Rockwell Automation 1734-IK User Manual

Encoder/Counter

Modules

1734-IJ and 1734-IK

User Manual

Important User Information Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1 available from your local Rockwell Automation sales office or online at http://literature.rockwellautomation.com/) describes some important differences between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

ATTENTION

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

SHOCK HAZARD |

Labels may be located on or inside the equipment (such as |

||||

|

|

|

|

|

a drive or motor) to alert people that dangerous voltage |

|

|

|

|

|

may be present. |

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Labels may be located on or inside the equipment (such as |

BURN HAZARD |

|||||

|

|

|

|

|

a drive or motor) to alert people that surfaces may be |

|

|

|

|

|

dangerous temperatures. |

|

|

|

|

|

|

|

|

|

|

|

|

POINT I/O, POINTBus, and RSLogix 5000 are trademarks of Rockwell Automation.

ControlNet is a trademark of ControlNet International, Ltd. DeviceNet is a trademark of Open DeviceNet Vendor Association, Inc.

Summary of Changes

This publication contains new and revised information not in the last release.

New and Revised Information

See the table for a summary of the major changes in this manual.

Chapter |

Change |

|

|

2 |

Addition of Before You Begin section |

|

Addition of attention and warning statements |

|

Update of the Communicate with Your Module section |

|

|

Appendix A |

Addition of information on how to configure modules in |

|

RSLogix 5000 |

|

|

Change Bars

We marked with change bars (as shown with this paragraph) the areas in this manual that are different from previous editions and indicate the addition of new or revised information.

Publication 1734-UM006B-EN-P - August 2005

Summary of Changes |

2 |

|

|

Notes:

Publication 1734-UM006B-EN-P - August 2005

|

Table of Contents |

|

|

Preface |

|

Preface |

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

Related Products and Documentation. . . . . . . . . . . . . . . . . |

P-1 |

|

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-3 |

|

Chapter 1 |

|

About the Modules |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

|

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

Counter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

Encoder Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

|

Period/Rate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

|

Operation of Scalar . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

Rate Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

|

New Data Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

|

Default Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

|

Operating Mode Features . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

|

Operating Mode Features . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

|

Chapter 2 |

|

Install the Modules |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

Install the Mounting Base/Wiring Base Assembly . . . . . . . . |

2-1 |

|

Install an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

|

Install the Removable Terminal Block . . . . . . . . . . . . . . . . |

2-4 |

|

Remove a Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . . |

2-4 |

|

Wire the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

|

Communicate with the Modules. . . . . . . . . . . . . . . . . . . . . |

2-6 |

|

Default Data Map for the 1734-IJ/IK Counter Module . . |

2-6 |

|

Configure Your Encoder/Counter Module . . . . . . . . . . . . . |

2-7 |

|

Counter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . |

2-7 |

|

Filter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-8 |

|

Scalar Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-8 |

Publication 1734-UM006B-EN-P - August 2005

Chapter 3

Input and Output Data |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

|

Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

|

Detailed Description of Data Table Information . . . . . . . . . |

3-2 |

|

Stored/Accumulated Channel Data (Input Word 2) . . . . |

3-2 |

|

Module/Channel Status and Programming Error Codes |

|

|

(Input Words 3 and 4) . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

|

Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

|

Counter Configuration (Configuration Word 1) . . . . . . . |

3-5 |

|

Filter Selection (Configuration Word 2 . . . . . . . . . . . . . |

3-5 |

|

Decimal Position (Configuration Word 3) . . . . . . . . . . . |

3-6 |

|

Word 4 is reserved. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

|

Time Base and Gate Interval (Configuration Words |

|

|

5 and 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

|

Scalar (Configuration Word 7) . . . . . . . . . . . . . . . . . . . |

3-7 |

|

Scalar Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

|

Rollover (Configuration Word 8). . . . . . . . . . . . . . . . . . |

3-7 |

|

Preset (Configuration Word 9) . . . . . . . . . . . . . . . . . . . |

3-7 |

|

Safe State Values (Configuration Word 10) . . . . . . . . . . |

3-8 |

|

Communicate Real Time/Nonreal Time Information . . . . . . |

3-8 |

|

Chapter 4 |

|

Configure Your Module |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Add the Adapter to Your Network . . . . . . . . . . . . . . . . |

