Rockwell Automation 20D-700S User Manual

Installation Instructions

PowerFlex 700S Adjustable Frequency Drive - Phase II Control

Frames 1…6

0.75…132 kW (1…200 Hp)

Introduction

This document explains the 5 primary steps for mechanical installation and for

connecting incoming power, the motor, and basic I/O to the PowerFlex® 700S

adjustable frequency AC drive with Phase II control.

The information provided is intended for qualified installers only.

The Additional Resources section on page 5

Automation publications that provide detailed drive information from wiring

and grounding recommendations to troubleshooting and repair.

ATTENTION: This product contains a 3V Lithium battery if the DriveLogix

Controller option board is installed. Perchlorate Material - special handling may

apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

is a directory of Rockwell

Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

2 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Table of Contents

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 1: Read the General Precautions

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Class 1 LED Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 2: Prepare for Installation

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drive Rating to Frame Size Cross References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Common Bus and Precharge Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Conditions and Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Minimum Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Approximate Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Step 3: Lift and Mount the Drive

Drive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Attaching the Lifting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Step 4: Power Wiring

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shield Termination - SHLD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Unbalanced, Ungrounded or Resistive Grounded Distribution Systems . . . . . . 26

RFI Filter Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

AC Input Phase Selection (Frames 5 and 6 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Selecting/Verifying Fan Voltage (Frames 5 and 6 Only) . . . . . . . . . . . . . . . . . . . . . 34

Important Common Bus (DC Input) Application Notes . . . . . . . . . . . . . . . . . . . 36

Auxiliary Control Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Accessing the Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power Wire Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Terminal Block Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dynamic Brake Resistor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Using Input/Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Using PowerFlex 700S Drives with Regenerative Power Units . . . . . . . . . . . . . . . 43

Regenerative Unit to Drive Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fusing and Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 3

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 5: Control and I/O Wiring

Control and I/O Wiring Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Main Control Board DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Hardware Enable Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

DriveLogix 5730 Controller Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DriveGuard® Safe Torque Off with Second Encoder Option . . . . . . . . . . . . . . . . 61

Second Encoder Feedback Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Stegmann Hi-Resolution Encoder Feedback Option . . . . . . . . . . . . . . . . . . . . . . . 64

Resolver Feedback Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Multi-Device Interface (MDI) Feedback Option. . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

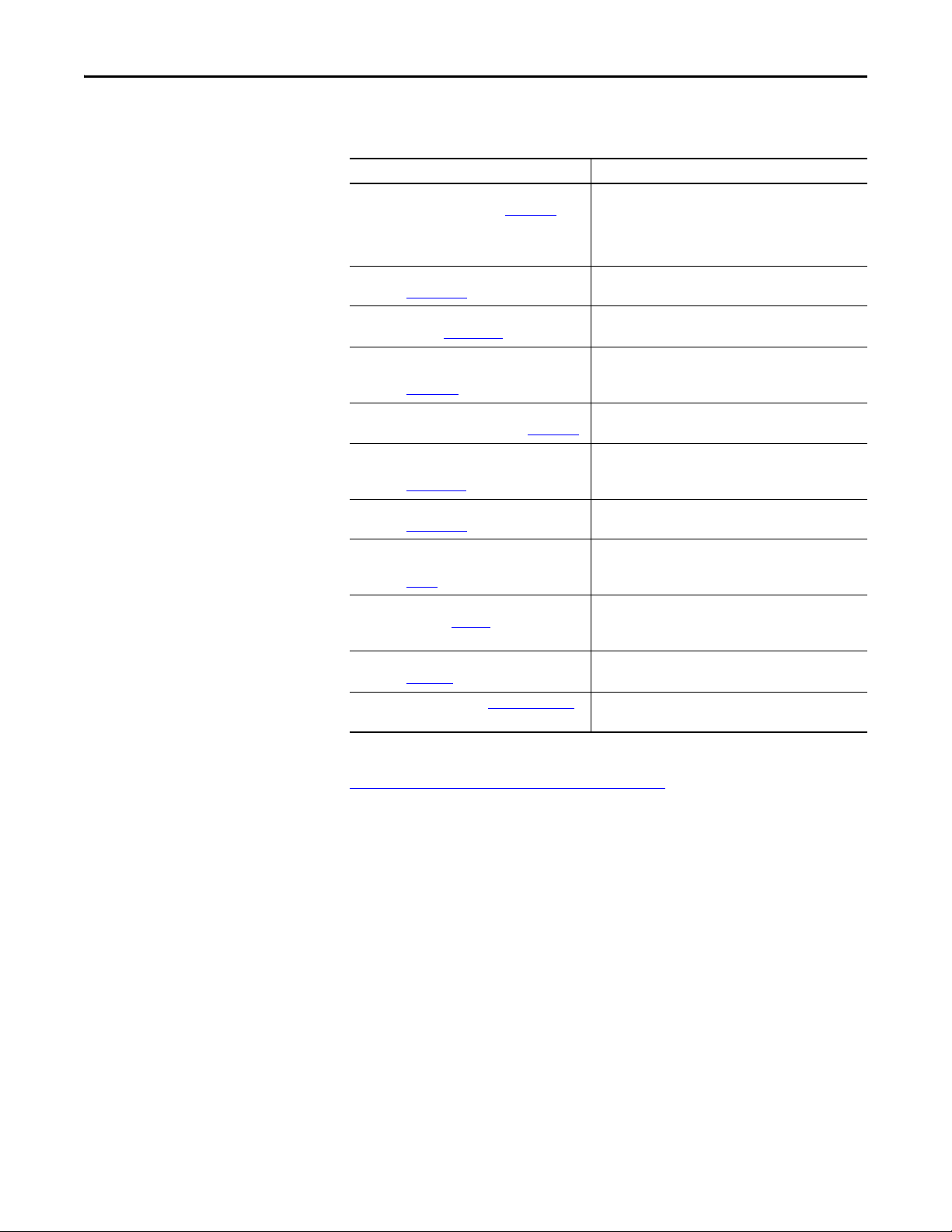

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PowerFlex 700S Drives with Phase II Control

Programming Manual, publication 20D-PM001

PowerFlex 7-Class HIM (DPI) Quick Reference,

publication 20HIM-QR001

PowerFlex 700S Drives with Phase II Control Reference

Manual, publication PFLEX-RM003

DriveLogix5730 Controller for PowerFlex 700S Drives

with Phase II Control User Manual,

publication 20D-UM003

DriveGuard® Safe-Off Option for PowerFlex 700S

Drives with Phase II Control, publication 20D-UM007

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives,

publication DRIVES-IN001

PowerFlex AC Drives in Common Bus Configurations,

publication DRIVES-AT002

Safety Guidelines for the Ap plication, Installation and

Maintenance of Solid State Control,

publication SGI-1.1

A Global Reference Guide for Reading Schematic

Diagrams, publication 100-2.10

Guarding Against Electrostatic Damage,

publication 8000-4.5.2

Product Certifications website, http://www.ab.com

Provides the following detailed information:

• Drive start-up instructions

• Parameters and programming

• Faults, alarms, and troubleshooting

• Human Interface Module (HIM) Operation Instructions

Provides a quick reference guide for using the PowerFlex 7Class HIM.

Provides detailed control functions and application

programming examples.

Provides instructions for developing DriveLogix controller

projects.

Provides information and instructions for properly planning

for and installing the DriveGuard Safe Torque Off option board.

Provides basic information needed to properly wire and

ground PWM AC drives.

Provides basic information needed to properly wire and

ground PWM AC drives using a common DC bus.

Provides general guidelines for the application, installation,

and maintenance of solid-state control.

Provides a simple cross-reference of common schematic/

wiring diagram symbols used throughout various parts of the

world.

Provides practices for guarding against Electrostatic damage

(ESD)

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 5

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 1: Read the General

Precautions

ATTENTION: Only qualified personnel familiar with adjustable frequency AC drives and associated machinery should plan or

implement the installation, startup and subsequent maintenance of the system. Failure to comply may result in personal injury

and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged before per forming any

work on the drive. Measure the DC bus voltage at the +DC and –DC terminals of the Power Terminal Block (refer to page 40

location). The voltage must be zero.

ATTENTION: Hazard of personal injury or equipment damage exists when using bipolar input sources. Noise and drift in sensitive

input circuits can cause unpredictable changes in motor speed and direction. Use speed command parameters to help reduce input

source sensitivity.

ATTENTION: Risk of injury or equipment damage exists. DPI or SCANport host products must not be directly connected together

via 1202 cables. Unpredictable behavior can result if two or more devices are connected in this manner.

Qualified Personnel

Personal Safety

for

ATTENTION: The drive start/stop/enable control circuitry includes solid state components. If hazards due to accidental contact

with moving machinery or unintentional flow of liquid, gas or solids exists, an additional hardwired stop circuit may be required to

remove the AC line to the drive. An auxiliary braking method may be required.

ATTENTION: Hazard of personal injury or equipment damage due to unexpected machine operation exists if the drive is

configured to automatically issue a Start or Run command. Do not use these functions without considering applicable local,

national and international codes, standards, regulations or industry guidelines.

ATTENTION: Parameters 365 [Encdr0 Loss Cnfg] - 394 [VoltFdbkLossCnfg] let you determine the action of the drive in response to

operating anomalies. Precautions should be taken to be sure that the settings of these parameters do not create hazards of

personal injury or equipment damage.

ATTENTION: Parameters 383 [SL CommLoss Data] - 392 [NetLoss DPI Cnfg] let you determine the action of the drive if

communications are disrupted. You can set these parameters so the drive continues to run. Precautions should be taken to ensure

the settings of these parameters do not create hazards of personal injury or equipment damage.

ATTENTION: This product contains a 3V Lithium battery if the DriveLogix Controller option board is installed. Perchlorate Material special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

6 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Product Safety

ATTENTION: An incorrectly applied or installed drive can result in component damage or a reduction in product life. Wiring or

application errors such as under sizing the motor, incorrect or inadequate AC supply, or excessive surrounding air temperatures may

result in malfunction of the system.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are

required when installing, testing, servicing or repairing this assembly. Component damage may result if ESD control procedures are

not followed. If you are not familiar with static control procedures, reference Guarding Against Electrostatic Damage, publication

8000-4.5.2 or any other applicable ESD protection handbook.

ATTENTION: Configuring an analog input for 0-20 mA operation and driving it from a voltage source could cause component

damage. Verify proper configuration prior to applying input signals.

