Parkside PESG 120 A1 User Manual

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:18 Uhr Seite 1

PESG 120 A1

|

|

ARC WELDER |

ΣΥΣΚΕΥΗ ΗΛΕΚΤΡΟΣΥΓΚΟΛΗΣΗΣ |

Operation and Safety Notes |

Υποδείξεις χειρισμού και ασφαλείας |

Original operating instructions |

Πρωτότυπες Οδηγίες χρήσης |

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:18 Uhr Seite 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις λειτουργίες της συσκευής.

GB/IE/CY |

Operation and Safety Notes |

Page |

5 |

GR/CY |

Υποδείξεις χειρισμού και ασφαλείας |

Σελίδα |

15 |

2

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:18 Uhr Seite 3

1

1

8

2

7

3

6

5

12

|

|

4 |

|

2 |

3 |

9 |

8 |

|

8 |

|

|

|

9 |

|

|

11 |

10 |

|

|

|

|

|

3 |

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 |

|

4 |

10 |

8:19 Uhr Seite 4

5 |

11 |

8 |

4

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:19 Uhr Seite 5

GB/IE/

CY

Table of contents: |

Page |

|

1. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.6 |

2. |

Layout and items supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

3. |

Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-9 |

4. |

Symbols and technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

5. |

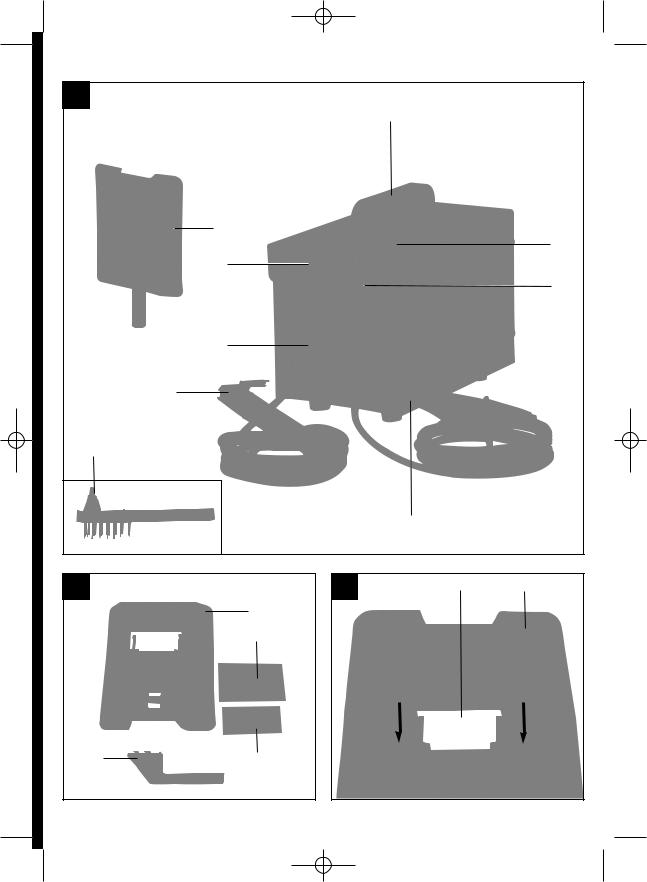

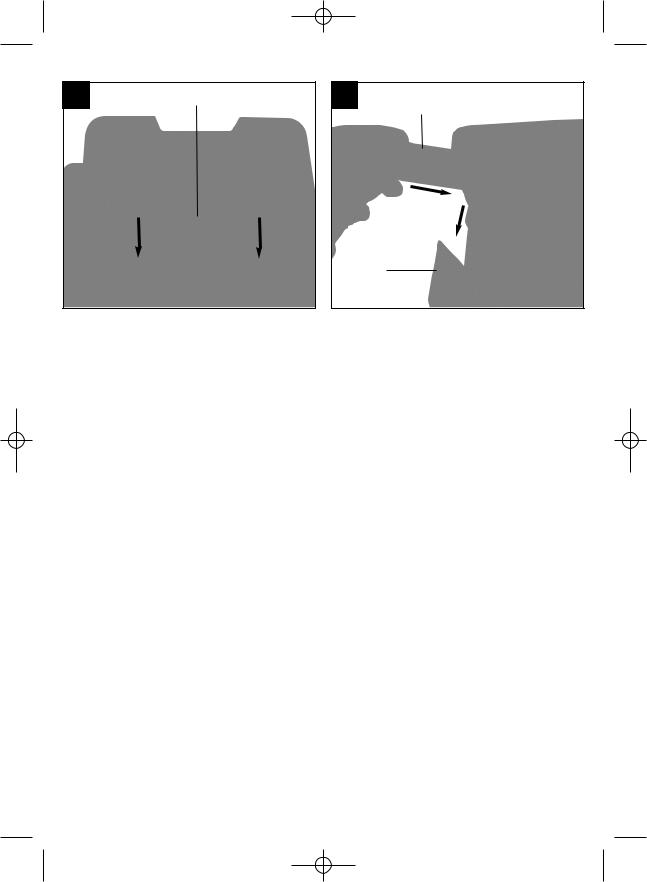

Assembling the welding screen . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

6. |

Welding preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

7. |

Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

8. |

Overheating guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

9. |

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

10. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

11. Ordering spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

12. Disposal and recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

13. Circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

14. Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

