Rockwell Automation 6186M-xxxx User Manual

User Manual

Industrial Performance Monitors

Catalog Numbers 6186M-12PN, 6186M-12PT, 6186M-15PN, 6186M-15PT, 6186M-15PNSS, 6186M-15PTSS, 6186M17PN, 6186M-17PT, 6186M-17PNSS, 6186M-17PTSS, 6186M-19PN, 6186M-19PT, 6186M-19PNSS, 6186M-19PTSS

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/) describes some important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Summary of Changes

New and Updated

Information

This manual contains new and updated information. Changes throughout this revision are marked by change bars, as shown to the right of this paragraph.

This table contains the changes made to this revision.

Topic |

Page |

Added ‘Linux’ as a compatible operating system |

11, 35 |

Changed Series letter from ‘F’ to ‘G’ in Table 1 |

12 |

Revised hyperlink for finding accessories online |

12 |

Added ‘(USB Port-Type A)’ to section title |

15 |

Added USB Port Type A illustration and callout to Figure 1 |

15 |

Added ‘(USB Port-Type B)’ to section title |

16 |

Added USB Port Type B illustration and callout to Figure 2 |

16 |

Added Important table and revised information in ‘Application Information’ section |

17 |

Updated website link for CE Mark certification |

18 |

Revised instructions for panel-mounting the monitor |

26 |

Relocated RS-232 Touch Screen Interface table from Appendix B to Chapter 2 |

35 |

Removed column of DB-25 information from RS-232 Touch Screen Interface table |

35 |

Changed catalog number for replacement AC power adapter |

37 |

Added Important table in ‘Adjust the Monitor Brightness’ section |

42 |

Updated Important table in ‘Using the Auto Adjust Control’ section |

44 |

Removed existing graphic in ‘Changing Monitor Settings with the On-screen Display (OSD)’ section |

45 |

Added introductory paragraph and icons to ‘General OSD Menu Navigation Guidelines’ section |

45 |

Created separate table for Temperature submenu choices |

48 |

Revised Tools menu graphics |

50 |

Created separate tables to correspond with revised Tools menu graphics |

50 |

Revised typical luminance value for 1700M monitor |

57 |

Revised contrast ratios for 1200M and 1500M monitors |

57 |

Revised typical response time for all monitors |

57 |

Revised UL Listed and cUL Listed certifications |

58 |

Revised descriptions for Pins 2, 14, and 15 in Table 30 |

60 |

Removed ‘Setting the Monitor Type Manually’ section in Chapter 2 |

|

Removed previous Appendix B (previous Appendix C is now Appendix B) |

|

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

3 |

Summary of Changes

Notes:

4 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

|

|

Table of Contents |

Preface |

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 9 |

|

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 9 |

|

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 9 |

|

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 9 |

|

Chapter 1 |

|

Monitor Overview |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 11 |

|

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 11 |

|

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 11 |

|

Product Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 12 |

|

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 12 |

|

Chapter 2 |

|

Installing the Monitor |

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 13 |

|

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 13 |

|

Control Drawing - Class I Division 2 and Zone 2 |

|

|

(USB port, type A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 15 |

|

Control Drawing - Class I Division 2 and Zone 2 |

|

|

(USB port, type B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 16 |

|

Application Information . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 17 |

|

European Union Directive Compliance . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 18 |

|

Backlight Assembly Disposal . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 18 |

|

Environment and Enclosure Information . . . . . . . . . . . . |

. . . . . . . . . . . . . . 19 |

|

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 19 |

|

Product Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 21 |

|

1200M Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 21 |

|

1500M Monitor - Aluminum Bezel . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 22 |

|

1500M Monitor - Stainless Steel Bezel . . . . . . . . . . . |

. . . . . . . . . . . . . . 22 |

|

1700M Monitor - Aluminum Bezel . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 23 |

|

1700M Monitor - Stainless Steel Bezel . . . . . . . . . . . |

. . . . . . . . . . . . . . 23 |

|

1900M Monitor - Aluminum Bezel . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 24 |

|

1900M Monitor - Stainless Steel Bezel . . . . . . . . . . . |

. . . . . . . . . . . . . . 24 |

|

Panel Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 25 |

|

Mounting Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 25 |

|

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 25 |

|

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 25 |

|

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 26 |

|

Mounting the Monitor in Panel . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 26 |

|

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 28 |

|

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 28 |

|

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 28 |

|

Mounting the Monitor in a Rack . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 28 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