ATTENTION: A contactor or other device that routinely disconnects and reapplies the AC line to the drive to start and stop the

motor can cause drive hardware damage. The drive is designed to use control input signals that will start and stop the motor. If an

input device is used, operation must not exceed one cycle per minute or drive damage will occur.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical transmission equipment. This product emits intense

light and invisible radiation. Do not look into module ports or fiber optic cable connectors.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 7

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 2: Prepare for

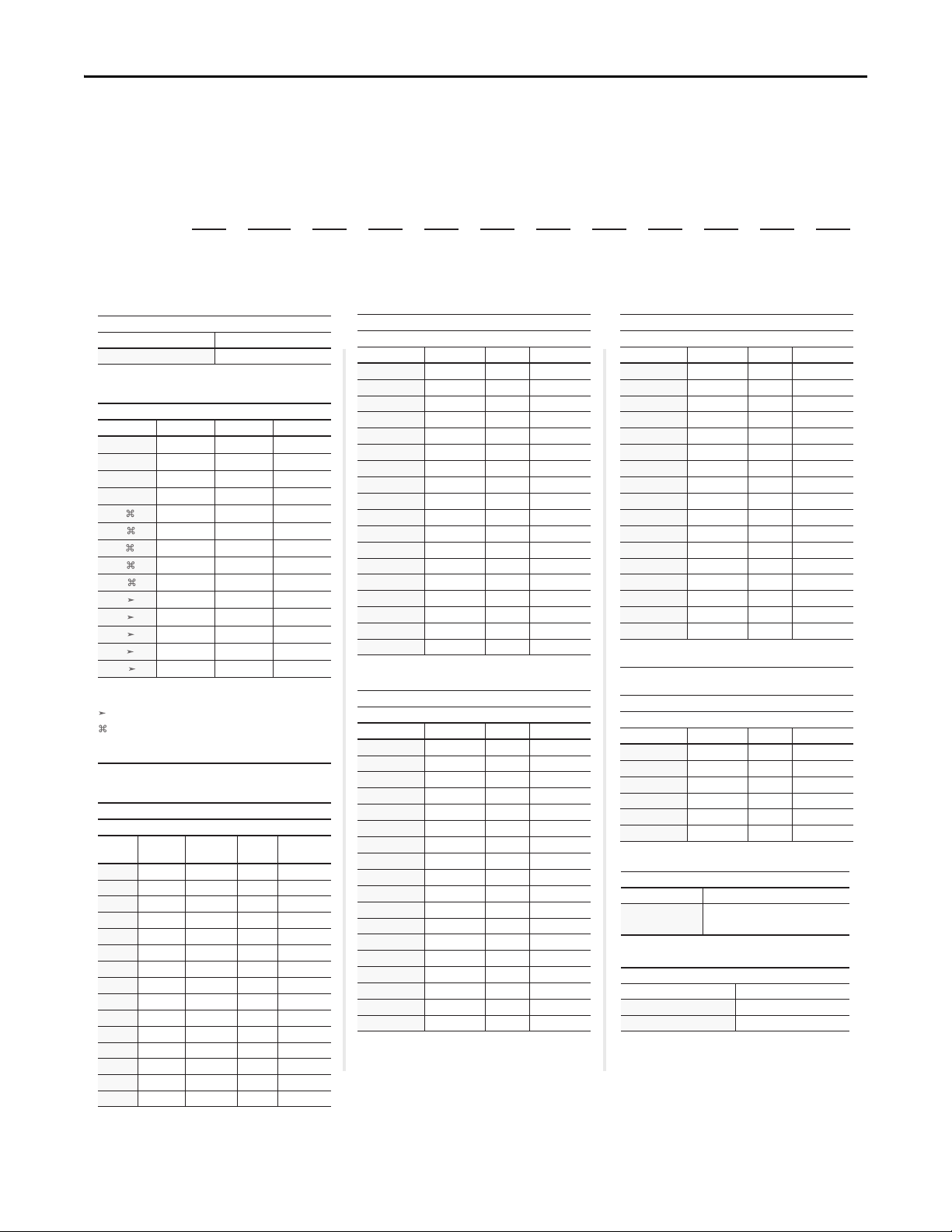

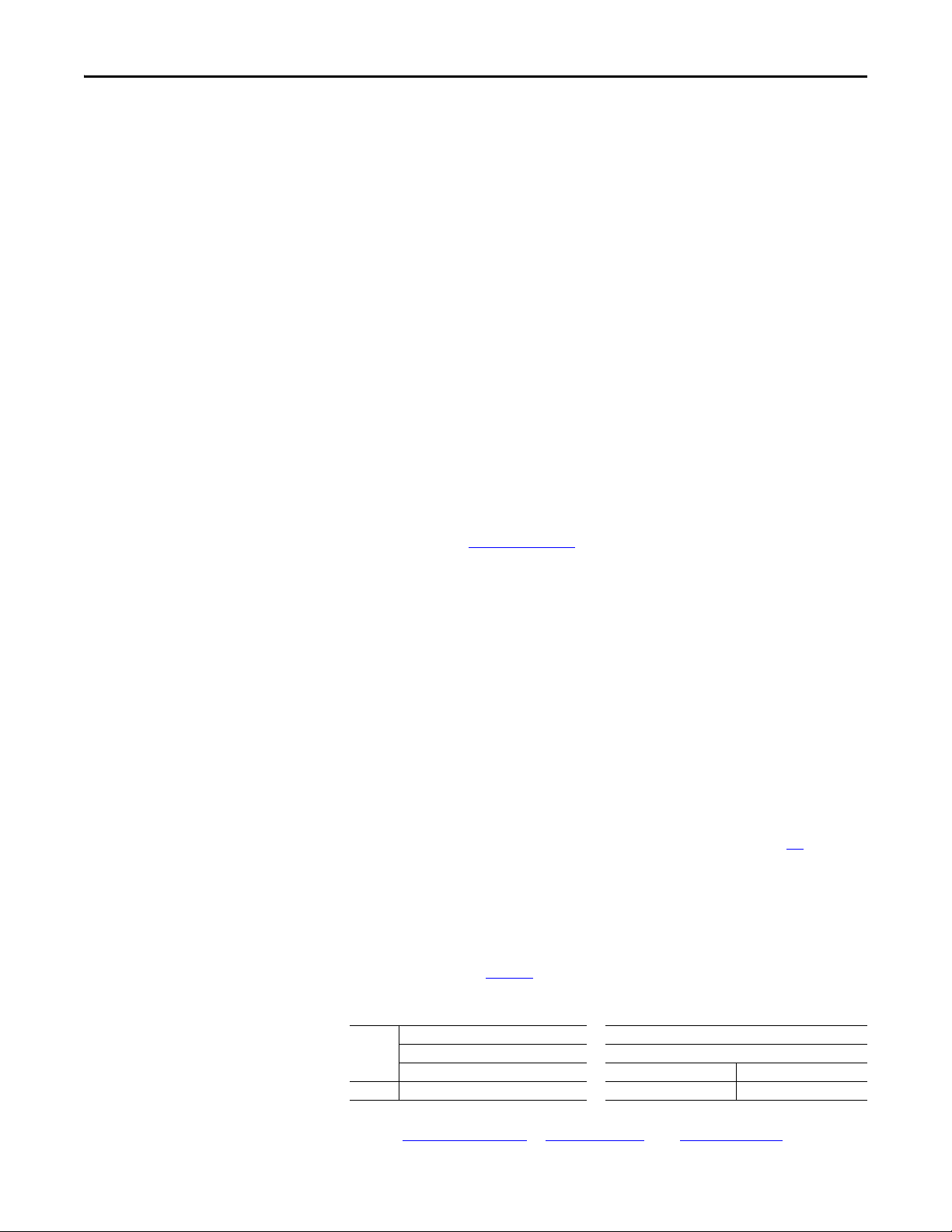

Catalog Number Explanation

Installation

Position

1-3 4 5-7 8 9 10 11 12 13 14 15 16 17

20D D 2P1 A 0 E Y N A N A N E

abcdefghijklm

a

Drive

Code Type

20D PowerFlex 700S

b

Voltage Rating

Code Voltage Ph. Prechg.

B §

240V AC

C §

400V AC

D §

480V AC

E ♣ §

F

H

J

K

M

N

P

R

T

W

♣ Note: CE Certication testing has not been

performed on 600V class drives, Frames 1…4.

Frames 5 & 6 only.

Frames 5 & 6 only.

§ For DC input on Frames 1…4, use the

corresponding AC input code B, C, D, or E.

600V AC

690V AC

540V DC

650V DC

810V DC

932V DC

325V DC

540V DC

650V DC

810V DC

932V DC

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

3 (6 pulse)

_

_

_

_

_

_

_

_

_

c1

ND Rating

208/240V, 60Hz Input

Code

4P2

6P8

9P6

015

022

028

042

052

070

080

104

130

154

192

260

208V

Amps

17.5

25.3

32.2

48.3

78.2

120

130

177

221

260

4.8

7.8

240V

Amps

4.2

6.8

11

56

92

9.6

15.3

22

28

42

52

70

80

104

130

154

192

260

Hp

1.0

2.0

3.0

5.0

7.5

10

15

20

25

30

40

50

60

75

100

_

_

_

_

_

N

N

N

N

Y

Y

Y

Y

Y

Frame

1

1

1

1

1

2

3

3

4

4

5

5

6

6

6

c2

ND Rating

400V, 50 Hz Input

Code Amps kW

2P1

3P5

5P0

8P7

011

015

022

030

037

043

056

072

085

105

125

170

205

260

2.1

3.5

5.0

8.7

11.5

15.4

22

30

37

43

56

72

85

105

125

170

205

260

0.75

1.5

2.2

4.0

5.5

7.5

18.5

110

132

c3

ND Rating

480V, 60 Hz Input

Code Amps Hp

2P1

3P4

5P0

8P0

011

014

022

027

034

040

052

065

077

096

125

156

180

248

2.1

3.4

5

8

11

14

22

27

34

40

52

65

77

96

125

156

180

248

1.0

2.0

3.0

5.0

7.5

100

125

150

200

Frame

1

1

1

1

1

1

11

15

22

30

37

45

55

55

90

10

15

20

25

30

40

50

60

75

1

2

2

3

3

3

4

5

5

6

6

6

Frame

1

1

1

1

1

1

1

2

2

3

3

3

4

5

5

6

6

6

Code Amps Hp

1P7

2P7

3P9

6P1

9P0

011

017

022

027

032

041

052

062

077

099

125

144

♣ Note: CE Certication testing has not been

performed on 600V class drives Frames 1…4.

