Rockwell Automation 1771-QB User Manual

Linear Positioning Module

Cat. No. 1771-QB

User Manual

Important User Information |

Because of the variety of uses for the products described in this publication, |

||

|

those responsible for the application and use of this control equipment must |

||

|

satisfy themselves that all necessary steps have been taken to assure that each |

||

|

application and use meets all performance and safety requirements, including |

||

|

any applicable laws, regulations, codes and standards. |

||

|

The illustrations, charts, sample programs and layout examples shown in this |

||

|

guide are intended solely for purposes of example. Since there are many |

||

|

variables and requirements associated with any particular installation, the |

||

|

Allen-Bradley Company, Inc. does not assume responsibility or liability (to |

||

|

include intellectual property liability) for actual use based upon the examples |

||

|

shown in this publication. |

||

|

Allen-Bradley Publication SGI-1.1, ªSafety Guidelines for the Application, |

||

|

Installation and Maintenance of Solid State Controlº (available from your local |

||

|

Allen-Bradley office) describes some important differences between solid-state |

||

|

equipment and electromechanical devices which should be taken into |

||

|

consideration when applying products such as those described in this |

||

|

publication. |

||

|

Reproduction of the contents of this copyrighted manual, in whole or in part, |

||

|

without written permission of the Allen-Bradley Company Inc. is prohibited. |

||

|

Throughout this manual we use notes to make you aware of safety |

||

|

considerations: |

||

|

|

|

|

|

ATTENTION: Identifies information about practices or |

||

|

circumstances that can lead to personal injury or death, property |

||

|

damage or economic loss. |

||

|

|

|

|

|

Attentions help you: |

||

|

identify a hazard |

||

|

avoid the hazard |

||

|

recognize the consequences |

||

|

Important: Identifies information that is especially important for |

||

|

successful application and understanding of the product. |

||

|

PLC is a registered trademark of Allen-Bradley Company, Inc. |

||

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

P 1 |

Organization of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

P 1 |

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

P 2 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Related Publications |

|

P 2 |

Related Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

P 2 |

Frequently Used Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

P 3 |

Introducing the Linear Positioning Module . . . . . . . . . . . . |

1 1 |

|

What is the Linear Positioning Module? . . . . . . . . . . . . . . . . . . . . |

|

1 1 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Product Compatibility |

|

1 2 |

Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1 2 |

Servo and Proportional Valves . . . . . . . . . . . . . . . . . . . . . . . . |

|

1 3 |

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

1 4 |

Positioning Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 1 |

|

Axis Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 1 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Closed Loop Positioning |

|

2 2 |

Linear Displacement Transducer . . . . . . . . . . . . . . . . . . . . . . . |

|

2 2 |

. . . . . . . . . . . . . . . . . . . . . . . . . . .A Simple Positioning Loop |

|

2 3 |

Proportional Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 4 |

Feedforwarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 5 |

Integral Control (Reset Control) . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 5 |

Derivative Control (Rate Control) . . . . . . . . . . . . . . . . . . . . . . . |

|

2 6 |

Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 7 |

PID Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

2 7 |

Positioning with the Linear Positioning Module . . . . . . . . . |

3 1 |

|

How the Module Fits in a Positioning System . . . . . . . . . . . . . . . . |

|

3 1 |

How the Module Interacts with a PLC . . . . . . . . . . . . . . . . . . . . . . |

|

3 2 |

Read Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 2 |

Write Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 2 |

Axis Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 2 |

Commanding Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 4 |

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 4 |

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 5 |

Motion Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

3 5 |

ii |

Table of Contents |

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 1 |

|

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 1 |

Wiring Arm Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 2 |

Transducer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 3 |

. . . . . . . . . . . . .Determining the Optimum Number of Circulations |

|

4 3 |

Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 5 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Auto/Manual Input |

|

4 6 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hardware Start Input |

|

4 6 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hardware Stop Input |

|

4 7 |

Jog Forward Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 7 |

Jog Reverse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 7 |

General Purpose Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 7 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Analog Output Interface |

|

4 7 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Discrete Outputs |

|

4 8 |

OUTPUT 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 9 |

OUTPUT 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 9 |

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

4 9 |

Installing the Linear Positioning Module . . . . . . . . . . . . . . |

|

5 1 |

|

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 1 |

|

Avoiding Backplane Power Supply Overload . . . . . . . . . . . . . . . |

|

5 1 |

|

Planning Module Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 1 |

|

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 2 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . .Setting Analog Output Switches |

|

5 2 |

|

Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 5 |

|

Inserting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 5 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Wiring Guidelines |

|

5 6 |

|

Using Shielded Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 6 |

|

Using Twisted Wire Pairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 8 |

|

Connecting AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

5 8 |

|

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 10 |

||

Connecting the Transducer Interface . . . . . . . . . . . . . . . . . . . . . . |

5 10 |

||

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 11 |

||

Transducer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 12 |

||

Connecting the Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 12 |

||

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 14 |

||

Auto/Manual Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 14 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hardware Start Input |

5 14 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hardware Stop Input |

5 14 |

||

Jog Forward Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 15 |

||

Jog Reverse Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 16 |

||

General Purpose Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 16 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . .Connecting Multiple Modules |

5 16 |

||

Table of Contents |

|

|

iii |

Connecting the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 18 |

||

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 19 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Analog Output |

5 19 |

||

Connecting the Discrete Outputs . . . . . . . . . . . . . . . . . . . . . . . . . |

5 20 |

||

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 21 |

||

OUTPUT 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 21 |

||

OUTPUT 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 21 |

||

Interpreting Module to PLC Data (READS) . . . . . . . . . . . . . |

|

6 1 |

|

PLC Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 1 |

|

Status Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 1 |

|

Word Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 2 |

|

Module Configuration Word (word 1) . . . . . . . . . . . . . . . . . . . . |

|

6 2 |

|

Status Word 1 (words 2 and 6) . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 3 |

|

Status Word 2 (words 3 and 7) . . . . . . . . . . . . . . . . . . . . . . . . |

|

6 7 |

|

Position/Error/Diagnostic Words . . . . . . . . . . . . . . . . . . . . . . . |

|

6 9 |

|

Active Motion Segment/Setpoint (words 10 and 11) . . . . . . . . . . |

6 13 |

||

Measured Velocity (words 20 and 21) . . . . . . . . . . . . . . . . . . . |

6 14 |

||

Desired Velocity (words 22 and 23) . . . . . . . . . . . . . . . . . . . . . |

6 14 |

||

Desired Acceleration (words 24 and 25) . . . . . . . . . . . . . . . . . . |

6 15 |

||

Desired Deceleration (words 26 and 27) . . . . . . . . . . . . . . . . . . |

6 15 |

||

Percent Analog Output (words 28 and 29) . . . . . . . . . . . . . . . . |

6 16 |

||

Maximum Velocity (words 30, 31 and 32, 33) . . . . . . . . . . . . . . |

6 17 |

||

Formatting Module Data (WRITES) . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Data Blocks Used in Write Operations . . . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Parameter Block (Required) . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Setpoint Block (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Command Block (Required) . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Parameter Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