5 |

Table of Contents |

|

|

|

Bench or Tabletop Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

Mounting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

Mount the Monitor on a Bench or Tabletop . . . . . . . . . . . . . . . . . . . . |

31 |

|

Mount the DIN Rail of the AC Power Adapter . . . . . . . . . . . . . . . . . . . . . |

31 |

|

Monitor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

Video Source Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

Connect to a Host Digital Video Source . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

Connect to a Host Analog Video Source. . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

Connect the Optional Touch Screen Interface . . . . . . . . . . . . . . . . . . |

35 |

|

Power Source Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

Connect AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

Connect DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

Secure the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

|

Functional Ground Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

|

Chapter 3 |

|

Display Configuration |

Chapter Objective. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

Setting the Monitor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

Check and Change the Display Resolution . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

Adjust the Monitor Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

Adjust the Monitor by Using Control Keypad . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

Lock Access to the OSD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

Use the Auto Adjust Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

|

Change Monitor Settings with the On-screen Display (OSD). . . . . . . . |

45 |

|

General OSD Menu Navigation Guidelines. . . . . . . . . . . . . . . . . . . . . |

45 |

|

OSD Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

OSD Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

Signal Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

Brightness and Contrast Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

Color Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

Image Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

Tool Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

Chapter 4 |

|

Perform Routine Maintenance |

Chapter Objective. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Cleaning the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Replacing a Line Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Other Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

Shipping or Transporting Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

6 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

|

|

Table of Contents |

|

Chapter 5 |

|

Troubleshoot the System |

Chapter Objective. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . 53 |

|

Run the Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 53 |

|

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 54 |

|

Appendix A |

|

Specifications |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 57 |

|

Appendix B |

|

Video Cables |

HD-15 Video Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 59 |

|

DVI Video Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 60 |

Index |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 61 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

7 |

Table of Contents

Notes:

8 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Preface

About This Publication

Intended Audience

Purpose of This Manual

Additional Resources

Read this preface to familiarize yourself with the rest of the manual. The preface covers the following:

•Who should use this manual

•The purpose of the manual

•Conventions used in this manual

Use this manual if you are responsible for installing, using, or troubleshooting the monitors.

This manual is a user guide for the monitors. It gives an overview of the system and describes procedures to do the following:

•Install a monitor in a panel or rack, or on a bench or tabletop

•Make monitor connections

•Configure a monitor’s video setup

•Troubleshoot a monitor

For additional information on the industrial performance monitors, refer to the Industrial Performance Monitors installation instructions, publication 6186M-IN002.

You can download electronic versions of these publications from the Rockwell Automation website http://www.rockwellautomation.com/literature/.

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

9 |

Preface

Notes:

10 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Chapter 1

Monitor Overview

Overview

The industrial performance monitors provide the latest in LCD flat panel technology. Combine these monitors with the heavy industrial non-display computers to create a visualization, maintenance, control, or information computing solution. The monitors offer the following features:

•12, 15, 17, or 19-inch active matrix display

•Native video resolutions from 800x600 to 1280x1024

•Wide viewing angle with antiglare coating

•One-button automatic screen adjust

•Rear panel keypad with lockout feature

•Windows, Linux, and DOS compatible

•Input power, AC or DC

•Space efficient enclosure that is less than 63 mm (2.49 in.) deep

•Optional resistive touch screen

Before You Begin

Before unpacking the product, inspect the shipping carton for damage. If damage is visible, immediately contact the shipper and request assistance. Otherwise, proceed with unpacking.

Keep the original packing material in case you need to return the product for repair or transport it to another location. Use the inner and outer packing cartons to provide adequate protection for a unit returned for service.

Parts List

The monitors are shipped with these items:

•Mounting clips and cutout template

•AC power supply and applicable power cord

•HD-15 analog video cable

•DVI cable

•Touch screen serial cable (only for monitors with touch screen display)

•USB cable

•Cable retention tie wraps

•Installation Instructions

•Accessories CD (contains the installation files for the monitor drivers and the ScreenSet monitor setup utility)

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

11 |

Chapter 1 Monitor Overview

Product Catalog Numbers |

Table 1 - Catalog Numbers and Sizes of Performance Monitors |

|

|

|

|||

|

Cat. No. |

Display Size |

Series |

Bezel |

Touch Screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-12PN |

12 in. |

|

Aluminum |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-12PT |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-15PN |

15 in. |

|

Aluminum |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-15PT |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-15PNSS |

|

|

Stainless Steel |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-15PTSS |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-17PN |

17 in. |

G |

Aluminum |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-17PT |

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

6186M-17PNSS |

|

|

Stainless Steel |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-17PTSS |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-19PN |

19 in. |

|

Aluminum |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-19PT |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

|

6186M-19PNSS |

|

|

Stainless Steel |

None |

|

|

|

|

|

|

|

|

|

|

|

6186M-19PTSS |

|

|

|

Resistive touch screen |

|

|

|

|

|

|

|

|

|

|

Accessories

You can view a current list of accessories at the Rockwell Automation Allen-Bradley® website, http://ab.rockwellautomation.com/Industrial-Monitors.