4-1 |

|

Add I/O Modules to Your Network. . . . . . . . . . . . . . . . |

4-2 |

|

Set Counter Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|

Check I/O Status and View/Edit the EDS File . . . . . . . . . . . |

4-6 |

|

Chapter 5 |

|

Access Instantiated Instances |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

|

Using Instantiated Instances. . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

|

Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-3 |

|

Chapter 6 |

|

Troubleshoot with the Indicators |

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . |

6-1 |

|

Use the Indicators for Troubleshooting . . . . . . . . . . . . . . . |

6-1 |

Appendix A

Configure Modules in

RSLogix 5000

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . A-1 Understand Data, Connections, and Communication Formats A-1

Configure Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Work with the Fault/Program Action Dialog. . . . . . . . . . . . A-4 Work with the Counter Configuration Dialog . . . . . . . . . . . A-5

Index

Publication 1734-UM006B-EN-P - August 2005

Preface

Purpose of This Manual

Read this manual for information about how to install, configure and troubleshoot your Encoder/Counter module.

For This Information: |

See: |

|

|

About the Modules |

Chapter 1 |

|

|

Install the Modules |

Chapter 2 |

|

|

Encoder/Counter Module Input and Output Data |

Chapter 3 |

|

|

Configure Your Encoder/Counter Module |

Chapter 4 |

|

|

Access Instantiated Instances |

Chapter 5 |

|

|

Troubleshoot with the Indicators |

Chapter 6 |

|

|

Who Should Use This

Manual

You must be able to use RSNetworx software or similar configuration software to set up and calibrate these modules. You must have the capability to download and use Electronic Data Sheet files.

We assume you know how to do this in this manual. If you do not, refer to your software user manuals or online help before attempting to use these modules.

Publication 1734-UM006B-EN-P - August 2005

Preface 2

Related Products and

Documentation

For specification, safety approval, and other information refer to the following.

•Publication Number 1734-IN005 Encoder/Counter Installation Instructions

For related 1734 products and documentation see the table.

Description |

Cat. No. |

Publication |

|

|

|

Very High Speed Counter Modules |

1734-VHSC5 |

1734-IN003 |

Installation Instructions |

1734-VHSC24 |

|

|

|

|

Analog Input Modules |

1734-IE2C |

1734-IN027 |

Installation Instructions |

17340IE2V |

|

|

|

|

Analog Output Modules |

1734-OE2C |

1734-IN002 |

Installation Instructions |

1734-OE2V |

|

|

|

|

DeviceNet Communication Interface |

1734-PDN |

1734-IN057 |

Installation Instructions |

|

|

|

|

|

Field Potential Distributor |

1734-FPD |

1734-IN059 |

Installation Instructions |

|

|

|

|

|

POINT I/O 24V dc Expansion Power Supply |

1734-EP24DC |

1734-IN058 |

Installation Instructions |

|

|

|

|

|

POINT I/O Selection Guide |

1734 series |

1734-SG001 |

|

|

|

Protected Output Module s |

1734-OB2E |

1734-IN056 |

Installation Instructions |

1734-OB4E |

|

|

1734-OB8E |

|

|

|

|

Relay Output Modules |

1734-OW2 |

1734-IN055 |

Installation Instructions |

1734-OW4 |

|

|

|

|

Sink Input Modules |

1734-IB2 |

1734-IN051 |

Installation Instructions |

1734-IB4 |

|

|

1734-IB8 |

|

|

|

|

Source Output Modules |

1734-IV2 |

1734-IN052 |

Installation Instructions |

1734-IV4 |

|

|

1734-IV8 |

|

|

|

|

Wiring Base Assembly |

1734-TB |

1734-IN511 |

Installation Instructions |

1734-TBS |

|

|

|

|

Wiring Base Assembly |

1734-TB3 |

1734-IN013 |

Installation Instructions |

1734-TB3S |

|

|

|

|

Publication 1734-UM006B-EN-P - August 2005

Preface 3

Definitions

The following define the intended operation of the Encoder/Counter module.

