Rockwell Automation 1769-IF4XOF2 User Manual

Compact™ 8-Bit

Low Resolution

Analog I/O

Combination

Module

(Catalog Number 1769-IF4XOF2)

User Manual

Important User Information Because of the variety of uses for the products described in this publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps have been taken to assure that each application and use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some important differences between solid-state equipment and electromechanical devices that should be taken into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION |

Identifies information about practices or |

|

circumstances that can lead to personal injury or |

||

|

!death, property damage or economic loss

Attention statements help you to:

•identify a hazard

•avoid a hazard

•recognize the consequences

|

Identifies information that is critical for successful |

|

IMPORTANT |

||

application and understanding of the product. |

||

|

||

|

||

|

|

MicroLogix, Compact, RSLogix and RSLinx are trademarks of Rockwell Automation. Belden is a trademark of Belden, Inc.

DeviceNet is a trademark of Open DeviceNet Vendor Association (ODVA).

Table of Contents

Preface

|

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

Manual Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-1 |

|

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . |

P-2 |

|

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . |

P-2 |

|

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . |

P-3 |

|

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . |

P-3 |

|

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . |

P-3 |

|

Your Questions or Comments on the Manual . . . . . . . . |

P-3 |

|

Chapter 1 |

|

Overview |

How to Use Analog I/O . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

|

General Description of the Module’s Hardware |

|

|

and Diagnostic Features . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

|

General Diagnostic Features . . . . . . . . . . . . . . . . . . . . . |

1-4 |

|

Overview of the Analog System . . . . . . . . . . . . . . . . . . . . . |

1-4 |

|

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

|

Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

Module Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

|

Chapter 2 |

|

Quick Start for Experienced Users |

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . |

2-1 |

|

What You Need To Do . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

|

Chapter 3 |

|

Installation and Wiring |

Compliance to European Union Directives . . . . . . . . . . . . . |

3-1 |

|

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

|

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

|

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

|

General Considerations to Avoid Electrostatic Damage . . . . |

3-2 |

|

Hazardous Location Considerations . . . . . . . . . . . . . . . |

3-3 |

|

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . |

3-3 |

|

Remove Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

|

Reducing Electrical Noise Interference . . . . . . . . . . . . . |

3-4 |

|

Protecting the Circuit Board from Contamination. . . . . . |

3-5 |

|

System Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-5 |

|

Mounting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

|

Minimum Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

|

Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

|

DIN Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

|

Replacing a Single Module within a System . . . . . . . . . . . . |

3-9 |

Publication 1769-UM008A-EN-P - November 2001

Table of Contents |

ii |

|

|

1769-IF4XOF2 Module Data, Status,

and Configuration Channels

Module Diagnostics and

Troubleshooting

Field Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

System Wiring Guidelines. . . . . . . . . . . . . . . . . . . . . . . 3-10

Removing the Finger-Safe Terminal Block. . . . . . . . . . . 3-14

Wiring the Finger-Safe Terminal Block . . . . . . . . . . . . . 3-15

Analog Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Terminal Door Label . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Analog Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Chapter 4

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 Input/Output/Configuration Data Registers . . . . . . . . . . 4-2 Input Data File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 Input Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 Input Data Words 0 through 3 . . . . . . . . . . . . . . . . . . . 4-4 Input Data Words 4 through 7 . . . . . . . . . . . . . . . . . . . 4-4 Bit Definitions for Input Data . . . . . . . . . . . . . . . . . . . . 4-4 Input Data Resolution and Format . . . . . . . . . . . . . . . . 4-6 Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7 Output Data Words 0 and 1 . . . . . . . . . . . . . . . . . . . . . 4-7 Output Data Resolution and Format . . . . . . . . . . . . . . . 4-8 Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8 Bit Definitions for Configuration Data . . . . . . . . . . . . . . 4-9 Input Filter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Chapter 5

Safety Considerations When Troubleshooting . . . . . . . . . . . 5-1 Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 Activating Devices When Troubleshooting . . . . . . . . . . 5-1 Stand Clear of the Machine. . . . . . . . . . . . . . . . . . . . . . 5-2 Program Alteration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Safety Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Module Operation vs. Channel Operation . . . . . . . . . . . . . 5-2 Power-up Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 Channel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 Out-of-Range Detection . . . . . . . . . . . . . . . . . . . . . . . . 5-3 Critical vs. Non-Critical Errors . . . . . . . . . . . . . . . . . . . . . . 5-4 I/O Module Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 Extended Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 Module Condition Errors . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 Common Hardware Errors . . . . . . . . . . . . . . . . . . . . . . 5-6 Hardware Specific Errors . . . . . . . . . . . . . . . . . . . . . . . 5-6 Module Inhibit Function . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 Contacting Rockwell Automation . . . . . . . . . . . . . . . . . . . . 5-7

Publication 1769-UM008A-EN-P - November 2001

Table of Contents |

iii |

|

|

Specifications

Module Addressing and Configuration with MicroLogix 1500

Configuration Using the 1769-IF4XOF2 Combination Analog Module with a CompactLogix System

