Rockwell Automation 1747-L40 User Manual

Allen Bradley |

SLC 500t Fixed |

Hardware Style |

(Cat. No. 1747 L20, 1747 L30, |

and 1747 L40 Processors) |

product icon |

Installation and

Operation Manual

Allen-Bradley

SLC 500t Fixed

Hardware Style

(Cat. No. 1747-L20, 1747-L30,

and 1747-L40 Processors)

Installation and

Operation Manual

Important User Information |

Solid state equipment has operational characteristics differing from those of |

||

|

electromechanical equipment. ªSafety Guidelines for the Application, |

||

|

Installation and Maintenance of Solid State Controlsº (Publication SGI-1.1) |

||

|

describes some important differences between solid state equipment and |

||

|

hard±wired electromechanical devices. Because of this difference, and also |

||

|

because of the wide variety of uses for solid state equipment, all persons |

||

|

responsible for applying this equipment must satisfy themselves that each |

||

|

intended application of this equipment is acceptable. |

||

|

In no event will the Allen-Bradley Company be responsible or liable for |

||

|

indirect or consequential damages resulting from the use or application of |

||

|

this equipment. |

||

|

The examples and diagrams in this manual are included solely for illustrative |

||

|

purposes. Because of the many variables and requirements associated with |

||

|

any particular installation, the Allen-Bradley Company cannot assume |

||

|

responsibility or liability for actual use based on the examples and diagrams. |

||

|

No patent liability is assumed by Allen-Bradley Company with respect to use |

||

|

of information, circuits, equipment, or software described in this manual. |

||

|

Reproduction of the contents of this manual, in whole or in part, without |

||

|

written permission of the Allen-Bradley Company is prohibited. |

||

|

Throughout this manual we use notes to make you aware of safety |

||

|

considerations. |

||

|

|

|

|

|

! |

ATTENTION: Identifies information about practices or |

|

|

circumstances that can lead to personal injury or death, property |

||

|

damage, or economic loss. |

||

|

|

|

|

Attentions help you:

•identify a hazard

•avoid the hazard

•recognize the consequences

Important: Identifies information that is especially important for successful application and understanding of the product.

PLC and PLC 5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, SLC 500, Dataliner, and DTAM are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Tandy is a trademark of the Tandy Corporation.

Gateway 2000 is a trademark of Gateway 2000, Inc.

Toshiba is a trademark of Toshiba America, Inc.

Compaq is a registered trademark of Compaq Computer Corporation.

Deskpro is a trademark of Compaq Computer Corporation.

Summary of Changes

Summary of Changes

New Information

The information below summarizes the changes to this manual since the last printing as 1747-NI001 in November, 1993.

To help you find new information and updated information in this release of the manual, we have included change bars as shown to the right of this paragraph.

The table below lists sections that document new features and additional information about existing features, and shows where to find this new information.

For This New Information |

See |

|

|

Updated list of related publications |

Preface |

|

|

High voltage warning |

Chapters 2, 4, and 7 |

|

|

Table of Contents

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

i |

||

New Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

i |

||

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-1 |

||||

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-1 |

||||

How to Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-2 |

||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Related Publications |

|

|

P-3 |

||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Related Publications |

|

|

P-3 |

||||

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-4 |

||||

Allen-Bradley Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-4 |

||||

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-4 |

||||

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

P-4 |

||||

Your Questions or Comments on this Manual . . . . . . . . . . . . . . |

|

|

P-4 |

||||

Selecting Your Hardware Components . . . . . . . . . . . . . . . |

1-1 |

||||||

What Your SLC 500 Controller Can Do for You . . . . . . . . . . . . . . . |

|

1-1 |

|||||

. . . . . . . . . . . . . . . . . . . .Overview of Your Fixed Control System |

|

1-2 |

|||||

Fixed Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-3 |

|||||

Memory Backup for the SLC 500 Fixed Controller . . . . . . . . . . . |

|

1-4 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Configuration Options |

|

1-5 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Input Specifications |

|

1-6 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Output Specifications |

|

1-7 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Relay Contact Ratings |

|

1-8 |

|||||

Selecting the 2-Slot Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-8 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . . .Selecting Discrete I/O Modules |

|

1-8 |

|||||

. . . . . . . . . . . . . . . . . . . . . . . . .Selecting Speciality I/O Modules |

|

1-8 |

|||||

Selecting Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-9 |

|||||

Selecting Operator Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-9 |

|||||

Programming with a Hand-Held Terminal (1747-PT1) . . . . . . . . |

1-9 |

||||||

Programming with Advanced Programming Software (APS) |

|

|

|

|

|

||

on an IBM Compatible Computer . . . . . . . . . . . . . . . . . . . . |

|

1-9 |

|||||

Advanced Programming Software, 1747-PA2E . . . . . . . . . . . |

|

1-10 |

|||||

DH-485 Interface Converter (1747-PIC) . . . . . . . . . . . . . . . |

|

1-10 |

|||||

Monitoring with a Data Table Access Module (1747-DTAM-E) . . |

|

1-10 |

|||||

EEPROM and UVPROM Memory Modules . . . . . . . . . . . . . . . . . . |

|

1-11 |

|||||

Selecting Isolation Transformers . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-12 |

|||||

Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-13 |

|||||

Excessive Line Voltage Variations . . . . . . . . . . . . . . . . . . . . . . |

|

1-13 |

|||||

Excessive Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-13 |

|||||

Selecting Surge Suppressors . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-14 |

|||||

Selecting Contact Protection . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1-16 |

|||||

Transistor Output Transient Pulses . . . . . . . . . . . . . . . . . . . . . |

|

1-17 |

|||||

ii |

Table of Contents |

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

System Installation Recommendations . . . . . . . . . . . . . . . |

2-1 |

|

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-1 |

Spacing Your Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-2 |

Preventing Excessive Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-2 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Grounding Guidelines |

|

2-3 |

Master Control Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-5 |

Emergency-Stop Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-6 |

Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-7 |

Common Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-7 |

Loss of Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-7 |

Input States on Power Down . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-7 |

Other Types of Line Conditions . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-7 |

