Parkside PABK 60 A1 User Manual [en, de, cs]

AIRBRUSH SET PABK 60 A1

AIRBRUSH SET

Operation and Safety Notes

SÚPRAVA STRIEKACEJ PIŠTOLE

Pokyny pre obsluhu a bezpečnostné pokyny

SADA STŘÍKACÍ PISTOLE

Pokyny pro obsluhu a bezpečnostní pokyny

AIRBRUSH-SET

Bedienungs- und Sicherheitshinweise

IAN 73868

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 3 05.07.12 16:58

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Před čtením si odklopte obě dvě strany s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte obidve strany s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 15

SK Pokyny pre obsluhu a bezpečnostné pokyny Strana 25

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 35

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 4 05.07.12 16:58

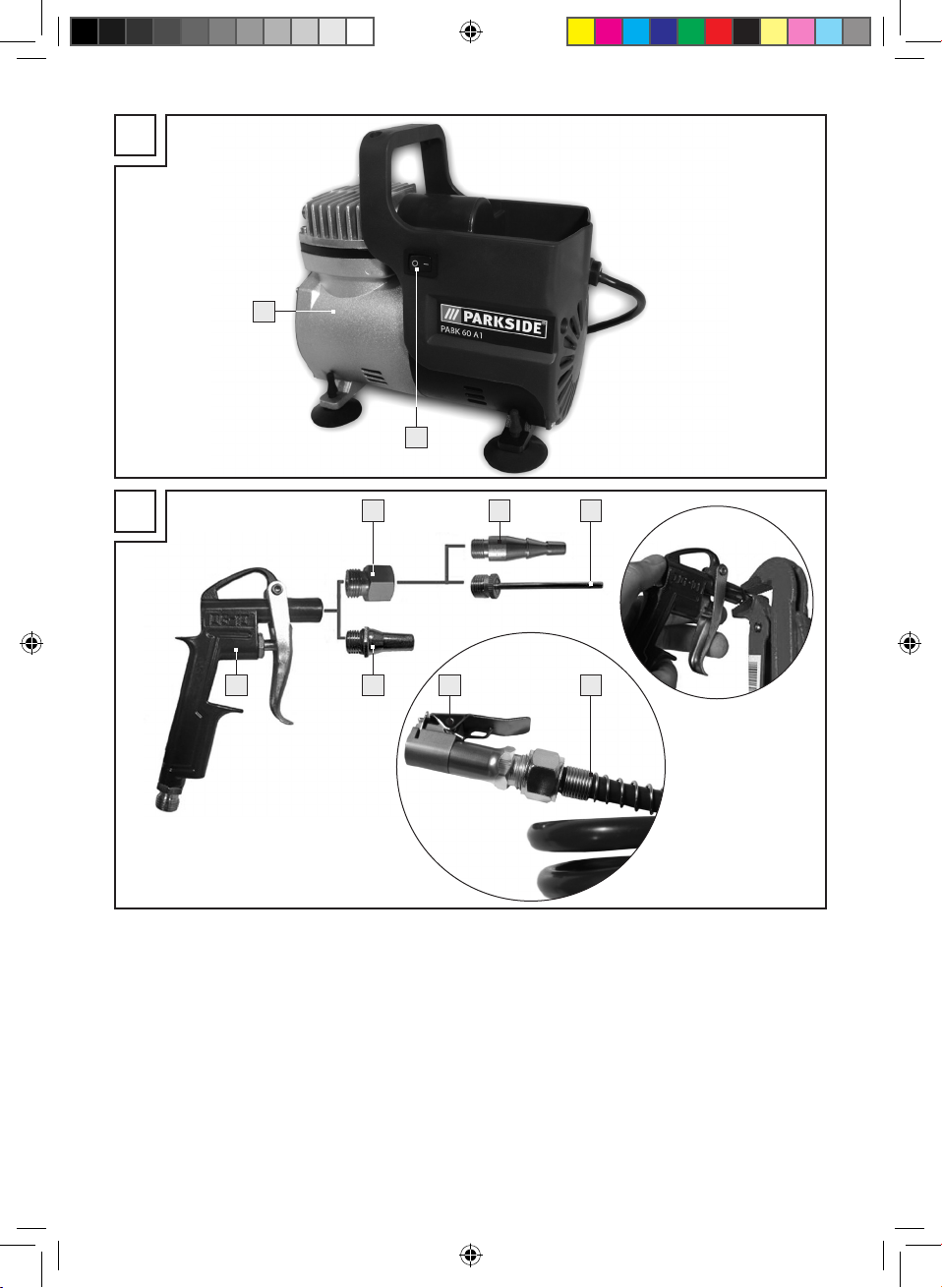

1 2

8

9

4 5 6 7

2 a

9 a

10 11 12

3

13

A

B

2

2 a

1

13

3

5

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 5 05.07.12 16:58

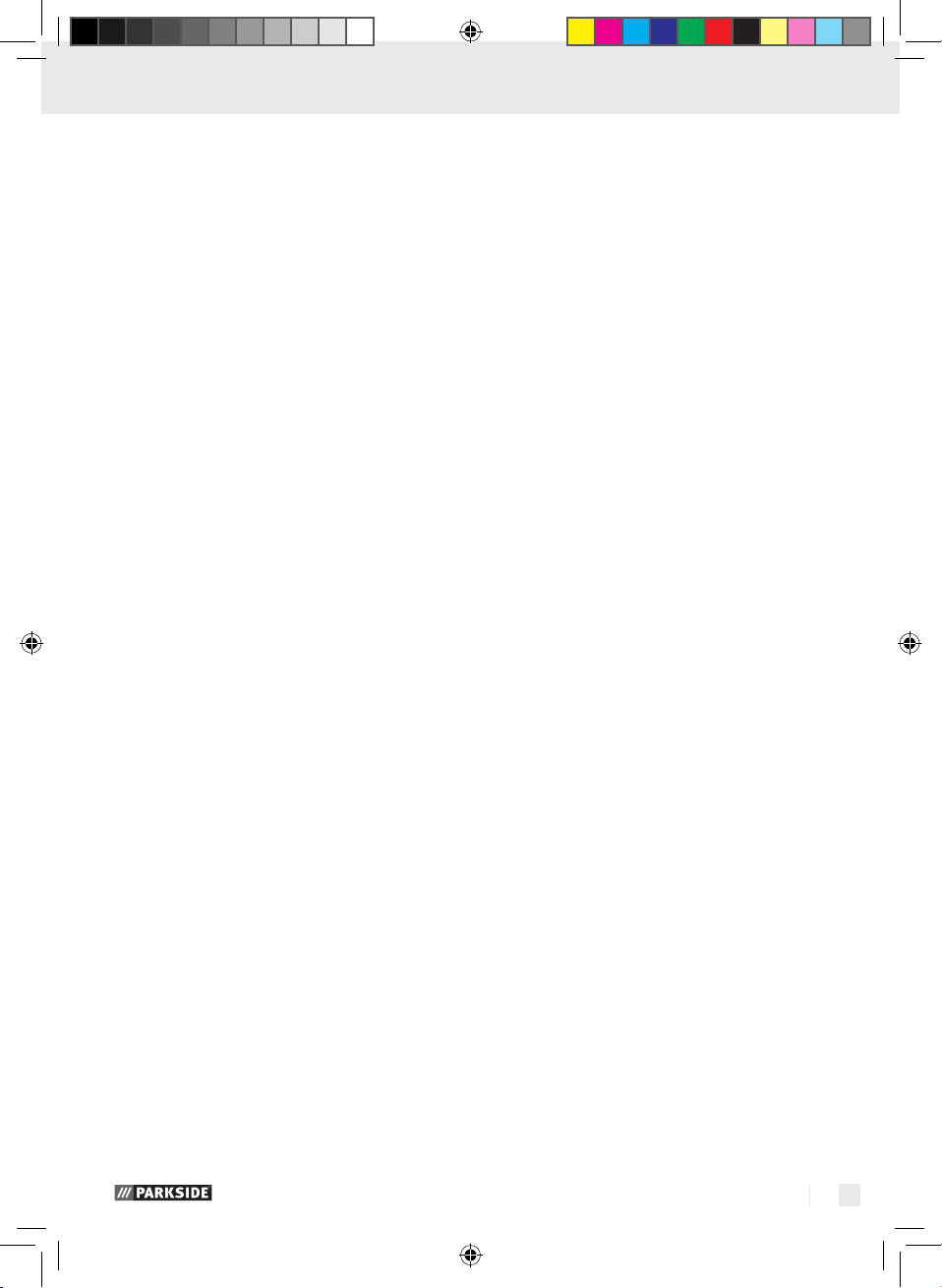

C

1

14

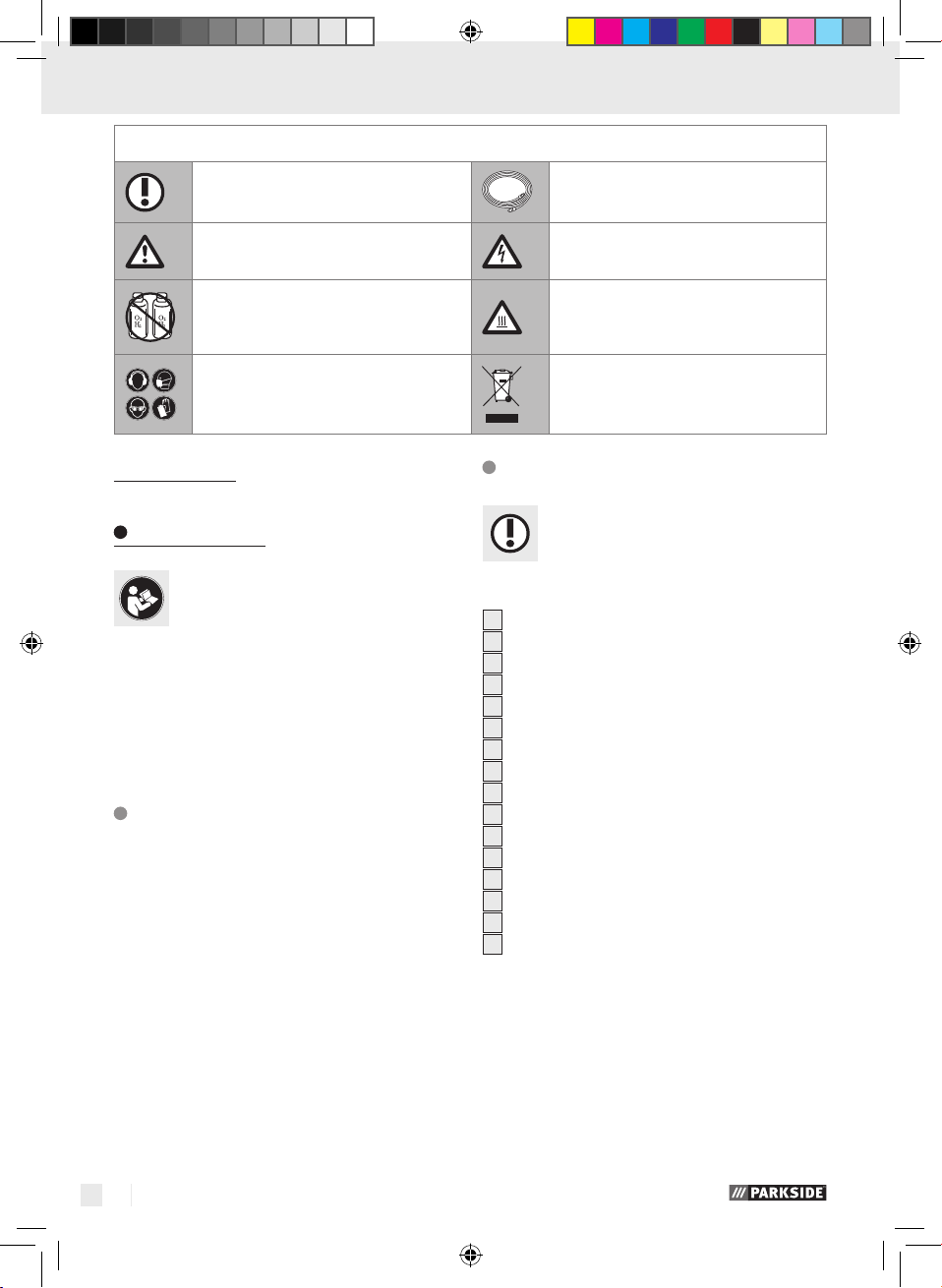

D

9 9a

7 12

6

10 8

73868_par_Airbrush_Set_Cover_LB4 (CZ-SK).indd 8 05.07.12 16:58

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features and fittings ............................................................................................................................ Page 6

