |

|

|

Automation, is prohibited. |

|

|

Throughout this manual we use notes to make you aware of |

|

|

safety considerations: |

|

|

|

|

|

|

Identifies information about practices or |

|

ATTENTION |

|

|

circumstances that can lead to personal injury |

|

|

! |

|

|

or death, property damage or economic loss. |

|

|

|

|

Attention statements help you to:

•identify a hazard

•avoid a hazard

•recognize the consequences

|

Identifies information that is critical for |

|

IMPORTANT |

||

successful application and understanding of the |

||

|

||

|

||

|

product. |

|

|

|

Allen-Bradley is a registered trademark of Rockwell Automation.

ControlLogix, RSLogix 5000, Ultra5000, and Ultraware are trademarks of Rockwell Automation.

CSA is a registered trademark of Canadian Standards Association.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

UL and C-UL are registered trademarks of Underwriters Laboratories, Inc.

|

Table of Contents |

||

|

|

|

|

Preface |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

|

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

|

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

|

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-2 |

|

|

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-3 |

|

|

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . |

P-4 |

|

|

Product Receiving and Storage Responsibility . . . . . . . . . . . |

P-4 |

|

|

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-5 |

|

|

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . |

P-5 |

|

|

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . |

P-5 |

|

|

Comments Regarding this Manual . . . . . . . . . . . . . . . . . |

P-5 |

|

|

Chapter 1 |

|

|

Installing Your Ultra5000 |

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

|

|

Complying with European Union Directives . . . . . . . . . |

1-1 |

|

|

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

|

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

|

Before Mounting Your System . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

|

|

How to Store Your Ultra5000 Before Installation . . . . . . |

1-3 |

|

|

How to Unpack the System. . . . . . . . . . . . . . . . . . . . . . |

1-4 |

|

|

Minimum Mounting Requirements. . . . . . . . . . . . . . . . . |

1-5 |

|

|

Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

|

Sizing an Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

|

|

Transformer Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

|

|

Calculating Transformer Size Based on Speed/Torque |

||

|

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

|

|

Fuse Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

|

|

Bonding Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-10 |

|

|

Bonding Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-10 |

|

|

Bonding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . |

1-11 |

|

|

Mounting Your Ultra5000 Drive . . . . . . . . . . . . . . . . . . . . |

1-12 |

|

|

Chapter 2 |

|

|

Ultra5000 Connector |

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

Information |

Understanding Ultra5000 Controller Functions. . . . . . . . . . . |

2-2 |

|

|

Ultra5000 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

|

|

Understanding Ultra5000 Connectors . . . . . . . . . . . . . . . . . |

2-3 |

|

|

230V Ultra5000 Front Panel Connections . . . . . . . . . . . . |

2-4 |

|

|

500W, 1 kW, and 2 kW Ultra5000 |

|

|

|

(2098-IPD-005, -010, and -020). . . . . . . . . . . . . . . . . |

2-4 |

|

|

I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

|

|

Motor Encoder Connector . . . . . . . . . . . . . . . . . . . . |

2-6 |

|

|

Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . . |

2-7 |

|

|

Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-7 |

|

|

3 kW Ultra5000 |

|

|

|

(2098-IPD-030) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-8 |

|

|

Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

|

Publication 2098-IN001E-EN-P — April 2002

ii |

Table of Contents |

|

|

7.5 kW, and 15 kW Ultra5000

(2098-IPD-075, and -150) . . . . . . . . . . . . . . . . . . . . 2-10 I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11 Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-11 Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-11 Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

230V Ultra5000 with DeviceNet Front Panel Connections . . .

2-13

500W, 1 kW, and 2 kW Ultra5000 with DeviceNet (2098-IPD-005-DN, -010-DN, and -020-DN) . . . . . . . 2-13 I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-14 Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-14 DeviceNet Connector . . . . . . . . . . . . . . . . . . . . . . . 2-14 3 kW, 7.5 kW, and 15 kW Ultra5000

(2098-IPD-005-DN, -010-DN, and -020-DN) . . . . . . . 2-15 460V Ultra5000 Front Panel Connections . . . . . . . . . . . 2-16 I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17 Motor Encoder Connector . . . . . . . . . . . . . . . . . . . 2-17 Serial Port Connectors . . . . . . . . . . . . . . . . . . . . . . 2-17 Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Understanding Ultra5000 I/O Specifications. . . . . . . . . . . . 2-19 Digital I/O Power Supply . . . . . . . . . . . . . . . . . . . . . . 2-19 Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20 Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22 Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Understanding Motor Encoder Feedback Specifications . . . 2-25 AM, BM, and IM Inputs . . . . . . . . . . . . . . . . . . . . . . . . 2-25 Hall Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27 Thermostat Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27 + Limit and - Limit Inputs . . . . . . . . . . . . . . . . . . . . . . 2-28 Encoder Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29 Motor Encoder Connection Diagram . . . . . . . . . . . . . . 2-31 Unbuffered Motor Encoder Outputs . . . . . . . . . . . . . . 2-31 Buffered Motor Encoder Outputs . . . . . . . . . . . . . . . . 2-31

Understanding Auxiliary Encoder Feedback Specifications . 2-32 Auxiliary Encoder Interface . . . . . . . . . . . . . . . . . . . . . 2-32 Understanding the Serial Interface. . . . . . . . . . . . . . . . . . . 2-34 Default Serial Interface Settings . . . . . . . . . . . . . . . . . . 2-34

Publication 2098-IN001E-EN-P — April 2002

Table of Contents |

iii |

|

|

Chapter 3

Connecting Your Ultra5000 Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Powering the Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Accessing the Internal Digital I/O Power Supply . . . . . . 3-2 Understanding Basic Wiring Requirements . . . . . . . . . . . . . 3-4 Building Your Own Cables . . . . . . . . . . . . . . . . . . . . . . 3-4 Routing High and Low Voltage Cables. . . . . . . . . . . . . . 3-5 Grounding Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 Grounding Your System to the Subpanel . . . . . . . . . . . . 3-6 Grounding Multiple Subpanels . . . . . . . . . . . . . . . . . . . 3-7 Motor Power Cable Shield Termination . . . . . . . . . . . . . 3-7 Wiring Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 Connecting Interface Cables . . . . . . . . . . . . . . . . . . . . . 3-9 Wiring I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . 3-9 Connecting to a DeviceNet Network . . . . . . . . . . . . . . 3-10 Connecting Your DeviceNet Cable . . . . . . . . . . . . . . . 3-11 Assigning Your Ultra5000 DeviceNet Address . . . . . . . 3-12 Wiring Power Connections . . . . . . . . . . . . . . . . . . . . 3-14

