Rockwell Automation 1734-AENT User Manual

POINT I/O EtherNet/IP Adapter Module

Catalog Number 1734-AENT

User Manual

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell Automation sales office or online at http://literature.rockwellautomation.com) describes some important differences between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

ATTENTION

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous temperatures.

Allen-Bradley, Rockwell Automation, POINT I/O, RSLinx, RSLogix 5000 and TechConnect are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

Preface

What This Preface Contains |

This preface describes how to use this manual. See the table for a list of where |

||

|

to find specific information within this chapter. |

|

|

|

|

|

|

|

Topic |

Page |

|

|

|

|

|

|

Who Should Use This Manual |

iii |

|

|

|

|

|

|

Common Techniques Used in This Manual |

iii |

|

|

|

|

|

|

How to Use This Manual |

iv |

|

|

|

|

|

|

About the Example Applications |

iv |

|

|

|

|

|

|

System Components |

v |

|

|

|

|

|

|

Where to Find More Information |

vi |

|

|

|

|

|

|

Terminology |

vii |

|

|

|

|

|

Who Should Use This

Manual

This manual is intended for control engineers and technicians who are installing, configuring, and maintaining an EtherNet/IP control system that communicates with POINT I/O modules through a 1734-AENT adapter. We assume you have a good understanding of Ethernet networks and the TCP/IP protocol.

|

|

|

You must use series C POINT I/O modules with the 1734-AENT |

|

ATTENTION |

||||

adapter. Series A or B POINT I/O modules will not work with |

||||

|

|

|

||

|

|

|

||

|

|

|

this adapter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Common Techniques Used

in This Manual

We use the following conventions throughout this manual:

•Numbered lists provide sequential steps.

•Bulleted lists provide information, not procedural steps.

The screen captures shown in this manual are pictures of the software’s actual screens.

|

This symbol identifies helpful tips. |

|

TIP |

||

|

||

|

|

Publication 1734-UM011D-EN-P - January 2011

iv Preface

How to Use This Manual |

This manual contains an overview of the 1734-AENT adapter. It describes |

|

how to install and configure the adapter and provides examples showing how |

|

to use the adapter to communicate with POINT I/O modules over an |

|

EtherNet/IP network. |

About the Example Applications

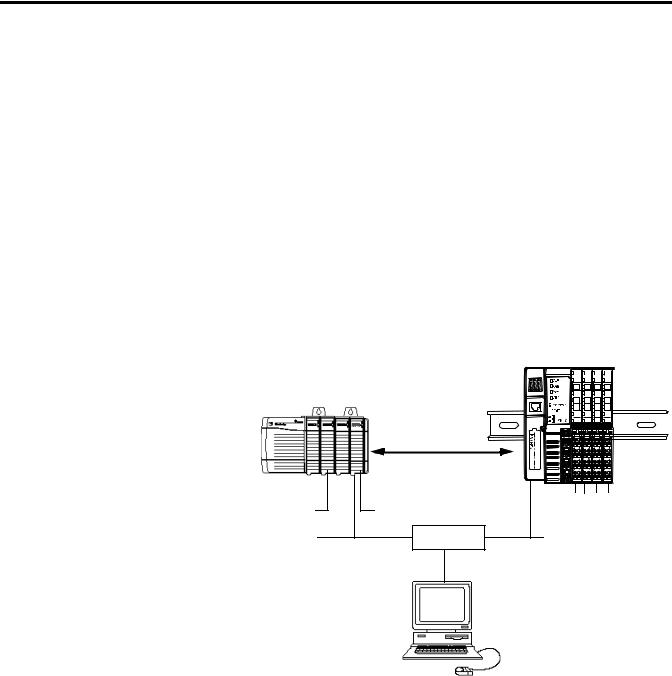

This manual presents two example applications that demonstrate the procedures for configuring and communicating with POINT I/O modules using the 1734-AENT adapter. We intend the example applications as building blocks to help you get your own system up and running. We recommend that you set up and run the example applications and use them as guides.

Here is the type of system you’ll be setting up.

|

|

|

1734-AENT |

|

|

|

|

|

10.88.70.2 |

|

POINT I/O |

|

|

|

|

|

|

Slot |

0 |

1 2 |

3 |

|

|

Local |

|

|

Data |

|

|

chassis |

|

|

|

|

|

|

|

|

|

|

|

Logix5555 |

|

1756-ENBT |

Slot 0 1 2 |

3 4 |

|

|

10.88.70.4 (slot 3) |

|

|

||

controller (slot 1) |

|

|

|||

Switch |

|

|

|||

|

|

|

|

|

|

|

|

|

10.88.70.26 |

|

|

|

|

|

Programming |

|

|

|

|

|

terminal |

|

|

|

|

|

|

|

31393-M |

Publication 1734-UM011D-EN-P - May 2011

Preface v

System Components

We used the following components for the example applications. You need the same or similar components to set up your own control system using POINT I/O modules on an EtherNet/IP network.

Quantity |

Product Name |

Catalog Number |

|

|

|

|

Hardware |

|

|

|

|

1 |

POINT I/O EtherNet/IP adapter |

1734-AENT |

|

|

|

1 |

POINT I/O 24V DC sink output |

1734-OV4E/C |

|

module |

|

|

|

|

1 |

POINT I/O relay output module |

1734-OW2/C |

|

|

|

1 |

DIN rail |

199-DR1 or equivalent |

|

|

|

1 |

ControlLogix chassis |

1756-A4 (or 1756-A7, |

|

|

1756-A13,1756-A17) |

|

|

|

1 |

ControlLogix power supply |

1756-PA72 (or 1756-PB72) |

|

|

|

1 |

Logix5555 controller |

1756-L55 |

|

|

|

1 |

ControlLogix EtherNet/IP bridge |

1756-ENBT |

|

module |

|

|

|

|

1 |

Personal computer that supports |

Any appropriate model running Windows |

|

RSLogix 5000 software |

NT 4.0, Service Pack 6A or higher |

|

|

|

1 |

Ethernet switch |

Refer to manufacturer’s specifications |

|

|

|

1 |

24V DC power supply |

1734-EP24DC |

|

|

|

|

Associated media and connectors as needed |

|

|

|

|

|

Software |

|

|

|

|

1 |

RSLinx communications software, |

9355-WAB, 9355-WABOEM, 9355-WABC |

|

version 2.31.00 or later |

|

|

|

|

1 |

RSLogix 5000 programming |

9324-RLD300ENE |

|

software, |

|

|

version 11.11 or later |

|

|

|

|

Publication 1734-UM011D-EN-P - May 2011

vi Preface

Where to Find More Information

Refer to the following Rockwell publications as needed for additional help when setting up and using your EtherNet/IP network.