7 1 |

|

Parameter Control Word (word 1) . . . . . . . . . . . . . . . . . . . . . . |

|

7 3 |

|

Analog Range (words 2 and 31) . . . . . . . . . . . . . . . . . . . . . . . |

|

7 5 |

|

Analog Calibration Constants (words 3, 4 and 32, 33) . . . . . . . . |

|

7 6 |

|

Transducer Calibration Constant (words 5, 6 and 34, 35) . . . . . . |

|

7 7 |

|

. . . . . . . . . . . . . . .Zero Position Offset (words 7, 8 and 36, 37) |

|

7 8 |

|

Software Travel Limits (words 9, 10 and 38, 39) . . . . . . . . . . . . |

|

7 9 |

|

. . . . . . . . . .Zero Position and Software Travel Limit Examples |

7 10 |

||

In Position Band (words 11 and 40) . . . . . . . . . . . . . . . . . . . . . |

7 13 |

||

PID Band (words 12 and 41) . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 14 |

||

Deadband (words 13 and 42) . . . . . . . . . . . . . . . . . . . . . . . . . |

7 15 |

||

Excess Following Error (words 14 and 43) . . . . . . . . . . . . . . . . |

7 16 |

||

Maximum PID Error (words 15 and 44) . . . . . . . . . . . . . . . . . . |

7 16 |

||

Integral Term Limit (words 16 and 45) . . . . . . . . . . . . . . . . . . . |

7 17 |

||

Proportional Gain (words 17 and 46) . . . . . . . . . . . . . . . . . . . . |

7 18 |

||

Gain Break Speed (words 18 and 47) . . . . . . . . . . . . . . . . . . . |

7 19 |

||

iv |

Table of Contents |

Gain Factor (words 19 and 48) . . . . . . . . . . . . . . . . . . . . . . . . |

7 20 |

Integral Gain (words 20 and 49) . . . . . . . . . . . . . . . . . . . . . . . |

7 21 |

Derivative Gain (words 21 and 50) . . . . . . . . . . . . . . . . . . . . . . |

7 22 |

Feedforward Gain (words 22 and 51) . . . . . . . . . . . . . . . . . . . . |

7 22 |

Global Velocity (words 23 and 52) . . . . . . . . . . . . . . . . . . . . . . |

7 23 |

Global Acceleration/Deceleration (words 24, 25 and 53, 54) . . . . |

7 24 |

Velocity Smoothing (Jerk) Constant (words 26 and 55) . . . . . . . |

7 24 |

Jog Rate (Low and High) (words 27, 28 and 56, 57) . . . . . . . . . |

7 26 |

Reserved (words 29, 30 and 58, 59) . . . . . . . . . . . . . . . . . . . . |

7 27 |

Setpoint Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 27 |

Setpoint Block Control Word (word 1) . . . . . . . . . . . . . . . . . . . . |

7 29 |

Incremental/Absolute Word (word 2) . . . . . . . . . . . . . . . . . . . . |

7 29 |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Setpoint Position |

7 30 |

Local Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 31 |

Local Acceleration/Deceleration . . . . . . . . . . . . . . . . . . . . . . . |

7 32 |

Command Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 32 |

Axis Control Word 1 (words 1 and 8) . . . . . . . . . . . . . . . . . . . . |

7 33 |

Axis Control Word 2 (words 2 and 9) . . . . . . . . . . . . . . . . . . . . |

7 38 |

Setpoint 13 Words (words 3 to 7 and 10 to 14) . . . . . . . . . . . . . |

7 39 |

Initializing and Tuning the Axes . . . . . . . . . . . . . . . . . . . . . |

|

8 1 |

|

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 1 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . .Adjusting the Servo Valve Nulls |

|

8 2 |

|

Initializing the Parameter Block . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 2 |

|

Verifying Analog Output Polarity . . . . . . . . . . . . . . . . . . . . . . . . . |

|

8 7 |

|

Verifying Transducer Calibration Constants . . . . . . . . . . . . . . . . . |

|

8 7 |

|

Axis Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 10 |

||

Analog Calibration Constants . . . . . . . . . . . . . . . . . . . . . . . . . |

8 10 |

||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Feedforward Gain |

8 11 |

||

PID Loop Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 12 |

||

Update the Application Program . . . . . . . . . . . . . . . . . . . . . . . |

8 13 |

||

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 1 |

|

Motion Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 1 |

|

Motion Block Control Word . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 4 |

|

. . . . . . . . . . . . . . . . . . . . . . . . .Programmable Input and Output |

|

9 5 |

|

. . . . . . . . . . . . . . . . . . . . . . .Programmable I/O Control Word |

|

9 5 |

|

Default I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 8 |

|

Motion Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 8 |

|

Motion Segment Control Words . . . . . . . . . . . . . . . . . . . . . . . . |

9 8 |

||

Desired Position, Local Velocity, Local Acceleration |

|

|

|

and Local Deceleration Words . . . . . . . . . . . . . . . . . . . . . . |

9 11 |

||

. . . . . . . . . . . . . . . . . . . . . . . .Trigger Velocity/Position Words |

9 11 |

||

The Command Block and the Motion Block . . . . . . . . . . . . . . . . . . |

9 11 |

||

The Status Block and the Motion Block . . . . . . . . . . . . . . . . . . . . |

9 11 |

||

Table of Contents |

|

|

|

|

|

v |

Using the Motion Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

9 12 |

||||

Sample Application Programs . . . . . . . . . . . . . . . . . . . . . . |

|

10 1 |

||||

Programming Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

10 1 |

||||

Block Transfer Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

10 2 |

||||

PLC 5 Block Transfer Instructions . . . . . . . . . . . . . . . . . . . . . . . . |

|

10 3 |

||||

Application Program #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

10 3 |

||||

Planning the Data Blocks for Application Program #1 . . . . . . . . . |

|

10 5 |

||||

Program Rungs for Application Program #1 . . . . . . . . . . . . . . . |

|

10 8 |

||||

Application Program #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 11 |

|||||

Planning the Data Blocks for Application Program #2 . . . . . . . . . |

10 12 |

|||||

Program Rungs for Application Program #2 . . . . . . . . . . . . . . . |

10 16 |

|||||

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

11 1 |

||||

Fault Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

11 1 |

||||

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Module Fault Indicator |

|

11 2 |

||||

Loop Active Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

11 2 |

||||

Indicator Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . |

|

11 2 |

||||

Troubleshooting Feedback Faults . . . . . . . . . . . . . . . . . . . . . . . . |

|

11 3 |

||||

Troubleshooting Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

11 4 |

||||

Flowchart Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 7 |

|||||

Glossary of Terms & Abbreviations . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

A 1 |

Status Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

B 1 |

Parameter Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

C 1 |

Setpoint Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

D 1 |

Command Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

E 1 |

Motion Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

F 1 |

Hexadecimal Data Table Forms . . . . . . . . . . . . . . . . . . . . . |

|

|

|

|

|

G 1 |

vi |

Table of Contents |

Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 1 |

|

BCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 1 |

|

2’s Complement Binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 1 |

|

Bit Inversion Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 2 |

|

Subtraction Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 2 |

|

Implied Decimal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 2 |

|

Position Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 3 |

|

Double Word Position Format . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

H 4 |

|

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

I 1 |

Preface

Preface

This manual explains how to install and configure the Linear Positioning

Module. It includes sample application programs to illustrate how to program a

PLC to work with the Linear Positioning Module.