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2-8 |

High Voltages - SLC 500 Fixed Hardware Style Controller (Series C) (Applies to 1747-L20A, -L30A, -L40A, -L20C, -L30C, and -L40C

controllers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-8 |

Disconnecting Main Power . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-8 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Wiring Safety Circuits |

2-9 |

Distributing Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

Testing the Master Control Relay Circuit . . . . . . . . . . . . . . . . . . |

2-9 |

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

Mounting Your SLC 500 Control System . . . . . . . . . . . . . . |

3-1 |

|

Mounting Fixed Hardware Style Units . . . . . . . . . . . . . . . . . . . . . . |

|

3-1 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 I/O Fixed ControllerÀ |

|

3-2 |

30 and 40 I/O Fixed ControllerÀ . . . . . . . . . . . . . . . . . . . . . . . . |

|

3-3 |

2-Slot Expansion ChassisÀ . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3-4 |

Link Coupler (AIC)À . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3-5 |

Data Table Access Module (DTAM)À . . . . . . . . . . . . . . . . . . . . |

|

3-5 |

Installing Your Hardware Components . . . . . . . . . . . . . . . . |

4-1 |

|

Mounting the 2-Slot Expansion Chassis . . . . . . . . . . . . . . . . . . . . |

|

4-1 |

. . . . . . . . . . . . . . . . . . . . . .Installing I/O and Speciality Modules |

|

4-2 |

Installing Your Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4-4 |

Removing Your Memory Module . . . . . . . . . . . . . . . . . . . . . . . |

|

4-5 |

Using the High-Speed Counter . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4-5 |

High-Speed Counter Operation . . . . . . . . . . . . . . . . . . . . . . . . |

|

4-5 |

. . . . . . . . . . . . . . . . .High-Speed Counter Input Compatibility |

|

4-6 |

Wiring Diagram of a High-Speed Counter Sinking Input Circuit . |

|

4-7 |

Wiring Diagram of a High-Speed Counter Sourcing Input Circuit |

|

4-7 |

Table of Contents |

|

|

iii |

Wiring Your Control System . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-1 |

|

Defining Sinking and Sourcing . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-1 |

|

Contact Output Circuits AC or DC . . . . . . . . . . . . . . . . . . . . |

|

5-2 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . .Solid-State DC I/O Circuits |

|

5-2 |

|

. . . . . . . . . . .Sourcing Device with Sinking Input Module Circuit |

|

5-2 |

|

Sinking Device with Sourcing Input Module Circuit . . . . . . . . . . . |

|

5-3 |

|

Sinking Device with Sourcing Output Module Circuit . . . . . . . . . |

|

5-3 |

|

. . . . . . . . .Sourcing Device with Sinking Output Module Circuit |

|

5-3 |

|

Preparing Your Wiring Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-4 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Features of an I/O Module |

|

5-5 |

|

Recommendations for Wiring I/O Devices . . . . . . . . . . . . . . . . . . . |

|

5-6 |

|

Wiring Your I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-7 |

|

Using Removable Terminal Blocks (RTBs) . . . . . . . . . . . . . . . . . . |

|

5-8 |

|

Removing RTBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-8 |

|

Installing RTBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5-9 |

|

Starting Up Your Control System . . . . . . . . . . . . . . . . . . . . |

|

6-1 |

|

Procedures for Starting Up the Control System . . . . . . . . . . . . . . . |

|

6-1 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1. Inspect Your Installation |

|

6-2 |

|

2. Disconnect Motion-causing Devices . . . . . . . . . . . . . . . . . . . . |

|

6-2 |

|

. . . . . . . . . . . . . . . . . . . . . .3. Initialize and Test Your Processor |

|

6-3 |

|

4. Test Your Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6-4 |

|

Input Troubleshooting Steps . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6-5 |

|

5. Test Your Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6-6 |

|

Output Troubleshooting Steps . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6-7 |

|

6. Enter and Test Your Program . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6-8 |

|

7. Observe Control Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-10 |

||

8. Conduct a Dry Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-11 |

||

Maintaining Your Control System . . . . . . . . . . . . . . . . . . . . |

7-1 |

||

Handling, Storing, and Transporting Battery, |

|

|

|

Catalog Number 1747-BA . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-1 |

|

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-1 |

|

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-1 |

|

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-2 |

|

Installing or Replacing Your SLC 500 Battery . . . . . . . . . . . . . . . . |

|

7-4 |

|

Replacing the Power Supply Fuse . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-5 |

|

. . . . . . . . . . . . . . . . . .Replacing Retainer Clips on an I/O Module |

|

7-6 |

|

Removing Damaged Retainer Clips . . . . . . . . . . . . . . . . . . . . . |

|

7-6 |

|

Installing New Retainer Clips . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7-6 |

|

iv |

Table of Contents |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8-1 |

|

Calling Allen-Bradley for Assistance . . . . . . . . . . . . . . . . . . . . . . |

|

8-1 |

|

Tips for Troubleshooting Your Control System . . . . . . . . . . . . . . . . |

|

8-2 |

|

Removing Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8-2 |

|

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8-3 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Program Alteration |

|

8-3 |

|

Troubleshooting Your Fixed Controller . . . . . . . . . . . . . . . . . . . . . |

|

8-3 |

|

Identifying Fixed Controller Errors . . . . . . . . . . . . . . . . . . . . . . |

|

8-4 |

|

Troubleshooting Your Input Modules . . . . . . . . . . . . . . . . . . . . . . |

|

8-8 |

|

Input Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8-8 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Corrective Action |

|

8-9 |

|

Troubleshooting Your Output Modules . . . . . . . . . . . . . . . . . . . . . |

8-10 |

||

Output Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-10 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Corrective Action |

8-11 |

||

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9-1 |

||

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9-1 |

||

Replacement Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9-2 |

|||

Setting Up the DH-485 Network . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-1 |

DH-485 Network Description . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-1 |

DH-485 Network Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-1 |

DH-485 Token Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-2 |

. . . . . . . . . . . . . . . . . . . . . . . . . . .DH-485 Network Initialization |

|

|

|

A-2 |

Devices that Use the DH-485 Network . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-3 |

