Rockwell Automation 1734-485ASC User Manual

POINT I/O ASCII

Modules

1734-232ASC, 1734-485ASC

User Manual

Important User Information Because of the variety of uses for the products described in this publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been taken to assure that each application and use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards. In no event will Allen-Bradley be responsible or liable for indirect or consequential damage resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some important differences between solid-state equipment and electromechanical devices that should be taken into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety considerations. The following annotations and their accompanying statements help you to identify a potential hazard, avoid a potential hazard, and recognize the consequences of a potential hazard:

WARNING

!

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION |

Identifies information about practices or |

|

circumstances that can lead to personal injury or |

||

|

!death, property damage, or economic loss.

|

Identifies information that is critical for successful |

|

IMPORTANT |

||

application and understanding of the product. |

||

|

||

|

||

|

|

Rockwell Automation

Support

Before you contact Rockwell Automation for technical assistance, we suggest you please review the troubleshooting information contained in this publication first.

If the problem persists, call your local Rockwell Automation representative or contact Rockwell Automation in one of the following ways:

Phone |

United |

1.440.646.5800 |

|

States/Canada |

|

|

|

|

|

Outside United |

You can access the phone number for your |

|

States/Canada |

country via the Internet: |

|

|

1.Go to http://www.ab.com |

|

|

2. Click on Product Support |

|

|

(http://support.rockwellautomation.com) |

|

|

3. Under Support Centers, click on Contact |

|

|

Information |

|

|

|

Internet |

|

1. Go to http://www.ab.com |

|

|

2. Click on Product Support |

|

|

(http://support.rockwellautomation.com) |

|

|

|

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the enclosed How Are We Doing form.

Preface

Purpose of This Manual

Who Should Use

This Manual

This manual describes how to install, configure, and troubleshoot your POINT I/O 1734-232ASC module (for the RS-232 network) or 1734-485ASC module (for the RS-485 or RS-422 network).

For Information on |

See |

|

Chapter/ |

|

Appendix |

|

|

Installing the ASCII Module |

1 |

|

|

Configuring Your ASCII Module |

2 |

|

|

Diagnostics |

3 |

|

|

Specifications |

A |

|

|

You must be able to use RSNetWorx for DeviceNet software or similar configuration software to set this module. You must have the capability to download and use Electronic Data Sheet (EDS) files.

We assume you know how to do this in this manual. If you do not, refer to your software user manuals or online help before attempting to use this module.

Publication 1734-UM009B-EN-P - July 2003

Preface 2

Related Products and

Documentation

The following table lists related POINT I/O products and documentation.