Technical data ..................................................................................................................................... Page 7

General safety instructions for compressed air tools................................Page 7

General safety information for electrical devices .............................................................................Page 9

Product-specific safety instructions .....................................................................................................Page 9

Before initial use ....................................................................................................................... Page 9

Preparations for use

Connecting the airbrush set ................................................................................................................ Page 9

Mixing paints for use .......................................................................................................................... Page 10

Turning airbrush compressor on / off .................................................................................................Page 10

Regulating the air pressure ................................................................................................................. Page 10

Regulating the spraying results...........................................................................................................Page 10

Using the accessories (see Ill. D) .......................................................................................................Page 11

Cleaning and care .................................................................................................................... Page 11

Information about warranty and service processing

Warranty terms ...................................................................................................................................Page 12

Scope of warranty ..............................................................................................................................Page 12

Procedure in the case of warranty ..................................................................................................... Page 12

Environmental instructions and disposal information .............................. Page 13

Paint disposal instructions ................................................................................................ Page 13

CE Declaration of Conformity ......................................................................................... Page 13

5 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 5 06.07.12 12:26

Introduction

The following pictograms are used in these operating instructions / on the device:

Note Supply hose

Observe caution and safety notes! Danger of electric shock

Never use hydrogen, oxygen, carbon

dioxide or other bottled gases as an

energy source.

Risk of burns!

Wear hearing protection, dust protection mask, protective glasses and

protective gloves.

Airbrush set

Introduction

Congratulations! You have chosen a

high-quality device from our company.

Familiarise yourself with the product

before using it for the first time. In addition, please

carefully refer to the operating instructions and the

safety advice below. Initial operation of this tool

must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

This device is a portable air compressor optimised for

use with airbrushes. With the accessories included,

it is suitable for use in numerous applications. It is

maintenance-free and equipped with noise suppression so it is also suitable for use in closed rooms.

Keep these instructions in a safe place. When passing this product on to others please also include all

documents. Any use other than the intended is prohibited and potentially dangerous. Damages resulting from noncompliance or misuse are not covered

by the warranty and are not included in the manufacturer‘s liability. This device has been designed

for household use and may not be used for commercial or industrial purposes.

Dispose of packaging and device in

an environmentally friendly way!

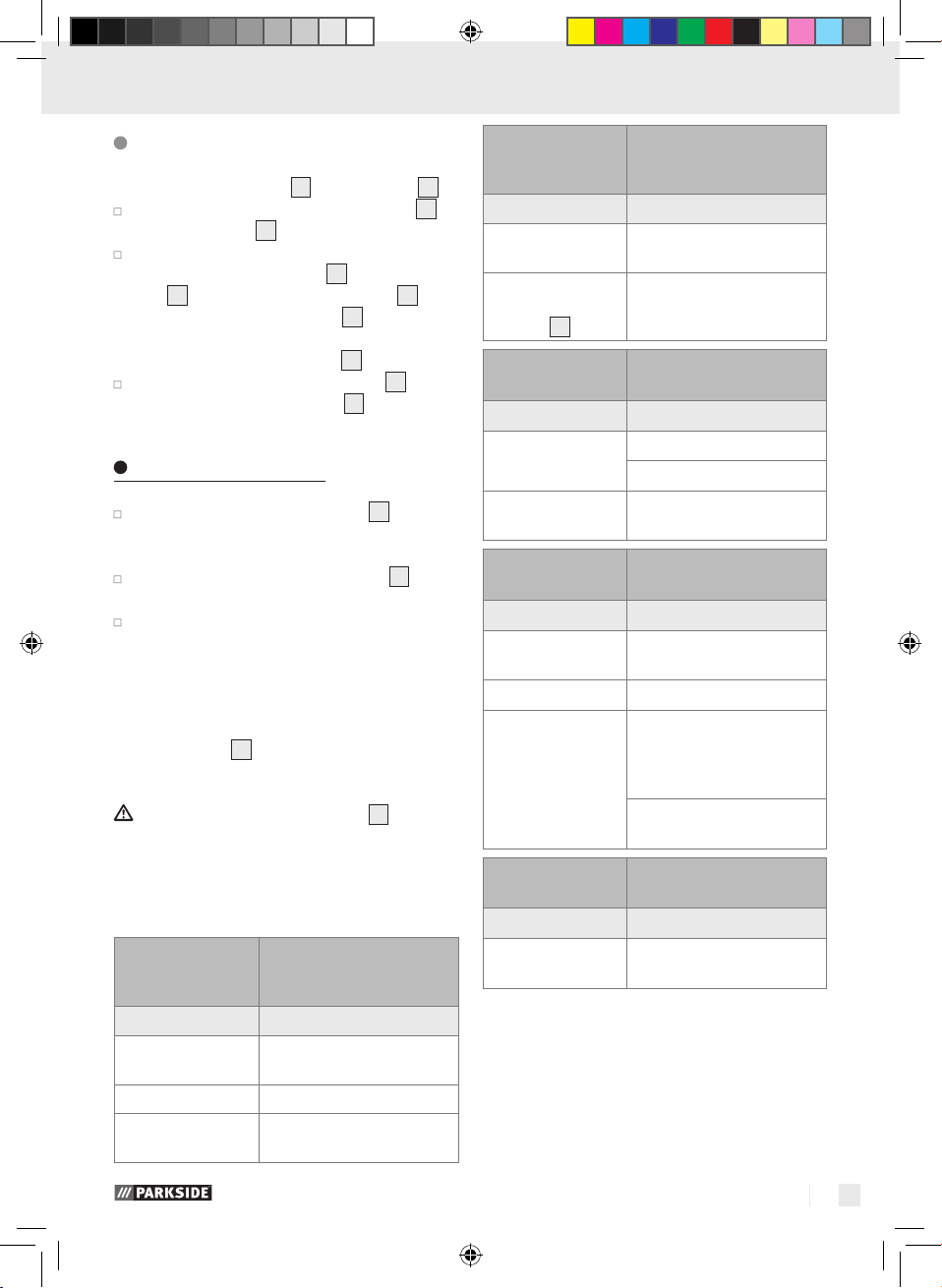

Features and fittings

Check that all the items are present and

that the product is in perfect condition

immediately after unpacking. Never use

the product if it is defective.