Term |

Definition |

|

|

Lead Breakage |

Typically requires a shunt resistor (across the load) to detect |

|

3 levels of current/input states - |

|

• Open (Wire Off, Device = ?) |

|

• Off (Wire OK, Device Off) |

|

• On (Wire OK, Device On) |

|

This method does not check the input against a time base, |

|

only that the device wiring (current loop) is intact |

|

|

Missing Pulse |

Typically uses an input pulse to reset a watchdog timer (fixed |

|

or programmable HW). This method does detect “Lead |

|

Breakage”, since a broken wire will time-out the watchdog. |

|

|

Zero Frequency |

Typically uses an input pulse to calculate an input frequency |

|

and verify it is above an error threshold. This method does |

|

detect Lead Breakage, since a broken wire will generate a |

|

0Hz frequency. |

|

Missing Pulse or Zero Frequency will also detect a customer |

|

device stuck high or low, since the counter is monitoring for a |

|

change in the input state. Currently, the Counter/Encoder |

|

Modes do not have Zero Frequency Detection - the A & B |

|

inputs are time independent, only looking for input edge |

|

changes to increment/decrement the count value. |

|

The Period/Rate and Continuous Rate modes do have Zero |

|

Frequency Detection, since the Z input is monitored for Zero |

|

Frequency in Firmware (A and B inputs are not used and not |

|

monitored). |

|

The Rate Measurement mode inherently has Zero Frequency |

|

Detection, since no A pulses in any sample period are = 0Hz |

|

(B and Z inputs are not used and not monitored). |

|

|

Publication 1734-UM006B-EN-P - August 2005

Preface 4

Operational Mode |

Zero Frequency Detection |

Input Monitored |

|

|

|

Counter |

No |

None |

|

|

|

Encoder |

No |

None |

|

|

|

Period/Rate |

Yes |

Z Only |

|

|

|

Rate Measurement |

Y |

A Only |

|

|

|

Publication 1734-UM006B-EN-P - August 2005

Chapter 1

About the Modules

What This Chapter Contains

Module Description and

Features

Read this chapter to learn about types, features, and capabilities of encoder/counter modules.

Encoder/counter modules install into the Point I/O terminal base (1734-TB or 1734-TBS) and interface with the Point I/O DeviceNet Pass-through (1734-PDN) or the Point I/O DeviceNet Adapter (1734-ADN).

An encoder/counter module serves as a signal conditioner, function block, and counter between the customer process signals on the terminal base and the POINTBus containing the command information. The main functional blocks are the the following.

•Customer digital I/O interface

•Counter ASIC

•Microprocessor

The encoder/counter module accepts feedback from the following.

•Encoders (either single-ended or differential)

•Pulse generators

•Mechanical limit switches

•Frequencies up to 1 MHz

A filter is available with the following settings.

•50 Hz

•500 Hz

•5 kHz

•50 kHz

Turn the filter off to achieve the fastest counting rate.

The input voltage range is 5V dc (1734-IJ) or 15-24V dc (1734-IK). The module returns the count or frequency in the form of a 24 bit binary number (0 - 16,777,215) expressed in a 32 bit long word.

Each counter has a user-selectable preset and rollover value associated with it.

Publication 1734-UM006B-EN-P - August 2005

1-2 About the Modules

Operating Modes

The encoder/counter modules operate in the modes shown in the table.

Mode |

Description |

|

|

Counter Mode |

Read incoming single phase pulses, return a binary |

|

count |

|

|

Encoder Mode |

Read incoming 2 phase quadrature pulses, return a |

|

binary count |

|

|

Period/Rate Mode |

Count internal clocks during the On period, return a |

|

frequency |

|

|

Rate Measurement Mode |

Read pulses during the sample period, return a |

|

frequency |

|

|

The operation of the counter and encoder modes is nearly identical. The difference between the two modes is in the type of feedback (1 phase versus 2 phase) for the count direction (up or down).

•In encoder mode, a transition is expected on B for counting to proceed in a direction.

•In counter mode, the B input may be left at a static level.

Select operating modes by writing appropriate configuration data to the module.

