Rockwell Automation 1771-IFEC User Manual

Contents

This icon is used when additional information

is available in the Analog Input Module User Manual, publication 1771 6.5.115.

If you need a copy of this manual, fax the enclosed User Manual Request Card to 1 800 576 6340. If you are outside the U.S., fax the card to1 330 723 4036.

Prevent Electrostatic

Discharge

Installation Instructions

Analog Input Module

(Catalog Number 1771-IFE/C)

Use this document as a guide when installing the 1771-IFE/C analog input module.

To |

|

See page |

|

|

|

Prevent Electrostatic Discharge |

|

Below |

|

|

|

|

|

|

|

Understand Compliance to European Union Directives |

2 |

|

|

|

|

|

|

|

|

Understand Product Compatibility |

2 |

|

|

|

|

|

|

|

|

Calculate Power Requirements |

3 |

|

|

|

|

|

|

|

|

Determine Module Placement |

3 |

|

|

|

|

|

|

|

|

Set the A/B Simulation Jumper |

3 |

|

|

|

|

|

|

|

|

Set the Configuration Jumpers |

4 |

|

|

|

|

|

|

|

|

Key the Backplane Connector |

4 |

|

|

|

|

|

|

|

|

Install the Module and Field Wiring Arm |

5 |

|

|

|

|

|

|

|

|

Connect Wiring to the Field Wiring Arm |

6 |

|

|

|

|

|

|

|

|

Ground the Chassis and Module |

9 |

|

|

|

|

|

|

|

|

Configure the Module |

10 |

|

|

|

|

|

|

|

For this reference information |

|

See page |

|

|

|

Status Indicators |

12 |

|

|

|

|

|

|

|

|

Troubleshooting |

13 |

|

|

|

|

|

|

|

|

Specifications |

13 |

|

|

|

|

|

|

|

|

CSA Hazardous Approval |

15 |

|

|

|

|

|

|

|

|

Differences Between Series A, B and C Modules |

16 |

|

|

|

|

|

|

|

The analog input module is sensitive to electrostatic discharge.

ATTENTION: Electrostatic discharge can damage integrated circuits or semiconductors if you touch

! backplane connector pins. Follow these guidelines when you handle the module:

•Touch a grounded object to discharge static potential

•Wear an approved wrist-strap grounding device

•Do not touch the backplane connector or connector pins

•Do not touch circuit components inside the module

•If available, use a static-safe work station

•When not in use, keep the module in its static-shield box

Publication 1771 5.45 - July 1997

2 |

Analog Input Module |

Understand Compliance to European Union Directives

If this product has the CE mark it is approved for installation within the European Union and EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic Compatibility (EMC) and the following standards, in whole or in part, documented in a technical construction file:

•EN 50081-2EMC ± Generic Emission Standard, Part 2 ± Industrial Environment

•EN 50082-2EMC ± Generic Immunity Standard, Part 2 ± Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131±2 Programmable Controllers, Part 2 ± Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate sections in this publication, as well as these Allen-Bradley publications:

Publication |

Publication number |

Industrial Automation Wiring and Grounding Guidelines |

1770 4.1 |

For Noise Immunity |

|

|

|

Guidelines for Handling Lithium Batteries |

AG 5.4 |

|

|

Automation Systems Catalog |

B111 |

|

|

Understand Product

Compatibility

The 1771-IFE module can be used with any 1771 I/O chassis. Compatibility and data table use is listed below.

|

|

|

Use of Data Table |

|

|

Compatibility |

|

|||

|

Catalog |

|

|

|

|

|

|

|

|

|

|

Input |

Output |

Read |

Write |

|

Addressing |

|

Chassis |

||

|

Number |

|

|

|||||||

|

Image |

Image |

Block |

Block |

|

|

|

|

||

|

|

Bits |

Bits |

Words |

Words |

1/2 Slot |

1 Slot |

|

2 Slot |

Series |

|

|

|

|

|||||||

|

1771 IFE |

8 |

8 |

22 |

39 |

Y |

Y |

|

Y |

A, B |

|

|

|

|

|

|

|

|

|

|

|

A |

= Compatible with 1771 A1, A2, A4 |

|

|

|

|

|

|

|

||

B = Compatible with 1771 A1B, A2B, A3B, A3B1, A4B |

|

|

|

|

|

|

||||

Y |

= Compatible without restriction. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Do not use this module with cat. no. 1771-AL PLC-2/20 or 2/30 Local Adapter.