Code Amps kW

052

060

082

098

119

142

Code

A

Code Operator Interface

0 Blank Cover

3 Full Numeric LCD

c4

ND Rating

600V, 60 Hz Input

1.7

2.7

3.9

6.1

9

11

17

22

27

32

41

52

62

77

99

125

144

c5

ND Rating

690V, 50 Hz Input

52

60

82

98

119

142

d

Enclosure

Description

IP20, NEMA Type 1

with Conformal Coat

e

HIM

♣

0

2

3

5

7.5

10

15

20

25

30

40

50

60

75

100

125

150

45

55

75

90

110

132

Frame

1

1

1

1

1

1

1

2

2

3

3

3

4

5

5

6

6

Frame

5

5

5

5

6

6

8 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Feedback

Code Option

N

Standard (Incremental Encoder)

A

Resolver

B

Stegmann Hi-Resolution Encoder

C

Multi-Device Interface

E

2nd Encoder

S

Safe-O (w/2nd Encoder)

Expanded cassette required.

One encoder interface included with base drive.

m

Additional Cong.

Code Description

E Phase II Control

K Phase II DriveLogix5730

L

Phase II DriveLogix5730

w/EtherNet/IP

This is an embedded EtherNet/IP option that is

only available with DriveLogix5730.

T

Stegmann Hi-Res Enc. (w/2nd Encoder)

U

Stegmann Hi-Res Enc. (w/Safe-O)

Documentation

Code Documents

N No Documentation

g

Brake

Code w/Brake IGBT ‡

seYY

oNN

‡ Brake IGBT is standard on Frames 1…3 and

optional on Frames 4…9 ONLY.

h

Brake Resistor

Code w/Resistor

Y Ye s

oNN

Not available for Frame 3 drives or larger.

English ManualE

j

Comm Slot

Code Version

N None

C DPI ControlNet (Coax)

D DPI DeviceNet

E DPI EtherNet/IP

1 DriveLogix ControlNet (Coax)

2

DriveLogix ControlNet Redundant

(Coax)

3 DriveLogix ControlNet (Fiber)

4

DriveLogix ControlNet Redundant

(Fiber)

5 DriveLogix DeviceNet (Open Conn.)

6 DriveLogix EtherNet/IP

i

Emission

Code

CE Filter ♣

CM Choke

A

♣ Note: CE Certication testing has not been

performed on 600V class drives Frames 1…4.

Ye sYe s

du/dt Filter

No

k

Control Options

Code Cassette

A

Phase II Contol available only.

B

C

D

G

H

Logix Expansion Synchlink

No Expanded

Slim

No

No ExpandedYes

Yes ExpandedNo

Yes ExpandedYes

NoN/A

SlimYesN/A

Frames 1...9 only.

Catalog Number Explanation, Continued

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 9

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

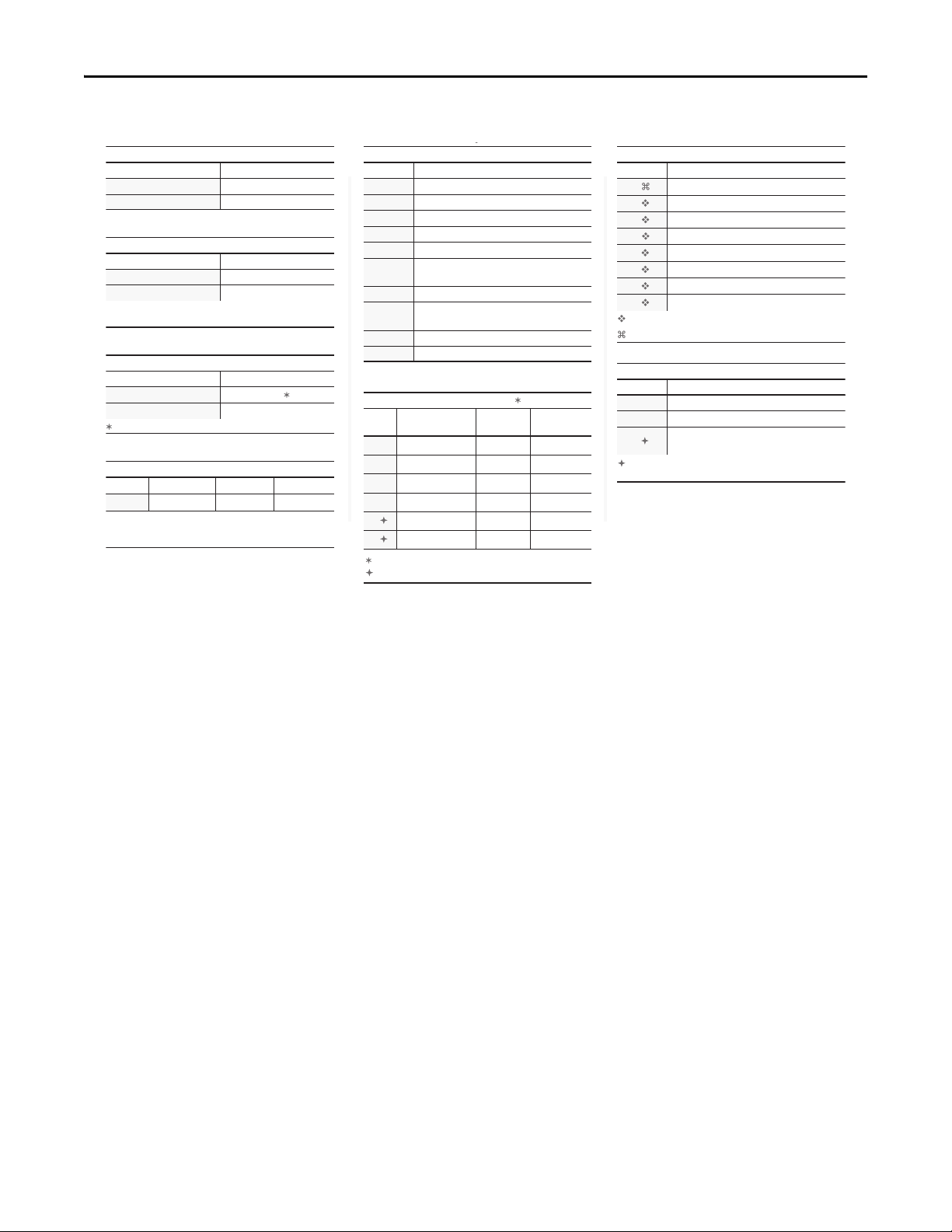

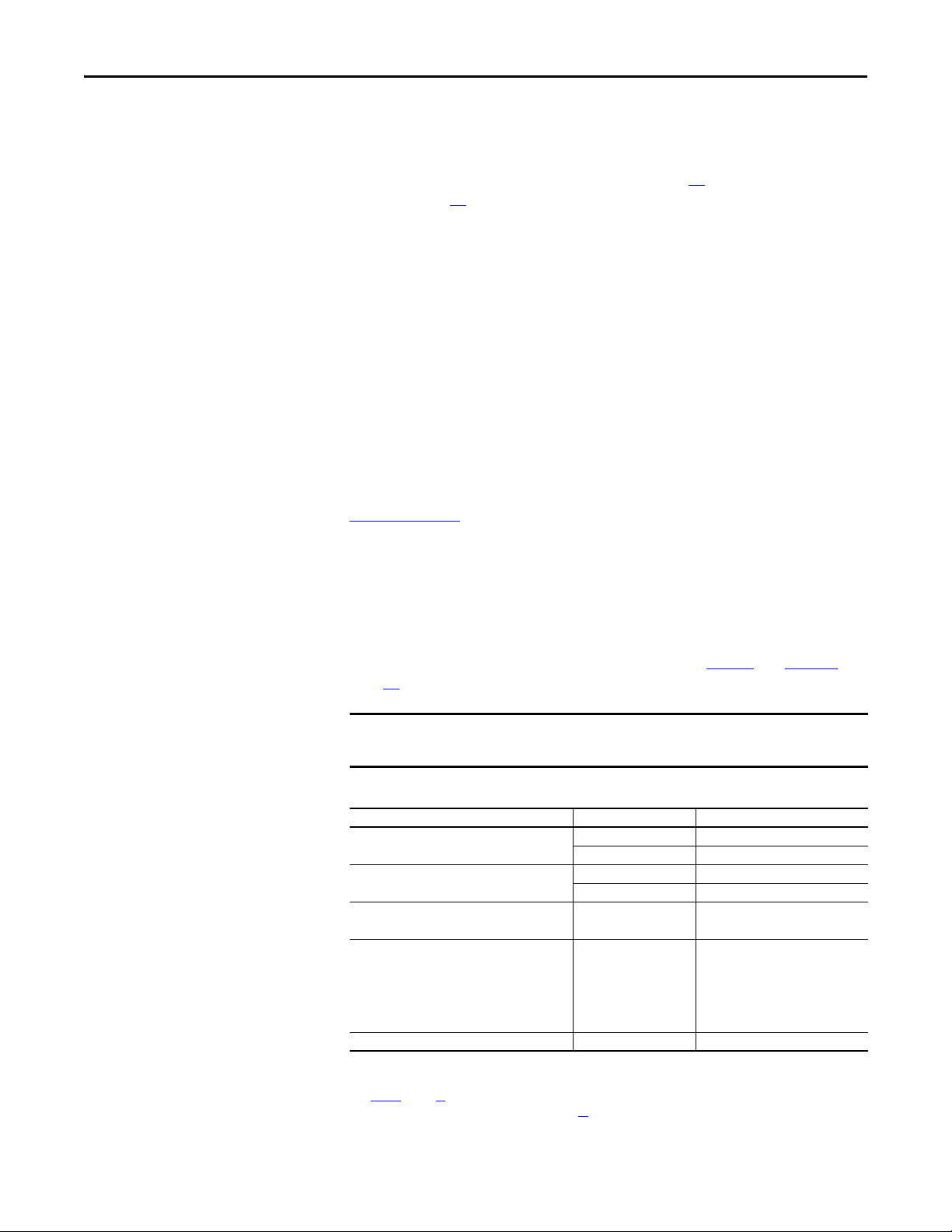

Drive Rating to Frame Size Cross References

Table 1 - 208/240 Volt AC Input, Six Pulse Drives

208V AC Input

Cat. No. Normal Duty

20DB4P2 0.75 0.55 20DB4P2 1 0.75 1

20DB6P8 1.5 1.1 20DB6P8 2 1.5 1

20DB9P6 2.2 1.5 20DB9P6 3 2 1

20DB015 4.0 3.0 20DB015 5 3 1

20DB022 5.5 4.0 20DB022 7.5 5 1

20DB028 7.5 5.5 20DB028 10 7.5 2

20DB042 11 7.5 20DB042 15 10 3

20DB052 15 11 20DB052 20 15 3

20DB070 18.5 15 20DB070 25 20 4

20DB080 22 18.5 20DB080 30 25 4

20DB104 30 22 20DB104 40 30 5

20DB130 37 30 20DB130 50 40 5

20DB154 45 37 20DB154 60 50 6

20DB192 55 45 20DB192 75 60 6

20DB260 66 55 20DB260 100 75 6

(1) The drive must be programmed to this voltage.

