Parkside PDNE 4000 A1 User Manual [cs, en, de]

AIR NEEDLE SCALER PDNE 4000 A1

AIR NEEDLE SCALER |

PNEU JEHLOVÝ ODREZOVAČ |

|

|

|

|

Operation and Safety Notes |

Pokyny pro obsluhu a bezpečnostní pokyny |

|

Translation |

of original operation manual |

Překlad originálního provozního návodu |

DRUCKLUFT-NADELENTROSTER

Bedienungs - und Sicherheitshinweise

Originalbetriebsanleitung

IAN 43098

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 2 |

|

|

04.06.14 13:18 |

|

|

||

|

|

|

|

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen Funktionen des Gerätes vertraut.

GB |

Operation and Safety Notes |

Page |

5 |

CZ |

Pokyny pro obsluhu a bezpečnostní pokyny |

Strana |

15 |

DE / AT / CH |

Bedienungsund Sicherheitshinweise |

Seite |

25 |

|

|

|

|

|

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 3 |

|

|

04.06.14 13:18 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

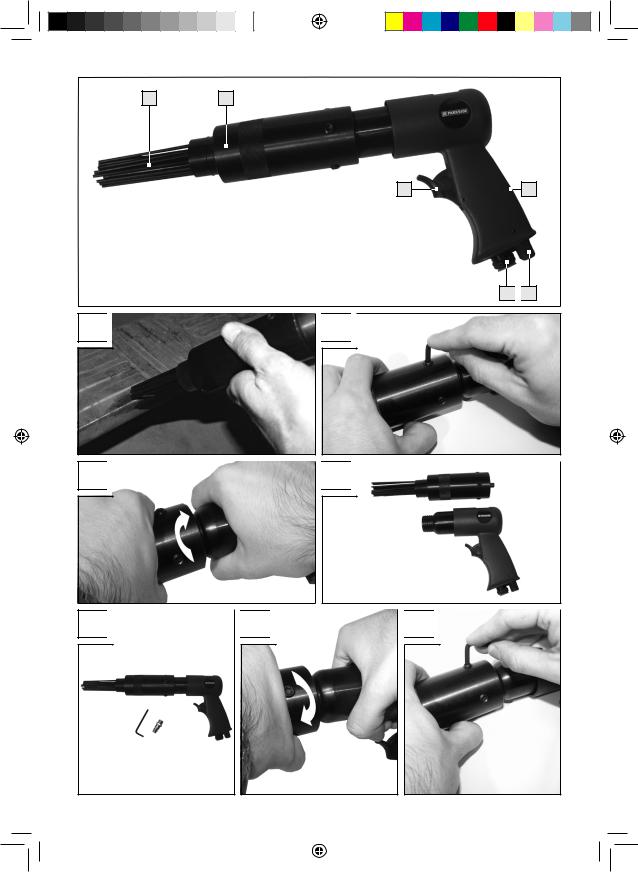

1 |

2 |

6 |

3 |

5

4

4

A

B

B

C

D

D

E

F

F

G

G

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 4 |

|

|

04.06.14 13:18 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 5 |

|

|

04.06.14 13:18 |

|||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table of contents

Introduction |

|

|

Intended use......................................................................................................................................... |

Page |

6 |

Features................................................................................................................................................ |

Page |

6 |

Technical Data..................................................................................................................................... |

Page |

6 |

Scope of delivery................................................................................................................................. |

Page |

7 |

Safety notices |

|

|

General safety rules............................................................................................................................ |

Page |

7 |

Risks due to projected parts................................................................................................................ |

Page |

7 |

Operating hazards.............................................................................................................................. |

Page |

7 |

Hazards due to repetitive motions...................................................................................................... |

Page |

8 |

Risks associated with accessories....................................................................................................... |

Page |

8 |

Hazards in the work environment....................................................................................................... |

Page |

8 |

Hazards due to dust and vapours...................................................................................................... |

Page |

8 |

Noise hazards..................................................................................................................................... |

Page |

9 |

Hazard due to vibration...................................................................................................................... |

Page |

9 |

Additional safety instructions for pneumatic machinery.................................................................... |

Page |

9 |

Before use....................................................................................................................................... |

Page 10 |

|

Start-up.............................................................................................................................................. |

Page 10 |

|

After initial use............................................................................................................................ |

Page 10 |

|

Changing spare parts............................................................................................................ |

Page 10 |

|

Maintenance................................................................................................................................. |

Page 10 |

|

Cleaning and Care.................................................................................................................... |

