Rockwell Automation 1771-N User Manual

Allen Bradley

High Resolution |

User Manual |

Isolated Analog |

|

Modules |

|

(Cat. No. 1771 N Series) |

|

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the application and use of these products must satisfy themselves that all necessary steps have been taken to assure that each application and use meets all performance and safety requirements, including any applicable laws, regulations, codes and standards. In no event will Rockwell Automation be responsible or liable for indirect or consequential damage resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication are intended solely for purposes of example. Since there are many variables and requirements associated with any particular installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property liability) for actual use based upon the examples shown in this publication.

Allen–Bradley publication SGI–1.1, Safety Guidelines for Application, Installation, and Maintenance of Solid–State Control (available from your local Rockwell Automation office), describes some important differences between solid–state equipment and electromechanical devices that should be taken into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety considerations. The following annotations and their accompanying statements help you to identify a potential hazard. avoid a potential hazard, and recognize the consequences of a potential hazard.

WARNING

!

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal injury or death, property damage, or economic loss.

|

Identifies information about practices or |

|

ATTENTION |

||

circumstances that may lead to personal injury or |

!death, property damage, or economic loss.

Identifies information that is critical for IMPORTANT successfulproduct. application and understanding of the

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution

!Degree 2 industrial environment, in overvoltage Category II applications (as defined in IEC publication 60664–1), at altitudes up to 2000 meters without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR Publication 11. Without appropriate precautions, there may be potential difficulties ensuring electromagnetic compatibility in other environments due to conducted as well as radiated disturbance.

This equipment is supplied as “open type” equipment. It must be mounted within an enclosure that is suitably designed for those specific environmental conditions that will be present, and appropriately designed to prevent personal injury resulting from accessibility to live parts. The interior of the enclosure must be accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific enclosure type ratings that are required to comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as applicable, for explanations of the degrees of protection provided by different types of enclosures. Also, see the appropriate sections in this publication, as well as the Allen–Bradley publication 1770–4.1, (“Industrial Automation Wiring and Grounding Guidelines”), for additional installation requirements pertaining to this equipment.

ATTENTION Preventing Electrostatic Discharge

!which can cause internal damage and affect normal operation. Follow these guidelines when you handle this equipment:

•Touch a grounded object to discharge potential static.

•Wear an approved grounding wriststrap.

•Do not touch connectors or pins on component boards.

•Do not touch circuit components inside the equipment.

•If available, use a static–safe workstation.

•When not in use, keep modules in appropriate static–safe packaging.This equipment is sensitive to electrostatic discharge,

Preface

Using this Manual

Purpose of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your high resolution isolated analog series input/output modules with an Allen-Bradley programmable controller. It helps you install, program, calibrate, and troubleshoot your modules.

You must be able to program and operate an Allen-Bradley programmable controller (PLC) to make efficient use of your analog module. In particular, you must know how to program block transfer instructions.

We assume that you know how to do this in this manual. If you do not, refer to the appropriate PLC programming and operations manual before you attempt to program this module.

In this manual, we refer to:

•the individual module as the “module.”

•the programmable controller, as the “controller” or the “processor.”

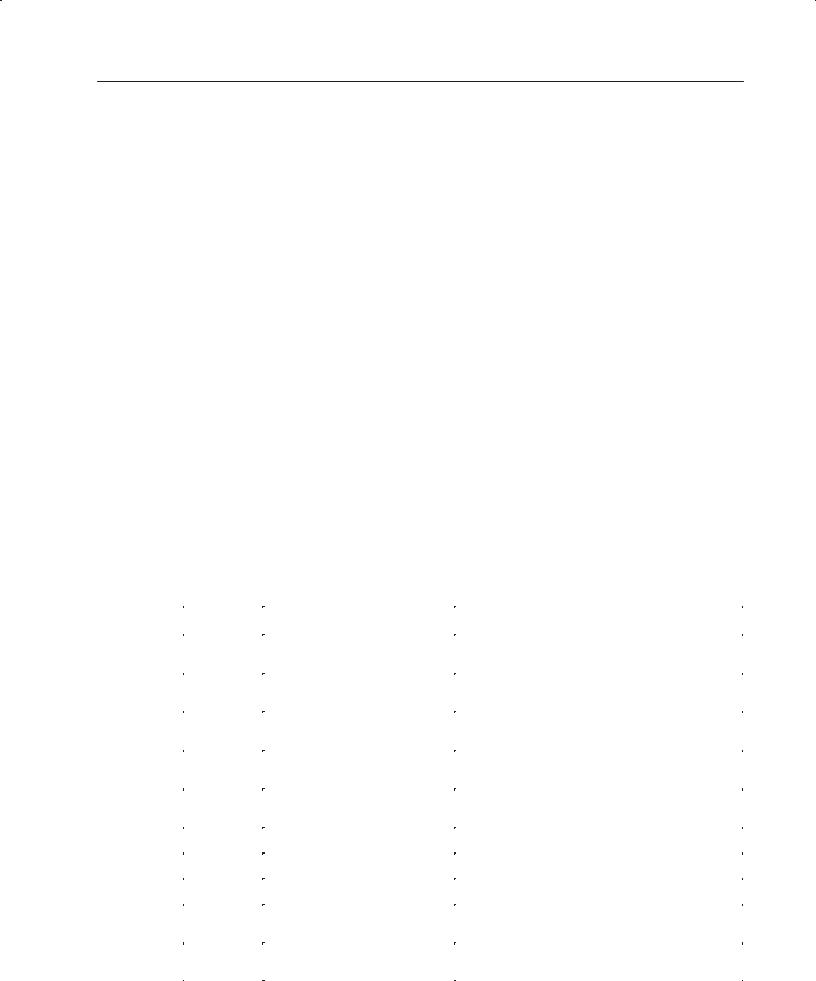

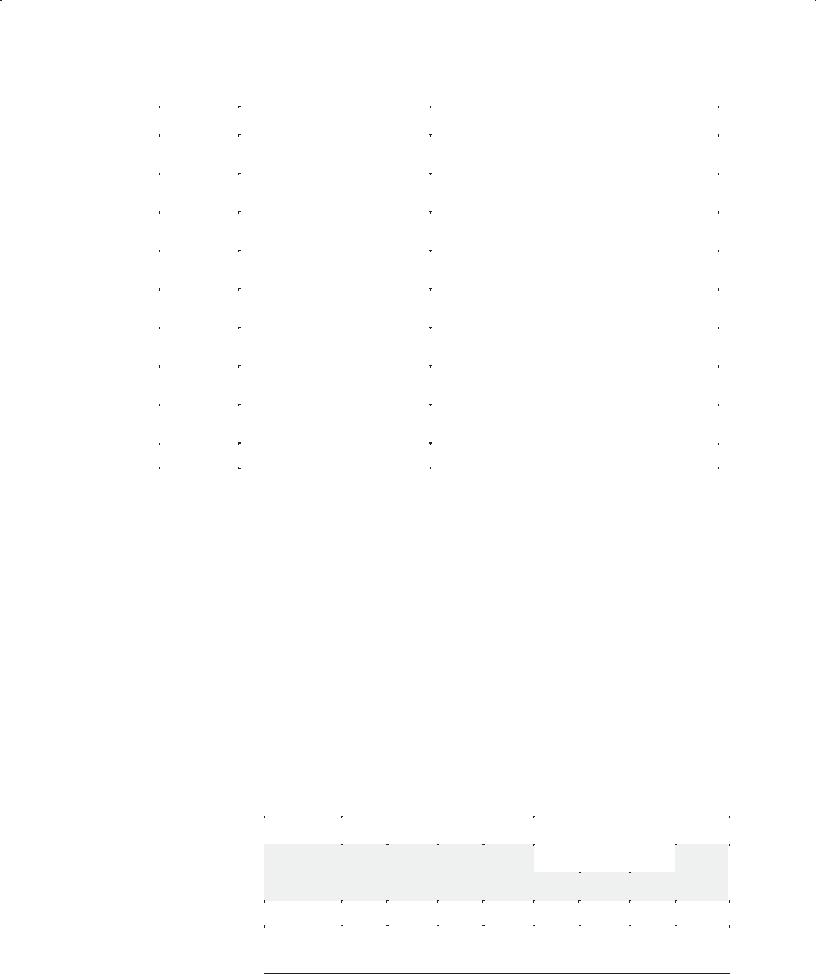

This manual is divided into seven chapters. The following chart shows each chapter with its corresponding title and a brief overview of the topics covered in that chapter.