Chapter 4

Commissioning Your Ultra5000 Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Startup Precautions . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Understanding Communication Switch Settings . . . . . . . . . . 4-2

Applying Power To Your System . . . . . . . . . . . . . . . . . . . . 4-3

Configuring Your Ultra5000 . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5

Maintaining Your Ultra5000 Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Maintaining the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Cleaning the Drive . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Inspecting the Cables . . . . . . . . . . . . . . . . . . . . . . . 5-2 General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Troubleshooting for DeviceNet Drives . . . . . . . . . . . . . . . . 5-6 DeviceNet Module Status LED . . . . . . . . . . . . . . . . . . . . 5-6 DeviceNet Network Status LED . . . . . . . . . . . . . . . . . . . 5-7 Node Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8 Device Failure - LED Status Check. . . . . . . . . . . . . . . . . 5-8 Scanner Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9 Power Supply Problems . . . . . . . . . . . . . . . . . . . . . . . . 5-9 Cable Installation and Design Problems . . . . . . . . . . . . 5-10 Adjusting the Physical Network Configuration . . . . . . . 5-10

Publication 2098-IN001E-EN-P — April 2002

iv |

Table of Contents |

|

|

Specifications and

Dimensions

Interconnect Diagrams

Appendix A

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 Ultra5000 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 General Power Specifications . . . . . . . . . . . . . . . . . . . . A-1 2098-IPD-005-xx, -010-xx, and -020-xx . . . . . . . . . . . A-1 2098-IPD-030-xx, -075-xx, and -150-xx . . . . . . . . . . . A-2

2098-IPD-HV030-xx, -HV050-xx, -HV100-xx, -HV150-xx, and -HV220-xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Physical and Environmental. . . . . . . . . . . . . . . . . . . . . . A-4 Power Dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5 User Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6 Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6 Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7 Motor Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8 Auxiliary Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Appendix B

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 Ultra5000 and Motor Cable Diagrams . . . . . . . . . . . . . . . . . B-1 Ultra5000 Drive and Motor Cable Combinations . . . . . . . B-1 Ultra5000 to Motor Interconnect Diagrams . . . . . . . . . . . B-3 Ultra5000 Power Wiring Diagrams . . . . . . . . . . . . . . . . . . B-15 Using an Emergency Stop Contactor . . . . . . . . . . . . . . . . . B-20 Grounding for Ultra5000 CE Requirements . . . . . . . . . . . . B-22 Ultra5000 Shunt Module Information. . . . . . . . . . . . . . . . . B-23 300 Watt Active Shunt Module. . . . . . . . . . . . . . . . . . . B-23 200 Watt Passive Shunt Module . . . . . . . . . . . . . . . . . . B-23 900 Watt Passive Shunt Module . . . . . . . . . . . . . . . . . . B-24 2090 Passive Shunt Module . . . . . . . . . . . . . . . . . . . . . B-24

Publication 2098-IN001E-EN-P — April 2002

Table of Contents |

v |

|

|

Catalog Numbers and

Accessories

WiringThreePhas ePowertoa

Single Phase Ultra5000

Appendix C

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Ultra5000 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Ultraware Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

External Shunt Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

300 Watt Active Shunt Ferrites. . . . . . . . . . . . . . . . . . . . C-5

2090 Series Passive Shunts . . . . . . . . . . . . . . . . . . . . . . C-5

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Motor Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Motor Feedback Cables . . . . . . . . . . . . . . . . . . . . . . . . C-7

MP-Series Motor Brake Cable . . . . . . . . . . . . . . . . . . . . C-8

Ultra5000 Interface Cables. . . . . . . . . . . . . . . . . . . . . . . C-8

Break Out Boards, Cables, and Kits . . . . . . . . . . . . . . . . . . C-8

Mating Connector Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Appendix D

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1 Applicable Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1 Mandatory Neutral Connection of Isolation Transformer . . . D-2 Adding a Safety Ground to the Isolation Transformer . . . D-3 Three Phase Line Filtering Requirements for EMC . . . . . . . . D-3 Voiding of CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Publication 2098-IN001E-EN-P — April 2002

vi |

Table of Contents |

|

|

Publication 2098-IN001E-EN-P — April 2002

Preface

Introduction

Read this preface to familiarize yourself with the rest of the manual. This preface contains the following topics:

•Who Should Use this Manual

•Purpose of this Manual

•Contents of this Manual

•Related Documentation

•Conventions Used in this Manual

•Product Receiving and Storage Responsibility

•Allen-Bradley Support

Who Should Use this Manual

Purpose of this Manual

Use this manual for designing, installing, programming, and troubleshooting the Ultra5000™ Intelligent Positioning Drive (IPD). If you do not have a basic understanding of the Ultra5000, contact your local Allen-Bradley representative for information on available training courses before using this product.

This manual describes the function and installation of the Ultra5000 products and standard Rockwell Automation/Allen-Bradley motors recommended for use with the Ultra5000. The manual is intended for engineers or technicians directly involved in the installation, operation, and field maintenance of the Ultra5000.

Publication 2098-IN001E-EN-P — April 2002

P-2 |

Preface |

|

|

Contents of this Manual

Refer to the following listing for the descriptive contents of this installation manual.