For Information About |

See This Publication |

Publication Number |

|

|

|

|

|

Using EtherNet/IP for industrial control |

EtherNet/IP Performance and Application Guide |

ENET-AP001 |

|

|

|

|

|

Ethernet communication interface |

Ethernet Communication Interface Module Installation |

1756-IN053 |

|

modules |

Instructions |

|

|

|

|

|

|

|

Ethernet Communication Interface Module User Manual |

1756-UM051 |

|

|

|

|

|

ControlLogix chassis |

ControlLogix Chassis Installation Instructions |

1756-IN080 (series B) |

|

|

|

|

|

ControlLogix power supplies |

ControlLogix Power Supplies Installation Instructions |

1756-IN613 (PA72/PB72) |

|

|

|

|

|

Logix5555 programmable controllers |

Logix5555 Controller User Manual |

1756-UM523 |

|

|

|

|

|

SoftLogix5800 controller |

SoftLogix5800 User Manual |

1789-UM002 (L10, L30, L60) |

|

|

|

|

|

ControlLogix EtherNet/IP bridge module |

ControlLogix EtherNet/IP Bridge Module Installation Instructions |

1756-IN019 |

|

with firmware revision 2.3 or later |

|

|

|

|

|

|

|

RSLogix 5000 programming software |

Getting Results with RSLogix 5000, version 3.2.1 or later |

9399-RLD300GR |

|

|

|

|

|

1734-AENT adapter |

POINT I/O EtherNet/IP Adapter Installation Instructions |

1734-IN590 |

|

|

|

|

|

POINT I/O digital and analog modules |

POINT I/O Digital and Analog Modules and PointBLOCK I/O |

1734-UM001 |

|

and PointBLOCK I/O modules |

Modules User Manual |

|

|

|

|

|

|

POINT I/O interface modules |

POINT I/O RS-232 ASCII Module User Manual |

1734-UM009 |

|

|

|

|

|

|

POINT I/O RS-232 ASCII Module Installation Instructions |

1734-IN588 |

|

|

|

|

|

POINT I/O expansion power supply |

POINT I/O |

24V DC Expansion Power Supply Installation |

1734-IN058 |

|

Instructions |

|

|

|

|

|

|

POINT I/O field potential distributor |

POINT I/O Field Potential Distributor Installation Instructions |

1734-IN059 |

|

|

|

|

|

POINT I/O input modules |

POINT I/O 120V AC Input Module Installation Instructions |

1734-IN010 |

|

|

|

|

|

|

POINT I/O Input Module Installation Instructions |

1734-IN051 |

|

|

|

|

|

POINT I/O encoders/counter modules |

POINT I/O Encoders/Counter Module User Manual |

1734-UM006 |

|

|

|

|

|

|

POINT I/O Encoders/Counter Module Installation Instructions |

1734-IN005 |

|

|

|

|

|

POINT I/O 22V AC input module |

POINT I/O 220V AC Input Module Installation Instructions |

1734-IN008 |

|

|

|

|

|

POINT I/O RTD and isolated |

POINT I/O RTD and Isolated Thermocouple Input Module |

1734-IN011 |

|

thermocouple input module |

Installation Instructions |

|

|

|

|

|

|

POINT I/O thermocouple and RTD input |

Thermocouple and RTD Input Module User Manual |

1734-UM004 |

|

module |

|

|

|

|

|

|

|

POINT I/O IV2 and IV4 input module |

POINT I/O Input Module Installation Instructions |

1734-IN052 |

|

|

|

|

|

POINT I/O 120/220V AC output module |

POINT I/O 120/220V AC Output Module Installation Instructions |

1734-IN009 |

|

|

|

|

|

POINT I/O protected output module |

POINT I/O Protected Output Module Installation Instructions |

1734-IN056 |

|

|

|

|

|

|

POINT I/O Protected Output Module Installation Instructions |

1734-IN586 |

|

|

(OB2EP) |

|

|

|

|

|

|

POINT I/O voltage output analog |

POINT I/O 2 Voltage Output Analog Module Installation |

1734-IN002 |

|

module |

Instructions |

|

|

|

|

|

|

POINT I/O protected sink output module |

POINT I/O Protected Sink Output Module Installation Instructions |

1734-IN585 |

|

|

|

|

|

Publication 1734-UM011D-EN-P - May 2011

Preface vii

For Information About |

See This Publication |

Publication Number |

|

|

|

POINT I/O 2 relay output module |

POINT I/O 2 Relay Output Module Installation Instructions (OX2) |

1734-IN587 |

|

|

|

|

POINT I/O 2 Relay Output Module Installation Instructions (OW2) |

1734-IN055 |

|

|

|

POINT I/O synchronous serial interface |

POINT I/O Synchronous Serial Interface Absolute Encoder |

1734-UM007 |

absolute encoder module |

Module Installation Instructions |

|

|

|

|

POINT I/O cold junction compensation |

POINT I/O Cold Junction Compensation Wiring Base Assembly |

1734-IN583 |

wiring base assembly |

Installation Instructions |

|

|

|

|

POINT I/O wiring base assembly |

POINT I/O Wiring Base Assembly Installation Instructions |

1734-IN013 |

|

|

|

Very high-speed counter module |

POINT I/O Very High-speed Counter Module Installation |

1734-IN003 |

|

Instructions |

|

|

|

|

|

Very High-speed Counter Module User Manual |

1734-UM003 |

|

|

|

RSLinx |

RSLinx Enterprise Getting Results Guide |

LNXENT-GR001 |

|

|

|

Terminology

|

Many of these publications are available online from: |

|

TIP |

||

http://literature.rockwellautomation.com/ |

||

|

||

|

||

|

Rockwell Software products contain extensive tutorials and |

|

TIP |

||

help screens. We recommend that you use the tutorials and |

||

|

||

|

||

|

help screens to learn about these products. |

|

|

For more information about Rockwell Software products, |

|

|

visit the Rockwell Software internet site: |

|

|

http://www.software.rockwell.com |

Refer to the table for the meaning of common terms.