Two’s Complement Binary

Numbers

Appendix A

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Appendix B

Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

1769-IF4XOF2 Input Image. . . . . . . . . . . . . . . . . . . . . . B-2

1769-IF4XOF2 Configuration File . . . . . . . . . . . . . . . . . B-3

Configuring 1769-IF4XOF2 in a MicroLogix 1500 System. . . B-3

Configuring the 1769-IF4XOF2 . . . . . . . . . . . . . . . . . . . B-6

Appendix C

Adding a 1769-IF4XOF2 Module to Your System . . . . . . . . C-1 Thin Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3 Generic Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Configuring the 1769-IF4XOF2 Analog

Combination Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5 Accessing the Input and Output Tags. . . . . . . . . . . . . . . . . C-9 Thin Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9 Generic Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Appendix D

Positive Decimal Values . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Glossary

Index

Publication 1769-UM008A-EN-P - November 2001

Table of Contents |

iv |

|

|

Publication 1769-UM008A-EN-P - November 2001

Preface

Who Should Use This

Manual

How to Use This Manual

Read this preface to familiarize yourself with the rest of the manual. This preface covers the following topics:

•Who Should Use This Manual on page P-1

•How to Use This Manual on page P-1

•Related Documentation on page P-2

•Conventions Used in This Manual on page P-2

•Rockwell Automation Support on page P-3

Use this manual if you are responsible for designing, installing, programming, or troubleshooting control systems that use Allen-Bradley Compact™ I/O.

As much as possible, we organized this manual to explain, in a task-by-task manner, how to install, configure, program, operate and troubleshoot a control system using the analog I/O modules.

Manual Contents

If you want... |

See |

|

|

An overview of the analog combination module |

Chapter 1 |

|

|

A quick start guide for experienced users |

Chapter 2 |

|

|

Installation and wiring guidelines |

Chapter 3 |

|

|

Module addressing, configuration and status information |

Chapter 4 |

|

|

Information on module diagnostics and troubleshooting |

Chapter 5 |

|

|

Specifications for the combination module |

Appendix A |

|

|

Information on addressing and configuration using MicroLogix 1500 |

Appendix B |

and RSLogix 500 |

|

|

|

Information on configuring the module using CompactLogix and |

Appendix C |

RSLogix 5000 |

|

|

|

Information on understanding two’s complement binary numbers |

Appendix D |

|

|

Definitions of terms used in this manual |

Glossary |

|

|

Publication 1769-UM008A-EN-P - November 2001

P-2

Related Documentation

The table below provides a listing of publications that contain important information about MicroLogix 1500 systems.

For |

Read this document |

Document number |

|

|

|

A user manual containing information on how to install, |

MicroLogix™ 1500 User Manual |

1764-UM001A-US-P |

use and program your MicroLogix 1500 controller. |

|

|

|

|

|

A user manual containing information on how to install, |

DeviceNet Adapter User Manual |

1769-UM001A-US-P |

and use your 1769-ADN DeviceNet Adapter. |

|

|

|

|

|

A user manual containing information on how to install, |

CompactLogix User Manual |

1769-UM007C-EN-P |

use and program your CompactLogix controller. |

|

|

|

|

|

An overview of 1769 Compact Discrete I/O modules |

1769 Compact Discrete Input/Output Modules Product |

1769-2.1 |

|

Data |

|

|

|

|

An overview of the MicroLogix 1500 System, including |

MicroLogix™ 1500 System Overview |

1764-SO001B-EN-P |

1769 Compact I/O. |

|

|

|

|

|

In-depth information on grounding and wiring |

Allen-Bradley Programmable Controller Grounding and |

1770-4.1 |

Allen-Bradley programmable controllers. |

Wiring Guidelines |

|

|

|

|

Conventions Used in This

Manual

If you would like a manual, you can:

•download a free electronic version from the internet at www.theautomationbookstore.com

•purchase a printed manual by:

–contacting your local distributor or Rockwell Automation representative

–visiting www.theautomationbookstore.com and placing your order

–calling 1.800.963.9548 (USA/Canada) or 001.330.725.1574 (Outside USA/Canada)

The following conventions are used throughout this manual:

•Bulleted lists (like this one) provide information not procedural steps.

•Numbered lists provide sequential steps or hierarchical information.

•Italic type is used for emphasis.

•Text in this font indicates words or phrases you should type.

Publication 1769-UM008A-EN-P - November 2001

P-3

Rockwell Automation

Support

Rockwell Automation offers support services worldwide, with over 75 Sales/Support Offices, 512 authorized distributors and 260 authorized Systems Integrators located throughout the United States alone, plus Rockwell Automation representatives in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

•sales and order support

•product technical training

•warranty support

•support service agreement

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance, please review the information in Chapter 5, Module Diagnostics and Troubleshooting first. Then call your local Rockwell Automation representative.