1747-AIC Isolated Link Coupler for DH-485 . . . . . . . . . . . . . . . . . |

|

|

|

A-4 |

Example System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-5 |

Important Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-6 |

Hardware Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-6 |

Number of Devices and Length of Communication Cable . . . . |

|

|

|

A-6 |

Planning Cable Routes . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-6 |

Software Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-7 |

Number of Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-7 |

Setting Node Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-8 |

Setting Processor Baud Rate . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-8 |

Maximum Node Address Setting . . . . . . . . . . . . . . . . . . . . . |

|

|

|

A-8 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . .DH-485 Network Installation |

|

|

|

A-9 |

DH-485 Communication Cable and Isolated Link Coupler . . . . . |

|

|

|

A-9 |

Installing the DH-485 Communication Cable . . . . . . . . . . . . . . |

A-10 |

|||

Connecting the Communication Cable to the Isolated Link Coupler |

|

A-11 |

||

Single Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

A-11 |

||

Single Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

A-11 |

||

Multiple Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

A-11 |

||

Grounding and Terminating the DH-485 Network . . . . . . . . . . . |

A-13 |

|||

Powering the Link Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-14 |

|||

Table of Contents |

v |

Installing and Attaching the Link Couplers . . . . . . . . . . . . . . . . .

The 1771-Remote I/O Network . . . . . . . . . . . . . . . . . . . . . .

1771-Remote I/O Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Communication Interface . . . . . . . . . . . . . . . . . . .

RS-232 and SCADA Applications . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Communication Interface Overview . . . . . . . . . . . . . . . . .

SLC 500 Devices that Support RS-232 Communication . . . . . . . .

1770-KF3 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1747-KE Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1746-BAS Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connectors for RS-232 Communication . . . . . . . . . . . . . .

Types of RS-232 Connectors . . . . . . . . . . . . . . . . . . . . . . . . .

DTE Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DCE Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pin Assignments for Wiring Connectors . . . . . . . . . . . . . . . . . .

IBM AT to a Modem (Hardware Handshaking Enabled) . . . . .

IBM AT to a 5/03 Processor, 1770-KF3, 1775-KA, 1773-KA, 5130-RM, or PLC-5 (Hardware Handshaking Disabled) À . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1747-KE to a Modem (Hardware Handshaking Enabled) . . . .

1747-KE to a 5/03 Processor, IBM AT, 1770-KF3, 1775-KA, 1773-KA, 5130-RM, or PLC-5

(Hardware Handshaking Disabled) À . . . . . . . . . . . . . . .

1746-BAS to a Modem (Hardware Handshaking Enabled) . . .

1746-BAS to a 5/03 Processor, IBM AT, 1770-KF3, 1775-KA, 1773-KA, 5130-RM, or PLC-5 (Hardware Handshaking Disabled)À . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1770-KF3 to a Modem (Hardware Handshaking Enabled) . . .

2760-RB to a Modem (Hardware Handshaking Enabled) . . . .

2760-RB to a 5/03 Processor, IBM AT, 1770-KF3, 1775-KA, 1773-KA, 5130-RM, or PLC-5

(Hardware Handshaking Disabled) À . . . . . . . . . . . . . . .

1771-KGM to a Modem (Hardware Handshaking Enabled) . .

1771-KGM to a 5/03 Processor, IBM AT, 1770-KF3, 1775-KA, 1773-KA, 5130-RM, or PLC-5

(Hardware Handshaking Disabled) À . . . . . . . . . . . . . . .

1775-KA to a Modem (Hardware Handshaking Enabled) . . . .

1775-KA to a 5/03 Processor, IBM AT, 1770-KF3, 1773-KA, 5130-RM, or PLC-5 (Hardware Handshaking Disabled) À

PLC-5 (Channel 0) to a Modem

(Hardware Handshaking Enabled) . . . . . . . . . . . . . . . . .

PLC-5 (Channel 0) to a 5/03 Processor, IBM AT, 1770-KF3, 1773-KA, 5130-RM, PLC-5, 1747-KE, or 1746-BAS (Hardware Handshaking Disabled) À . . . . . . . . . . . . . . .

5130-RM to a Modem (Hardware Handshaking Enabled) . . .

A-16

B-1

B-1

C-1

C-1 C-1 C-2 C-2 C-2 C-2 C-3 C-3 C-4 C-4 C-5 C-6

C-6 C-7

C-7 C-8

C-8 C-8 C-9

C-9 C-10

C-10 C-11

C-11

C-12

C-12 C-13

vi |

Table of Contents |

5130-RM to a 5/03 Processor, IBM AT, 1770-KF3, 1773-KA, |

|

5130-RM, PLC-5, 1747-KE, or 1746-BAS |

|

(Hardware Handshaking Disabled) À . . . . . . . . . . . . . . . |

C-13 |

Calculating Heat Dissipation for the SLC 500 |

|

|

|

|

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

D-1 |

Definition of Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

D-1 |

Module Heat Dissipation: Calculated Watts vs. Maximum Watts . . . |

|

|

|

D-1 |

. . . . . . . . . .Use this Table to Calculate the Power Supply Loading |

|

|

|

D-2 |

. . . . . . . . . . . . . . . . . . . . .Example Heat Dissipation Calculation |

|

|

|

D-4 |

Example Worksheet for Calculating Heat Dissipation . . . . . . . . . |

|

|

|

D-4 |

. . . . . . . . . . . . . . . . .Worksheet for Calculating Heat Dissipation |

|

|

|

D-5 |

Wiring and Circuit Diagrams and Voltage Ranges |

|

|

|

|

for Your Fixed Controller . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-1 |

Wiring Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-1 |

Wiring and Circuit Diagrams and Voltage Range Locations . . . . . . |

|

|

|

E-2 |

Catalog Number 1747-L20A (12) 120 VAC Inputs & (8) |

|

|

|

|

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-4 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-5 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

|

|

|

E-5 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-5 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-5 |

Catalog Number 1747-L20B (12) 120 VAC Inputs & (8) |

|

|

|

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-6 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-7 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

|

|

|

E-7 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-7 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-7 |

