Rockwell Automation 1746-HSRV User Manual

SLCtm Servo Control

Module

(Catalog No. 1746-HSRV)

User Manual

Important User Information Because of the variety of uses for the products described in this publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some important differences between solid-state equipment and electromechanical devices that should be taken into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION

Identifies information about practices or circumstances that can lead to personal injury or death, property damage or economic loss

!

Attention statements help you to:

∙identify a hazard

∙avoid a hazard

∙recognize the consequences

IMPORTANT |

Identifies information that is critical for successful |

|

application and understanding of the product. |

||

|

Allen-Bradley is a trademark of Rockwell Automation

European Communities (EC)

Directive Compliance

If this product has the CE mark it is approved for installation within the European Union and EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic Compatibility (EMC) by applying the following standards, in whole or in part, documented in a technical construction file:

∙EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial Environment

∙EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 - Equipment Requirements and Tests. For specific information required by EN 61131-2, see the appropriate sections in this publication, as well as the Allen-Bradley publication Industrial Automation Wiring and Grounding Guidelines For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an enclosure during operation to provide safety protection.

Table of Contents

Using This Manual |

Preface |

Overview of the SLC Servo

Module

Selecting Power Supplies,

Encoders, and Drives

Planning Hardware

Installation

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . P-1 Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1 Contents of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . P-2 Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4 Conventions Used in this Manual. . . . . . . . . . . . . . . . . . . . P-5 Product Receiving and Storage Responsibility. . . . . . . . . . . P-5 Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . P-6

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-6 Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-6 On the Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-7

Chapter 1

SLC Servo Module Overview . . . . . . . . . . . . . . . . . . . . . . . 1-1

SLC Servo Module Operation. . . . . . . . . . . . . . . . . . . . . . . 1-2

Configuration Mode Operation . . . . . . . . . . . . . . . . . . . 1-3

Command Mode Operation . . . . . . . . . . . . . . . . . . . . . 1-3

SLC Servo Module Specifications and Compatibility . . . . . . 1-4

Chapter 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 Selecting a Power Supply for the Backplane. . . . . . . . . . . . 2-1 Calculations for Backplane Current Requirements . . . . . 2-2 Selecting a User-Side Power Supply . . . . . . . . . . . . . . . . . . 2-3 Calculations for User-Side Current Requirements . . . . . . 2-4 Using Fast Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . 2-4 Selecting an Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 Selecting a Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Chapter 3

General Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using Shielded Cables . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Publication 1746-6.1.2 - July 2000

Table of Contents |

ii |

|

|

Installing Your SLC Servo

Module

Routing Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Classifying Your Conductors . . . . . . . . . . . . . . . . . . . . . . . 3-3

Placing Your SLC Servo Module. . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4

Unpacking and Inspecting Your SLC Servo Module System . 4-1 Installing the SLC Servo Module. . . . . . . . . . . . . . . . . . . . . 4-2 Grounding the SLC Servo Module . . . . . . . . . . . . . . . . . . . 4-4 Mounting the Termination Panel . . . . . . . . . . . . . . . . . . . . 4-5 Connecting the Termination Panel . . . . . . . . . . . . . . . . . . . 4-7

Wiring the SLC Servo

Module

Chapter 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Complying with European Union Directives . . . . . . . . . . . . 5-1 EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Wiring Fast Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . 5-2 Wiring Hardware Overtravels. . . . . . . . . . . . . . . . . . . . . . . 5-4 Software Overtravel Limits . . . . . . . . . . . . . . . . . . . . . . 5-5 Connecting Home Limit Switch as a Fast Input . . . . . . . . . . 5-5 Wiring Estop Connections . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 Wiring the Estop for a One-Axis System . . . . . . . . . . . . 5-7

Wiring for Normal Operation . . . . . . . . . . . . . . . . . . . . . . 5-7 Maintaining Electrical Continuity . . . . . . . . . . . . . . . . . . . 5-7 Verifying Connections and Operation . . . . . . . . . . . . . . . . 5-7

Wiring the Estop for System with Two or More Axes. . . 5-10 Wiring Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12 Wiring Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13 Typical Vendor Encoder Wiring . . . . . . . . . . . . . . . . . . 5-15 Encoder Feedback Direction . . . . . . . . . . . . . . . . . . . 5-16 Wiring the SLC Servo to Allen-Bradley Drives. . . . . . . . . . . 5-18 Wiring the SLC Servo Module to 1398 ULTRA 100/200. . 5-27

Wiring the SLC Servo Module – Homing to a Marker . . 5-28

Connecting the Velocity Command . . . . . . . . . . . . . . . . . . 5-32

Testing Your SLC Servo

Module Hardware

Chapter 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Powering Up Your SLC Servo Module . . . . . . . . . . . . . . . . 6-1

Publication 1746-6.1.2 - July 2000

Table of Contents |

iii |

|

|

Testing Estop Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Setting Up Your SLC Servo