Your Questions or Comments on the Manual

If you find a problem with this manual, please notify us. If you have any suggestions for how this manual could be made more useful to you, please contact us at the address below:

Rockwell Automation

Automation Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

Publication 1769-UM008A-EN-P - November 2001

P-4

Publication 1769-UM008A-EN-P - November 2001

Chapter 1

Overview

How to Use Analog I/O

This chapter explains how analog data is used and describes the 1769-IF4XOF2 combination analog I/O module. Included is information about:

•How to Use Analog I/O on page 1-1

•General Description of the Module’s Hardware and Diagnostic Features on page 1-2

•Overview of the Analog System on page 1-4

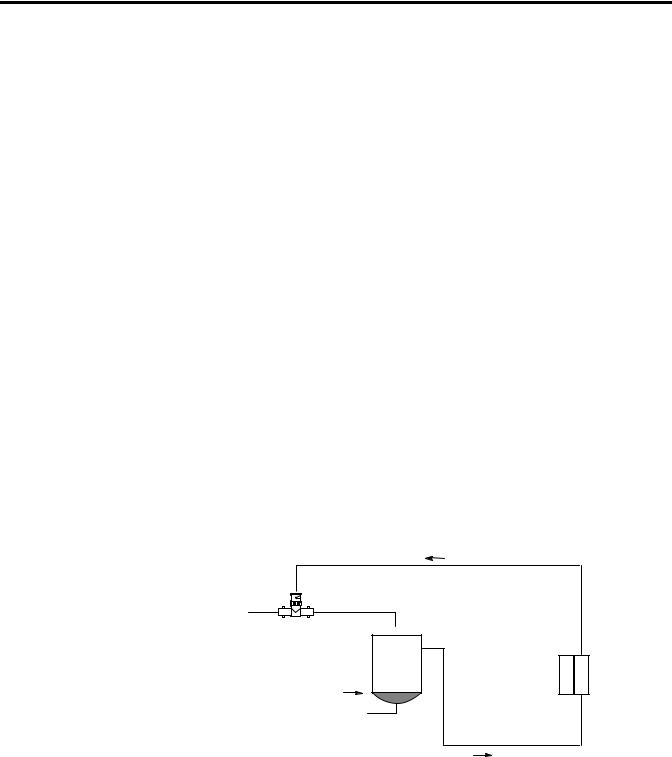

Analog refers to the representation of numerical quantities by the measurement of continuous physical variables. Analog applications are present in many forms. The following application shows a typical use of analog data.

In this application, the processor controls the amount of fluid in a holding tank by adjusting the valve opening. The valve is initially open 100%. As the fluid level in the tank approaches the preset point, the processor modifies the output to close the valve 90%, 80%, and so on, continuously adjusting the valve to maintain the fluid level.

Analog output wired to valve

Valve

Analog I/O

Controller Module

Level Sensor

Analog input wired to tank

Publication 1769-UM008A-EN-P - November 2001

1-2 Overview

General Description of the

Module’s Hardware and

Diagnostic Features

The analog input channels convert and digitally store analog data for retrieval by controllers, such as the MicroLogix™ 1500 and CompactLogix, and from network adapters like the 1769-ADN (Series B) DeviceNet Adapter. The module supports connections from any combination of up to four voltage or current analog sensors. The four high-impedance input channels can be wired as either single-ended or differential inputs.

The output channels provide two single-ended analog outputs, each individually configurable for voltage or current.

The module provides the following input/output types/ranges:

Table 1.1 Normal and Full Input and Output Ranges

Normal Operating Range |

Full Module Range(1) |

0 to +10V dc |

0.0 to +10.5V dc |

|

|

0 to 20 mA |

0 to 21 mA |

|

|

(1)The module provides an overrange band of 0.5V for the 0 to 10V range and 1 mA for the 0 to 20 mA range.

The modules provide the data as raw/proportional data. If scaling to engineering units is required, it must be done in your control program.

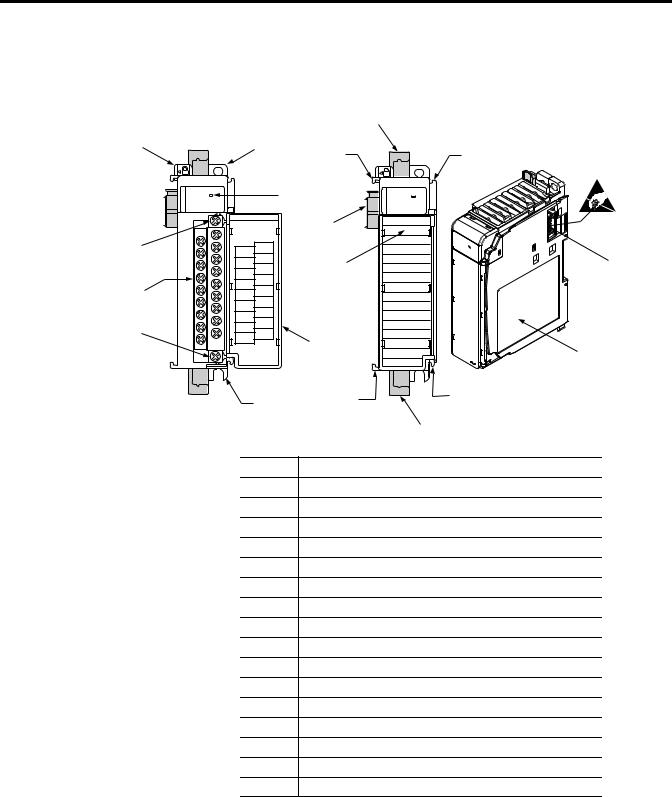

Hardware Features

The module has a removable terminal block. The module’s four input channels can be wired as either single-ended or differential inputs. The module’s two output channels are single-ended only. Module configuration is done via proper wiring of the I/O and the controller’s programming software. In addition, some controllers support configuration via the user program. In either case, the module configuration is stored in the memory of the controller. Refer to your controller’s user manual for more information.