Catalog Number 1747-L20C (12) 24 VDC Sinking Inputs, High-Speed |

|

|

|

|

Counter Input & (8) Relay Outputs . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-8 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

E-9 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

|

|

|

E-9 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

|

|

|

E-9 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-10 |

|||

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-10 |

|||

Catalog Number 1747-L20D (12) 24 VDC Sinking Inputs, High-Speed |

|

|

|

|

Counter Input & (8) Triac Outputs . . . . . . . . . . . . . . . . . . . . . . |

|

E-11 |

||

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-12 |

|||

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-12 |

|||

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-12 |

|||

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-13 |

|||

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-13 |

|||

Table of Contents |

vii |

Catalog Number 1747-L20E (12) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (8) Transistor Sourcing Outputs . . . . . . . . . . . |

E-14 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-15 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-15 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-15 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-16 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-16 |

Catalog Number 1747-L20F (12) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (8) Relay Outputs . . . . . . . . . . . . . . . . . . . . . |

E-17 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-18 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-18 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-18 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-19 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-19 |

Catalog Number 1747-L20G (12) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (8) Transistor Sourcing Outputs . . . . . . . . . . . |

E-20 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-21 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-21 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-21 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-22 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-22 |

Catalog Number 1747-L20L (12) 24 VDC Sourcing Inputs, High-Speed |

|

Counter Input & (8) Transistor Sinking Outputs . . . . . . . . . . . . |

E-23 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-24 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-24 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-24 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-25 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-25 |

Catalog Number 1747-L20N (12) 24 VDC Sourcing Inputs, High-Speed |

|

Counter Input & (8) Transistor Sinking Outputs . . . . . . . . . . . . |

E-26 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-27 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-27 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-27 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-28 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-28 |

Catalog Number 1747-L20P (12) 240 VAC Inputs & (8) |

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-29 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-30 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-30 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-30 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-30 |

Catalog Number 1747-L20R (12) 240 VAC Inputs & (8) |

|

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-31 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-32 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-32 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-32 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-32 |

viii |

Table of Contents |

Catalog Number 1747-L30A (18) 120 VAC Inputs & (12) |

|

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-33 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-34 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-34 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-34 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-34 |

Catalog Number 1747-L30B (18) 120 Vac Inputs & (12) |

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-35 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-36 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-36 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-36 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-36 |

Catalog Number 1747-L30C (18) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (12) Relay Outputs . . . . . . . . . . . . . . . . . . . . |

E-37 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-38 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-38 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-38 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-39 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-39 |

Catalog Number 1747-L30D (18) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (12) Triac Outputs . . . . . . . . . . . . . . . . . . . . . |

E-40 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-41 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-41 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-41 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-42 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-42 |

Catalog Number 1747-L30L (18) 24 VDC Sourcing Inputs, High-Speed |

|

Counter Input & (12) Transistor Sinking Outputs . . . . . . . . . . . |

E-43 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-44 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-44 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-44 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-45 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-45 |

Catalog Number 1747-L30P (18) 240 VAC Inputs & (12) |

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-46 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-47 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-47 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-47 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-47 |

Catalog Number 1747-L40A (24) 120 VAC Inputs & (16) |

|

Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-48 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-49 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-49 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-49 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-49 |

Table of Contents |

ix |

Catalog Number 1747-L40B (24) 120 VAC Inputs & (16) |

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-50 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-51 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-51 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-51 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-51 |

Catalog Number 1747-L40C (24) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (16) Relay Outputs . . . . . . . . . . . . . . . . . . . . |

E-52 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-53 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-53 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-53 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-54 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-54 |

Catalog Number 1747-L40E (24) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (16) Transistor Sourcing Outputs . . . . . . . . . . |

E-55 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-56 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-56 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-56 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-57 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-57 |

Catalog Number 1747-L40F (24) 24 VDC Sinking Inputs, High-Speed |

|

Counter Input & (16) Relay Outputs . . . . . . . . . . . . . . . . . . . . |

E-58 |

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-58 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-59 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-59 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-59 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-60 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-60 |

Catalog Number 1747-L40L (24) 24 VDC Sourcing Inputs, High-Speed |

|

Counter Input & (16) Transistor Sinking Outputs . . . . . . . . . . . |

E-61 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-62 |

. . . . . . . . . . . .On/Off State Voltage Ranges - Input 0 (HSC) |

E-62 |

. . . . . . . . . . .On/Off State Voltage Ranges - All Other Inputs |

E-62 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-63 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-63 |

Catalog Number 1747-L40P (24) 240 VAC Inputs & (16) |

|

Triac Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-64 |

Input Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-65 |

. . . . . . . . . . . . . . . . . . . . . . . .On/Off State Voltage Ranges |

E-65 |

Output Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-65 |

Operating Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-65 |

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

G-1 |

Preface

Preface

Read this preface first. It provides an overview of the entire manual and will acquaint you with the information that is provided throughout these pages. In this preface, you will learn about:

•who should use this manual

•how to use this manual

•related publications

•conventions used in this manual

•Allen±Bradley support

Who Should Use this Manual The tasks and procedures in this manual require you to have some knowledge of programmable controller installation and electrical wiring. We also assume that you have a ªworkingº knowledge of SLC products. If you do not have this knowledge base, obtain the proper training before attempting any of the tasks and/or procedures detailed in this manual.

