Rockwell Automation 2094-EN02D-M01-S0 User Manual

Safety Reference Manual

Kinetix 6200 and Kinetix 6500

Safe Torque-off Multi-axis Servo Drives

Catalog Numbers 2094-SE02F-M00-S0, 2094-EN02D-M01-S0

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Kinetix, RSLogix, TechConnect, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

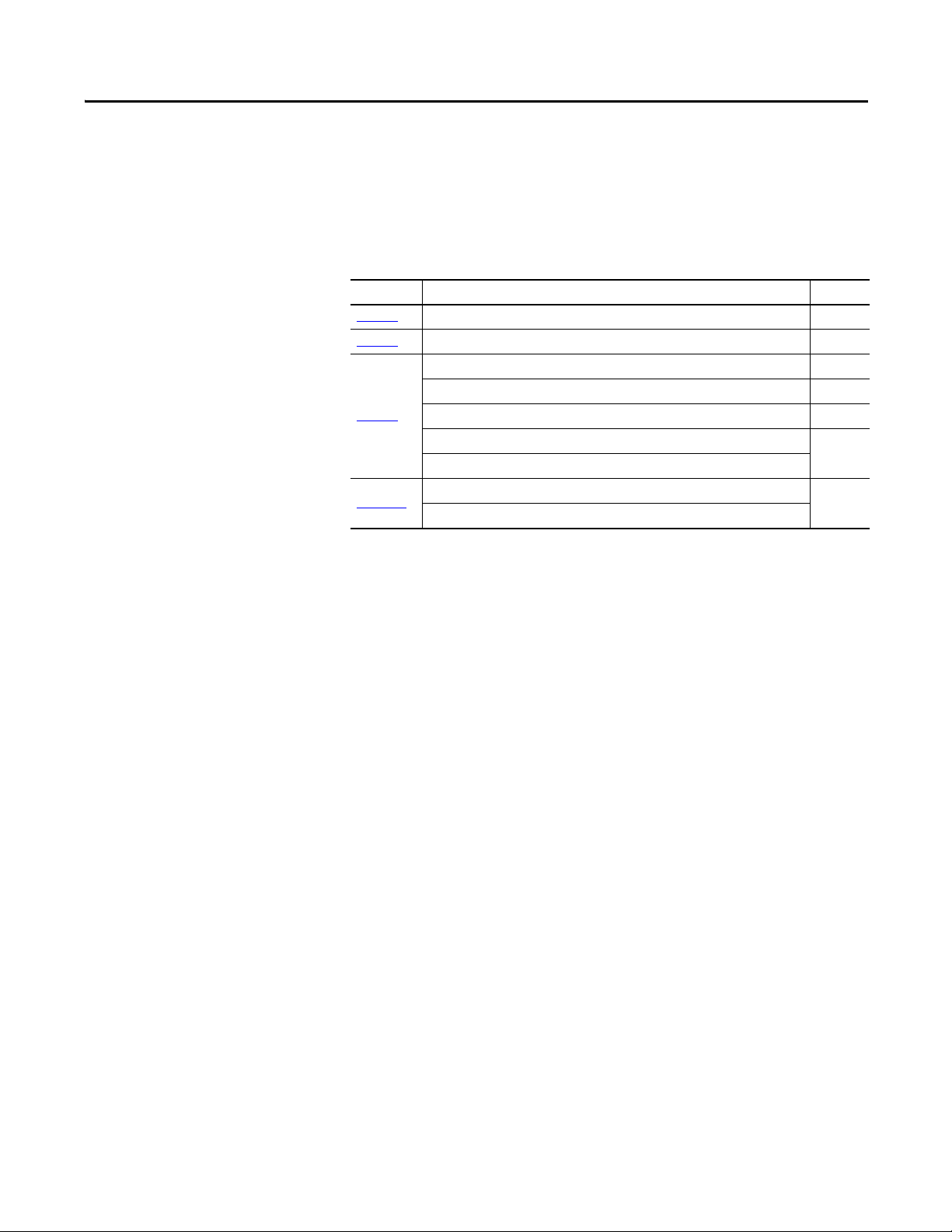

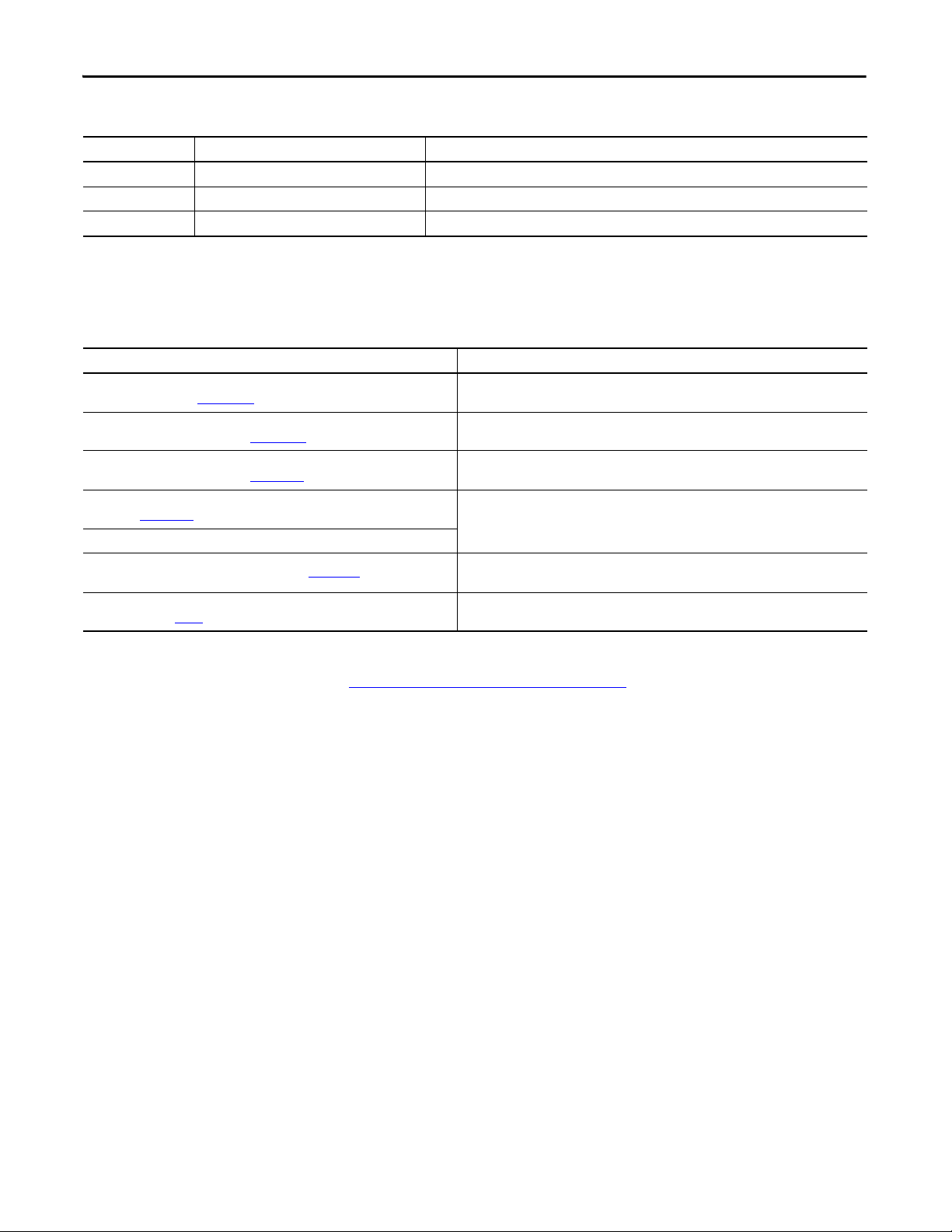

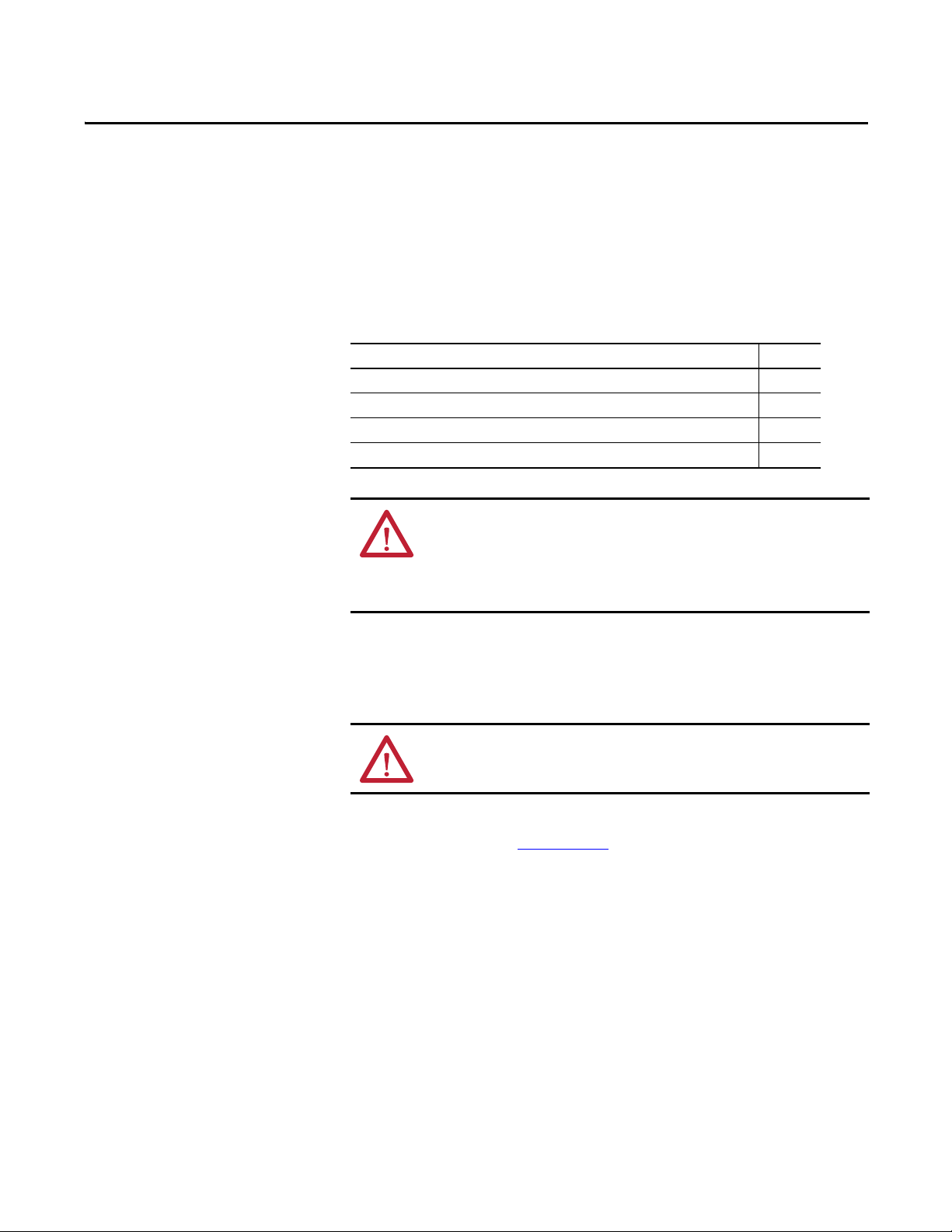

This manual contains new and updated information.

Summary of Changes

New and Updated Information

This revision includes new material for the 2090-K6CK-D44S0 low-profile

connector kit and 2090-CS0DSDS-AAxx interface cable for cascading the safe

torque-off signals from drive-to-drive.

Section Topic Page

Chapter 2

Chapter 3 Updated Safety Input Wiring diagram to use 24VPWR (IOD-14, IOD-15) 22

Chapter 4

Appendix A

Added a description and connection diagram for the 2090-K6CK-D44S0 connector kit. 16

Updated Cascaded Connections diagram to use 24VPWR (IOD-14, IOD-15) 27

Updated 2090-K6CK-D44M wiring examples to use 24VPWR (IOD-14, IOD-15) 28

Added 2090-K6CK-D44S0 wiring examples 29…30

Added Kinetix 6200/6500 cascading safe torque-off cable example

Added 2090-CS0DSDS-AAxx cable pinout diagram and termination table

Updated General Specifications with value for reset time

Added footnotes to clarify the effect cascading drives has on reaction time and reset time

31

37

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 3

Summary of Changes

Notes:

4 Rockwell Automation Publication 2094-RM002B-EN-P - May 2012

Safety Concept

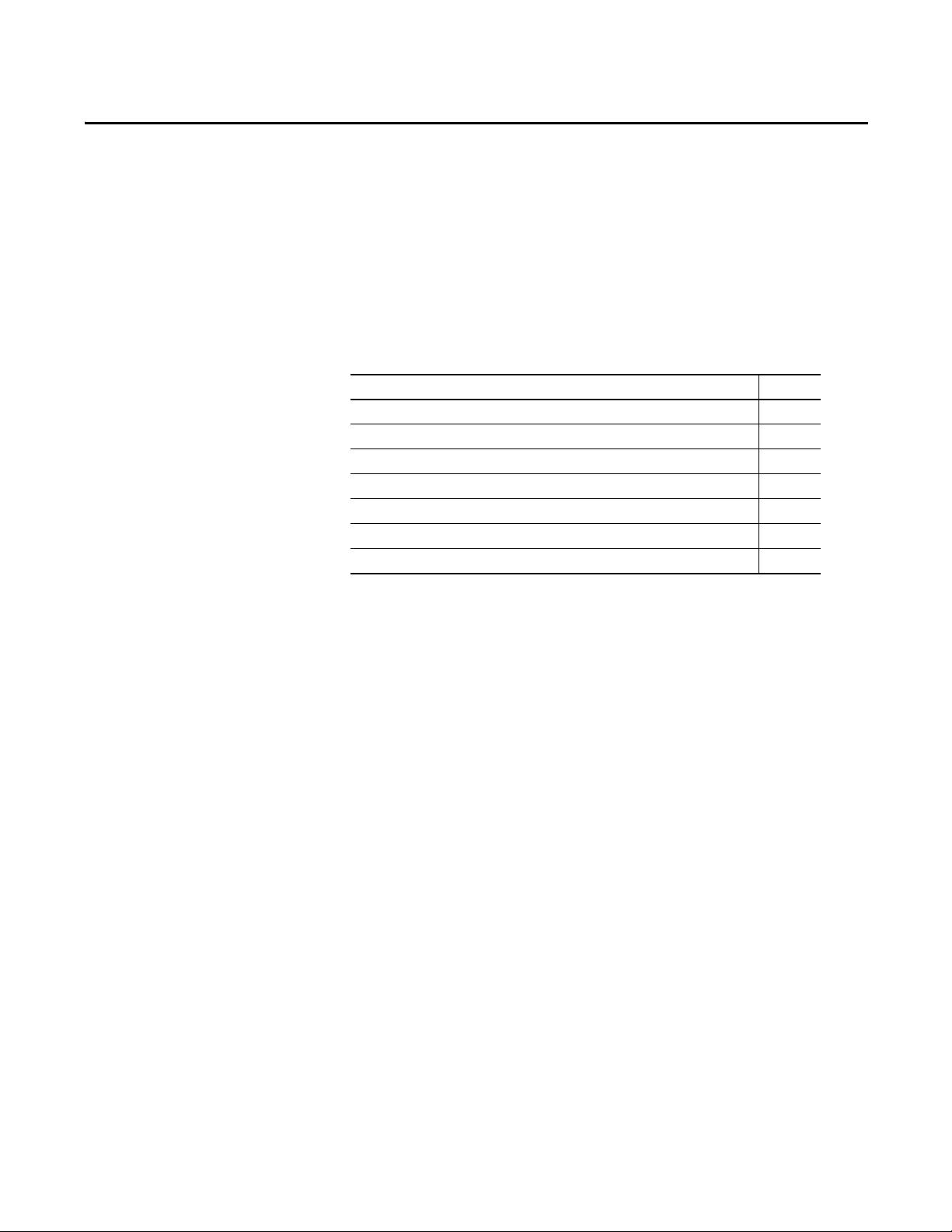

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Category 4 Performance Definition. . . . . . . . . . . . . . . . . . . . . . 10

Stop Category 0 Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance Level and Safety Integrity Level (SIL) CL3 . . . . . . . . . 11

PFD and PFH Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PFD and PFH Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safe State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Reaction Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contact Information If Failure Occurs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Automatic Drive Replacement (ADR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation and Wiring

Safe Torque-off I/O Signals

Chapter 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring the Safety Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the 2090-K6CK-D44M Low-profile Connector Kit . . . . . . 14

Using the 2090-K6CK-D44S0 Low-profile Connector Kit . . . . . . 16

Using the Motion-allowed Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Discrepancy Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reset Input (Reset_In). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safe Stop Output (SS_Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Safe Stop Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safe Stop Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 5

Table of Contents

Chapter 4

Multi-axis Cascaded Systems

Troubleshooting the Safe Torque-off

Drive

Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cascaded Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safe Stop Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2090-K6CK-D44M Connector Kit Examples. . . . . . . . . . . . . . . . . . . 28

2090-K6CK-D44S0 Connector Kit Examples . . . . . . . . . . . . . . . . . . 29

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Nonrecoverable Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fault Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Input and Output Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Fault Codes and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Guard Status Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Guard Fault Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Appendix A

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Index

6 Rockwell Automation Publication 2094-RM002B-EN-P - May 2012

Preface

About This Publication

This manual explains how the Kinetix® 6200 and Kinetix 6500 drives can be used

in Safety Integrity Level (SIL) CL3, Performance Level [PLe], or Category

(CAT) 4 applications. It describes the safety requirements, including PFD and

PFH values and application verification information, and provides information

on configuring and troubleshooting the Kinetix 6200 and Kinetix 6500 drives

with safe torque-off functionality.