Chapter |

Title |

Contents |

|

|

|

|

Preface |

Describes the purpose, background, and |

|

|

scope of this manual. Also specifies the |

|

|

audience for whom this manual is intended. |

|

|

|

1 |

Installing Your Ultra5000 |

Provides mounting information for the |

|

|

Ultra5000. |

|

|

|

2 |

Ultra5000 Connector |

Provides connection and wiring information |

|

Information |

for the Ultra5000. |

|

|

|

3 |

Connecting Your Ultra5000 |

Provides steps to follow when applying |

|

|

power to the Ultra5000 for the first time. |

|

|

|

4 |

Commissioning Your |

Powering-up and configuring the Ultra5000 |

|

Ultra5000 |

drive. |

|

|

|

5 |

Maintaining Your Ultra5000 |

Provides diagnostic aids that help isolate |

|

|

problems with a drive. |

|

|

|

Appendix A |

Specifications and |

Provides physical, electrical, environmental, |

|

Dimensions |

and functional specifications for the |

|

|

Ultra5000. |

|

|

|

Appendix B |

Interconnect Diagrams |

Provides interconnect diagrams for the |

|

|

Ultra5000. |

|

|

|

Appendix C |

Catalog Numbers and |

Provides catalog numbers and descriptions |

|

Accessories |

of the Ultra5000 and related products. |

|

|

|

Appendix D |

Wiring Three Phase Power |

Discusses star (Y) connection of single |

|

to a Single Phase Ultra5000 |

phase Ultra5000 drives to a three phase |

|

|

power source. |

|

|

|

Publication 2098-IN001E-EN-P — April 2002

Preface |

P-3 |

|

|

Related Documentation

The following documents contain additional information concerning related Allen-Bradley products. To obtain a copy, contact your local Rockwell Automation office or distributor, or access the documents on-line at www.theautomationbookstore.com or www.ab.com/manuals/gmc.

For: |

Read This Document: |

Catalog Number: |

|

|

|

Active shunt installation instructions for: |

300 Watt Active Shunt Regulator Installation |

2090-IN001 |

• 2098-IPD-005, -005-DN |

Instructions |

|

• 2098-IPD-010, -010-DN |

|

|

• 2098-IPD-020, -020-DN |

|

|

|

|

|

Passive shunt installation instructions for: |

900 Watt Passive Shunt Module Installation |

2090-IN002 |

• 2098-IPD-075, -075-DN |

Instructions |

|

• 2098-IPD-150, -150-DN |

|

|

|

|

|

Passive shunt installation instructions for: |

200 Watt Passive Shunt Module Installation |

2090-IN003 |

• 2098-IPD-030, -030-DN |

Instructions |

|

|

|

|

Passive shunt installation instructions for: |

2090 Series Passive Shunts Installation |

2090-IN004 |

• 2098-IPD-HV030, -HV030-DN |

Instructions |

|

• 2098-IPD-HV050, -HV050-DN |

|

|

• 2098-IPD-HV100, -HV100-DN |

|

|

• 2098-IPD-HV150, -HV150-DN |

|

|

• 2098-IPD-HV220, -HV220-DN |

|

|

|

|

|

Ultraware™ installation instructions |

Ultraware CD Installation Instructions |

2098-IN002 |

|

|

|

Information on how to add a DeviceNet™ |

Ultra5000 DeviceNet Expansion Kit Installation |

2098-IN004 |

Expansion Kit to a Ultra5000 drive |

Instructions |

|

|

|

|

Information on programming the Ultra5000 using |

Ultra5000 Motion Library C Programming |

2098-PM001 |

the Motion Library |

Manual |

|

|

|

|

Information on communicating with the |

Ultra5000 DeviceNet Reference Manual |

2098-RM002 |

Ultra5000 using DeviceNet |

|

|

|

|

|

Information on configuring your Ultra5000 using |

Ultraware User Manual |

2098-UM001 |

Ultraware |

|

|

|

|

|

How to minimize and control system-level noise |

System Design for Control of Electrical Noise |

GMC-RM001 |

|

|

|

Information on attaching Ultra5000 drives to a |

DeviceNet Cable System Planning and |

DNET-UM072 |

DeviceNet network |

Installation Manual |

|

|

|

|

A copy of the DeviceNet Specification, Volumes I and II, Release 2.0 may be ordered from the web site http://www.odva.org of the Open

Device Vendor Association.

Publication 2098-IN001E-EN-P — April 2002

P-4 |

Preface |

|

|

Conventions Used in this Manual

The following conventions are used throughout this manual.

•Bulleted lists such as this one provide information, not procedural steps.

•Numbered lists provide sequential steps or hierarchical information.

•Words that you type or select appear in bold.

•When we refer you to another location, the section or chapter name appears in italics.

Product Receiving and

Storage Responsibility

You, the customer, are responsible for thoroughly inspecting the equipment before accepting the shipment from the freight company. Check the item(s) you receive against your purchase order. If any items are obviously damaged, it is your responsibility to refuse delivery until the freight agent has noted the damage on the freight bill. Should you discover any concealed damage during unpacking, you are responsible for notifying the freight agent. Leave the shipping container intact and request that the freight agent make a visual inspection of the equipment.

Store the product in its shipping container prior to installation. If you are not going to use the equipment for a period of time, store using the following guidelines.

•Use a clean, dry location

•Maintain an ambient temperature range of -40 to 70° C (-40 to 158° F)

•Maintain a relative humidity range of 5% to 95%, non-condensing

•Store it where it cannot be exposed to a corrosive atmosphere

•Store it in a non-construction area

Publication 2098-IN001E-EN-P — April 2002

Preface |

P-5 |

|

|

Allen-Bradley Support

Allen-Bradley offers support services worldwide, with over 75 Sales/ Support Offices, 512 authorized Distributors and 260 authorized Systems Integrators located throughout the United States alone, plus Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

•Sales and order support

•Product technical training

•Warranty support

•Support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please review the information in the chapter Maintaining Your Ultra5000 first, then call your local Allen-Bradley representative. For the quickest possible response, please have the catalog numbers of your products available when you call.

Comments Regarding this Manual

To offer comments regarding the contents of this manual, go to www.ab.com/manuals/gmc and download the Motion Control Problem Report form. Mail or fax your comments to the address/fax number given on the form.

Publication 2098-IN001E-EN-P — April 2002

P-6 |

Preface |

|

|

Publication 2098-IN001E-EN-P — April 2002

Chapter 1

Installing Your Ultra5000

Chapter Objectives

This chapter provides system installation guidelines and procedures for mounting your Ultra5000. This chapter covers the following topics:

•Complying with European Union Directives

•Before Mounting Your System

•Bonding Your System

•Mounting Your Ultra5000 Drive

ATTENTION

!