Catalog Number |

Description |

Related Publications |

|

|

|

|

|

Communication |

DeviceNet Adapter (Cat. No. 1734-ADN) |

Installation Instructions |

1734-IN007 |

Adapter |

|

|

|

|

|

|

|

Communication |

DeviceNet Interface (Cat. No. 1734-PDN) |

Installation Instructions |

1734-IN057 |

Interface |

|

|

|

|

|

|

|

1734D Series |

1734D Series 24V dc 8 In/8 Out Combo Module (Cat. No. 1734D-IB8XOB8E, |

Installation Instructions |

1734-5.20 |

|

-IB8XOB8ES) |

|

|

|

|

|

|

|

1734D Series 24V dc 8 In/8 N.O. Relay Combo Module (Cat. No. |

Installation Instructions |

1734-5.21 |

|

1734D-IB8XOW8, -IB8XOW8S) |

|

|

|

|

|

|

|

1734D Series 120V ac 8 In/8 Out Combo Module (Cat. No. 1734D-IA8XOA8, |

Installation Instructions |

1734-5.22 |

|

-IA8XOA8S) |

|

|

|

|

|

|

|

1734D Series 120V ac 8 In/8 N.O. Relay Combo Module (Cat. No. |

Installation Instructions |

1734-5.23 |

|

1734D-IA8XOW8, -IA8XOW8S) |

|

|

|

|

|

|

Wiring Base |

Wiring Base Assembly with 8 Screw-Clamp or Spring-Clamp Removable |

Installation Instructions |

1734-IN511 |

Assemblies |

Terminal Blocks (Cat Nos. 1734-TB, -TBS) |

|

|

|

|

|

|

|

Wiring Base Assembly with 12 Screw-Clamp or Spring-Clamp Removable |

Installation Instructions |

1734-IN013 |

|

Terminal Blocks (Cat Nos. 1734-TB3, -TB3S) |

|

|

|

|

|

|

AC Modules |

120V ac 2 Input Module (Cat. No. 1734-IA2) |

Installation Instructions |

1734-IN010 |

|

|

|

|

|

120/220V ac 2 Output Module (Cat. No. 1734-OA2) |

Installation Instructions |

1734-IN009 |

|

|

|

|

|

220V ac 2 Input Module (Cat. No. 1734-IM2) |

Installation Instructions |

1734-IN008 |

|

|

|

|

DC Modules |

24V dc 2 Input Sink Module (Cat. No. 1734-IB2) |

Installation Instructions |

1734-IN051 |

|

|

|

|

|

24V dc 4 Input Sink Module (Cat. No. 1734-IB4) |

Installation Instructions |

1734-IN051 |

|

|

|

|

|

24V dc 2 Input Source Module (Cat. No. 1734-IV2) |

Installation Instructions |

1734-IN052 |

|

|

|

|

|

24V dc 4 Input Source Module (Cat. No. 1734-IV4) |

Installation Instructions |

1734-IN052 |

|

|

|

|

|

24V dc Electronically Protected 2 Point Output Module (Cat. No. |

Installation Instructions |

1734-IN056 |

|

1734-OB2E) |

|

|

|

|

|

|

|

24V dc Electronically Protected 4 Point Output Module (Cat. No. 1734-0B4E) |

Installation Instructions |

1734-IN056 |

|

|

|

|

Analog Modules |

24V dc Analog 2 Current Input Module (Cat. No. 1734-IE2C) |

Installation Instructions |

1734-IN053 |

|

|

|

|

|

24Vdc Analog 2 Current Output Module (Cat. No. 1734-OE2C) |

Installation Instructions |

1734-IN054 |

|

|

|

|

|

24V dc Analog 2 Voltage Input Module (Cat. No. 1734-IE2V) |

Installation Instructions |

1734-IN001 |

|

|

|

|

|

24Vdc Analog 2 Voltage Output Module (Cat. No. 1734-OE2V) |

Installation Instructions |

1734-IN002 |

|

|

|

|

RTD Module |

RTD Input Module (Cat. No. 1734-IR2) |

Installation Instructions |

1734-IN012 |

|

|

|

|

Thermocouple |

Isolated Thermocouple Input Module (Cat. No. 1734-IT2I) |

Installation Instructions |

1734-IN011 |

Module |

|

|

|

|

|

|

|

Publication 1734-UM009B-EN-P - July 2003

Preface |

3 |

|

|

Catalog Number |

Description |

Related Publications |

|

|

|

|

|

Counter Modules |

24V Encoder/Counter Module (Cat. No. 1734-IK) |

Installation Instructions |

1734-IN006 |

|

|

User Manual |

1734-UM006 |

|

|

|

|

|

5V Encoder/Counter Module (Cat. No. 1734-IJ) |

Installation Instructions |

1734-IN005P |

|

|

User Manual |

1734-UM006 |

|

|

|

|

|

24V dc Very High Speed Counter Module (Cat. No. 1734-VHSC24) |

Installation Instructions |

1734-IN003 |

|

|

User Manual |

1734-UM003 |

|

|

|

|

|

5V dc Very High Speed Counter Module (Cat. No. 1734-VHSC5) |

Installation Instructions |

1734-IN004 |

|

|

User Manual |

1734-UM003 |

|

|

|

|

Relay Module |

24V dc, 120V ac, and 240V ac 2 Relay Sink/Source Output Module (Cat. No. |

Installation Instructions |

1734-IN055 |

|

1734-OW2) |

|

|

|

|

|

|

Field Power |

Field Power Distributor (Cat. No. 1734-FPD) |

Installation Instructions |

1734-IN059 |

Distributor |

|

|

|

|

|

|

|

Expansion Power |

24V dc Expansion Power Supply (Cat. No. 1734-EP24DC) |

Installation Instructions |

1734-IN058 |

Supply |

|

|

|

|

|

|

|

Publication 1734-UM009B-EN-P - July 2003

Preface 4

Notes:

Publication 1734-UM009B-EN-P - July 2003

Table of Contents

Chapter 1

Installing the ASCII Module |

General Information on the ASCII Modules . . . . . . . . . . . . |

1-1 |

|

Installing the Mounting Base/ Wiring Base Assembly . . . . . |

1-1 |

|

Installing an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

|

Installing the Removable Terminal Block . . . . . . . . . . . . . . |

1-4 |

|

Removing a Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

|

Wiring the 1734-232ASC Module . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

Wiring the 1734-485ASC Module . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

Cable Pinouts for Standard DB Connectors. . . . . . . . . . . . . |

1-8 |

|

How to Install a Serial Network . . . . . . . . . . . . . . . . . . . . . |

1-8 |

|

How to Read Serial Device Input Data from the ASCII Module . |

|

|

1-9 |

|

|

How to Write Serial Output Data to the ASCII Module . . . . |

1-10 |

|

Setting Up DeviceNet Communications . . . . . . . . . . . . . . . |

1-11 |

|

Polled I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

|

Cyclic and Change of State I/O. . . . . . . . . . . . . . . . . . . |

1-12 |

|

Setting Up the DeviceNet I/O Connections . . . . . . . . . . |

1-12 |

|

Setting Up the Connection Timer (EPR) . . . . . . . . . . . . |

1-13 |

|

Operating Mode Selections . . . . . . . . . . . . . . . . . . . . . . . . |

1-14 |

|

Transmit Handshake vs. Transmit Immediate Option . . . |

1-14 |

|

Produce Immediate vs. Master/Slave Handshake Option 1-15 |

|

|

Pad vs. No Pad Option. . . . . . . . . . . . . . . . . . . . . . . . . |

1-15 |

|

Chapter 2 |

|

Configuring Your ASCII Module |

About Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

|

Adding the ASCII Modules to Your Network . . . . . . . . . |

2-4 |

|

Adding I/O Modules to Your Network . . . . . . . . . . . . . |

2-5 |

|

Setting the ASCII Module’s Parameters . . . . . . . . . . . . . . . . |

2-6 |

|

Checking I/O Status and Viewing the EDS File . . . . . . . . . . |

2-8 |

|

Configuration Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

|

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-10 |

|

POINT I/O Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-15 |

|

Receiving Serial Data from the ASCII Device . . . . . . . . . |

2-15 |

|

Setting Up the Receive Character Buffer Length. . . . . . . |

2-15 |

|

Setting Up and Using Pad Mode . . . . . . . . . . . . . . . . . . |

2-16 |

|

Setting Up and Using the Swap Bytes Mode . . . . . . . . . |

2-17 |

|

Setting Up and Using Delimiter Operation . . . . . . . . . . |

2-18 |

|

Receive String Data Type . . . . . . . . . . . . . . . . . . . . . . . |

2-18 |

|

Setting Up the Scanner I/O Receive Size . . . . . . . . . . . . |

2-19 |

|

Explicit Messages to Receive the Serial Data String . . . . 2-20 |

|

|

Status Byte Description . . . . . . . . . . . . . . . . . . . . . . . . |

2-20 |

|

Transmitting Serial Data to the ASCII Device . . . . . . . . . . . |

2-21 |

|

Setting Up the Transmit Character Buffer Length . . . . . . |

2-22 |

|

Setting Up and Using the Transmit Delimiter. . . . . . . . . |

2-22 |

|

Transmit String Data Assemblies . . . . . . . . . . . . . . . . . . |

2-23 |

Publication 1734-UM009B-EN-P - July 2003

Table of Contents |

ii |

|

|

Diagnostics

Specifications

Using the ASCII Modules with the ControlLogix System Application Examples

Transmit Handshake vs. Transmit Immediate Mode . . . . 2-24 Transmitting Serial Data . . . . . . . . . . . . . . . . . . . . . . . . 2-26 Setting Up the Scanner I/O Transmit Size . . . . . . . . . . . 2-26 Produce Immediate vs. Master/Slave Handshake Mode . 2-27 Explicit Messages to Transmit Serial Data String . . . . . . 2-28