Publication 1769-UM008A-EN-P - November 2001

1

10a

10

10b

Overview 1-3

The following illustration shows the hardware features of the Compact combination analog I/O module.

|

|

|

|

|

8a |

|

|

|

2a |

|

7a |

7a |

|

|

|

|

|

|

||

OK |

|

|

|

3 |

OK |

|

Analog |

|

|

|

|

Analog |

|

|

DANGER |

|

5a |

|

||

Do Not Remove RTB Under Power |

|

|

|

|||

Unless Area is Non-Hazardous |

|

|

|

|||

|

|

V in 0 + |

|

|

|

|

V in 1 + |

|

|

|

|

|

|

I in 1 |

+ |

V/I in 0- |

|

9 |

5b |

|

I |

in 1 + |

|

||||

V/I in |

1- |

|

|

|

|

|

V in 3+ |

V in 2+ |

|

|

|

||

|

|

|

|

|

||

|

|

V/I in 2 - |

|

|

|

|

V/I in 3 - |

|

|

|

|

|

|

I in 3+ |

I |

in 2+ |

|

|

|

|

|

|

|

|

|

||

|

|

ANGL |

|

|

|

|

ANGL |

|

Com |

|

|

|

|

Com |

|

|

|

|

|

|

V out 1+ |

V out 0+ |

|

|

|

||

I out 1+ |

I out 0+ |

|

|

|

||

|

|

|

4 |

|

||

|

|

Ensure Adjacent |

|

|

||

Bus Lever is Unlatched/Latched |

|

6 |

||||

Before/After |

|

|

||||

Removing/Inserting Module |

|

|

||||

1769-IF4XOF2 |

|

|

||||

|

|

2b |

|

7b |

7b |

|

|

|

|

|

|

||

|

|

|

|

|

8b |

|

|

Item |

|

Description |

|

||

|

1 |

|

|

|

bus lever (with locking function) |

|

|

2a |

|

|

upper panel mounting tab |

|

|

|

2b |

|

|

lower panel mounting tab |

|

|

|

3 |

|

|

|

green module status OK LED |

|

|

4 |

|

|

|

module door with terminal identification label |

|

|

5a |

|

|

movable bus connector (bus interface) with female pins |

||

|

5b |

|

|

stationary bus connector (bus interface) with male pins |

||

|

6 |

|

|

|

nameplate label |

|

|

7a |

|

|

upper tongue-and-groove slots |

||

|

7b |

|

|

lower tongue-and-groove slots |

||

|

8a |

|

|

upper DIN rail latch |

|

|

|

8b |

|

|

lower DIN rail latch |

|

|

|

9 |

|

|

|

write-on label for user identification tags |

|

|

10 |

|

|

removable terminal block (RTB) with finger-safe cover |

||

|

10a |

|

RTB upper retaining screw |

|

||

|

10b |

|

RTB lower retaining screw |

|

||

Publication 1769-UM008A-EN-P - November 2001

1-4 Overview

Overview of the Analog

System

General Diagnostic Features

The module contains diagnostic features that can help you identify the source of problems that may occur during power-up or during normal channel operation. These power-up and channel diagnostics are explained in Chapter 5, Module Diagnostics and Troubleshooting.

The module communicates to the controller through the bus interface. The module also receives 5 and 24V dc power through the bus interface.

You can install as many analog modules as your power supply can support. However, the 1769-IF4XOF2 module has a power supply distance rating of 8, which means that it may not be located more than 8 modules away from the system power supply. The illustration below shows how power supply distance is determined.

|

MicroLogix 1500 Controller |

|

I/O |

|

I/O |

|

I/O |

|

I/O |

|

Cable |

|

|

||||||||

|

|

Compact |

|

Compact |

|

Compact |

|

Compact |

|

CapEndor |

|

|

|||||||||

|

with Integrated System |

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Power Supply |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

Power Supply Distance |

||||||

|

|

|

|

|

|

|

OR |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

CompactLogix Controller or I/O Communication Adapter |

|

Compact I/O |

Compact I/O |

|

Compact I/O |

|

System Power Supply (e.g. 1769-PA2) |

|

Compact I/O |

|

Compact I/O |

|

Compact I/O |

|

End Cap or Cable |

|

||||

|

4 |

3 |

2 |

|

1 |

|

|

|

|

1 |

2 |

|

|

3 Power |

Supply Distance |

||||||

Publication 1769-UM008A-EN-P - November 2001

Overview 1-5

System Operation

At power-up, the module performs a check of its internal circuits, memory, and basic functions. During this time, the module status LED remains off. If no faults are found during power-up diagnostics, the module status LED is turned on.

After power-up checks are complete, the module waits for valid channel configuration data. If an invalid configuration is detected, the module generates a configuration error. Once a channel is properly configured and enabled, it begins the analog-to-digital or digital-to-analog conversion process.