Counter Mode

The counter mode reads incoming pulses and returns a binary number (0 - 16,777,215max) to the POINTBus. The counter mode only accepts single phase inputs. The module determines the Phase B input state, and counts up or down accordingly.

Channel A input is used as the counting pulse while channel B is used to determine the direction.

[B = High, Count = Down; B = Low or floating (not connected), Count = Up]

The Channel B input may be tied high or low for unidirectional counting, or toggled for bidirectional counting.

Publication 1734-UM006B-EN-P - August 2005

About the Modules |

1-3 |

|

|

Example of Counter Mode

|

|

|

|

A |

Input |

Input A |

|

|

|

|

B |

Direction |

|

|

|

|

|

Input B |

||

|

|

|

||||

|

|

|

|

Z (Store Count) |

||

|

|

|

|

|||

|

|

|

|

Input Z |

||

|

|

|

|

(Gate / Reset ) |

||

|

|

|

|

|||

|

|

|

|

|

||

Single Phase Pulse Generator |

|

|

||||

|

1734-VHSC |

|||||

|

|

|

|

|

|

|

|

|

|

Count Up |

Count Down |

||

A Input

B Input

Outputs

Count Updated

Continuously

0 |

1 |

2 |

3 |

2 |

1 |

0 |

Encoder Mode

The encoder mode reads incoming pulses and returns a binary number (0 - 16,777,215max) to the POINTBus. The encoder mode only accepts 2 phase quadrature inputs. The module senses the relationship between the 2 phases, and counts up or down accordingly.

The two basic encoder types are absolute and incremental. A single output incremental encoder is called a tachometer encoder. A dual channel incremental encoder with one channel leading the other by 90° is called a quadrature encoder.

A system using a quadrature encoder may include an optional zero pulse, or index, serving as a reference mark for system reset. The principal disadvantage of a system using incremental encoders is that a power interruption causes the loss of position reference, so a system must be reinitialized or returned to a known zero position.

Absolute encoders typically have higher speed requirements (200 KHz typical) for motion control applications. An absolute encoder has a unique code associated with each position, so the exact position is always known, even if the system power is turned off.

Publication 1734-UM006B-EN-P - August 2005

1-4 About the Modules

EXAMPLE

Example of Multiplying Encoder Mode X1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

Input A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z |

(Store Count) |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Z |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Gate / Reset ) |

|

|

|

|

|

|

|

|||||||

Quadrature Encoder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1734-VHSC |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Forward Rotation |

|

|

|

|

|

|

Reverse Rotation |

|

|

|

|

|

|||||||||||||||

A Input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

B Input |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

|

|

|

|

2 |

|

|

|

|

3 |

|

|

|

|

|

|

|

|

2 |

|

|

|

1 |

|

|

|

0 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

X1 Count |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

1 |

|

|

2 |

|

3 |

|

|

4 |

|

5 |

|

|

6 |

|

|

|

5 |

|

4 |

|

3 |

|

2 |

|

1 |

|

0 |

|

|

|||||

X2 Count |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outputs |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1 |

|

2 |

3 |

4 |

5 |

|

6 |

7 |

8 |

9 |

|

10 |

11 |

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

Updated |

|||||||

X4 Count |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Continuously |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X1 Multiplying Encoder Mode

Quadrature input signals are used to count on the leading (up direction) OR trailing (down direction) edge of A for a bidirectional count, and channel B is used to determine the direction.

[ B = leads A, Count = Down; B = follows A, Count = Up ]

X2 Multiplying Encoder Mode

Quadrature input signals are used to count on leading AND trailing edges of A for a bidirectional count, and channel B is used to determine the direction.

[ B = leads A, Count = Down; B = follows A, Count = Up ]

X4 Multiplying Encoder Mode

Quadrature input signals are used to count on leading AND trailing edges of A AND B for a bidirectional count, and channel B is used to determine the direction.