Chapter |

Title |

Topics Covered |

|

|

|

|

|

1 |

Overview of the High Resolution Isolated |

Descriptions of the modules, including general and |

|

Analog Series Modules |

hardware features |

||

|

|||

|

|

|

|

2 |

Installing the Module |

Module power requirements, keying, chassis location |

|

Wiring of module and remote termination panel |

|||

|

|

||

|

|

|

|

3 |

Communicating with your Analog Module |

How to program your programmable controller for this module |

|

Sample programs |

|||

|

|

||

|

|

|

|

4 |

Configuring the Module |

Hardware and software configuration |

|

Module write block format |

|||

|

|

||

|

|

|

|

5 |

Module Status and Input Data |

Reading data from your module |

|

Module read block format |

|||

|

|

||

|

|

|

|

6 |

Module Calibration |

How to calibrate your modules |

|

|

|

|

|

7 |

Troubleshooting |

Diagnostics reported by the module |

|

|

|

|

|

Appendix A |

Specifications |

Your module's specifications |

|

|

|

|

|

Appendix B |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

Configurations for 0 out/8 in |

|||

|

|

||

|

|

|

|

Appendix C |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

Configurations for 8 out/0 in |

|||

|

|

||

|

|

|

Publication 1771 UM127B-EN-P - December 2002

P–2 |

Using this Manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chapter |

Title |

Topics Covered |

|

|

|

|

|

|

|

Appendix D |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 2 out/2 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix E |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 2 out/6 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix F |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 1 out/7 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix G |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 3 out/5 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix H |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 4 out/4 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix I |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 6 out/2 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix J |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 5 out/3 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix K |

Block Transfer Read and Write |

Description of BTR/BTW words. |

|

|

Configurations for 7 out/1 in |

|||

|

|

|

|

|

|

|

|

|

|

|

Appendix L |

UL/CSA Hazardous Location |

|

|

|

|

|

|

|

Related Products

Product Compatibility

You can install your module in any system that uses Allen-Bradley processors that support block transfer and the 1771 I/O structure.

Contact your nearest Allen-Bradley office for more information about your programmable controllers.

These modules can only be used with 1771-A1B, A2B, A3B, A3B1, A4B or later 1771 I/O chassis and 1771-AM1, -AM2 chassis. Communication between the analog module and the processor is bidirectional. The processor block-transfers output data through the output image table to the module and block-transfers input data from the module through the input image table. The module also requires an area in the data table to store the read block and write block data. I/O image table use is an important factor in module placement and addressing selection. Refer to the table below.

Compatibility and Use of Data Table

|

|

Use of Data Table |

|

|

|

Compatibility |

|

|||

|

|

|

|

|

|

|

|

|

|

|

Catalog |

Input |

Output |

Read |

Write |

|

Addressing |

|

|

||

Number |

|

|

|

|||||||

|

|

|

|

|

|

|||||

Image |

Image |

Block |

Block |

|

|

|

|

|

Chassis |

|

|

|

|

|

|

|

|||||

|

Bits |

Bits |

Words |

Words |

1/2)slot |

|

1)slot |

|

2)slot |

|

|

|

|

|

|

|

|

|

|

|

|

1771 N Series |

8 |

8 |

28 |

59 |

Yes |

|

Yes |

|

Yes |

B |

|

|

|

|

|

|

|

|

|

|

|

A = Compatible with 1771 A1, A2, A4 chassis.

B = Compatible with 1771 A1B, A2B, A3B, A3B1, A4B, 1771 AM1, AM2 chassis.

Yes = Compatible without restriction

No = Restricted to complementary module placement

Publication 1771 UM127B-EN-P - December 2002

Using this Manual |

P–3 |

|

|

Related Publications

You can place your analog module in any I/O module slot of the I/O chassis.

Do not put the analog module in the same module group as a digital high density module unless you are using 1 or 1/2-slot addressing. Avoid placing the analog module close to ac modules or high voltage dc modules.

For a list of publications with information on Allen-Bradley programmable controller products, consult our publication index SD499.

Publication 1771 UM127B-EN-P - December 2002

P–4 |

Using this Manual |

|

|

Publication 1771 UM127B-EN-P - December 2002

Table of Contents

Overview of the High Resolution

Isolated Analog Modules

Installing the Module

Communicating With Your Analog

Module

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

Features of the High Resolution Isolated Analog Series Modules . . . |

1-2 |

Catalog/Channel Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

How the High Resolution Isolated Analog Modules Communicate with |

|

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Before You Install Your Analog Module . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Electrostatic Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Calculate Power Requirements for the I/O Chassis . . . . . . . . . . . . . |

2-1 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Determine Module Location in the I/O Chassis . . . . . . . . . . . . . . . . |

2-2 |

Install the Analog Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

Install the Module in the Chassis and Connect the Cable . . . . . . . . . |

2-3 |

Connecting Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

Connecting 4 Wire Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

Sourcing Input Analog Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-10 |

Making Your Own Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-11 |

Grounding the Field Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-12 |

Interpreting the Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-13 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-13 |

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

Block Transfer Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

PLC 2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

PLC 3 Program Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

PLC 5 and PLC 5/250 Program Example . . . . . . . . . . . . . . . . . . . . |

3-3 |

Module Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Programming Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Sample Ladder Diagram PLC 3 Family Processors . . . . . . . . . . . |

3-5 |

Sample Ladder Diagram PLC 5 Family Processors . . . . . . . . . . . |

3-6 |

Setting Up the Data Table File . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

Publication 1771 UM127B-EN-P - December 2002

toc-ii Table of Contents

Configuring the Module |

Chapter 4 |

|

|

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Configuring the High Resolution Isolated Analog Modules . . . . . . . . |

4-1 |

|

Default Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

|

Module Level Programming Features . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Module •Configuration" Verification . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Temperature Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Two's Complement Binary . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

|

Real Time Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

|

Output Channel Programming Features . . . . . . . . . . . . . . . . . . . . . |

4-6 |

|

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-6 |

|

Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-9 |

|

Ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

|

Alarm Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

|

Reset State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

|

Reset Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

|

Input Channel Programming Features . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

|

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

|

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

|

Alarm Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-12 |

|

Rate Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-13 |

|

Digital Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-13 |

|

Thermocouple Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-14 |

|

RTD Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

|

10 Ohm Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

|

Configuration Block for a Block Transfer Write . . . . . . . . . . . . . . . . |

4-15 |

|

Block Transfer Write Configuration Data Header . . . . . . . . . . . . . . . |

4-15 |

|

Module Configuration Data Header . . . . . . . . . . . . . . . . . . . . |

4-15 |

|

Bit/Word Description of Word 0 . . . . . . . . . . . . . . . . . . . . . . . |

4-16 |

|

Output Configuration Words 1 and 2 . . . . . . . . . . . . . . . . . . . |

4-16 |

|

Bit/Word Description of Output Configuration Words 1 and 2 . . |

4-16 |

|

Output Configuration Words 3 and 4 . . . . . . . . . . . . . . . . . . . |

4-16 |

|

Bit/Word Description of Output Configuration Words 3 and 4 . . |

4-17 |

|

Output Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-17 |

|

Output Configuration Words 5 through 10 . . . . . . . . . . . . . . . |

4-17 |

|

Bit/Word Description of Output Configuration Words 5 through 10 |

4-18 |

|

Input Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-19 |

|

Bit/Word Description of Input Configuration Words 17 through 23 |

4-19 |

|

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-20 |

Publication 1771 UM127B-EN-P - December 2002

Table of Contents |

toc-iii |

|

|

Module Status and Input Data

Module Calibration

Troubleshooting

Specifications

Block Transfer Write and Block Transfer Read Configurations for 0 Output/8 Input 1771)N Series Modules

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

Reading Data from the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

Block Transfer Read Data Format . . . . . . . . . . . . . . . . . . . . . . . . . |

5-2 |

•Outputs Only" Block Transfer Read Data Header . . . . . . . . . . . . . . |

5-2 |

•Inputs Only" and •Output/Input" Block Transfer Read Data Header . |

5-3 |

Input Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-4 |

Bit/Word Description for Input Status Data Words . . . . . . . . . . |

5-5 |

Output Status Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-6 |

Bit/Word Description for Output Status Data Words . . . . . . . . . |

5-7 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-7 |

Chapter 6

Chapter Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-1 |

Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-1 |

Calibrating Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-2 |

Indicator Operation During Calibration . . . . . . . . . . . . . . . . . . . . . . |