1

Airbrush compressor

2

Coiled hose

2 a

Coiled hose adapter

3

Spray stylus

4

Paint mixing beaker with closure lid

5

Paint mixing beaker with connection lid

6

Air mattress adapter

7

Thread adapter

8

Compressed air hose

9

Air blow gun

9a

Air blow gun nozzle

10

Universal valve connection

11

Mixing pipette

12

Ball needle

13

Open-end wrench

14

On / Off Switch

Note: This package also includes six different colours of highly concentrated, water-soluble paints in

plastic containers as well as a beaker of thinner

(transparent). These are referred to as „consumables“ in the following.

6 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 6 06.07.12 12:26

Introduction / General safety instructions for compressed air tool

Technical data

Output power: approx. 15 l / min

Theoretical suction capacity: max. 40 l / min

Operating pressure: approx. 0.16 Mpa

Max. operating pressure: approx. 0.35 Mpa

(approx. 3 bar)

Weight without accessories: approx. 4140 g

Motor output

without load: 100 W

Operating voltage: 230 V∼, 50 Hz

Output of

compressor speed: 1440 min

Protection class: IPX 0

Protection class: I /

-1

General safety instructions

for compressed air tools

Note: When used in the following text, the terms

„compressed air device“ or „device“ refer to the

compressed air device specified in these instructions

for use.

Basic safety measures must be

followed when using compressed air devices to

eliminate the risk of fire, electric shock and personal

injury. Be sure to read and follow the notices within

these operating instructions prior to using the device

and store them in a safe location. The manufacturer

assumes no liability for damages or personal injury

resulting from failure to follow these operating instructions.

Children or persons who lack the knowledge

or experience to use the device or whose physical, sensory or intellectual capacities are limited must never be allowed to use the device

without supervision or instruction by a person

responsible for their safety.

Prevent children from playing with the device.

RISK OF INJURY! Before

performing maintenance tasks, disconnect the

compressed air supply.

Only use the device in applications for which it

was designed!

Do not overload the device.

Never use hydrogen, oxygen, car-

bon dioxide or other bottled gasses

to power this tool as doing so may

result in explosion, causing severe injuries.

Maintain and clean the device regularly as

prescribed (see Chapter „Cleaning and care“).

DANGER OF EXPLOSION!

Never use petrol or other flammable liquids to

clean the compressed air tool! Sparks could ignite residual vapours inside the compressed air

device resulting in the compressed air device

exploding. Do not use the device in explosive

environments with flammable liquids, gasses or

dust. Never work on materials which are or could

potentially be highly flammable or explosive.

Check the device for damage before bringing

it into use. Always make sure that the device is

in perfect condition each time before use.

Remain alert at all times and always watch

what you are doing! Unexpected movement of

the device may cause hazards.

Avoid placing your body in an unnatural position.

Keep proper footing and balance at all times.

By doing this you will be in a better position to

control the compressed air device in unforeseen

circumstances.

Do not use any device if its switch is defective.

A device that can no longer be switched on

and off is dangerous and must be repaired.

Store the device out of the reach of children

when it is not in use. Do not let anyone use the

device if he or she is not familiar with it or has

not read the instructions and advice. Compressed

air devices are dangerous when they are used

by inexperienced people.

Maintain the device carefully. Check that mov-

ing device parts are working properly and move

freely. Check for any parts that are broken or

damaged enough to detrimentally affect the

functioning of the device. Have damaged parts

repaired before you use the device. Many accidents have their origins in poorly maintained

devices.

Switch off the device off when it is not in use.

Always wear personal protective

device and safety glasses. Wearing

personal protective devices such as

7 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 7 06.07.12 12:26

General safety instructions for compressed air tools

dust mask, non-slip safety shoes, safety helmet

or ear protectors, depending on the type of

compressed air tool and its application, reduces

the risk of injuries.

Check the connections and supply lines. All

maintenance units, couplings and hoses must be

equipped to meet the pressure and air amounts

specified in the device specific values. Pressure

that is too low influences the functioning of the

device; pressure that is too high can cause

damage to property and personal injury.

Protect hoses from kinks, constrictions, solvents

and sharp edges. Keep hoses away from heat,

oil and rotating parts.

Make sure that the hose clamps are always

tightly fastened. If the hose clamps are not

tightly fastened or are damaged, the air could

escape uncontrollably.

Replace damaged hoses immediately. A dam-

aged supply line may result in the air hose

whipping about and may result in injuries.

If the power cable of the device is damaged, it

has to be replaced by the manufacturer or its

service department or a similarly qualified person in order to avoid hazards.

Do not use the device when tired or under the

influence of drugs, alcohol or medications. One

moment of carelessness when using the device

may result in serious injuries.

Do not directly inhale the exhaust air. Keep eyes

away from exhaust air. Exhaust air from the

compressed air device may contain water, oil,

metal particles or contamination from inside the

compressor. This may result in injury to health.

BE CAREFUL WHEN

SETTING DOWN THE DEVICE! Always put

down the device so it does not come into contact

with the trigger. This could potentially result in

accidental activation of the device, which again

could result in hazards.

Only use suitable accessories. These may be

purchased from the manufacturer. Using nonOEM accessories may result in hazards.

Only use filtered and regulated compressed

air. Dust, caustic vapours and / or moisture may

damage the motor of a compressed air tool.

8 GB

The hose must be designed for pres-

sures of at least 8.6bar or 125PSI,

but at least 150 % of the maximum

pressure generated in the system.

The tool and supply line must be

equipped with a hose coupling to

completely remove pressure when

disconnecting the coupling hose.

Do not modify this device in any way without

the manufacturer‘s approval.

Only use the compressed air device with the

specified pressure (max. 0.35 Mpa / approx.

3 bar).

Disconnect the compressed air device from the

air supply after each use and when not in use.