(1)

kW Rating

Heavy Duty kW

Rating

240V AC Input Frame

Cat. No. Normal Duty

Hp Rating

Heavy Duty Hp

Rating

Size

Table 2 - 400/480 Volt AC Input, Six Pulse Drives

400V AC Input 480V AC Input Frame

Cat. No. Normal Duty kW

Rating

20DC2P1 0.75 0.55 20DD2P1 1.0 0.75 1

20DC3P5 1.5 1.1 20DD3P4 2.0 1.5 1

20DC5P0 2.2 1.5 20DD5P0 3.0 2.0 1

20DC8P7 4.0 3.0 20DD8P0 5.0 3.0 1

20DC011 5.5 4.0 20DD011 7.5 5.0 1

20DC015 7.5 5.5 20DD014 10 7.5 1

20DC022 11 7.5 20DD022 15 10 1

20DC030 15 11 20DD027 20 15 2

20DC037 18.5 15 20DD034 25 20 2

20DC043 22 18.5 20DD040 30 25 3

20DC056 30 22 20DD052 40 30 3

20DC072 37 30 20DD065 50 40 3

20DC085 45 37 20DD077 60 50 4

20DC105 55 45 20DD096 75 60 5

20DC125 55 45 20DD125 100 75 5

20DC140 75 55

20DC170 90 75 20DD156 125 100 6

20DC205 110 90 20DD180 150 125 6

20DC260 132 110 20DD248 200 150 6

Heavy Duty kW

Rating

Cat. No. Normal Duty

Hp Rating

Heavy Duty Hp

Rating

Size

5

Table 3 - 600/690 Volt AC Input, Six Pulse Drives

600V AC Input 690V AC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE1P7 1.0 0.75

20DE2P7 2.0 1.5

20DE3P9 3.0 2.0

20DE6P1 5.0 3.0

20DE9P0 7.5 5.0

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

Heavy duty

kW Rating

Size

1

1

1

1

1

10 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

600V AC Input 690V AC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE011 10 7.5 1

20DE017 15 10

20DE022 20 15 2

20DE027 25 20

20DE032 30 25

20DE041 40 30

20DE052 50 40 3

20DE062 60 50 4

20DE077 75 60 20DF082 75 55 5

20DE099 100 75 20DF098 90 75 5

20DE125 125 100 20DF119 110 90 6

20DE144 150 125 20DF142 132 110 6

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

20DF052 45 37.5 5

20DF060 55 45 5

Heavy duty

kW Rating

Size

1

2

3

3

Table 4 - 325 Volt DC Input, Six Pulse Drives

325V DC input Frame

Cat. No. Normal Duty

Hp Rating

20DB015 5.0 3.0 1

20DB022 7.5 5.0 1

20DB028 10 7.5 2

20DB042 15 10 3

20DB052 20 15 3

20DB070 25 20 4

20DB080 30 25 4

20DN104 40 30 5

20DN130 50 40 5

20DN154 60 50 6

20DN192 75 60 6

20DN260 100 75 6

Heavy Duty Hp

Rating

Size

Table 5 - 540/650 Volt DC Input Drives

540V DC Input 650V DC Input Frame

Cat. No. Normal Duty kW

Rating

20DC3P5 1.5 1.1 20DD2P1 1.0 0.75 1

20DC5P0 2.2 1.5 20DD3P4 2.0 1.5 1

20DC8P7 4.0 3.0 20DD5P0 3.0 2.0 1

20DC011 5.5 4.0 20DD8P0 5.0 3.0 1

20DC015 7.5 5.5 20DD011 7.5 5.0 1

20DC022 11 7.5 20DD014 10 7.5 1

20DC030 15 11 20DD027 20 15 2

20DC037 18.5 15 20DD034 25 20 2

20DC043 22 18.5 20DD040 30 25 3

20DC056 30 22 20DD052 40 30 3

20DC072 37 30 20DD065 50 40 3

20DC085 45 37 20DD077 60 50 4

20DH105 55 45 20DJ096 75 60 5

20DH125 55 45 20DJ125 100 75 5

20DH140 75 55

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 11

Heavy Duty kW

Rating

Cat. No. Normal Duty

HP Rating

20DD022 15 10 1

Heavy Duty

HP Rating

Size

5

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

540V DC Input 650V DC Input Frame

Cat. No. Normal Duty kW

Rating

20DH170 90 75 20DJ156 125 100 6

20DH205 110 90 20DJ180 150 125 6

20DH260 132 110 20DJ248 200 150 6

Heavy Duty kW

Rating

Cat. No. Normal Duty

HP Rating

Heavy Duty

HP Rating

Size

Table 6 - 810/932 Volt DC Input Drives

810V DC Input 932V DC Input Frame

Cat. No. Normal Duty Hp

Rating

20DE1P7 1.0 0.75

20DE2P7 2.0 1.5 1

20DE3P9 3.0 2.0

20DE6P1 5.0 3.0 1

20DE9P0 7.5 5.0 1

20DE011 10 7.5

20DE017 15 10 1

20DE022 20 15 2

20DE027 25 20

20DE032 30 25 3

20DE041 40 30 3

20DE052 50 40

20DE062 60 50 4

20DT099 100 75 20DW098 90 75 5

20DT144 150 125 20DW142 132 110 6

Heavy Duty Hp

Rating

Cat. No. Normal Duty

kW Rating

Heavy Duty

kW Rating

Size

1

1

1

2

3

CE Conformity

Compliance with the Low Voltage (LV) Directive and Electromagnetic

Compatibility (EMC) Directive has been demonstrated using harmonized

European Norm (EN) standards published in the Official Journal of the

European Communities. PowerFlex drives comply with the EN standards listed

below when installed according to the PowerFlex 700S AC Drives Phase II

Control User and Reference Manuals.

CE Declarations of Conformity are available online at:

http://www.rockwellautomation.com/products/certification/

Low Voltage Directive (2006/95/EC)

• EN 61800-5-1 Adjustable speed electrical power drive systems –

Part 5-1: Safety requirements – Electrical, thermal and energy.

EMC Directive (2004/108/EC)

• EN 61800-3 Adjustable Speed Electrical Power Drive Systems Part 3: EMC Product Standard Including Specific Test Methods.

12 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

General Considerations

• If the adhesive label is removed from the top of the drive, the drive must be

installed in an enclosure with side openings less than 12.5 mm (0.5 in.) and

top openings less than 1.0 mm (0.04 in.) to maintain compliance with the

LV Directive.

• The motor cable should be kept as short as possible to avoid

electromagnetic emission as well as capacitive currents.

• Use of line filters in ungrounded systems is not recommended.

• PowerFlex drives may cause radio frequency interference if used in a

residential or domestic environment. The installer is required to take

measures to prevent interference, in addition to the essential requirements

for CE compliance provided in this section, if necessary.

• Conformity of the drive with CE EMC requirements does not guarantee

an entire machine or installation complies with CE EMC requirements.

Many factors can influence total machine/installation compliance.

• PowerFlex drives can generate conducted low frequency disturbances

(harmonic emissions) on the AC supply system.

• More information regarding harmonic emissions can be found in the

PowerFlex 700S AC Drives Phase II Control, Reference Manual,

publication PFLEX-RM003

• When operated on a public supply system, it is the responsibility of the

installer or user to be sure, by consultation with the distribution network

operator and Rockwell Automation, if necessary, that applicable

requirements have been met.

.

Essential Requirements for CE Compliance

Conditions 1…6 listed below must be satisfied for PowerFlex 700S Phase II

drives to meet the requirements of EN61800-3.

1. Standard PowerFlex 700S CE compatible drive.

2. Review important precautions/attentions statements throughout this

document before installing drive.

3. Grounding as described in Grounding Requirements on page 25

4. Output power, control (I/O) and signal wiring must be braided, shield

cable with a coverage of 75% or better, metal conduit or have shielding/

cover with equivalent attenuation.