6-3 |

Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-3 |

Input Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-3 |

Output Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-7 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-8 |

Chapter 7

Chapter Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-1 |

Diagnostics Reported by the Module . . . . . . . . . . . . . . . . . . . . . . . |

7-1 |

Troubleshooting with the Indicators . . . . . . . . . . . . . . . . . . . . . . . . |

7-2 |

Status Reported by the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-2 |

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-4 |

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-1 |

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-1 |

Appendix B

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

Block Transfer Write Configuration Block for 8 Input Modules . . . . . |

B-1 |

Block Transfer Write Bit/Word Descriptions for 8 Input Modules . . . . |

B-3 |

Block Transfer Read Word Assignments for 8 Input Modules . . . . . . |

B-5 |

Block Transfer Read Bit/Word Descriptions for 8 Input Modules . . . . |

B-7 |

Publication 1771 UM127B-EN-P - December 2002

toc-iv Table of Contents

Block Transfer Write and Block Transfer Read Configurations for 8 Output/0 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 2 Output/2 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 2 Output/6 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 1 Output/7 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 3 Output/5 Input 1771)N Series Modules

Appendix C

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

C-1 |

Block Transfer Write Configuration Block for 8 Output Modules . . . . |

C-1 |

Block Transfer Write Bit/Word Descriptions for 8 Output Modules . . . |

C-3 |

Block Transfer Read Word Assignments for 8 Output Modules . . . . |

C-5 |

Block Transfer Read Bit/Word Description for 8 Output Module . . . . |

C-6 |

Appendix D

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-1 |

Block Transfer Write Configuration Block for the |

|

2 Output/2 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-1 |

Block Transfer Write Bit/Word Descriptions for |

|

2 Output/2 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-2 |

Block Transfer Read Word Assignments for 2 Output/2 Input Module |

D-5 |

Block Transfer Read Bit/Word Description for 2 Output/2 Input Module |

D-6 |

Appendix E

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-1 |

Block Transfer Write Configuration Block for 2 Output/6 Input Modules |

E-1 |

Block Transfer Write Bit/Word Descriptions for |

|

2 Output/6 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-3 |

Block Transfer Read Word Assignments for 2 Output/6 Input Modules |

E-6 |

Block Transfer Read Bit/Word Description for |

|

2 Output/6 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-7 |

Appendix F

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

F-1 |

Block Transfer Write Configuration Block for 1 Output/7 Input Modules |

F-1 |

Block Transfer Write Bit/Word Descriptions for |

|

1 Output/7 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

F-3 |

Block Transfer Read Word Assignments for 1 Output/7 Input Module |

F-6 |

Block Transfer Read Bit/Word Description for 1 Output/7 Input Module |

F-7 |

Appendix G

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

G-1 |

Block Transfer Write Configuration Block for 3 Output/5 Input Modules |

G-1 |

Block Transfer Write Bit/Word Descriptions for |

|

3 Output/5 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

G-3 |

Block Transfer Read Word Assignments for 3 Output/5 Input Modules |

G-6 |

Block Transfer Read Bit/Word Descriptions for |

|

3 Output/5 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

G-7 |

Publication 1771 UM127B-EN-P - December 2002

Table of Contents |

toc-v |

|

|

Block Transfer Write and Block Transfer Read Configurations for 4 Output/4 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 6 Output/2 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 5 Output/3 Input 1771)N Series Modules

Block Transfer Write and Block Transfer Read Configurations for 7 Output/1 Input 1771)N Series Modules

CSA Hazardous Location

Appendix H

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-1 |

Block Transfer Write Configuration Block for 4 Output/4 Input Modules |

H-1 |

Block Transfer Write Bit/Word Descriptions for |

|

4 Output/4 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-3 |

Block Transfer Read Word Assignments for 4 Output/4 Input Modules |

H-6 |

Block Transfer Read Bit/Word Descriptions for |

|

4 Output/4 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

H-7 |

Appendix I

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

I-1 |

Block Transfer Write Configuration Block for 6 Output/2 Input Modules |

I-1 |

Block Transfer Write Bit/Word Descriptions for |

|

6 Output/2 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

I-3 |

Block Transfer Read Word Assignments for 6 Output/2 Input Modules |

I-6 |

Block Transfer Read Bit/Word Descriptions for |

|

6 Output/2 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

I-8 |

Appendix J

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

J-1 |

Block Transfer Write Configuration Block for |

|

5 Output/3 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

J-1 |

Block Transfer Write Bit/Word Descriptions for |

|

5 Output/3 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

J-3 |

Block Transfer Read Word Assignments for the |

|

5 Output/3 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

J-6 |

Block Transfer Read Bit/Word Descriptions for |

|

5 Output/3 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

J-7 |

Appendix K

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

K-1 |

Block Transfer Write Configuration Block for 7 Output/1 Input Modules |

K-1 |

Block Transfer Write Bit/Word Descriptions for |

|

7 Output/1 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

K-3 |

Block Transfer Read Word Assignments for 7 Output/1 Input Modules |

K-6 |

Block Transfer Read Bit/Word Descriptions for |

|

7 Output/1 Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

K-7 |

Appendix L

CSA Hazardous Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

L-1 |

Publication 1771 UM127B-EN-P - December 2002

toc-vi Table of Contents

Publication 1771 UM127B-EN-P - December 2002

Chapter 1

Overview of the High

Resolution Isolated

Analog Modules

Chapter Objectives

Module Description

This chapter gives you information on:

•features of the input/output modules

•how the modules communicate with programmable controllers

The high resolution isolated analog modules are intelligent block transfer modules that interface analog signals with Allen-Bradley PLC-3 and PLC-5 family programmable controllers that have block transfer capability. Block transfer programming moves input data words from the module’s memory to a designated area in the processor data table in a single scan. It also moves configuration words and output data from the processor data table to module memory.

The N-series family includes modules with both analog inputs and outputs on the same module. The modules use 16-bit analog-to-digital converters and 14-bit digital-to-analog converters for high resolution and accuracy. All of these modules require only a single slot in the I/O chassis, and do not require an external power supply.

Since the N-series modules are combination modules, with input and output capabilities on the same module, block transfer reads from the module are structured differently from dedicated input or output modules. Normally, block transfer read information is contiguous, and is stored in contiguous locations in the data block. N-series modules transmit channel data on an individual basis with status information in between. This results in non-contiguous blocks of data in non-contiguous data locations. Care must be taken when transferring this information. Additional programming may be required.

Use with PLC-2 family programmable

IMPORTANT controllers isnot recommended. Refer to chapter 3, page 3-2.

Input data is converted to a specified data type in a digital format to be transferred to the processor’s data table on request. Output data is converted to analog signals and sent to the appropriate output channels. If real time sampling is selected, block transfer reads will only occur at the time selected. Consequently, the minimum interval between block transfer reads is the same as the total input update time for each analog input module (25ms).

Publication 1771 UM127B-EN-P - December 2002

1–2 |

Overview of the High Resolution Isolated Analog Modules |

|

|

Features of the High

Resolution Isolated

Analog Series Modules

The modules have either four or eight channels, each electrically isolated from each other and from the backplane. Input and output terminations are made through prefabricated cables which connect to remote termination panels (RTP). The modules are compatible with all 1771-A1B, A2B, A3B, A3B1, A4B, and later 1771 universal

I/O chassis. In addition, they can be used in 1771-AM1, and -AM2 chassis.

The analog modules are comprised of modular analog signal conditioning blocks that are plugged into a common circuit board.

These signal conditioning blocks provide the following:

•4–20mA output range

•0–50mA output range

•+10V output (scalable +5V, 0-5V, 0-10V, etc.)

•thermocouple input (+100mV)

•+5V input (+20mA with resistor RTP)

•+10V input (+20mA with resistor RTP)

•4–20mA input with sourcing/sinking input

•1–650 ohm RTD input

Your particular module may have a combination of the above conditioning blocks.