Term |

Definition |

|

|

BootP |

BootP (Bootstrap Protocol) is a low-level protocol that provides |

|

configurations to other nodes on a TCP/IP network. BootP |

|

configuration files let you automatically assign IP addresses to an |

|

Ethernet module. You can also obtain subnet masks and gateway |

|

addresses from BootP. |

|

|

Bridge |

A node between two similar communication subnets where protocol |

|

translation is minimal. |

|

|

CIP |

Control and information protocol, the EtherNet/IP application layer |

|

uses the producer/consumer networking model. In this model one |

|

producer broadcasts (multicasts) the data once to all the consumers. |

|

All consumers see the data simultaneously and may choose whether |

|

to consume (receive) the data or not. Delivery time is consistent, no |

|

matter how many consumers there are. |

|

|

Connection |

The communication mechanism from the controller to another |

|

module in the control system, usually used to exchange I/O data. |

|

|

Consumer |

A destination device in the CIP networking model. See CIP. |

|

|

Publication 1734-UM011D-EN-P - May 2011

viii Preface

Term |

Definition |

|

|

CSMA/CD |

Carrier sense multiple access/collision detection is the access |

|

method used in Ethernet. When a device wants to gain access to the |

|

network, it checks to see if the network is quiet (senses the carrier). |

|

If it is not, it waits a random amount of time before retrying. If the |

|

network is quiet and two devices access the line at exactly the same |

|

time, their signals collide. When the collision is detected, they both |

|

back off and each waits a random amount of time before retrying. |

|

|

Determinism |

The ability to predict wheninformation will be delivered. Importantin |

|

time-critical applications. |

|

|

DHCP |

The dynamic host configuration protocol is an Internet protocol, |

|

similar to BootP, for automating the configuration of computers that |

|

use TCP/IP. DHCP can be used to automatically assign IP addresses, |

|

to deliver IP stack configuration parameters, such asthe subnet mask |

|

and default router, and to provide other configuration information, |

|

such as the addresses for printer, time, and news servers. |

|

The 1734-AENT factory default is DHCP enabled. When you apply |

|

power, the module sends a message containing its hardware address |

|

to any DHCP server on the network. The server(s) replies by sending a |

|

message with an appropriate IP address for the adapter. The adapter |

|

responds by acknowledging to a server that it will use the offered IP |

|

address. |

|

|

DNS |

The domain name system is a hierarchical, distributed method of |

|

organizing the name space of the Internet. The DNS administratively |

|

groups hosts into a hierarchy of authority that allows addressing and |

|

other information to be widely distributed and maintained. A big |

|

advantage to the DNS is that using it eliminates dependence on a |

|

centrally-maintained file that maps host names to addresses. |

|

|

Ethernet |

A physical layer standard using carrier sense multiple access with |

|

collision detection (CSMA/CD) methods. |

|

|

EtherNet/IP |

Ethernet industrial protocol applies a common application layer (CIP) |

|

over Ethernet by encapsulating messages in TCP/UDP/IP. |

|

|

Ethernet network |

A local area network designed for the high-speed exchange of |

|

information between computers and related devices. |

|

|

Explicit messaging |

Non-time critical messaging used for device configuration and data |

|

collection, such as downloading programs or peer-to-peer messaging |

|

between two PLC units. |

|

|

Full duplex |

A mode of communication that allows a device to send and receive |

|

information at the same time, effectively doubling the bandwidth. |

|

|

Fully qualified |

A fully qualifieddomain name (FQDN) is a domain namethat includes |

domain name |

all higher level domains relevant to the entity named. If you think of |

|

the DNS as a tree-structure with each node having its own label, a |

|

fully qualified domain name for a specific node would be its label |

|

followed by the labels of all the other nodes between it and the root |

|

of the tree. For example, for a host, a FQDN would include the string |

|

that identifies the particular host, plus all domains of which the host |

|

is a part, up to and including the top-level domain (the root domain is |

|

always null). For example, PARIS.NISC.SRI.COM is a fully qualified |

|

domain name for the host at 192.33.33.109. |

|

|

Gateway |

A module or set of modules that allows communications between |

|

nodes on dissimilar networks. |

|

|

Publication 1734-UM011D-EN-P - May 2011

Preface ix

Term |

Definition |

|

|

Hardware address |

Each Ethernet device has a unique hardware address (sometimes |

|

called a MAC address) that is 48 bits. The address appears as six |

|

digits separated by colons (such as, xx:xx:xx:xx:xx:xx). Each digit has a |

|

value between 0 and 255 (0x00 to 0xFF). This address is assigned in |

|

the hardware and cannot be changed. The hardware address is |

|

required to identify the device if you are using a BOOTP utility. |

|

|

Host name |

The host name is the unique name for a computer within its domain. |

|

It's always the first element of a full name, and, with its domain and |

|

top-level domain suffix, creates the unique name of thatcomputer on |

|

the Internet. For example, let's say a trading website is |

|

www.trading.com. The host name is www, which is not unique on |

|

the web, but is unique within the trading domain. |

|

The host name can also refer to the fully qualified domain name |

|

(FQDN), or in this example, www.trading.com. Both naming methods |

|

seem to be used interchangeably in various documents. For the |

|

purposes of this document, the host name will refer to the FQDN, or |

|

as in this example, www.trading.com. |

|

|

Hub |

A central connecting device that joins devices together in a star |

|

configuration. Hubs are generally not suitable for use in I/O control |

|

systems, since they aretime-critical applications that cannot tolerate |

|

lost packets. |

|

|

Implicit messaging |

Real-time messaging of I/O data. |

|

|

IP |

Internet protocol that provides the routing mechanism for messages. |

|

All messages contain not only the address of the destination station, |

|

but the address of a destination network, which allows messages to |

|

be sent to multiple networks within an organization or around the |

|

world. |

|

|

IP address |

A 32-bit identification number for each node on an Internet Protocol |

|

network. These addresses are represented as four sets of 8-bit |

|

numbers (numbers from 0 to 255), with decimals betweenthem. Each |

|

node on the network must have a unique IP address. |

|

|

Latency |

The time between initiating a request for data and the beginning of |

|

the actual data transfer. |

|

|

Multicast |

In the CIP producer/consumer model, one producer multicasts |

|

(broadcasts) the data once to all the consumers. |

|

|

Producer |

The source of information in the CIP networking model. See CIP. |

|

|

Rack-optimized |

A physical and logical collection of application modules. |

|

|

Subnet mask |

An extension of the IP address that allows a site to use a single net |

|

ID for multiple networks. |

|

|

Switch |

A network device that cross connects devices or network segments. |

|

A switch provides each sender/receiver the full network bandwidth |

|

(2x in full duplex mode), reduces collisions, and increases |

|

determinism. |

|

|

TCP |

The transport control protocol is a more reliable but slower transport |

|

protocol than UDP. It is used for explicit (not time critical) messaging |

|

in EtherNet/IP. |

|

|

Publication 1734-UM011D-EN-P - May 2011

xPreface

Term |

Definition |

|

|

TCP/IP |

The transmission control protocol/internet protocol is a |

|

transport-layer protocol (TCP) and a network-layer protocol (IP) |

|

commonly used for communication within networks and across |

|

internetworks. |

|

|

Transaction |

An exchange of request and data and response and data. |

|

|

UDP |

The user datagram protocol (UDP) is a transport protocol that |

|

