Rockwell Automation 1756-IF4FXOF2F User Manual

User Manual

ControlLogix High-speed Analog I/O Module

Catalog Number 1756-IF4FXOF2F

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, ControlFLASH, ControlLogix, ControlLogix-XT, Logix5000, Rockwell Software, Rockwell Automation, RSLogix, RSNetWorx, Studio 5000, and TechConnect are trademarks o f Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

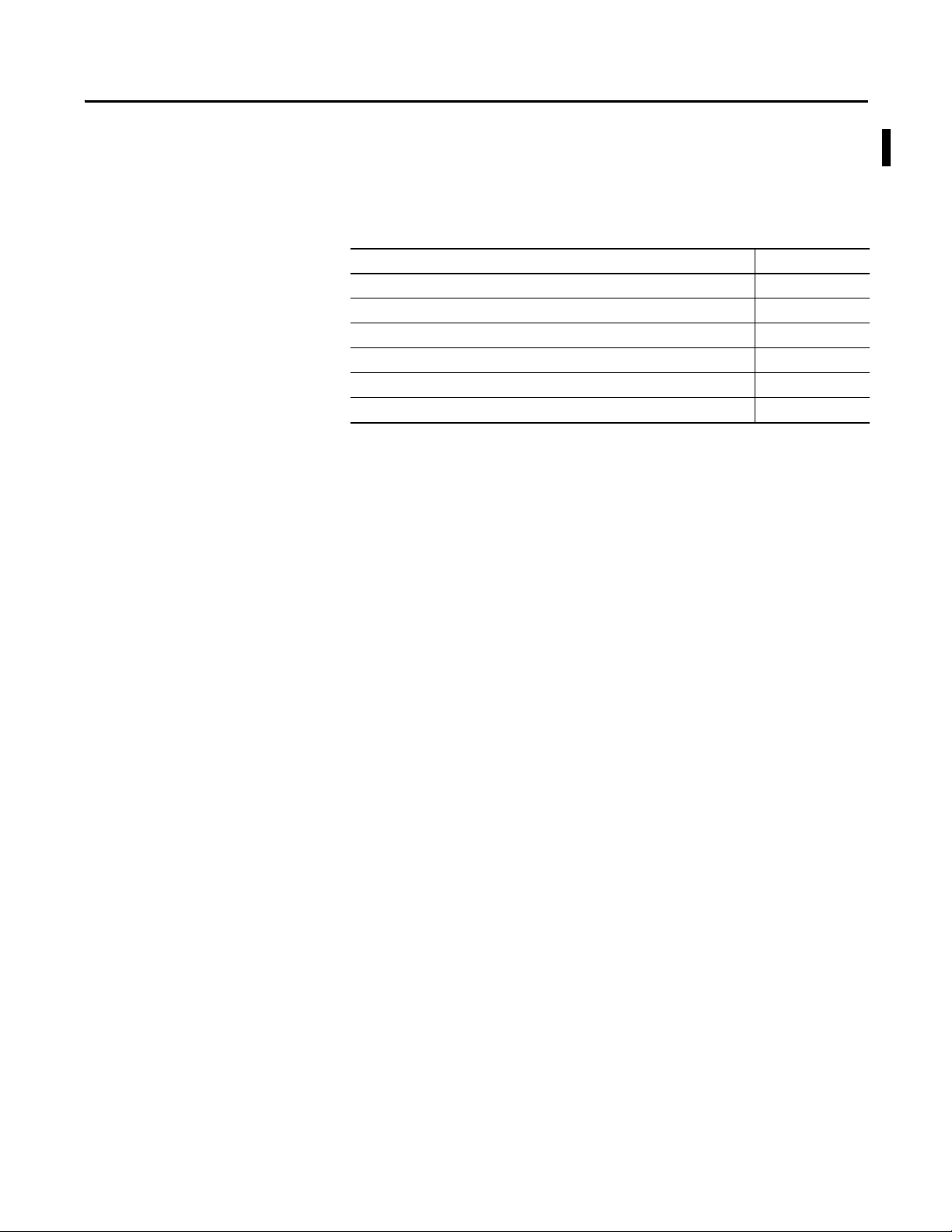

New and Updated Information

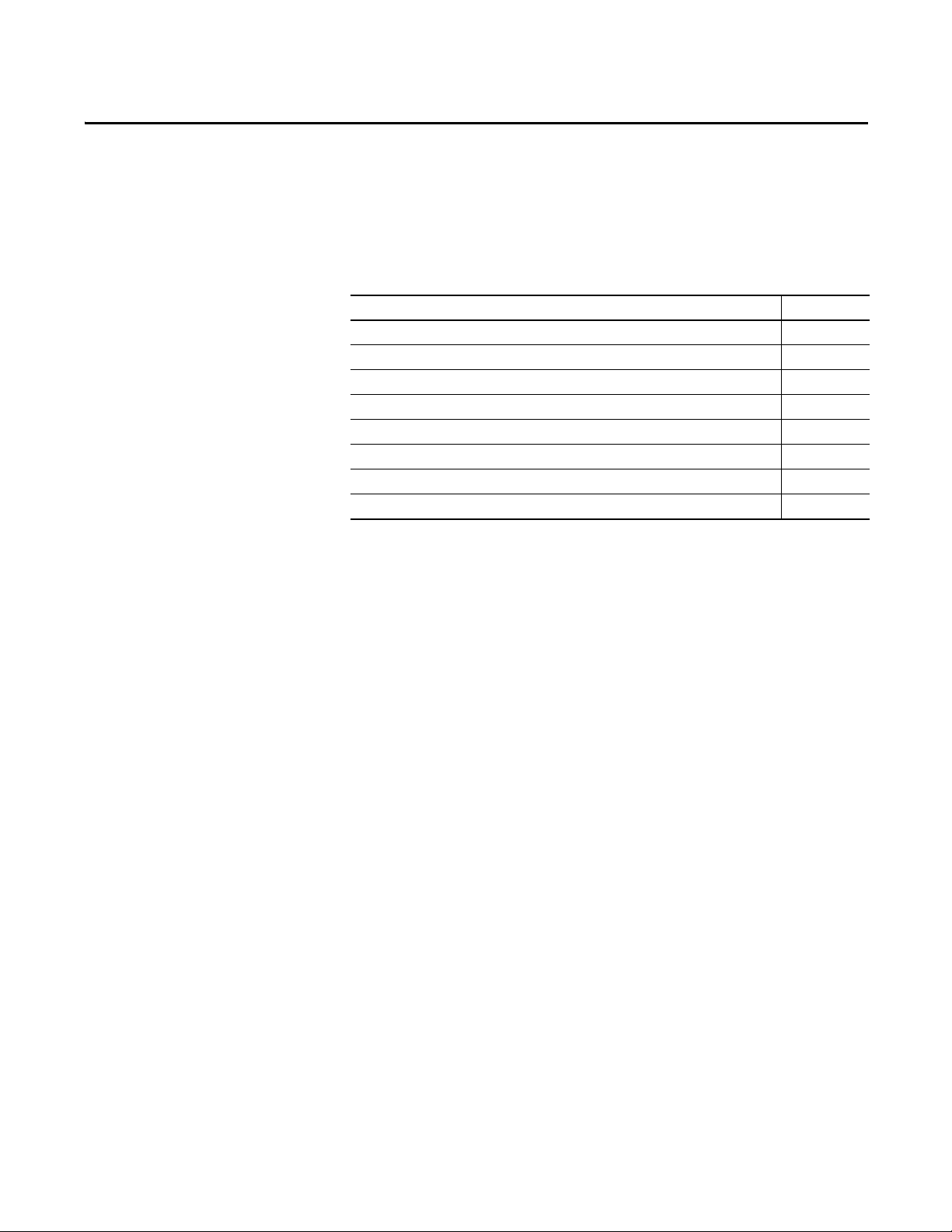

This table contains the changes made to this revision.

Top ic Pag e

Studio 5000™ Logix Designer application is the rebranding of RSLogix™ 5000 software 9

Archiving 38

Archiving Connection communication format 75

Data storage 101

Archiving tags 117

Module revision history 143

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 3

Summary of Changes

Notes:

4 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Table of Contents

Preface

What is the ControlLogix

High-speed Analog I/O Module?