5. All shielded cables should terminate with proper shielded connector.

6. Conditions in Ta b l e 7

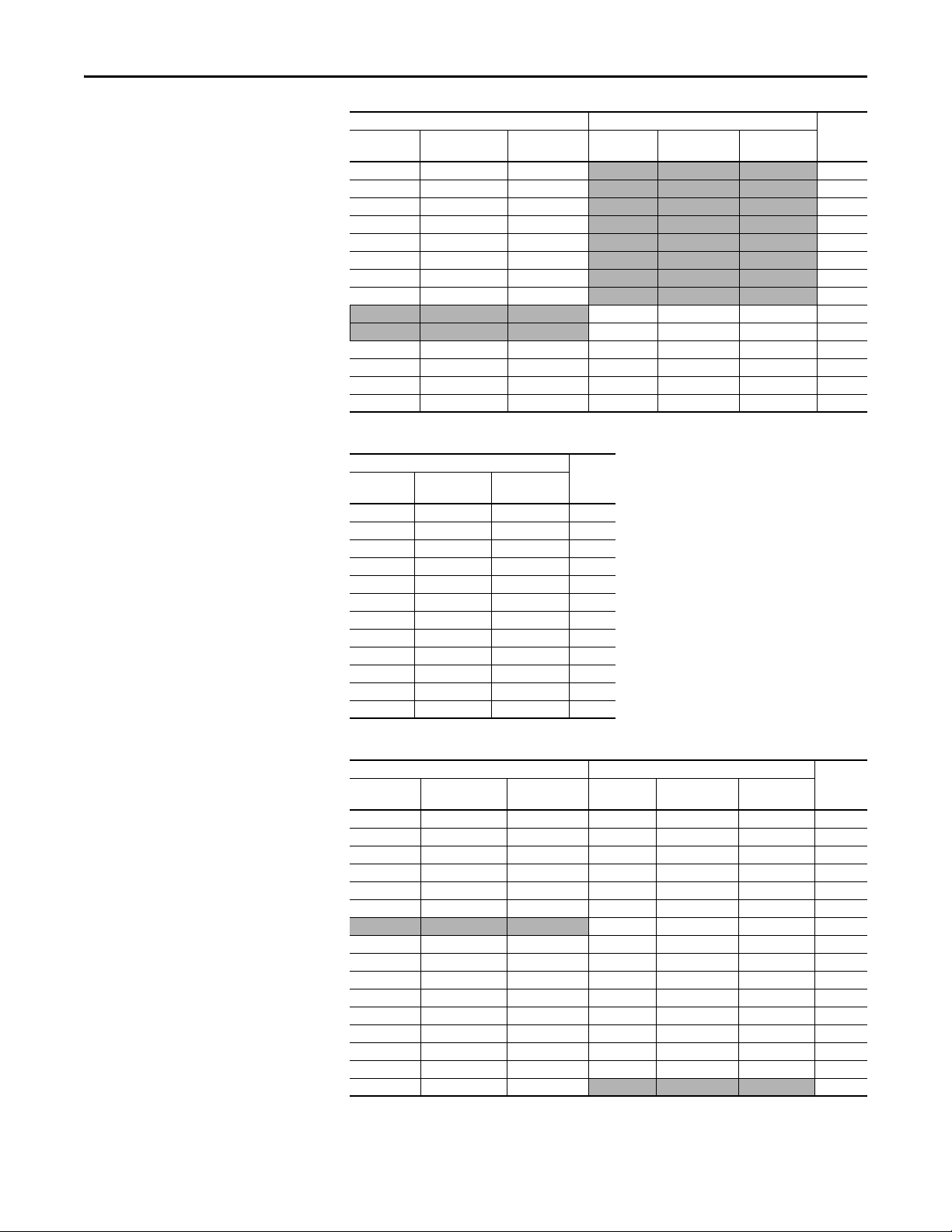

Table 7 - PowerFlex 700S EN61800-3 EMC Compatibility

Frames Second Environment First Environment Restricted Distribution

Restrict Motor Cable to 30 m (98 ft) Restrict Motor Cable to 150 m (492 ft)

Any Drive and Option Any Drive and Option External Filter Required

1…6 √√√

(1) External filters for First Environment installations and increasing motor cable lengths in Second Environment installations are

available. Roxburgh models KMFA (RF3 for UL installations) and MIF or Schaffner FN3258 and FN258 models are recommended.

Refer to http://www.deltron-emcon.com

below.

(1)

and http://www.mtecorp.com (USA) or http://www.schaffner.com, respectively.

.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 13

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

Common Bus and Precharge Considerations

The following notes must be read and understood. Also refer to Selecting/

Verifying Fan Voltage (Frames 5 and 6 Only) on page 34

Blocks on page 41

for additional common bus information.

1. If drives without internal precharge are used (frames 5 and 6 only), then:

a. precharge capability must be provided in the system to guard against

possible damage, and

b. disconnect switches Must Not be used between the input of the drive

and a common DC bus without the use of an external precharge device.

2. If drives with internal precharge (frames 1…6) are used with a disconnect

switch to the common bus, then an auxiliary contact on the disconnect

must be connected to a digital input of the drive. The corresponding input

(parameter 361…366) must be set to option 30, “Precharge Enable.” This

provides the proper precharge interlock, guarding against possible damage

to the drive when connected to a common DC bus.

Refer to PowerFlex AC Drives in Common Bus Configurations, publication

DRIVES-AT002

, for more information.

through Power Terminal

Operating Conditions and Temperatures

PowerFlex 700S frame 1…6 drives are designed to operate at 0…40 °C (32…104

°F) ambient. To operate most frame 1…4 drives in installations between 41 and

50 ° C (105.8 and 122 °F), you must remove the top adhesive label from the

drive. Frames 5 and 6 do not have an adhesive label. See Ta b l e 8

page 15

below for more information.

Removing the adhesive label from the top of frame 1…4 drives changes the

NEMA/UL enclosure rating from Type 1 to Type Open.

Table 8 - Enclosure Types and Acceptable Surrounding Air Temperature

Enclosure Type Temperature Rating Drive

IP20, NEMA/UL Type 1

(with Top Label)

IP20, NEMA/UL Type Open

(Top Label Removed)

IP00, NEMA/UL Type Open

(Top Label and Vent Plate Removed)

Flange Mount

Front (Inside Encl.) - IP00, NEMA/UL Type Open

Back/Heat Sink - IP54, NEMA/UL

Typ e 12

Stand-Alone/Wall Mount - IP54, NEMA/UL Type 12 0…40 °C (32…104 °F) Frames 5 and 6

(1) Frames 5 and 6 do not have a label.

(2) To remove the vent plate, lift the top edge of the plate away from the chassis and ro tate the plate out from the back plate. Refer to

Figure 3

(3) Refer to the Fusing and Circuit Breakers tables on page 44, for exceptions.

(1)

(1)

(2)

on page 17 for location of vent plate.

0…40 °C (32…104 °F) Frame 1…4, All Ratings

0…50 °C (32…122 °F) Frames 5 and 6, Most Ratings

0…50 °C (32…122 °F) Most Ratings

0…45 °C (32…113 °F) 20DC072 and 20DE062 Only

0…50 °C (32…122 °F) 20DC072 Only

Frames 5 a nd 6

0…55 °C (32…131 °F)

0…40 °C (32…104 °F)

and Figure 1 on

(3)

(2)

14 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

IMPORTANT

With Ad hesive

Label Removed

Adhesive LabelWith Adhesive Label

Left in Place

Air flow through the drive

must not be impeded.

PowerFlex 700S drives must be mounted in a clean, dry location. Contaminants

such as oils, corrosive vapors and abrasive debris must be kept out of the

enclosure. These enclosures are intended for indoor use primarily to provide a

degree of protection against contact with enclosed equipment. These

enclosures offer no protection against airborne contaminants.

Minimum Mounting Clearances

Specified vertical clearance requirements are intended to be from the drive to the

closest object that can restrict airflow through the drive heat sink and chassis. The

drive must be mounted in a vertical orientation as shown, and must make full

contact with the mounting surface. Do not use standoffs or spacers. In addition,

inlet air temperature must not exceed the product specification. See Ta b l e 8

page 14

Figure 1 - Minimum Mounting Clearance Requirements

for ambient air temperature limits.

on

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

50.8 mm

(2.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

101.6 mm (4.0 in.)

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 15

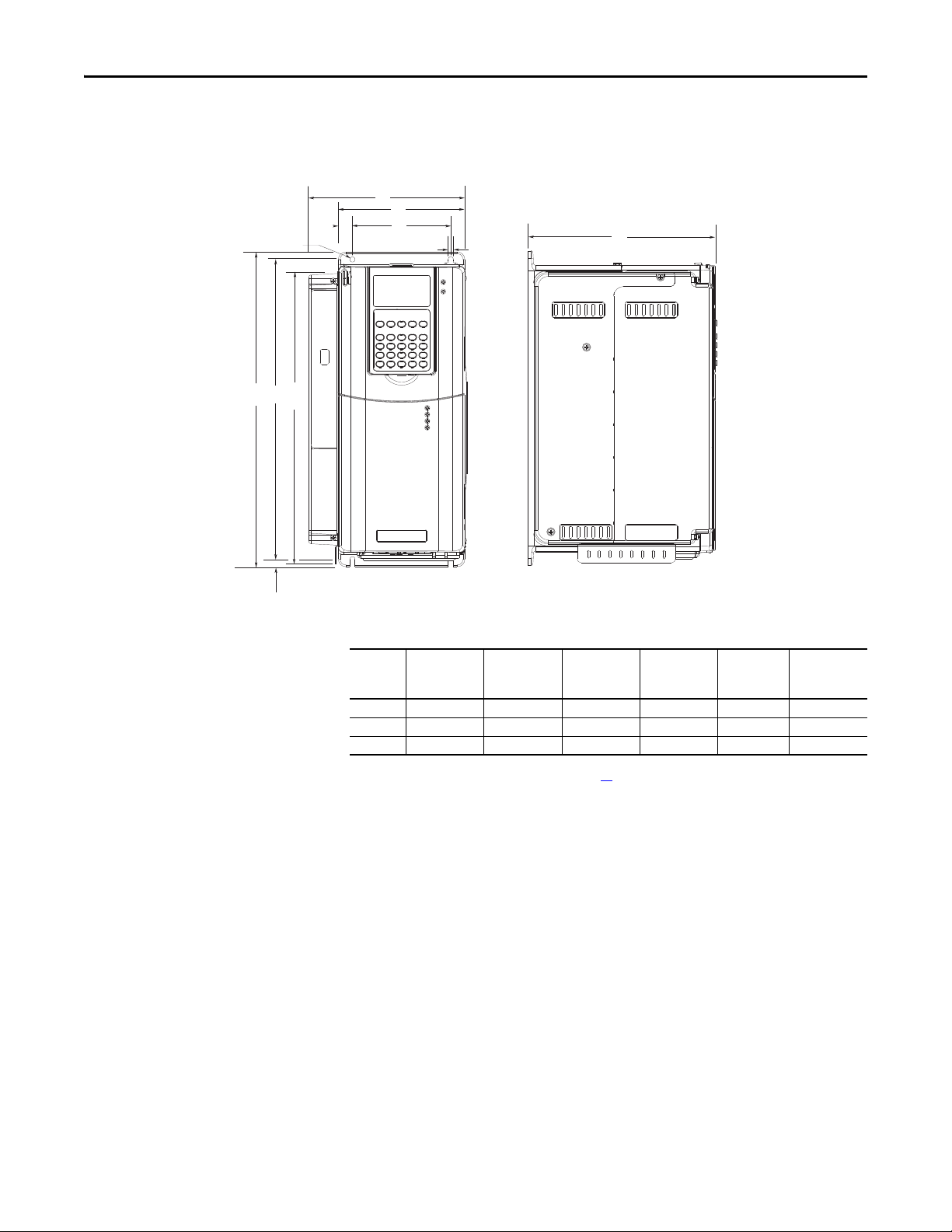

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Dimensions are in millimeters and (inches)

Frame 1 Shown

15.0

(0.59)

5.8

(0.23) dia.