Input Channels

Each time an input channel is read by the module, that analog data value is tested by the module for an over-range condition (e.g. input voltage greater than 10V dc). If such a condition is detected, a unique bit is set in the channel status word. The channel status word is described in Input Data File on page 4-3.

The controller reads the analog data from the module. This typically occurs at the end of the program scan or when commanded by the control program. If the controller and the module determine that the bus data transfer was made without error, the data is used in your control program.

Output Channels

The module monitors output channels for over-range conditions. If such a condition is detected, a unique bit is set in the channel status word. The channel status word is described in Output Data File on page 4-7.

The module receives proportional binary values from the bus master (e.g. controller). This typically occurs at the end of the program scan or when commanded by the control program. If the controller and the module determine that the bus transfer was completed without error, the module converts the data to an analog output signal.

Publication 1769-UM008A-EN-P - November 2001

1-6 Overview

CH0

Vin+

Input

Iin+

(same as CH0) V/Iin-

CH1 CH2 CH3 |

A-GND |

|

Output

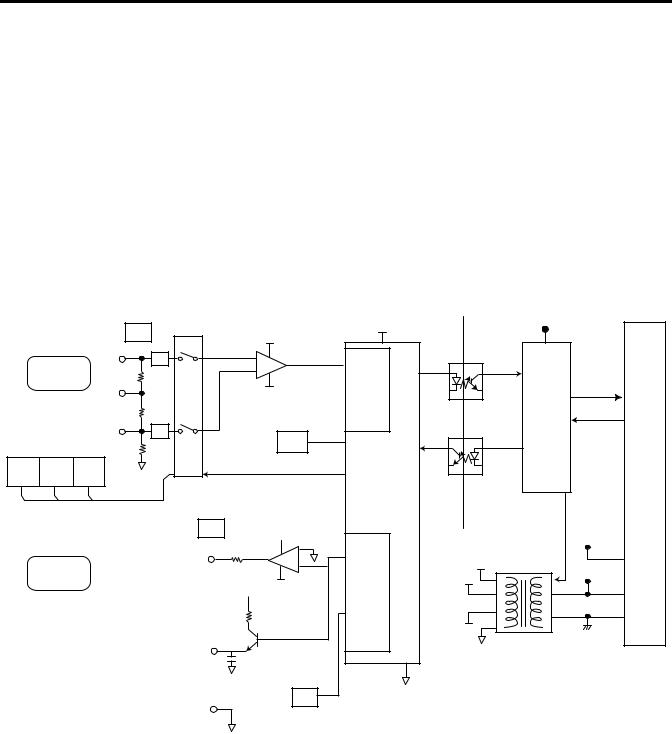

Module Operation

Module Block Diagram

The module’s input channel circuitry consists of four differential analog inputs multiplexed into a single analog-to-digital (A/D) converter. The A/D converter reads the selected input signal and converts it to a digital value which is presented to the controller. The multiplexer sequentially switches each input channel to the module’s A/D converter. The module’s output channel uses a digital-to-analog (D/A) converter to read the digital output data from the controller and convert it to an analog output signal. See the block diagram below.

VA2

Multiplexer |

VA3 |

|

Vref

Channel Select

CH0 |

VA2 |

|

|

Vout+ |

|

VA2 |

VA3 |

|

|

Iout+ |

|

A-GND |

|

ANLG COM |

CH1 |

|

(same as CH0) |

A-GND |

|

|

Galvanic |

|

|

VA1 |

Isolation |

VS1 |

|

|

|

||

AIN+ |

TXD |

|

|

|

|

|

|

A/D |

|

|

|

|

|

ASIC |

|

VREF |

RXD |

|

|

|

|

|

|

|

|

|

Bus |

MCU |

|

|

|

|

|

DC/DC |

VS1 |

|

|

Power |

|

|

VA1 |

Supply |

VS2 |

|

VA2 |

|

|

|

|

|

|

D/A |

|

|

|

|

VA3 |

|

S-GND |

|

|

|

|

|

A-GND |

|

|

|

A-GND |

|

|

Module Calibration

The module’s input/output channel calibration is guaranteed by its design. No field calibration is required.

Publication 1769-UM008A-EN-P - November 2001

Chapter 2

Before You Begin

Required Tools and

Equipment

Quick Start for Experienced Users

This chapter can help you to get started using the analog module. We base the procedures here on the assumption that you have an understanding of Allen-Bradley controllers. You should understand electronic process control and be able to interpret the ladder logic instructions required to generate the electronic signals that control your application.

Because it is a start-up guide for experienced users, this chapter does not contain detailed explanations about the procedures listed. It does, however, reference other chapters in this book where you can get more information about applying the procedures described in each step.

If you have any questions or are unfamiliar with the terms used or concepts presented in the procedural steps, always read the referenced chapters and other recommended documentation before trying to apply the information.