High-speed Analog I/O Operation

in the ControlLogix System

Module Features

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

Available Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

High-speed Analog I/O Modules in the ControlLogix System . . . . . . . 12

Chapter 2

Ownership and Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configure the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Direct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inputs and Outputs on the Same Module . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Real Time Sample (RTS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Differences between Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Module Input Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Module Output Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Listen-only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 3

Input Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Output Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

General Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removal and Insertion Under Power (RIUP) . . . . . . . . . . . . . . . . . . . 24

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fully Software Configurable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Exact Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Compatible Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Disabled Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Access to System Clock for Timestamping Functions. . . . . . . . . . . . 32

Rolling Timestamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Producer/Consumer Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Full Class I Division 2 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CE/CSA/UL/C-Tick Agency Certification . . . . . . . . . . . . . . . . . . . . 33

Field Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Latching of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Alarm Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Module Inhibiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Understand Module Resolution, Scaling and Data Format. . . . . . . . . . . 35

Module Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 5

Table of Contents

Features Specific to Module Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Multiple Input Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Underrange/Overrange Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rate Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Synchronize Module Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Features Specific to Module Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Multiple Output Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Ramping/Rate Limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Hold for Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Open Wire Detection—Current Mode Only . . . . . . . . . . . . . . . . . . . 47

Clamping/Limiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Clamp/Limit Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Output Data Echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Fault and Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fault Reporting Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Module Fault Word Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Channel Fault Word Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Input Channel Status Word Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Output Channel Status Word Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Install the Module

Configure the Module

Chapter 4

Install theModule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Key the Removable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Connect the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Connect the Grounded End of the Cable . . . . . . . . . . . . . . . . . . . . . . . 61

Connect Ungrounded End of the Cable . . . . . . . . . . . . . . . . . . . . . . . . 61

Two Types of RTBs (each RTB comes with housing) . . . . . . . . . . . . 62

Wire the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Assemble the Removable Terminal Block and the Housing . . . . . . . . . . 66

Install the Removable Terminal Block onto the Module . . . . . . . . . . . . . 67

Remove the Removable Terminal Block from the Module . . . . . . . . . . . 68

Remove the Module from the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

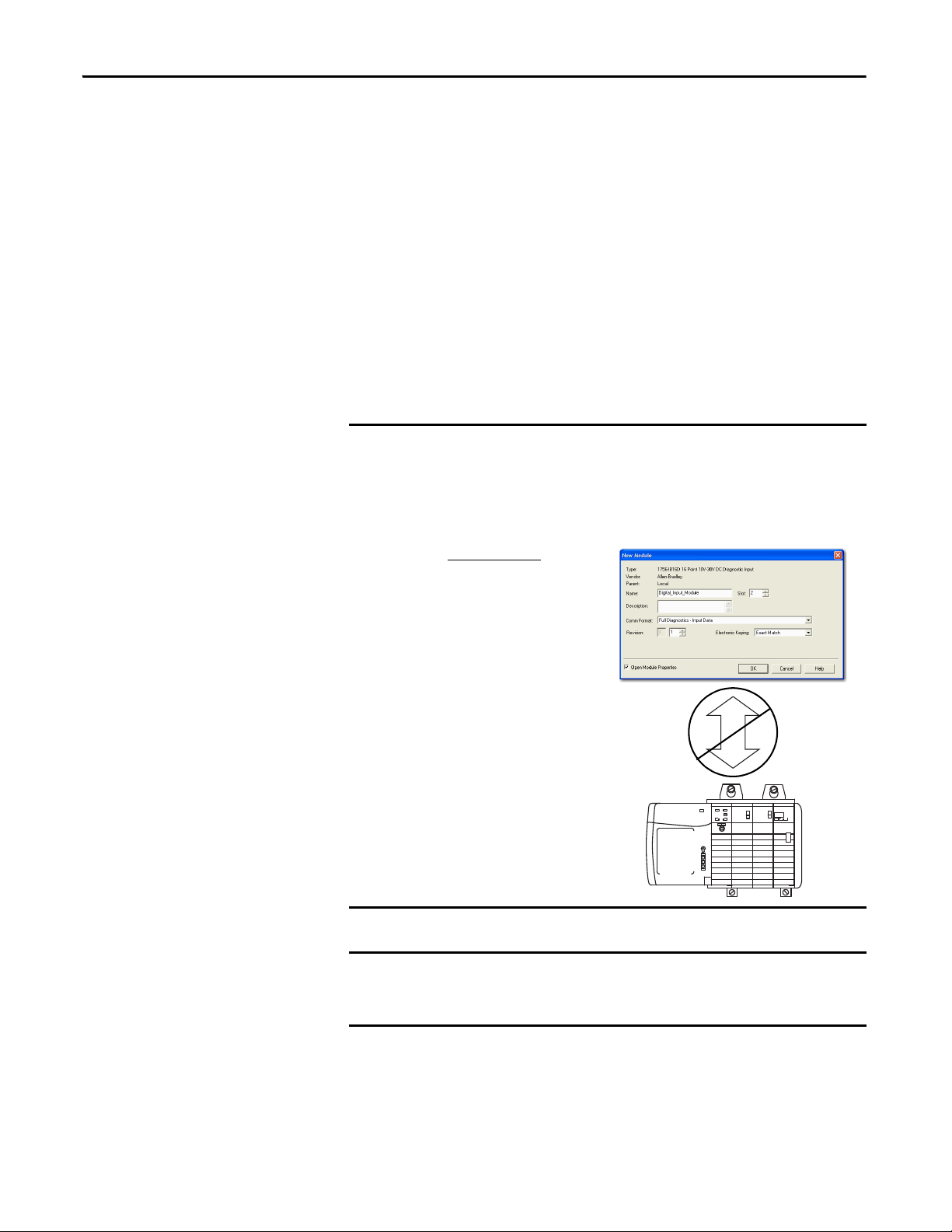

Chapter 5

Overview of the Configuration Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Create a New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Use the Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Alter the Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Download New Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Edit the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Reconfigure Module Parameters in Run Mode . . . . . . . . . . . . . . . . . . . . . . 81

6 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Table of Contents

Reconfigure Module Parameters in Program Mode. . . . . . . . . . . . . . . . . . 82

View and Change Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Chapter 6

Calibrate the Module

Troubleshoot the Module

Data Storage

Tag Definitions

Differences for Each Channel Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Calibrate Input Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Calibrate Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Chapter 7

Use Module Indicators to Troubleshoot . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Use the Logix Designer Application to Troubleshoot . . . . . . . . . . . . . . . 98

Determine the Fault Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix A

Timing Relationships. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Remote Module Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Choose a Communication Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Use an Event Task to Store Module Data . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix B

Updated Data Tag Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Data Tag Names and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Configuration Data Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Input Data Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Output Data Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Access Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Download New Configuration Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Use Message Instructions to Perform

Run-time Services and Module

Reconfiguration

Simplified Circuit Schematics

Appendix C

Message Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Real-time Control and Module Services . . . . . . . . . . . . . . . . . . . . . . . 122

One Service Performed per Instruction. . . . . . . . . . . . . . . . . . . . . . . . 122

Add the Message Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Configure the Message Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Reconfigure the Module with a Message Instruction . . . . . . . . . . . . . . . 128

Considerations with the Module Reconfigure Message Type . . . . 128

Appendix D

Module Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Input Channel Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Output Channel Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 7

Table of Contents

Appendix E

Module Operation

in a Remote Chassis

Module Revision History

Glossary

Index

Remote Modules Connected via the ControlNet Network. . . . . . . . . . 137

Best Case RTS Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Worst Case RTS Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Best Case RPI Scenario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Worst Case RPI Scenario. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Use RSNetWorx Software and Logix Designer Application . . . . . . . . . 140

Configure High-speed Analog I/O Modules in a Remote Chassis. . . . 141

Appendix F

Series A versus Series B Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Archiving Enhancement with Revision 3.005 and Later . . . . . . . . . 143

Corrected Anomaly with Revision 3.005 and Later . . . . . . . . . . . . . 143

Series B Modules as Direct Replacements for Series A Modules. . . . . . 144

Install Series B Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Preface

This manual describes how to install, configure, and troubleshoot your

ControlLogix® high-speed analog I/O module. You must be able to program and

operate a ControlLogix controller to efficiently use your high-speed analog I/O

module.

Studio 5000 Environment

The Studio 5000 Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the

Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix 5000 software and will continue to be

the product to program Logix5000™ controllers for discrete, process, batch,

motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. It is the one place for

design engineers to develop all the elements of their control system.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 9

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

1756 ControlLogix I/O Modules Specifications

Technical Data, publication 1756-TD002

ControlLogix Analog I/O Modules User Manual,

publication 1756-UM009

ControlLogix System User Manual, publication 1756-UM001 Describes how to install, configure, program, and

ControlLogix Chassis and Power Supplies Installation

Instructions, publication 1756-IN005

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

Provides specifications for ControlLogix I/O modules.

Describes how to install, configure, and troubleshoot

ControlLogix analog I/O modules.

operate a ControlLogix system.

Describes how to install and troubleshoot standard and

ControlLogix-XT™ versions of the 1756 chassis and

power supplies, including redundant power supplies.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

10 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Chapter 1

What is the ControlLogix

High-speed Analog I/O Module?

Top ic Pag e

Available Features 11

High-speed Analog I/O Modules in the ControlLogix System 12

The ControlLogix high-speed analog I/O module is an interface module that

converts analog signals to digital values for inputs and converts digital values to

analog signals for outputs. Using the producer/consumer network model, the

module produces information when needed while providing additional system

functions.