Page 11 |

|

Information about warranty and service processing |

|

|

Warranty terms.................................................................................................................................... |

Page 11 |

|

Extent of warranty............................................................................................................................... |

Page 11 |

|

Processing of warranty claims............................................................................................................ |

Page 12 |

|

Environmental instructions and disposal information............................... |

Page 12 |

|

Declaration of Conformity................................................................................................. |

Page 12 |

|

GB 5

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 5 |

04.06.14 13:17 |

|

|

Introduction

The following pictograms are used in these instructions for use / on the equipment:

|

|

|

|

|

|

Please read the operating instructions! |

|

|

|

|

|

Observe the warning and safety |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

instructions! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note |

|

|

|

|

|

Wear ear protection, dust mask, sa- |

|

|

|

|

|

|

|

|

|

|

|

fety glasses and protective gloves. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil daily |

|

|

|

|

|

Dispose of packaging and device in |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

an environmentally-friendly way! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air needle scaler PDNE 4000 A1  Features

Features

Introduction

Congratulations!

You have chosen high-quality device by our company. Familiarise yourself with the product before using it for the first time. In

You have chosen high-quality device by our company. Familiarise yourself with the product before using it for the first time. In

addition, please carefully refer to the operating instructions and the safety advice below. Initial operation of this tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

Intended use

The needle scaler is solely for removing rust and coatings (paint, lacquer, etc.) from solid metal parts, and for shaping jobs. Only use the product as described and for the indicated purpose. Keep these instructions in a safe place. When passing this product on to others, please also include all the documents. Any use other than the intended is prohibited and potentially dangerous. Damages resulting from noncompliance or misuse are not covered by the warranty and are not included in the manufacturer‘s liability. This device has been designed for household use and may not be used for commercial or industrial purposes.

6 GB

Check that all the items are present and that the device is in perfect condition immediately after unpacking. Do not use the

device if it is defective.

1Needles

2Needle guide

3Handle

4Air adjusting screw

5¼“ Compressed air connection

6Trigger

Technical Data

Operating pressure: |

6.3 bar |

Compressed air connection: |

¼“ (0.63 cm) |

Percussion rate: |

4000 rpm |

Sound pressure level: |

100.2 dB(A) |

|

(EN ISO 15744) |

Weight: |

1900 g |

Noiseand vibration information: Measured values determined in accordance with ISO 15744.

Noise level LpA: |

100.2 dB(A) |

Sound power level LWA: |

111.2 dB(A) |

LpC, peak = 117.4 dB(A) |

|

Uncertainty K = 3 dB |

|

These values are characteristic values referenced to the device and do not reflect noise development at

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 6 |

04.06.14 13:17 |

|

|

the work location. Noise development at the work location depends e.g. on the work environment, the work piece, the work piece support and the number of fastener driving processes.

In accordance with conditions at the work location, individual noise reduction measures may need to be carried out, such as placing the work piece on a noise-suppressing surface, clamping or covering to prevent work piece vibration and adjusting to the minimum pressure required by the work process. In certain cases, wearing personal hearing protection is require.

Wear hearing protection!

Total vibration values in accordance with ISO 28927-10, EN 12096:

Vibration emission value ah = 69.83 m / s2 Uncertainty K = 1.5 m / s2

Scope of delivery

1 Needle scaler (head preinstalled)

1 Threaded plug nipple

1 Allen key

1 Instructions for use

Safety notices

Safety notices

General safety rules

To connect the device to the air hose, never point the front end (needle head) of the tool at yourself or others.

Never point the tool at yourself or others.

In the cases of multiple hazards the safety instructions must be read and understood before attaching, operating, repairing and exchanging accessories and before working near the non-rotating, percussive machine. Otherwise severe bodily injuries may result.

The non-rotating, percussive machine should only be set up, adjusted and used by qualified and trained users.

Introduction / Safety notices

Never modify the non-rotating, percussive machine. Modifications may reduce the effectiveness of safety measures and increase operator risks.

Do not lose the safety instructions – hand them to the operator.

Never use a damaged non-rotating, percussive machine.

Regularly maintain machines to verify all required rated values and markings required by ISO 11148 are legible on the machine. If necessary, the employee/user must contact the manufacturer for replacement labels for markings.

Risks due to projected parts

Disconnect the non-rotating, percussive machine from the power supply before replacing the inserted tool or accessories.

If the work piece, one of the accessories, or the tool itself breaks, parts may be projected at a great speed.