Publication 1771 5.45 - July 1997

Analog Input Module |

3 |

Calculate Power

Requirements

The module receives its power through the 1771 I/O power supply and requires 500mA from the backplane.

Add this current to the requirements of all other modules in the I/O chassis to prevent overloading the chassis backplane and/or backplane power supply.

Determine Module

Placement in the I/O

Chassis

Set the A/B Simulation

Jumper

Place your module in any I/O module slot of the I/O chassis except for the extreme left slot. This slot is reserved for PC processors or adapter modules.

ATTENTION: Do not insert or remove modules from the I/O chassis while system power is ON. Failure to

! observe this rule could result in damage to module circuitry.

Group your modules to minimize adverse affects from radiated electrical noise and heat. We recommend the following.

•Group analog input and low voltage dc modules away from ac modules or high voltage dc modules to minimize electrical noise interference.

•Do not place this module in the same I/O group with a discrete high-density I/O module when using 2-slot addressing. This module uses a byte in both the input and output image tables for block transfer.

The module is shipped with the A/B simulation jumper set in position POS G for Series C applications. This setting returns input data above and below the range end points. If you are replacing a Series A or B 1771-IFE module with this module, reset the simulation jumper to the POS E position as shown below.

Set the Series A/B Simulation Jumper

1.Locate the simulation jumper at the top edge of the module circuit board.

2.Using your fingers, slide the jumper off the 2 posts.

3.Carefully position the jumper on 2 of the 3 posts that correspond to your requirement.

A/B Simulation Jumper

Top edge of circuit board

POS G |

|

|

|

|

|

POS E |

|

|

|

Series A and B

Simulation

Simulation Jumper (shown in A/B position)

Top edge of circuit board

POS G |

|

|

|

|

|

POS E |

|

|

|

Series C

Application

Simulation Jumper (shown in series C position)

Publication 1771 5.45 - July 1997

4 |

Analog Input Module |

Set the Configuration

Jumpers and Key the

Backplane Connector

The module has configuration jumpers for determining the input type (voltage or current) desired for each input. The module is shipped with the configuration jumpers positioned for voltage mode and the A/B simulation jumper set for Series C. If you are replacing a Series A or B 1771-IFE module with this module, reset the simulation jumper as shown above.

You can select either voltage or current for each input, but all inputs must be either single-ended or differential. Do not mix single-ended and differential inputs on the module.

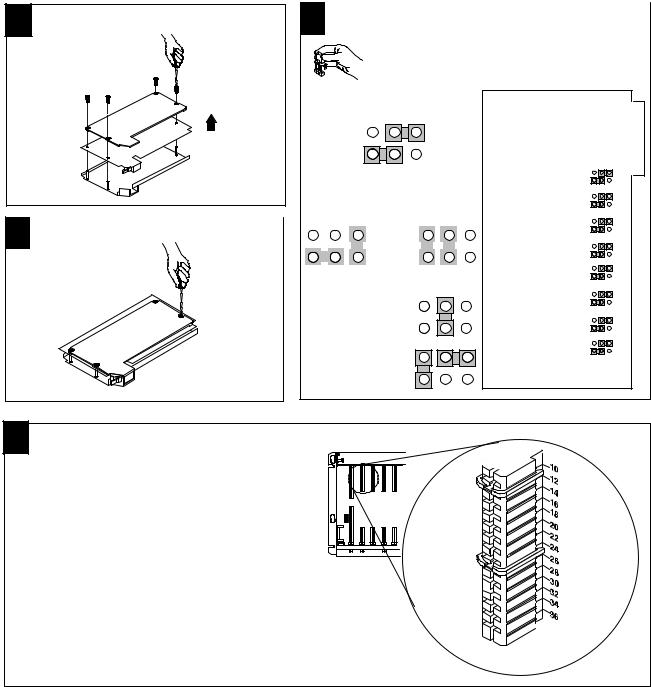

1Remove the four screws securing the side cover to the module and remove the covers.