Available Features

The following are some of the features available on the module:

• Input Synchronization—This feature lets you synchronize the sampling of

inputs across multiple fast analog modules in the same chassis, allowing

those inputs to sample at the same rate within microseconds of each other.

For more information, see Synchronize Module Inputs

• Combination module offering 4 differential inputs and 2 outputs

• Sub-millisecond input sampling

• One millisecond output updates

• On-board alarms and scaling

• Removal and insertion under power (RIUP)

• Producer/consumer communication

• Rolling timestamp of data in milliseconds

• Coordinated System Time (CST) timestamp of data in microseconds

• IEEE 32 bit floating point

• Class I/Division 2, UL, CSA, CE, and C-Tick Agency Certification

To see a complete listing, including detailed explanations of all module features,

see Chapter 3

.

on page 45.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 11

Chapter 1 What is the ControlLogix High-speed Analog I/O Module?

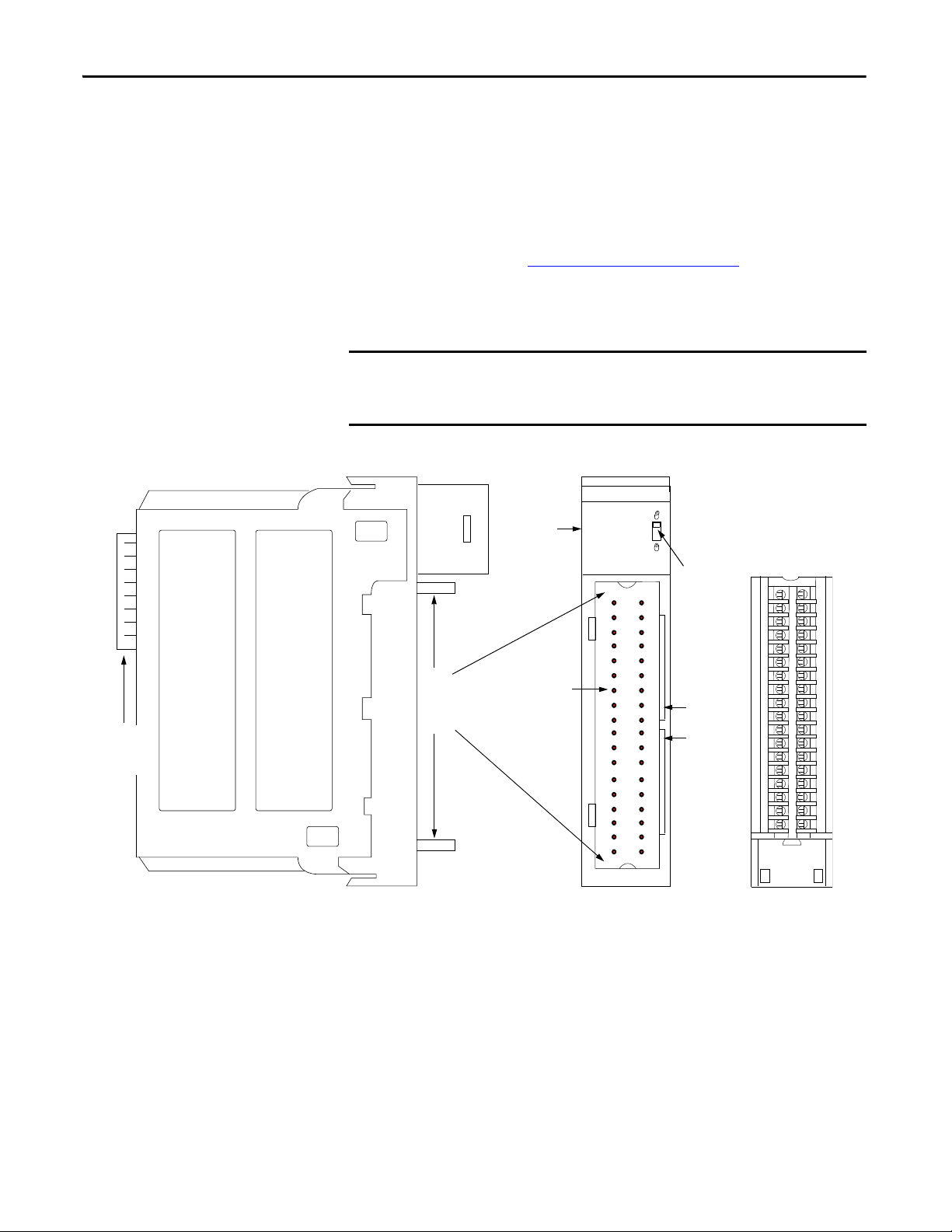

IMPORTANT

Control Logix

Backplane

Connector

Removable

Ter mi nal Bl ock

Indicators

Locking Tab

Slots for

Keying the

RTB

Connector Pins

Top an d

Bottom

Guides

41623

High-speed Analog I/O Modules in the ControlLogix System

A ControlLogix high-speed analog I/O module mounts in a ControlLogix

chassis and uses a Removable Terminal Block (RTB) or Interface Module (IFM)

to connect all field-side wiring.

Before you install and use your module, do the following :

• Install and ground a 1756 chassis and power supply. Refer to the

publications listed in Additional Resources

on page 10.

• Order and receive an RTB or IFM and its components for your

application.

RTBs and IFMs are not included with your module purchase. You must order

them separately. For more information, contact your local distributor or

Rockwell Automation representative.

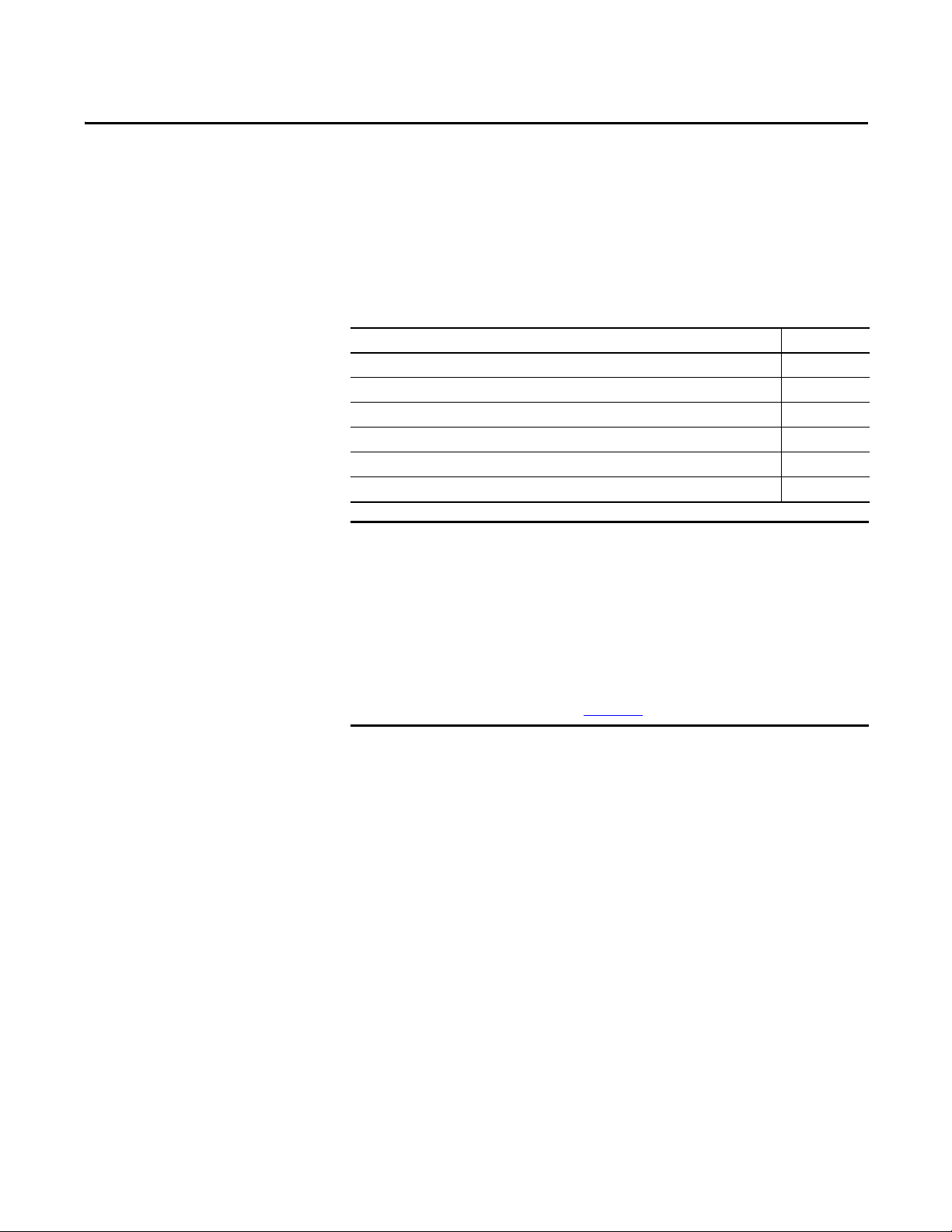

Figure 1 - Physical Features of the High-speed Analog I/O Module

12 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

What is the ControlLogix High-speed Analog I/O Module? Chapter 1

Ta b l e 1 lists the physical features on the ControlLogix high-speed analog I/O

module.