The following information is a guideline for proper installation. The National Electrical Code and any other governing regional or local codes overrule this information. The Allen-Bradley Company cannot assume responsibility for the compliance or the noncompliance with any code, national, local or otherwise, for the proper installation of this system or associated equipment. If you ignore codes during installation, the hazard of personal injury and/or equipment damage exists.

Complying with European Union Directives

If this product is installed within the European Union or EEC regions and has the CE mark, the following regulations apply.

Note: Declarations of Conformity (DOCs) to EU Directives are available on-line at www.ab.com/certification for Motion Control products. The web site is the authoritative source for verifying compliance and suitability for use of this and other Rockwell Automation/Allen-Bradley products.

The web site also provides links to other certification agencies (UL, CSA, etc.).

Publication 2098-IN001E-EN-P — April 2002

1-2 |

Installing Your Ultra5000 |

|

|

EMC Directive

This unit is tested to meet Council Directive 89/336/EEC Electromagnetic Compatibility (EMC) using a technical construction file and the following standards, in whole or in part:

•EN 50081-2 EMC - Emission Standard, Part 2 - Industrial Environment

•EN 50082-2 EMC - Immunity Standard, Part 2 - Industrial Environment

•EN 61800-3 - Adjustable Speed Electrical Power Drive Systems, Part 3 - EMC Product Standard including specific test methods

The product described in this manual is intended for use in an industrial environment.

To meet CE requirements, the following additions are required:

•Install a power line filter between the AC power source and the drive input, as close to the drive as possible. (Refer to AC Line Filters on page C-3.)

•Terminate the motor power cable shield to the chassis clamp provided.

•To meet CE requirements, the following additions may also be required:

–Run single-phase input wiring in conduit that is grounded to the enclosure.

–Terminate the shields of the motor power cables and the motor feedback cables to the enclosure at the point of entry.

Low Voltage Directive

These units are tested to meet Council Directive 73/23/EEC Low Voltage Directive. The EN 60204-1 Safety of Machinery-Electrical Equipment of Machines, Part 1-Specification for General Requirements standard applies in whole or in part. Additionally, the standard

EN 50178 Electronic Equipment for use in Power Installations applies in whole or in part.

Refer to Appendix B for interconnect information.

Publication 2098-IN001E-EN-P — April 2002

Installing Your Ultra5000 |

1-3 |

|

|

Before Mounting Your

System

Before you mount your Ultra5000 system make sure you understand the following:

•How to Store Your Ultra5000 Before Installation

•How to Unpack the System

•Minimum Mounting Requirements

How to Store Your Ultra5000 Before Installation

The Ultra5000 should remain in the shipping container prior to installation. If the equipment is not to be used for a period of time, store it as follows:

•Use a clean, dry location

•Maintain an ambient temperature range of -40 to 70° C (-40 to 158° F)

•Maintain a relative humidity range of 5% to 95%, non-condensing

•Store it where it cannot be exposed to a corrosive atmosphere

•Store it in a non-construction area

Publication 2098-IN001E-EN-P — April 2002

1-4 |

Installing Your Ultra5000 |

|

|

How to Unpack the System

Each Ultra5000 ships with the following:

•One Ultra5000 drive

•One installation manual, publication 2098-IN001

•Two I/O connector plugs (28 pin CN1A and 14 pin CN1B)

•One screwdriver

•One clear plastic terminal strip cover

|

Do not discard the clear plastic terminal strip cover. |

|

IMPORTANT |

||

Installing the plastic strip on the power terminal strip |

||

|

||

|

||

|

provides a physical barrier and protection. |

|

|

|

Ultra5000 drives with DeviceNet (2098-IPD-xxx-DN and -HVxxx-DN only) ship with the following additional items:

•One reference manual, publication 2098-RM002, for Ultra5000 drives with DeviceNet

•One DeviceNet connector plug for Ultra5000 drives with DeviceNet

Remove all packing material, wedges, and braces from within and around the components. After unpacking, check the item(s) name plate catalog number against the purchase order.

Publication 2098-IN001E-EN-P — April 2002

Installing Your Ultra5000 |

1-5 |

|

|

Minimum Mounting Requirements

There are several things that you need to take into account when preparing to mount the Ultra5000:

•The Ultra5000 is classified as IEC controlgear, and must be housed in an enclosure that meets IEC60529 requirements for electrical enclosure of controlgear.

•The ambient temperature of the location in which you will install the Ultra5000 must not exceed 55° C (131° F).

•You must install the enclosure on a flat, rigid, vertical surface that will not be subjected to shock, vibration, moisture, oil mist, dust, or corrosive vapors.

•You need to maintain minimum clearances (refer to Figure 1.1) within the enclosure for proper airflow, easy module access, and proper cable bend radius.

Refer to Appendix A for mounting dimensions, power dissipation, and environmental specifications for the Ultra5000.

Publication 2098-IN001E-EN-P — April 2002

1-6 |

Installing Your Ultra5000 |

|

|

Ventilation Requirements

This section provides information to assist you in sizing your cabinet and locating your Ultra5000 drive(s) inside the cabinet.

Figure 1.1

Minimum Clearance Requirements

Allow 12.7 mm (0.5 in.) side clearance

50.8 mm (2.0 in.) clearance for airflow and installation

Motor cable entry area for ground clamp

50.8 mm (2.0 in.) clearance for airflow and installation

Allow 12.7 mm (0.5 in.) side clearance

Minimum cabinet depth = 243.8 mm (9.6 in.)

Minimum front clearance = 76.2 mm (3.0 in.)

|

If the cabinet is ventilated, use filtered or |

|

IMPORTANT |

||

conditioned air to prevent the accumulation of dust |

||

|

||

|

||

|

and dirt on electronic components. The air should be |

|

|

free of oil, corrosives, or electrically conductive |

|

|

contaminates. |

|

|

|

Refer to Power Dissipation on page A-5 for Ultra5000 power dissipation specifications.