Chapter 3

Using the Indicators for Troubleshooting . . . . . . . . . . . . . . 3-1

Appendix A

Specifications for the ASCII Modules . . . . . . . . . . . . . . . . . A-1

Appendix A

About These Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 Serial Port Connector . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 EDS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2 DeviceNet Data Details . . . . . . . . . . . . . . . . . . . . . . . . B-3 Sending Data Through the ASCII Modules. . . . . . . . . . . B-3 Receiving Data From the ASCII Modules . . . . . . . . . . . . B-3 Reading Data from the ASCII Modules into ControlLogix B-4 Transmitting Data from ControlLogix Through the

ASCII Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Publication 1734-UM009B-EN-P - July 2003

Chapter 1

General Information on the ASCII Modules

Installing the ASCII Module

The ASCII modules provide a flexible DeviceNet interface to a wide variety of RS-232, RS-485, and RS-422 ASCII devices. The modules provide the communication connections to the ASCII device.

The 1734-232ASC module connects to the RS-232 network while the 1734-485ASC module connects to the RS-485 or RS-422 network.

Installing the Mounting

Base/ Wiring Base

Assembly

The wiring base assembly (1734-TB or -TBS) consists of a mounting base (cat. no. 1734-MB) and a removable terminal block (cat. no. 1734-RTB or -RTBS). You can install the assembly, or just the mounting base. To install the mounting base/wiring base assembly on the DIN rail, proceed as follows.

ATTENTION

!

POINT I/O is grounded through the DIN rail to chassis ground. Use zinc-plated, yellow-chromated steel DIN rail to assure proper grounding. Using other DIN rail materials (e.g. aluminum, plastic, etc.) which can corrode, oxidize or are poor conductors, can result in improper or intermittent platform grounding.

WARNING |

When you connect or disconnect the Removable |

|

|

Terminal Block (RTB) with field side power applied, |

|

! |

||

an electrical arc can occur. This could cause an |

||

explosion in hazardous location installations. |

||

Be sure that power is removed or the area is |

||

|

nonhazardous before proceeding. |

|

|

|

Publication 1734-UM009B-EN-P - July 2003

1-2 Installing the ASCII Module

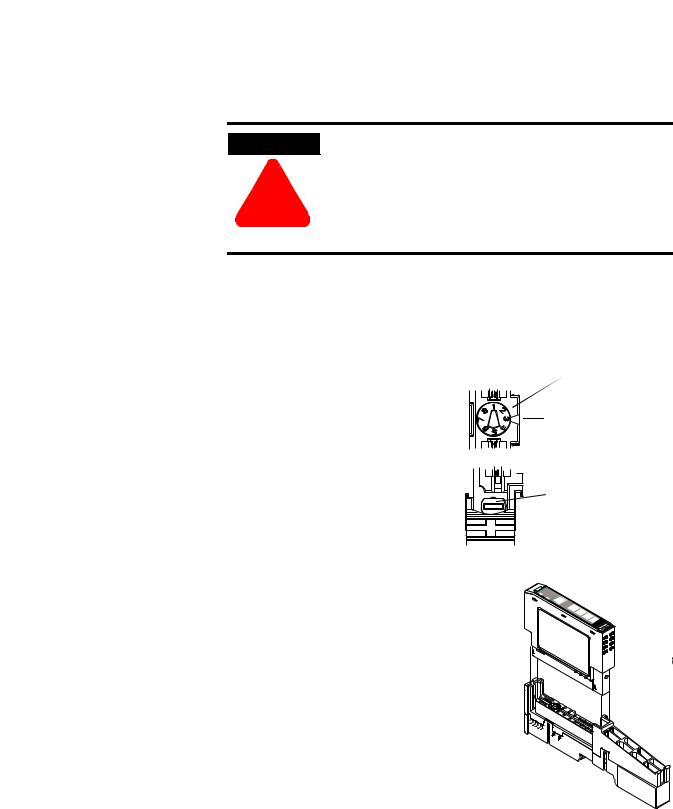

1.Position the mounting base/wiring base assembly vertically above the installed units (adapter, power supply or existing module).

2.Slide the mounting base down allowing the interlocking side pieces to engage the adjacent module or adapter.

ModuleStatus

: NODE

TX

RX

Module Locking Mechanism

Slide-in Writable Label

1734232ASC

Insertable I/O Module

Module Wiring Diagram |

|

Mechanical Keying |

DIN Rail Locking Screw RTB Removing Handle |

(orange) |

(orange) |

|

Removable Terminal Block (RTB) |

Interlocking Side Pieces

Mounting Base

3.Press firmly to seat the mounting base on the DIN rail. The mounting base will snap into place.