Table 1 - ControlLogix High-speed Analog I/O Module Physical Features

Feature Description

ControlLogix backplane connector Provides an interface to the ControlLogix system by connecting the module to

Connector pins Input/output, power, and grounding connections are made to the module

Locking tab Anchors the RTB on the module to maintain wiring connections.

Slots for keying Slots mechanically key the RTB to prevent you from making the wrong wire

Status indicators Display the status of communication, module health, and calibration

Top and bottom guides Provide assistance in seating the RTB onto the module.

the backplane.

through these pins with the use of an RTB.

connections to your module.

information. Use these indicators to help in troubleshooting.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 13

Chapter 1 What is the ControlLogix High-speed Analog I/O Module?

Notes:

14 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Chapter 2

IMPORTANT

High-speed Analog I/O Operation

in the ControlLogix System

Top ic Pag e

Ownership and Connections 16

Configure the Module 16

Direct Connections 17

Inputs and Outputs on the Same Module 18

Differences between Inputs and Outputs 20

Listen-only Mode 22

A ControlLogix high-speed analog I/O module’s performance behavior varies

depending upon whether it operates in the local chassis or in a remote chassis.

Module performance is limited in a remote chassis. The network cannot

effectively accommodate the fastest module update rates because the size of

the data broadcast requires a large portion of the network’s bandwidth. For

maximum module performance, we recommend you use it in a local chassis.

This chapter describes how the ControlLogix high-speed analog I/O module

operates in a local chassis. For more information on how the module operates

in a remote chassis, see Appendix

E.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 15

Chapter 2 High-speed Analog I/O Operation in the ControlLogix System

Ownership and Connections

Configure the Module

Every high-speed analog I/O module in the ControlLogix system must be owned

by a ControlLogix controller. This owner-controller stores configuration data for

the module and can be local or remote in reference to the module’s position. The

owner-controller sends the high-speed analog I/O module configuration data to

define the module’s behavior and begin operation.

The ControlLogix high-speed analog I/O module is limited to a single owner

and must continuously maintain communication with the owner to operate

normally.

ControlLogix input modules allow multiple owner-controllers that each store the

module’s configuration data. The high-speed analog I/O module, however, also

has outputs and cannot support multiple owner-controllers. Other controllers

can make listen-only connections to the module, though. For more information

on listen-only connections, see page 22

The I/O configuration portion of the Studio 5000 Logix Designer application

generates the configuration data for each high-speed analog I/O module in the

control system.

With the configuration dialog boxes in the Logix Designer application, you can

configure the inputs and outputs of a high-speed analog module at the same time.

Configuration data is transferred to the owner-controller during the program

download and subsequently transferred to the appropriate modules.

.

Follow these guidelines when configuring high-speed analog I/O modules.

1. Configure all modules for the controller by using the software.

2. Download configuration information to the controller.

3. Go online with your Logix Designer project to begin operation.

For more information on how to use the software to configure the module, see

Chapter 5

.

16 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

High-speed Analog I/O Operation in the ControlLogix System Chapter 2

Direct Connections

A direct connection is a real-time data transfer link between the controller and

the module that occupies the slot that the configuration data references. When

module configuration data is downloaded to an owner-controller, the controller

attempts to establish a direct connection to each of the modules referenced by the

data.

If a controller has configuration data referencing a slot in the control system, the

controller periodically checks for the presence of a device there. When a device’s

presence is detected, the controller automatically sends the configuration data

and one of the following events occurs:

• If the data is appropriate to the module found in the slot, a connection is

made and operation begins.

• If the configuration data is not appropriate, the data is rejected, and an

error message appears in the software. In this case, the configuration data

can be inappropriate for any of a number of reasons. For example, a

module’s configuration data may be appropriate except for a mismatch in

electronic keying that prevents normal operation.

The controller continuously maintains and monitors its connection with a

module. Any break in the connection, such as removal of the module from the

chassis while under power, causes the controller to set fault status bits in the data

area associated with the module. Relay ladder logic may be used to monitor this

data area to detect the module’s failures.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 17

Chapter 2 High-speed Analog I/O Operation in the ControlLogix System

IMPORTANT

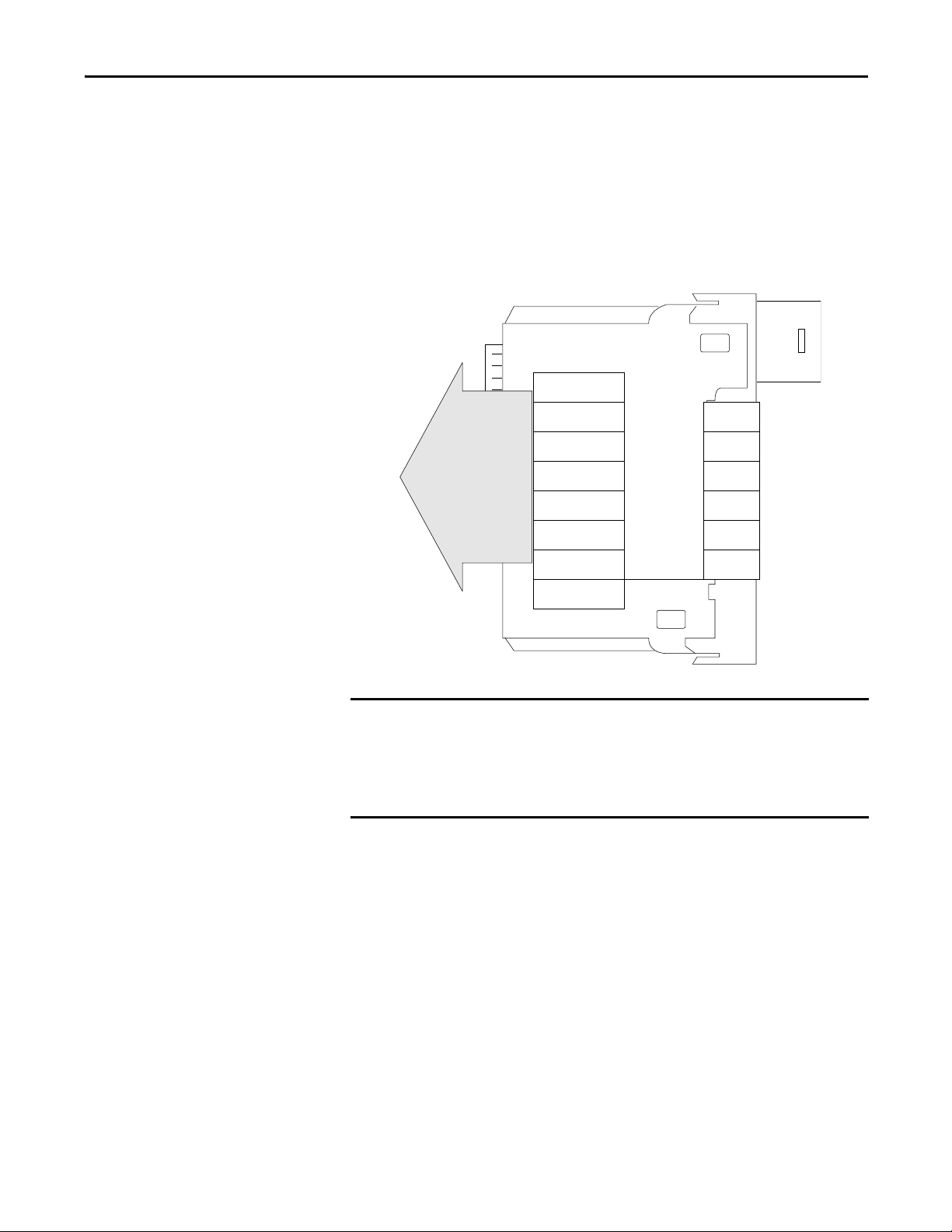

1

2

On-Board Memory

Status Data

Channel Data

Channel Data

Channel Data

Channel Data

Input 0

Input 1

Input 2

Input 3

Timestamp

Output Data Echo

Output Data Echo

Output 0

Output 1

Inputs and Outputs on the Same Module

The ControlLogix high-speed analog I/O module has 4 inputs and 2 outputs.

The following configurable parameters affect module behavior:

• Real Time Sample (RTS)

• Requested Packet Interval (RPI)

—Defines the input update rate.

—Defines the output update rate and

additional transfers of input data.

Real Time Sample (RTS)

The RTS is a configurable parameter (0.3…25 ms) that defines the input update

rate. This parameter causes the module to do the following.

