Rockwell Automation 1785-L11B, 1785-L20B, 1785-L30B, 1785-L40B, 1785-L40L User Manual

...

Installation Instructions

|

Enhanced PLC 5 |

|

Programmable Controller |

|

Firmware Upgrade |

|

(Catalog Numbers 1785-L11B, -L20B, -L30B, |

|

-L40B, -L40L, -L60B, -L60L, -L80B) |

Using These Instructions |

These instructions describe: |

|

• an important safety precaution involving static electricity |

|

discharges |

|

• how to upgrade the processor firmware |

|

For more information about PLC-5 processors, see the Enhanced and |

A B |

Ethernet PLC-5 User Manual, publication number 1786-6.5.12. For |

|

more information, contact your Allen-Bradley service representative. |

Before You Install ... Printed circuit board components and Programmable Read-only Memory (PROM) devices can be damaged during routine handling and installation. Follow these precautions to reduce static electricity discharges before you upgrade the processor firmware.

•Handle the printed circuit boards and PROMs by the case or carrier without touching the pins or the edge connector.

•Use a static-free workstation.

•Connect the static-free workstation to ground through a minimum 200K ohm resistance.

•Wear a grounded, conductive wrist strap with a minimum 200K ohm resistance.

•Ground all tools before you begin to upgrade the firmware.

•Control the relative humidity of the installation area ± ideal conditions are 40% to 60% relative humidity.

Publication1785 5.13 April 1996

2 |

Enhanced PLC-5 Programmable Controller Firmware Upgrade |

To Upgrade the Processor

Firmware ...

Follow these steps to upgrade the processor firmware.

1Save processor memory using the programming software.

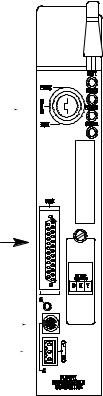

keyswitch;

selects processor mode

channel 0 serial port

channel 1A status indicator

8 pin mini DIN, DH+ programming terminal connection

terminal connection

channel 1A communication  port;

port;

2Remove the battery cover and disconnect the battery.

Skip this step if you have a PLC 5/11 or 5/20 processor.

3Remove the phillips head screw near the channel 1B LED and gently remove the channel 1 communication plug. Be aware that the memory grounding clip may move or drop off from the cover mounting tab.

Skip this step if you have a PLC 5/11 or 5/20 processor.

4Remove the lug nuts that hold the serial channel to the metal face plate. These lug nuts are located on the exposed circuit board for PLC 5/40 and 5/60 processors.

5 Remove the four screws that hold the right side plastic cover.

6Remove the washers and two remaining screws located in the middle of the exposed circuit board.

Separate the two processor boards by pulling the exposed circuit board at the backplane edge connector away from the metal cover

7as you would open a book. Notice the direction in which the battery cable is wrapped around the nearby standoff to prevent obstruction of the dip switch. After you separate the boards, pull the battery cable through the battery housing (still attached to the circuit board.)

8Disconnect the wires leading from the keyswitch to the stake pins on the exposed circuit board.

Publication1785 5.13 April 1996

Loading...

Loading...