Publication 2098-IN001E-EN-P — April 2002

Installing Your Ultra5000 |

1-7 |

|

|

Sizing an Enclosure

As an additional aid in sizing an enclosure, with no active method of heat dissipation, either of the following approximate equations can be used:

Metric |

Standard English |

|

|

0.38Q |

4.08Q |

A = ------------------------ |

A = ---------------- |

1.8T – 1.1 |

T – 1.1 |

|

|

Where T is temperature difference between |

Where T is temperature difference between |

inside air and outside ambient (°C), Q is |

inside air and outside ambient (°F), Q is |

heat generated in enclosure (Watts), and A |

heat generated in enclosure (Watts), and A |

is enclosure surface area (m2). The exterior |

is enclosure surface area (ft²). The exterior |

surface of all six sides of an enclosure is |

surface of all six sides of an enclosure is |

calculated as |

calculated as |

|

|

A = 2dw + 2dh + 2wh |

A = (2dw + 2dh + 2wh) / 144 |

|

|

Where d (depth), w (width), and h (height) |

Where d (depth), w (width), and h (height) |

are in meters. |

are in inches. |

|

|

Transformer Sizing

The Ultra5000 does not require isolation transformers. However, a transformer may be required to match the voltage requirements of the controller to the available service. To size a transformer for the main AC power inputs, the power output (KVA) of each axis must be known. This can be derived by calculating the horsepower for each axis and converting that horsepower into units of watts. If you are supplying power to more than one motor and an Ultra5000, simply add the kW ratings together from each calculation to get a system kW total.

|

If using an autotransformer, ensure that the phase to |

|

IMPORTANT |

||

neutral/ground voltages do not exceed the input |

||

|

||

|

||

|

voltage rating of the drive referenced in General |

|

|

Power Specifications on Page A-1. |

|

|

|

Calculating Transformer Size Based on Speed/Torque Data

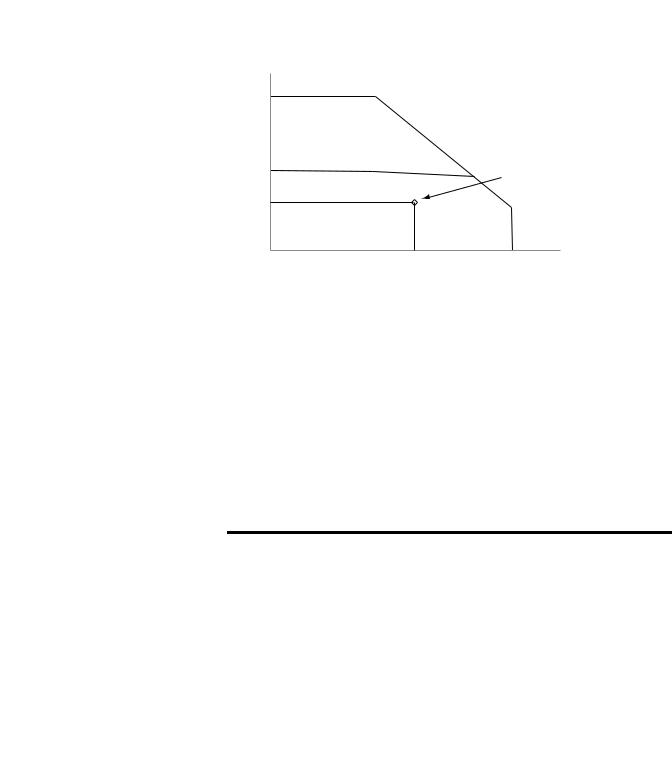

Base the transformer size on the operating point within the speed/ torque curve for the drive and motor application as shown in Figure 1.2. The operating point for this hypothetical 230V drive/motor combination is 23 lb-in and 3200 rpm.

Publication 2098-IN001E-EN-P — April 2002

1-8 |

Installing Your Ultra5000 |

|

|

Figure 1.2

Transformer Sizing Based on Speed/Torque Data for Single Phase System

TORQUE (lb-in)

Application

Operating Point

23.0 lb-in

3200 rpm |

SPEED (RPM) |

The formula and calculation are:

Speed(RPM) × Torque(lb – in) ×

KVA = --------------------------------------------------------------------------------

63, 025

3200rpm × 23.0lb – in KVA = -------------------------------------------------------

42, 250

TransformerSize = 1.75KVA

746----------Watts------------- |

× |

--------KVA------------------ |

× 2.0 |

HP |

|

1000Watts |

|

Definitions:

kW = power or real power KVA = apparent power

Transformer KVA rating = (Sum of average output power of each axis) x 2.0.

|

Calculations are multiplied by a factor to compensate |

|

IMPORTANT |

||

for the power and loss elements within a power |

||

|

||

|

||

|

system. |

|

|

•A factor of 2.0 is used with a single phase system. |

|

|

•A factor of 1.5 is used with a three phase system. |

|

|

This factor minimizes the effects of the secondary |

|

|

line voltage sagging in the transformer during peak |

|

|

current periods. |

|

|

|

|

|

|

|

|

If you are using the Rockwell Automation/ |

|

IMPORTANT |

||

Allen-Bradley system sizing program, the average |

||

|

||

|

||

|

speed and average torque data has already been |

|

|

calculated and can be used in the equation. If you |

|

|

are not sure of the exact speed and torque in your |

|

|

application, another approach is to look at the |

|

|

speed/torque curve for your Ultra5000/motor |

|

|

combination and use the values for the worst case |

|

|

continuous speed and torque. |

|

|

|

Publication 2098-IN001E-EN-P — April 2002

Installing Your Ultra5000 |

1-9 |

|

|

Fuse Sizing

The Ultra5000 is listed by Underwriters Laboratories, Inc. with fuses sized as four times the continuous output current of the drives (FLA), according to UL 508C.

In most cases, fuses selected to match the drive input current rating will meet the NEC requirements and provide the full drive capabilities. Dual element, time delay (slow acting) fuses should be used to avoid nuisance trips during the inrush current of power initialization. Refer to the section General Power Specifications in Appendix A for input current and inrush current specifications.

The Ultra5000 utilizes solid state motor short circuit protection rated as shown in the table below.