Do not use the compressed air device if it leaks

or is in need of repair.

Never connect the compressed air device to an

air hose with pressure exceeding 7bar.

Keep your working area clean and well lit. Un-

tidy or poorly lit working areas can lead to ac-

cidents. Working under proper conditions will

allow you better control of the device, particu-

larly under unforeseen circumstances.

Only have the device repaired

by qualified specialist personnel using OEM

spare parts. This will ensure that your device

remains safe to use.

Keep children and other individuals away from

the device during use. Distractions can cause

you to lose control of the device.

Wear suitable clothing. Do not wear loose cloth-

ing or jewellery. Keep your hair, clothing and

gloves clear of moving parts. Loose clothing,

jewellery or long hair can become trapped in

moving parts.

Put down the trigger and device in the event of

unexpected compressor failure.

Whenever possible, use a condensate trap or

regularly empty the compressed air device

hoses and tubing before and during use to re-

move condensate (water).

ATTENTION! An undersized com-

pressed air system may minimise the

efficiency of your device.

Never point the compressed air device at your-

self, other persons or animals. Otherwise there

is a risk of injury.

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 8 06.07.12 12:26

General safety instructions … / Before initial use / Preparations for use

Always observe all the safety advice attached

to the compressor.

Make sure that the compressor intake opening

is never blocked and the airflow is never hindered.

Clean the suction filter with a cloth when it is

dirty. Switch off the device and pull the plug

from the socket to prevent it from being accidentally switched on.

Do not allow yourself to become distracted while

working with the device.

General safety information

for electrical devices

Never connect the device to a residual current

(FI) protective switch.

Protect yourself against electric shock. As you

are working, avoid touching grounded parts

(e.g. refrigerator, water supply pipes etc.).

DANGER! Avoid contact with live lines. This

device is not insulated against electric shock.

Check extension and power supply cables reg-

ularly. Replace any faulty cables with new ones

immediately.

If the mains power cable of this device is dam-

aged, it has to be replaced by the manufacturer

or its service department or a similarly qualified

person in order to avoid hazards.

Store the device in a dry environment when it is

not being used over a longer period.

Make sure that the connection cable does not

hang over a corner or be stretched; otherwise

there is a risk of injury.

Do not use the mains lead for any purpose for

which it was not intended, e.g. to carry the

product, to hang it up or to pull the mains plug

out of the mains socket.

Never pull on the mains cable to remove the

mains plug from the socket.

Never use electrical tool in damp or wet envi-

ronments and never expose it to rain or high

humidity.

Never switch on the device in the vicinity of in-

flammable liquids or gases.

If the device is used outdoors, only use exten-

sion cables that are expressly designed for out-

door use.

Product-specific safety

instructions

CAUTION! RISK OF BURNS!

The compressor heats up after ex-

tended operation. Therefore always

use the handle on the device to move it. Never

touch the device itself!

ATTENTION! The casing of the airbrush com-

pressor may become hot during use. Do not

touch hot surfaces in order to prevent burns.

Never leave the device in operation unattended.

Built-up heat generated by the device can be a

source of danger.

Before initial use

Check that all parts of the device are in perfect

condition.

Make sure that the available mains voltage is

compatible with the voltage intended for operating the compressor.

Note: You will find the intended mains voltage

on the type plate of the device.