Have the following tools and equipment ready:

•medium blade or cross-head screwdriver

•analog input or output device

•shielded, twisted-pair cable for wiring (Belden™ 8761 or equivalent)

•controller (for example, a MicroLogix™ 1500 controller)

•analog combination (1769-IF4XOF2) module

•programming device and software (for example, RSLogix 500™)

Publication 1769-UM008A-EN-P - November 2001

2-2 Quick Start for Experienced Users

What You Need To Do This chapter covers:

•Verify power supply is adequate on page 2-2

•Attach and lock the module. on page 2-2

•Mount the I/O bank. on page 2-3

•Wire the module. on page 2-4

•Configure the module on page 2-5

•Start the system. on page 2-6

•Monitor the module status. on page 2-6

Step 1: |

Verify power supply is adequate |

Reference |

|

|

Chapter 3 |

|

|

(Installation and Wiring) |

|

|

|

Ensure that your power supply has sufficient current output to support your system configuration. The modules maximum current draw is shown below.

Module |

|

5V dc |

|

24V dc |

|

|

|

|

|

||

1769-IF4XOF2 |

120 mA |

|

160 mA |

||

|

|

|

|

|

|

|

|

The module cannot be located more than 8 modules |

|||

TIP |

|

||||

|

away from the system power supply. |

|

|||

|

|

|

|||

|

|

|

|||

Step 2: |

Attach and lock the module. |

Reference |

|

|

Chapter 3 |

|

|

(Installation and Wiring) |

|

|

|

a.Check that the bus lever of the module to be installed is in the unlocked (fully right) position.

b.Use the upper and lower tongue-and-groove slots to secure the modules together (or to a controller).

c.Move the module back along the tongue-and-groove slots until the bus connectors line up with each other.

d.Push the bus lever back slightly to clear the positioning tab. Use your fingers or a small screwdriver.

Publication 1769-UM008A-EN-P - November 2001

Quick Start for Experienced Users |

2-3 |

|

|

e.To allow communication between the controller and module, move the bus lever fully to the left until it clicks. Ensure it is locked firmly in place.

ATTENTION

When attaching I/O modules, it is very important

!together to ensure proper electrical connection.

f.Attach an end cap terminator to the last module in the system by using the tongue-and-groove slots as before.

g.Lock the end cap bus terminator.that the bus connectors are securely locked

|

|

ATTENTION |

|

|

|

|

! |

Remove power before removing or inserting this |

|

|

module. When you remove or insert a module |

|||

|

with power applied, an electrical arc may occur. |

|||

|

|

|

||

Step 3: |

Mount the I/O bank. |

Reference |

||

|

|

|

|

Chapter 3 |

|

|

|

|

(Installation and Wiring) |

|

|

|

||

|

Be sure to observe minimum spacing guidelines on page 3-7 for |

|||

|

adequate ventilation. |

|

||

Publication 1769-UM008A-EN-P - November 2001

2-4 Quick Start for Experienced Users

Step 4: |

Wire the module. |

Reference |

|

|

Chapter 3 |

|

|

(Installation and Wiring) |

|

|

|

The terminal connections are shown below:

V in 0 +

V in 1 +

V/I in 0 -

V/I in 1 -

I in 0 +

I in 1 +

V in 2 +

V in 3 +

V/I in 2 -

V/I in 3 -

I in 2 +

I in 3 +

ANLG Com

ANLG Com

V out 0 +

V out 1 +

I out 0 +

I out 1 +

D A N G E R

Do Not Remove RTB Under Power Unless Area is Non-Hazardous.

V in 0 +

V in 1 +

V/I in 0 -

V/I in 1 -

I in 0 +

I in 1 +

V in 2 +

V in 3 +

V/I in 2 -

V/I in 3 -

I in 2+

I in 3 +

ANLG

ANLG Com

Com

V out 0 +

V out 1 +

I out 0 +

I out 1 +

Ensure Adjacent Bus Lever is Unlatched/Latched Before/After

Removing/Inserting Module

1769-IF4XOF2

Be sure to follow the system wiring guidelines on page 3-10. See the 1769-IF4XOF2 Wiring Diagram Showing Differential Inputs on page 3-18 and the Wiring Single-ended Sensor/Transmitter Input Types on page 3-19 for examples of wiring using differential and single-ended inputs.

Publication 1769-UM008A-EN-P - November 2001

Quick Start for Experienced Users |

2-5 |

|

|

Step 5: |

Configure the module |

Reference |

|

|

Chapter 4 |

|

|

(Module Data, Status, and |

|

|

Configuration Channel for |

|

|

1769-IF4XOF2) |

|

|

|

The 1769-IF4XOF2 module is configured for current or voltage operation by proper wiring of the analog I/O device to the module. However, a channel is enabled using its configuration file.

Table 2.1 Configuration Data File

Word |

|

|

|

|

|

|

|

|

|

Bit Position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

14 |

13 |

|

12 |

11 |

10 |

9 |

8 |

7 |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

Not Used(1) |

|

|

|

EI3 |

EI2 |

EI1 |

EI0 |

FM0(2) |

PM0(2) |

Not |

PFE0(2) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Used(1) |

|

1 |

|

|

|

|

|

Not Used(1) |

|

|

|

|

EO1 |

EO0 |

FM1(2) |

PM1(2) |

Not |

PFE1(2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Used(1) |

|

2 |

SGN |

|

|

|

Channel 0 Fault Value(2) |

|

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|||

3 |

SGN |

|

|

Channel 0 Program (Idle) Value(2) |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|||||

4 |

SGN |

|

|

|

Channel 1 Fault Value(2) |

|

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|||

5 |

SGN |

|

|

Channel 1 Program (Idle) Value(2) |

|

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|||||

(1)Any attempt to write a non-valid (1’s) bit configurations into any not used selection field results in a module configuration er ror.