Who Should Use This Manual

Use this manual if you are responsible for designing, configuring, or

troubleshooting safety applications that use Kinetix 6200 or Kinetix 6500 drives

with safe torque-off functionality.

You must have a basic understanding of electrical circuitry and familiarity with

Kinetix 6200 and Kinetix 6500 drives. You must also be trained and experienced

in the creation, operation, and maintenance of safety systems.

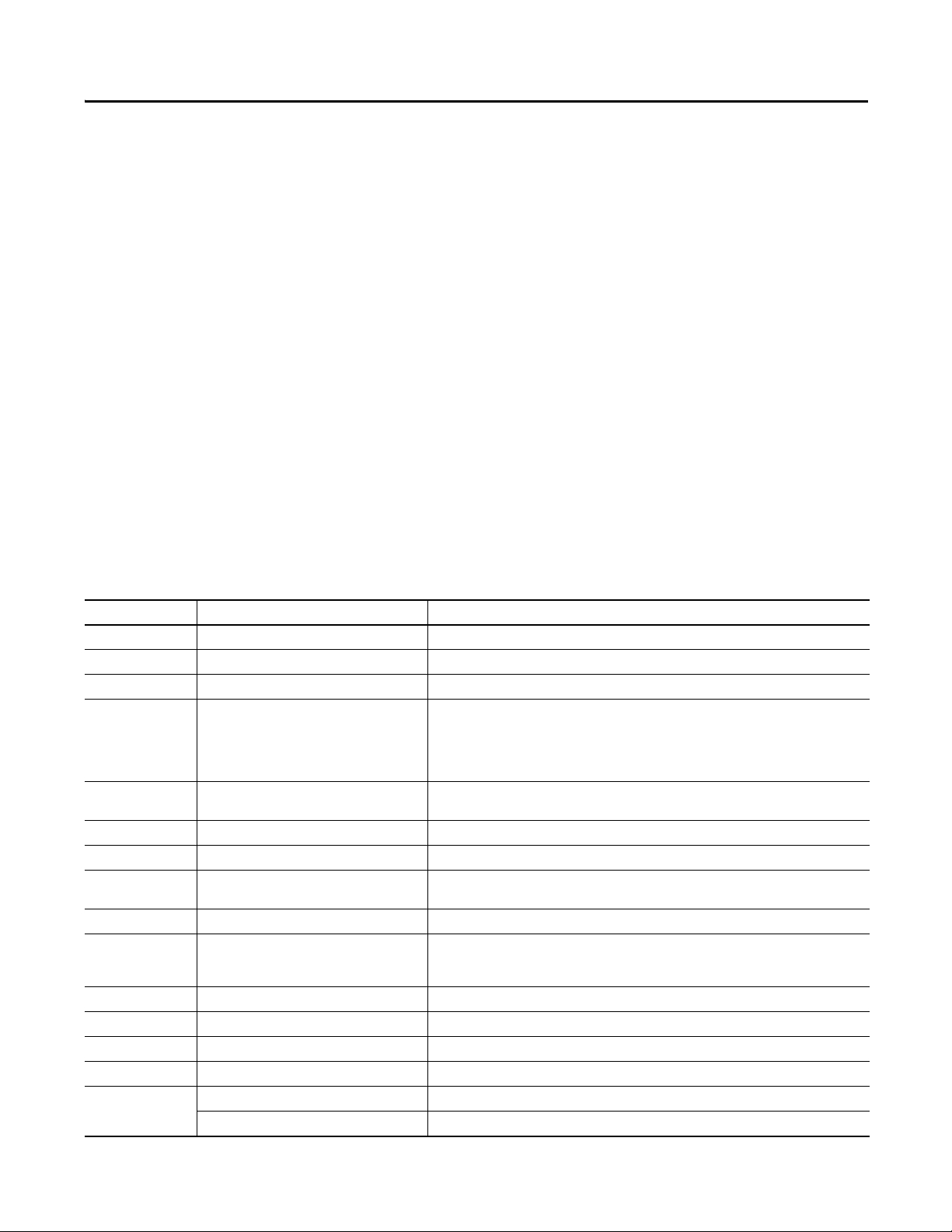

Terminology

Table 1 - Common Safety Terminology

Abbreviation Full Term Definition

1oo2 One out of Two Refers to the behavioral design of a dual-channel safety system.

CAT Category –

EN European Norm The official European Standard.

ESPE Electro-sensitive Protective Equipment

FMEA Failure Mode and Effects Analysis

IEC International Electrotechnical Commission –

IGBT Insulated Gate Bi-polar Transistors Typical power switch used to control main current.