Organization of the Manual This manual contains eleven chapters and nine appendices that address the following topics:

Chapter |

Title |

Describes: |

|

|

|

1 |

Introducing the Linear Positioning |

the functions and features of the Linear Positioning |

|

Module |

Module |

|

|

|

2 |

Positioning Concepts |

concepts and principles of closed loop servo |

|

|

positioning |

|

|

|

3 |

Positioning with the Linear |

using the Linear Positioning Module in a positioning |

|

Positioning Module |

system |

|

|

|

4 |

Hardware Description |

module hardware, module interfaces, and other |

|

|

hardware items you need for a positioning system |

|

|

|

5 |

Installing the Linear Positioning |

configuring the module’s analog outputs and |

|

Module |

installing the module in your system |

|

|

|

6 |

Interpreting Module to PLC Data |

monitoring module operation from a logic controller |

|

(READS) |

by reading and interpreting data that the module |

|

|

transfers to the logic controller’s data tables |

|

|

|

7 |

Formatting Module Data |

formatting parameter, move description, and control |

|

(WRITES) |

data for block transfers to the Linear Positioning |

|

|

Module |

|

|

|

8 |

Initializing and Tuning the Axes |

bringing the module online |

|

|

|

9 |

Advanced Features |

using the motion block to perform blended moves; |

|

|

using programmable input and output operations |

|

|

|

10 |

Sample Application Programs |

two application programs, one using basic concepts |

|

|

and the other using advanced features, to control |

|

|

and monitor the module |

|

|

|

11 |

Troubleshooting |

using the module’s indicators and the status block |

|

|

to diagnose and remedy module faults and errors |

|

|

|

Appendix A |

Glossary |

common terms and abbreviations |

|

|

|

Appendix B |

Status Block |

status block word assignments |

|

|

|

Appendix C |

Parameter Block |

parameter block word assignments |

|

|

|

Appendix D |

Setpoint Block |

setpoint block word assignments |

|

|

|

P 1

Preface

Chapter |

Title |

Describes: |

|

|

|

Appendix E |

Command Block |

command block word assignments |

|

|

|

Appendix F |

Motion Block |

motion block word assignments |

|

|

|

Appendix G |

Hexadecimal Data Table Form |

hexadecimal data worksheets |

|

|

|

Appendix H |

Data Formats |

valid data formats |

|

|

|

Appendix I |

Product Specifications |

1771 QB product specifications |

|

|

|

Audience |

Read this manual if you intend to install or use the Linear Positioning Module |

|

(Cat. No. 1771-QB). |

|

To use the module, you must be able to program and operate an Allen-Bradley |

|

PLC. In particular you must be able to program block transfer instructions. |

|

In this manual, we assume that you know how to do this. If you don't, refer to |

|

the User Manual for the PLC you'll be programming. |

Related Publications |

Consult the Allen-Bradley Industrial Computer Division Publication Index |

|

(SD 499) if you would like more information about your modules or PLCs. This |

|

index lists all available publications for Allen-Bradley programmable controller |

|

products. |

Related Software |

The Hydraulics Configuration and Operation Option (Cat. No. 6190-HCO) |

|

operates within the ControlView Core (Cat. No. 6190-CVC) environment to |

|

provide full configuration and realtime monitoring for the Linear Positioning |

|

Module. Both software packages are available from: |

|

Allen-Bradley Company, Inc. |

|

1201 South Second Street |

|

Milwaukee, WI 53204 |

|

(414) 382-2000 |

|

Servo Analyzer is a software package that aids in tuning the axes by letting you |

|

display an axis profile as you tune it. The resulting graphics may be plotted, |

|

printed or saved to a file. The software is available from: |

|

Computer Software Design |

|

P.O. Box 962 |

|

Roseburg, OR 97470 |

|

(503) 673-8583 |

P 2

Preface

Frequently Used Terms |

Appendix A contains a complete glossary of terms and abbreviations used in |

|

this manual. |

|

To make this manual easier for you to read and understand, product names are |

|

avoided where possible. The Linear Positioning Module is also referred to as |

|

the ªmoduleº. |

P 3

Chapter 1

Introducing the Linear Positioning Module

What is the Linear Positioning Module?

The Linear Positioning Module (Cat. No. 1771-QB) is a dual-loop position controller occupying a single slot in the Allen-Bradley 1771 Universal I/O chassis. It can control servo or proportional hydraulic valves, or some electric servos. Position is measured with a linear displacement transducer. You use the module to control and monitor the linear position of a tool or workpiece along one or two axes.

Figure 1.1

Linear Positioning Module

50110

1 1

Chapter 1

Introducing the Linear Positioning Module

Product Compatibility |

PLCs |

|

|

|

You can use the module with any Allen-Bradley PLC that uses block transfer |

||

|

programming in local 1771 I/O systems including: |

||

|

PLC-2 family |

|

|

|

PLC-3 family |

|

|

|

PLC-5 family |

|

|

|

- |

PLC-5/10 |

(Cat. No. 1785-LT4) |

|

- |

PLC-5/11 |

(Cat. No. 1785-LT11) |

|

- |

PLC-5/12 |

(Cat. No. 1785-LT3) |

|

- |

PLC-5/15 |

(Cat. No. 1785-LT) |

|

- |

PLC-5/20 |

(Cat. No. 1785-L20) |

|

- |

PLC-5/25 |

(Cat. No. 1785-LT2) |

|

- |

PLC-5/30 |

(Cat. No. 1785-L30) |

|

- |

PLC-5/40 |

(Cat. No. 1785-L40) |

|

- |

PLC-5/60 |

(Cat. No. 1785-L60) |

Transducers

The Linear Positioning (QB) Module is compatible with linear displacement transducers manufactured by:

MTS Systems Corporation Sensors Divisions

Box 13218, Research Triangle Park North Carolina 27709

(919) 677±0100

Balluff Inc.

P.O. Box 937 8125 Holton Drive

Florence, KY 41042 (606) 727±2200

1 2

Chapter 1

Introducing the Linear Positioning Module

Santest Co. Ltd.

c/o Ellis Power Systems 123 Drisler Avenue White Plains, NY 10607 (914) 592-5577

Lucas Schaevitz Inc.

7905 N. Route 130 Pennsauken, NJ 08110-1489 (609) 662-8000

All four manufacturers provide versions of the transducer that connect directly to the module's wiring arm, without an external digital interface box. The module may also be compatible with other linear displacement transducers.

Servo and Proportional Valves

The module provides current ranges of up to +100 mA for direct interface to most servo valves, most proportional valves, and a +10 volt option for compatibility with other devices, such as electric servo interfaces. The module is compatible with valves supplied by the following manufacturers:

Moog, East Aurora NY |

servo/proportional |

Parker Hannifin Corporation, Elyria OH |

servo/proportional |

Robert Bosch Corporation |

proportional |

Rexroth Corporation, Lehigh Valley PA |

servo/proportional |

ATOS |

proportional |

Atchley, Canaga Park CA |

servo |

Pegasus |

servo |

Vickers Inc., Grand Blanc, MI |

servo/proportional |

The module may also be compatible with other valves.

Important: Some proportional valves with LVDT loop controllers may limit the module's output and thus prevent the module from providing optimal control.