Module

Chapter 7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Understanding the Theory of Motion Control . . . . . . . . . . . 7-2 Machine Mechanics . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Velocity Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Position Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 Powering Up the SLC Servo Module. . . . . . . . . . . . . . . . . . 7-3 Configuring the SLC Processor . . . . . . . . . . . . . . . . . . . . . . 7-3 Configuring Your Processor Using AI-500 Software . . . . 7-4 Configuring Your Processor Using APS Software . . . . . . 7-5 Configuring Your Processor Using RSLogix 500 Software 7-7 Automatically Configuring the SLC Servo Module . . . . . 7-7 Manually Configuring the SLC Servo Module . . . . . . . . . 7-8 The SLC Servo Module Interface . . . . . . . . . . . . . . . . . . . . 7-11 Configuring the SLC Servo Module. . . . . . . . . . . . . . . . . . . 7-11 Data Type Conversions . . . . . . . . . . . . . . . . . . . . . . . . 7-12 Before Programming the SLC Servo Module . . . . . . . . . . . . 7-12 Communicating – SLC Processor & SLC Servo Module . . . . 7-13 Entering Encoder Lines and Computing Counts . . . . . . . . . 7-13 Computing Counts Per Position Unit . . . . . . . . . . . . . . 7-14 Computing Maximum Speed Scaler . . . . . . . . . . . . . . . 7-14 Initializing DAC Output Voltage for Drive Symmetry. . . . . . 7-16 Setting Initial Loop Type . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16 Defining Positive Axis Movement for SLC Servo Module . . . 7-17 Coarse Calibrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18 Fine Calibrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18 Computing Excess Following Error Limit . . . . . . . . . . . . . . 7-19 Selecting Loop Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20 Selecting Axis Acceleration Rate. . . . . . . . . . . . . . . . . . . . . 7-21 Determining Velocity and Acceleration Feedforward. . . . . . 7-23 Velocity Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23 Acceleration Feedforward. . . . . . . . . . . . . . . . . . . . . . . 7-23 Setting Axis and Home Specific Parameters . . . . . . . . . . . . 7-24 Programming Conventions . . . . . . . . . . . . . . . . . . . . . . . . 7-24 Downloading Your Configuration . . . . . . . . . . . . . . . . . 7-24 Configuration Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25 Configuring the M0 File Data Tables . . . . . . . . . . . . . . . 7-25 Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7-26 Feedback Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 7-26 Servo Loop Parameters. . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Motion Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Publication 1746-6.1.2 - July 2000

Table of Contents |

iv |

|

|

Programming the SLC Processor to Run the SLC Servo Module

Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30 Homing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31 Homing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32 Homing Without a Limit Switch or Marker . . . . . . . . . . 7-32 Homing to a Marker. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Option 1 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33 Option 2 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34 Option 3 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35 Option 4 Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Homing to a Limit Switch . . . . . . . . . . . . . . . . . . . . . . 7-37 Homing to a Limit Switch and Marker . . . . . . . . . . . . . 7-38

Chapter 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 Blend Move Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 Downloading Your Blend Move Profiles . . . . . . . . . . 8-1

Understanding Configuration Errors . . . . . . . . . . . . . . . . . 8-2

Command and Status Information . . . . . . . . . . . . . . . . . . . 8-4 Module Communication Interface . . . . . . . . . . . . . . . . . . . 8-4 Discrete Bit Commands from the SLC Processor . . . . . . . . . 8-5

Word 0 Discrete Bit Commands . . . . . . . . . . . . . . . . . . . . 8-6 Word 1 Discrete Bit Commands . . . . . . . . . . . . . . . . . . . . 8-8

Discrete Block Commands from the SLC Processor . . . . . . . 8-8 Recovering from Estop . . . . . . . . . . . . . . . . . . . . . . . . . 8-9 Incremental Position Command . . . . . . . . . . . . . . . . . . 8-9

Executing Simultaneous Moves. . . . . . . . . . . . . . . . . . . . 8-10

Simple Move Commands . . . . . . . . . . . . . . . . . . . . . . . 8-11 Using Simple Move Commands . . . . . . . . . . . . . . . . . . . . 8-11 Using the Absolute/Incremental Move Command . . . . . 8-11

Planning an Absolute/Incremental Move. . . . . . . . . . . . . 8-13

Using the Speed Move Command . . . . . . . . . . . . . . . . . 8-15

Planning a Speed Move . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Using the Monitor Move Command . . . . . . . . . . . . . . . 8-17

Planning a Monitor Move . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Using the Run Blend Move Profile Command . . . . . . . . 8-18

Planning the Run Blend Move Profile Command . . . . . . 8-19 Executing a Run Blend Move Profile . . . . . . . . . . . . . . . 8-20 Executing Several Blend Moves . . . . . . . . . . . . . . . . . . . 8-21

Blending Moves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Blending Absolute Moves . . . . . . . . . . . . . . . . . . . . . . . . 8-22 Blending Incremental Moves . . . . . . . . . . . . . . . . . . . . . . 8-24 Blending Speed Moves . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Publication 1746-6.1.2 - July 2000

Table of Contents |

v |

|

|

Programming System

Variables

Troubleshooting

Plan Synchronized Move . . . . . . . . . . . . . . . . . . . . . . . 8-25

Chapter 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 Using Position Initialization Commands . . . . . . . . . . . . . . 9-1 Using the Home Axis Command. . . . . . . . . . . . . . . . . . 9-1

Planning a Home Axis Move . . . . . . . . . . . . . . . . . . . . . . 9-2

Using the Set Home Command. . . . . . . . . . . . . . . . . . . 9-3

Typical Set Home Move Data Tables . . . . . . . . . . . . . . . 9-4

Using the Set Retract Position Command. . . . . . . . . . . . 9-4

Typical Set Retract Position Move Data Tables . . . . . . . 9-5

Using the Preset Position Command . . . . . . . . . . . . . . . 9-5

Typical Preset Position Move Data Tables . . . . . . . . . . . 9-6

Using Online Configuration Commands . . . . . . . . . . . . . . 9-6 Using the Set Offset Command . . . . . . . . . . . . . . . . . . . 9-6