HFT Hardware Fault Tolerance

MP Motion Power –

OSSD Output Signal-switching Device

PC Personal Computer Computer used to interface with and program your safety system.

PFD Probability of Failure on Demand The average probability of a system to fail to perform its design function on demand.

PFH Probability of Failure per Hour The probability of a system to have a dangerous failure occur per hour.

PL Performance Level ISO 13849-1 safety rating.

S0

2094-SE02F-M00-S0 Catalog number for Kinetix 6200 drives with Safe Torque-off functionality.

2094-EN02D-M01-S0 Catalog number for Kinetix 6500 drives with Safe Torque-off functionality.

The following table defines common safety terms used in this manual.

An assembly of devices and/or components working together for protective tripping or presencesensing purposes and compri sing as a minimum:

·a sensing device.

·controlling/monitoring devices.

·output signal-switching devices (OSSD).

Analysis of potential failure modes to determine the effect upon the system and identify ways to

mitigate those effects.

The HFT equals n, where n+1 faults could cause the loss of the safety function. An HFT of 1 means

that 2 faults are required before safety is lost.

The component of the electro-sensitive protective equipment (ESPE) connected to the control system

of a machine, which, when the sensing device is actuated during normal operation, responds by

going to the OFF-state.

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 7

Preface

Table 1 - Common Safety Terminology (continued)

Abbreviation Full Term Definition

SFF Safe Failure Fraction The sum of safe failures plus the sum of dangerous detected failures divided by the sum of all failures.

SIL Safety Integrity Level A measure of a products ability to lower the risk that a dangerous failure could occur.

SS Safe Stop –

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drive

User Manual, publication 2094-UM002

Kinetix 6200 and Kinetix 6500 Safe Speed Monitoring

Safety Reference Manual, publication 2094-RM001

Kinetix Safe-off Feature

Safety Reference Manual, publication GMC-RM002

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

EMC Noise Management DVD, publication GMC-SP004

Kinetix Motion Control Selection Guide, publication GMC-SG001

Safety Guidelines for the Ap plication, Installation and Maintenance of Solid State

Control, publication

SGI-1.1

Information on installing, configuring, startup, troubleshooting, and applications for your

Kinetix 6200 and Kinetix 6500 servo drive system.

Information on wiring, troubleshooting, and configuring your Kinetix 6200 and Kinetix6500

servo drives with the safe speed-monitoring functionality.

Information on wiring and troubleshooting your Kinetix 6000 servo drives with the safe-off

feature.

Information, examples, and techniques designed to minimize system failures caused by

electrical noise.

Specifications, motor/servo- drive system combinations, and accessories for Kinetix motion

control products.

Describes important differences between solid state control and hardwired electromechanical

devices.

You can view or download publications at:

http://www.rockwellautomation.com/literature

documentation, contact your local Allen-Bradley® distributor or Rockwell

Automation sales representative.

. To order paper copies of technical

8 Rockwell Automation Publication 2094-RM002B-EN-P - May 2012

Safety Concept

Chapter 1

Introduction

Safety Certification

This chapter describes the safety performance level concept and how the

Kinetix 6200 and Kinetix 6500 drives can meet the requirements for SIL CL3,

CAT 4, or PLe applications.

Top ic Pag e

Safety Certification 9

PFD and PFH Definitions 11

PFD and PFH Data 11

Safe State 12

Safety Reaction Time 12

Contact Information If Failure Occurs 12

Automatic Drive Replacement (ADR) 12

The Kinetix 6200 and Kinetix 6500 drives are certified for use in safety

applications up to and including SIL CL3 according to EN 61800-5-2,

EN 61508, and EN 62061, Performance Level PLe and CAT 4 according to

ISO 13849-1. Safety requirements are based on the standards current at the time

of certification.

The TÜV Rheinland group has approved the Kinetix 6200 and Kinetix 6500

drives for use in safety-related applications where the de-energized state is

considered to be the safe state. All of the examples related to I/O included in this

manual are based on achieving de-energization as the safe state for typical

Machine Safety and Emergency Shutdown (ESD) systems.

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 9

Chapter 1 Safety Concept

IMPORTANT

Important Safety Considerations

You are responsible for the following:

• The set-up, safety rating, and validation of any sensors or actuators

connected to the system

• Completing a system-level risk assessment and reassessing the system any

time a change is made

• Certification of the system to the desired safety performance level

• Project management and proof testing

• Access control to the system, including password handling

When applying functional safety, restrict access to qualified, authorized

personnel who are trained and experienced.