(2)Not all controllers support these functions. Refer to your controller’s user manual for details.

The configuration file is typically modified using the programming software configuration screen. It can also be modified through the control program, if supported by the controller. See the configuration file chart on page 4-8.

For an example of module configuration using MicroLogix 1500 and RSLogix 500, see Appendix B. For an example of module configuration using CompactLogix and RSLogix 5000, see Appendix C.

Publication 1769-UM008A-EN-P - November 2001

2-6 Quick Start for Experienced Users

Step 6: |

Start the system. |

Reference |

|

|

Chapter 5 |

|

|

(Module Diagnostics and |

|

|

Troubleshooting) |

|

|

|

a.Apply power.

b.Download your program, which contains the analog module configuration settings, to the controller and put the controller into Run mode.

c.During a normal start-up, the module status LED turns on.

d.If the module status LED does not turn on, cycle power. If the condition persists, replace the module.

Step 7: |

Monitor the module status. |

Reference |

|

|

Chapter 6 |

|

|

(Module Diagnostics and |

|

|

Troubleshooting) |

|

|

|

Module and channel configuration errors are reported to the controller. These errors are typically reported in the controller’s I/O status file. Check the controller’s I/O file.

Channel status data is also reported in the module’s input data table, so these bits can be used in your control program to flag a channel error. See Input Data File on page 4-3.

Publication 1769-UM008A-EN-P - November 2001

Chapter 3

Installation and Wiring

Compliance to European Union Directives

This chapter tells you about:

•Compliance to European Union Directives on page 3-1

•Power Requirements on page 3-2

•General Considerations to Avoid Electrostatic Damage on page 3-2

•System Assembly on page 3-5

•Mounting the Module on page 3-6

•Field Wiring Connections on page 3-10

•Analog Input Wiring on page 3-16

•Analog Output Wiring on page 3-21

This product is approved for installation within the European Union and EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

The analog modules are tested to meet Council Directive 89/336/EEC Electromagnetic Compatibility (EMC) and the following standards, in whole or in part, documented in a technical construction file:

•EN 50081-2

EMC – Generic Emission Standard, Part 2 - Industrial Environment

•EN 50082-2

EMC – Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Publication 1769-UM008A-EN-P - November 2001

3-2 Installation and Wiring

Low Voltage Directive

Power Requirements

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 – Equipment Requirements and Tests.

For specific information required by EN61131-2, see the appropriate sections in this publication, as well as the following Allen-Bradley publications:

•Industrial Automation, Wiring and Grounding Guidelines for Noise Immunity, publication 1770-4.1

•Automation Systems Catalog, publication B113

The module receives its power through the bus interface from the +5V dc/+24V dc system power supply.

The maximum current drawn by the module is shown in the table below.

Module |

5V dc |

24V dc |

|

|

|

1769-IF4XOF2 |

120 mA |

160 mA |

|

|

|

General Considerations to Avoid Electrostatic Damage

Compact I/O is suitable for use in an industrial environment when installed in accordance with these instructions. Specifically, this equipment is intended for use in clean, dry environments (Pollution

degree 2(1)) and to circuits not exceeding Over Voltage Category II(2) (IEC 60664-1).(3)

(1)Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally a temporary conductivity caused by condensation shall be expected.

(2)Over Voltage Category II is the load level section of the electrical distribution system. At this level transient voltages are controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Publication 1769-UM008A-EN-P - November 2001

Installation and Wiring |

3-3 |

|

|

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or non-hazardous locations only. The following WARNING statement applies to use in hazardous locations.

WARNING |

EXPLOSION HAZARD |

•Substitution of components may impair suitability

!for Class I, Division 2.

•Do not replace components or disconnect equipment unless power has been switched off or the area is known to be non-hazardous.

•Do not connect or disconnect components unless power has been switched off or the area is known to be non-hazardous.

•This product must be installed in an enclosure.

•All wiring must comply with N.E.C. article 501-4(b)

Prevent Electrostatic Discharge

ATTENTION |

Electrostatic discharge can damage integrated circuits |

|

or semiconductors if you touch bus connector pins |

||

|

||

|

or the terminal block. Follow these guidelines when |

!you handle the module:

•Touch a grounded object to discharge static potential.

•Wear an approved wrist-strap grounding device.

•Do not touch the bus connector or connector pins.

•Do not touch circuit components inside the module.

•If available, use a static-safe work station.

•When not in use, keep the module in its static-shield box.

Publication 1769-UM008A-EN-P - November 2001

3-4 Installation and Wiring

Remove Power

ATTENTION

!

Remove power before removing or inserting this module. When you remove or insert a module with power applied, an electrical arc may occur. An electrical arc can cause personal injury or property damage by:

•sending an erroneous signal to your system’s field devices, causing unintended machine motion

•causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and its mating connector. Worn contacts may create electrical resistance.

Reducing Electrical Noise Interference

Most applications require installation in an industrial enclosure to reduce the effects of electrical interference. Analog inputs and outputs are highly susceptible to electrical noise. Electrical noise coupled to the analog inputs will reduce the performance (accuracy) of the module.

