Rockwell Automation 440R-MSR42 User Manual

MSR42 Control Module

User Manual

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the

application and use of this control equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission

of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

The illustrations, charts, sample programs and layout examples shown in the guide are intended solely for

purposes of example. Since there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application, Installation and

Maintenance of Solid-State Control (available from your local Rockwell Automation sales oce), describes

some important dierences between solid-state equipment and electromechanical devices that should be

taken into consideration when applying products such as those described in this publication.

It is recommended that you save this user manual for future use.

Identies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identies information that is critical for successful application and understanding of

the product.

Identies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard, and recognize the consequences.

SHOCK HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

WARNING

IMPORTANT

ATTENTION

MSR42 Control Module User Manual

Main module

Expansion modules

Content

Approvals and Conformity . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Customer Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Typical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Customer Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Status outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LED display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Micro 400 safety light curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Other safety components connected to GPIO terminals . . . . . . . . 5

MSR45E relay expansion module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cable and wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Earth connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Micro400 light curtain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Minimum off time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EDM or start release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OSSD connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Muting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Blanking Teach-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Single Scan Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Testing the MSR42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Te ch n ical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Interrupt Ignore Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . .15

Approvals and Conformity

The CE-declaration as well as the safety approval, performed by TÜV

Rheinland GmbH are available online at www.ab.com. The actual list of

relevant safety data and applied standards is given in these documents.

MSR42 units can only achieve their

function as a safety control module, if the

instructions in these manual and

accompanying documents are followed

and all laws and regulations are observed

at the time of installation.

Should these instructions not be carefully

followed, serious injury or death may

occur. The installer or system integrator

has full responsibility for a safe

integration of this product.

This instruction manual is part of the

MSR45E expander module. It must be

kept accessible together with the other

machine documentation during its entire

life cycle for all personnel responsible for

assembly, installation, operation and

maintenance.

Introduction

The MSR4x is a family of extremely compact safety controller modules.

The main controlling module allows for the connection and control of

the compact Allen-Bradley GuardShield Micro400 safety light curtain.

Depending on the configuration, other safety components can also be

connected and monitored simultaneously.

Diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

External faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Internal faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Selection tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Accessories / Components . . . . . . . . . . . . . . . . . . . . . . . .11

Inspection and service . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Product labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Original instructions