Drive Models: |

Short Circuit Current Rating with No |

Short Circuit Current Rating with Fuse |

|

Fuse Restrictions: |

Restrictions: |

|

|

|

|

||

|

|

|

|

2098-IPD-xxx-xx |

Suitable for use on a circuit capable of |

Suitable for use on a circuit capable of |

|

|

delivering not more than 5000 rms |

delivering not more than 200,000 rms |

|

|

symmetrical amperes, 240V maximum. |

symmetrical amperes, 240V maximum, |

|

|

|

when protected by high interrupting |

|

|

|

capacity, current limiting fuses meeting UL |

|

|

|

198C (Class CC, G, J, L, R, T). |

|

|

|

|

|

2098-IPD-HVxxx-xx |

Suitable for use on a circuit capable of |

Suitable for use on a circuit capable of |

|

|

delivering not more than 5000 rms |

delivering not more than 200,000 rms |

|

|

symmetrical amperes, 480V maximum. |

symmetrical amperes, 480V maximum, |

|

|

|

when protected by high interrupting |

|

|

|

capacity, current limiting fuses meeting UL |

|

|

|

198C (Class CC, G, J, L, R, T). |

|

|

|

|

|

|

|

Mains Input Fuses |

|

|

|

Mains input fuses shall be dual element |

|

|

|

time delay types class RK5, J or CC only. |

|

|

|

Fuse current ratings shall be the following, |

|

|

|

or the closest standard value to these |

|

|

|

minimums: |

|

|

|

2098-IPD-HV030-xx (3kW) |

5 A |

|

|

2098-IPD-HV050-xx (5kW) |

8 A |

|

|

2098-IPD-HV750-xx (10kW) |

17 A |

|

|

2098-IPD-HV100-xx (15kW) |

25 A |

|

|

2098-IPD-HV220-xx (22kW) |

35 A |

|

|

|

|

|

|

Auxiliary Input Fuses |

|

|

|

Auxiliary input fuses shall be dual element |

|

|

|

time delay types class RK5, J or CC only. |

|

|

|

Fuse current rating shall be the following, or |

|

|

|

the closest standard value to these |

|

|

|

minimums. |

|

|

|

All drive sizes |

0.4 A |

|

|

|

|

Publication 2098-IN001E-EN-P — April 2002

1-10 |

Installing Your Ultra5000 |

|

|

Bonding Your System

Bonding is the practice of connecting metal chassis, assemblies, frames, shields and enclosures to reduce the effects of electromagnetic interference (EMI).

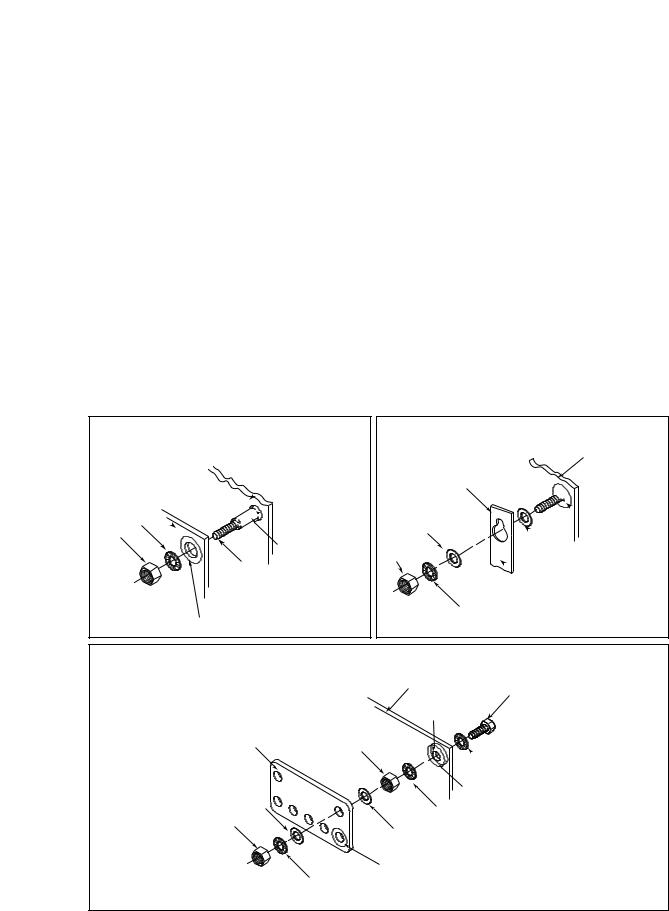

Bonding Modules

Unless specified, most paints are not conductive and they act as insulators. To achieve a good bond between modules and the subpanel, surfaces need to be paint-free or plated. Bonding metal surfaces creates a low-impedance exit path for high-frequency energy.

Improper bonding blocks that direct exit path and allows high-frequency energy to travel elsewhere in the cabinet. Excessive high-frequency energy can effect the operation of other microprocessor controlled equipment. The illustrations that follow (refer to Figure 1.3) show details of recommended bonding practices for painted panels, enclosures, and mounting brackets.

Figure 1.3

Recommended Bonding Practices

Stud-mounting the subpanel to the enclosure back wall

Subpanel

Star washer  Nut

Nut

Back wall of

enclosure

enclosure

Welded stud

Use a wire brush to remove paint from threads to maximize ground connection.

Use plated panels or scrape paint on front of panel.

Stud-mounting a ground bus or chassis to the subpanel

Mounting bracket or ground bus

Flat washer

Nut

Star washer

Subpanel

Welded stud

Welded stud

Scrape

Scrape  Flat washer

Flat washer

If the mounting bracket is coated with a non-conductive material (anodized, painted, etc.), scrape the material around the mounting hole.

If the mounting bracket is coated with a non-conductive material (anodized, painted, etc.), scrape the material around the mounting hole.