Preparations for use

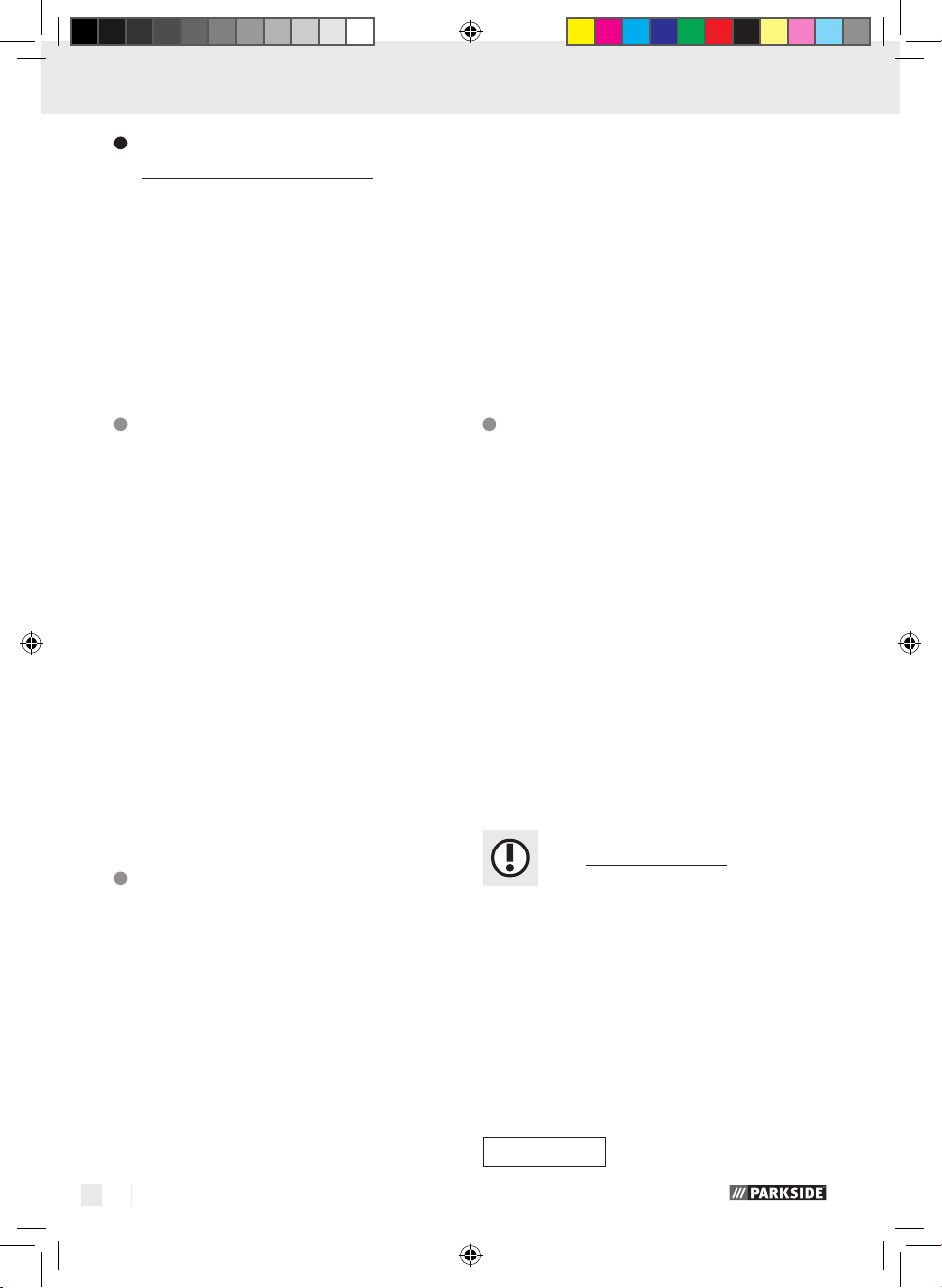

Connecting the airbrush set

Be absolutely certain to disconnect the mains

plug before connecting the airbrush set to the

compressor and release the pressure in the lines

by actuating the vent of the air blow gun

Use the respective screw connection to connect

the spray stylus

the coiled hose to the airbrush connection

Use the included open-end wrench. 13 (see Ill. A).

Fasten the paint mixing beaker with connection

5

lid

to the spray stylus 3 (see Ill. B).

Insert the mains plug into the mains socket.

3

with the coiled hose 2 and

9

.

1

.

9 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 9 06.07.12 12:26

Preparations for use

Note: For optimal results, professionals connect

an intermediate pressure reducer (not included

with delivery). The pressure reducer can be used

to adjust the compressed air at the spray gun

and optimise it to your needs.

Note: During use of the blow gun

corresponding hose

compressor

2 a

ning on the adapter

2

incl. adapter for the

, there is a small discharge ope-

2 a

, which releases air. This

9

with the

serves to create a more uniform airflow for easier and better handling of the blow gun

9

. This

is not a defect, rather, it serves for better handling and an improvement of the spray results by

means of a uniform airflow.

Mixing paints for use

The paints included are water-soluble. In order to

properly apply the paints, add water and stir. As

delivered, the paints are too viscous.

First fill the beaker with your selected paint

colour with water.

Now screw the cover back on the beaker and

shake it.

Now use the pipette 11 to remove two drops

of the slightly diluted paint paste and add them

to a paint mixing beaker completely filled with

4, 5

water (

Shake the beaker. Now your paint has reached

the correct consistency.

Attach the paint mixing glass (4, 5) accord-

ing to Ill. B.

Note: If desired, you can adjust the amount of

water added to influence the colour intensity

yourself as with a watercolour box. The more

water you add, the „thinner“ the colour.

You can also mix individualised colour tones

from the available colour pastes. Please take

note, there must be no paint clumps remaining

in the paint containers. The consistency should

correspond to that of water.

Note: If the paint used does not cover well, increase the amount of paint in the mixture ratio.

).

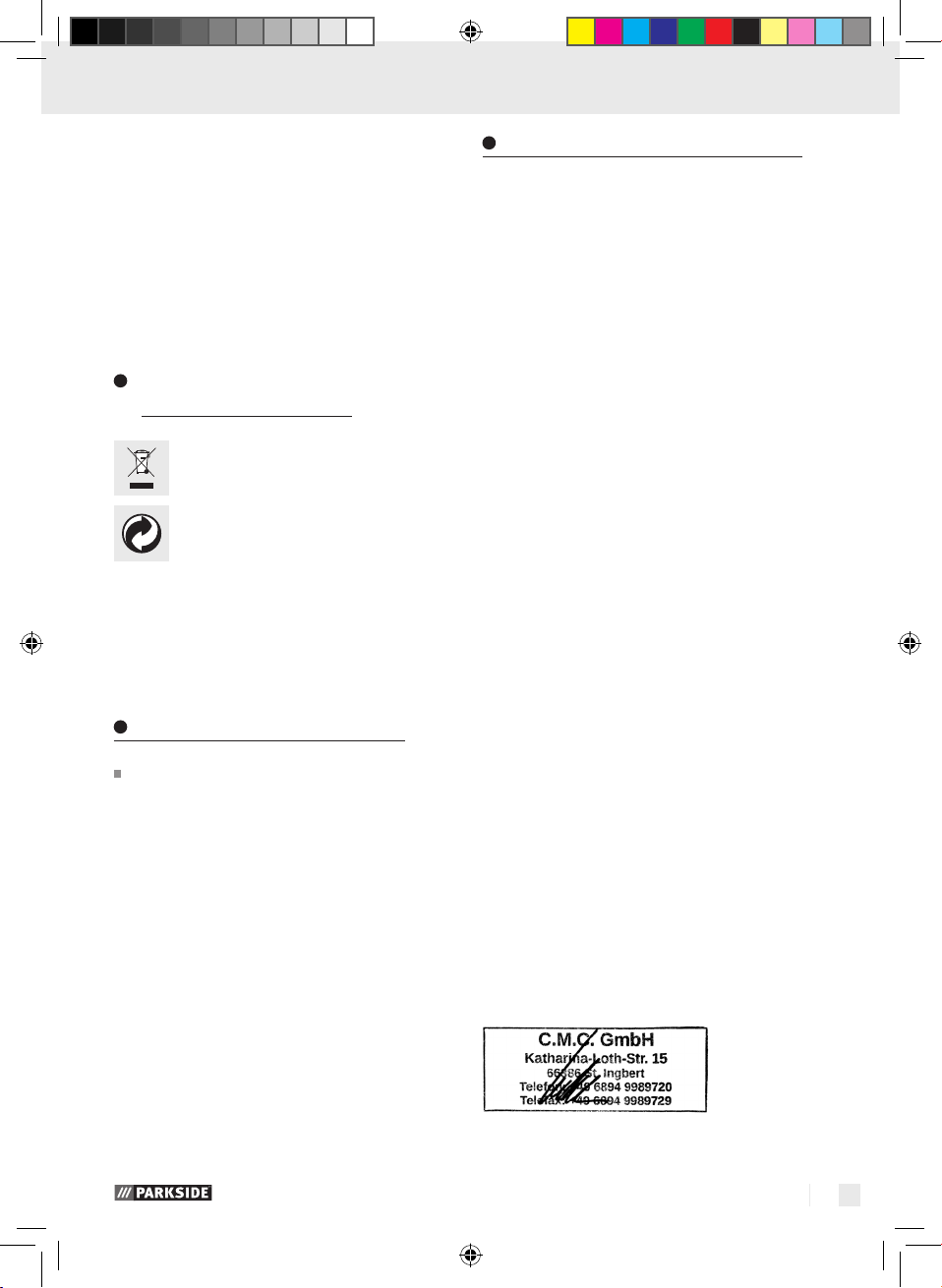

Turning airbrush compressor

on / off

Turn the airbrush compressor 1 on by setting the

on / off switch

14

to the position “I“ (see Ill. C).