12 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Chapter 2

Installing the Monitor

Chapter Objectives

Hazardous Locations

This chapter shows you how to install the monitor in a panel or rack, or on a bench or tabletop, and how to make monitor connections.

Review mounting types and product dimensions before installation.

This equipment is suitable for the following hazardous locations specified on the product nameplate:

·Class I, Division 2 Groups A, B, C, D

·Nonhazardous locations

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

13 |

Chapter 2 Installing the Monitor

The following statement applies to use in hazardous locations.

WARNING: Explosion Hazard

• Substitution of any components may impair suitability for hazardous locations.

• Do not disconnect equipment unless power has been removed or the area is known to be free of ignitable concentrations of flammable gases or vapors.

• Do not connect or disconnect cables or components unless power has been removed or the area is known to be free of ignitable concentrations of flammable gases or vapors.

• Do not connect or disconnect components unless power has been removed or the area is known to be free of ignitable concentrations of flammable gases or vapors.

• All wiring must be in accordance with Class I, Division 2 wiring methods of Article 501 of the National Electrical Code, and/or in accordance with Section 18-1J2 of the Canadian Electrical Code, and in accordance with the authority having jurisdiction.

• The monitor and its AC adapter have a temperature code of T4 when operating in an environment that is within its specified operating temperature range. Do not install the equipment in an environment where atmospheric gases have an ignition temperature of less than 135 °C (275 °F).

• Peripheral equipment must be suitable for the location in which it is used.

• All hazardous-location equipment must be mounted in an enclosure that is suitably designed or rated for those specific environmental conditions that will be present, and designed to prevent personal injury resulting from accessibility to live parts.

• The monitor may be powered directly from the included AC adapter (100...240 V AC input), or an external 9...36 V DC power source wired to the terminal block. Do not use the AC adapter and external DC at the same time.

14 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Installing the Monitor |

Chapter 2 |

|

|

Control Drawing - Class I Division 2 and Zone 2 (USB port, type A)

The following control drawing is provided to comply with the National Electrical

Code, Article 500 pertaining to Class I, Division 2, Groups A, B, C, D and Class

I, Zone 2, Group IIC.

Figure 1 - Industrial Performance Monitors USB Port, Type A, and Peripheral Devices

|

|

|

Associated Nonincendive |

Nonincendive |

||

|

|

|

Field-wiring Apparatus |

Field-wiring Apparatus |

||

|

|

|

|

|

|

|

|

|

|

6186M Hub Product |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

USB Port, Type A |

|

USB Peripheral Device |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

USB Port, Type A |

|

|

|

USB Port, Type A |

|

USB Peripheral Device |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2 - Industrial Performance Monitors USB Port, Type A, and Peripheral Device

Circuit Parameters

Parameter |

Value |

Parameter Definition |

|

|

|

VOC (USB) |

5.25V DC |

Open circuit voltage of each host USB port. |

|

|

The maximum applied voltage rating, Vmax (peripheral), of each peripheral device shall |

|

|

be greater than or equal to VOC (USB). |

|

|

Vmax (peripheral) VOC (USB), as appropriate |

ISC (USB) |

950 mA |

Maximum output current of each host USB port. |

|

|

The maximum current, I max (peripheral), to which each USB peripheral device can be |

|

|

subjected shall be greater than or equal to ISC (USB). |

|

|

Imax (peripheral) ISC (USB) |

C a (USB) |

20 μF |

This value is the maximum total capacitance that can be connected to each USB port. |

|

|

The total capacitance of each USB peripheral and its cable must not exceed the |

|

|

indicated value. |

|

|

The maximum total capacitance, Ci (peripheral), and cable capacitance of each separate |

|

|

USB peripheral device shall be less than or equal to Ca (USB). |

|

|

Ci ( peripheral) + Ccable Ca (USB) |

L a (USB) |

3.11 μH |

This value is the maximum total inductance that can be connected to each USB port. |

|

|

The total inductance of each peripheral device and its cable must not exceed the |

|

|

indicated value. |

|

|

The maximum total inductance, Li (peripheral), and cable inductance of each separate |

|

|

USB peripheral device shall be less than or equal to La (USB). |

|

|

Li (peripheral) + Lcable La (USB) |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

15 |

Chapter 2 Installing the Monitor

Control Drawing - Class I Division 2 and Zone 2 (USB port, type B)

The following control drawing is provided to comply with the National Electrical

Code, Article 500 pertaining to Class I, Division 2, Groups A, B, C, D and Class

I, Zone 2, Group IIC.