[ B = leads A, Count = Down; B = follows A, Count = Up ]

Publication 1734-UM006B-EN-P - August 2005

About the Modules |

1-5 |

|

|

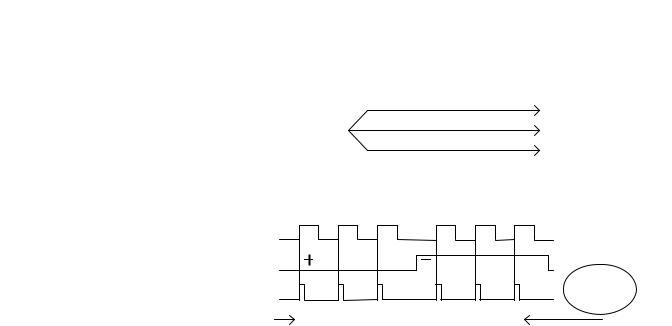

Period / Rate Mode

The Period/Rate Mode will return an incoming frequency and a total accumulated count to the POINTBus, by gating an internal 5MHz internal clock with an external signal.

This mode determines the frequency and total number of input pulses by counting the number of internal 5MHz clock pulses over a user-specified number of input signal pulses. At the end of the specified number of pulses, the module returns the frequency

(0 - 1 MHz).

EXAMPLE

Example of Period/Rate Mode

|

|

A ( Not Used ) |

|

Input A |

|

|

B ( Not Used ) |

|

|

|

|

|

Input B |

|

|

|

Z |

|

|

|

|

|

Input Z |

|

|

|

(Gate / Reset ) |

|

|

Encoder / Pulse Generator |

|

Scalar |

||

|

|

|||

|

|

|

|

5 MHz Clk |

|

|

|

1734-IJ/IK |

|

Z Input ( Pulse ) |

|

|

|

|

5 MHz Internal |

|

|

|

|

Sampling Clock |

1 |

10 |

20 |

Frequency |

|

||||

Accumulated Count |

|

|

|

Updated Here |

|

|

|

|

|

Assumes symmetrical pulse, 50% duty cycle, so Period = Sample Time On X 2 {On & Off}

Frequency = 1 / Period If Count = 20, Scalar = 1, and Clock Period = ( 1 / 5 MHz )

Frequency = 1 / [ ( 20 / 1 ) X ( 1 / 5 MHz ) X 2 ] = 125 kHz

As the frequency of the incoming pulse train at the Z (Gate/Reset) terminal increases, the number of sampled pulses from the 5 MHz clock decreases. Since accuracy is related to the number of pulses received over the sample period, the accuracy decreases with increasing frequencies at the Gate/Reset terminal. Refer to the following Scaling table.

Publication 1734-UM006B-EN-P - August 2005

1-6 About the Modules

Relationship Between Sampled Pulses and Input Frequency

Input Frequency at Z |

Sample Pulses for 1/2 Cycle |

Gate/Reset Terminal |

of Z Gate/Reset Pulse |

|

|

2.5Hz |

1M |

|

|

5Hz |

500k |

|

|

10Hz |

250k |

|

|

20Hz |

125k |

|

|

50Hz |

50k |

|

|

100Hz |

25k |

|

|

200Hz |

12.5k |

|

|

500Hz |

5k |

|

|

1kHz |

2.5k |

|

|

2 Hz |

1.25k |

|

|

5kHz |

500 |

|

|

10kHz |

250 |

|

|

20kHz |

125 |

|

|

50kHz |

50 |

|

|

100kHz |

25 |

|

|

Scaling the input frequency through the use of a scalar can lessen the decrease in accuracy. A scalar value of 1 returns an accurate input frequency only if incoming input pulses have a 50% duty cycle.

Operation of Scalar

In the Period/Rate mode, the scalar lets the incoming pulse train at the Z Gate/Reset pin be divided by a user-defined number. There is one scalar value for each counter. Acceptable values for the scalar are 1, 2, 4, 8, 16, 32, 64, and 128. The default value for each scalar is 1.

Note that a “0” scalar is equivalent to a “1”.

The product of the Sample Period times the scalar should be less than 6.71 seconds in order to avoid a zero frequency detect indication.