The N-Series analog modules feature:

•scaling of data to engineering units

•self-calibration (external reference required)

•software configuration

•user-selectable high and low alarms with deadband (hysteresis)

•self diagnostics

•input open circuit detection

•programmable ramped outputs

Specific analog modules have these additional features:

• Thermocouple input channels

–input channels configurable for thermocouple input ranges — Types B, E, J, K, R, S and T thermocouples (1771-NT2 also includes types C and N)

–cold junction compensation

–scaling to selected temperature range oinC oroF

–temperature resolution —

up to 0.03oC/0.06°F (E, J, K, T, N) up to 0.1oC/0.2°F (B, R, S)

up to 0.07oC/0.1°F (C)

–millivolt resolution up to 1 microvolt

Publication 1771 UM127B-EN-P - December 2002

Overview of the High Resolution Isolated Analog Modules |

1–3 |

|

|

•RTD input channels

–reportsoC, oF, or ohms for 100Ω platinum, 120Ω nickel, or 10Ω copper sensors

–reports ohms for other types of sensors

–0.1oC/0.1oF resolution on 100Ω platinum sensor

–resistance resolution to 10mΩ

•+5V and +10V input channels — can be used with remote termination panelresistor to achieve a nonsourcing current input

•4-20mA input with internal loop power supply

•±10V output channels

•0-25mA output channels

•0-50mA output channels

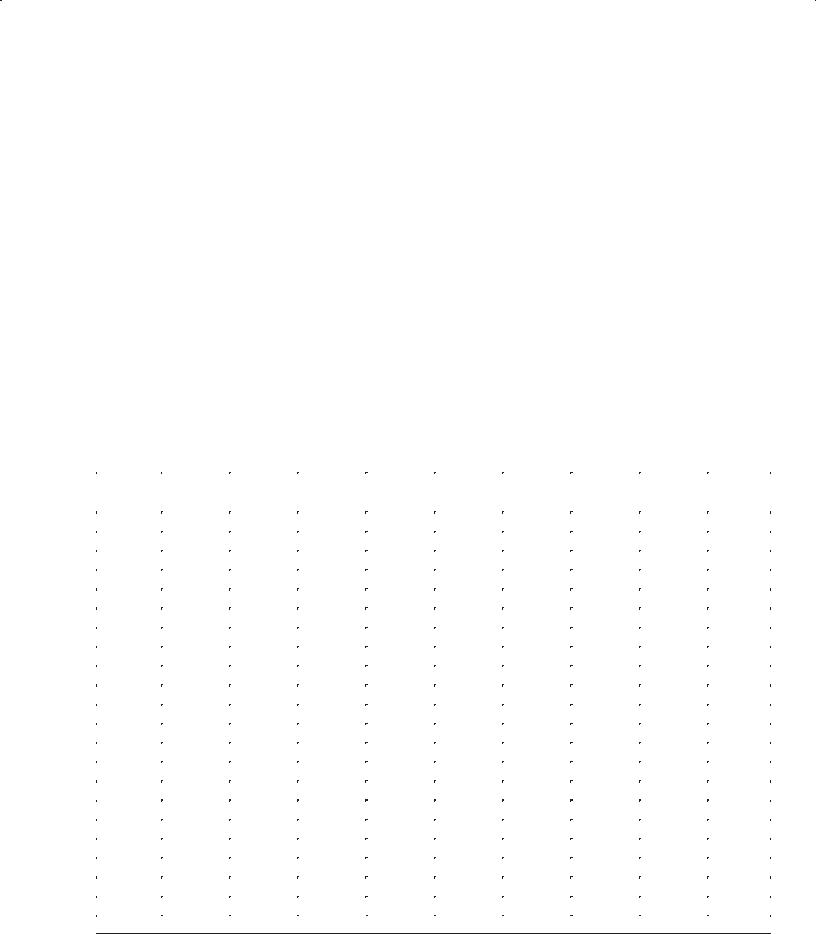

Catalog/Channel Numbers

The following are standard catalog numbers and their respective channel configurations:

Module |

|

Channel 1 |

|

Channel 2 |

|

Channel 3 |

|

Channel 4 |

|

Channel 5 |

|

Channel 6 |

|

Channel 7 |

|

Channel 8 |

Refer to |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

Appendix |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1771 NIS |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

B |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

1771 NIV |

|

+5V (+20mA) |

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

+5V (+20mA) |

+5V (+20mA) |

B |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

1771 NIV1 |

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

|

+10V |

|

|

|

|

|

|

|

+10V |

B |

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

1771 NIVR |

|

+5V (+20mA) |

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

B |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

1771 NIVT |

|

+5V (+20mA) |

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

|

+100mV/TC |

|

|

+100mV/TC |

|

+100mV/TC |

|

+100mV/TC |

B |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

1771 NR |

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

B |

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||

1771 NT1 |

|

|

+100mV/TC |

|

|

+100mV/TC |

|

+100mV/TC |

|

+100mV/TC |

|

|

+100mV/TC |

|

|

+100mV/TC |

|

+100mV/TC |

|

+100mV/TC |

B |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

1771 NT2 |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

-5/+55mV/TC |

B |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

1771 NOC |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

C |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

1771 NOV |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

C |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

1771 NB4T |

|

0-25mA out |

|

0-25mA out |

|

+100mV/TC |

|

+100mV/TC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

1771 NB4S |

|

0-25mA out |

|

0-25mA out |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

1771 NBSC |

|

0-25mA out |

|

0-25mA out |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

|

|

|

|

4-20mA |

E |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||

1771 NBRC |

|

0-25mA out |

|

0-25mA out |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

E |

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1771 NBTC |

|

0-25mA out |

|

0-25mA out |

|

+100mV/TC |

|

+100mV/TC |

|

|

+100mV/TC |

|

|

+100mV/TC |

|

+100mV/TC |

|

+100mV/TC |

E |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

1771 NBV1 |

|

|

|

|

+10V out |

|

|

|

|

+10V out |

|

|

|

|

+10V in |

|

|

|

|

+10V in |

|

|

|

|

|

+10V in |

|

|

|

|

|

+10V in |

|

|

|

|

+10V in |

|

|

|

|

+10V in |

E |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1771 NBVC |

|

0-25mA out |

|

0-25mA out |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

|

+5V (+20mA) |

+5V (+20mA) |

+5V (+20mA) |

E |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

1771 NX1 |

|

0-50mA out |

|

0-25mA out |

|

0-50mA out |

|

0-25mA out |

|

0-25mA out |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

100mV/TC |

F |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1771 NX2 |

|

0-50mA out |

|

0-25mA out |

|

0-50mA out |

|

0-25mA out |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

100mV/TC |

|

|

|

100mV/TC |

G |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

1771 NX3 |

|

0-50mA out |

|

0-25mA out |

|

0-50mA out |

|

0-25mA out |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

|

|

|

|

|

RTD |

|

|

|

100mV/TC |

G |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1771 NX4 |

|

0-50mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

0-25mA out |

|

|

|

|

|

|

|

|

RTD |

|

|

|

100mV/TC |

H |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Appendices I thru L cover other variations of the 1771 N series module.