Figure 2 - Industrial Performance Monitors USB Port, Type B

Associated |

Nonincendive |

|

|

Field-wiring Apparatus |

Field-wiring Apparatus |

|

|

|

|

|

|

|

6186M Hub Product |

|

|

|

|

|

|

USB Port, Type B |

|

Host Product |

|

USB Port, Type B |

|

Table 3 - Required Circuit Parameters for USB, Type B, Connector - Connecting to Host

Parameter |

Value |

Parameter Definition |

|

|

|

|

|

VBmax (USB) |

5.25V DC, max |

Maximum applied voltage rating of the 6186M USB Type B connector. The |

|

|

|

output of the host product shall not exceed this value. |

|

|

|

V |

V |

|

|

Bmax (USB) |

OC (Host USB) |

IBmax (USB) |

110 μA, min |

Maximum current required at the 6186M USB Type B connector. The host |

|

|

|

product must be capable of a minimum of this value. |

|

|

|

ISC (Host USB) IBmax (USB) |

|

CiB (USB) |

0 μF |

Total capacitance of the 6186M USB Type B connector. The host product must be |

|

|

|

capable of tolerating this value of capacitance. |

|

|

|

Ca (Host USB) CiB (USB) + Ccable |

|

LiB (USB) |

0 μH |

Total Inductance of the 6186M USB Type B connector. The host product must be |

|

|

|

capable of tolerating this value of inductance. |

|

|

|

La (Host USB) LiB (USB) + Lcable |

|

16 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Installing the Monitor |

Chapter 2 |

|

|

Application Information

The circuit parameters of associated field-wired apparatus for use in hazardous locations shall be coordinated with the host product such that their combination remains nonincendive. The industrial performance monitors and USB peripheral devices shall be treated in this manner.

Each industrial performance monitor provides two separately powered USB ports. The circuit parameters for each USB port are found in tables on page 15 and page 16.

IMPORTANT Circuit parameters of USB peripheral devices and their associated cabling must be within the limits in the tables on page 15 and page 16 for the devices and their cabling to remain nonincendive when used with the USB ports of industrial performance monitors.

For the comparison of Ca (USB) and Ci (peripheral), use the capacitance of each individual connected USB peripheral device and its associated cable Ccable.

For the comparison of La (USB) with Li (peripheral), use the inductance of each individual peripheral device and its associated cable for Lcable.

If cable capacitance and inductance are not known, the following values may be used:

Ccable = 60 pF/ft (197 pF/m)

Lcable = 0.20 μH/ft (0.66 μH/m)

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

17 |

Chapter 2 Installing the Monitor

European Union Directive

Compliance

Backlight Assembly Disposal

This product meets the European Union Directive requirements when installed within the European Union or EEA regions and has the CE mark. A copy of the Declaration of Conformity is available at the following website: http://www.rockwellautomation.com/products/certification/ under Product Certification.

ATTENTION: This product is intended to operate in an industrial or control room environment, which uses some form of power isolation from the public low-voltage mains. Some computer configurations may not comply with the EN 61000-3-2 Harmonic Emissions standard as specified by the EMC Directive of the European Union. Obtain permission from the local power authority before connecting any computer configuration that draws more than 75 W of AC power directly from the public mains.

ATTENTION: The backlight assembly in this unit contains mercury. At the end of its life, this equipment should be collected separately from any unsorted municipal waste.

18 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Installing the Monitor |

Chapter 2 |

|

|

Environment and Enclosure

Information

Installation Guidelines

Review the information on enclosures and environments before installing your monitor.