P±1

Preface

How to Use this Manual |

As much as possible, we organized this manual to explain, in a task±by±task |

|

|

manner, how to install and operate (preliminary start±up operations) the SLC |

|

|

500 fixed programmable controller. This manual also provides some system |

|

|

design information. |

|

|

Before using this manual, read over the table below and familiarize yourself |

|

|

with the general content of the chapters and appendixes. If you already have |

|

|

a topic in mind that you want to find specific information about, turn to the |

|

|

index at the back of the manual. |

|

|

|

|

|

If You Want |

See |

|

|

|

|

An overview of the manual |

The Preface |

|

|

|

|

Information on how to select certain components |

Chapter 1 Selecting Your Hardware Components |

|

for your SLC 500 control system |

|

|

|

|

|

|

|

|

A guide on how to prepare for the installation of |

Chapter 2 System Installation Recommendations |

|

your control system |

|

|

|

|

|

|

|

|

Mounting dimensions of your fixed controller, |

Chapter 3 Mounting Your SLC 500 Control System |

|

DTAM , and/or 1747-AIC |

|

|

|

|

|

Procedures on how to install your hardware |

Chapter 4 Installing Your Hardware Components |

|

components |

|

|

|

|

|

|

|

|

Information on how to wire the components of |

Chapter 5 Wiring Your Control System |

|

your SLC 500 control system |

|

|

|

|

|

|

|

|

A guide on how to start up your control system |

Chapter 6 Starting Up Your Control System |

|

|

|

|

Information on how to maintain your control |

Chapter 7 Maintaining Your Control System |

|

system |

|

|

|

|

|

|

|

|

To identify error messages generated by your |

Chapter 8 Troubleshooting |

|

control system |

|

|

|

|

|

|

|

|

To replace parts of your SLC 500 control system |

Chapter 9 Replacement Parts |

|

or purchase other SLC components |

|

|

|

|

|

|

|

|

Information on setting up the DH-485 network |

Appendix A Setting Up the DH-485 Network |

|

|

|

|

Information on the 1771-Remote I/O network |

Appendix B The 1771-Remote I/O Network |

|

|

|

|

Information on configuring the RS-232 network |

Appendix C RS-232 Communication Interface |

|

|

|

|

Information on how to calculate the heat |

Appendix D Calculating Heat Dissipation for the |

|

dissipation of your controller |

SLC 500 Control System |

|

|

|

|

Wiring and circuit diagrams and voltage ranges |

Appendix E Wiring and Circuit Diagrams and |

|

Voltage Ranges for Your Fixed Controller |

|

|

|

|

|

|

|

|

Definitions of terms used in this manual |

The Glossary |

|

|

|

P±2

Related Publications

Preface

The table below provides a listing of publications that contain important information about Allen±Bradley Small Logic Controllers and their installation and application. You may want to reference them while you are installing the SLC 500 controller. (To obtain a copy of one of these publications, contact your local Allen±Bradley office or distributor.)

For |

Read this Document |

Document |

|

Number |

|||

|

|

||

|

|

|

|

An overview of the SLC 500 family of products |

SLC 500 System Overview |

1747-2.30 |

|

|

|

|

|

A description on how to install and use your Modular SLC 500 |

Installation & Operation Manual for Modular Hardware |

1747-6.2 |

|

programmable controller |

Style Programmable Controllers |

||

|

|||

|

|

|

|

A procedural manual for technical personnel who use APS to develop |

Advanced Programming Software (APS) User Manual |

9399-APSUM |

|

control applications |

|||

|

|

||

|

|

|

|

A reference manual that contains status file data, instruction set, and |

SLC 500 and MicroLogix 1000 Instruction Set |

1747-6.15 |

|

troubleshooting information about APS |

Reference Manual |

||

|

|||

|

|

|

|

An introduction to APS for first-time users, containing basic concepts but |

|

|

|

focusing on simple tasks and exercises, and allowing the reader to begin |

APS Quick Start for New Users |

9399-APSQS |

|

programming in the shortest time possible |

|

|

|

|

|

|

|

A procedural and reference manual for technical personnel who use the |

|

|

|

APS import/export utility to convert APS files to ASCII and conversely |

APS Import/Export User Manual |

9399-APSIE |

|

ASCII to APS files |

|

|

|

|

|

|

|

A procedural and reference manual for technical personnel who use an |

Allen-Bradley Hand-Held Terminal User Manual |

1747-NP002 |

|

HHT to develop control applications |

|||

|

|

||

|

|

|

|

An introduction to HHT for first-time users, containing basic concepts but |

|

|

|

focusing on simple tasks and exercises, and allowing the reader to begin |

Getting Started Guide for HHT |

1747-NM009 |

|

programming in the shortest time possible |

|

|

|

|

|

|

|

In-depth information on grounding and wiring Allen-Bradley |

Allen-Bradley Programmable Controller Grounding and |

1770-4.1 |

|

programmable controllers |

Wiring Guidelines |

||

|

|||

|

|

|

|

A description on how to install a PLC-5r system |

PLC-5 Family Programmable Controllers Hardware |

1785-6.6.1 |

|

Installation Manual |

|||

|

|

||

|

|

|

|

A description of important differences between solid-state programmable |

Application Considerations for Solid-State Controls |

SGI-1.1 |

|

controller products and hard-wired electromechanical devices |

|||

|

|

||

|

|

|

|

|

|

Published by the |

|

|

|

National Fire |

|

An article on wire sizes and types for grounding electrical equipment |

National Electrical Code |

Protection |

|

|

|

Association of |

|

|

|

Boston, MA. |

|

|

|

|

|

A complete listing of current Automation Group documentation, including |

|

|

|

ordering instructions. Also indicates whether the documents are |

Allen-Bradley Publication Index |

SD499 |

|

available on CD-ROM or in multi-languages. |

|

|

|

|

|

|

|

A glossary of industrial automation terms and abbreviations |

Allen-Bradley Industrial Automation Glossary |

AG-7.1 |

|

|

|

|

P±3

Preface

Conventions Used in this Manual

The following conventions are used throughout this manual:

•Bulleted lists such as this one provide information, not procedural steps.

•Numbered lists provide sequential steps or hierarchical information.

•Italic type is used for emphasis.

•Dimensions are in millimeters. (Dimensions in parentheses are in inches.)

•Text in this font indicates words or phrases you should type.

Allen-Bradley Support

Allen±Bradley offers support services worldwide, with over 75 Sales/Support offices, 512 authorized Distributors and 260 authorized Systems Integrators located throughout the United States alone, plus Allen±Bradley representatives in every major country in the world.

Local Product Support

Contact your local Allen±Bradley representative for:

•sales and order support

•product technical training

•warranty support

•support service agreements

Technical Product Assistance

If you need to contact Allen±Bradley for technical assistance, please review the information in the Troubleshooting chapter first. Then call your local Allen±Bradley representative.

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the enclosed Publication Problem Report.