Publication 1771 UM127B-EN-P - December 2002

1–4 |

Overview of the High Resolution Isolated Analog Modules |

|

|

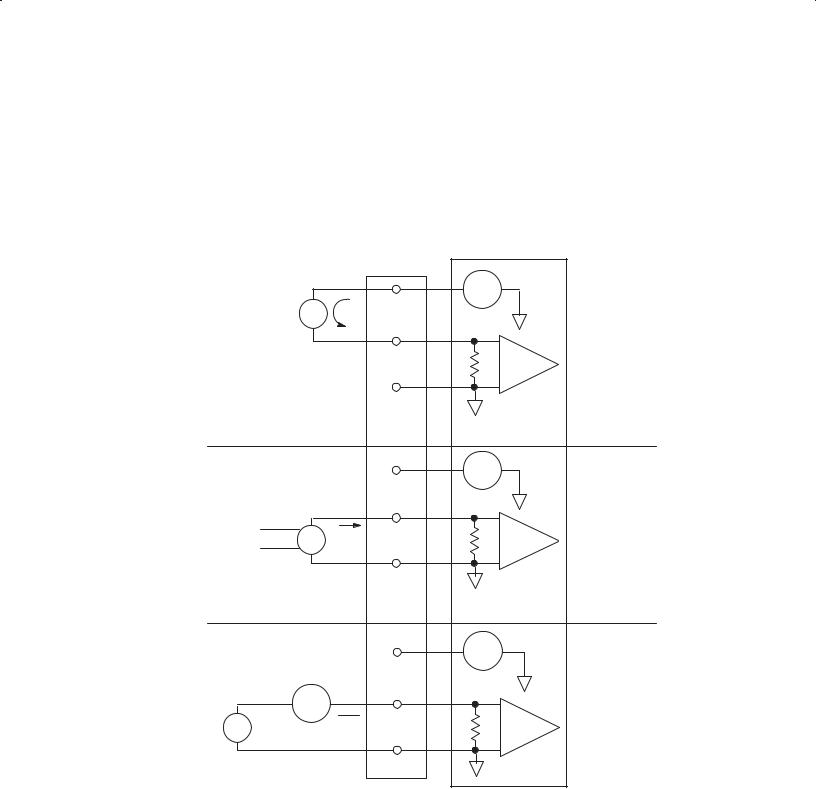

How the High Resolution Isolated Analog Modules Communicate with Processors

5

Memory

User Program

Accuracy

Chapter Summary

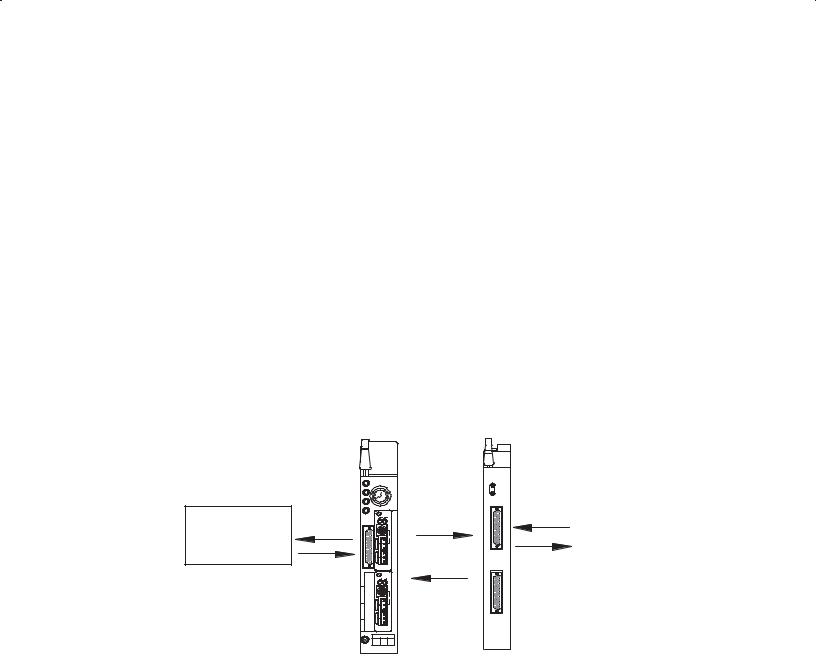

The processor transfers data to and from the module using BTW (block transfer write) and BTR (block transfer read) instructions in your ladder diagram program. These instructions let the processor obtain input values and status from the module, and let you establish the module’s mode of operation (Figure NO TAG).

1.The processor transfers your configuration data, output data and calibration values to the module using a block transfer write instruction.

2.External input devices generate analog signals that are transmitted to the module. Internal output circuitry generates analog signals that drive field devices.

3.The module converts the analog signals into binary or BCD format and stores theses values until the processor requests their transfer.

Table 1.A

Communication Between the Processor and the Module

3

1

BTW |

From input devices |

|

|

|

To output devices |

|

2 |

BTR |

|

4 |

|

PLC Processor |

High Resolution |

|

(PLC 5/40 Shown) |

Isolated Analog |

12933 I |

|

Module |

|

|

|

4.When instructed by your ladder program, the processor performs a read block transfer of the values and stores them in a data table.

5.The processor and module determine that the transfer was made without error, and that input values are within specified range.

6.Your ladder program can use and/or move the data (if valid) before it is written over by the transfer of new data in a subsequent transfer.

See chapter 4, “Configuring the Module,” for more information.

The accuracy of each of the high resolution isolated analog modules is described in Appendix A.

In this chapter you read about the functional aspects of the analog modules and how they communicate with programmable controllers.

Publication 1771 UM127B-EN-P - December 2002

Chapter 2

Installing the Module

Chapter Objectives

This chapter gives you information on:

For information on |

See page |

|

|

Before You Install Your Module . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Determining Power Requirements . . . . . . . . . . . . . . . . . . . . |

2-1 |

Determining Module Location in the Chassis . . . . . . . . . . . . . |

2-2 |

Installing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

Connecting Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

Connecting 4-wire sensors . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

Sourcing input Analog Modules . . . . . . . . . . . . . . . . . . . . . . |

2-10 |

Making Your Own Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-11 |

Grounding Field Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-12 |

Module Indicators . . . . . . . . . . . . . . . . . . |

2-13 |

|

|

Before You Install Your

Analog Module

Electrostatic Damage

Before installing your module in the I/O chassis you must:

|

Action required: |

Refer to: |

|

|

|

|

|

Calculate power requirements for the I/O chassis. |

page 2-1 |

|

|

|

|

|

|

Determine module location in the I/O Chassis |

page 2-2 |

|

|

|

|

|

|

Connect the cable and make wiring connections to the |

page 2-3 |

|

|

remote termination panel |

|

|

|

|

|

|

|

|

|

|

|

ATTENTION

!

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these guidelines when you handle this equipment:

•Touch a grounded object to discharge potential static.

•Wear an approved grounding wriststrap.

•Do not touch connectors or pins on component boards.

•Do not touch circuit components inside the equipment.

•If available, use a static–safe workstation.

•When not in use, keep modules in appropriate static–safe packaging.

Calculate Power Requirements for the I/O Chassis

Your module receives its power through the 1771 I/O chassis backplane from the chassis power supply. The maximum current drawn by the module from this supply ranges from 1.5 to 3.3A, dependent upon the particular type of module. Refer to the specifications in appendix A for standard modules.

Publication 1771 UM127B-EN-P - December 2002

2–2 |

Installing the Module |

|

|

Determine Module

Location in the I/O Chassis

Install the Analog Module

Add this value to the requirements of all other modules in the I/O chassis to prevent overloading the chassis backplane and/or backplane power supply.

Place your module in any slot of the I/O chassisexcept for the extreme left slot. This slot is reserved for processors or adapter modules.

Group your modules to minimize adverse affects from radiated electrical noise and heat. We recommend the following.

•Group analog and low voltage dc modules away from ac modules or high voltage dc modules to minimize electrical noise interference.

•Do not place this module in the same I/O group with a discrete high-density I/O module when using 2-slot addressing. This module uses a byte in both the input and output image tables for block transfer.

To install your module in an I/O chassis:

1. First, turn off power to the I/O chassis:

|

|

Remove power from the 1771 I/O chassis |

|

ATTENTION |

|

|

backplane and disconnect the cable from the |

|

! |

module before removing or installing an I/O |

|

module. |

||

• Failure to remove power from the backplane |

||

|

|

could cause injury or equipment damage due to |

|

|

possible unexpected operation. |

|

|

• Failure to remove power from the backplane |

|

|

could cause module damage, degradation of |

|

|

performance, or injury. |

|

|

|

Observe the following precautions when inserting ATTENTION or removing keys:

! |

• |

insert or remove keys with your fingers |

• |

make sure that key placement is correct |

Incorrect keying or the use of a tool can result in damage to the backplane connector and possible system faults.

Publication 1771 UM127B-EN-P - December 2002

Installing the Module |

2–3 |

|

|

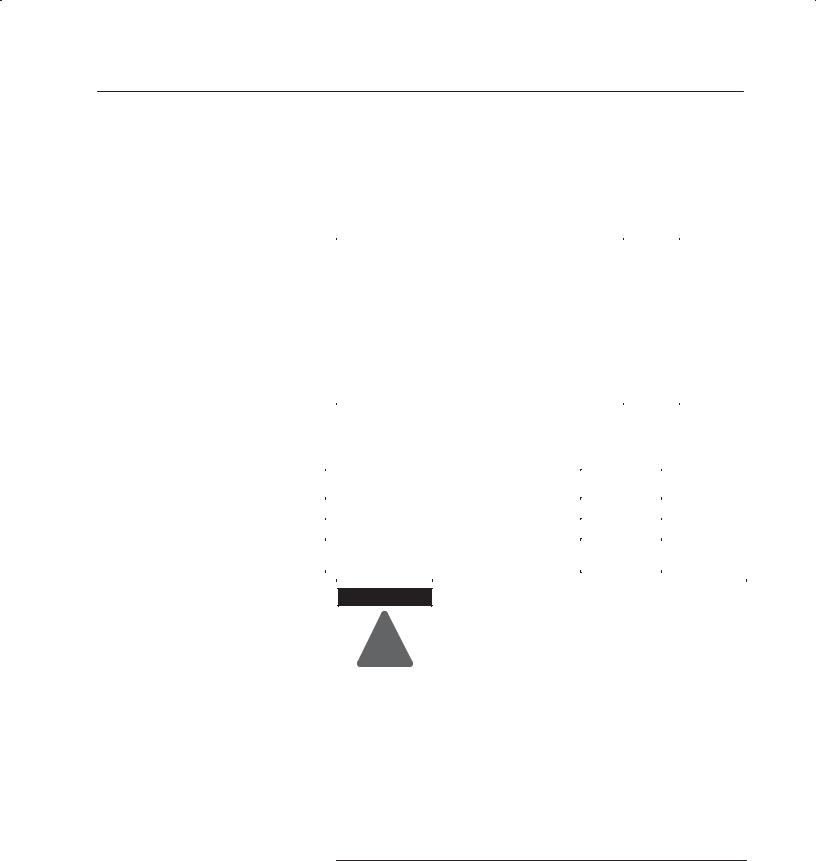

Key the Backplane Connector

Place your module in any slot in the chassis except the leftmost slot which is reserved for processors or adapters.