provides a very simple but fast capability to send datagrams between |

|

two devices. It is used for I/O (implicit) messaging in EtherNet/IP. |

|

|

Publication 1734-UM011D-EN-P - May 2011

|

Table of Contents |

|

|

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. ii |

Preface |

What This Preface Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

iii |

|

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

iii |

|

Common Techniques Used in This Manual . . . . . . . . . . . . . . . . . . . . . . |

iii |

|

How To Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

iv |

|

About the Example Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . |

iv |

|

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

v |

|

Where to Find More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

vi |

|

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

vii |

Summary of Changes |

New and Revised Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

|

Change Bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

|

Chapter 1 |

|

About the Adapter |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

Important Adapter Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

Set the Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

Adapter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

Empty Slots and RIUP Situations. . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

Cycle Power To a System For the First Time . . . . . . . . . . . . . . . . . |

4 |

|

Adapter Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

Hardware/Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

What the Adapter Does . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

Use of the Common Industrial Protocol (CIP) . . . . . . . . . . . . . . . . . . . |

5 |

|

Understand the Producer/Consumer Model . . . . . . . . . . . . . . . . . . . . . |

6 |

|

Specify the Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . |

6 |

|

Support of Rack-optimized and Direct Connections. . . . . . . . . . . . . . . |

7 |

|

Mix Rack-optimized and Direct Connections . . . . . . . . . . . . . . . . . |

7 |

|

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Determine Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Understand Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Establish I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Configure Autobaud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

Chapter 2 |

|

Install the Adapter |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

Identify Adapter Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

Mount the Adapter on a DIN Rail Before Installing Modules . . . . . . |

10 |

|

Mount (or Replace) the Adapter to an Existing System. . . . . . . . . . . . |

11 |

|

Wire Your Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

Chapter 3 |

|

Configure the Adapter for Your |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

EtherNet/IP Network |

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

Subnet Mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

Set the Network Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

Use the Rockwell BootP/DHCP Utility . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

Save the Relation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

Use DHCP Software to Configure Your Adapter . . . . . . . . . . . . . . . . |

23 |

Publication 1734-UM011D-EN-P - May 2011

xii

Configure the Adapter for Direct Connection in RSLogix 5000 Software

Configure the Adapter for Direct Connection and Rack Optimization in RSLogix 5000 Software

LED Status Indicators

Adapter Web Pages

Chapter 4

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Configure the I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Add the Local EtherNet/IP Bridge to the I/O Configuration. . . 28 Add the POINT I/O Adapter to the I/O Configuration . . . . . . . 30 Add the POINT I/O Modules to the I/O Configuration . . . . . . 33 Edit the Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 Create the Ladder Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . 39 Verify the Module Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Configure the Adapter with Fixed IP Address . . . . . . . . . . . . . . . . . . . 43 Recover From an Overloaded Adapter. . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 Configure the I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Add the Local EtherNet/IP Bridge to the I/O Configuration. . . 48 Add the POINT I/O Adapter to the I/O Configuration . . . . . . . 50

Add the POINT I/O Module and Configure for Direction Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 Add the POINT I/O Module and Configure For

Rack Optimization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . 58 Verify the Module Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Access Module Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Chapter 6

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

Interpret the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

Appendix A

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 Work with the Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 Work with the Diagnostics Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 Use the Diagnostic Overview Page. . . . . . . . . . . . . . . . . . . . . . . . . 70 Use the Network Settings Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 Use the Ethernet Statistics Page . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Use the I/O Connections Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 Use the Diagnostic Messaging Page . . . . . . . . . . . . . . . . . . . . . . . . 75 Work with the Configuration Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Use the Identity Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Use the Network Configuration Page. . . . . . . . . . . . . . . . . . . . . . . 78 Use the Services Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Work with the Browse Chassis Page . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Appendix B

Publication 1734-UM011D-EN-P - May 2011

xiii

Configure the RSLinx Ethernet

Communication Driver

1734 POINT I/O

Module/RSLogix 5000

Controller Tag Reference

Quick Start

Index

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Install the RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Configure the AB_ETH/IP Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Appendix C

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 1734 POINT I/O Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Valid Number Ranges for RSLogix 5000 Data Types . . . . . . . . . . . . . 92 Digital 2 POINT Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 Digital 2 POINT Output – With Over Load and

Open Load Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Digital 2 POINT Output – With Over

Load Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 Digital 4 POINT Output – With Over

Load and Open Load Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . 98 Digital 4 POINT Output – With Over

Load Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Analog 2 Channel Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Appendix D

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 Necessary Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131 Configure the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 Enter Adapter Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133 Add Another Module Under the Adapter . . . . . . . . . . . . . . . . . . 134 Configure 1734 POINT I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . 135 Configure an Ethernet Driver in RSLinx Software . . . . . . . . . . . . . . 138 Launch RSLinx Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Publication 1734-UM011D-EN-P - May 2011

xiv

Notes:

Publication 1734-UM011D-EN-P - May 2011

Summary of Changes

This publication contains new and revised information not in the last release.

New and Revised Information

See the table for a summary of the major changes in this manual.

Chapter |

Revised to include |

|

|

Appendix B - Configure the RSLinx |

Removal of Ethernet device installation |

Ethernet Communication Driver |

instructions |

|

|

Change Bars

Change bars (as shown with this paragraph) show the areas in this manual that are different from previous editions and indicate the addition of new or revised information.