Turn the airbrush compressor 1 off by setting

the on / off switch

14

in the position “0“ (see

Ill. C).

Note: Full pressure is built up after two seconds.

Regulating the air pressure

Regulate the air pressure by actuating the vent

of the air blow gun

9

to more or less of an

extent.

ATTENTION! The device has a pressure switch,

which periodically and automatically turns the device off if there is excess pressure or if it is not in use.

Shortly before reaching the switch-off point, the

compressor runs more roughly and vibrates. This

may also be the case when re-started under load.

The performance and functionality are not impaired

by this. This is not a defect, rather, serves to protect

the compressor from overloading.

Note: The blow pistol

9

blows air through the

discharge openings even without actuating the trigger. This is NOT A DEFECT.

Through actuating the trigger, the air discharge is

increased so that more air volume flows.

Note: During use of the blow gun

responding hose

2 a

sor

, there is a small discharge opening on the

2 a

adapter

2

incl. adapter for the compres-

, which releases air. This serves to create

9

with the cor-

a more uniform airflow for easier and better handling

of the blow gun

9

. This is not a defect, rather, it

serves for better handling and an improvement of

the spray results by means of a uniform airflow.

Regulating the spraying results

Regulate the amount of the paint supplied by

turning the paint nozzle of the spray stylus to

the right or left (see Ill. B).

10 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 10 06.07.12 12:26

Preparations for use / Cleaning and care

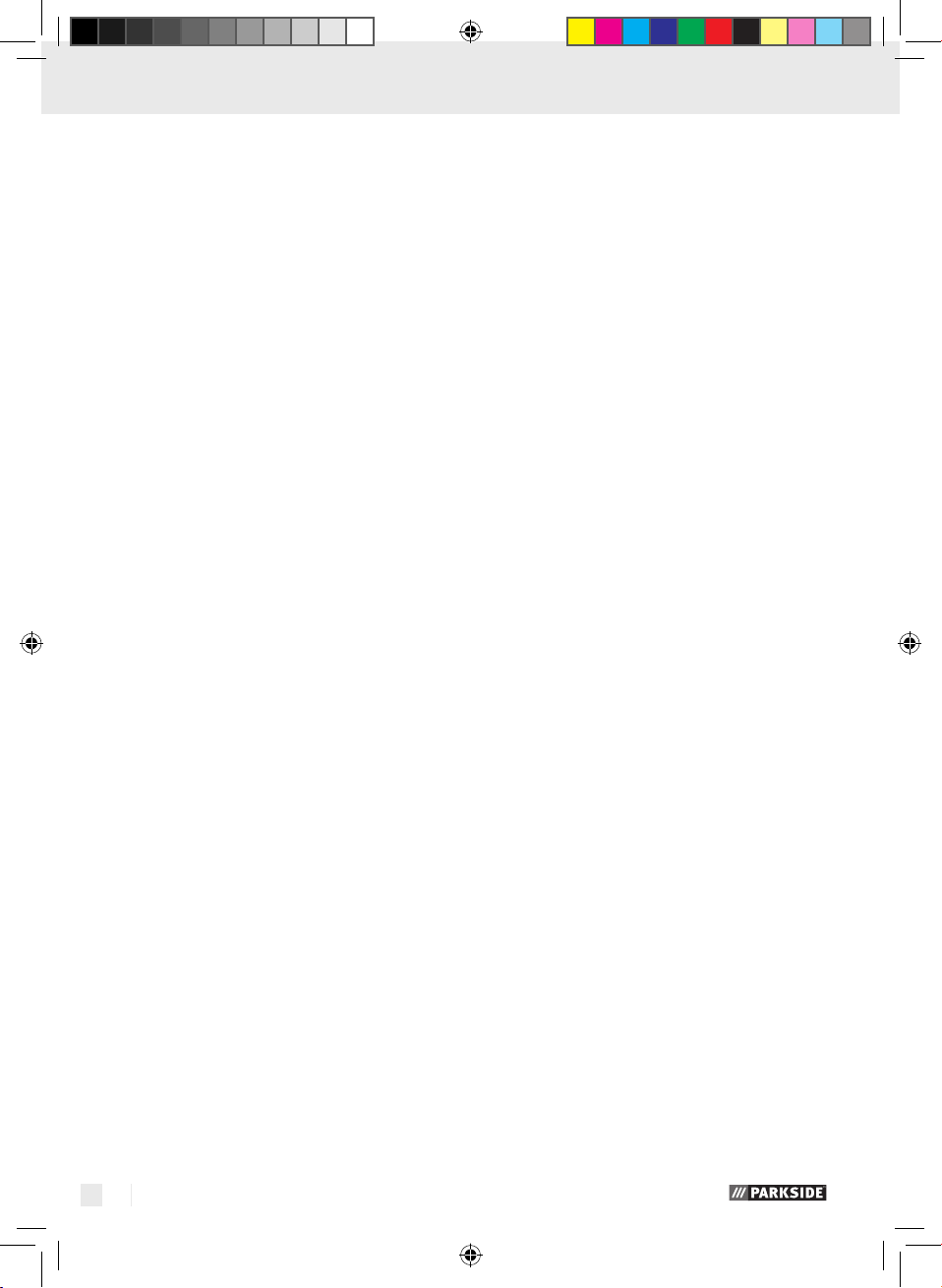

Using the accessories (see Ill. D)

Air mattress adapter 6, ball needle

Use a pipe wrench to unscrew the nozzle

the air blow gun

9

.