15. Guarantee certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

|

Read and follow the operating instructions and safety information before using for the first time.

The reprinting or reproduction by any other means, in whole or in part, of documentation and papers accompanying products is permitted only with the express consent of ISC GmbH.

Technical changes subject to change

5

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:19 Uhr Seite 6

GB/IE/

CY

1. Introduction

Important!

When using the equipment, a few safety precautions must be observed to avoid injuries and damage. Please read the complete operating manual with due care. Keep this manual in a safe place so that the information is available at all times. If you give the equipment to any other person, give them these operating instructions as well. We cannot accept any liability for damage or accidents which arise due to a failure to follow these instructions and the safety information.

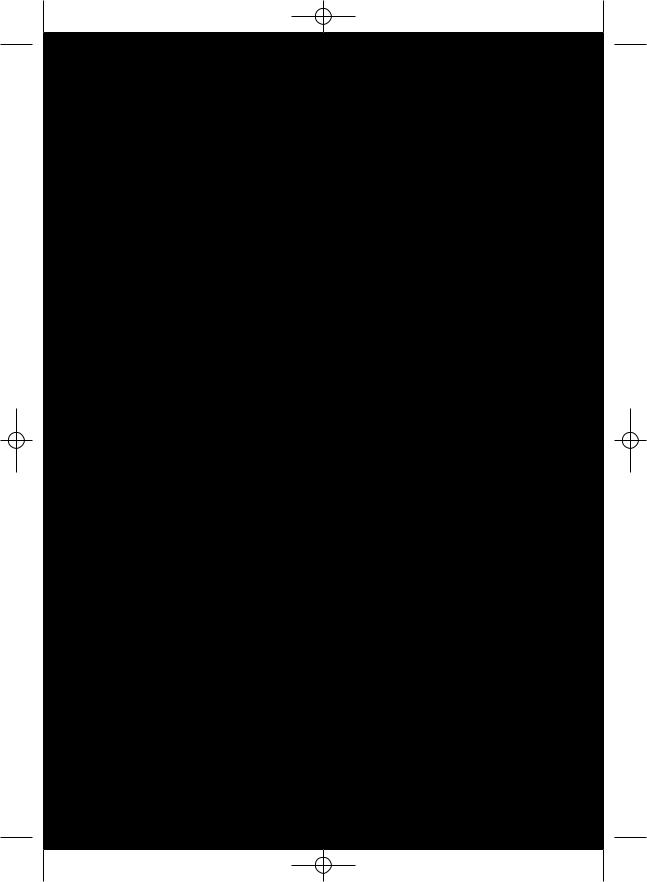

2.Layout and items supplied (Fig. 1/2)

1.Carry handle

2.Welding current scale

3.ON/OFF switch

4.Earth terminal

5.Electrode holder

6.Adjustment wheel for welding current

7.Warning lamp for overheating

8.Welding screen

9.Safety glass

10.Welding glass

11.Welding screen holder

12.Wire brush / slag hammer

3. Important information

The equipment is to be used only for its prescribed purpose. Any other use is deemed to be a case of misuse. The user / operator and not the manufacturer will be liable for any damage or injuries of any kind caused as a result of this.

Please note that our equipment has not been designed for use in commercial, trade or industrial applications. Our warranty will be voided if the equipment is used in commercial, trade or industrial businesses or for equivalent purposes.

6

Please read the operating instructions carefully and observe the information provided. It is important to consult these instructions in order to acquaint yourself with the equipment, its proper use and safety information.

Safety information

Please note

Warning!