1 3

Chapter 1

Introducing the Linear Positioning Module

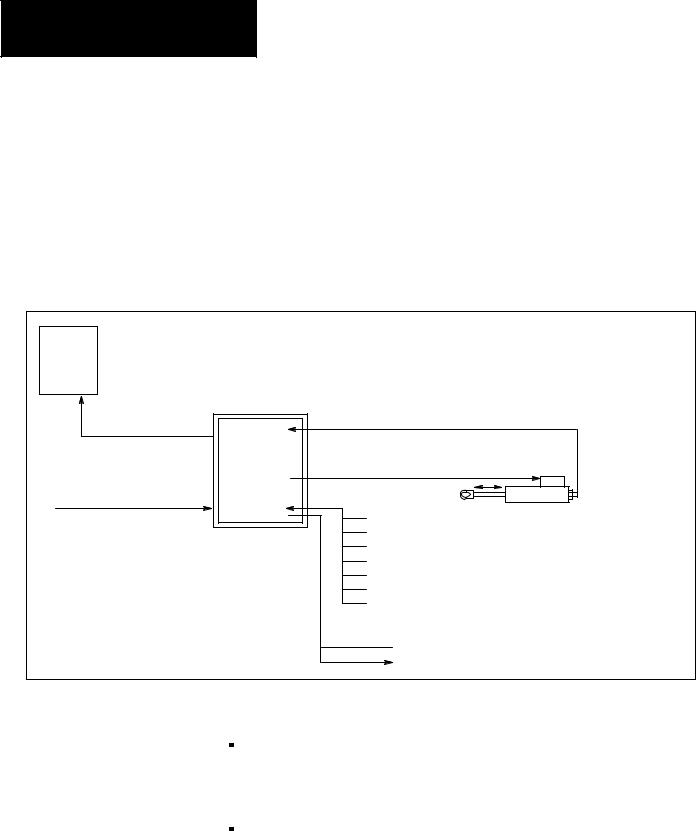

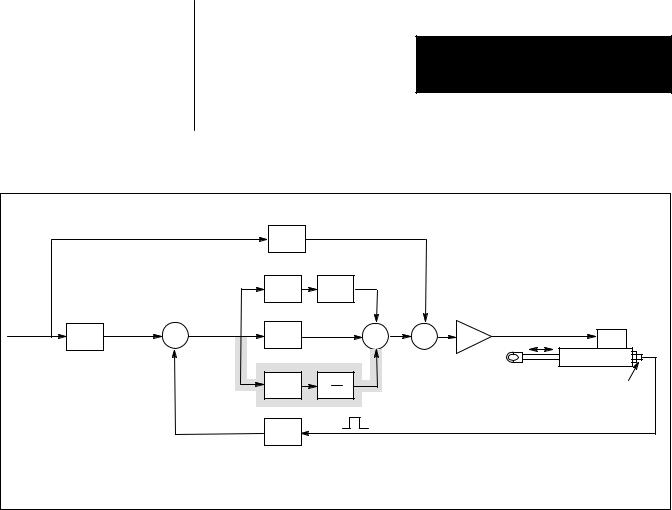

System Overview |

Figure 1.2 shows one of the module's two control loops within a linear |

|

positioning system for closed-loop axis control. The module communicates with |

|

a programmable controller through the 1771 backplane. |

|

The programmable logic controller sends commands and user-programmed data |

|

from the data table to the module as directed by a block-transfer write |

|

instruction. |

|

Figure 1.2 |

|

System Overview |

PLC

Processor

D Status Block

DParameter Block

DSetpoint Block

DMotion Block

DCommand Block

|

Transducer |

|

|

Interface |

|

Linear |

|

|

Positioning |

Analog Output |

Servo Valve |

Module |

|

|

|

Linear Displacement |

|

|

Discrete Inputs |

Transducer |

|

D Jog Forward |

Piston Type |

|

D Jog Reverse |

Cylinder |

DHardware Start

DAuto/Manual

DHardware Stop

DInput 1

D |

Input 2 |

NOTE: All inputs and outputs are |

|

duplicated for the second axis. |

|

|

|

Discrete Outputs

D D Output 1

D Output 1

D Output 2

50033

Using PLC programming, you can:

send configuration and control parameters to the module via parameter, setpoint, motion, and command blocks. With this data the module determines axis parameters, calculates velocity curves, and commands axis end-positions. (See Chapters 7 and 9.)

read status blocks to monitor axis position and status indicators in your process control system. (See Chapter 6.)

The module's analog outputs (one for each control loop) connect to servo or proportional valves via wiring arm terminals. The module controls speed and position by adjusting the voltage or current levels of the analog outputs 500 times each second.

1 4

Chapter 1

Introducing the Linear Positioning Module

The module also connects to linear displacement transducers (one for each of the two axes) via wiring arm terminals. The transducer senses the axis position and feeds it back to the module, thereby closing the control loop.

The module's built-in processor samples the linear displacement transducer interfaces and determines positions along each of the two axes every two milliseconds. The module then updates the analog outputs based on a proprietary algorithm designed specifically to handle hydraulic actuators. This rapid update rate provides repeatable positioning and superior control of velocity without jerky movement.

Motion blocks provide for complex motions by allowing motion segments to be blended or chained together. These motion segments may also be synchronized using the hardware input triggers and outputs.

Cam emulation permits motion segments in one axis to start motion segments in another axis. Articulated motions and axis sequencing may be easily accomplished.

1 5

Chapter 2

Positioning Concepts

|

This chapter explains concepts and principles of axis positioning. If you are |

|

thoroughly familiar with the concepts of closed-loop servo positioning, you can |

|

go on to Chapter 3. |

Axis Motion |

Figure 2.1 illustrates a typical method of converting the flow of fluid into a |

|

linear displacement. |

|

Figure 2.1 |

|

Piston Type Hydraulic Cylinder |

Electric

SERVO VALVE

Control

Hydraulic |

Hydraulic |

Fluid |

Fluid |

Axis

Motion

Hydraulic fluid |

Hydraulic fluid |

50032

The servo valve controls the flow of hydraulic fluid into or out of the hydraulic cylinder. Adding fluid to the left side of the cylinder extends the rod; adding fluid to the right side retracts it.

2 1

Chapter 2

Positioning Concepts

Closed Loop Positioning |

Closed-loop positioning is a precise means of moving an object from one |

|

position to another. In a typical application, a positioning device activates a |

|

servo valve controlling the movement of fluid in a hydraulic system. The |

|

movement of fluid translates into the linear motion of a hydraulic cylinder. A |

|

transducer monitors this motion and feeds it back to the positioning device. The |

|

positioning device, in turn, calculates a positioning correction and feeds it back |

|

to the servo valve. |

|

Important: Throughout this manual we refer to servo valves, but you can also |

|

use the analog outputs to control proportional valves or an electric servo. |

Linear Displacement Transducer

A linear displacement transducer (see Figure 2.2) is a device that senses the position of an external magnet to measure displacements.

Figure 2.2

Linear Displacement Transducer

Magnet |

Transducer |

|

Head |

||

|

||

Magnet mounted to |

|

|

the piston of actuator |

50034 |

|

|

The transducer sends a signal through the transducer wave guide where a permanent magnet generates the return pulse. You can use the time interval between the transducer's signal and the return pulse to measure axis displacement.