Group your modules to minimize adverse effects from radiated electrical noise and heat. Consider the following conditions when selecting a location for the analog module. Position the module:

•away from sources of electrical noise such as hard-contact switches, relays, and AC motor drives

•away from modules which generate significant radiated heat, such as the 1769-IA16. Refer to the module’s heat dissipation specification.

In addition, route shielded, twisted-pair analog input and output wiring away from any high voltage I/O wiring.

Publication 1769-UM008A-EN-P - November 2001

Installation and Wiring |

3-5 |

|

|

Protecting the Circuit Board from Contamination

System Assembly

The printed circuit boards of the analog modules must be protected from dirt, oil, moisture, and other airborne contaminants. To protect these boards, the system must be installed in an enclosure suitable for the environment. The interior of the enclosure should be kept clean and the enclosure door should be kept closed whenever possible.

The module can be attached to the controller or an adjacent I/O module or power supply before or after mounting. For mounting instructions, see Panel Mounting Using the Dimensional Template on page 3-7, or DIN Rail Mounting on page 3-8. To work with a system that is already mounted, see Replacing a Single Module within a System on page 3-9.

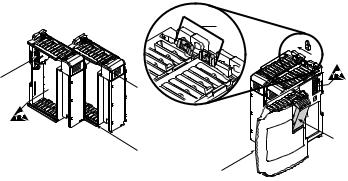

The following procedure shows you how to assemble the Compact I/O system.

C

D

B

A

F

A

E

1.Disconnect power.

2.Check that the bus lever of the module to be installed is in the unlocked (fully right) position.

3.Use the upper and lower tongue-and-groove slots (A) to secure the modules together (or to a controller or power supply).

4.Move the module back along the tongue-and-groove slots until the bus connectors (B) line up with each other.

5.Push the bus lever back slightly to clear the positioning tab (C). Use your fingers or a small screwdriver.

Publication 1769-UM008A-EN-P - November 2001

3-6 Installation and Wiring

6.To allow communication between the controller and module, move the bus lever fully to the left (D) until it clicks. Ensure it is locked firmly in place.

ATTENTION

!

When attaching I/O modules, it is very important that the bus connectors are securely locked together to ensure proper electrical connection.

7.Attach an end cap terminator (E) to the last module in the system by using the tongue-and-groove slots as before.

8.Lock the end cap bus terminator (F).

|

A 1769-ECR or 1769-ECL right or left end cap |

|

IMPORTANT |

||

must be used to terminate the end of the |

||

|

||

|

||

|

communication bus. |

|

|

|

Mounting the Module

ATTENTION

!

During panel or DIN rail mounting of all devices, be sure that all debris (metal chips, wire strands, etc.) is kept from falling into the module. Debris that falls into the module could cause damage on power up.

Publication 1769-UM008A-EN-P - November 2001

Installation and Wiring |

3-7 |

|

|

Minimum Spacing

Maintain spacing from enclosure walls, wireways, adjacent equipment, etc. Allow 50 mm (2 in.) of space on all sides for adequate ventilation, as shown below:

Side

Host Controller

Top

Compact I/O |

Compact I/O |

Compact I/O |

Compact I/O |

Compact I/O |

End Cap |

|

|

|

|

|

|

Side

Bottom

Panel Mounting

Mount the module to a panel using two screws per module. Use M4 or #8 panhead screws. Mounting screws are required on every module.

Panel Mounting Using the Dimensional Template

For more than 2 modules: (number of modules-1) X 35 mm (1.38 in.).

Refer to host controller documentation for this dimension. |

35 |

28.5 |

|

(1.38) |

(1.12) |

||

|

132

(5.197)

122.6±0.2

(4.826±0.008)

NOTE: All dimensions are in mm (inches).

Hole spacing tolerance: ±0.04 mm (0.016 in.).

Host Controller |

Compact I/O |

Compact I/O |

Compact I/O |

Right End Cap |

Publication 1769-UM008A-EN-P - November 2001

3-8 Installation and Wiring

Panel Mounting Procedure Using Modules as a Template

The following procedure allows you to use the assembled modules as a template for drilling holes in the panel. Due to module mounting hole tolerance, it is important to follow these procedures:

1.On a clean work surface, assemble no more than three modules.

2.Using the assembled modules as a template, carefully mark the center of all module-mounting holes on the panel.

3.Return the assembled modules to the clean work surface, including any previously mounted modules.

4.Drill and tap the mounting holes for the recommended M4 or #8 screw.

5.Place the modules back on the panel, and check for proper hole alignment.

6.Attach the modules to the panel using the mounting screws.

TIP |

If mounting more modules, mount only the |

|

last one of this group and put the others aside. |

||

|

||

|

||

|

This reduces remounting time during drilling |

|

|

and tapping of the next group. |

7. Repeat steps 1 to 6 for any remaining modules.

DIN Rail Mounting

The module can be mounted using the following DIN rails:

35 x 7.5 mm (EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latches.

Press the DIN rail mounting area of the module against the DIN rail.

The latches will momentarily open and lock into place.

Publication 1769-UM008A-EN-P - November 2001

Loading...

Loading...