312

E

B

(12.28)

Approximate Dimensions

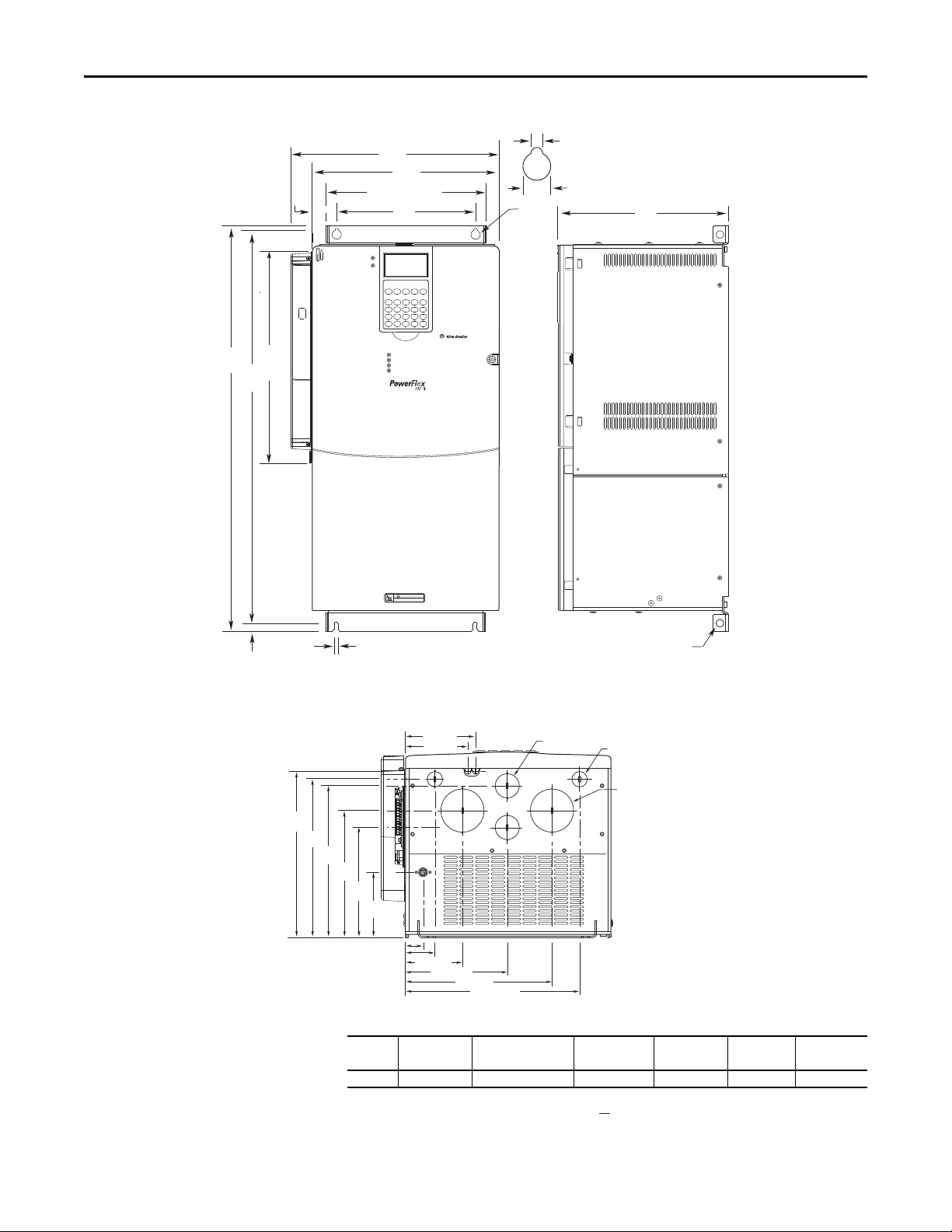

Figure 2 - Frames 1…3

AA

A

D

5.5 (0.22)

C

8.0

(0.31)

(1)

Frame

Slim CassetteAExpanded

BCDE

Cassette

AA

1 135.0 (5.31) 166.9 (6.57) 336.0 (13.23) 200.0 (7.87) 105.0 (4.13) 320.0 (12.60)

2 222.0 (8.74) 253.9 (9.99) 342.5 (13.48) 200.0 (7.87) 192.0 (7.56) 320.0 (12.60)

3 222.0 (8.74) 253.9 (9.99) 517.5 (20.37) 200.0 (7.87) 192.0 (7.56) 500.0 (19.69)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

16 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Figure 3 - Bottom Views, Frames 1…3

133.3

(5.25)

187.6

(7.39)

25.5

(1.00)

70.0 (2.76)

43.0 (1.69)

96.0 (3.78)

75.9 (2.99)

108.5 (4.27)

67.5 (2.66)

47.5 (1.87)

87.5 (3.44)

22.2 (0.87) Dia.

3 Places

28.6 (1.13) Dia.

185.1

(7.29)

162.3

(6.39)

66.0 (2.60)

94.7 (3.73)

105.3 (4.15)

97.0 (3.82)

137.2 (5.40)

187.0 (7.36)

22.7 (0.89)

29.0 (1.14)

127.7

(5.03)

151.1

(5.95)

160.1

(6.30)

165.1

(6.50)

184.5

(7.26)

22.2 (0.87) Dia.

28.7 (1.13) Dia.

2 Places

37.3 (1.47) Dia.

2 Places

66.0 (2.60)

94.7 (3.73)

105.3 (4.15)

130.0 (5.12)

186.0 (7.32)

22.7 (0.89)

29.0 (1.14)

127.7

(5.03)

160.1

(6.30)

165.1

(6.50)

184.5

(7.26)

28.7 (1.13) Dia.

2 Places

46.7 (1.84) Dia.

2 Places

34.9 (1.37) Dia.

2 Places

Vent Plate

Frame 1 Frame 2

Frame 3 - All Drives, except 50 Hp, 480V (37 kW, 400V) Frame 3 - 50 Hp, 480V (37 kW, 400V) Normal Duty

Dimensions are in millimeters and (inches)

22.4 (0.88) Dia.

2 Places

157.5

(6.20)

150.9

(5.94)

112.1

(4.41)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

167.5 (6.59)

39.3 (1.55)

57.2 (2.25)

72.7 (2.86)

156.9 (6.18)

106.0 (4.17)

139.4 (5.49)

177.4 (6.98)

28.7 (1.13) Dia.

3 Places

184.8

(7.28)

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 17

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

54.1 (2.13) Dia.

2 Places

47.0 (1.85) Dia.

2 Places

28.7 (1.13) Dia.

2 Places

26.8 (1.06)

36.8 (1.45)

50.7 (2.00)

141.9

(5.59)

105.1

(4.14)

157.9

(6.21)

177.9

(7.00)

189.7

(7.47)

22.2 (0.87) Dia.

63.8 (2.51)

112.0 (4.41)

180.0 (7.09)

65.3 (2.57)

76.0 (2.99)

Dimensions are in millimeters and (inches)

Bottom View

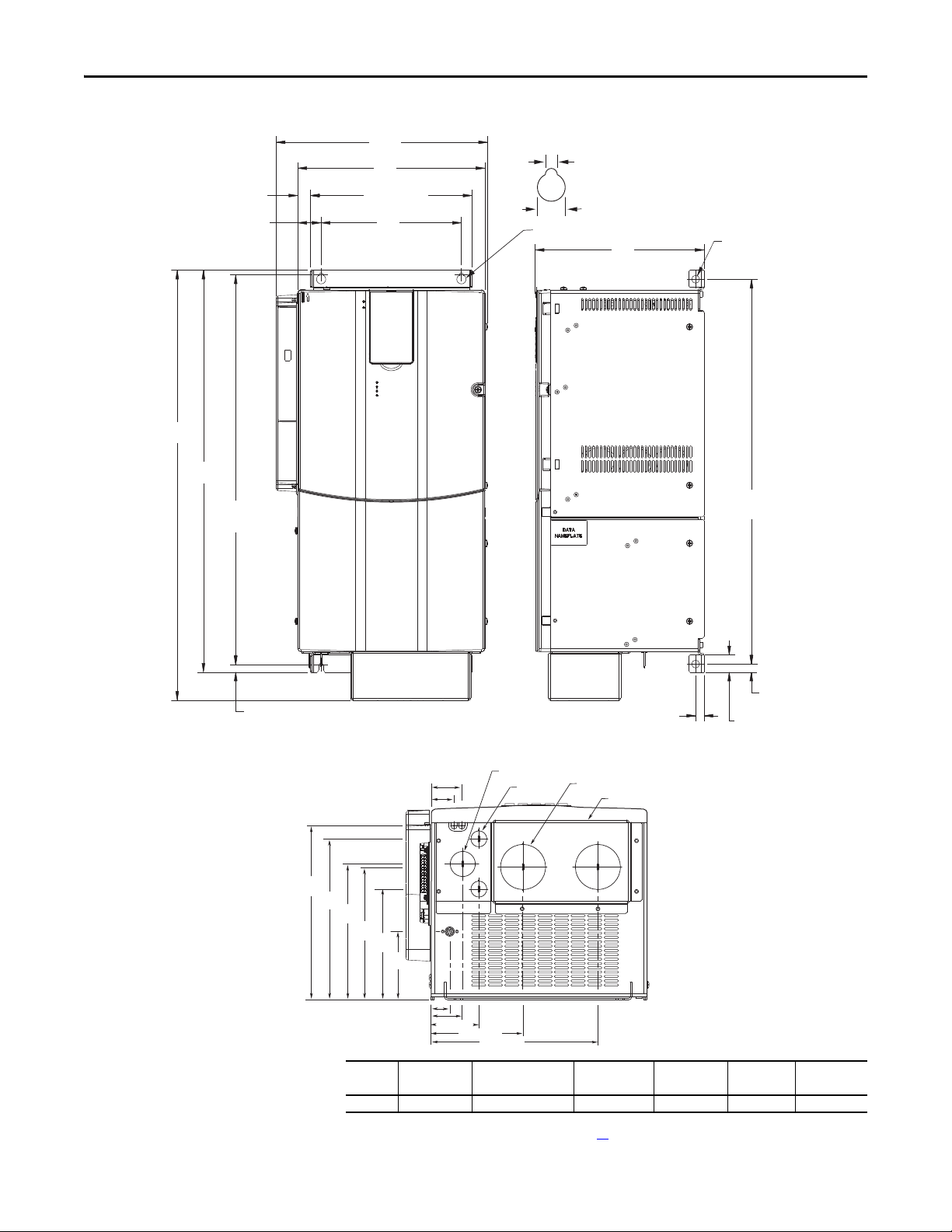

Figure 4 - Frame 4

AA

A

D

13.0 (0.55)