If you have any suggestions for how this manual could be made more useful to you, please contact us at the address below:

Allen±Bradley Company, Inc.

Automation Group

Technical Communication, Dept. 602V, T122

P.O. Box 2086

Milwaukee, WI 53201±2086

P±4

Chapter 1

Selecting Your Hardware Components

What Your SLC 500 Controller Can Do for You

This chapter provides general information on what your SLC 500 controller can do for you and an overview of the fixed control system. It also explains how to select:

•2±slot chassis

•discrete I/O modules

•specialty I/O modules

•enclosures

•operator interfaces

•memory modules

•isolation transformers

•suppressors

•output contact protection

There is also a section on special considerations for controller installations.

This chapter does not provide you with all the information that you need to select a complete SLC 500 control system. To do this, we recommend that you use the latest version of the system overview, SLC 500 Family of Small Programmable Controllers, Publication Number 1747±2.30.

The SLC 500 programmable controller has features that previously could only be found in large programmable controllers. It has the flexibility and power of a large controller with the size and simplicity of a small controller. The SLC 500 controller offers you more control options than any other programmable controller in its class.

These programmable controllers make up a technologically advanced control system having inherent flexibility and advantages characteristic of other programmable controllers, but with one important difference Ð simplicity!

1±1

Chapter 1

Selecting Your Hardware Components

Overview of Your Fixed

Control System

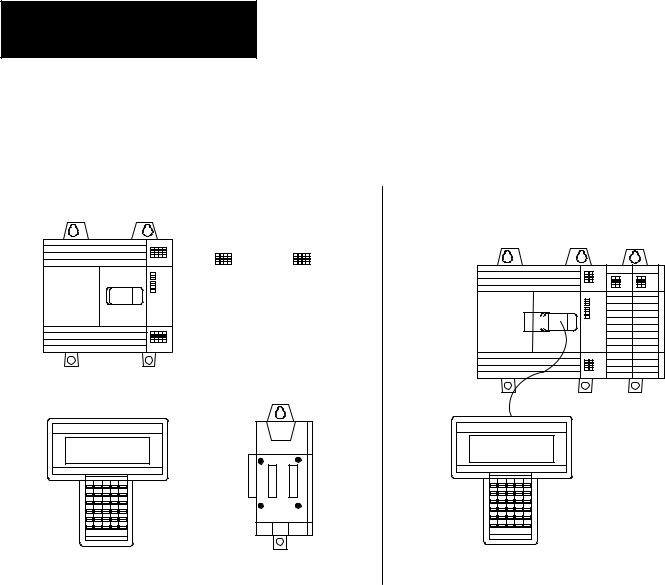

The basic fixed controller consists of a processor with 1,024 (1K) instruction capacity, a power supply, and a fixed number of I/O contained in a single package. The figure below shows typical hardware components for a fixed controller.

Fixed Hardware Components |

|

Fixed Controller with 2-slot Expansion Chassis |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Module |

Output Module |

Fixed Hardware Controller

Operator Interface |

2-Slot Expansion Chassis |

|

|

|

for I/O Modules |

1±2

Fixed Controller

Specifications

Chapter 1

Selecting Your Hardware Components

This section provides the specifications for the SLC 500 Fixed Controller.

Description |

|

Specification |

||

|

|

|||

Memory Type |

Capacitor-backed RAM memory. Battery back-up optional. |

|||

|

|

|

||

Memory Backup Options |

EEPROM or UVPROM |

|

||

|

|

|

||

Program Memory |

1K Instruction Capacity |

|

||

|

|

|

||

Capacitor Memory Back-up Time |

Refer to curve on page 1-4. |

|

||

|

|

|

|

|

Battery Life |

5 years |

|

|

|

|

|

|

||

Typical Scan Time |

8 milliseconds/1K |

|

||

Bit Execution (XIC) |

4 microseconds |

|

||

|

|

|

|

|

Program Scan Hold-up Time after |

20 milliseconds to 700 milliseconds (dependent on loading) |

|||

Loss of Power |

||||

|

|

|

||

|

|

|

|

|

Power Supply Operating Voltage |

AC units: |

85-265 VAC |

47-63 Hz |

|

DC units: |

21.6-26.4 VDC (24 VDC ± 10%) |

|||

|

||||

|

|

|

|

|

Power Supply Fuse Protection |

AC units: |

120/240 VAC |

1.25A |

|

DC units: |

24 VDC |

1.6A |

||

|

||||

|

|

|

||

Power Supply Inrush Rating |

30 Amperes maximum |

|

||

|

|

|

|

|

Maximum Power Requirement |

50 VA |

|

|

|

24 VDC User Power Output Current |

200mA |

|

|

|

24 VDC User Power Output Voltage |

20.4 - 27.6 VDC (24 VDC ± 15 %) |

|||

Wire Size |

#14 AWG Max. |

|

||

|

|

|

||

I/O Electrical-Optical Isolation |

1500 VAC at 1 minute |

|

||

|

|

|

|

|

1747-AIC Link Coupler |

1500 VDC |

|

|

|

Electrical-Optical Isolation |

|

|

||

|

|

|

||

|

|

|||

LED Indicators |

POWER, PC RUN, CPU FAULT, FORCED I/O, and |

|||

BATTERY LOW |

|

|||

|

|

|||

|

|

|

||

Noise Immunity |

NEMA Standard ICS 2-230 |

|

||

|

|

|

||

Ambient Temperature Rating |

Operating: |

0°C to +60°C (+32°F to +140°F) |

||

Storage: |

40°C to +85°C (-40°F to +185°F) |

|||

|

||||

|

|

|

||

Humidity |

5 to 95% without condensation |

|

||

|

|

|||

|

Displacement: .015 inch, peak-to-peak @ 5-57 Hz |

|||

|

|

|||

Vibration |

Acceleration: 2.5 Gs @ 57-2000 Hz |

|||

|

|

|

||

|

Duration: 1 hr per axis (x, y, z) |

|

||

|

|

|

|

|

Certification |

UL listed/ |

|

|

|

CSA approved |

|

|||

|

|

|||

|

|

|

|

|

The scan times are typical for a 1K ladder logic program consisting of simple ladder logic and communication servicing. Actual scan times depend on your program size, instructions used, and the DH-485 communication.