Publication 1734-UM011D-EN-P - May 2011

xvi Summary of Changes

Notes:

Publication 1734-UM011D-EN-P - May 2011

Chapter 1

About the Adapter

What This Chapter Contains |

This chapter provides an overview of the 1734-AENT POINT I/O |

||

|

EtherNet/IP adapter, its primary features, and how to use it. You need to |

||

|

understand the concepts discussed in this chapter to configure your adapter |

||

|

and use it in an EtherNet/IP control system. See the table for a list of where to |

||

|

find specific information in this chapter. |

|

|

|

|

|

|

|

Topic |

Page |

|

|

|

|

|

|

Important Adapter Considerations |

1 |

|

|

|

|

|

|

Set the Chassis Size |

1 |

|

|

|

|

|

|

Adapter Replacement |

2 |

|

|

|

|

|

|

Empty Slots and RIUP Situations |

2 |

|

|

|

|

|

|

Cycle Power To a System For the First Time |

4 |

|

|

|

|

|

|

Adapter Features |

4 |

|

|

|

|

|

|

Hardware/Software Compatibility |

5 |

|

|

|

|

|

|

What the Adapter Does |

5 |

|

|

|

|

|

|

Use of the Common Industrial Protocol (CIP) |

5 |

|

|

|

|

|

|

Understand the Producer/Consumer Model |

6 |

|

|

|

|

|

|

Specify the Requested Packet Interval (RPI) |

6 |

|

|

|

|

|

|

Support of Rack-optimized and Direct Connections |

7 |

|

|

|

|

|

|

Mix Rack-optimized and Direct Connections |

7 |

|

|

|

|

|

|

|

|

|

Important Adapter

Considerations

|

|

|

You must use series C POINT I/O modules with the |

|

ATTENTION |

||||

1734-AENT adapter. Series A or B POINT I/O modules will |

||||

|

|

|

||

|

|

|

||

|

|

|

not work with this adapter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Before you begin using your adapter, note the following important considerations.

Set the Chassis Size

The 1734-AENT POINT I/O adapter for EtherNet/IP requires configuration of its chassis size before you can make any I/O connections.

Publication 1734-UM011D-EN-P - May 2011

2About the Adapter

The default setting for the chassis size is 1 slot, which represents the adapter by itself.

Set the chassis size as the sum of the slot of the adapter plus the slots of each I/O module in the adapter backplane. For example, the adapter plus 4 I/O modules uses a chassis size of 5. The adapter stores this chassis size setting in non-volatile storage.

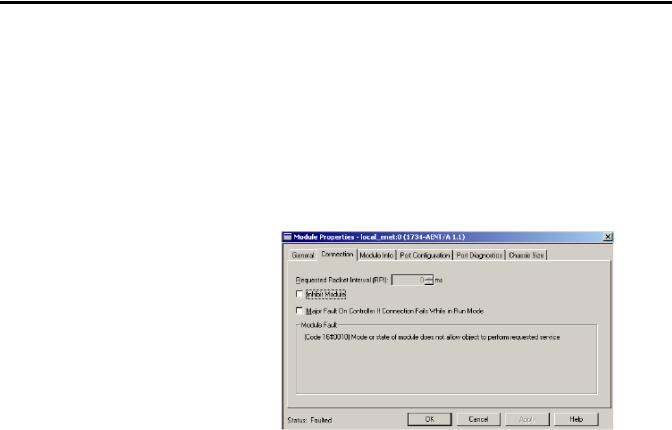

When the adapter’s non-volatile chassis size does not match the actual number of modules present on its backplane, the adapter does not make any I/O connections and an error occurs, as shown in the Module Properties dialog.

Adapter Replacement

It is important to note that during a connection request from the controller, the chassis size setting for a 1734-AENT adapter is not communicated to the adapter. You must always set this chassis size using a separate operation. This includes situations when you are replacing an adapter. The adapter does not make any I/O connections until it is configured with the appropriate chassis size.

Empty Slots and RIUP Situations

The POINT I/O system does not have the ability to detect an empty terminal base. Because of this, there are numerous situations in which you can potentially configure a system that is unusable or one that exercises unintended control.

In an attempt to address these situations, you must observe the following rules for POINT I/O system construction and the removal and reinsertion of modules:

Publication 1734-UM011D-EN-P - May 2011

About the Adapter |

3 |

|

|

•A correct POINT I/O system does not have any empty terminal bases.

•After you cycle power, the adapter does not run any I/O until the number of modules comprising the chassis equals the stored chassis size.

–Because the adapter cannot detect empty terminal bases, it cannot assume any safe operation until there is a match between the number of modules indicating their presence in the chassis and what the adapter has saved in non-volatile memory.

–Actual module identification (such as, electronic keying) is done when connection establishment requests are received from the controller or controllers.

•A module removed under power does not disrupt operation of the other I/O modules.

–When you remove a module, the adapter determines what changed.

–Whenever you remove a module with an active connection from the POINT I/O system, the adapter indicates this by flashing the POINTBus Status LED red and reports a minor recoverable fault.

•If more than one contiguous module is removed under power, connections to all modules in the contiguous missing module set are disallowed until all modules are replaced. Because the adapter cannot detect an empty base, it does not know the physical positioning of the modules until all the missing modules are replaced.

•If a module separating two sets of contiguous missing modules is removed, the two sets merge into a single set. All the modules must be replaced before connections are permitted to any module in the set.

•If modules of different types are removed and returned to the wrong locations, attempts to connect to these modules fail during verification of the electronic ID (providing that keying has not been disabled).

•If modules of the same type are removed and returned to the wrong locations, they accept connections from the controller or controllers and reconfigure with the correct data once they pass their electronic keying check.

•These removal and return conditions apply whether the system is under power or not. If the system is under power, the situation arises immediately. If the system is not under power, the situation arises in the next power cycle.

Publication 1734-UM011D-EN-P - May 2011

4About the Adapter

Cycle Power To a System for the First Time

Adapter Features

When you cycle power to the POINT I/O for the first time, the adapter must assign addresses to every module in the backplane. POINT I/O modules all ship configured at the same address.

When you first apply power, we expect that all but one module on the backplane exhibits a solid red Module Status LED.

One by one the adapter resets these modules and addresses them appropriately. The amount of time that this operation takes is proportional to the size of your POINT I/O system.

The 1734-AENT adapter has the following features:

•EtherNet/IP messages encapsulated within standard TCP/UDP/IP protocol

•Common application layer with ControlNet and DeviceNet networks

•Interfacing via Category 5 rated twisted pair cable

•Half/full duplex 10 Mbit or 100 Mbit operation

•DIN rail mounting

•Communication to and from other POINT I/O modules on the same DIN rail

•Communication supported by RSLinx software

•IP address assigned via standard BootP or DHCP tools

•I/O configuration via RSLogix 5000 software

•No network scheduling required

•No routing tables required

•Support of connections from multiple controllers simultaneously

Publication 1734-UM011D-EN-P - May 2011

About the Adapter |

5 |

|

|

Hardware/Software

Compatibility

The 1734-AENT adapter and the applications described in this manual are compatible with the following firmware revisions and software releases. Contact Rockwell Automation if you need software or firmware upgrades to use this equipment.