Position the keying bands in the backplane connectors to correspond to the key slots on the module.

Place the keying bands: between 26 and 28 between 32 and 34

You can change the position of these bands if subsequent system design and rewiring makes insertion of a different type of module necessary.

I/O chassis

Keying Bands

Upper Connector

11022 I

Install the Module in the

Chassis and Connect the

Cable

ATTENTION

!

Remove power from the 1771 I/O chassis backplane and field wiring arm before removing or installing an I/O module.

•Failure to remove power from the backplane or wiring arm could cause module damage, degradation of performance, or injury.

•Failure to remove power from the backplane could cause injury or equipment damage due to possible unexpected operation.

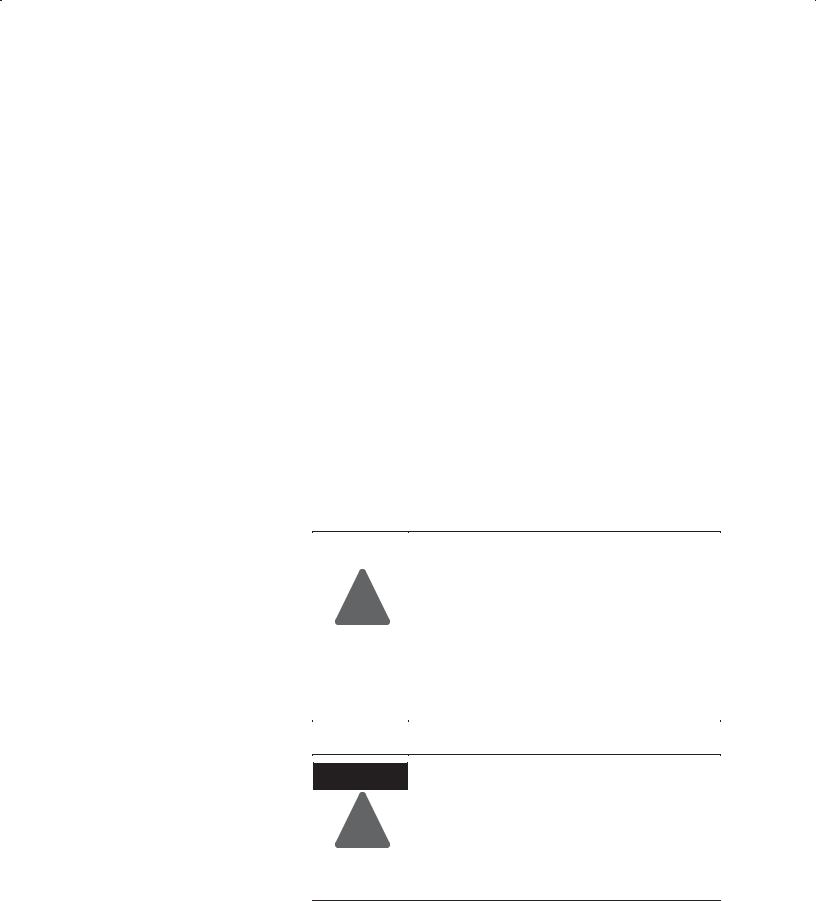

1.Place the module in the plastic tracks on the top and bottom of the slot that guides the module into position.

2.Do not force the module into its backplane connector. Apply firm even pressure on the module until it is firmly seated in the chassis. Note: The chassis locking bar will not close if all modules are not seated properly.

Publication 1771 UM127B-EN-P - December 2002

|

2–4 |

Installing the Module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

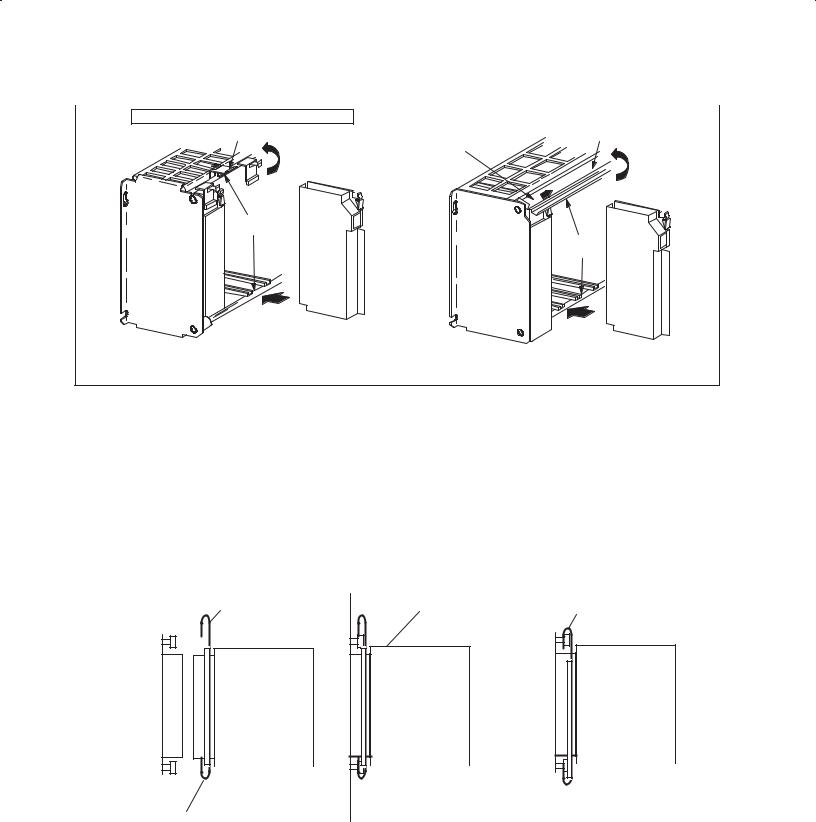

1771 A1B, A2B, A3B, A3B1, A4B I/O chassis |

|

|

|

|

1771 A1B, A2B, A3B1, A4B Series B I/O chassis |

|

|

|

|

locking tab |

locking bar |

|

|

|

|

locking bar pin |

|

card guides

card guides

module

Snap the chassis latch over

the top of the module to secure it.

module

Swing the chassis locking bar down into place to secure

the modules. Make sure the locking pins engage.