Always wear eye protection when operating the non-rotating, percussive machine. The level of required protection required should be assessed individually for each application. When working overhead, a safety helmet must be worn.

In this case, the risk to other people must also be assessed.

It must be ensured that the work-piece is properly secured.

Only operate the machine with the machine tool secured in the machine with a suitable retainer. To prevent injuries, any worn, broken or bent parts of the retainer must be replaced.

Before switching on the machine, the machine tool must be firmly applied to the surface you will be working on.

Operating hazards

During uses, the operator‘s hands may be exposed to hazards such as impact, cuts, abrasion and heat. Wear suitable gloves to protect hands.

GB 7

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 7 |

04.06.14 13:17 |

|

|

Safety notices

The operator and maintenance personnel must be physically capable of managing the size, weight and power of the machine.

Hold the machine correctly: be prepared to counteract typical or sudden movements – keep both hands ready.

Be sure your body is well balanced and maintain a solid stance.

In the event of power failure release the startor stop control.

Only use lubricants recommended by the manu facturer.

Avoid direct contact with the machine tool during and after use, as it may be hot.

Notice indicating safety goggles are required, and safety gloves and protective clothing are recommended.

Hazards due to repetitive motions

When using a non-rotating, percussive machine the operator may experience discomfort in hands, arms, shoulders, neck or other body parts whilst performing work-related tasks.

Maintain a comfortable position whilst working with the non-rotating, percussive machine, be mindful of a secure grip and avoid unfavourable positions or those making it difficult to maintain your balance. The operator should change his posture during extended periods of use, which may help to prevent discomfort and fatigue.

If the operator experiences symptoms such as persistently feeling unwell, discomfort, palpitations, pain, tingling, numbness, a burning sensation or stiffness, these warning signs should not be ignored. The user should consult a qualified healthcare professional.

Risks associated with accessories

Disconnect non-rotating, percussive machine from the power supply before attaching or changing tools or accessories.

8 GB

Only use accessories and consumables of the size and type recommended by the manufacturer of the non-rotating, percussive machine; do not use other accessory or consumables types or sizes.

Avoid direct contact with the machine tool during and after use, as it may become very hot or sharp-edged.

Hazards in the work environment

Slipping, tripping and falling are the main causes of injuries at the workplace. Keep in mind that surfaces may have become slippery during machine use, and remember tripping hazards caused by the airor hydraulic hose.

Proceed with caution in unfamiliar surroundings. There may be hidden dangers due to electrical cables or other supply lines.

The non-rotating, percussive machine is not intended for use in explosive atmospheres and not isolated against contact with electric power sources.

Verify that there are no electrical lines, gas lines, etc. that may result in a hazard in the event of them becoming damaged during machine use.

Hazards due to dust and vapours

Dusts and vapours generated by the use of non-rotating, percussive machines may result in damage to health (e.g. cancer, birth defects, asthma and / or dermatitis); it is imperative to perform a risk assessment for these hazards and implement the respective regulatory mechanisms. The risk assessment should include dust generated by machine use and the dust already present in the area, which is possibly being blown around.

The non-rotating, percussive machine must be operated and maintained according to the recommendations in these instructions to minimise the release of dust and vapours.

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 8 |

04.06.14 13:17 |

|

|

Exhaust air must be discharged in such a way that the amount of dust being blown about in a dusty environment is minimised.

If dust or vapours are generated, the principal task must be to control them in the area where they are released.

All machine mounting parts or accessories intended to collect, extract or eliminate airborne dust or vapours should be used and maintained according to manufacturer instructions.

Select, maintain and replace consumables and machine tools as recommended in these instructions to prevent an unnecessary increase in the production of dust or vapours.

Use respiratory protection equipment as required by labourand health protection regulations.

Noise hazards

With inadequate ear protection the impact of high noise levels may result in permanent hearing damage, hearing loss and other problems, e.g. tinnitus (ringing, whistling or buzzing in the ear). It is imperative to perform a risk assessment for these hazards and implement the respective regulatory mechanisms.

Suitable regulatory mechanisms to minimise the risk include measures such as using insulation to prevent pinging sounds on work pieces.

Use ear protection as required by labourand health regulations.

The non-rotating, percussive machine must be operated and maintained in accordance with the recommendations within these instructions to prevent an unnecessary increase in the noise levels.

Select, maintain and replace consumables and machine tools as recommended in these instructions to prevent an unnecessary increase in the noise level.

If the non-rotating, percussive machine is equipped with a silencer, always ensure it is available and in good working order when using this machine.