Product |

Firmware Revision/ |

|

Software Release |

|

|

1734-AENT adapter |

1.xx or later |

|

|

1756-ENBT module |

2.3 or later |

|

|

Logix 5555 controller |

11 or later |

|

|

RSLogix 5000 software |

11.11 or later |

|

|

RSLinx software |

2.3.1 or later |

|

|

What the Adapter Does

Use of the Common

Industrial Protocol (CIP)

The 1734-AENT adapter performs the following primary tasks:

•Control of real-time I/O data (also known as implicit messaging) – the 1734-AENT adapter serves as a bridge between POINT I/O modules and the network

L |

E |

|

5 |

N |

|

5 |

B |

|

5 |

|

|

T |

|

|

5 |

|

|

|

|

EtherNet/IP Network

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

POINT |

|

E |

ControlLogix |

|

Other |

|

|||

|

E |

|

N |

|

Network |

|

|||||

|

I/O |

|

I/O |

|

|

||||||

|

N |

|

B |

|

Devices |

|

|||||

|

T |

|

|

T |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

•Support of messaging data for configuration and programming information (also known as explicit messaging)

The 1734-AENT adapter uses the Common Industrial Protocol (CIP). CIP is the application layer protocol specified for EtherNet/IP, the Ethernet Industrial Protocol, as well as for ControlNet and DeviceNet networks. It is a message-based protocol that implements a relative path to send a message from the producing device in a system to the consuming devices.

The producing device contains the path information that steers the message along the proper route to reach its consumers. Since the producing device holds this information, other devices along the path simply pass this information; they do not need to store it.

This has the following significant benefits:

•You do not need to configure routing tables in the bridging modules, which greatly simplifies maintenance and module replacement.

Publication 1734-UM011D-EN-P - May 2011

6About the Adapter

Understand the

Producer/Consumer Model

Specify the Requested

Packet Interval (RPI)

•You maintain full control over the route taken by each message, which enables you to select alternative paths for the same end device.

The CIP producer/consumer networking model replaces the old source/destination (master/slave) model. The producer/consumer model reduces network traffic and increases speed of transmission. In traditional I/O systems, controllers poll input modules to obtain their input status. In the CIP system, input modules are not polled by a controller. Instead, they produce (multicast) their data either upon a change of state (COS) or periodically.

The frequency of update depends upon the options chosen during configuration and where on the network the input module resides. The input module, therefore, is a producer of input data, and the controller is a consumer of the data.

The controller can also produce data for other controllers to consume. The produced and consumed data is accessible by multiple controllers and other devices over the EtherNet/IP network. This data exchange conforms to the producer/consumer model.

The RPI is the update rate specified for a particular piece of data on the network. The RPI can be specified for the adapter and include all of the I/O modules communicating through it (using a rack-optimized connection) or specified for a particular module (using direct connection).

When you add a module or an adapter to the I/O configuration of a controller, you must enter the RPI as a parameter. This value specifies how often to produce the data for that device. For example, if you specify an RPI of 50 ms, it means that every 50 ms the device should send its data to the controller or the controller should send its data to the device.

Use RPIs only for devices that exchange data. For example, a ControlLogix EtherNet/IP bridge module in the same chassis as the controller does not require an RPI, because it is not a data-producing member of the system. Its use is only as a bridge to remote racks.

Publication 1734-UM011D-EN-P - May 2011

About the Adapter |

7 |

|

|

Support of Rack-optimized

and Direct Connections

The 1734-AENT adapter supports both direct and rack-optimized connections. A direct connection is a real-time data transfer link between the controller and whatever module occupies the slot that the configuration data references. Direct connection messaging occurs at a cyclic rate specified by the RPI during configuration. A rack-optimized connection is a grouping of data from more than one I/O module into a single block of data sent over a single connection at the same data rate.

Rack-optimized connections reduce the total number of connections needed to transfer data when using many I/O modules in a system. The following example illustrates the benefit of rack-optimized connections.

Assume you set up a system that contains 8 digital I/O modules interfaced to a 1734-AENT adapter. If you use direct connections to transfer data to each of the these I/O modules, you need 8 connections to transfer all of the data, one to each of the 8 I/O modules. If you use a rack-optimized connection to transfer the data, you only need a single connection – the connection to the 1734-AENT adapter.

|

Although rack-optimized connections offer an efficient |

|

IMPORTANT |

||

way to use resources, there are a few limitations on their |

||

|

||

|

||

|

use. |

|

|

• You can use only rack-optimized connections to |

|

|

send data to and from digital I/O modules. Analog |

|

|

or speciality I/O requires direct connections. |

• All data is sent at the same time as the RPI rate of the 1734-AENT adapter.

See the EtherNet/IP Performance and Application Guide, publication number ENET-AP001, for more information on connections.

Mix Rack-optimized and Direct Connections

You can mix communication formats for different I/O modules communicating through the same adapter. I/O modules set up to use rack optimization communicate at the rate of the RPI configured for the 1734-AENT adapter. I/O modules configured for direct communication communicate at their own set RPIs and ignore the 1734-AENT adapter’s RPI.

Publication 1734-UM011D-EN-P - May 2011

8About the Adapter

Before You Begin |

To effectively use your adapter, note the following considerations. |

Determine Compatibility

If using the adapter with a 1756-ENBT module or 1788-ENBT module, use the following required firmware revisions for these bridge modules:

•1756-ENBT firmware revision 2.3 or later

•1788-ENBT firmware revision 1.33 or later

If you use the BootP Utility to assign IP addresses to the adapter, use revision 2.3.2 or later.

Understand Messaging

Class 3 (Explicit Message) requests through the 1734-AENT adapter to a specific POINT I/O module may not always receive a response from the I/O modules. In the case where the I/O module does not reply to the request, the adapter responds with an error code indicating a timeout.

Establish I/O Connections

When you apply power to a POINT I/O system and establish I/O connections, the outputs transition to the idle state, applying idle state data before going to RUN mode. This occurs even when the controller making the connection is already in RUN mode.

Configure Autobaud

The adapter cannot reconfigure an I/O module that you previously configured to operate at a fixed communication rate. When you reuse a POINT I/O module from another POINT I/O system, configure the module to autobaud before using it with the adapter.