Typical Set Offset Move Data Tables . . . . . . . . . . . . . . . 9-7

Using the Set In-Position Band Command . . . . . . . . . . . 9-7

Typical Set In-Position Band Move Data Tables. . . . . . . 9-8

Using the Set Excess FE Limit Command. . . . . . . . . . . . 9-8

Typical Set Excess FE Limit Move Data Tables . . . . . . . 9-9

Using the Set Axis Gain Command . . . . . . . . . . . . . . . . 9-9

Typical Set Axis Gain Move Data Tables . . . . . . . . . . . . 9-9

Using the Set VFF Command . . . . . . . . . . . . . . . . . . . . 9-11

Typical Set VFF Move Data Tables . . . . . . . . . . . . . . . . 9-11

Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11 Word 0 Discrete Bit Status Specifications. . . . . . . . . . . . 9-12

Blend Move Profile Segment Number. . . . . . . . . . . . . . . 9-12

Word 1 Discrete Bit Status Specifications . . . . . . . . . . . 9-13 Word 2 Discrete Bit Status Specs SLC Servo Module . . . 9-14 Word 3 Discrete Bit Status Specifications . . . . . . . . . . . 9-15 SLC Servo Module Processor Status . . . . . . . . . . . . . . . . . . 9-15 Informational Message or Fault Code . . . . . . . . . . . . . . 9-15 Floating-Point Values . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Chapter 10

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

HSRV Quick Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Check wiring to diagram . . . . . . . . . . . . . . . . . . . . . . . 10-2

Publication 1746-6.1.2 - July 2000

Table of Contents |

vi |

|

|

Input/Output Quick

Reference

Do a battery box test. (If unable to control drive) . . . . . 10-2 Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2 Configure the HSRV module. . . . . . . . . . . . . . . . . . . . . 10-2

Downloading Your Configuration . . . . . . . . . . . . . . . . . . 10-2

If CONFIG INV LED is Lit. . . . . . . . . . . . . . . . . . . . . . . 10-3 Configuration Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3 Jog the Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Using the Speed Move Command . . . . . . . . . . . . . . . . . . 10-5

Troubleshooting LED Indicators. . . . . . . . . . . . . . . . . . . . . 10-6 Error Messages and Diagnosis . . . . . . . . . . . . . . . . . . . . . . 10-7 Informational Messages . . . . . . . . . . . . . . . . . . . . . . . 10-8 Minor Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . 10-10 Major Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Appendix A

Configuration Output Bit Parameters . . . . . . . . . . . . . . . . . |

A-1 |

Word 0 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . |

A-1 |

Word 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . |

A-4 |

Word 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . |

A-5 |

Multi-Word Parameters . . . . . . . . . . . . . . . . . . . . . |

A-5 |

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-9 |

Output Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-9 |

Discrete Bit Output Command (Word 0) . . . . . . . . . . . . |

A-10 |

Discrete Bit Output Command (Word 1) . . . . . . . . . . . . . |

A-10 |

Incremental Position Output Cmnd (Words 2 & 3) . . . . . |

A-10 |

Block Output Command (Word 4). . . . . . . . . . . . . . . . . . |

A-11 |

Block Output Command (Word 5). . . . . . . . . . . . . . . . . . |

A-11 |

Discrete Bit Input Status Specifications . . . . . . . . . . . . |

A-11 |

Word 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-11 |

Word 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-12 |

Word 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-12 |

Word 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-13 |

SLC Servo Module to SLC Processor Discrete Control Status A-13

Blended Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-14 |

Cable Dimensions and

Wiring Diagram

Appendix B

1746-HCA Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Publication 1746-6.1.2 - July 2000

Table of Contents |

vii |

|

|

Programming Examples

Wiring Without the

Termination Panel

Appendix C

SLC Servo Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1 Ladder Rung Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2 Rung 0 – Manual Triggering Configuration . . . . . . . . . . C-2 Rung 1 – Download Configuration . . . . . . . . . . . . . . . . C-2 Rung 2 – Timer Delay . . . . . . . . . . . . . . . . . . . . . . . . . C-4 Rung 3 – Checking For Successful Configuration . . . . . . C-5 Rung 4 – Downloading Blend Profiles . . . . . . . . . . . . . C-5 Rung 5 – Setting the Timer Delay . . . . . . . . . . . . . . . . . C-7 Rung 6 – Error Checking For Successful Download . . . . C-8 Rung 7 – Clear Fault Bits Command . . . . . . . . . . . . . . . C-8 Rung 8 – Clear All Faults Bit. . . . . . . . . . . . . . . . . . . . . C-9 Rung 9 – Cancel Move . . . . . . . . . . . . . . . . . . . . . . . . . C-9 Rung 10 – Hold/Unhold . . . . . . . . . . . . . . . . . . . . . . . . C-9 Rung 11 – Program an Estop Request . . . . . . . . . . . . . C-10 Rung 12 – ABSOLUTE Move. . . . . . . . . . . . . . . . . . . . C-10 Rung 13 – INCREMENTAL Move. . . . . . . . . . . . . . . . . C-12 Rung 14 – SPEED Command . . . . . . . . . . . . . . . . . . . C-14 Rung 15 – MONITOR Move . . . . . . . . . . . . . . . . . . . . C-15 Rung 16 – BLEND Move. . . . . . . . . . . . . . . . . . . . . . . C-16 Rung 17 – Clearing Move Bits. . . . . . . . . . . . . . . . . . . C-17 Rung 18 – Copying Status Information . . . . . . . . . . . . C-18 Rung 19 – HOME Axis . . . . . . . . . . . . . . . . . . . . . . . . C-19 Rung 20 – Final Rung. . . . . . . . . . . . . . . . . . . . . . . . . C-21