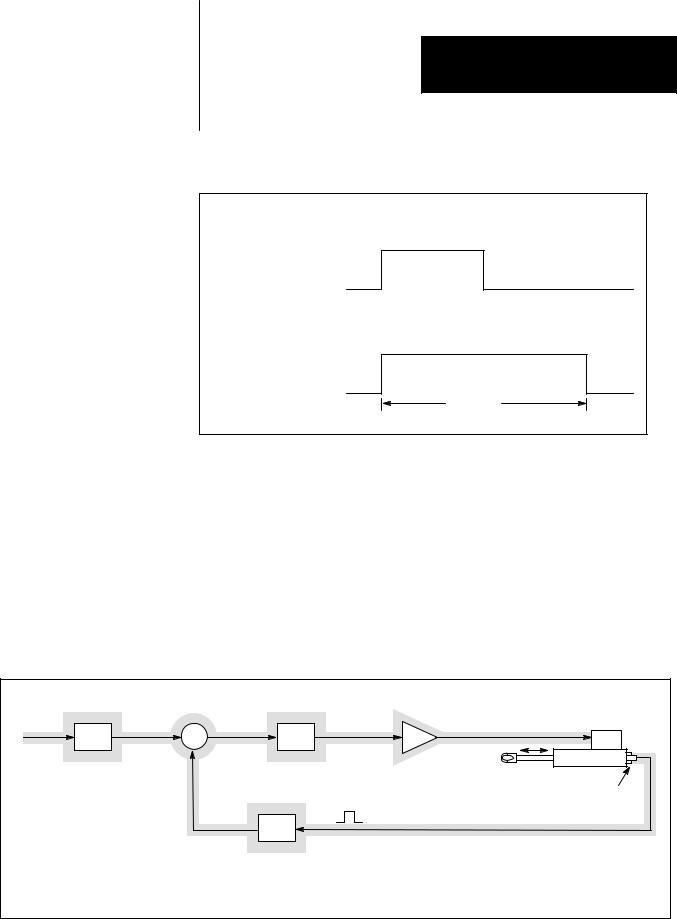

Circulations

Some linear displacement transducers provide circulations or recirculation to improve resolution. (See Figure 2.3.) This technique stretches the pulse by a factor of two or more and results in finer resolution in the circuitry monitoring the pulse width.

2 2

Chapter 2

Positioning Concepts

Figure 2.3

Circulations

resolution = 0.002

Gate

(received from transducer)

Duration

Duration

(1 circulation)

(1 circulation)

resolution = 0.001

Gate

(received from transducer)

Duration (2 circulations)

50035

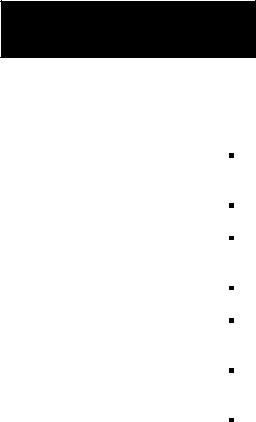

A Simple Positioning Loop

To move a specified distance along an axis, you can command the hydraulic device to move at a specific velocity for a specific length of time. However, this method can be imprecise. To control the position of the hydraulic device accurately you need a loop to monitor actual position. Figure 2.4 shows a simple positioning loop.

Figure 2.4

Positioning Loop

Desired |

Position |

Following |

Velocity |

|

Velocity |

Command |

Error |

Command |

Servo Valve |

|

dt |

Kp |

D/A |

|

|

s |

|

|

|

|

+ |

|

|

|

|

Integrator |

- |

|

Axis |

|

Actual |

|

||

|

|

|

Linear |

|

|

|

Position |

|

Displacement |

|

|

|

|

Transducer |

|

|

sdt |

|

|

|

|

|

|

50036 |

2 3

Chapter 2

Positioning Concepts

In Figure 2.4:

desired velocity is the desired speed of axis motion from one position to another

position command equals the integration of velocity over time

actual position value (transducer feedback) is the actual position of the axis as measured by the LDT

following error equals position command minus actual position

velocity command is generated by amplifying the following error and converting the result into an analog output

D/A (Digital to Analog convertor) generates the analog output controlling the servo valve

KP (proportional gain) is the component that causes an output signal to change as a direct ratio of the error signal variation

Proportional Gain

The following error is a function of the velocity command divided by the proportional gain (KP). To generate the velocity command, multiply the following error by the proportional gain. Proportional gain can be expressed in ips/mil (where 1 mil = 0.001 inches) or mmps/mil (where 1 mil = 0.001 mm).

For example, with a velocity of 12 ips and a gain of 1 ips/mil, the following error is:

Following Error |

= |

Velocity/Gain |

|

= |

12 ips/(1 ips/mil) |

|

= |

12 mil |

When you increase the gain, you decrease the following error and decrease the cycle time of the system. However, the capabilities of the system limit the gain. Too large a gain causes instability.

2 4

Chapter 2

Positioning Concepts

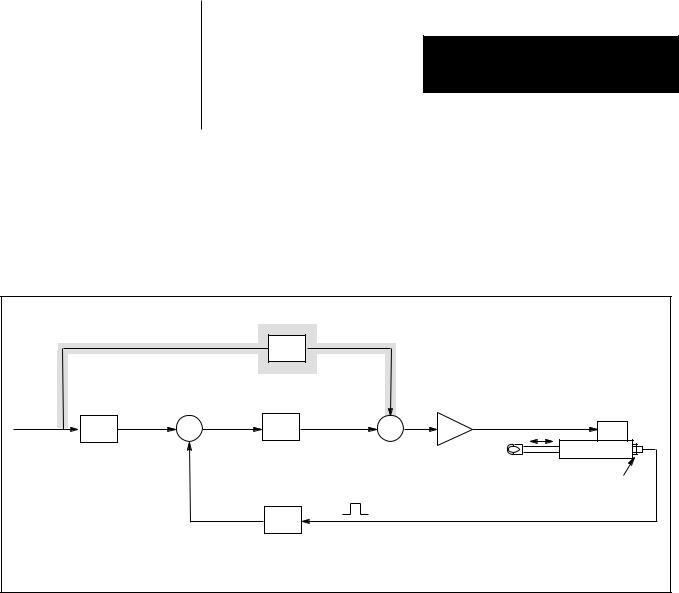

Feedforwarding

To decrease the following error without increasing the gain, you can add a feedforward component. (See Figure 2.5.)

Figure 2.5

Positioning Loop with Feedforwarding

|

|

|

|

Feed |

|

|

|

|

|

KF |

Forward |

|

|

|

|

|

|

|

|

|

Desired |

Position |

Following |

|

+ |

Velocity |

|

Velocity |

Command |

Error |

|

Command |

Servo Valve |

|

|

+ |

|||||

|

s |

|

Kp |

|

|

|

|

|

|

D/A |

|

||

|

dt |

|

|

|

|

|

|

+ |

- |

|

|

|

|

|

Integrator |

|

|

|

|

Axis |

|

|

Actual |

|

|

|

|

|

|

|

|

|

Linear |

|

|

|

Position |

|

|

|

Displacement |

|

|

|

|

|

|

Transducer |

|

|

|

sdt |

|

|

|

50037

Feedforwarding requires an additional summing point and an amplifier. Multiply the desired velocity by the feedforward gain KF to produce a feedforward value. The feedforward value, added to a multiplication of the following error by the proportional gain (KP), generates the velocity command.