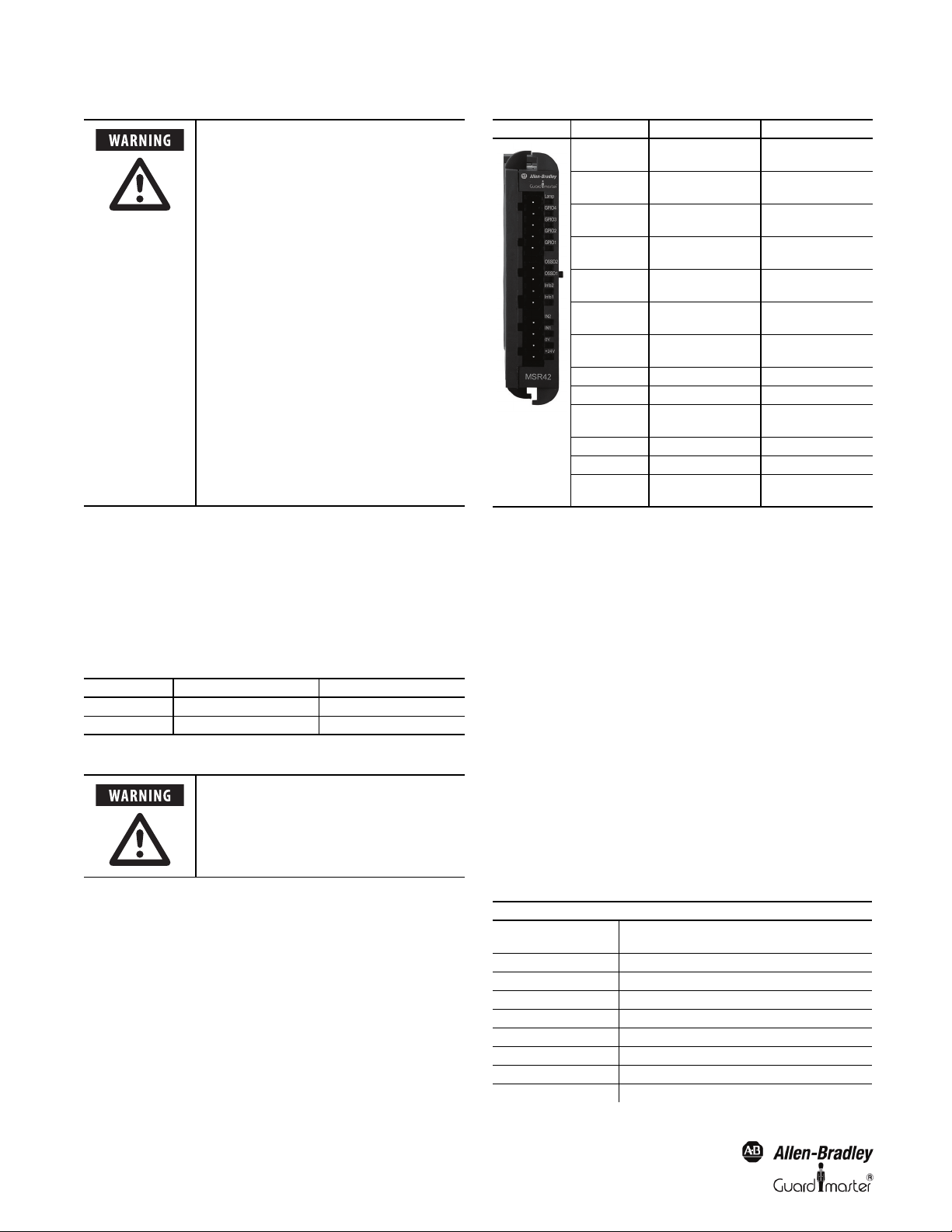

Figure 1: MSR42 controller with some safety components which can be connected

(depending on individual configuration)

Either the MSR41 or 42 offers two safety PNP outputs. Extension

modules are available for applications which need relay contact outputs.

1

Light Curtain Multi-Function Control Module User Manual

Up to three expander modules can be easy attached & controlled by the

base module.

In addition to the multifunction controllers, models are offered in special

configurations which are described in the appendix at the end of this

manual.

Special features

The characteristics of the MSR42 base module:

• Category 4, PLe according to EN ISO 13849-1

• Type 4 according to EN61496-1 / -2

• SIL CL3 according to EN62061

• SIL3 based on IEC 61508

• Short response times

•Expandable

• Up to 3 safety relay expander modules per base module

• Adjustable stop delay time

• Different safety components suitable for connection

•Blanking

•Muting

• Single scan selectable

Customer Configurations

The configuration of a MSR42 base module may very easily be adapted

to the customer requirements of an individual application with the help

of the USB/optical interface and the Allen-Bradley Guardmaster

Software “Configuration & Diagnostic Tool”. More information can be

found in the Software Technical Manual. The software is capable of

generating a configuration control document which lists configurations

and specifications of the controller and light curtain (Figure 16).

• Automatic storage facilities

Application restrictions

MSR42 base modules are not intended for application in explosive (EX)

or in radioactive environments.