312

(12.28)

7.0 (0.28) 2 Places

S

E

15.1 (0.59)

B

C

Lifting Holes

4 Places

7.0 (0.28)

3 Places

8.0

(0.31)

(1)

Frame

Slim Cassette

Expanded CassetteAABC (Max) DE

A (Max)

4 220.0 (8.66) 251.9 (9.92) 758.8 (29.87) 201.7 (7.94) 192.0 (7.56) 738.2 (29.06)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

18 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

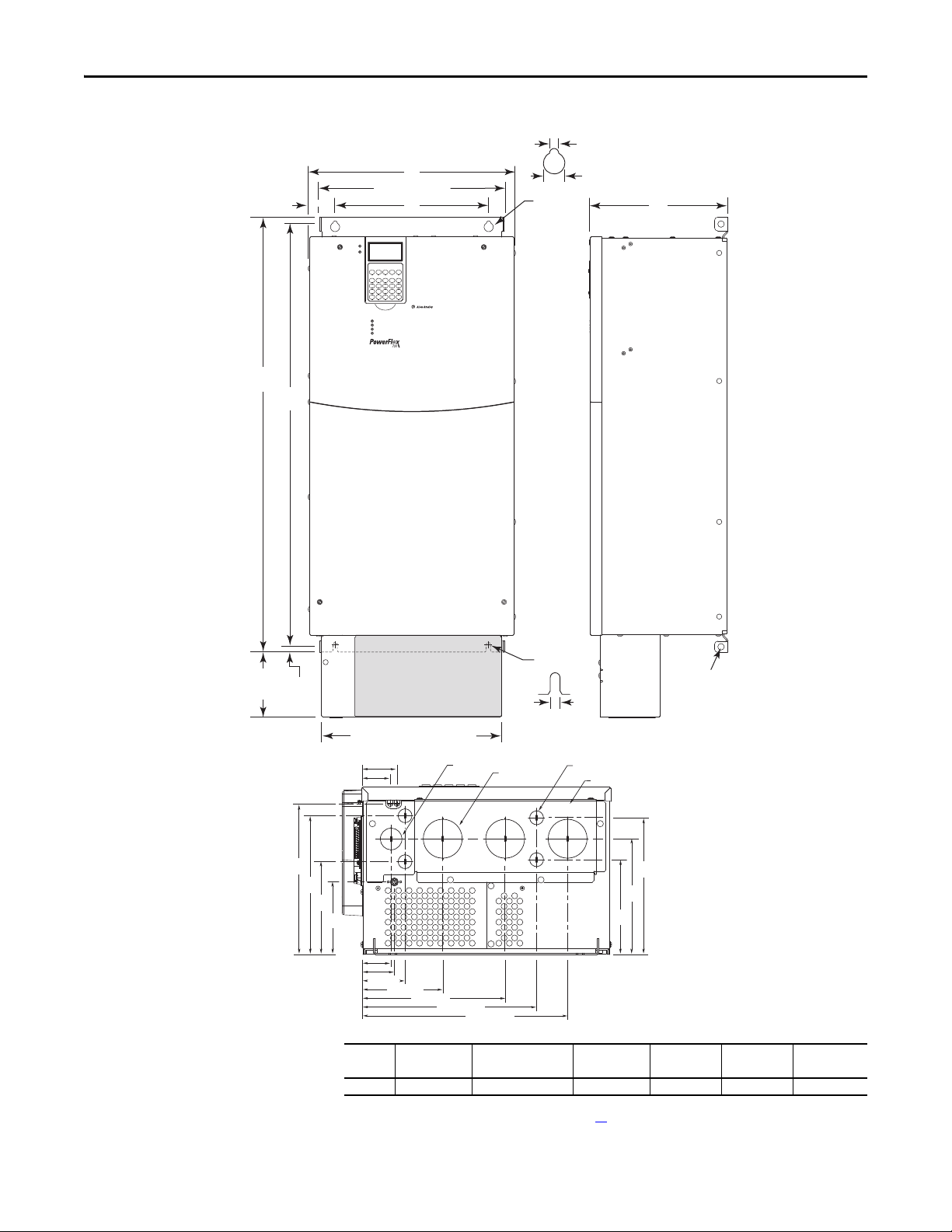

Figure 5 - Frame 5, 75 Hp, 480V (55kW, 400V)

Bottom View

HOT surfaces can cause severe burns

CAUTION

E

12.5

(0.49)

6.5 (0.26)

B

D

A

259.1 (10.20)

Detail

15.0 (0.59)

6.5 (0.26)

37.6

(1.48)

C

Lifting Holes - 4 Places

12.7 (0.50) Dia.

312

(12.28)

S

AA

96.0

(3.78)

159.5

(6.28)

184.0

(7.24)

220.0

(8.66)

229.5

(9.04)

241.9

(9.52)

45.0 (1.77)

85.0 (3.35)

93.2 (3.67)

104.0 (4.09)

150.0 (5.91)

215.0 (8.46)

255.0 (10.04)

28.0 (1.10)

22.2 (0.87) Dia.

2 Places

62.7 (2.47) Dia.

2 Places

34.9 (1.37) Dia.

2 Places

Dimensions are in millimeters and (inches)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Frame

(1)

Slim Cassette

Expanded CassetteAABC (Max) DE

A (Max)

5 308.0 (12.2) 339.9 (13.4) 644.5 (25.4) 275.4 (10.9) 225.0 (8.9) 625.0 (24.6)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 19

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Bottom View

Dimensions are in millimeters and (inches)

20.5 (0.8)

37.6 (1.48)

B

E

625.0

(24.6)

Figure 6 - Frame 5, 100 Hp, 480V (55kW, 400V)

AA

A

259.1 (10.20)

D

6.5 (0.3)

Detail

15.0 (0.6)

4 x Ø 12.7

C

(0.5)

617.0

(24.3)

12.0

(0.5)

241.9

(9.52)

223.5

(8.80)

188.5

(7.42)

184.3

(7.26)

Frame

42.6 (1.68)

31.9 (1.26)

153.5

(6.04)

96.0

(3.78)

28.0 (1.10)

44.0 (1.73)

(1)

Slim Cassette

13.0

(0.5)

66.4 (2.61)

128.0 (5.04)

34.9 (1.37) Dia.

232.3 (9.15)

22.2 (0.87) Dia.

2 Places

62.7 (2.47) Dia.

2 Places

Removable

Junction Box

Expanded CassetteAABC (Max) DE

27.6

(1.1)

A (Max)

5 308.9 (12.2) 340.8 (13.4) 689.6 (27.1) 270.35 (10.6) 225.0 (8.9) 644.5 (25.4)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

13.0

(0.5)