ATTENTION: When designing your system, consider how personnel will exit

the machine if the door locks while they are in the machine. Additional

safeguarding devices may be required for your specific application.

Safety Category 4 Performance Definition

The safety-related parts have to be designed with the following considerations to

achieve Safety Category 4 according to ISO 13849-1:2006:

• The safety-related parts of machine control systems and/or their protective

equipment, as well as their components, must be designed, constructed,

selected, assembled, and combined in accordance with relevant standards

so that they can withstand expected conditions.

• Basic safety principles must be applied.

• A single fault in any of its parts does not lead to a loss of safety function.

• A single fault is detected at or before the next demand of the safety

function, or, if this detection is not possible, then an accumulation of faults

must not lead to a loss of the safety function.

• The average diagnostic coverage of the safety-related parts of the control

system must be high, including the accumulation of faults.

• The mean time to dangerous failure of each of the redundant channels

must be high.

• Measures against common cause failure must be applied.

Stop Category 0 Definition

Stop Category 0 is achieved with immediate removal of power to the actuator,

resulting in an uncontrolled coast to stop. Safe Torque Off accomplishes a Stop

Category 0 stop.

10 Rockwell Automation Publication 2094-RM002B-EN-P - May 2012

Safety Concept Chapter 1

Performance Level and Safety Integrity Level (SIL) CL3

For safety-related control systems, Performance Level (PL), according to ISO

13849-1, and SIL levels, according to EN 61508 and EN 62061, include a rating

of the system’s ability to perform its safety functions. All of the safety-related

components of the control system must be included in both a risk assessment and

the determination of the achieved levels.

Refer to the ISO 13849-1, EN 61508, and EN 62061 standards for complete

information on requirements for PL and SIL determination.

PFD and PFH Definitions

PFD and PFH Data

Safety-related systems can be classified as operating in either a Low Demand

mode, or in a High Demand/Continuous mode:

• Low Demand mode: where the frequency of demands for operation made

on a safety-related system is no greater than one per year or no greater than

twice the proof-test frequency.

• High Demand/Continuous mode: where the frequency of demands for

operation made on a safety-related system is greater than once per year or

greater than twice the proof test interval.

The SIL value for a low demand safety-related system is directly related to orderof-magnitude ranges of its average probability of failure to satisfactorily perform

its safety function on demand or, simply, average probability of failure on demand

(PFD). The SIL value for a High Demand/Continuous mode safety-related

system is directly related to the probability of a dangerous failure occurring per

hour (PFH).