Appendix D

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1 Using Fast Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . D-1 Distances to User Devices . . . . . . . . . . . . . . . . . . . . . . . . . D-2 Wiring Your User Devices . . . . . . . . . . . . . . . . . . . . . . . . . D-2 Estop Circuitry Drawings . . . . . . . . . . . . . . . . . . . . . . . D-3

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .I-1

Publication 1746-6.1.2 - July 2000

Table of Contents |

viii |

|

|

Publication 1746-6.1.2 - July 2000

Preface

Who Should Use this Manual

Purpose of this Manual

Safety Precautions

Read this preface to familiarize yourself with the rest of the manual. This preface covers the following topics:

∙who should use this manual

∙purpose of this manual

∙safety precautions

∙contents of this manual

∙related documentation

∙conventions used in this manual

∙receiving and storage information

∙Allen-Bradley support

Use this manual if you are responsible for designing, installing, programming, or troubleshooting the SLC™ Servo Module (catalog number 1746-HSRV).

If you do not have a basic understanding of SLC 500™ products, understand programmable controllers or cannot interpret the ladder logic instructions required to control your application, contact your local Allen-Bradley representative for information on available training courses before using this product.

We recommend that you review one of the following before using the software:

Publication |

Publication Number |

|

|

Getting Results with RSLogix 500 |

9399-RL50GR |

|

|

AI Series Installation Guide |

9399-AIIG |

|

|

This manual is a user guide for the SLC Servo Module (catalog number 1746-HSRV). It gives you an overview of the SLC Servo Module and describes the procedures you use to install, set up, use, and troubleshoot the SLC Servo Module.

The following general precautions apply to the SLC Servo Control Module.

Publication 1746-6.1.2 - July 2000

Preface P-2

ATTENTION

!

Only those familiar with the SLC Servo Control Module and associated machinery should plan or implement the installation, start-up, and subsequent maintenance of the system. Failure to comply can result in personal injury and/or equipment damage.

This product contains stored energy devices. To avoid hazard of electrical shock, verify that all voltage on the capacitors has been discharged before attempting to service, repair, or remove this unit. You should only attempt the procedures in this manual if you are qualified to do so and familiar with solid-state control equipment and the safety procedures in publication NFPA 70E.

The system integrator is responsible for local safety and electrical codes.

ATTENTION

!

An incorrectly applied or installed controller can result in component damage or a reduction in product life. Wiring or application errors, such as undersizing the motor, incorrect or inadequate AC supply, or excessive ambient temperatures can result in malfunction of the drive.

This product contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are required when installing, testing, servicing, or repairing this assembly. Component damage can result if ESD control procedures are not followed. If you are not familiar with static control procedures, refer to Allen-Bradley publication 8000-4.5.2, Guarding Against Electrostatic Damage or any other applicable ESD Protection Handbook.

Contents of this Manual

This manual provides specific information relevant to the SLC Servo Module. The following table identifies the chapters, titles, and contents.

Publication 1746-6.1.2 - July 2000

Preface P- 3

Chapter |

Title |

Contents |

|

|

|

1 |

Overview of the SLC Servo |

Overview information about |

|

Module |

the product, its operation |

|

|

and hardware features. |

|

|

Describes interface |

|

|

selection, the module’s use |

|

|

of inputs and outputs, and |

|

|

operating modes. |

|

|

|

2 |

Selecting Power Supplies, |

Information about selecting |

|

Encoders and Drives |

the hardware to support an |

|

|

SLC Servo Module. |

|

|

|

3 |

Planning Hardware |

Interconnection diagrams |

|

Installation |

for various hardware |

|

|

interfaces for |

|

|

communication with the SLC |

|

|

Servo Module. |

|

|

|

4 |

Installing Your SLC Servo |

Installation information. |

|

Module |

|

|

|

|

5 |

Wiring the SLC Servo |

Information about wiring |

|

Module |

fast inputs, outputs, Estop |

|

|

connections, power |

|

|

supplies, encoders and drive |

|

|

connections. |

|

|

|

6 |

Testing Your SLC Servo |

Information about powering |

|

Module Hardware |

up the SLC Servo Module, |

|

|

testing the Estop and the |

|

|

fast I/O, integrating the axis |

|

|

and testing the homing |

|

|

function. |

|

|

|

7 |

Setting Up and Configuring |

Information about applying |

|

Your SLC Servo Module |

power and configuring the |

|

|

SLC Servo Module using |

|

|

command parameters. |

|

|

|

8 |

Programming the SLC |

Information about blend |

|

Processor to Run the SLC |

move profiles, module |

|

Servo Module |

communication interface, |

|

|

command, and status |

|

|

information. Describes |

|

|

discrete bit and block |

|

|

commands from the SLC |

|

|

Servo Module. |

|

|

|

9 |

Programming System |

Describes discrete block |

|

Variables |

commands for programming |

|

|

position and online system |

|

|

variables from the SLC |

|

|

processor. Information to |

|

|

understand servo module |

|

|

and processor status |

|

|

information. |

|

|

|

Publication 1746-6.1.2 - July 2000

Preface P-4

Related Documentation

Chapter |

Title |

Contents |

|

|

|

10 |

Troubleshooting |

Information about |

|

|

troubleshooting and error |

|

|

handling. |

|

|

|

Appendix A |

Input/Output Quick |

A quick reference of |

|

Reference |

parameters, commands, |

|

|

status specifications, and |

|

|

move profiles. |

|

|

|

Appendix B |

Cable Specifications |

Specifications and wiring |

|

|

diagram for 1746-HCA |

|

|

cable. |

|

|

|

Appendix C |

Application Examples |

Applications examples for |

|

|

constructing programs using |

|

|

the SLC processor. |

|

|

|

Appendix D |

Wiring Without the |

Information you need to |

|

Termination Panel |

wire the SLC Servo Module |

|

|

without a termination panel. |

|

|

|

The following documents contain additional information concerning Allen-Bradley SLC Servo and SLC products. To obtain a copy, contact your local Allen-Bradley office or distributor.