19809

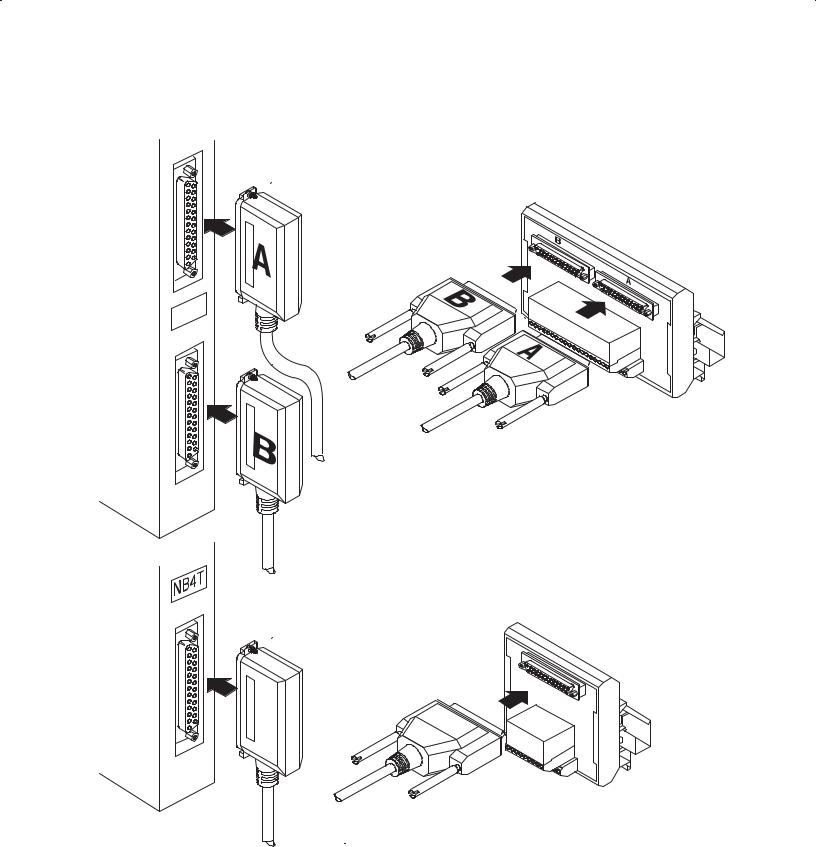

3.Connect the 1771-NC cable to the module as shown in Figure 2.1.

A.Slide the locking bar up.

B.Insert the cable connector into the mating connector on the front of the module.

C.Slide the locking bar down over the mating pins on the module to lock the connector onto the module.

Figure 2.1

Connecting the Cable to the Front of the Module

1. Position locking bar in up position. |

2. Insert connector into mating connector. |

3. Slide locking bar down to lock.

Cable Connector

Module Connector

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Locking bar |

|

|

|

|

|

|

|

|

|

|

11023 I |

||

|

|

|

|

|

|

|

|

|

|||||

Publication 1771 UM127B-EN-P - December 2002

Installing the Module |

2–5 |

|

|

Connecting Wiring

The N-series modules are cable-connected to a remote termination panel using cat. no. 1771-NC6 (6 ft) or -NC15 (15 ft) cables.

Variations of remote termination panels are used, depending on the type of module used. These are:

Catalog |

Description |

|

Number |

||

|

||

|

|

|

1771 RTP1 |

has cold junction compensation for thermocouples |

|

|

|

|

1771 RTP3 |

incorporates resistors and fuses; used primarily for 4 20mA inputs |

|

|

when using +5V inputs (Uses 5mm x 20mm fast acting 1/4A fuses |

|

|

such as Bussmann GMA-1/4, 250V/250mA.) |

|

|

|

|

1771 RTP4 |

a general use block with straight thru wiring that can be used for all |

|

|

applications except thermocouples1 |

|

1771 RT41 |

a 4 channel block with cold junction compensation for thermocouples |

|

|

|

|

1771 RT44 |

a general use 4 channel block with straight thru wiring that can be |

|

|

used for all applications except thermocouples1 |

1 RTP4 and RT44 can be used with thermocouples if a method of cold junction compensation is provided at the interface of thermocouple and copper wires within the system.

The remote termination panels are designed for mounting on standard DIN 1 or DIN 3 mounting rails.

Publication 1771 UM127B-EN-P - December 2002

2–6 |

Installing the Module |

|

|

|

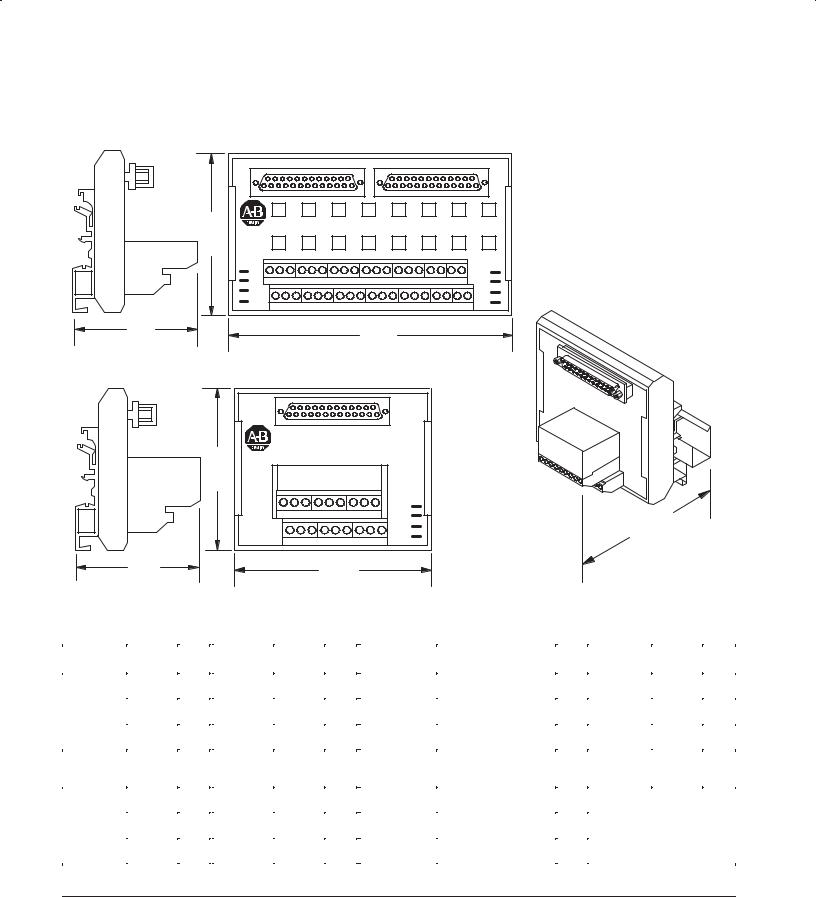

Figure 2.2 |

|

|

|

Mounting Dimensions for the Remote Termination Panels |

|

|

|

RTP1, RTP3, RTP4 |

|

|

|

B |

A |

Inches |

|

|

|

|

|

|

|

(Millimeters) |

|

3.0 |

|

|

|

(75.0) |

|

|

|

J8 |

J1 |

|

|

J7 |

J2 |

|

|

J6 |

J3 |

|

|

J5 |

J4 |

|

2.3 |

5.30 |

|

|

(58.4) |

|

|

|

(134.6) |

|

|

|

|

|

|

|

|

RT41, RT44 |

|

|

|

3.0 |

|

|

|

(75.0 |

|

|

|

) |

|

|

|

J1 |

|

|

|

J2 |

|

2.3 |

|

J3 |

|

(58.4) |

|

J4 |

|

|

|

|

|

|

2.3 |

|

|

Dimensions to |

3.5 |

|

back of DIN rail |

|

(58.4) |

|

||

(88.9) |

|

|

|

|

|

19366 |

|

|

|

|

|

Table 2.A

Remote Termination Panel Connection Points for Field Devices (Channel 1 shown)

Input Type |

Connect |

To |

Input Type |

Connect |

To |

Input Type |

Connect |

To |

Input Type |

Connect |

To |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

I1 |

Current |

+ |

I1 |

|

+ |

I1 |

|

+ |

I1 |

|

|

|

|

|

|

|

|

|

|

|

|

||

Voltage |

|

R1 |

(with |

|

R1 |

Thermocouple |

|

R1 |

Current |

2 |

R1 |

|

external |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

Shield |

S1 |

resistor) |

Shield |

S1 |

|

Shield |

S1 |

(Source/ |

Shield |

S1 |

|

|

|

|

Sink) |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Output |

Connect |

To |

Output |

Connect |

To |

Input Type |

Connect |

To |

|

Loop |

O1 |

|

Type |

Type |

|

Power |

|||||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

O1 |

|

+ |

O1 |

|

Excitation (A) |

O1 |

|

|

|

|

Voltage |

|

|

Current |

|

|

RTD1 |

|

|

|

|

|

|

|

R1 |

|

R1 |

Lead Compensation (B) |

I1 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shield |

S1 |

|

Shield |

S1 |

|

Common (C) |

R1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 When using 4 wire RTD, leave the 4th wire open.