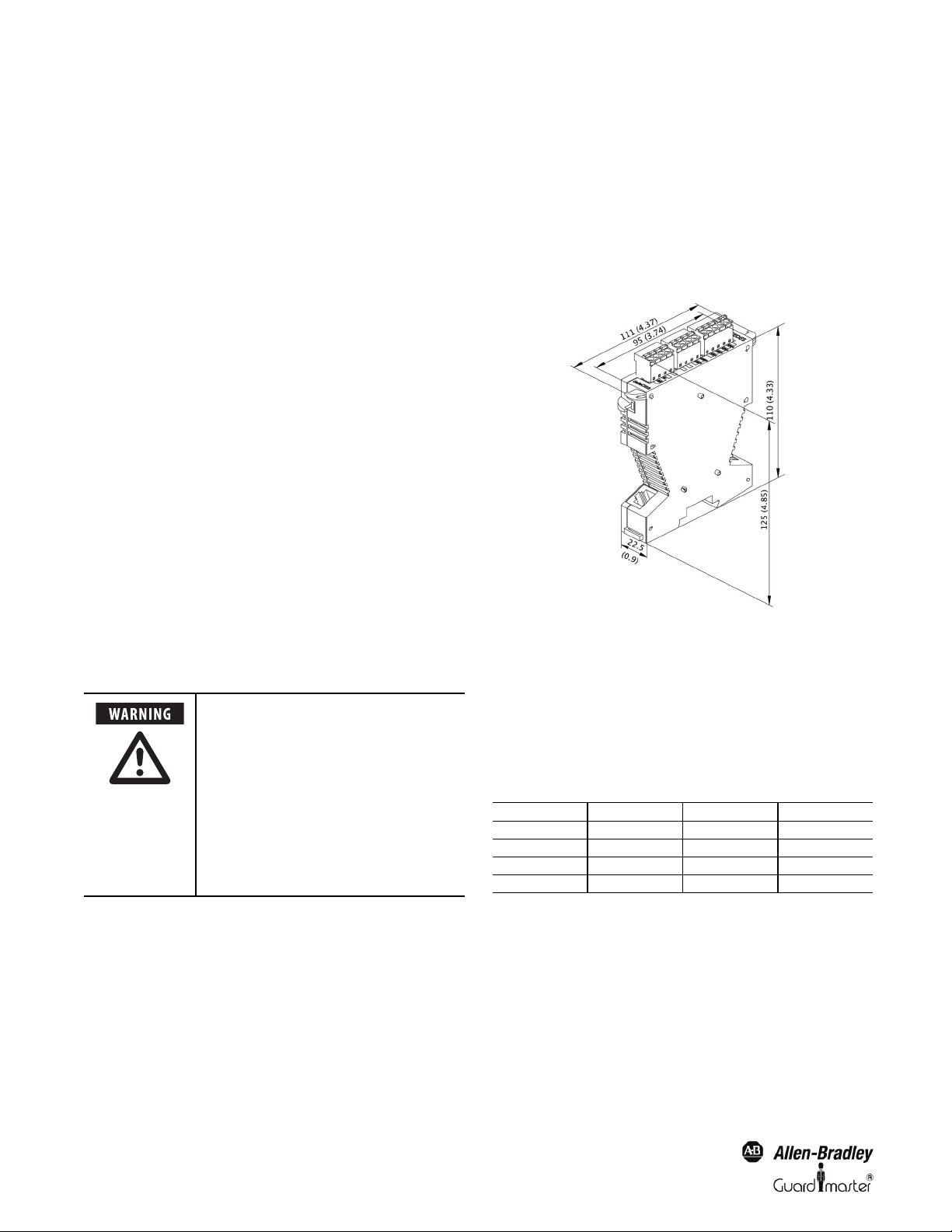

Dimensions

The dimensions of the MSR42 housing are illustrated in Figure 2.