For: |

Read this Document: |

Document |

|

|

Number: |

|

|

|

An overview of the SLC 500 family of products |

SLC 500 Controller System Overview |

1747-2.30 |

|

|

|

A description of how to install and use your Modular SLC 500 |

SLC 500 Modular Hardware Style Installation & |

1747-6.2 |

programmable controller |

Operation Manual |

|

|

|

|

A description of how to install and use your Fixed SLC 500 |

SLC 500 Fixed Hardware Style Programmable |

1747-621 |

programmable controller |

Controllers Installation & Operation Manual |

|

|

|

|

A training and quick reference guide for APS |

SLC 500 Software Programmer’s Quick Reference |

ABT-1747-TSG001 |

|

Guide |

|

|

|

|

In-depth information on grounding and wiring Allen-Bradley |

Industrial Automation Wiring and Grounding |

1770-4.1 |

programmable controllers |

Guidelines |

|

|

|

|

An article on wire sizes and types for grounding electrical |

National Electrical Code |

Published by the |

equipment |

|

National Fire |

|

|

Protection |

|

|

Association of |

|

|

Boston, MA |

|

|

|

A complete listing of current Allen-Bradley documentation, |

Allen-Bradley Publication Index |

SD499 |

including ordering instructions. Also indicates whether the |

|

|

documents are available on CD-ROM or in multiple languages |

|

|

|

|

|

A glossary of industrial automation terms and abbreviations |

Allen-Bradley Industrial Automation Glossary |

AG-7.1 |

|

|

|

Publication 1746-6.1.2 - July 2000

Preface P- 5

Conventions Used in this Manual

Product Receiving and

Storage Responsibility

The following conventions are used throughout this manual:

∙Bulleted lists provide information, not procedural steps.

∙Numbered lists provide sequential steps or hierarchical information.

∙Words that you type or select appear in bold.

∙Key names match the names shown and appear in capital letters.

∙We use this symbol to represent a twisted pair:

Figure 0.1 Twisted Pair Symbol

Twisted Pair

∙ We use this symbol to represent a shielded twisted pair:

Figure 0.2 Shielded Twisted Pair Symbol

Shielded Twisted Pair

You are responsible for thoroughly inspecting the equipment before accepting the shipment from the freight company. Check the item(s) you receive against your purchase order. If any items are obviously damaged, it is your responsibility to refuse delivery until the freight agent has noted the damage on the freight bill. Should you discover any concealed damage during unpacking, you are responsible for notifying the freight agent. Leave the shipping container intact and request that the freight agent make a visual inspection of the equipment.

Publication 1746-6.1.2 - July 2000

Preface P-6

Rockwell Automation

Support

Leave the product in its shipping container prior to installation. If you are not going to use the equipment for a period of time, store it:

∙in a clean, dry location

∙within an ambient temperature range of 0° to 65°C (32° to 149°F)

∙within a relative humidity range of 5% to 95%, non-condensing

∙in an area where it cannot be exposed to a corrosive atmosphere

∙in a non-construction area

Rockwell Automation offers support services worldwide, with over 75 sales/support offices, 512 authorized distributors, and 260 authorized systems integrators located throughout the United States. In addition, Rockwell Automation representatives are located in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

∙sales and order support

∙product technical training

∙warranty support

∙support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance, please review the information in the Troubleshooting chapter first. Then call your local Rockwell Automation representative. For the quickest possible response, we recommend that you have the catalog number of your products available when you call. The Rockwell Automation Technical Support number is:

1-603-443-5419

Publication 1746-6.1.2 - July 2000

Preface P- 7

On the Web

For information about Allen-Bradley, visit the following World Wide Web site:

http://www.ab.com/

Publication 1746-6.1.2 - July 2000

Preface P-8

Publication 1746-6.1.2 - July 2000

Chapter 1

SLC Servo Module

Overview

Overview of the SLC Servo Module

This chapter explains the basic functions of the SLC Servo Module, and its hardware requirements. This chapter includes the following SLC Servo Module topics:

∙Overview

∙Operation

∙Specifications and compatibility

The SLC Servo Module (catalog number 1746-HSRV) is compatible with the SLC 500 family and only used with SLC 5/03™ FRN 5.0, SLC 5/04™, or SLC 5/05™ SLC Servo Modules. The SLC Servo Module is programmed for incremental, absolute or speed moves, depending on the application.