4.To remove the mounting base from the DIN rail, remove any installed module (and any module immediately to the right), and use a small bladed screwdriver to rotate the DIN rail locking screw to a vertical position. This releases the locking mechanism. Then lift straight up to remove the mounting base.

5.Repeat this procedure for the next mounting base assembly.

Publication 1734-UM009B-EN-P - July 2003

|

Installing the ASCII Module 1-3 |

|

|

Installing an I/O Module |

The module can be installed before, or after base installation. Make |

|

sure that the mounting base is correctly keyed before installing the |

|

module into the mounting base. In addition, make sure the mounting |

|

base locking screw is positioned horizontal referenced to the base. |

WARNING

!

When you insert or remove the module while backplane power is on, an electrical arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1.Using a bladed screwdriver, rotate the keyswitch on the mounting base clockwise till the number required for the type of module being installed aligns with the notch in the base.

Turn the keyswitch to align the number with the notch.

Position 2

Notch (position 3 shown)

2.Make certain the DIN rail locking screw is in the

horizontal position. (You cannot insert the module if the locking mechanism is unlocked.)

3. Insert the module straight down into the mounting base and press to secure. The module will lock into place.

Make sure the DIN rail locking screw is in the horizontal position.

Publication 1734-UM009B-EN-P - July 2003

1-4 Installing the ASCII Module

Installing the Removable

Terminal Block

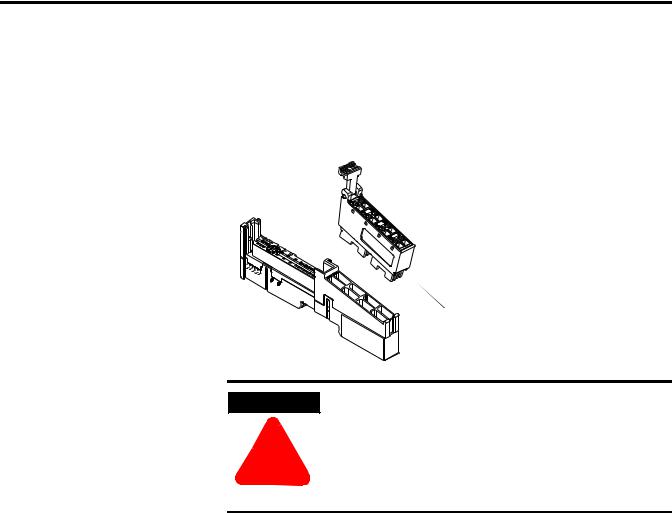

A removable terminal block is supplied with your mounting base assembly. To remove, pull up on the RTB handle. This allows the base to be removed and replaced as necessary without removing any of the wiring. To reinsert the removable terminal block, proceed as follows.

1.Insert the RTB end opposite the handle into the base unit. This end has a curved section that engages with the mounting base.

Hook the RTB end into the mounting base end, and rotate until it locks into place.

WARNING

!

When you connect or disconnect the Removable Terminal Block (RTB) with field side power applied, an electrical arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

2.Rotate the terminal block into the mounting base until it locks itself in place.

3.If an I/O module is installed, snap the RTB handle into place on the module.

Publication 1734-UM009B-EN-P - July 2003

Installing the ASCII Module 1-5

Removing a Mounting Base To remove a mounting base, you must remove any installed module, and remove the removable terminal block (if wired).

1.Unlatch the RTB handle on the I/O module.

2.Pull on the RTB handle to remove the removable terminal block.

WARNING

!

When you connect or disconnect the Removable Terminal Block (RTB) with field side power applied, an electrical arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

3.Press in on the module lock on the top of the module and pull up on the I/O module to remove from the base.

WARNING

!

When you insert or remove the module while backplane power is on, an electrical arc can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

4.Remove the module to the right of the base you are removing. (The interlocking portion of the base sits under the adjacent module.)

5.Use a small bladed screwdriver to rotate the orange DIN rail locking screw on the mounting base to a vertical position. This releases the locking mechanism.

6.Then lift the mounting base straight up to remove.