1. Scan all input channels and store the data in on-board memory.

2. Multicast the updated channel data, as well as other status data, to the

backplane of the local chassis.

18 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

The RTS value is set during the initial configuration. This value can be adjusted

anytime. To use sub-millisecond values, type values with a decimal point. For

example, to use 800 ms, type 0.8.

For more information on how to set the RTS, see Chapter 5

.

High-speed Analog I/O Operation in the ControlLogix System Chapter 2

IMPORTANT

On-Board Memory

Status Data

Channel Data

Channel Data

Channel Data

Channel Data

Timestamp

Output Data Echo

Output Data Echo

Input 0

Input 1

Input 2

Input 3

Output 0

Output 1

Requested Packet Interval (RPI)

The RPI is a configurable parameter that also instructs the module to multicast

its channel and status data to the local chassis backplane. However, the RPI

instructs the module to multicast the current contents of its on-board memory,

including input and output data echo, when the RPI expires. When the RPI

expires, the module does not update its channels prior to the multicast. The RPI

also instructs the owner-controller to update the module outputs.

The owner-controller sends output data to the high-speed analog I/O module

outputs asynchronously to when channel data and output data echo data are

returned over the ControlLogix backplane.

The RPI value is set during the initial module configuration. Adjusting the RPI

causes the connection to close and reopen.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 19

Chapter 2 High-speed Analog I/O Operation in the ControlLogix System

IMPORTANT

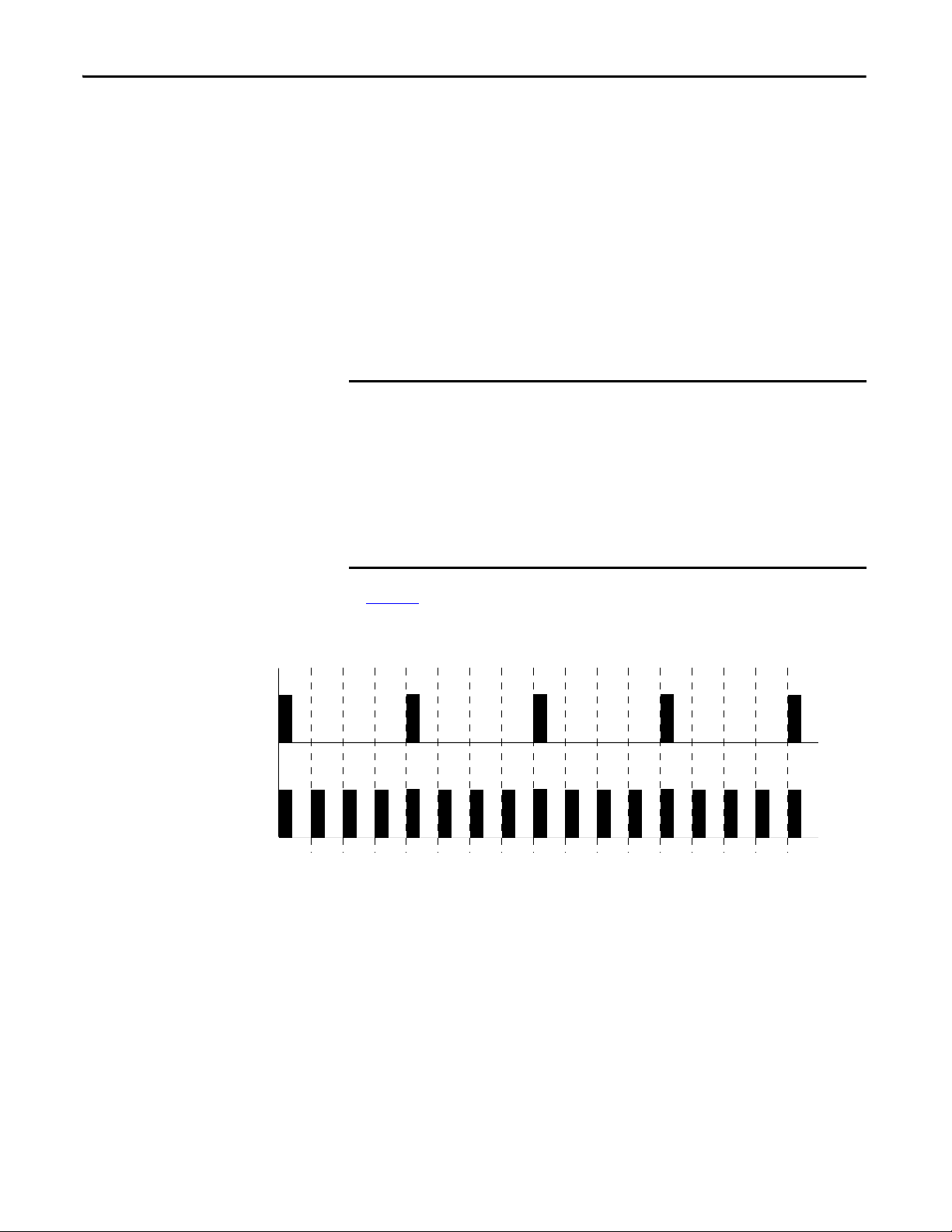

RTS

20 ms—Updated Input Data

RPI

5 ms—Updated and Old Data,

Depending on Time

5 10152025303540455055 60657075 80

Time (ms)

Updated input channel data is received at 0 ms, 20 ms, 40 ms, 60 ms, and 80 ms. The data

received at other RPI times repeats the most previous RTS. For example, data received at

30 ms repeats that received at 20 ms.

Differences between Inputs and Outputs

The ControlLogix high-speed analog I/O module uses both inputs and outputs.

However, there are significant differences between how each channel type

operates.

Module Input Operation

In traditional I/O systems, controllers poll module inputs to obtain their status.

The owner-controller does not poll the ControlLogix high-speed analog inputs

once a connection is established. Rather, the module multi-casts its input data

periodically. Multicast frequency depends on module configuration, such as RTS

and RPI rates.

The module only sends data at the RPI in these scenarios:

• RPI < RTS. In this case, the module multicasts at both the RTS rate and the

RPI rate. Their respective values dictate how often the owner-controller

receives data and how many multicasts from the module contain updated

channel data.

• If the RPI > RTS, each multicast from the module has updated channel

data. In effect, the module is only multicasting at the RTS rate.

• The module is operating in a mode where inputs are not being sampled, for

example calibration.

In Figure 2

, the RTS value is 20 ms and the RPI value is 5 ms. Only every fourth

multicast contains updated channel data.