Bolt-mounting a ground bus or chassis to the back-panel

Ground bus or |

Nut |

|

mounting bracket |

||

|

Flat washer

Nut

Star washer

Subpanel

Bolt

Tapped

Star washer

Star washer

Scrape paint on both sides

of panel and use star Star washer

Flat washer

If the mounting bracket is coated with a non-conductive material (anodixed, painted, etc.), scrape the material around the mounting

Publication 2098-IN001E-EN-P — April 2002

Installing Your Ultra5000 |

1-11 |

|

|

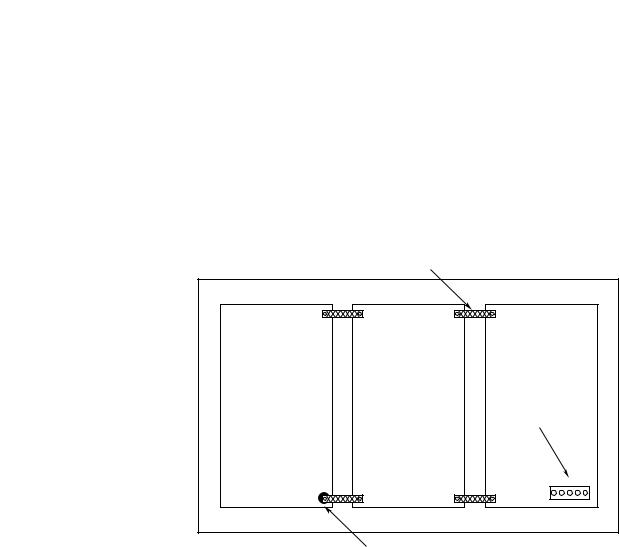

Bonding Multiple Subpanels

Bonding multiple subpanels creates a common low impedance exit path for the high frequency energy inside the cabinet. Subpanels that are not bonded together may not share a common low impedance path. This difference in impedance may affect networks and other devices that span multiple panels. Refer to the figure below for recommended bonding practices.

Figure 1.4

Multiple Subpanels and Cabinet

Recommended:

Bond the top and bottom of each subpanel to the cabinet using 25.4 mm (1.0 in.) by 6.35 mm (0.25 in.) wire braid.

Bonded cabinet |

ground bus to |

subpanel |

Scrape the paint around each fastener to maximize metal to metal contact.

Publication 2098-IN001E-EN-P — April 2002

1-12 |

Installing Your Ultra5000 |

|

|

Mounting Your Ultra5000

Drive

The procedures in this section assume you have prepared your panel and understand how to bond your system. For installation instructions regarding other equipment and accessories, refer to the instructions that came with each of the accessories for their specific requirements.

ATTENTION

!

This product contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Follow static control precautions when you install, test, service, or repair this assembly.

Refer to Allen-Bradley publication 8000-4.5.2, Guarding Against Electrostatic Damage or any other applicable ESD Protection Handbook.

Failure to observe this precaution may result in damage to the equipment.

To mount your Ultra5000 drive:

1.Layout the positions for the Ultra5000 and accessories in the enclosure. Mounting hole dimensions for the Ultra5000 are shown in Appendix A.

2.Attach the Ultra5000 to the cabinet, first using the upper mounting slots of the drive and then the lower. The recommended mounting hardware is M5 metric (1/4-20) or #10 MS bolts. Observe bonding techniques as described in Bonding Your System.

2. Tighten all mounting fasteners.

Publication 2098-IN001E-EN-P — April 2002

Chapter 2

Ultra5000 Connector Information

Chapter Objectives

This chapter provides connector information and procedures for wiring your Ultra5000 and making cable connections. This chapter includes:

•Understanding Ultra5000 Controller Functions

•Understanding Ultra5000 Connectors

•Understanding Ultra5000 I/O Specifications

•Understanding Motor Encoder Feedback Specifications

•Understanding Auxiliary Encoder Feedback Specifications

•Understanding the Serial Interface

Publication 2098-IN001E-EN-P — April 2002

2-2 |

Ultra5000 Connector Information |

|

|

Understanding Ultra5000

Controller Functions

This section provides a short overview of the Ultra5000.

Ultra5000 Block Diagram

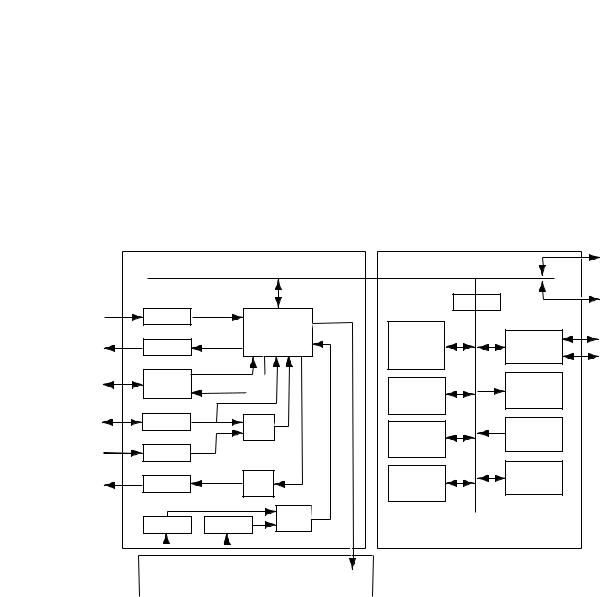

The Ultra5000 uses a two-stage circuit card solution with the capability of adding two additional option cards. The first stage is the processor circuit board and the second stage handles I/O connections including a power module interface. Figure 2.1 depicts the stages and the interfaces.