|

This specification does not include input and output values. (See page 1-6.) |

|

This applies only to fixed controllers that have AC line power and DC input circuits. |

1±3

Chapter 1

Selecting Your Hardware Components

Memory Backup for the SLC 500 Fixed Controller

The curve below illustrates the ability of the memory back±up capacitor to maintain the contents of the RAM in a fixed controller. To back up the memory for a longer period of time, a lithium battery, Catalog Number 1747±BA, is required.

|

30 |

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

Capacitor Memory Back-up Time |

|

||

|

20 |

|

|

|

VS |

|

|

|

|

|

|

|

Temperature |

|

|

|

|

|

|

|

|

|

|

|

|

|

Time |

|

|

|

|

|

|

|

|

(Days) |

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

|

(77°) |

(86°) |

(95°) |

(104°) |

(113°) |

(122°) |

(131°) |

(140°) |

|

|

|

|

|

Temperature °C (°F) |

|

|

|

1±4

Chapter 1

Selecting Your Hardware Components

Configuration Options

The following table provides configuration options for 20, 30, or 40 I/O points.

Catalog |

Line Power |

|

|

I/O Configuration |

High-Speed |

User Power |

||||

|

|

|

|

|

|

|||||

Number |

|

|

Input |

|

|

Output |

Counter |

|||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

1747-L20A |

|

(12) |

120 Volts AC |

(8) |

AC/DC Relay |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L30A |

|

(18) |

120 Volts AC |

(12) |

AC/DC Relay |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L40A |

|

(24) |

120 Volts AC |

(16) |

AC/DC Relay |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L20B |

|

(12) |

120 Volts AC |

(8) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L30B |

|

(18) |

120 Volts AC |

(12) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L40B |

|

(24) |

120 Volts AC |

(16) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|

||

1747-L20C |

|

(12) |

24 |

Volts DC Sink |

(8) |

AC/DC Relay |

Yes |

24V-200mA |

||

|

|

|

|

|

|

|

|

|

||

1747-L30C |

|

(18) |

24 |

Volts DC Sink |

(12) |

AC/DC Relay |

Yes |

24V-200mA |

||

|

|

|

|

|

|

|

|

|

||

1747-L40C |

|

(24) |

24 |

Volts DC Sink |

(16) |

AC/DC Relay |

Yes |

24V-200mA |

||

|

|

|

|

|

|

|

|

|

||

1747-L20D |

|

(12) |

24 |

Volts DC Sink |

(8) |

AC Triac |

Yes |

24V-200mA |

||

|

|

|

|

|

|

|

|

|

||

1747-L30D |

|

(18) |

24 |

Volts DC Sink |

(12) |

AC Triac |

Yes |

24V-200mA |

||

|

120/240 VAC |

|

|

|

|

|

|

|

||

1747-L20E |

(12) |

24 |

Volts DC Sink |

(8) |

DC Transistor |

Yes |

24V-200mA |

|||

|

Source |

|||||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

1747-L40E |

|

(24) |

24 |

Volts DC Sink |

(16) |

DC Transistor |

Yes |

24V-200mA |

||

|

Source |

|||||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

1747-L20L |

|

(12) |

24 |

Volts DC |

(8) |

DC Transistor |

Yes |

24V-200mA |

||

|

Source |

|

Sink |

|

||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

1747-L30L |

|

(18) |

24 |

Volts DC |

(12) |

DC Transistor |

Yes |

24V-200mA |

||

|

Source |

|

Sink |

|

||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

1747-L40L |

|

(24) |

24 |

Volts DC |

(16) |

DC Transistor |

Yes |

24V-200mA |

||

|

Source |

|

Sink |

|

||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

1747-L20R |

|

(12) |

240 Volts AC |

(8) |

AC/DC Relay |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L20P |

|

(12) |

240 Volts AC |

(8) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L30P |

|

(18) |

240 Volts AC |

(12) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|||

1747-L40P |

|

(24) |

240 Volts AC |

(16) |

AC Triac |

No |

NA |

|||

|

|

|

|

|

|

|

|

|

||

1747-L20F |

|

(12) |

24 |

Volts DC Sink |

(8) |

AC/DC Relay |

Yes |

NA |

||

|

|

|

|

|

|

|

|

|

||

1747-L40F |

|

(24) |

24 |

Volts DC Sink |

(16) |

AC/DC Relay |

Yes |

NA |

||

|

24 VDC± |

|

|

|

|

|

|

|

|

|

1747-L20G |

(12) |

24 |

Volts DC Sink |

(8) |

DC Transistor |

Yes |

NA |

|||

10% |

||||||||||

Source |

||||||||||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

1747-L20N |

|

(12) |

24 |

Volts DC |

(8) |

DC Transistor |

Yes |

NA |

||

|

Source |

|

Sink |

|

||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

1±5

Chapter 1

Selecting Your Hardware Components

Input Specifications

The following table details the input specifications for SLC 500 Fixed I/O units. See the glossary for a definition of specifications.