IMPORTANT |

Place the SLC Servo Module as close to the SLC |

|

processor as possible |

||

|

||

|

||

|

|

Publication 1746-6.1.2 - July 2000

1-2 Overview of the SLC Servo Module

SLC Servo Module

Operation

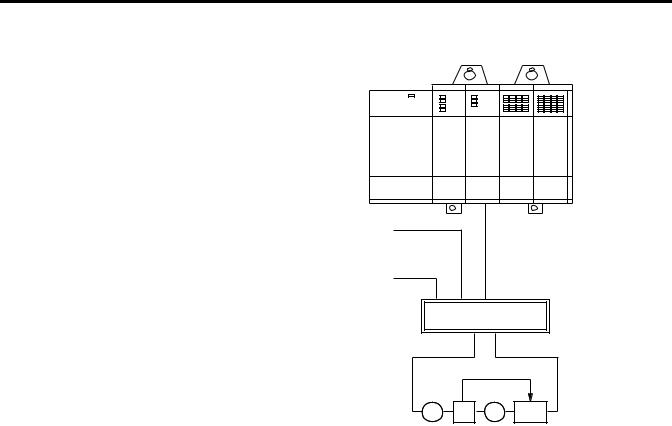

Figure 1.1 Example of an SLC Wiring

SLC |

1746- |

1746- |

5/04 |

HSRV |

IW16 |

CR-LPS-0503 +5V & –12V DC Power Supply

CR-IOPS-241 +24V DC Power Supply

1746-HCA Cable

1746-HT

Termination Panel

A-B 845

Encoder Motor

Tach |

Drive |

|

Amplifier |

The SLC Servo Module, compatible with the SLC family, is used with SLC 5/03 FRN 5.0 (and above) processors using RSLogix 500, AI500 or APS (version 5.0 or higher) software. Once the SLC processor is initiated, the execution of the motion block is independent of the scan time of the processor. Blended motion allows for complicated move profiles consisting of two to thirty-two segments. The blended move profiles are stored in the SLC Servo Module’s memory as a series of absolute moves and can be executed more than once. Other move or homing operations can be performed between blended move profiles.

The SLC Servo Module controls absolute position over a range of 32 bits. The SLC Servo Module performs an origin search (also called homing) and automatically resets the absolute position to the home position when the SLC processor requests a search function after detecting one of the following:

∙Encoder marker

∙Limit switch

∙Limit switch and marker

Publication 1746-6.1.2 - July 2000

Overview of the SLC Servo Module |

1-3 |

|

|

The SLC Servo Module operates in two modes:

∙Configuration

∙Command

When operating in the configuration or the command mode, the status of the module is reported to the SLC processor.

Configuration Mode Operation

You can enter configuration mode only if the system is in Estop. In the SLC Servo Module, you configure the SLC Servo Module by using M files containing data provided by the SLC 5/03 (or versions listed above) processors. All configuration parameters are internal to the SLC Servo Module and stored in non-battery backed RAM.

In configuration mode, you select the proper setup configuration to match the servo drive and motor without setting switches and without special software. If you do not set up your own configuration, the configuration is set to the default setting.

Command Mode Operation

Motor operations are performed in command mode. To operate in this mode, set the mode flag (bit 15 in output word 0) to 0. In the command mode, the SLC processor issues commands and activates the following operations or moves:

∙Absolute moves

∙Incremental moves

∙Speed moves

∙Monitor moves

∙Hold moves

∙Unhold moves

∙Blend moves

∙Emergency stop operations

∙Homing operations

∙Preset operations

∙Clear faults

∙Alternate home moves

Publication 1746-6.1.2 - July 2000

1-4 Overview of the SLC Servo Module

SLC Servo Module

Specifications and

Compatibility

Selected specifications for the SLC Servo Module appear in the table below.

SLC Servo Module |

Specification |

|

|

Class |

3 |

|

|

Number of Input |

12 |

Words |

|

|

|

Number of Output |

12 |

Words |

|

|

|

Selection for |

OTHER |

Configuration |

(with 10114 as the number specified) |

|

|

Configuration Mode |

Uses M files |

|

|

Recommended I/O |

Slot 1 or the lowest numbered I/O slot for SLC |

Slot in SLC Rack |

applications using the module interrupt option.1,2 |

Number of HSRVs in |

12 |

one rack |

with proper power supply |

|

|

1There must not be other modules that generate module interrupts. Also, the STI and FAULT routines execute at a higher priority than the module interrupt routine that is linked to the SLC Servo Module interrupt.

2The SLC Servo Module does not function in a remote I/O rack.

The SLC Servo Module is compatible with:

∙SLC 5/03 FRN 5.0 (and above) processors.

∙RSLogix 500, AI500, or APS (version 5.0 or higher) software.

Publication 1746-6.1.2 - July 2000

Chapter 2

Selecting Power Supplies, Encoders, and

Drives

Overview

In this chapter we explain how to select the hardware you need to support an SLC Servo Module system. This chapter includes the following topics:

∙Selecting a power supply for the backplane

∙Selecting a user-side power supply

∙Using fast inputs and outputs

∙Selecting an encoder

∙Selecting a drive

The amount of hardware you need depends on how many axes your application uses. Consult your local Allen-Bradley sales engineer or distributor to help you select the equipment for your application.

IMPORTANT |

The term user-side refers to the control circuitry on |

|

the SLC Servo Module card that is powered by |

||

|

||

|

||

|

customer-supplied power sources and isolated from |

|

|

the control circuitry that is powered by the |

|

|

backplane of an SLC rack. |

|

|

|

Selecting a Power Supply for the Backplane

Before you select a power supply, calculate the current requirements for your backplane. Use the table below for SLC Servo Module backplane current requirements:

Voltage |

Current Requirement |

|

|

+5V |

.300A |

|

|

+24V |

.104A |

|

|

In your calculations, include the current requirements of the I/O modules in your chassis. Refer to your SLC 500 documentation.