(5 MHz sample time = 200ns;

16,777,216 counts x 200ns x 2 half cycles of Z = 6.71 seconds)

Publication 1734-UM006B-EN-P - August 2005

About the Modules |

1-7 |

|

|

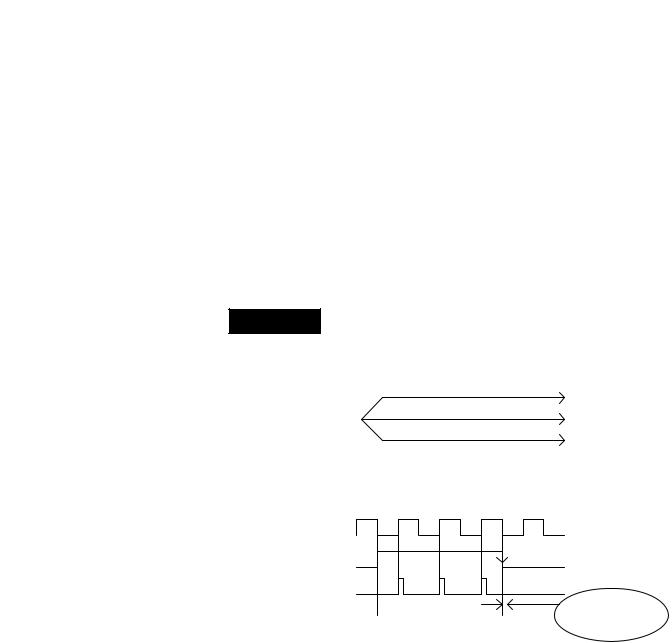

Rate Measurement Mode

The Rate Measurement mode determines the frequency and total number of input pulses over a user-specified sample period. At the end of the interval, the module returns a value representing the sampled number of pulses and a value indicating the incoming frequency.

When the count and frequency update, any associated outputs are checked against their associated presets. Frequency is calculated by dividing the accumulated count by the user selected time period, and is returned in the read data. Allowable time periods are 10ms to 3s in 10ms increments, with a default value of 1s. Note that a “0” time period is equivalent to the 1s default.

EXAMPLE

Example of Rate Measurement Mode

|

|

|

|

|

A Input |

Input A |

|

|

|

|

|

|

B ( Not Used ) |

||

|

|

|

|

|

Input B |

||

|

|

|

|

|

|||

|

|

|

|

|

Z ( Not Used ) |

||

|

|

|

|

|

|||

|

|

|

|

|

Input Z |

||

|

|

|

|

|

(Gate / Reset ) |

||

Encoder/Pulse Generator |

|||||||

|

|||||||

|

Time Base |

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1734-IJ/IK |

|

A Input ( Pulse )

Internal Sampling Gate

1 |

2 |

3 |

Accumulated Count

Frequency Calculated,

Updated Here

User Selectable Sample Period, 10ms to 2s in 10ms increments.

If Sample Period is 50ms, and Count = 3, then Frequency = 3 /50ms = 60Hz

Publication 1734-UM006B-EN-P - August 2005

1-8 About the Modules

New Data Indicator

A two-bit counter, C1 & C0, updates every time an "event" occurs, indicating that new data is available in the Stored/Accumulated Count words. Definitions for events are as follows.

•Any active gate transition in any of the Store Count (Counter or Encoder) modes

•The end of the gate sample period in either the Period mode or Rate mode

•The end of the programmed sample period in the Rate Measurement mode.

To use these bits reliably, acquisition of data from the Counter Module must occur faster than the events, which cause C1/C0 to increment. When C1/C0 is updated, a Change Of State (COS) message can be sent.

Default Configuration

The module's default configuration on startup is as follows.

•Counter Mode

•50Hz filter on A, B and Z

•No time base

•Rollover = 0x00FFFFFF

•Preset = 0

•No scalar

•Counter Control Safe State = 0

To modify the default settings to those required for your application, refer to the Input and Output section of this manual.