Publication 1734-UM009B-EN-P - July 2003

1-6 Installing the ASCII Module

Wiring the

1734-232ASC Module

Wiring the

1734-485ASC Module

|

RS-232 |

Module Status |

Module |

Status |

|

Network Status |

Network |

|

Status |

|

NODE: |

|

1734 |

|

232ASC |

|

TxD |

|

RxD |

Shielded Cable: The 1734-232ASC module requires shielded cable to help reduce the effects of electrical noise coupling. Ground each shield at one end only. A shield grounded at both ends forms a ground loop, which can cause module communications to fault. Never connect a shield to the common side of a logic circuit (this would introduce noise into the logic circuit).

|

Connect the shield directly to a chassis ground. |

|

This chassis ground connection is not available |

|

on the 1734-232ASC RTB (Removable Terminal |

1734 |

Block). On a POINT I/O system, the chassis |

232ASC |

ground connection can be made at the DIN |

|

|

|

Rail, at the metal panel the DIN Rail is |

Tx |

mounted to, or at the user’s I/O device. |

Rx |

|

NC |

NC |

NC |

NC |

NC |

SG |

|

43123 |

Tx = Transmit |

Rx = Receive |

NC = No Connection |

SG = Signal Ground |

|

RS-485 |

|

RS-422 |

Module |

|

|

Module |

Status |

|

|

|

Shielded Cable: The 1734-485ASC module requires |

|

Status |

|

Network |

|

||

shielded cable to help reduce the effects of electrical |

|

Network |

|

Status |

|

||

noise coupling. Ground each shield at one end only. A |

|

Status |

|

|

|

||

|

shield grounded at both ends forms a ground loop, which |

|

|

|

can cause module communications to fault. Never connect |

|

|

|

a shield to the common side of a logic circuit (this would |

|

|

|

introduce noise into the logic circuit). |

|

|

|

Connect the shield directly to a chassis ground. This |

|

|

|

chassis ground connection is not available on the |

|

|

|

1734-485ASC RTB (Removable Terminal Block). On a |

|

|

|

POINT I/O system, the chassis ground connection can be |

|

|

|

made at the DIN Rail, at the metal panel the DIN Rail is |

|

|

|

mounted to, or at the user’s I/O device. |

|

|

S+ |

NC |

Tx+ |

Rx+ |

S- |

NC |

Tx- |

Rx- |

|

|

||

NC |

NC |

NC |

NC |

|

|

||

CG |

SG |

CG |

SG |

|

43487 |

|

43487 |

S+ = Transmit |

S- = Receive |

Tx = Transmit |

Rx = Receive |

|

CG = Chassis Ground |

NC = No Connection |

|||

CG = Chassis Ground |

NC = No Connection |

|||

|

|

SG = Signal Ground |

SG = Signal Ground |

|

Publication 1734-UM009B-EN-P - July 2003

Installing the ASCII Module |

1-7 |

|

|

|

Module Terminations |

|

||

Terminal |

|

RS-232 |

RS-485 |

RS-422 |

0 |

|

Tx1 |

S+1 |

Tx+1 |

1 |

|

Rx2 |

NC |

Rx+1 |

2 |

|

NC |

S-2 |

Tx-2 |

3 |

|

NC |

NC |

Rx-2 |

4 |

|

NC |

NC |

NC |

5 |

|

NC |

NC |

NC |

6 |

|

NC |

CG |

CG |

7 |

|

SG |

SG |

SC |

1 S+ and Tx+ are transmit from the module 2 S- and Rxare receive into the module

RS-232

0 |

|

1 |

|

Tx |

Rx |

|

|

|

2 |

|

3 |

|

NC |

NC |

|

|

|

4 |

|

5 |

|

NC |

NC |

|

|

7 SG |

6 |

NC |

|

|

|

|

|

RS-485 |

|

0 |

|

1 |

|

S+ |

NC |

2 |

|

3 |

|

S- |

NC |

4 |

|

5 |

|

NC |

NC |

6 |

CG |

7 SG |

RS-422

0 1

Tx+ Rx+

2 3

TxRx-

4 5

NC NC

6 CG 7 SG

43124 |

43488 |

43489 |

Tx, S+ = Transmit |

Rx, S- = Receive |

NC = No Connection |

SG = Signal Ground |

CG = Chassis Ground |

|

Publication 1734-UM009B-EN-P - July 2003

1-8 Installing the ASCII Module

Cable Pinouts for Standard DB Connectors

How to Install a Serial Network

Table 1.1 ASCII Functions

|

Pin Number |

||

Function |

DB-25 |

|

DB-9 |

|

|||

|

|

|

|

Transmit Data (TXD) |

2 |

|

3 |

|

|

|

|

Receive Data (RXD) |

3 |

|

2 |

|

|

|

|

Signal Ground (SG) |

7 |

|

5 |

|

|

|

|

The communication between your serial device(s) and the:

1734-232ASC is an RS-232 3-wire network.