Without feedforwarding, axis motion does not begin until the following error is large enough to overcome friction and inertia. The feedforward component generates a velocity command to move the cylinder almost immediately. This immediate response keeps the actual position closer to the desired position and thereby reduces the following error.

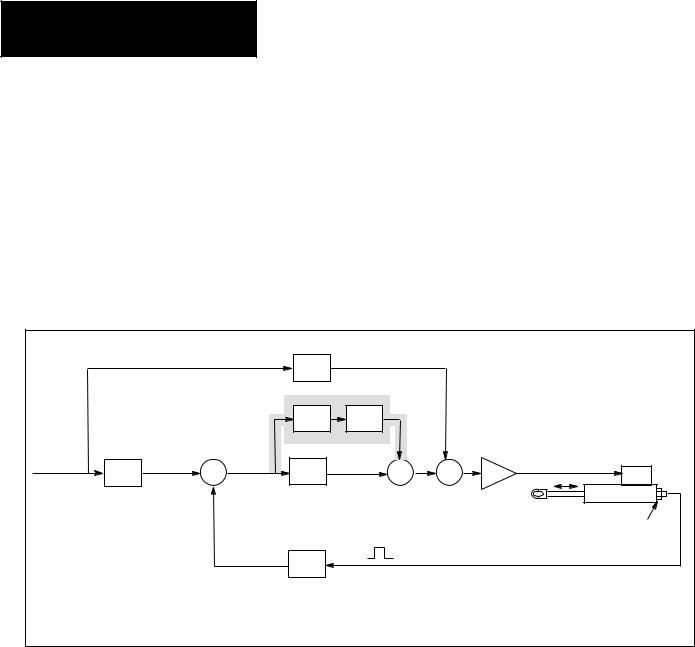

Integral Control (Reset Control)

You can increase the positioning accuracy of the control loop by adding an integral component. (See Figure 2.6.)

To achieve the integral component of the positioning loop, integrate the following error over time and amplify it to produce an integral value. Then add this integral value to the proportional component and the feedforward value to generate the velocity command.

2 5

Chapter 2

Positioning Concepts

Without integral control, the axis responds only to the size of the positioning error, not its duration. Integral control responds to both the size and duration of the positioning error. Thus, the integral term continues to adjust the velocity command until it achieves an exact correction.

When you increase the integral gain (KI), you increase the rate at which the positioning loop responds to a following error. However, the capabilities of the system limit gain KI. Too large a gain causes instability.

Figure 2.6

Integral Control

|

|

|

|

Feed |

|

|

|

|

|

|

|

KF |

Forward |

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

Integrator |

|

|

|

|

|

|

|

K |

I |

s |

|

|

|

|

|

|

|

|

dt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Desired |

Position |

Following |

|

|

|

|

|

Velocity |

|

Velocity |

Command |

Error |

|

+ |

+ |

+ |

+ |

Command |

Servo Valve |

|

s |

Kp |

|

|

|

|

|||

|

|

|

|

|

D/A |

|

|||

|

dt |

|

|

|

|

|

|

|

|

|

+ |

- |

|

|

|

|

|

|

|

|

Integrator |

|

|

|

|

|

|

Axis |

|

|

|

Actual |

|

|

|

|

|

Linear |

|

|

|

|

|

|

|

|

|

||

|

|

Position |

|

|

|

|

|

|

Displacement |

|

|

|

|

|

|

|

|

|

Transducer |

|

|

sdt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50038 |

Derivative Control (Rate Control)

Proportional and integral gains can cause instability in a positioning loop. The cylinder can overshoot its programmed endpoints and oscillate or hunt around them. You can increase the stability of the positioning loop by adding a derivative component. (See Figure 2.7.)

Derivative control operates on the rate of change of positioning error. It helps to stabilize the system by opposing changes in positioning error. However, a derivative gain that is too large can cause instability. Derivative control is also very susceptible to electrical noise.

2 6

Chapter 2

Positioning Concepts

Figure 2.7

Derivative Control

|

|

|

|

|

Feed |

|

|

|

|

|

|

|

|

KF |

Forward |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Integrator |

|

|

|

|

|

|

|

|

K |

I |

dt |

|

|

|

|

|

|

|

|

|

s |

|

|

|

|

|

|

Desired |

Position |

Following |

|

|

|

|

|

|

Velocity |

|

Velocity |

Command |

Error |

|

|

+ |

+ |

+ |

+ |

Command |

Servo Valve |

|

|

|

Kp |

|

|

|

|

|||

|

dt |

|

|

|

|

|

D/A |

|

||

|

s |

|

|

|

|

|

|

|

|

|

|

+ |

- |

|

|

Derivative+ |

|

|

|

|

|

|

Integrator |

|

|

|

|

|

|

|

Axis |

|

|

|

Actual |

|

|

d |

|

|

|

Linear |

|

|

|

KD |

|

|

|

|

||||

|

|

Position |

dt |

|

|

|

|

Displacement |

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Transducer |

|

|

|

|

dt |

|

|

|

|

|

|

|

|

|

s |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50039 |

|

|

Deadband |

|

|

|

|

|

|

|

|

Most systems have friction and play in their mechanical linkages. These characteristics can cause a cylinder to oscillate around a programmed endpoint±especially if you use an integral term. You can use a deadband to reduce these oscillations.

A deadband is an area surrounding the programmed endpoint where the error is ignored. Outside the deadband, error is reduced by one half the width of the deadband.

If you apply a deadband to an integral term, the integral output remains constant while the axis is within the deadband. This reduces oscillations around the endpoint. However, if the deadband is too large, it can also reduce the positioning accuracy of the system.

PID Band

Integral and derivative control can cause undesirable results when the axis moves from one position to another. The integral term can cause the axis to overshoot the programmed endpoint. The derivative term opposes changes in error, and thereby changes in position.

2 7

Chapter 2

Positioning Concepts

You can control the integral and derivative components by defining a PID (proportional, integral and derivative) band. The PID band is a region surrounding the programmed endpoint where the system enables integral or derivative terms. As a result, the integral and derivative components affect only the final positioning of the axis.