19805

13 |

Reposition the cover and secure with the four |

screws removed in step 1. |

19813

12 |

Reposition the configuration jumpers associated with each input |

channel according to your requirements |

|

|

|

You can mix voltage mode and current mode settings on the module. Make sure that the entire module is set for either single ended or differential. Do not mix them.

Voltage Mode

Differential or Single ended (factory set)

Current Mode

Differential |

Single ended |

||||||||

Current |

Current |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single ended

Odd channel current

Even channel voltage

Even channel current

Odd channel voltage

Configuration

Jumpers

Single ended Differential

Channel |

Channel 1 |

|

1 and 2 |

||

|

||

Channel |

Channel 2 |

|

3 and 4 |

||

|

||

Channel |

Channel 3 |

|

5 and 6 |

||

|

||

Channel |

Channel 4 |

|

7 and 8 |

||

|

||

Channel |

Channel 5 |

|

9 and 10 |

||

|

||

Channel |

Channel 6 |

|

11 and 12 |

||

|

||

Channel |

Channel 7 |

|

13 and 14 |

||

|

||

Channel |

Channel 8 |

|

15 and 16 |

||

|

4Key the Backplane Connector

Place your module in any slot in the chassis except the leftmost slot which is reserved for processors or adapters.

Position the keying bands in the backplane connectors to correspond to the key slots on the module.

Place the keying bands: between 10 and 12 between 24 and 26

You can change the position of these bands if subsequent system design and rewiring makes insertion of a different type of module necessary.

I/O chassis

Upper Connector

11022 I

Publication 1771 5.45 - July 1997

Analog Input Module |

5 |

Install the Module and |

|

ATTENTION: Remove power from the 1771 I/O |

Field Wiring Arm |

! |

chassis backplane and field wiring arm before |

|

removing or installing an I/O module. |

|

|

|

• Failure to remove power from the backplane or |

|

|

wiring arm could cause module damage, degradation |

|

|

of performance, or injury. |

|

|

• Failure to remove power from the backplane could |

|

|

cause injury or equipment damage due to possible |

|

|

unexpected operation. |

|

|

|

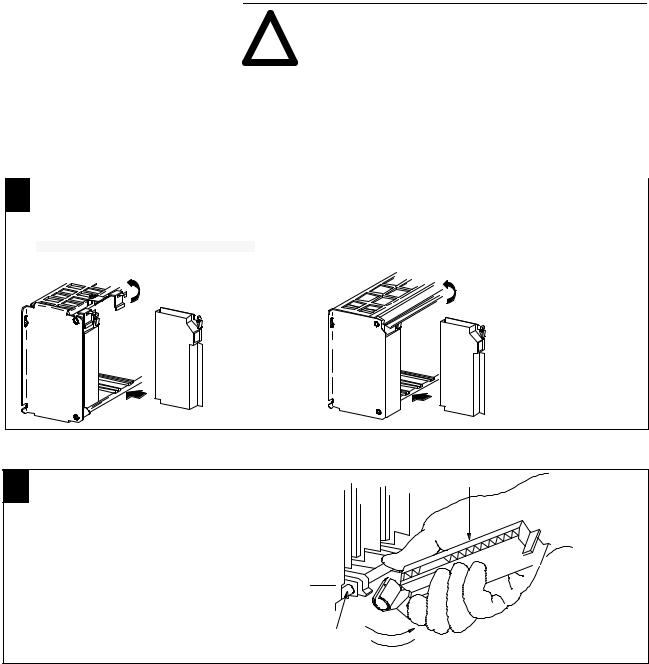

1 |

Place the module in the card guides on the top and bottom of the chassis that guide the module into position. |

|

|

Important: Apply firm even pressure on the module to seat it into its |

|

|

||

|

backplane connector. |

|

|

1771 A1B, A2B, A3B, A3B1, A4B I/O chassis |

1771 A1B, A2B, A3B1, A4B Series B I/O chassis |

Snap the chassis latch over the top of the module to secure it.

Swing the chassis locking bar down into place to secure the modules. Make sure the locking pins engage.

2Attach the wiring arm (1771 WG) to the horizontal bar at the bottom of the I/O chassis.

The wiring arm pivots upward and connects with the module so you can install or remove the module without disconnecting the wires.

wiring arm

1771 WG

1771 WG

remove

horizontal bar  install

install

17643

Publication 1771 5.45 - July 1997

Loading...

Loading...