Figure 2: Base module dimensions are the same for expansion modules

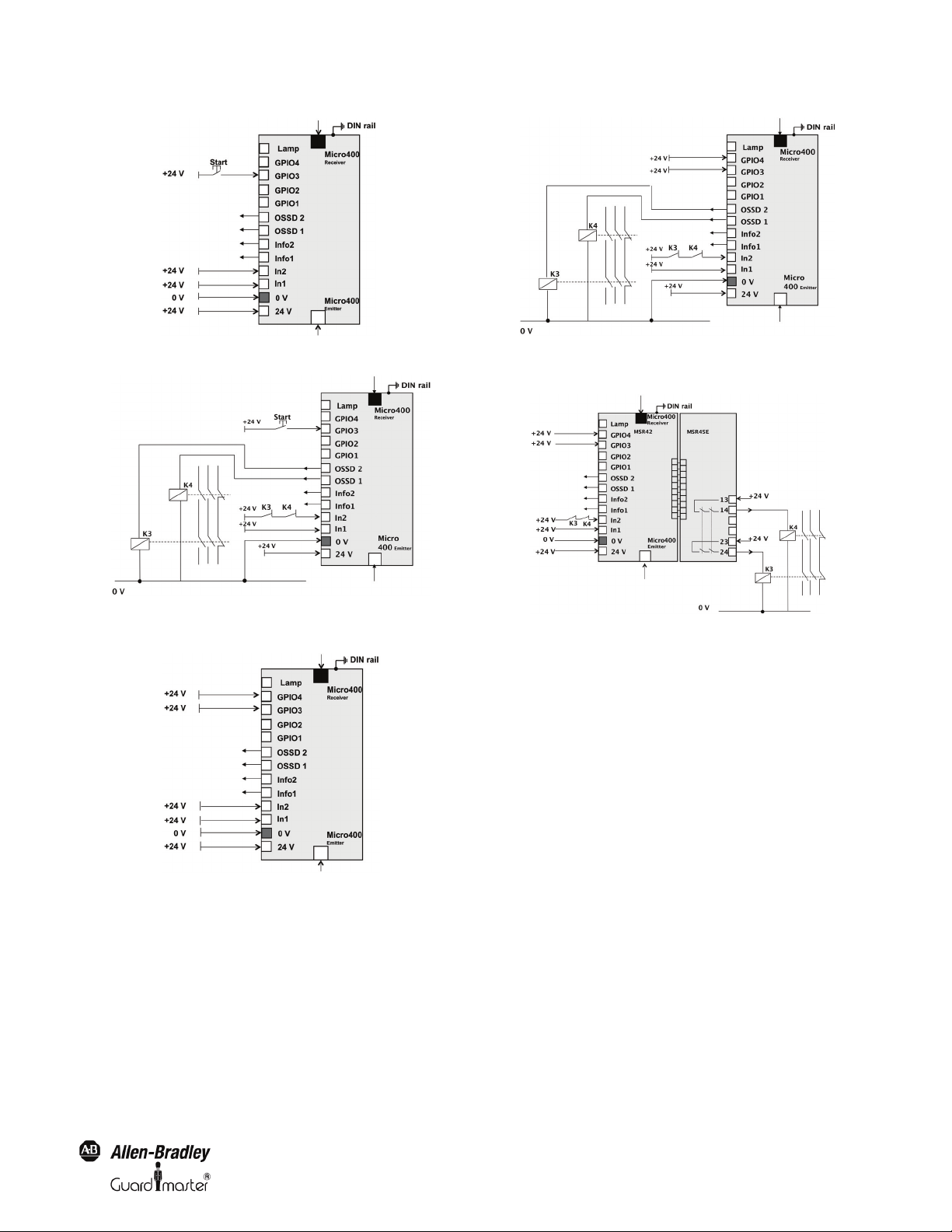

Wiring diagrams

The resolution and the response time may

increase due downloading other

configuration settings for the Micro 400

and other safety sensors connected to

MSR42. Consider the relevant resolution

and the maximum response time when

evaluating the safety distance. See

Chapter 7. All relevant data of the actual

configuration are always described in the

actual configuration control document

for that controller. Make sure that the

actual document is always stored near to

the control unit.

Applications

Typical applications

Typical MSR42 base module applications are:

•Presses

• Robotic cells with automatic insertion

•Assembly lines

• Indexing tables

• Conveyor systems

Basic configuration

The following figures show the connection possibilities for the MSR42

base module with the basic configuration. The logic of this basic version

is exemplified in the accompanying configuration control document:

Figure Safety component Start mode Start release

Figure 3 Micro400 manual no

Figure 4 Micro400 manual yes

Figure 5 Micro400 automat ic no

Figure 6 Micro400 automat ic yes

2

Original instructions

MSR42 Control Module User Manual

Figure 3: MSR42 base module (basic configuration, manual start) ). For teach-in see page 8

Figure 4: MSR42 base module (basic configuration, manual start, with start release).

For teach-in see page 8

Figure 5: MSR42 base module (basic configuration, automatic start). For teach-in see page 8

Figure 6: MSR42 base module (basic configuration, automatic start, with start release).

For teach-in see page 8

Figure 7: MSR42 base module and MSR45E expander module (basic configuration,

automatic start, with start release). For teach-in see page 8

Customer Configurations

The configuration of a MSR42 control module is set up via of the USB/

optical interface and the Allen-Bradley GuardShield Software

“Configuration & Diagnostic Tool”. The configuration procedure can be

found in the Technical Description Manual. Configuration details can be

found in the specific configuration control document for the MSR42.

