Rockwell Automation 440C-CR30-22BBB User Manual

Guardmaster® 440C-CR30

Software Configurable Safety Relay

Quick Start Guide

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-IN001_-EN-P available from your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/) describes some important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

It is recommended that you save this user manual for future use.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014

Quick Start Guide

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Assumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Schematic/Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Configuring the Guardmaster 440C-CR30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Configuring the PanelView 600. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Verify Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Introduction

Safety systems are often described as a safety function that consists of inputs devices, a logic device and output devices. In this example application, we have two safety input devices: a SensaGuard interlock that monitors a safety gate and an e-stop push button that is located in a readily accessible area. Our logic device is a Guardmaster 440C-CR30 software configurable safety relay. We have two safety rated output devices, both of which are 700HPS-2Z24 relays with positive opening contacts. The Guardmaster 440C-CR30 monitors the 700HPS output devices through the plug-in module. Opening the gate or pressing the e-stop causes the 700HPS relays to turn off, which disconnects the power to the hazards before the operator can reach the hazard.

Our next consideration is returning power to the machine. In our example application, the operator opens the gate and walks into the hazard area. In such cases, a manual reset of the safety system is required. The reset signal is not a safety signal and therefore can be provided by a graphical display.

Assumptions

1.The user has loaded CCW Version 6.0 (or later) onto their computer.

2.The user has setup an Ethernet connection to the PanelView.

Schematic/Setup

The schematic of our example safety system is shown below.

a.A PanelView C600 has a serial connection to the Guardmaster 440CCR30.

b.The PC has a USB connection to the Guardmaster 440C-CR30 and an Ethernet connection to the PanelView C600.

c.An e-stop is connected to Inputs 00 and 01 and the e-stop uses test pulses A and B from terminals 12 and 13.

d.A Trojan T15 GD2 tongue interlock monitors a safety gate. It also uses test pulses A and B from terminals 12 and 13.

e.Two 700HPS relays are connected to output terminals 18 and 19.

f.The normally closed outputs of the 700HPS are connected to terminals I-00 and I-01 of the Plug-in Module.

g.The reset signal is provided by the PanelView C600.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

1 |

Quick Start Guide

+24V DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To Ethernet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Network |

PanelView C600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2711C-T6T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modbus Master |

|

|

|

|

|

|

|

|

|

|

K1 |

|

|

Stratix 2000 |

|

|

|

|

|

|

|

|

|

|

|

|

||

1783-US05T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unmanaged |

|

|

|

|

|

|

Trojan T15 GD2 |

|

|

|

|

|

|

|

Ethernet Switch |

|

|

|

|

|

|

440K-T11463 |

|

|

|

|

K2 |

|

|

|

00 |

01 |

02 |

03 |

04 |

05 06 07 |

08 |

09 |

10 |

11 |

I-00 |

I-01 COM +24 O-00 O-01 |

||

|

|

1 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

4 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

7 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

1761-CBL-PM02 |

|

|

|

440C-CR30-22BBB |

|

|

|

|

|

2080-IQ4OB4 |

|||

|

|

|

|

|

|

|

|

|

|

|||||

|

USB Cable |

|

|

|

|

|

|

|

|

|

|

|

|

|

Personal |

Male A to Male B |

|

|

A |

B |

|

|

|

|

|

|

I-02 |

I-03 COM |

-24 O-02 O-03 |

A1 A2 |

12 |

13 |

14 |

15 16 17 |

18 |

19 |

20 |

21 |

||||||

Computer |

|

|

|

|

|

|

|

|

700HPS-XZ24 Relay |

|

||||

|

|

|

|

|

|

|

|

K1 |

|

|||||

24V Com |

|

|

|

|

|

|

|

K2 700HN-123 Base |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Configuring the Guardmaster 440C-CR30

In this section, we will configure the Guardmaster 440C-CR30 workspace to match the schematic.

2 |

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

Quick Start Guide

1.Start the CCW. Click on the Windows Start button and then click on the Connected Components Workbench.

2.Expand the catalog items. Double click on the 440C-Guardmaster 440C-CR30-22BBB to load it into the Project Organizer.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

3 |

Quick Start Guide

3.Double click on the controller.

4.Load the Plug-in Module

4 |

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

Quick Start Guide

5.Open the Logic Editor. Also note that the Digital Input Module shows in the project.

6.Load the e-stop.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

5 |

Quick Start Guide

7.Load the Gate Switch.

8.Load the Feedback monitoring. (Use the vertical scroll bar to adjust the workspace up to see the next available safety monitoring spot.)

6 |

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

Quick Start Guide

9.Modify the feedback block. Set the number of inputs to two.

10.Assign the feedback wiring terminal. Set the Input Terminals to Plug-in 00 and 01.

11. Load the reset block.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

7 |

Quick Start Guide

12. Change the reset input terminal to Modbus 00.

13. Load the Immediate OFF block.

14. Change the Feedback connection to SMF3 (Safety Monitoring Function 3).

15. Change the reset Input to SMF4 (Safety Monitoring Input 4).

8 |

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

Quick Start Guide

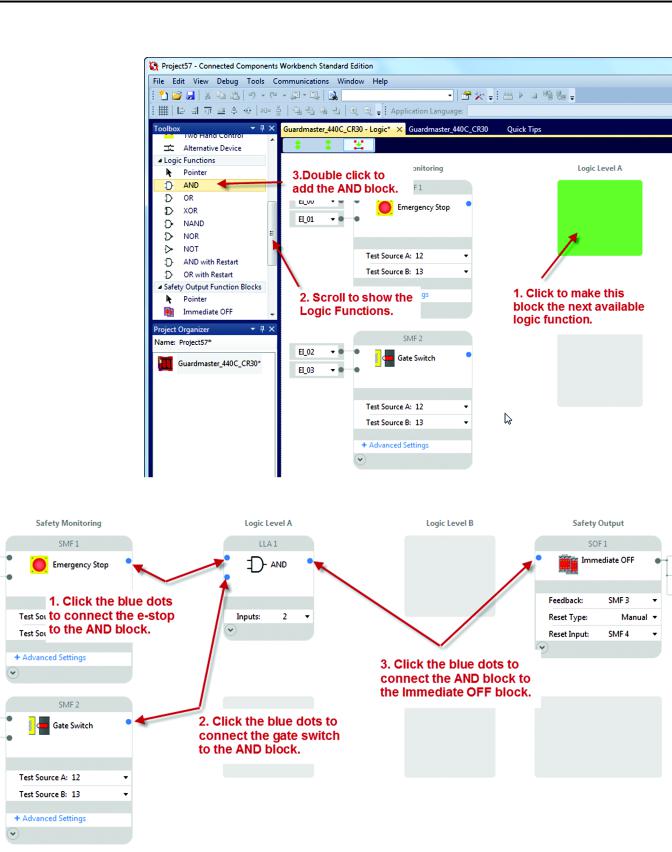

16. Load an AND block.

17. Make the connections.

Rockwell Automation Publication 440C-QS001A-EN-P — January 2014 |

9 |

Loading...

Loading...