Use this equipment only for the purpose for which it is designed, as described in these instructions: Manual arc welding with coated electrodes. Handling this system incorrectly may be hazardous for persons, animals and property and may result in burning buildings, electric shocks, eye injuries, etc. The user of this system is responsible for his/her own safety and for the safety of others. Read these operating instructions and follow all the information.

Repairs and/or maintenance work must be left strictly to qualified personnel.

Only use the welding cables supplied (H07RN-F 3x1.5 mm2 /

H01N2-D 1x10 mm2).

Ensure that the equipment is looked after properly.

To ensure that sufficient air can be drawn in through the ventilation slits, the equipment should not be constricted or placed next to a wall while it is operating. Make sure that the equipment is correctly connected to the mains supply (see 4.). Do not subject the mains lead to any tensile stress. Unplug the equipment before you change its position.

Check the condition of the welding cables, the electrode holder and the earth terminals; wear on the insulation and the live parts may result in dangerous conditions and reduce the quality of the welding work.

Arc welding generates sparks, molten metal particles and smoke, so the following is required: Remove all inflammable substances and/or materials from the working area.

Ensure that there is adequate ventilation.

Do not weld on tanks, vessels or pipes that have contained inflammable liquids or

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:19 Uhr Seite 7

GB/IE/

CY

gases. Avoid all direct contact with the welding circuit; the idling voltage between the electrode holder and the earth terminal may be dangerous.

Do not store or use the equipment in wet or damp conditions or in the rain.

Protect your eyes with specially designed goggles (DIN level 9-10), which you can attach to the supplied welding screen. Wear gloves and dry safety clothing that are not contaminated by any oil or grease to ensure that your skin is not exposed to ultraviolet radiation from the arc.

Do not use this welder to defrost pipes.

Make sure that the equipment is set up so it stands firmly. If the equipment is set up on an angled surface, it may need to be secured by tying or blocking the wheels.

Hazard!

The radiation from the arc can damage your eyes and cause burns on skin.

Arc welding generates sparks and droplets of molten metal; the welded workpiece may start to glow and will remain very hot for a relatively long period of time. Never touch the workpiece with bare hands.

Arc welding releases vapors that may be harmful. Every electric shock is potentially fatal. Do not approach the arc within a radius of 15 m unprotected.

Protect yourself (and others around you) against the possible hazardous effects of the arc.

Warning: depending on the mains connection conditions at the connection point of the welding set, other consumers connected to the mains may suffer faults.

Warning!

If the supply mains and circuits are overloaded, other consumers may suffer interference during the welding work. If you have any doubts, contact your electricity supply company.

Sources of danger during arc welding

Hazard!

Arc welding results in a number of sources of danger. It is therefore particularly important for the welder to comply with the following rules so as not to place himself or others in danger and to avoid endangering people and equipment.

Have all work on the mains voltage system, for example on cables, plugs, sockets, etc., performed only by trained electricians. This particularly applies to configuring intermediate cables.

If an accident occurs, disconnect the welding power source from the mains immediately.

If electric touch voltages occur, switch off the welding set immediately and have it checked by an expert.

Always check for good electrical contacts on the welding current side.

Wear insulating gloves on both hands for welding. These offer protection from electric shocks (idling voltage in the welding circuit), harmful radiation (heat and UV radiation) and from glowing metal and slag spatter.

Wear firm, insulated footwear. Your shoes must also be suitable to protect you in wet conditions. Open-toed footwear is not suitable since falling droplets of glowing metal will cause burns.

Wear suitable clothing, do not wear synthetic clothes.

Do not look into the arc with unprotected eyes, use only a welding screen with the proper safety glass in compliance with DIN standards. In addition to light and heat, which may cause dazzling and burns, the arc also gives off UV radiation. Without proper protection, this invisible ultraviolet radiation causes very painful conjunctivitis, which will only be noticeable several hours later. In addition, UV radiation will cause harmful sunburn-type symptoms on unprotected parts of the body.

Personnel or assistants in the vicinity of the arc must also be notified of the dangers and provided with the required protection; if necessary install safety walls.

7

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:19 Uhr Seite 8

GB/IE/

CY

Ensure adequate ventilation for welding, particularly in small rooms since the process causes smoke and harmful gases.

Do not carry out any welding work on tanks that have been used to store gases, fuels, mineral oil or the like, even if they have been empty for a lengthy period of time, since any residue will result in a danger of explosion.

Special regulations apply in areas where there is a potential risk of fire and/or explosion.