The following features may be selected:

•Stop delay

• Single scan for faster response times

• Configuring GPIO terminals for one or two safety inputs

• Configuring GPIO terminals for E-Stop or door switch

•Safety Override

•Muting

•Blanking

A new configuration has to be downloaded to the MSR42 controller by

authorized personnel using the USB/optical interface (445L-AF6150).

Original instructions

3

Light Curtain Multi-Function Control Module User Manual

If authorized personnel reconfigure the

control module using the USB/optical

interface, then depending on the

configuration the response time or the

stop delay time t(delay) may increase. So

it is very important that after every new

configuration.

a. the configuration change label

(page 13) is placed on the control

module and

b. the new response time is confirmed to

be within the limits given by the risk

analysis of the machine and

c. All relevant data of the actual

configuration are always described in

the actual configuration control

document for that controller. Make

sure that the actual document is

always stored near to the control unit.

d. Using the blanking mode, the

resolution of the Micro 400 will be

reduced. Label the Micro 400 with the

new resolution. A label is supplied

with the Micro 400 light curtain

mounting kit.

Status outputs

The MSR42 base module has two status outputs (“Info1” and “Info2”).

The logic of these two outputs depends on the configuration. A

description of these outputs is given in the configuration control

document. The following table shows the logic of the two status outputs

for the basic configuration. The state of the status outputs will also be

displayed through LED, visible on the front side of the main module.

Terminal (LED) Output "high" (+24 V) Output "low" (0 V)

Info1 (LED) Start ok (green) No start possible (red)

Info2 (LED) System okay (green) Error (Lock out) (red)

Tab le 1

These outputs may not perform any

safety relevant functions. They are

diagnostic outputs which provide status

to a machine controller.

LED Signal / Color /Status Signal / Color /Status

Lamp

GPIO4

GPIO3

GPIO2

GPIO1

OSSD2

OSSD1

Info2 (LED) See page 4 See page 4

Info1 (LED) See page 4 See page 4

IN2

IN 1 +24 V / green / no test 0 V / red / test

0 V - -

+24 V

Orange / muting or blanking

activated

+24 V / green / automatic

start

+24 V / green / manual start

signal high or automatic start

+24 V / green / Teach-in

Blanking active

+24 V / green / Teach-in

Blanking active

+24 V / green / Micro 400 not

Activated

+24 V / green / Micro 400 not

Activated

+24 V / green / start release

okay

+24 V / green / power

connected

Off / muting or blanking not

activated

0 V / off / manual start

0 V / off / manual start

0 V / off / Teach-in Blanking

inactive

0 V / off / Teach-in Blanking

inactive

0 V / red / Micro 400 activated

(e.g. interrupted)

0 V / red / Micro 400 activated

(e.g. interrupted)

0 V / red / no start release

signal

0 V / off / no power

connected

Tab le 2

Response time

General

The response time of a MSR42 main module depends on the

configuration.

The relevant maximum response times for the MSR42 control module,

with respect to a specific Micro 400 light curtain and MSR45E expander

module, as well as a specific safety component may be calculated using

the formulas below.

The response time may be increased if a stop delay time t(delay) is

configured for a safety component or a Micro 400 light curtain. During

this delay, all start impulses are ignored. The safety outputs will switch

off at the end of this delay period.

The controlle r is sh ipped with th e double scan fi lter. Single s can filter ca n

be selected to reduce the response time. The relevant times may be found

in the corresponding configuration control document (e.g. see

configuration software manual).

LED display elements

Table 2 gives information about the LED on the front side of a MSR42

control unit with the basic configuration:

4

Original instructions

Term ino log y

t(C)

t(LC) Response time of the light curtain

t(delay) Stop delay time for the outputs

t(em) Response time for the MSR45E expansion module

t(GPIO) Evaluation time for the safety component (GPIO filter time)

t(SCext) Response time of the external safety component (e.g. Safe4)

t(totLCOSSD) Maximum OSSD response time triggered by the light curtain

t(totLCEXT) Maximum relay extension module response time for the light curtain

t(totSCOSSD) Maximum OSSD response time for the safety components on GPIO

Response time for the MSR42 control module (evaluation time),

without light curtain evaluation time

Loading...

Loading...