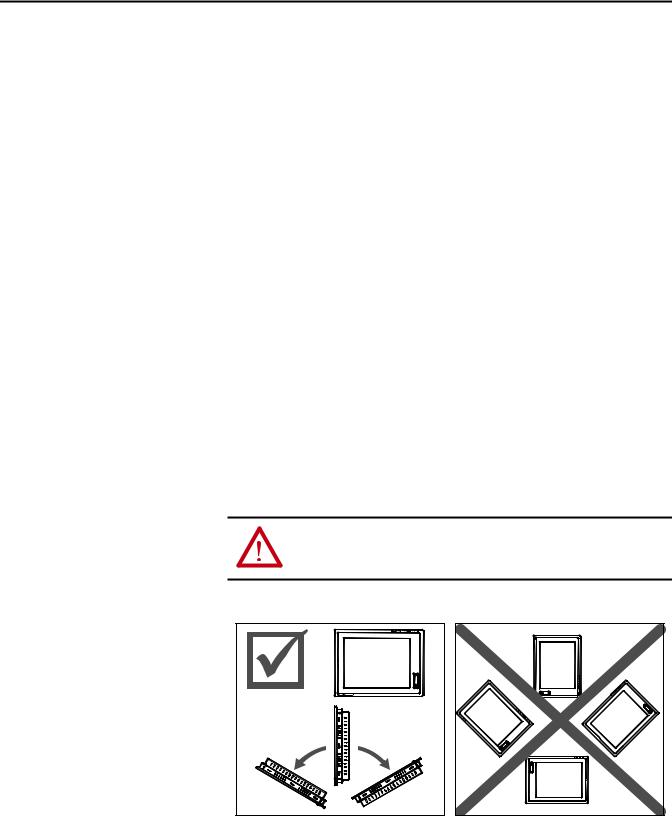

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR Publication 11. Without appropriate precautions, there may be potential difficulties ensuring electromagnetic compatibility in other environments due to conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. UL recognized and hazardous location equipment must be mounted in an enclosure that is suitably designed or rated for those specific environmental conditions that will be present, and designed to prevent personal injury resulting from accessibility to live parts. UL Listed equipment need not be mounted inside another enclosure in ordinary (nonhazardous) locations if NEMA Type and IEC ratings are not required, but the mounting method must limit the tilt of the product to ± 60° from vertical. Examples include an articulated arm, table-top stand, or other means having sufficient mechanical stability. The mounting means must be firmly attached to the supporting surface using screws, bolts, or clamps so the monitor cannot tip. All units ship with a gasketed bezel to meet specified NEMA and IEC ratings only when mounted in a panel or enclosure with an equivalent rating.

Subsequent sections of this publication may contain additional information regarding specific enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

•Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

•NEMA Standards publication 250 and IEC publication 60529, as applicable, for explanations of the degrees of protection provided by different types of enclosure

Follow these guidelines to make sure your product provides safe and reliable service:

• The installation site must have sufficient power.

ATTENTION: The monitor’s AC adapter must be grounded to maintain an electrically safe installation. Grounding the monitor itself is not required.

To ground the AC adapter, connect the product to earth ground using the

supplied AC cord ground wire or 0.9 mm2 (18 AWG) or larger external wire. The ground wire should have green insulation with a yellow stripe for easy identification.

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

19 |

Chapter 2 Installing the Monitor

•The enclosure must have sufficient space around air inlets and outlets to provide the circulation necessary for cooling. Never let air passages become obstructed.

•The surrounding air temperature must not exceed the maximum operating temperature, either inside or outside of the enclosure. Consider heat produced by other devices in the enclosure. You may need a user-supplied fan, heat exchanger, or air conditioner to meet this condition.

TIP |

Hot air rises. The temperature at the top of the enclosure is often higher |

|

than the temperature in other parts of the enclosure, especially if air is not |

|

circulating. |

|

|

IMPORTANT |

The product can operate at a range of extremes. However, the life span of |

|

any electronic device is shortened if you continuously operate the product |

|

at its highest rated temperature. |

|

|

•The humidity of the surrounding air must not exceed specified limits. In very dry environments, static charges build up readily. Proper grounding of the equipment through the AC power cord helps to reduce static discharges, which may cause shocks and damage electronic components.

•The enclosure or cover must remain in place at all times during operation. The cover provides protection against high voltages inside the product and inhibits radio-frequency emissions that might interfere with other equipment.

ATTENTION: Industrial computers and monitors are not safety devices. Follow standard safety practice and redundancy in the application of this product.

• When mounted, the product cannot be tilted more than 60° from vertical.

60° |

60° |

from Vertical |

from Vertical |

20 |

Rockwell Automation Publication 6186M-UM002B-EN-P - March 2012 |

Loading...

Loading...