Welds that are exposed to large stresses and must comply with safety requirements may only be completed by specially trained and approved welders. Examples of such welds include pressure vessels, rails, trailer hitches, etc.

Notes:

It must be noted that the protective conductor in electrical systems or equipment may be destroyed by the welding current in the event of negligence, for example if the earth terminal is placed on the welding set casing to which the protective conductor of the electrical system is connected. The welding work is completed on a machine with a protective conductor connection. It is therefore possible to weld on the machine without having connected the earth terminal to it. In this case the welding current will flow from the earth terminal through the protective conductor to the machine. The high welding current may cause the protective conductor to melt.

The fuses on the supply cables to the mains sockets must comply with the relevant regulations (VDE 0100). To comply with these regulations, only fuses or circuit breakers suitable for the cross-section of the cables may be used (for earthing contact sockets max. 13 A fuses or 13 A circuit breakers). The use of too high a fuse may result in the cable burning and fire damage to the building.

8

Constricted and wet areas

Caution!

When working in constricted, wet or hot areas, use insulating supports and intermediate layers as well as slip-on gloves made of leather or other non-conductive materials to insulate your body against the floor, walls, conductive parts of the equipment and the like.

If you use small welding transformers for welding in places with an increase electrical risk, for example in constricted areas with conductive walls, (tanks, pipes, etc.), in wet areas (which make work clothes wet) and in hot areas (perspiration on work clothes), the output voltage of the welding set when idling must not exceed 42 V (effective value). Therefore, the equipment may not be used for these purposes because its output voltage is higher than this.

Safety clothing

Caution!

While working, the welder must protect his entire body from radiation and burns by wearing suitable clothing and a face guard.

Slip-on gloves made of a suitable material (leather) must be worn on both hands. They must be in perfect condition.

Suitable aprons must be worn to protect clothing from sparks and burns. A safety suit and, if necessary, head protection must be worn if required by the type of work in question, e.g. overhead welding.

The safety clothing used as well as all accessories must comply with the directive on “personal safety equipment”.

Protection from radiation and burns

Caution!

Provide information about the risk to eyes at the working site in the form of a poster with the wording “Caution – do not look at the flames”. Workplaces are to be screened off wherever possible so that personnel in the vicinity are protected. Unauthorized persons are to be kept away from the welding work.

Anleitung_1549054_GB_IE_CY:_ 03.11.2011 8:19 Uhr Seite 9

GB/IE/

CY

The walls in the immediate vicinity of stationary workplaces may not have a light color or a sheen. Windows up to head height are to be protected against radiation passing through them or reflecting off them, for example by coating them with a suitable paint.

4. Symbols and technical data

EN 60974-6

S

European standard for arc welding sets and welding power supplies with limited on time (part 6).

Symbol for welding power supplies which are suitable for welding in environments with increased electrical danger.

~ 50 Hz |

Alternating current and |

|

rated frequency value [Hz] |

U0 |

Rated idling voltage [V] |

40A/19.6V - 80 A/21.2 V

Maximum welding current and the corresponding standardized operating voltage [A/V]

Ø |

Electrode diameter [mm] |

I2 |

Welding current [A] |

tw |

Average load time [s] |

tr |

Average reset time [s] |

|

Line input; number of |

|

phases, the alternating |

1~ 50 Hz |

current symbol and the |

|

rated frequency value |

|

Do not store or use the |

|

equipment in wet or damp |

|

conditions or in the rain. |

|

Use the equipment only |

|

indoors. |

U1 |

Line voltage [V] |

I1max |

Highest rated value of the |

|

line current [A] |

I1eff |

Effective value of the |

|

highest line current [A] |

IP 21S |

Protection type |

H |

Insulation class |

|

Electrode holder |

|

connection |

|

Ground terminal |

|

connection |

Mains connection: |

|

230 V ~ 50 Hz |

||

Welding current (A) at cos ϕ= 0.73: |

40 - 80 |

|||

ø (mm) |

|

1.6 |

2.0 |

2.5 |

I2 |

|

40 |

55 |

80 |

tw (s) |

|

217 |

116 |

64 |

tr (s) |

|

1450 |

1381 |

1351 |

Idling voltage (V): |

|

|

|

48 |

Power input: |

4 kVA at 80 A cos ϕ = 0.73 |

|||

Fuse (A): |

|

|

|

13 |

Weight: |

|

|

10.6 kg |

|

The welding times apply for an ambient temperature of 40° C.

9

Loading...

Loading...