2 8

Chapter 3

Positioning with the Linear Positioning Module

How the Module Fits in a

Positioning System

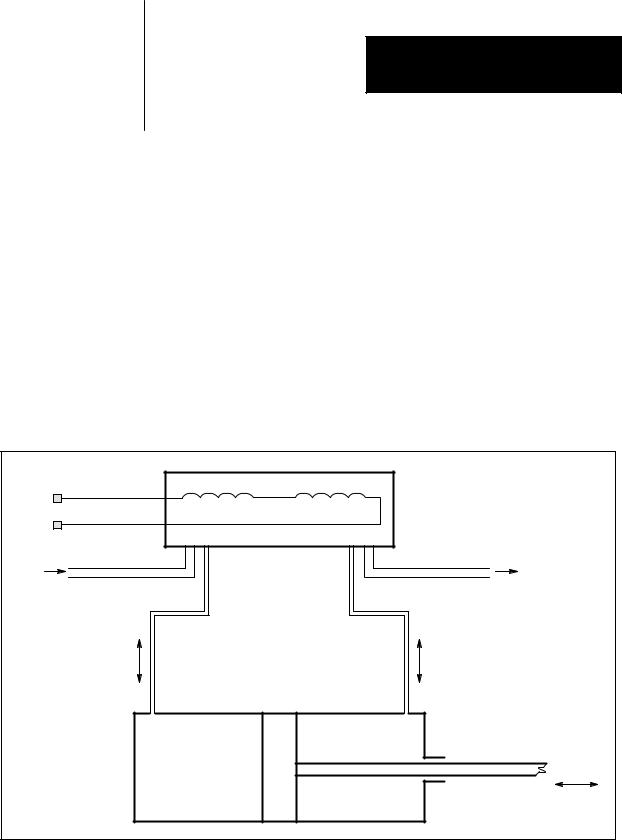

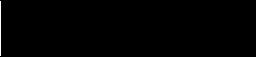

This chapter explains how the Linear Positioning Module interacts with a programmable controller to control axis movement within a linear positioning system.

Figure 3.1 shows how the module functions in a typical positioning system. Note that the positioning loop closes in the module and functions independently of the programmable controller's I/O scan rate. The fast loop update time of

2 ms is possible, because the module has a built-in microprocessor.

Figure 3.1

The Module in a Positioning System

1771-QB MODULE |

|

|

|

Feed |

|

|

|

|

|

|

Forward |

|

|

|

|

|

|

|

KF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Integrator |

|

|

|

|

|

|

I |

s |

|

|

|

|

|

|

K |

dt |

|

|

|

|

|

|

|

|

|

|

|

Desired |

Position |

Following |

|

|

|

Velocity |

|

Velocity |

Command |

Error |

Kp |

+ + |

+ + |

Command |

Servo Valve |

s |

|

|

|

|

D/A |

|

|

dt |

+ |

|

|

|

|

|

|

|

|

|

+ |

|

|

|

|

|

- |

|

|

|

|

|

|

Integrator |

|

|

Derivative |

|

|

|

|

|

|

|

|

Axis |

|

||

|

|

|

|

d |

|

Linear |

|

|

|

Actual |

KD |

|

|

||

|

|

dt |

|

|

Displacement |

||

|

|

Position |

|

|

|

|

Transducer |

|

|

|

s |

|

|

|

|

|

|

|

dt |

|

|

|

|

50040

3 1

Chapter 3

Positioning with the Linear Positioning Module

How the Module Interacts with a PLC

The module is a dual-loop position controller, occupying a single slot in the Allen-Bradley 1771 universal I/O chassis. The module communicates with the PLC through the 1771 backplane. There are two kinds of transfers±read operations and write operations. By programming the PLC you can transfer parameter, setpoint, motion and command blocks to the module to control the two axes. You can also use the PLC to monitor the status of the module's two loops through block read operations. For more details on block transfers, see Chapters 6 and 7.

Read Operations

Read operations enable the programmable logic controller to monitor the status of both axes through the status block. The status block includes detailed information on the two axes: fault conditions, current axis position, positioning error, and diagnostic information.

Write Operations

The following four types of write operations enable the programmable controller to control axis movement:

|

Parameter Block - defines the module's operating parameters for each axis. |

|

These parameters include calibration constants, software travel limits, |

|

zero-position offset, in-position and PID bands, PID gains, maximum |

|

velocities, jog rates, maximum accelerations and decelerations and more. |

|

Setpoint Block - defines up to 12 setpoints for each axis with optional |

|

acceleration, deceleration and velocity parameters for each setpoint move. |

|

The programmable controller selects from among the 12 setpoints using the |

|

command block. |

|

Motion Block - permits complex profiles to be executed by the module. This |

|

advanced feature can be used to blend or chain multiple motion segments in a |

|

single, continuous motion. |

|

Command Block - you use the command block to select the next setpoint or |

|

motion segment to which the axis will move; to set a delayed start, software |

|

stop or reset; to set jog bits; to select jog rate (low or high); to set |

|

auto/manual, to enable/disable integral control and to define a 13th setpoint. |

Axis Movement |

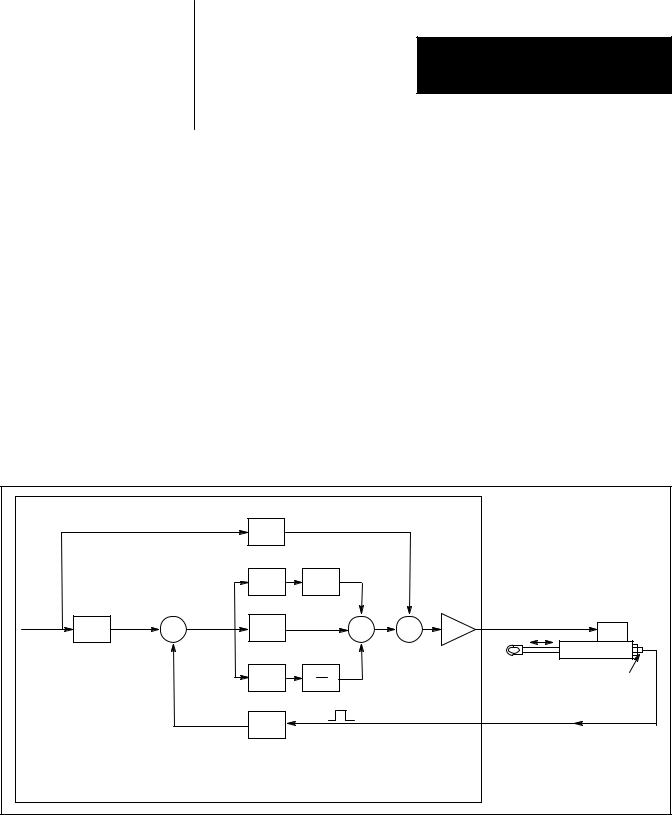

When the module receives a setpoint command, motion segment command, jog |

|

command, or a discrete jog input, it automatically calculates the velocity curve |

|

for the requested axis movement using parameters that you define for the move. |

|

(See Figure 3.2.) |

3 2

Chapter 3

Positioning with the Linear Positioning

Module

Figure 3.2

Trapezoidal Axis Movement

Velocity |

|

|

|

|

Constant |

Final |

|

Velocity |

|

|

|

Velocity |

|

|

|

|

Acceleration |

|

|

Deceleration |

|

|

Time |

0 |

Start |

Finish |

|

|

50002 |

The actuator may not reach the final velocity during a short move which may only consist of acceleration and deceleration phases without a constant velocity phase. This produces a ramp movement. (See Figure 3.3.)