Then – depending on what is needed – screw

on the air mattress adapter

12

dle

, as well as the thread adapter 7 into

the barrel of the air blow gun

Universal valve connection

6

or the ball nee-

9

10

Screw the universal valve connection 10 directly

onto the compressed air hose

8

12

9 a

.

.

Cleaning and care

Thoroughly clean the spray stylus 3 immedi-

ately after use. Otherwise the paint can dry and

cause problems during the next use.

Thoroughly rinse out the spray stylus 3 with

water.

Use the thinner included to clean any stubborn

dried paint.

Note: The thinner is not suitable for water-soluble paints. Rather, it corresponds to a varnish

for thinning paints containing solvents.

Note: If you remove the paint nozzle of the

air blow gun

threads before reattaching it so its freedom of

movement is not affected.

Never lay the entire air blow gun 9 in a sol-

vent bath.

Note: If the air intake of the compressor should

become dirty, use a dry cloth to remove the accumulated dirt.

Fault Interrupted paint jet

Cause Solution

1. Paint almost

empty

2. Paint too viscous 2. Lower viscosity

3. Dry / defective

nozzle

9

during cleaning, lubricate the

or intermittent paint

delivery

1. Fill paint

3. Screw in nozzle tightly

or replace

Fault Interrupted paint jet

or intermittent paint

delivery

of

Cause Solution

4. Paint supply

4. Cleaning

restricted

5. Incorrect posi-

5. Correct position angle

tion of spray

3

stylus

.

Fault Spray pattern

incomplete

Cause Solution

1. Air head

dirty / defective

2. Nozzle dirty /

defective

1. Clean / replace air head

1. Rinse with clear water

2. Clean / replace air

nozzle

Fault Spray pattern irregu-

lar with drips

Cause Solution

1. Defective nozzle 1. Replace nozzle. Contact

a respective service centre.

2. Paint too viscous 2. Lower viscosity

3. Insufficient

working pressure

3. Increase working pressure (if necessary, not included accessories, e.g.

pressure reducer)

3. Hose defective; replace

hose

Fault Non-uniform paint

amount delivered

Cause Solution

Nozzle dirty /

Clean / replace air nozzle

defective

11 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 11 06.07.12 12:26

… / Environmental … / Paint disposal instructions / CE Declaration of Conformity

Information about warranty and service processing

Information about warranty

and service processing

Creative Marketing Consulting GmbH

warranty

Dear customer, the warranty for this device is 3 years

from the date of purchase. In the event the product

is defective, you have legal rights vis-à-vis the retailer

of this product. Your statutory rights are not limited

in any way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This receipt

is required as proof of purchase.

Should this device show any fault in materials or

manufacture within three years from date of purchase,

it will be repaired or replaced - at our choice - by us

free of charge. In order for the warranty to be valid,

the defective device and the proof of purchase (receipt) must be presented within the three-year warranty

period, accompanied by a brief written description

of the nature of the defect and of the date it arose.

If the defect is covered by our warranty, you will receive the repaired device or replacement in return.

A repair or exchange of the device does not extend

a new warranty period.

Scope of warranty

This device has been manufactured to strict quality

guidelines and meticulously examined before delivery.

instructions provided in the operating instructions must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. The warranty is void in the case of inappropriate and improper handling, use of force and

of any intervention which was not carried out by our

authorized service branch.

Procedure in the case of warranty

Please follow the instructions below to ensure quick

processing of your matter:

When inquiring about your product please have

your receipt and product number (e.g. IAN) ready

as your proof of purchase.

The item number can be found on the type plate,

an engraving, the cover page of your instructions

(bottom left) or the decal at the back or bottom. In

the event of malfunctions or other defects please

first contact the service department below by

phone or e-mail.

A product recorded as defective, along with the

proof of purchase (receipt) and a description of the

defect and when it occurred, can then be returned

free of charge to you at the service address provided.

Note:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts

subject to normal wear and tear and which can therefore be considered as wear items, or to damage to

fragile parts, e.g. switches, storage batteries or

glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All

12 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 12 06.07.12 12:26

Name: C. M. C. GmbH

Internet address: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Telephone: +49 (0) 06894 9989752

(standard German landline

rates apply)

Registered office: Germany

IAN 73868

… / Environmental … / Paint disposal instructions / CE Declaration of Conformity

Please note that the following address is not a

service address.

Please first contact the service centre listed above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Environmental instructions and

disposal information

Don‘t waste, recycle!

The device, accessories and packaging

should be recycled in an environmentally friendly manner.

Do not dispose of the compressed air tool through

your household waste, or throw into fire or water. If

possible, non-operational devices should be recycled. Contact your local retailer for information.

Paint disposal instructions

Do not allow to enter sewage system, open

bodies of water or soil.

Product: Dispose of at collection facility for old

paints / varnishes.

European list of waste materials

08 01 12 waste paint and varnish other than those

mentioned in 08 01 11.

Uncleaned packaging:

Only completely emptied containers may be dis

of through recycling. Dispose of residual material

that has not hardened in the same manner as the

product.

posed

CE Declaration of Conformity

We,

C. M. C. GmbH

Documentation officer: Marc Uhle

Katharina-Loth-Str. 15

66386 St. Ingbert

declare on our sole responsibility the product

Compressed air airbrush set

Serial number: 1454

Year of manufacture: 2012 / 36

IAN: 73868

Model: PARKSIDE AIRBRUSH SET PABK 60 A1

to meet the basic safety requirements of European

Directives

EC Low Voltage Directive

2006 / 95 / EC,

EC Directive for Electromagnetic

Compatibility

2004 / 108 / EC

and its amendments.

The conformity assessment is based on the following

harmonised standards:

EN 55014–1:2000+A2:2003

EN 55014–2:1997+A1:2001

EN 61000–3–2:2000

EN 61000–3–3:1995+A1:2001

EN 60335–1:2002+A1+A11+A12+A2+A13

+A14+A15

EN 62233:2008

St. Ingbert, 30. June 2012

Karl Peter Uhle

– Managing Director –

13 GB

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 13 06.07.12 12:26

14

73868_par_Airbrush_Set_Content_LB4 (CZ-SK).indd 14 06.07.12 12:26

Loading...

Loading...