Figure 2.1

Block Diagram of Ultra5000 Controller Functions

|

|

I/O CARD |

|

PROCESSOR CARD |

|

Option Card Port 1 |

|

|

|

|

Interface |

|

Option Card Port 2 |

Digital Inputs |

Interface |

|

|

512Kx8 |

|

|

|

|

Gate Array |

|

Serial Port 1 |

||

|

|

Low Speed |

Serial |

|||

Digital Outputs |

Interface |

|

|

|||

|

|

Flash |

Interface |

Serial Port 2 |

||

|

|

|

|

|||

|

|

|

|

Memory |

|

|

|

|

|

|

|

|

|

Auxiliary Encoder Inputs |

Interface |

|

|

256Kx32 |

7-Segment |

|

Motor Encoder Outputs |

|

|

LED |

|

||

|

|

|

System Flash |

|

||

|

|

|

|

Display |

|

|

|

|

|

|

Memory |

|

|

Motor Encoder |

|

|

|

|

|

|

Interface |

|

|

128Kx32 |

Rotary DIP |

|

|

|

|

ADC |

|

|

||

|

|

|

High Speed |

Switches |

|

|

|

Interface |

|

|

|

||

Analog Inputs |

|

|

SRAM |

|

|

|

|

Interface |

Dual |

|

64Kx8 |

TMS320C32 |

|

Analog Outputs |

|

Non-Volatile |

DSP |

|

||

DAC |

|

|

||||

|

|

|

SRAM |

|

|

|

|

|

|

|

|

|

|

|

Interface |

|

Quad |

|

|

|

|

Interface |

ADC |

|

|

|

|

|

|

|

|

POWER MODULE |

|

|

|

|

|

Bus Voltage |

Current |

PWM |

||

Input |

Inputs |

Outputs |

||

Publication 2098-IN001E-EN-P — April 2002

Ultra5000 Connector Information |

2-3 |

|

|

Understanding Ultra5000

Connectors

The following table provides a brief description of the Ultra5000 front panel connectors and describes the connector type.

Designator |

Description |

Connector |

|

|

|

CN1A |

User Input/Output |

28-pin, 3.5mm, double-row, plugable spring |

|

|

clamp |

|

|

|

CN1B |

User Input/Output |

14-pin, 3.5mm, double-row, plugable spring |

|

|

clamp |

|

|

|

CN2 |

Motor Feedback |

15-pin high-density D-shell |

|

|

|

CN3A |

Main Serial Port |

9-pin standard D-shell |

|

|

|

CN3B |

Auxiliary Serial Port |

9-pin standard D-shell |

|

|

|

TB |

DC bus, Motor and |

9-position screw style barrier terminal strip |

|

AC power |

(2098-IPD-005xx, -010-xx, and -020-xx) |

|

|

|

TB1 |

DC bus, Motor, AC |

11or 12-position screw style barrier |

|

power, and Auxiliary |

terminal strip (2098-IPD-030-xx, -075-xx, |

|

AC power |

-150-xx, and HVxxx-xx) |

|

|

|

TB2 |

Shunt |

3-position screw style barrier terminal strip |

|

|

(2098-IPD-030-xx, -075-xx, -150-xx, and |

|

|

HVxxx-xx) |

|

|

|

CN1A and CN1B signal connections on the Ultra5000 use plugable, spring-clamp connectors with 3.5mm spacing. Mating connectors for discrete user wiring are included with your Ultra5000.

CN2, CN3A and CN3B signal connections on the Ultra5000. Mating connectors for these D-shell type connectors are commonly available.

DeviceNet signal connections on the Ultra5000 with DeviceNet (2098-IPD-xxx-DN and -HVxxx-DN only) use a 5-pin DeviceNet connector. The mating connector is included with your Ultra5000.

For connector pin-outs and |

For I/O, Motor |

For Terminal Block |

the location of connectors, |

Feedback and Serial |

(Power) Connections |

switches, and status LEDs |

Communications Port |

refer to: |

on: |

Connections refer to: |

|

|

|

|

2098-IPD-xxx Ultra5000 drives |

Figure 2.2 and the tables |

table on page 3-17. |

|

on pages 2-5 through 2-7. |

|

|

|

|

2098-IPD-xxx-DN Ultra5000 |

Figure 2.5 and the tables |

table on page 3-17. |

drives with DeviceNet interface |

on pages 2-13 through |

|

|

2-15. |

|

|

|

|

2098-IPD-HVxxx high voltage |

Figure 2.7 and the tables |

table on page 3-17. |

(460VAC) Ultra5000 drives |

on pages 2-5 through |

|

|

2-17. |

|

|

|

|

Publication 2098-IN001E-EN-P — April 2002

2-4 |

Ultra5000 Connector Information |

|

|

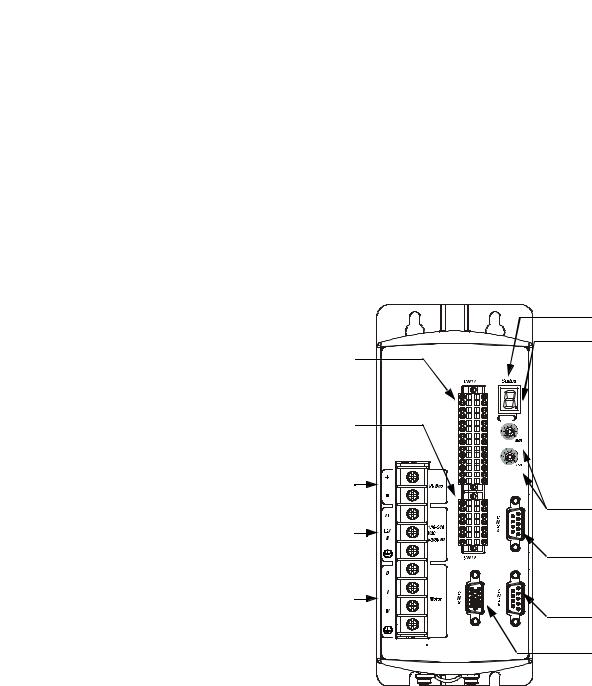

230V Ultra5000 Front Panel Connections

This section describes and provides a visual reference to the drive’s connectors.

500W, 1 kW, and 2 kW Ultra5000 (2098-IPD-005, -010, and -020)

Use the figure below to locate the front panel connections on the Ultra5000 230V drives (500W, 1 kW, and 2 kW). Detailed descriptions of the connections are provided.

Figure 2.2

Ultra5000 Front Panel Connections for 2098-IPD-005, -010, and -020

CN1A 28-pin

Digital I/O

CN1B 14-pin

Auxiliary Encoder

and Analog I/O

DC Bus Terminals for

Active Shunt Resistor Kit

AC Input Power Terminals

otor Power Terminals

PWR |

Seven Segment

Status LED

Logic Power LED

Node Address

Selector Switche

CN3A 9-pin

Main Serial Port

CN3B 9-pin

Auxiliary Serial P

CN2 15-pin

Motor Encoder

Publication 2098-IN001E-EN-P — April 2002

Loading...

Loading...