Inputs |

|

Specifications |

|

|

|

|

|

|

On-State Voltage |

|

85-132 VAC |

|

|

|

|

|

Frequency |

|

47-63 Hz |

|

|

|

|

|

Off-State Voltage |

|

30 VAC (maximum) |

|

|

|

|

120 VAC |

Inrush Current |

|

0.8A peak |

|

|

|

|

|

Nominal Input Current |

|

12mA at 120 VAC |

|

|

|

|

|

Turn-On Time |

|

35 milliseconds (maximum) |

|

|

|

|

|

Turn-Off Time |

|

45 milliseconds (maximum) |

|

|

|

|

|

Maximum Off-State Current |

|

2mA |

|

|

|

|

|

On-State Voltage |

|

170-265 VAC |

|

|

|

|

|

Frequency |

|

47-63 Hz |

|

|

|

|

|

Off-State Voltage |

|

50 VAC (maximum) |

|

|

|

|

240 VAC |

Inrush Current |

|

1.6A peak |

|

|

|

|

|

Nominal Input Current |

|

12mA at 240 VAC |

|

|

|

|

|

Turn-On Time |

|

35 milliseconds (maximum) |

|

|

|

|

|

Turn-Off Time |

|

45 milliseconds (maximum) |

|

|

|

|

|

Maximum Off-State Current |

|

2mA |

|

|

|

|

|

On-State Voltage |

|

10-30 VDC |

|

|

|

|

|

Off-State Voltage |

|

4 VDC maximum for input 0 (HSC) |

|

|

5 VDC for all others |

|

|

|

|

|

|

|

|

|

|

Nominal Input Current |

|

20mA at 24 VDC (for input 0 only) |

DC Sink & Source |

|

8mA at 24 VDC (all others inputs) |

|

|

|

||

|

|

|

|

|

Turn-On Time |

|

8 milliseconds (maximum) |

|

|

|

|

|

Turn-Off Time |

|

8 milliseconds (maximum) |

|

|

|

|

|

Maximum Off-State Current |

|

1mA |

|

|

|

|

1±6

Chapter 1

Selecting Your Hardware Components

Output Specifications

The following table details the output specifications for SLC 500 Fixed I/O Units.

Outputs |

Specifications |

||

|

|

|

|

|

Output Voltage |

85-265 VAC |

|

|

|

|

|

|

Continuous Current (per output) |

0.5 Amp at +30°C |

|

|

0.25 Amp at +60°C (maximum) |

||

|

|

||

|

|

|

|

|

Minimum Load Current |

10mA |

|

|

|

|

|

Triac |

Turn-On Time |

0.1 milliseconds (maximum) |

|

|

|

||

|

Turn-Off Time |

10 milliseconds (maximum) |

|

|

|

|

|

|

Maximum Off-State Leakage Current |

2mA |

|

|

|

|

|

|

Maximum On-State Voltage Drop |

1.5V @ 0.5 Amps |

|

|

|

|

|

|

Maximum Surge Current |

10 Amps for 25 milliseconds |

|

|

Output Voltage |

10-50 VDC |

|

|

|

|

|

|

Continuous Current (per output) |

0.5 Amp at +30°C |

|

|

0.25 Amp at +60°C (maximum) |

||

|

|

||

|

|

|

|

|

Minimum Load Current |

1mA |

|

Transistor Sink & |

|

|

|

Turn-On Time |

0.1 millisecond (maximum) |

||

Source |

|

|

|

Turn-Off Time |

1 millisecond (maximum) |

||

|

|||

|

|

|

|

|

Maximum Off-State Leakage Current |

1mA |

|

|

|

|

|

|

Maximum On-State Voltage Drop |

1.5V @ 0.5 Amps |

|

|

|

|

|

|

Maximum Surge Current |

3.0 Amps for 25 milliseconds |

|

|

Output Voltage Range |

5-265 VAC, 5-125 VDC |

|

|

|

|

|

|

Continuous Current (per output) |

2.5 Amps (maximum) |

|

|

|

|

|

|

Continuous Current (per group) |

8 Amps (maximum) |

|

Relay |

Maximum Load (per chassis) |

1440 VA |

|

|

|

||

Turn-On Time |

10 milliseconds (maximum) |

||

|

|||

|

|

|

|

|

Turn-Off Time |

10 milliseconds (maximum) |

|

|

|

|

|

|

Maximum Off-State Leakage Current |

0mA |

|

|

|

|

|

|

Minimum Load Current at 5 VDC |

10mA |

|

|

|

|

|

Repeatability is once every 1 second at +30°C. Repeatability is once every 2 seconds at +60°C.

Refer to the wiring diagrams for output groupings on the fixed I/O chassis.

Surge suppression across the output device is recommended to protect relay contacts.

1±7

Chapter 1

Selecting Your Hardware Components

Relay Contact Ratings

Maximum |

|

|

Amperes |

Amperes |

Voltamperes |

||||

|

Volts |

|

Make |

|

Break |

Continuous |

Make |

|

Break |

|

|

|

|

|

|

|

|

|

|

240 |

VAC |

7.5A |

|

|

0.75A |

|

|

|

|

120 |

VAC |

15A |

|

|

1.5A |

2.5A |

1800 VA |

|

180 VA |

|

|

|

|

|

|

|

|

|

|

125 |

VDC |

|

|

0.22A |

1.0A |

|

28 VA |

||

|

|

|

|

|

|

|

|||

24 VDC |

|

|

1.2A |

2.0A |

|

28 VA |

|||

|

|

|

|

|

|

|

|

|

|

To calculate make and break ratings for other load voltages, divide the voltampere rating by the load voltage; for example:

28 VA/48 VDC = 0.583 A

Selecting the 2-Slot Chassis For the 20, 30, and 40 I/O fixed controllers, an optional 2±slot expansion chassis lets you add two additional I/O modules providing even more versatility. The power supply provides backplane power for the modules in the optional expansion chassis.

Refer to chapter 3 for chassis dimensions and chapter 4 for mounting directions.

Selecting Discrete I/O

Modules

Selecting Speciality I/O

Modules

There are three types of I/O modules: input, output, and combination I/O. They are available in a wide variety of densities including 4, 8, 16, and 32 point and can interface to AC, DC, and TTL voltage levels. Output modules are available with solid±state AC, solid±state DC, and relay contact type outputs.

For a complete, up±to±date listing of discrete I/O modules and their specifications, contact your Allen±Bradley sales office for the latest product data entitled Discrete Input and Output Modules, Publication Number 1746±2.35.

Refer to chapter 4 for installation directions.

The SLC 500 family offers specialty I/O modules that enhance your control system. These modules range in function from analog interface to motion control, from communication to high±speed counting.

For a complete, up±to±date listing of specialty I/O modules and their specifications, contact your Allen±Bradley sales office for the latest System Overview entitled SLC 500 Family of Small Programmable Controllers,

Publication Number 1747±2.30, or for a related product data.

Refer to chapter 4 for installation directions.

1±8

Selecting Enclosures

Chapter 1

Selecting Your Hardware Components