1734-485ASC is an RS-485 2-wire network or RS-422 4-wire network

1.Connect an appropriate cable to your device.

2.Connect the other end of the cable to the ASCII module using the designated positions on the 1734-TB terminal block.

Notice the terminal markings on the ASCII module case.

3.Turn on power to the serial device and the ASCII module.

4.Set up the ASCII buffer sizes on the ASCII module.

The defaults are 20 and 20. If more than 20 bytes are required for the transmit or receive buffers, set the appropriate parameters in your configuration file to the buffer size you need for your ASCII data.

This will modify the I/O message size. You will need to reconfigure the poll/COS/cyclic transmit and receive data sizes if you modify the ASCII buffer size from the default value.

In many configuration tools, this will unmap the data in your scanner’s scan list. They must be remapped in order to process the data in your PLC or PC software. These values are displayed in the Parameter Object, Class 15 (Fhex).

Publication 1734-UM009B-EN-P - July 2003

Installing the ASCII Module |

1-9 |

|

|

5.The ASCII module produces and consumes the number of ASCII characters selected plus four.

These produce and consume sizes are presented for your information in parameters 13 and 23, respectively.

TIP |

Make sure that you set up your scanner to the |

|

correct sizes using this data. |

||

|

||

|

How to Read Serial Device Input Data from the

ASCII Module

1.Connect to the ASCII module from your configuration tool.

2.Connect the serial side of the ASCII module to your computer’s serial port or another serial device.

3.Go to the device configuration screen in the configuration tool.

4.Make sure that the ASCII module is in the default factory configuration.

5.Set the baud rate and framing format of the serial port to the baud rate and framing format of the serial device that you are using.

6.Put the configuration tool in monitor mode.

7.Direct the device that you are communicating with to send data.

For example, if you are connected to a computer terminal program, type a message into the terminal. When you hit enter, the module will update the data with the message that you typed, and increment the transaction ID.

The default assembly of the poll response message is shown below.

Table 1.2 Default Receive Data Assembly Format (Default Mode)

Byte 1 |

Byte 2 |

Byte 3 |

Byte 4 |

Byte 5-23 |

Byte 24 |

|

|

|

|

|

|

RX Transaction ID |

Status Byte |

Reserved |

Length |

ASCII Data |

<CR> |

Byte |

|

|

|

|

(Terminator) |

|

|

|

|

|

|

Publication 1734-UM009B-EN-P - July 2003

1-10 Installing the ASCII Module

How to Write Serial Output Data to the ASCII Module

1.Connect to the ASCII module from your configuration tool.

2.Connect the serial side of the ASCII module to your computer’s serial port or another serial device.

3.Go to the device configuration screen in the configuration tool.

4.Make sure that the ASCII module is in the default factory configuration.

5.Set the baud rate and framing format of the serial port to the baud rate and framing format of the serial device that you are using.

6.Enter the serial data that you wish to send in the transmit data parameter and choose apply.

7.Change the length of the data in the length byte to reflect the length you wish to send and choose apply.

8.Change the transmit transaction ID and choose apply.

The ASCII module will generate the characters you typed on the computer screen.

Poll messages work in the same manner as the parameter object interface.

Table 1.3 Default Transmit Data Assembly Format (Default Mode)

Byte 1 |

Byte 2 |

Byte 3 |

Byte 4 |

Byte 5-23 |

Byte 24 |

|

|

|

|

|

|

Reserved |

TX Transaction ID |

Reserved |

Length |

ASCII Data |

<CR> |

|

Byte |

|

|

|

(Terminator) |

|

|

|

|

|

|

Publication 1734-UM009B-EN-P - July 2003

Installing the ASCII Module |

1-11 |

|

|

Setting Up DeviceNet

Communications

The ASCII module supports 4 modes of data transfer of the serial buffer:

Polled I/O

Change of State I/O

Cyclic I/O

Explicit Message

Polled I/O

The ASCII module monitors the transaction ID for a change in the transaction ID. If the transaction ID changes, then the ASCII module transmits the data buffer on its serial link. If the transaction ID does not change, then the device does not transmit the data buffer.