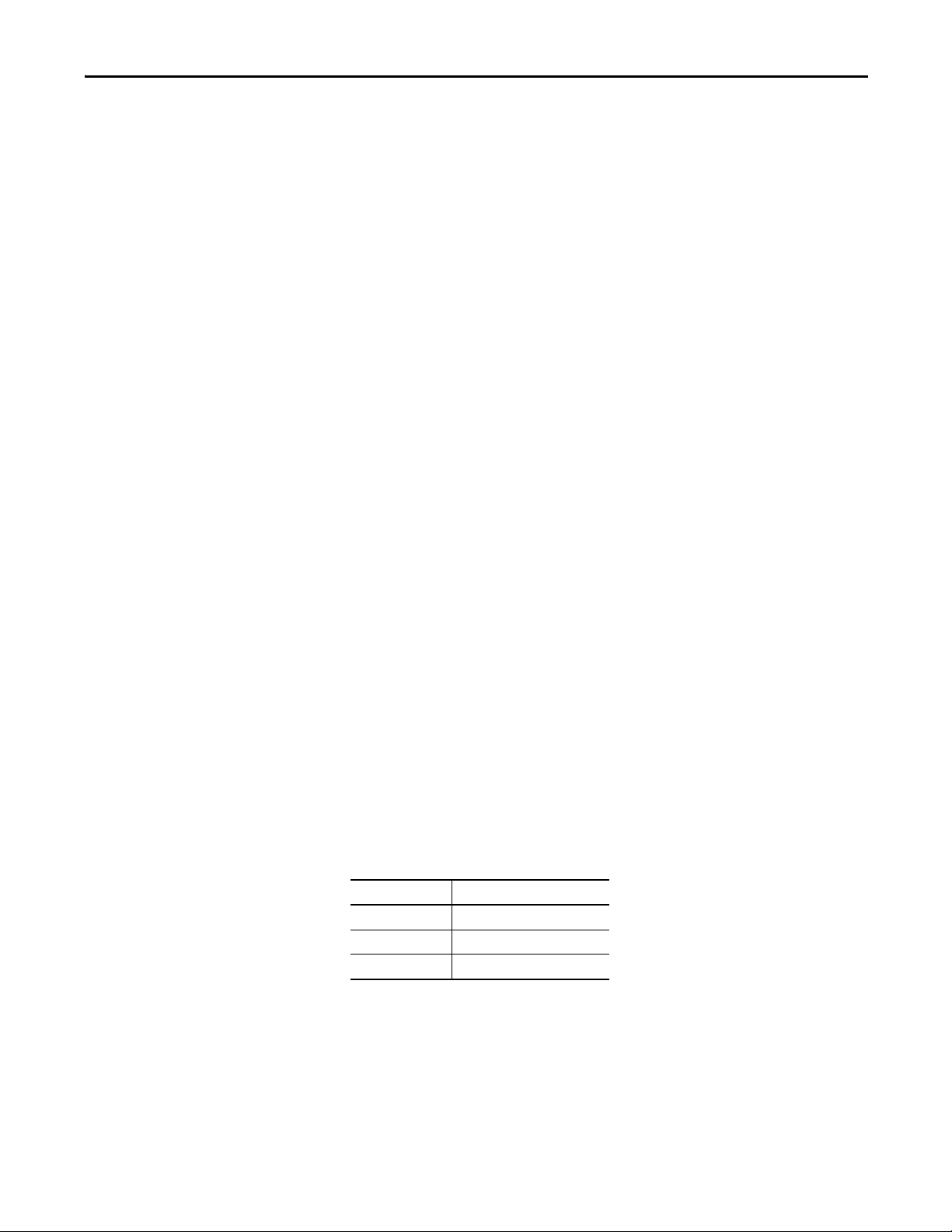

These PFD and PFH calculations are based on the equations from Part 6 of

EN 61508 and show worst-case values.

This table provides data for a 20-year proof test interval and demonstrates the

worst-case effect of various configuration changes on the data.

Table 2 - PFD and PFH for 20-year Proof Test Interval

Attribute Value

PFH [1e-9] 4.09

PFD [1e-4] 3.90

SFF % 99.5

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 11

Chapter 1 Safety Concept

IMPORTANT

Safe State

Safety Reaction Time

The Safe State encompasses all operation that occurs outside of the other

monitoring and stopping behavior defined as part of the drive. While the drive is

in the Safe State, all safety control outputs are in their safe state (de-energized).

When you cycle power, the drive enters the Safe State for self-testing. If the selftests pass, the drive remains in the Safe State until a successful safe stop reset

occurs.

If a Safe State fault is detected, the drive goes to the Safe State. This includes

faults related to integrity of hardware or firmware.

For more information on faults, refer to Chapter 5

The safety reaction time is the amount of time from a safety-related event as

input to the system until the system is in the Safe State.

The safety reaction time from an input signal condition that triggers a safe stop,

to the initiation of the Safe Stop Type, is 12 ms, max.

For cascaded systems, the reaction time is multiplied by the number of drives

in the drive system. For example, drive systems with three cascaded drives

(first, middle, and last), have a reaction time of 36 ms, max.

.

Contact Information If Failure Occurs

Automatic Drive Replacement (ADR)

If you experience a failure with any safety-certified device, contact your local

Rockwell Automation distributor. With this contact, you can do the following:

• Return the device to Rockwell Automation so the failure is appropriately

logged for the catalog number affected and a record is made of the failure.

• Request a failure analysis (if necessary) to determine the probable cause of

the failure.

You can replace IAM and AM power modules, and the associated control

modules, at any time without any need for configuration or program changes.

12 Rockwell Automation Publication 2094-RM002B-EN-P - May 2012

Installation and Wiring

Chapter 2

Introduction

General Safety Information

This chapter provides details on connecting devices and wiring the

2090-K6CK-D44M and 2090-K6CK-D44S0 low-profile connector kits.

Top ic Pag e

General Safety Information 13

Power Supply Require ments 14

Wiring the Safety Connections 14

Terminal Connections 18

ATTENTION: The drive is intended to be part of the safety-related control

system of a machine. Before installation, a risk assessment should be

performed to determine whether the specifications of this safety option are

suitable for all foreseeable operational and environmental characteristics for

the system to which it is to be installed.

Observe all electrical safety regulations stipulated by the appropriate technical

authorities.

ATTENTION: Make sure that the electrical power supplied to the drive is

switched off before making connections.

Refer to the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drive

User Manual, publication 2094-UM002

Rockwell Automation Publication 2094-RM002B-EN-P - May 2012 13

, for more information.

Loading...

Loading...