Publication 1734-UM006B-EN-P - August 2005

About the Modules |

1-9 |

|

|

Operating Mode Features |

The following table summarizes which features are active in each |

||||

|

mode: |

|

|

|

|

|

|

|

|

|

|

|

Operating Feature |

Counter |

Encoder |

Period |

Rate |

|

|

Up / Down |

X1, X2 & X4 |

/Rate |

Measurement |

|

|

|

|

|

|

|

Preset |

Y |

Y |

N |

N |

|

|

|

|

|

|

|

Rollover |

Y |

Y |

N |

N |

|

|

|

|

|

|

|

Software Reset |

Y |

Y |

Y |

Y |

|

|

|

|

|

|

|

Store Count - Z Gate / Reset 4 modes |

Y |

Y |

N |

N |

|

|

|

|

|

|

|

Scale Input Count at Z Gate / Reset |

N |

N |

Y |

N |

|

|

|

|

|

|

|

Z Gate / Reset Invert Bit |

Y |

Y |

Y |

N |

|

|

|

|

|

|

|

Sample Period |

N |

N |

N |

Y |

|

|

|

|

|

|

Operating Mode Features

The Z Gate/Reset Terminall will operate in one of four modes when the Store Count feature is in use. The following figures detail the operation in each mode:

•Store/Continue

•Store/Wait/Resume

•Store-Reset/Wait/Start

•Store-Reset/Start

Store Count Mode 1: Store/Continue

In mode 1, the rising edge of a pulse input on the Z Gate/Reset terminal causes the current counter value to be read and stored in the Read Data file. The counter continues counting. The stored count is available in the Stored/Accumulated Count word. The stored count information remains until it is overwritten with new data.

Store/Continue

Read, Store Count,

and Continue Counting

Store Count Mode 2: Store/Wait/Resume

In mode 2, the rising edge of a pulse input on the Z Gate/Reset terminal reads and stores the current counter value in the Stored/Accumulated Count word and inhibits counting while the Z

Publication 1734-UM006B-EN-P - August 2005

1-10 About the Modules

Gate/Reset terminal is high. Counting resumes on the falling edge of the pulse at the Z Gate/Reset terminal. The stored count information remains until it is overwritten with new data.

Store/Wait/Resume

Stop Counting

Store Count |

|

Resume Counting |

|

|

|||

|

|

|

|

Store Count Mode 3: Store-Reset/Wait/Start

In mode 3, the rising edge of a pulse input on the Z Gate/Reset terminal stops counting, reads, and stores the current counter value in the Stored/Accumulated Count word, and resets the counter to zero. The counter does not count while the input pulse on the Z Gate/Reset terminal is high. Counting resumes from zero on the falling edge of the pulse at the Gate/Reset terminal. The stored count information will remain until it is overwritten with new data.

Store-Reset/Wait/Start

Counter has stopped Counting |

|

|||

Stop Count, Store, |

Start Counting |

|||

and Reset to zero |

|

|

from zero |

|

|

||||

|

|

|

|

|

Store Count Mode 4: Store-Reset/Start

In mode 4, the rising edge of a pulse input on the Z Gate/Reset terminal will store the current counter value in the Stored/Accumulated Count word and reset the counter to zero. The counter will continue counting while the Z Gate/Reset terminal is high. The stored count information will remain until it is overwritten with new data.

Store-Reset/Start

|

|

Start Counting |

|

Store Count, |

|

|

|

and Reset to zero |

|

Continue Counting |

|

|

|||

|

|

|

|

Publication 1734-UM006B-EN-P - August 2005

Chapter 2

Install the Module

What This Chapter Contains Read this chapter for information about how to install Encoder/ Counter modules.

For information about how to |

See page |

|

|

Before You Begin |

2-1 |

|

|

Install the Mounting Base and Wiring Base Assembly |

2-1 |

|

|

Install the Module |

2-4 |

|

|

Install the Removable Terminal Block |

2-6 |

|

|

Remove a Mounting Base |

2-6 |

|

|

Wire the Modules |

2-7 |

|

|

Communicate with Your Module |

2-9 |

|

|

Before You Begin

ATTENTION

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these guidelines when you handle this equipment:

•Touch a grounded object to discharge potential static.

•Wear an approved grounding wriststrap.

•Do not touch connectors or pins on component boards.

•Do not touch circuit components inside the equipment.

•If available, use a static-safe workstation.

•When not in use, store the equipment in appropriate static-safe packaging.

Publication 1734-UM006B-EN-P - August 2005

Loading...

Loading...