After the device has transmitted its data out to the serial link, the ASCII module then takes any information that is stored in its current serial input buffer and sends this data to the DeviceNet master. It sends all characters up to and including the received delimiter, including pad characters if not deselected.

When the ASCII module receives a new message (either with a delimiter or with an overflow condition without a delimiter) the device then increments the receive record, updates the length byte, and copies the new information from the last receive delimiter into the buffer. If an overflow occurs, the ASCII module indicates so in its receive status bit. The receive status byte also reflects parity errors in the device.

Publication 1734-UM009B-EN-P - July 2003

1-12 Installing the ASCII Module

Cyclic and Change of State I/O

The Cyclic and Change of State (COS) connections initiate a DeviceNet message (production) every time the connection timer (EPR) expires. They report the most current data in the ASCII module’s serial port receive buffer. In addition, the COS sends a data string each time a new serial input is received from the external serial device. This initiates the data transfer upon receipt of the delimiter or an overflow at its serial port.

The format of the message is the same as for a Poll response. Each message is handled in the same fashion, with respect to string delimiters, overflows, etc., regardless of which connection mechanism is used.

The purpose of these connections is to send data from the ASCII modules to the scanner without a direct command from the Master, thus conserving network bandwidth. The COS connection provides the Master with the current data as fast (or faster) than a Poll connection. The COS/Cyclic mechanism automatically activates when the connection is created.

The COS and Cyclic connections are mutually exclusive per DeviceNet definition - that is, you cannot use both of them at the same time. You can use each one, however, in conjunction with a Poll connection.

Setting Up the DeviceNet I/O Connections

It is useful to first set up your serial link before setting up your connection. To set up the communications with your network configuration tool, it is necessary to know the connection input and output sizes. Instructions for setting up your serial connection are provided above. See Table 2.3 for receive and transmit sizes.

The input and output sizes are computed from the transmit size and the receive sizes plus selected options. These sizes are defined in the parameter object of your device.

Publication 1734-UM009B-EN-P - July 2003

Installing the ASCII Module |

1-13 |

|

|

The transmit and receive sizes of the I/O connection are automatically computed for you by the ASCII module. You must set the maximum RX and TX sizes first and then choose apply. Upload the data to the ASCII module by clicking Upload. The scanner’s I/O connection TX field should be set to the value of "Consume Assembly Size" parameter 23.

The RX size of the scanner should be set to the value of "Produce Assembly Size" parameter 13. If you are in the COS I/O connection and do not wish to transmit data out of the ASCII module, you may set the scanner’s TX size to 0. This will only work with the COS/cyclic connection. You will see the best results if you do not allocate the poll and COS connections at the same time (you will conserve bandwidth). The best selection in regards to bandwidth conservation is the COS connection.

|

Remember to re-map the data (if necessary) after you |

|

IMPORTANT |

||

set the sizes, because many configuration tools will |

||

|

||

|

||

|

automatically unmap your data when you change the |

|

|

connection sizes. If you are not using such a |

|

|

software package, it is probably not necessary to set |

|

|

up the transmit and receive sizes. |

|

|

|

Setting Up the Connection Timer (EPR)

EPR stands for Expected Packet Rate. This is the timer value that the ASCII module uses for the cyclic and polled connection. This is also the value it uses in the connections to calculate the time the device should wait before signaling a timeout. If you have a scanner or scanning software, you must configure it with the EPR that you want the ASCII module to be scanned with.

The scanner configures the EPR in the ASCII module at the beginning of communications. Consult your scanner’s manuals on how to configure the EPR.

TIP |

EPR is automatically set via RSNetWorx for |

|

DeviceNet. However, if you need to set up the EPR |

||

|

||

|

||

|

manually, perform a set (Service 10hex) on the |

|

|

connection class (Class 5hex) attribute 9. The polled |

|

|

connection uses instance 2, where as the COS and |

|

|

cyclic connections use instance 4. This must be done |

|

|

after allocating the connection. |

Publication 1734-UM009B-EN-P - July 2003

Loading...

Loading...