Publication 1734-UM011D-EN-P - May 2011

Chapter 2

Install the Adapter

What This Chapter Contains |

This chapter describes how to physically install the adapter on the DIN rail |

||

|

and connect it to the EtherNet/IP network. The following table lists where to |

||

|

find specific information. |

|

|

|

|

|

|

|

Topic |

Page |

|

|

|

|

|

|

Identify Adapter Components |

9 |

|

|

|

|

|

|

Mount the Adapter on a DIN Rail Before Installing |

10 |

|

|

Modules |

|

|

|

|

|

|

|

Mount or Replace the Adapter to an Existing System |

11 |

|

|

|

|

|

|

Wire Your Adapter |

12 |

|

|

|

|

|

|

Mounting Dimensions |

13 |

|

|

|

|

|

|

|

|

|

Identify Adapter

Components

|

|

|

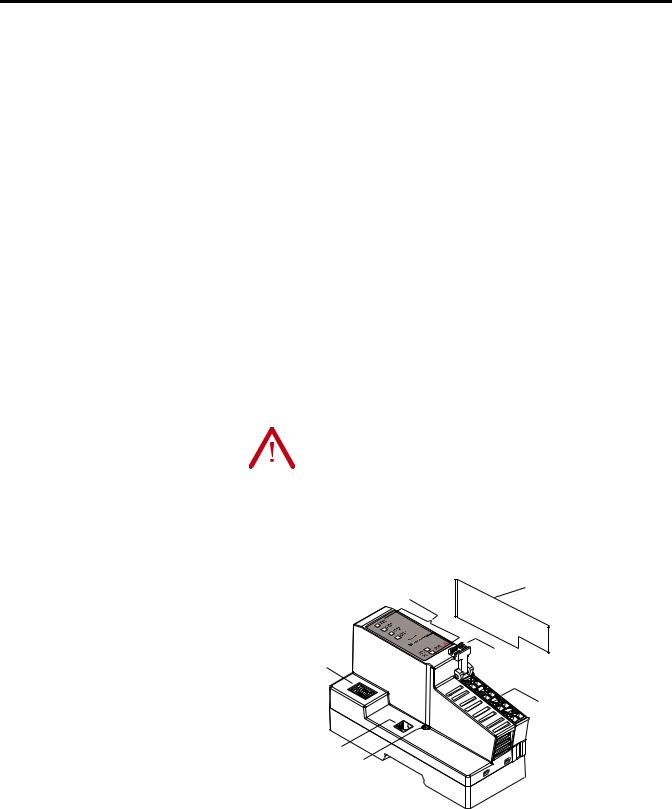

You must use series C POINT I/O modules with the 1734-AENT |

|

ATTENTION |

||||

adapter. Series A or B POINT I/O modules will not work with |

||||

|

|

|

||

|

|

|

||

|

|

|

this adapter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

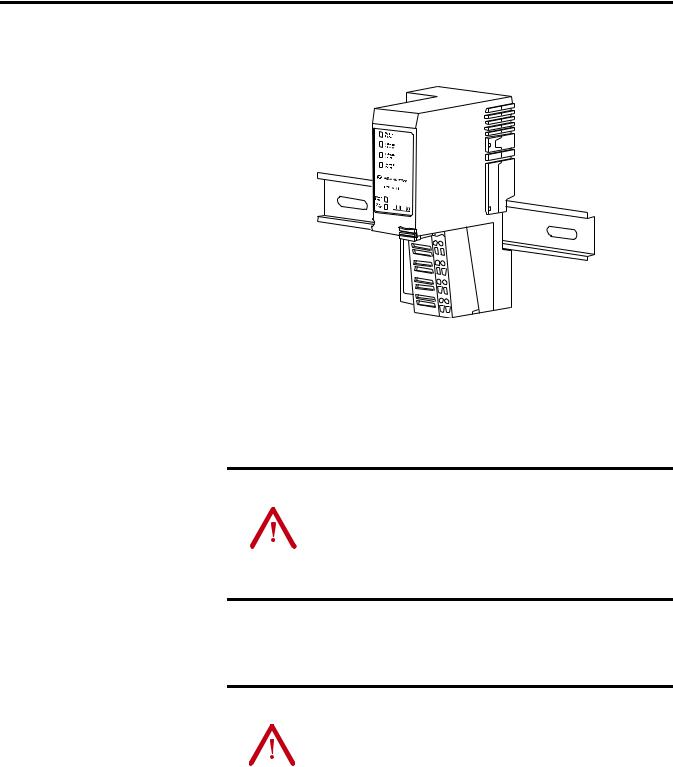

Use the figure to identify the external features of the adapter.

|

LED indicators |

Safety end cap |

|

|

|

||

|

|

|

RTB |

Node address |

|

|

removable |

thumbwheel |

|

|

handle |

|

|

|

Removable Terminal |

|

|

|

Block (RTB) |

EtherNet |

|

|

|

network |

|

DIN rail |

|

RJ45 |

|

|

|

|

locking screw |

|

|

connector |

|

||

(orange) |

|

||

|

|

31533-M |

|

Publication 1734-UM011D-EN-P - May 2011

10 Install the Adapter

Mount the Adapter on a DIN Rail Before Installing Modules

Use the following procedure to mount the adapter on a new system before you install any I/O modules.

43520

1.Position the adapter vertically above the DIN rail.

2.Press down firmly to install the adapter on the DIN rail, noting that the locking mechanism locks the adapter to the DIN rail.

3.Set the network address thumbwheel switches to the desired value. For more information, see Set the Network Address on page 19.

|

|

|

If you connect or disconnect the Ethernet cable with power |

|

WARNING |

||||

applied to this module or any device on the network, an |

||||

|

|

|

||

|

|

|

||

|

|

|

electrical arc can occur. This could cause an explosion in |

|

|

|

|

hazardous location installations. |

|

|

|

|

|

|

Be sure that power is removed or the area is nonhazardous before proceeding.

4.Slide the safety end cap up to remove it.

This exposes the backplane and power interconnections.

|

|

|

Do not discard the adapter’s end cap. Use this end cap to cover |

|

ATTENTION |

||||

the exposed interconnections on the last mounting base on the |

||||

|

|

|

||

|

|

|

||

|

|

|

DIN rail. Failure to do so could result in equipment damage or |

|

|

|

|

injury from electric shock. |

|

|

|

|

|

|

|

|

|

|

|

Publication 1734-UM011D-EN-P - May 2011

Install the Adapter |

11 |

|

|

Mount or Replace the Adapter to an Existing System

Follow these steps to mount or replace an adapter.