Publication 1746-6.1.2 - July 2000

2-2 Selecting Power Supplies, Encoders, and Drives

Example of Calculations for Backplane Current Requirements

In this example, the system includes:

∙One seven-slot modular rack

∙One 1747-L543 CPU module

∙One 1746-IB8 DC input module with eight inputs @ +24V

∙One 1746-OV8 DC output module with eight outputs @ +24V

∙An SLC Servo Module system that contains:

∙SLC Servo Modules

∙Termination panels

∙Allen-Bradley 845H encoders

∙Fast inputs

∙Fast outputs

Use the table below to find the current requirements of the devices using backplane power. Those devices that are not included in the backplane calculations are included in the example’s user-side calculations.

Device |

+5V |

+24V |

|

|

|

1746-L543 processor |

1A |

.200A |

|

|

|

SLC Servo Module |

.300A |

0 |

|

|

|

1746-IB8 |

.040A |

0 |

|

|

|

1746-OV8 |

.125A |

0 |

|

|

|

|

Total = 1.465A |

Total = .200A |

|

|

|

If optional processor is used:

Device |

+5V |

+24V |

|

|

|

1747-L532 processor |

.500A |

.175A |

|

|

|

SLC Servo Module |

.300A |

0 |

|

|

|

1746-IB8 |

.040A |

0 |

|

|

|

1746-OV8 |

.125A |

0 |

|

|

|

|

Total = .965A |

Total = .175A |

|

|

|

Publication 1746-6.1.2 - July 2000

Selecting Power Supplies, Encoders, and Drives |

2-3 |

|

|

Selecting a User-Side

Power Supply

Use the table below to find the power supplies Allen-Bradley recommends for the backplane:

Power Supply |

Operating |

Output Capacity |

|

|

Voltage |

|

|

|

5V DC |

24V DC |

|

|

Requirements |

||

|

|

|

|

|

|

|

|

1746-P1 |

85-130V AC or |

2A |

.46A |

|

170-265V AC |

|

|

|

|

|

|

1746-P2 |

85-130V AC or |

5A |

.96A |

|

170-265V AC |

|

|

|

|

|

|

1746-P3 |

19.2-28.8 DC |

3.6A |

.87A |

|

|

|

|

1746-P4 |

85-132V AC or |

10.0A |

2.88A |

|

170-265V AC |

|

|

|

|

|

|

You must provide a power supply that meets your system requirements. The following devices require user-side power:

∙SLC Servo Module

∙Encoders

∙I/O modules

∙Estop circuitry

∙Fast inputs and outputs

You must select a power supply that meets the specifications of a NEC class 2 power supply. The power supply must have +5V, ±15V capacity, and +24V capacity for fast I/O and Estop circuitry.

IMPORTANT |

We recommend that you do not use the +24V |

|

included with the 1746-P1, P2, P3, or P4 to power |

||

|

||

|

||

|

your Estop or fast I/O. |

|

|

|

Before you select a power supply, calculate the system’s user-side current requirements.

IMPORTANT |

The user-side power must be present for the SLC |

|

processor to communicate with the SLC Servo |

||

|

||

|

||

|

Module. |

|

|

|

Publication 1746-6.1.2 - July 2000

2-4 Selecting Power Supplies, Encoders, and Drives

Using Fast Inputs and

Outputs

Example of the Calculations for User-Side Current Requirements

In this example, the system includes:

∙One seven-slot modular rack

∙One 1747-L541 CPU module

∙One 1746-IB8 DC input module with eight inputs @ +24V

∙One 1746-OV8 DC output module with eight outputs @ +24V

∙An SLC Servo Module system that contains:

∙Two SLC Servo Modules

∙Two termination panels

∙Two Allen-Bradley 845H encoders

∙Six fast inputs

∙Two fast outputs

Use the table below to find the current requirements of the devices that draw user-side power.

Device |

+5V |

+15V |

–15V |

+24V |

1746-IB8 |

0 |

0 |

0 |

.064A |

1746-OV8 |

0 |

0 |

0 |

.800A |

SLC Servo |

.150A |

.030A |

.030A |

0 |

Module |

|

|

|

|

Estop circuitry |

0 |

0 |

0 |

.100A |

6 fast inputs |

0 |

0 |

0 |

.015A |

2 fast outputs |

0 |

0 |

0 |

.100A |

845H encoder |

.200A |

0 |

0 |

0 |

845H encoder |

.200A |

0 |

0 |

0 |

|

Total = .700A |

Total = .060A |

Total = .060A |

Total = 1.079A |

The fast I/O (FIN1through FIN3, and FOUT1) are 24V DC compatible and are used with a user-side +24V power supply. Review potential

Publication 1746-6.1.2 - July 2000

Selecting Power Supplies, Encoders, and Drives |

2-5 |

|

|

Selecting an Encoder

24V DC I/O devices for compatibility with the electrical specifications as shown in the table below.