20 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

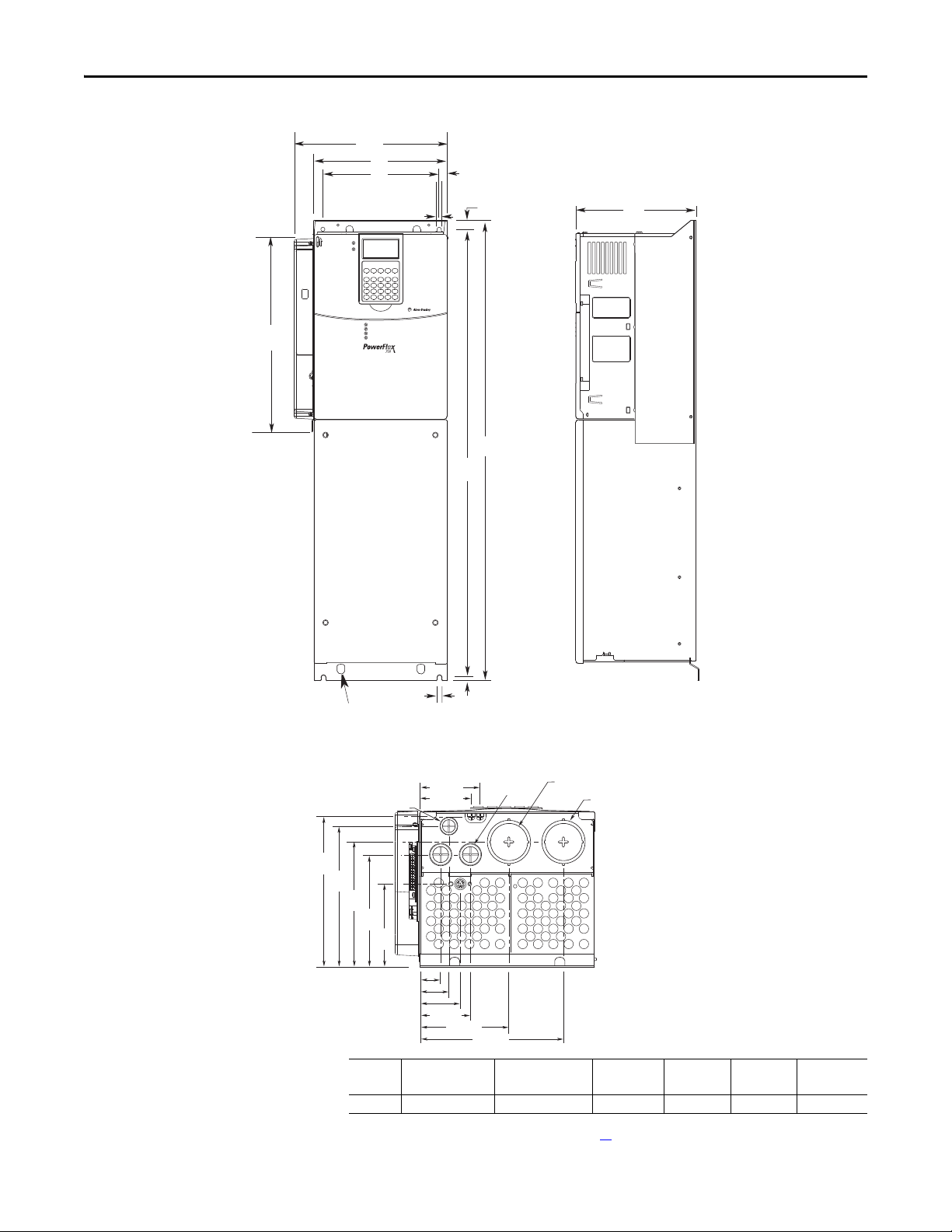

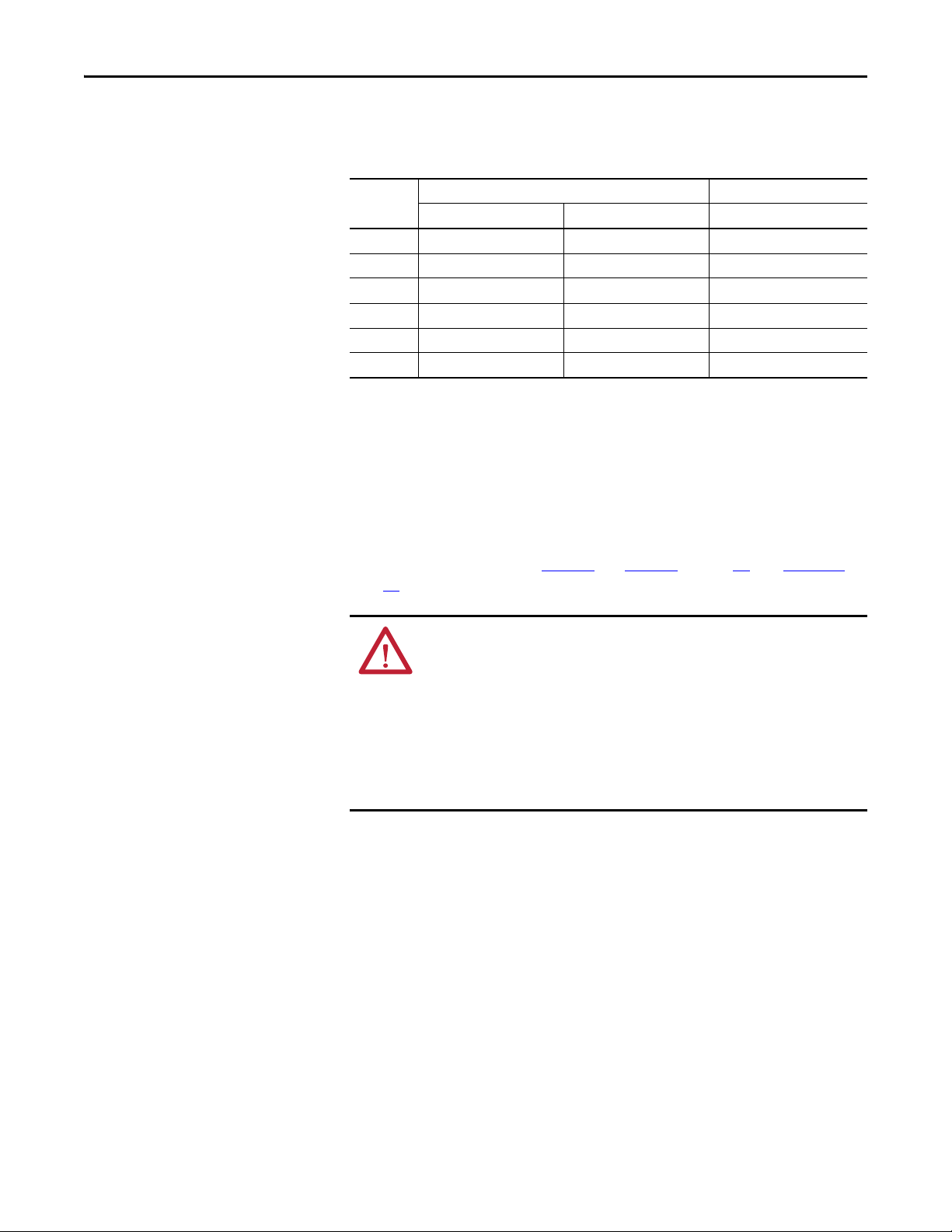

Figure 7 - Frame 6

Dimensions are in millimeters and (inches)

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

8.5 (0.33)

49.6

(1.95)

B

A

360.6 (14.20)

D

Detail

18.0 (0.71)

C

E

126.3

(4.97)

13.5

(0.53)

242.0

(9.53)

222.3

(8.75)

Detail

Old Style Junction Box

Lifting Holes

4 Places

12.7 (0.50) Dia.

219.0

(8.62)

C (Max) DE

New Style Junction Box

56.2 (2.21)

45.6 (1.80)

148.5

(5.85)

116.6

(4.59)

47.1 (1.85)

52.1 (2.05)

69.1 (2.72)

Frame

130.1 (5.12)

(1)

Slim Cassette

230.1 (9.06)

280.1 (11.03)

(0.33)

34.9 (1.37) Dia.

3 Places

62.7 (2.47) Dia.

3 Places

330.1 (13.00)

Expanded CassetteAAB

8.5

22.2 (0.87) Dia.

4 Places

Removable Junction Box

151.8

(5.98)

(2)

185.4

(7.30)

A (Max)

6 403.9 (15.90) 435.8 (17.16) 850.0 (33.46) 275.5 (10.85) 300.0 (11.81) 825.0 (32.48)

(1) Refer to Drive Rating to Frame Size Cross References on page 10 for frame information.

(2) Junction Box can be removed if drive is mounted in a cabinet.

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 21

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Step 3: Lift and Mount the

Drive

Drive Weights

Table 9 - Approximate Drive Weights

Frame Size Drive Rating Drive Weight

kW Hp kg (lb)

1 0.75…11 1…10 7.0 (15.5)

2 7.5…18.5 10…25 12.5 (27.6)

3 11…37 15…50 18.6 (40.9)

4 25…60 18.5…55 24.5 (54.0)

5 40…100 30…90 37.2 (82.0)

6 60…200 45…132 71.5 (157.5)

(1) Weights include HIM, DriveLogix controller with ControlNet daughtercard, Hi-Resolution Encoder Option, and 20-COMM-C

Contro lNet adapt er.

(2) Add an additional 3.6 kg (8.0 lb) for 200 Hp drives.

(1)

(2)

Attaching the Lifting Hardware

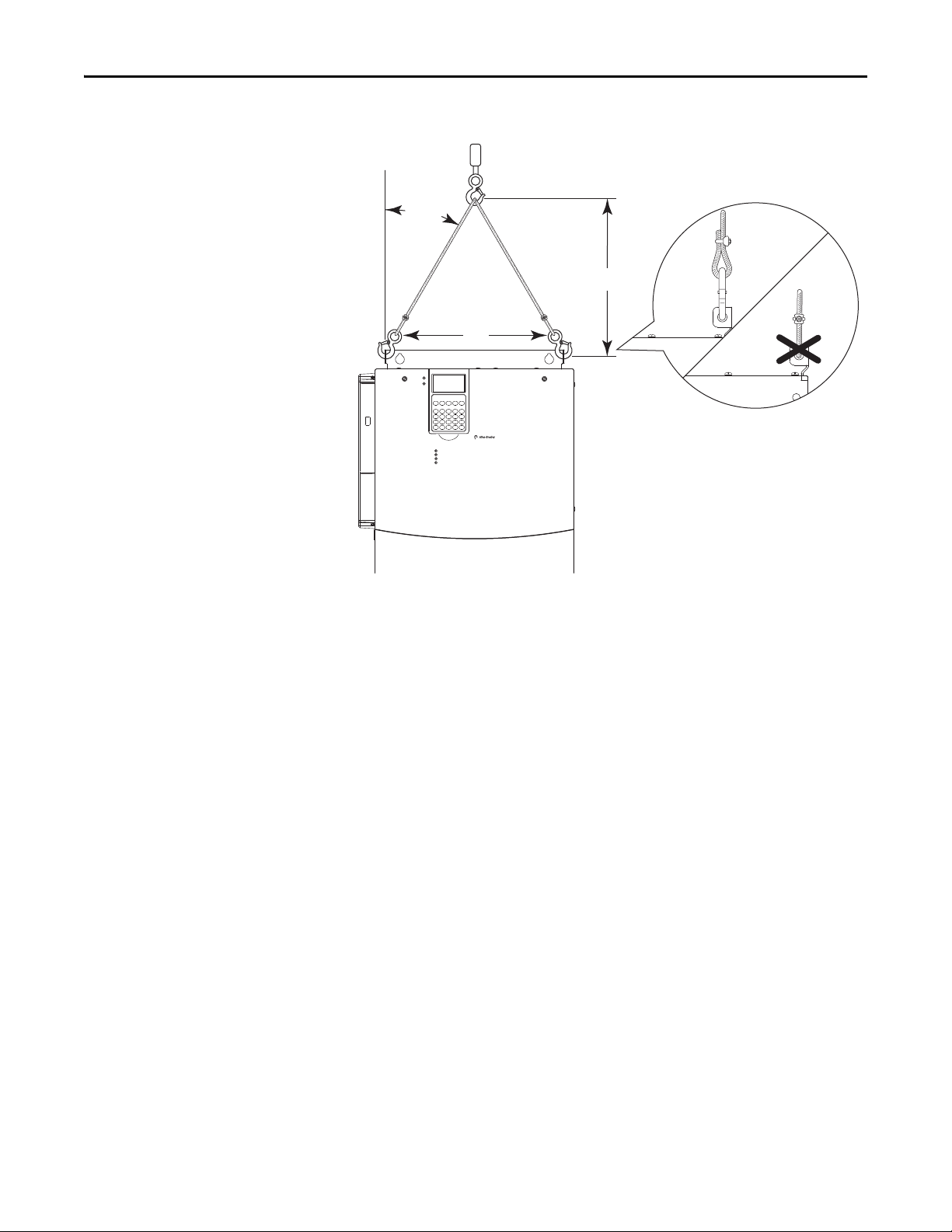

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

and so forth) must be properly sized and rated to safely lift and hold the weight of

the drive while mounting. See Figure 8

page 24

for lifting instructions.

and Figure 9 on page 23, and Figure 10 on

ATTENTION: To guard against possible personal injury and/or equipment

damage…

• Inspect all lifting hardware for proper attachment before lifting drive.

• Do not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• Do not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do not allow personnel or their limbs directly underneath the drive when it is

being lifted and mounted.

22 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Figure 8 - Lifting Frame 4 Drives

S

>

1

/

2 A

A

< 45°

S

>

1

/

2 A

A

< 45°

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

Figure 9 - Lifting Frame 5 Drives

Rockwell Automation Publication 20D-IN024C-EN-P - July 2013 23

PowerFlex 700S Adjustable Frequency AC Drive - Phase II Control

>

1

/

2 A

A

< 45°

Figure 10 - Lifting Frame 6 Drives

24 Rockwell Automation Publication 20D-IN024C-EN-P - July 2013

Loading...

Loading...