1.Remove the existing adapter (if there is one) from the DIN rail as follows:

a.Pull up on the RTB removal handle to remove the terminal block.

b.Disconnect the Ethernet connector from the adapter.

c.Remove the adjacent module from its base.

d.Use a small-bladed screwdriver to rotate the DIN-RAIL locking screw to a vertical position.

This releases the locking mechanism.

e. Lift straight up to remove.

2.For the replacement adapter, slide the safety end cap up to remove. This exposes the backplane and power connections.

3.Position the replacement adapter vertically above the DIN rail.

4.Make certain the DIN rail lock is in the horizontal position.

5.Slide the adapter down, allowing the interlocking side pieces to engage the adjacent module.

6.Press firmly to seat the adapter on the DIN rail. The adapter locking mechanism snaps into place.

7.Replace the adjacent module in its base.

8.Reconnect the Ethernet cable to the adapter.

9.Set the network address thumbwheel switches to the value used on the replaced module. For more information, see Set the Network Address on page 19.

10.Insert the end of the terminal block (RTB) opposite the handle into the base unit.

This end has a curved section that engages with the wiring base.

11.Rotate the terminal block into the wiring base until it locks itself into place.

Publication 1734-UM011D-EN-P - May 2011

12 Install the Adapter

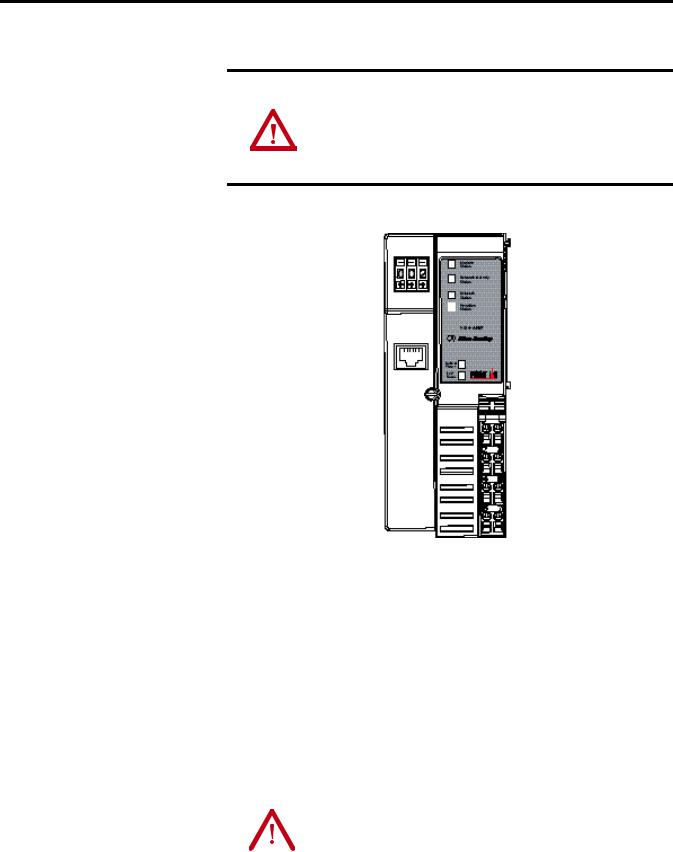

Wire Your Adapter

Refer to the illustration to wire the adapter.

|

If you connect or disconnect wiring while the field-side power is |

|

WARNING |

||

on, an electrical arc can occur. This could cause an explosion in |

||

|

||

|

||

|

hazardous location installations. |

Be sure that power is removed or the area is nonhazardous before proceeding.

|

|

|

Network address |

|

|

Module status |

|

|

|

|

Thumbwheels |

|

|

Network activity status |

|

|

|

|

|

|

|

|

Network status |

|

|

|

|

|

|

|

POINTBus status |

|

|

|

Ethernet RJ-45 |

|

|

|

|

|

|

|

connector |

|

|

System Power |

|

|

|

|

|

|

|

|

Field Power |

|

|

|

|

|

|

|

NC |

|

|

|

|

|

|

|

CHAS GND |

NC = No Connection |

|

|

C |

||||

|

|

|

|||||

CHAS GND = Chassis Ground |

|

|

|

||||

C = Common |

|

|

|

|

V |

||

V = Supply |

|

|

|

|

43264 |

||

|

|

|

|

|

|

12/24V DC |

|

|

|

|

|

|

|

0 |

1 |

|

|

|

|

|

|

NC |

NC |

|

|

|

|

|

|

2 |

3 |

|

|

|

|

|

|

Chas |

Chas |

|

|

|

|

|

|

Gnd |

Gnd |

|

|

|

|

|

|

4 |

5 |

|

|

|

|

This DC supply will be |

V DC |

C |

C |

|

|

|

|

|

|

||

|

|

|

|

connected to the |

6 |

7 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

internal power bus. |

|

V |

V |

|

|

|

|

|

|||

|

|

|

|

Do not connect 120/240V AC power to this supply. |

|||

ATTENTION |

|

||||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Publication 1734-UM011D-EN-P - May 2011

Install the Adapter |

13 |

|

|

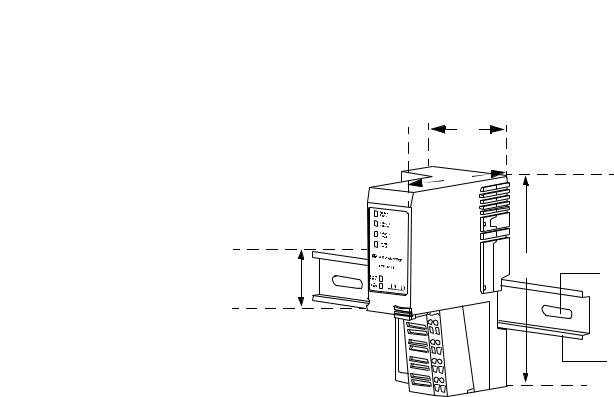

Mounting Dimensions

Refer to the figure for mounting dimensions.

millimeters (inches)

54.9

(2.16)

76.5 (3.0)

76.5 (3.0)

36.51

(1.44)

A = DIN rail

B = Secure DIN rail approximately every 200 mm (7.8 in.)

133.4

(5.25) B

A

43520

1734-AENT

76.2H x 54.9W x 133.4D

(3.0H x 2.16W x 5.25D)

Publication 1734-UM011D-EN-P - May 2011

14 Install the Adapter

Notes:

Publication 1734-UM011D-EN-P - May 2011

Loading...

Loading...