Outputs (source drivers)

Specification |

Rating |

|

Voh (high-level, on-state output |

Refer to the specifications for your |

|

voltage) |

user-side power supply |

|

Ioh (high-level, on-state output current |

+24V @ .20A (for resistive and |

|

for each output) |

inductive loads); +24V @ .10A (for |

|

|

capacitive loads) |

|

Turn on time |

500 µs |

|

Turn off time |

500 µs |

|

Inputs |

|

|

Specification |

Rating |

|

VT (input low/high trip threshold) |

10.51V (min) |

|

|

12.5V (typ) |

|

|

14.61V (max) |

|

VT (input high/low trip threshold) |

6.4V |

(min) |

|

8.3V |

(typ) |

|

10.3V (max) |

|

VHYST |

1.9V |

(min) |

|

4.1V |

(typ) |

|

6.5V |

(max) |

IIN @ 27V |

2.5 mA (max) |

|

TPD+ (input low/high debounce filter) |

.2 msec (typ) |

|

TPD- (input low/high debounce filter) |

.2 msec (typ) |

|

VIN (absolute max.) |

+75V (max) |

|

The SLC Servo Module system supports Allen-Bradley 845H encoders. Other encoders are compatible if they comply with the specifications listed in the following table.

Publication 1746-6.1.2 - July 2000

2-6 Selecting Power Supplies, Encoders, and Drives

Specification |

Rating |

|

|

Maximum |

Incoming quadrature frequency is limited by the following |

channel |

relationship: |

frequency |

FQUAD (Hz) = (3334)(90°–EQ) |

|

|

|

where: |

|

EQ = quadrature error (degrees, electrical) |

|

For example, for an 845H encoder with 22° quadrature error, |

|

the maximum frequency would be: |

|

FQUAD (Hz) = (3334)(90°-22° quadrature error) = 226,712 Hz |

|

Important:The maximum quadrature error is a limit, and |

|

system design should include acceptable margins. |

|

|

Maximum axis |

The SLC Servo Module decodes the incoming encoder |

speed |

feedback in quadrature to extract the maximum resolution with |

|

four counts per electrical cycle. The maximum number of |

|

encoder counts per second can be determined by: |

|

Maximum # of counts/second = 4 counts/cycle × FQUAD |

|

The maximum axis speed as limited by the encoder feedback |

|

would be: |

|

(maximum # of counts/second)(60) |

|

(4E)(N) |

|

where: |

|

E = the number of encoder lines per revolution |

|

N = number of revolutions of the encoder per inch or millimeter |

|

of axis travel. (For a rotary axis, N = number of revolutions of |

|

the encoder per revolution of the axis.) For a linear axis the |

|

units are inches or millimeters per minute. For a rotary axis the |

|

units are revolutions per minute. |

|

|

Input signal |

Encoder feedback must be differential with 5V compatible |

|

output signals, open-collector outputs are not supported (i.e., |

|

channels A, B, and Z must have source and sink current |

|

capability, 8830 line driver outputs or equivalent). The encoder |

|

input must have a 0.00 to 0.80 for off state and 4.75 to 5.25 for |

|

on state to encoder common reference. |

|

|

Input sink current |

7 mA (max) |

|

|

Marker channel |

Gated markers |

|

|

Cable length |

Depends on the user-side power supply. Power voltage at the |

|

encoder must be greater than or equal to the power voltage |

|

requirement specified by the manufacturer. The minimum |

|

power requirement for the 845H is 4.75V, and the maximum |

|

limit is 5.25V. To meet the power requirement of the encoder |

|

and still attain maximum cable length, you can: |

|

∙ Raise the voltage of the power supply to meet the |

|

encoder requirement, but you cannot exceed the 5.25V |

|

limit of the control. |

|

∙ Increase the gage of the wire from the termination |

|

panel to the encoder (12 AWG maximum). |

|

|

Publication 1746-6.1.2 - July 2000

Selecting Power Supplies, Encoders, and Drives |

2-7 |

|

|

Selecting a Drive

The SLC Servo Module supports Allen-Bradley 1386, 1388, 1389, 1391, 1392, 1394, and 1398 servo drive systems. References that help you select a suitable drive system appear in the table below.

Allen-Bradley |

Publication |

Title |

Drive |

Number |

|

|

|

|

1386 |

1386-2.0 |

DC Servo Drive Product Data Sheet |

|

|

|

1388 |

1388-2.0 |

DC PWM Servo Drive Product Data Series B |

|

|

|

1389 |

1389-2.0 |

AC Servo Amplifier System Product Data |

|

|

Sheet |

|

|

|

1391 |

1391-2.0 |

AC PWM Servo Controller Product Data |

|

|

Sheet |

|

|

|

1392 |

1392-2.1 |

High Performance AC Drive (460V and 230V) |

|

|

Product Data |

|

|

|

1394 |

1394-2.0 |

1394 Digital Multi-Axis Motion Control |

|

|

Systems Product Data |

|

|

|

1398 |

1398-2.0 |

ULTRA Series Product Data |

|

|

|

The SLC Servo Module provides a ±10V analog output to one drive amplifier for a velocity command. This analog voltage is 11 bits plus an additional sign bit (12 bits total) and interfaces to drive amplifiers with a 2K through 20K ohm range. Servo drive signal analog out specifications appear in the table below.

Specification |

Rating |

|

|

|

|

Resolution |

12 bits or 4.88 mV/bit |

|

|

|

|

Output voltage swing |

±10V |

|

|

|

|

Load range |

2K through 20K ohms |

|

|

|

|

Conversion time |

100 |

µs |

|

|

|

Output step response (20V |

|

|

swing) |

|

|

∙ Rise time |

110 |

µs typical |

∙ Overshoot |

5% typical |

|

∙ Settling time |

60µs typical |

|

|

|

|

Differential linearity |

±1 LSB Max. (monotonic over the entire |

|

|

temperature range) |

|

|

|

|

Output offset voltage |

500 |

µV (max) |

|

|

|

Gain error drift |

7 LSB (max) |

|

|

|

|

Publication 1746-6.1.2 - July 2000

Loading...

Loading...