2 Not used when N Series module is supplying loop power. Refer to Figure 2.6 in this document.

Publication 1771 UM127B-EN-P - December 2002

Installing the Module |

2–7 |

|

|

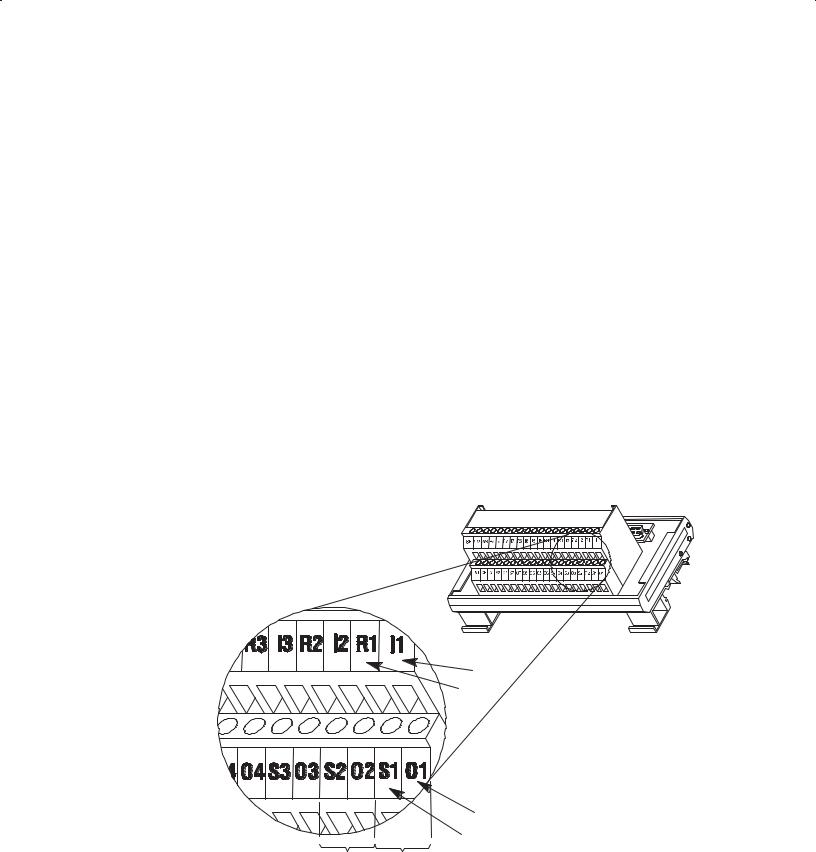

Module End of 1771 NC cable

Module End of 1771 NC cable

Figure 2.3

Remote Termination Panel Wiring

Example: Channel 1 Connections

R1 = Return 1

I1 = Input 1

O1 = Output 1

S1 = Shield 1

RTP End of 1771 NC cable

Channel 1 Connections

R1 = Return 1

I1 = Input 1

O1 = Output 1

S1 = Shield 1

RTP End of 1771 NC cable

Note: Terminals W1, W2 and W3 are spares.

Do not use terminals CR and CL.

RTP1

DIN Rail

Note: Terminals W1, W2 and W3 are spares.

Do not use terminals CR and CL.

RT41

DIN Rail

11024 I

Publication 1771 UM127B-EN-P - December 2002

2–8 |

Installing the Module |

|

|

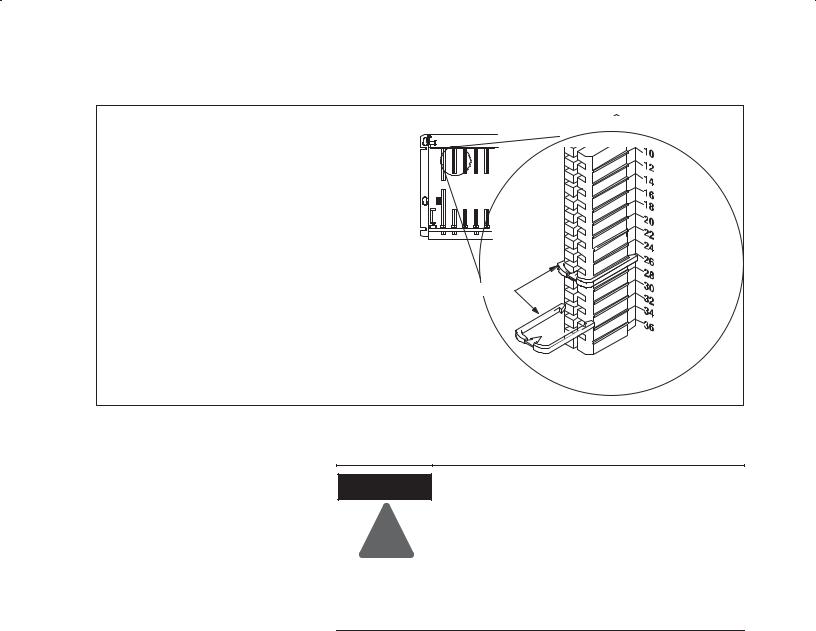

Field wiring to the remote termination panel is the same for all remote termination panel variations. Refer to Figure 2.4.

Each channel has 4 connections: R, I, O, and S.

•R = return

•I = input

•O = output

•S = shield

Channel 1 would use R1, I1, O1, and S1; channel 2 would use R2,

I2, O2, and S2; and so on for the remaining channels.

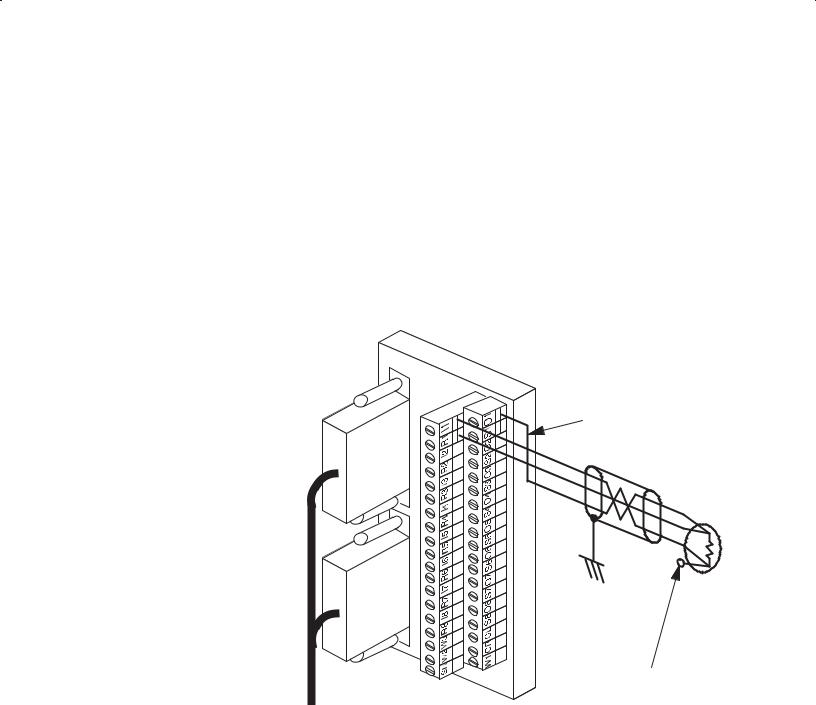

To connect field wiring to the remote termination panel:

1.Strip 3/8 inch (9.25 mm) of insulation from the 22-12 AWG wire.

2.Insert the wire into the open connector slot.

3.Tighten the screw to 4.4–5.2 lb–in. (0.5–0.6Nm) to clamp the wire.

Figure 2.4

Connecting Wire to the Remote Termination Panel

Each channel has four connections: R, I, O, and S.

Field wiring to the RTP is the same for all RTP variations. Channel 1 uses R1, I1, O1, and S1; channel 2 uses R2, I2, O2, and S2; and so on for the remaining channels.

Remote

Termination

Panel (RTP)

I = input

R = return

Field Wiring

O = output

S = shield

channel 2 channel 1

19621

Publication 1771 UM127B-EN-P - December 2002

Installing the Module |

2–9 |

|

|

Connecting 4)Wire Sensors

Figure 2.5 shows how to connect 4-wire sensors to the remote termination panel. A 4-wire sensor has two pairs of leads; one pair for each resistor junction. One wire of the four is not used (it does not matter which one). This leaves three wires – one pair and one single wire. You must connect the single wire to the terminal marked “O_”. You connect the remaining pair of wires to terminals “I_” and “R_”. It doesn’t matter which wire of the pair connects to terminal “I_” and which wire connects to terminal “R_” so long as all three wires are the same AWG gauge.

Figure 2.5

Connecting a 4)Wire Sensor to the Remote Termination

Panel

Single lead connects to terminal O

Chassis |