Figure 3.3

Ramp Movement

Velocity |

|

|

Peak |

|

|

Velocity |

|

|

|

Acceleration |

Deceleration |

|

|

|

|

|

Time |

0 |

Start |

Finish |

|

|

50003 |

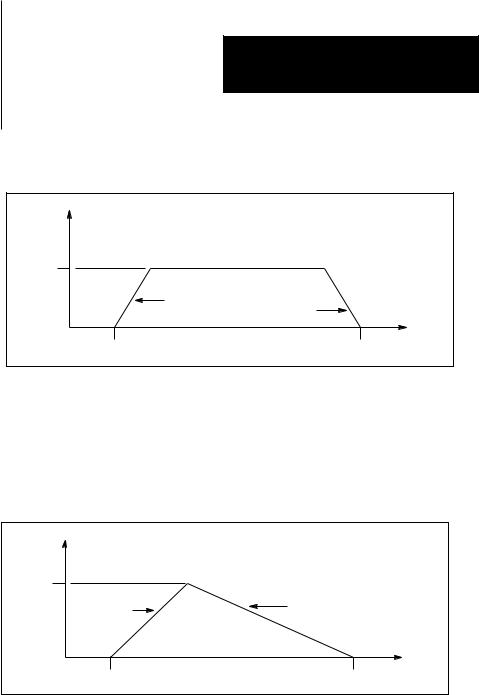

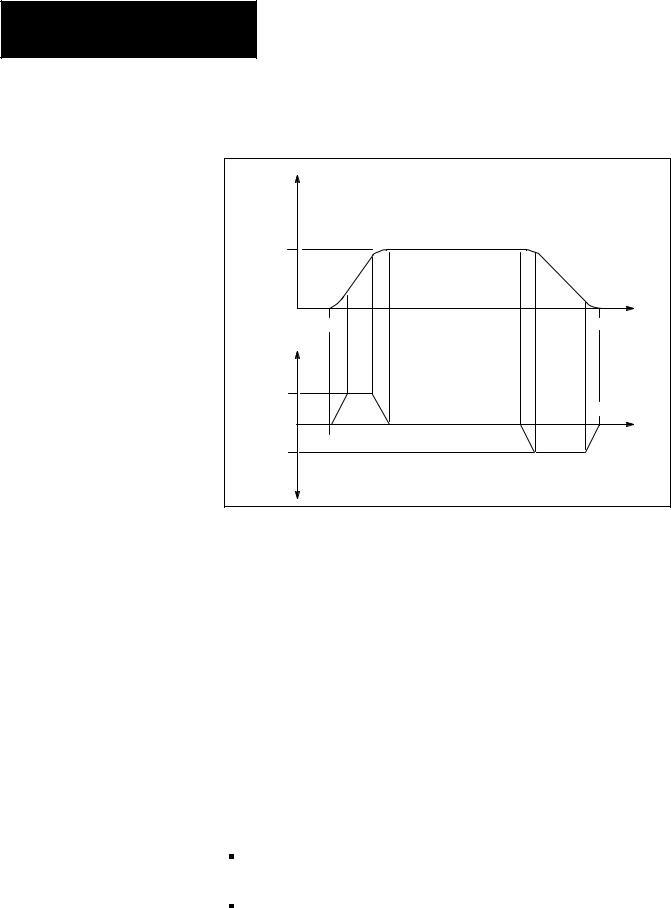

The module employs a technique called velocity curve smoothing to shape the velocity curve into an ªS curveº. To achieve this smoothing, acceleration and deceleration rates are changed to provide more gradual application and removal of force, thus reducing mechanical wear. The velocity smoothing constant that you set in the parameter block determines how quickly acceleration and deceleration change. The lower the value of the velocity smoothing constant, the more slowly acceleration and deceleration change, producing a smoother transition. Figure 3.4 shows the effect of velocity curve smoothing on the axis movement.

3 3

Chapter 3

Positioning with the Linear Positioning

Module

Figure 3.4

Axis Movement with Velocity Curve Smoothing

Velocity |

|

|

|

|

Constant |

Final |

|

Velocity |

|

|

|

Velocity |

|

|

|

Acceleration |

Deceleration |

|

|

Time |

0 |

Start |

Finish |

Acceleration |

|

|

Final |

|

|

Accel |

|

Finish |

|

|

|

0 |

|

Time |

Final |

Start |

|

|

|

|

Decel |

|

|

Deceleration |

|

|

|

|

50004 |

Commanding Motion |

There are three ways to specify module axis motion: by setpoints, by jogging or |

|

by motion blocks. All motion must be started using the command block and/or |

|

hardware inputs. |

Setpoints

The module must have the axis controller in auto mode if you are using setpoint moves. You can switch between modes using the auto/manual bit in the command block or the auto/manual discrete input.

Important: The auto/manual bit and the auto/manual input must both be high to enter auto mode.

In the auto mode, you position the actuator by commanding desired setpoints using the command block. You can:

define up to 12 setpoints through the setpoint block. You can define the 13th setpoint within the command block.

specify acceleration, deceleration, and velocity for each setpoint move.

3 4

Chapter 3

Positioning with the Linear Positioning

Module

turn on a hardware start enable bit (using the command block), which causes the module to delay movement to the commanded setpoint. The delay ends and movement starts when you activate the hardware start input or send a software start command in the command block.

command a setpoint while the axis is moving towards another setpoint. If the new setpoint is in the opposite direction of travel, the axis decelerates to zero speed (at the current deceleration rate) and then moves in the opposite direction. If the new setpoint is in the same direction of travel, the old setpoint is abandoned and the axis movement accelerates or decelerates to the specified velocity and continues toward the new setpoint.

Jogging

In the manual mode, you position the actuator by jogging, i.e., directly commanding movement in one direction or the other. You make these movement commands by turning on forward or reverse jog bits (via the command block) or activating forward or reverse hardware jog inputs (typically via momentary action switches).

If you command a jog, the axis movement continues until the actuator reaches the software travel limit or until you turn off the jog bit or jog input, whichever occurs first.

Jog Rates

You define two jog rates (high and low) through the parameter block. You select between low and high jog rates through the jog rate select bit in the command block.

If you change jog rates (from high to low or from low to high) during a jog movement, the axis decelerates/accelerates to the new rate.

Important: Jog commands are ignored in auto mode.

Motion Blocks

A motion block contains information similar to that which the setpoint block uses to define axis movement. In addition, a motion block also contains trigger conditions that will initiate a subsequent axis movement, thus changing the motion of the axis without the intervention of the programmable controller. See Chapter 9 for a full explanation of motion blocks.

3 5

Chapter 4

Hardware Description

This chapter describes the Linear Positioning Module hardware, as well as other hardware required for a positioning system.

Indicators |

Figure 4.1 shows the three indicators on the module. |

Figure 4.1

Indicators

LINEAR |

POSITIONING |

FAULT |

LOOP1 |

ACTIVE |

LOOP2 |

ACTIVE |

50009

When you first power up the module, all three indicators turn on for about one second. Next, the LOOP 1 ACTIVE and LOOP 2 ACTIVE indicators turn off while the module performs diagnostics. If the diagnostics discover a module fault, the red FAULT indicator stays on and the module remains inactive. When the programmable controller is in run mode, the indicators behave as follows:

FAULT - a red indicator that is normally off. The indicator turns on if there is a module fault in one loop or both loops. See Chapter 11 for more information on module faults.

LOOP 1 ACTIVE - a green indicator that is on when loop 1 is active. The indicator blinks if a fault occurs on loop 1 and turns off if loop 1 is inactive.

LOOP 2 ACTIVE - a green indicator that is on when loop 2 is active. The indicator blinks if a fault occurs on loop 2 and turns off if loop 2 is inactive.

4 1

Loading...

Loading...