Figure 2 - Input Data Update Rate

20 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

High-speed Analog I/O Operation in the ControlLogix System Chapter 2

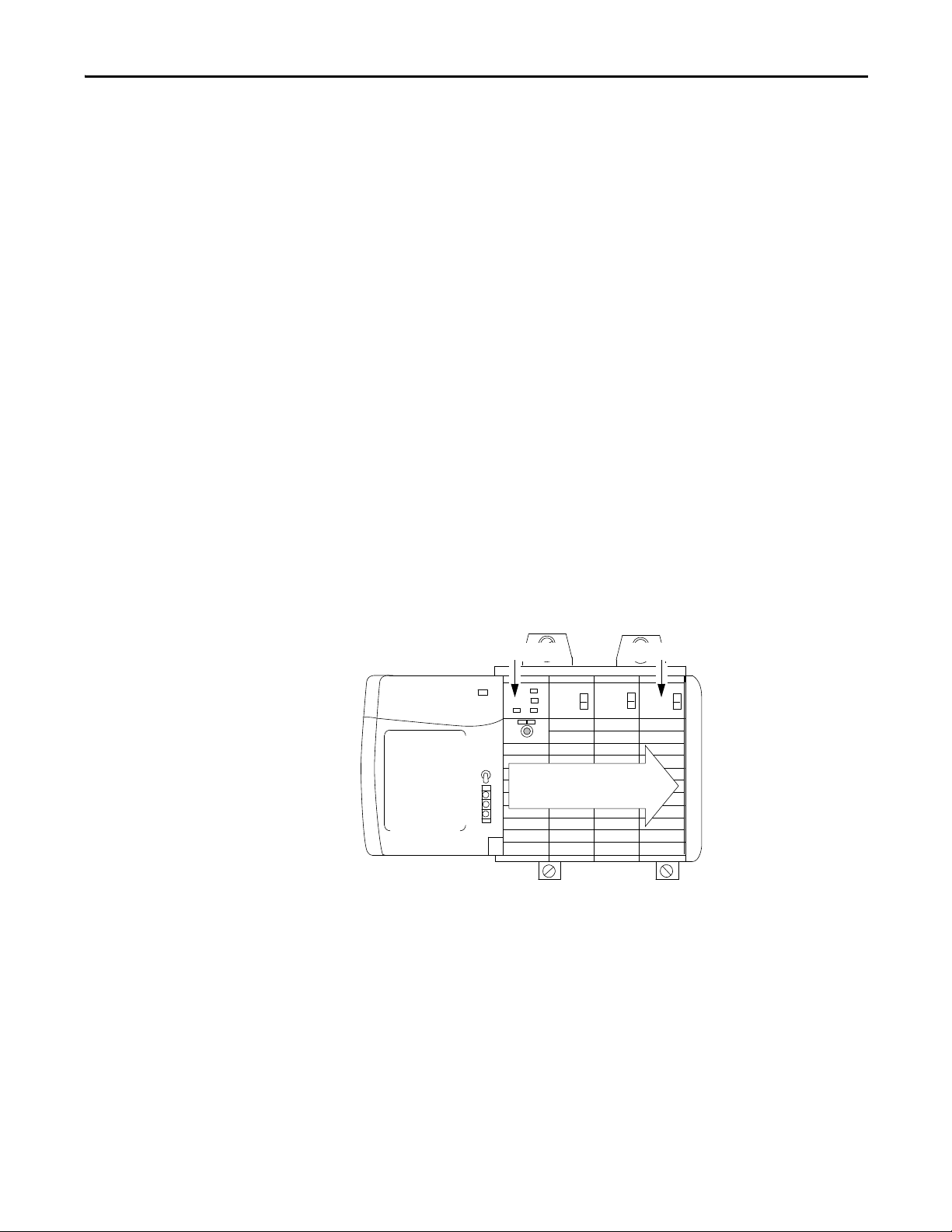

Data Sent from Owner at the RPI

Owner-controller High-speed Analog I/O Module

Module Output Operation

When specifying an RPI value for the high-speed analog I/O module, you define

when the controller broadcasts output data to the module. If the module resides

in the same chassis as the owner-controller, the module receives the data almost

immediately.

High-speed analog module outputs receive data from the owner-controller and

echo output data only at the period specified in the RPI. Data is not sent to the

module at the end of the controller’s program scan.

When a high-speed analog I/O module receives new data from an

owner-controller, the module multicasts or echoes the output data value that

corresponds to the analog signal applied to the output terminals

the control system at the next RPI or RTS, whichever occurs first. This feature,

called Output Data Echo.

Depending on the value of the RPI, with respect to the length of the controller

program scan, the module can receive and echo data multiple times during one

program scan.

(1)

to the rest of

Because it is not dependent on reaching the end of the program to send data, the

controller effectively allows the module’s output channels to change values

multiple times during a single program scan when the RPI is less than the

program scan length.

(1) Although the output value at the RTB screw terminal typically matches the output data e cho value, it is not guaranteed to match.

The output data echo that is multicast to the rest of the control system represents the value the outputs were commanded to be.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 21

Chapter 2 High-speed Analog I/O Operation in the ControlLogix System

IMPORTANT

Listen-only Mode

Any controller in the system can listen to the data from a high-speed analog I/O

module (input data or echoed output data) even if the controller does not own

the module. The module does not have to hold the module’s configuration data

to listen to the module.

During the I/O configuration process, you can specify a Listen-only mode in the

Communication Format field. For more information on Communication

Format, see page 75

Choosing a Listen-only mode option allows the controller and module to

establish communication without the controller sending any configuration data.

In this instance, another controller owns the module being listened to and stores

the module’s configuration data.

.

Controllers using the Listen-only mode continue to receive data multicast from

the I/O module as long as a connection between an owner and I/O module is

maintained.

If the connection between the owner and the module is broken, the module

stops multicasting data and connections to all listening controllers are also

broken.

22 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Chapter 3

Module Features

Top ic Pag e

Input Compatibility 23

Output Compatibility 23

General Module Features 24

Electronic Keying 25

Understand Module Resolution, Scaling and Data Format 35

Features Specific to ModuleInputs 37

Features Specific to Module Outputs 46

Fault and Status Reporting 49

Input Compatibility

Output Compatibility

ControlLogix high-speed analog I/O module inputs convert the following

analog signals into digital values:

• Vo l t s

• Milliamps

The digital value that represents the magnitude of the analog signal is then

transmitted on the backplane to an owner-controller or other control entities.

ControlLogix high-speed analog I/O module outputs convert a digital value

delivered to the module via the backplane into an analog signal:

• -10.5…10.5V

or

• 0…21 mA

The digital value represents the magnitude of the desired analog signal. The

module converts the digital value into an analog signal and provides this signal on

the module's screw terminals.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 23

Chapter 3 Module Features

General Module Features

This section describes features available on ControlLogix high-speed analog I/O

modules that are common with other ControlLogix I/O modules.

Removal and Insertion Under Power (RIUP)

ControlLogix high-speed analog I/O modules may be inserted and removed

from the chassis while power is applied. This feature allows greater availability of

the overall control system because, while the module is being removed or

inserted, there is no additional disruption to the rest of the controlled process.

Module Fault Reporting

ControlLogix high-speed analog I/O modules provide both hardware and

software indication when a module fault has occurred. Each module has a fault

status indicator. The Logix Designer application graphically displays the fault

and includes a fault message describing the nature of the fault. This feature lets

you to determine how your module has been affected and what action to take to

resume normal operation.

For more information about fault and status reporting, see page 49

.

Fully Software Configurable

The Logix Designer application uses an interface to configure the module. All

module features are enabled or disabled through the I/O configuration portion

of the application.

The user can also use the software to interrogate any module in the system to

retrieve the following:

• Serial number

• Revision information

• Catalog number

• Vendor identification

• Error/fault information

• Diagnostic counters

24 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Module Features Chapter 3

IMPORTANT

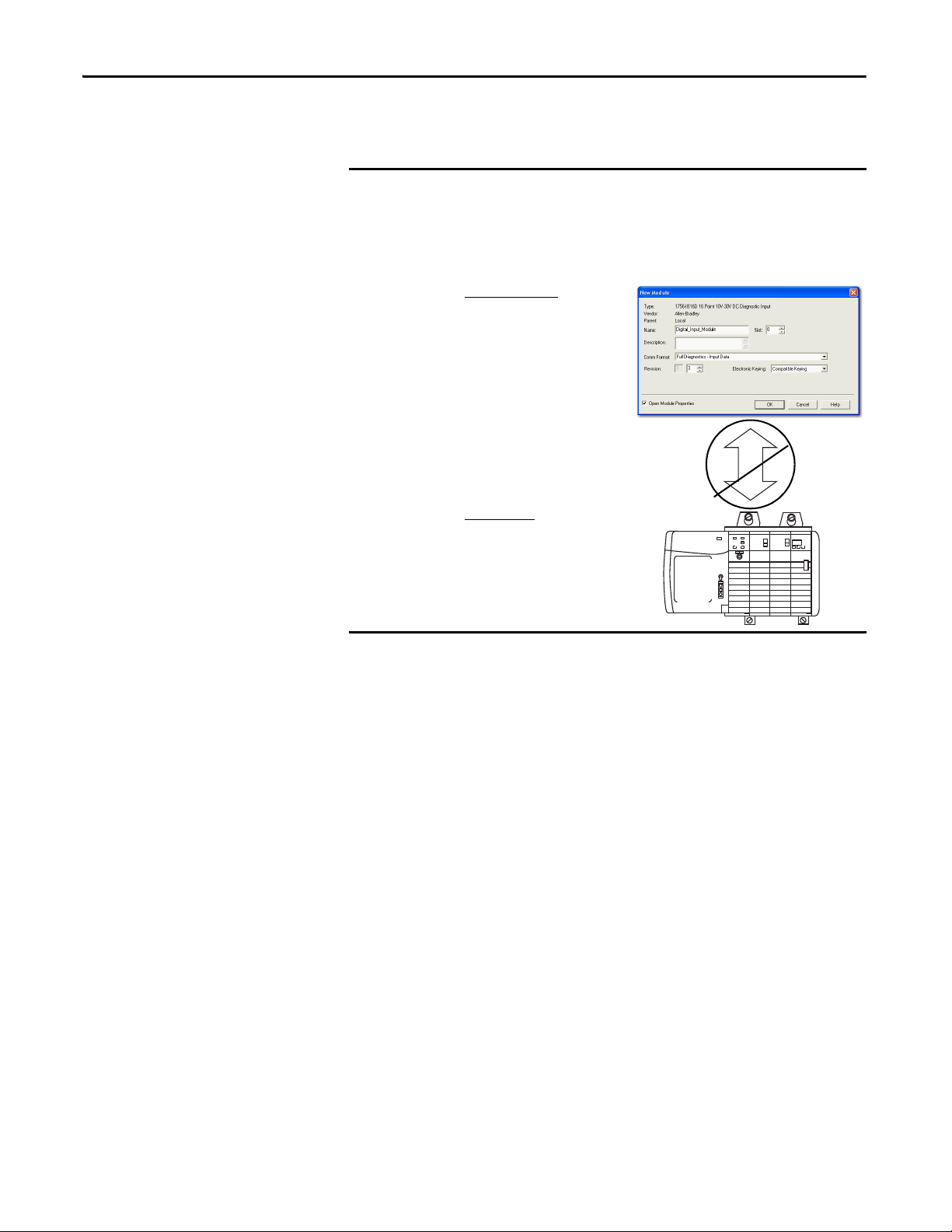

Electronic Keying

The electronic keying feature automatically compares the expected module, as

shown in the Logix Designer I/O Configuration tree, to the physical module

before I/O communication begins. You can use electronic keying to help prevent

communication to a module that does not match the type and revision expected.

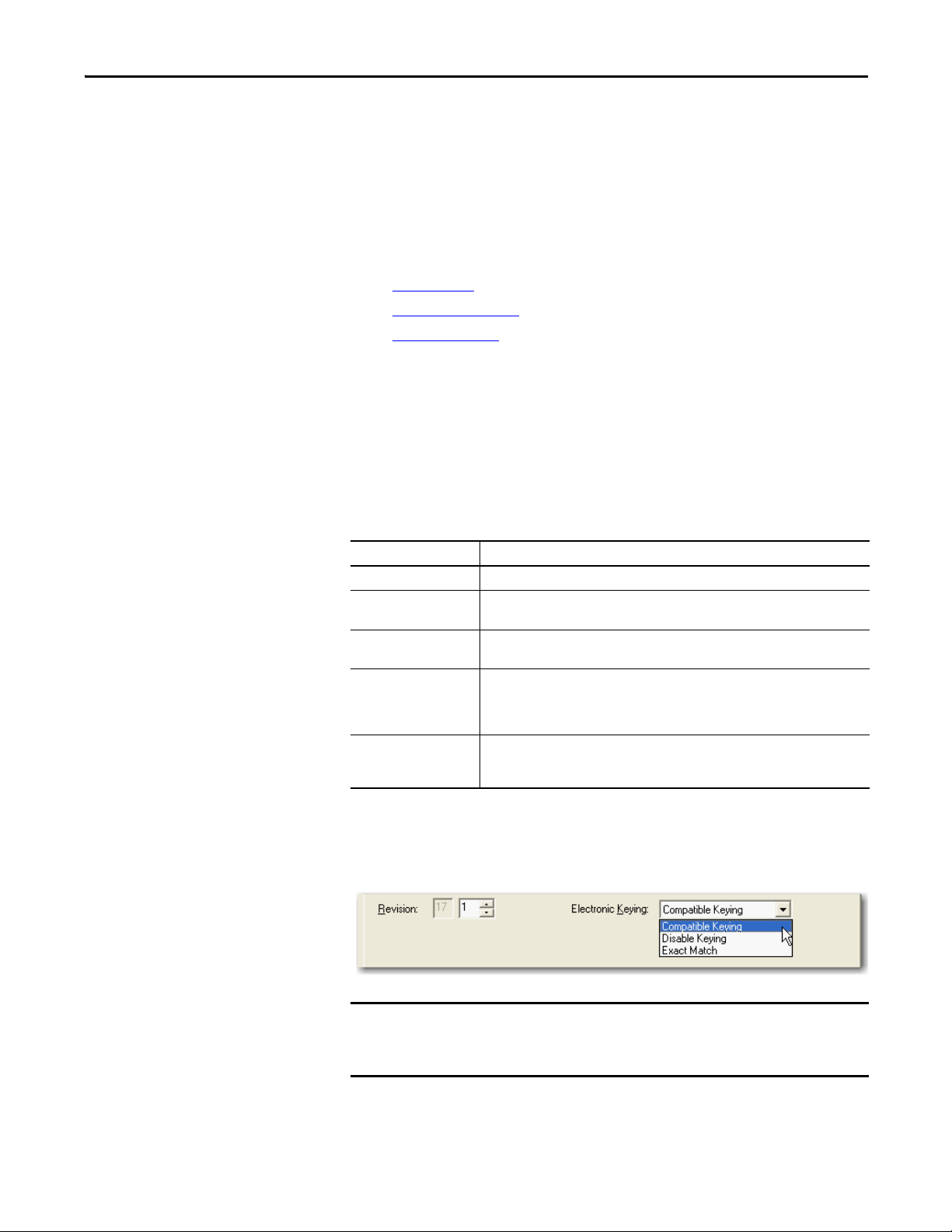

For each module in the I/O Configuration tree, the user-selected keying option

determines if, and how, an electronic keying check is performed. Typically, three

keying options are available:

• Exact Match

• Compatible Keying

• Disabled Keying

You must carefully consider the benefits and implications of each keying option

when selecting between them. For some specific module types, fewer options are

available.

Electronic keying is based on a set of attributes unique to each product revision.

When a Logix5000 controller begins communicating with a module, this set of

keying attributes is considered.

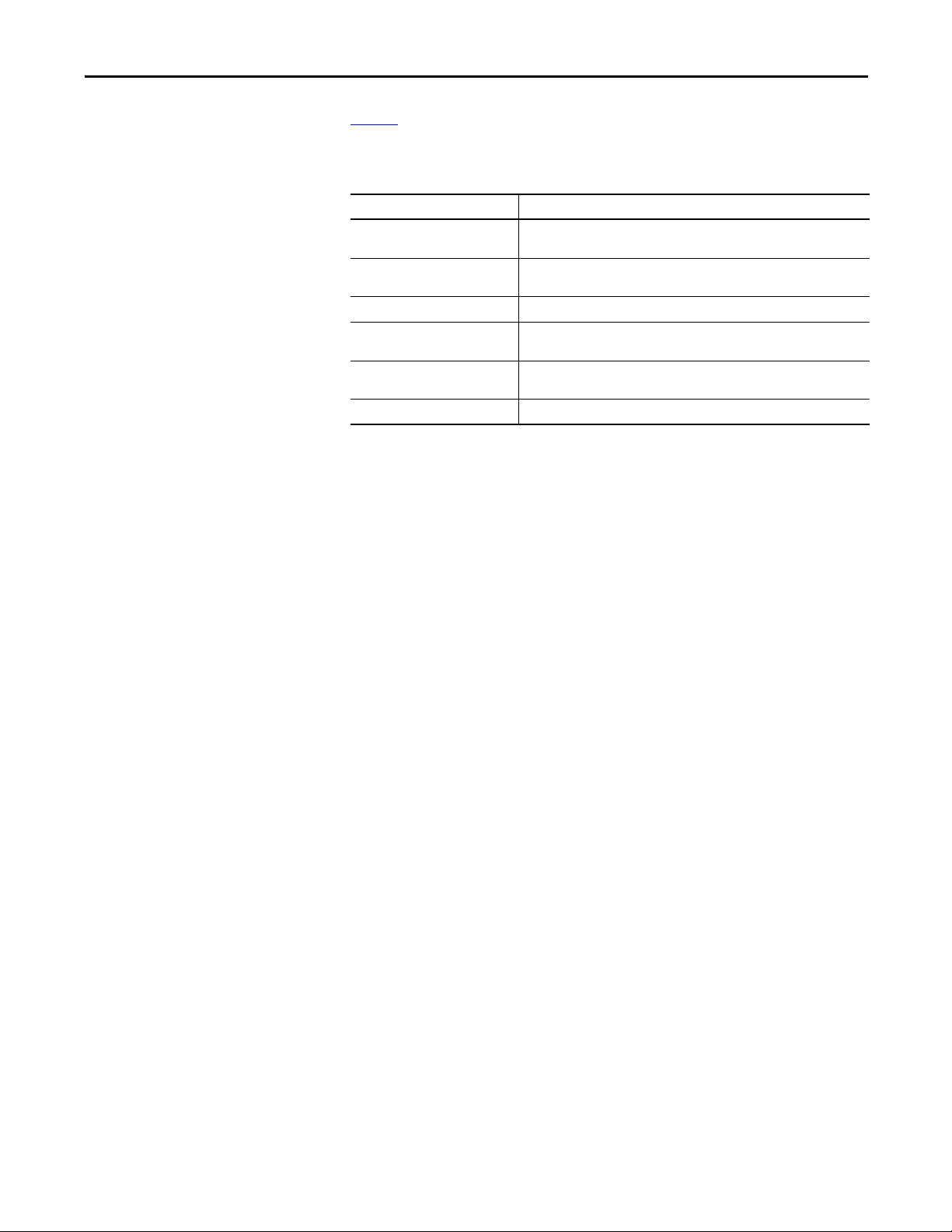

Table 2 - Keying Attributes

Attribute Description

Vendor The manufacturer of the module, for example, Rockwell Automation/Allen-Bradley.

Product Type The general type of the module, for example, communication adapter, AC drive, or digital

I/O.

Product Code The specific type of module, generally represented by its catalog number, for example,

1756-IB16I.

Major Revision A number that represents the functional capabilities and data exchange formats of the

module. Typically, although not always, a later, that is higher, Major Revision supports at

least all of the data formats supported by an earlier, that is lower, Major Revision of the

same catalog number and, possibly, additional ones.

Minor Revision A number that indicates the module’s specific firmware revision. Minor Revisions

typically do not impact data compatibility but may indicate performance or behavior

improvement.

You can find revision information on the General tab of a module’s Properties

dialog box.

Figure 3 - General Tab

Changing electronic keying selections online may cause the I/O

communication connection to the module to be disrupted and may result in a

loss of data.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 25

Chapter 3 Module Features

EXAMPLE

IMPORTANT

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Communication is prevented.

Exact Match

Exact Match keying requires all keying attributes, that is, Vendor, Product Type,

Product Code (catalog number), Major Revision, and Minor Revision, of the

physical module and the module created in the software to match precisely to

establish communication. If any attribute does not match precisely, I/O

communication is not permitted with the module or with modules connected

through it, as in the case of a communication module.

Use Exact Match keying when you need the system to verify that the module

revisions in use are exactly as specified in the project, such as for use in highlyregulated industries. Exact Match keying is also necessary to enable Automatic

Firmware Update for the module via the Firmware Supervisor feature from a

Logix5000 controller.

In this scenario, Exact Match keying prevents I/O communication.

The module configuration is for a 1756-IB16D module with module revision

3.1. The physical module is a 1756-IB16D module with module revision 3.2. In

this case, communication is prevented because the Minor Revision of the

module does not match precisely.

26 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Changing electronic keying selections online may cause the I/O

Communication connection to the module to be disrupted and may result in a

loss of data.

Module Features Chapter 3

Compatible Keying

Compatible Keying indicates that the module determines whether to accept or

reject communication. Different module families, communication adapters, and

module types implement the compatibility check differently based on the family

capabilities and on prior knowledge of compatible products. Release notes for

individual modules indicate the specific compatibility details.

Compatible Keying is the default setting. Compatible Keying allows the physical

module to accept the key of the module configured in the software, provided that

the configured module is one the physical module is capable of emulating. The

exact level of emulation required is product and revision specific.

With Compatible Keying, you can replace a module of a certain Major Revision

with one of the same catalog number and the same or later, that is higher, Major

Revision. If a Major Revision is the same, then make sure that the Minor Revision

is the same or higher than it is configured in the project. In some cases, the

selection makes it possible to use a replacement that is a different catalog number

than the original. For example, you can replace a 1756-CNBR module with a

1756-CN2R module.

When a module is created, the module developers consider the module’s

development history to implement capabilities that emulate those of the previous

module. However, the developers cannot know future developments. Because of

this, when a system is config ured, we recommend that you configure your module

using the earliest, that is, lowest, revision of the physical module that you believe

will be used in the system. By doing this, you can avoid the case of a physical

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 27

Chapter 3 Module Features

EXAMPLE

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 3

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Communication is prevented.

module rejecting the keying request because it is an earlier revision than the one

configured in the software.

In this scenario, Compatible Keying prevents I/O communication.

The module configuration is for a 1756-IB16D module with module revision

3.3. The physical module is a 1756-IB16D module with module revision 3.2.

In this case, communication is prevented because the minor revision of the

module is lower than expected and may not be compatible with 3.3.

28 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Module Features Chapter 3

EXAMPLE

IMPORTANT

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 2

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IB16D

Major Revision = 3

Minor Revision = 2

Communication is allowed.

In this scenario, Compatible Keying allows I/O communication.

The module configuration is for a 1756-IB16D module with module revision

2.1. The physical module is a 1756-IB16D module with module revision 3.2. In

this case, communication is allowed because the major revision of the physical

module is higher than expected and the module determines that it is

compatible with the prior major revision.

Changing electronic keying selections online may cause the I/O

communication connection to the module to be disrupted and may result in a

loss of data.

Rockwell Automation Publication 1756-UM005B-EN-P - January 2013 29

Chapter 3 Module Features

EXAMPLE

Module Configuration

Vendor = Allen-Bradley

Product Type = Digital Input Module

Catalog Number = 1756-IA16

Major Revision = 3

Minor Revision = 1

Physical Module

Vendor = Allen-Bradley

Product Type = Analog Input Module

Catalog Number = 1756-IF16

Major Revision = 3

Minor Revision = 2

Communication is prevented.

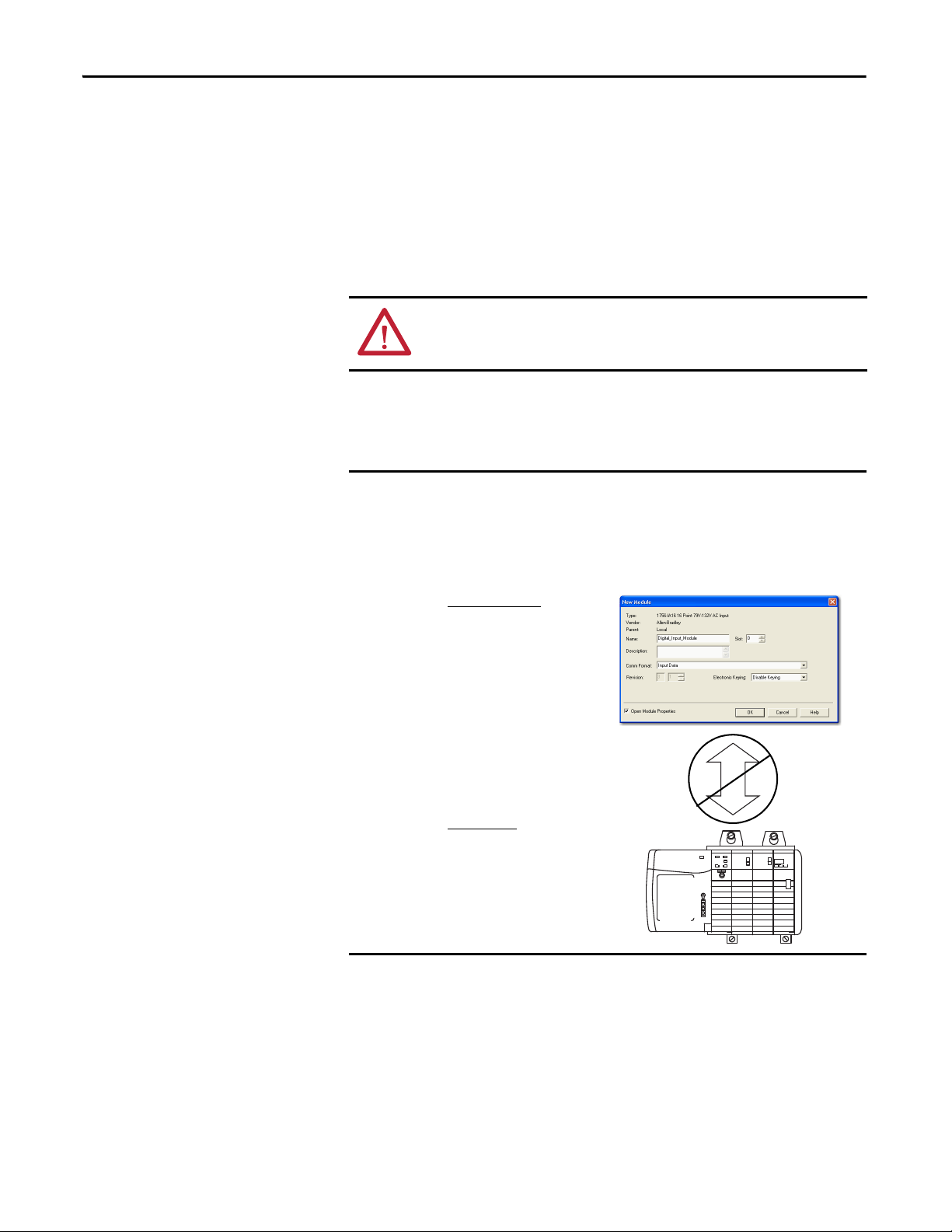

Disabled Keying

Disabled Keying indicates the keying attributes are not considered when

attempting to communicate with a module. Other attributes, such as data size

and format, are considered and must be acceptable before I/O communication is

established. With Disabled Keying, I/O communication may occur with a

module other than the type specified in the I/O Configuration tree with

unpredictable results. We generally do not recommend using Disabled Keying.

ATT EN TI ON : Be extremely cautious when using Disabled Keying; if used

incorrectly, this option can lead to personal injury or death, property damage,

or economic loss.

If you use Disabled Keying, you must take full responsibility for understanding

whether the module being used can fulfill the functional requirements of the

application.

In this scenario, Disable Keying prevents I/O communication.

The module configuration is for a 1756-IA16 digital input module. The physical

module is a 1756-IF16 analog input module. In this case, communication is

prevented because the analog module rejects the data formats that the digital

module configuration requests.

30 Rockwell Automation Publication 1756-UM005B-EN-P - January 2013

Loading...

Loading...