Safety notices

Hazard due to vibration

Exposure to vibration may cause damage to the nerves and disturb blood circulation in hands and arms.

Wear warm clothing and keep your hands warm and dry when working in cold environments.

If you notice the skin on your fingers or your hand becoming numb, tingling, hurting or becoming white, stop working with the machine and consult a physician.

The non-rotating, percussive machine must be operated and maintained in accordance with the recommendations within these instructions to prevent an unnecessary increase in the vibration. Do not hold the machine tool with your free hand, as this will result in an increase in the impact of vibration.

Hold the machine firmly, but not too tightly, maintaining the necessary hand reaction forces, as the vibration hazard typically increases when firming the grip.

Hold attached handles at the centre and avoid sliding the handles all the way in.

Additional safety instructions for pneumatic machinery

Compressed air can result in serious injuries. If the machine is not in use, always cut off the

air supply, depressurize the air hose and disconnect the machine from before replacing accessories or when performing repairs.

Never direc the air flow at yourself or others. Hoses flapping about can result in serious injuries. Therefore always inspect hoses and their fasteners for damage and a secure fit.

Direct cold air away from hands.

Do not use quick-disconnect couplers at the tool intake. Only use connectors made from hardened steel (or material with comparable impact resistance) on threaded hose connections. When using universal swivel couplings, always use locking pins and use whip-check hose safety cables for protection in the event the connection between the hose and the machine or in between hoses fails.

GB 9

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 9 |

04.06.14 13:17 |

|

|

… / Before use / Start-up / After initial use / Changing spare parts / Maintenance

Ensure not to exceed the maximum pressure specified on the machine.

Never carry pneumatic tools by the hose.

Before use

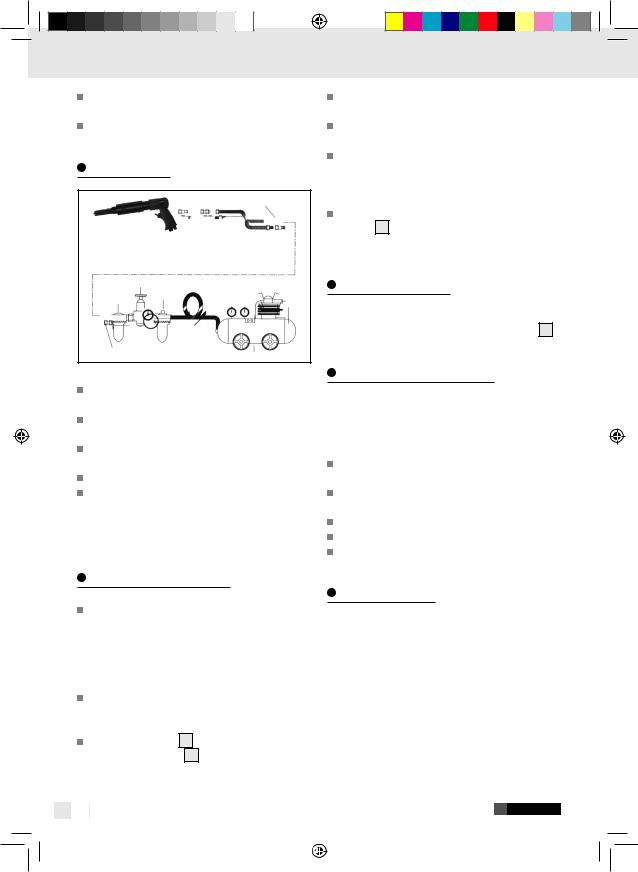

Quick-release socket

Compressed air hose

Quick-release socket

Pressure regulator

Oils Filter

Quick-opening sleeve |

Compressor |

|

Use the needle scaler to remove rust, paint, lacquier and similar items.

Never use excess force to push the equipment onto the tool, as this may cause damage. Applying the equipment at a slight angle and sliding it across the surface to be cleaned with a little pressure across the area to be cleaned for optimal results.

Regulate the air pressure using the air adjusting screw 4 (next to the air inlet at the bottom of the device) for optimal results.

After initial use

Once the task has been finished the equipment must be disconnect from the compressed air supply 5 .

ATTENTION! Never start up the air tool without oiling it.

Verify the compressor is positioned on solid ground.

Check if all hose connections are connected and secured correctly.

Connect the tool with the air hose.

If no function is detected after switching on despite reaching the maximum pressure, switch the device back off. Immediately contact the service hotline.

Changing spare parts

The head of the needle scaler must be replaced if it shows damage or is severely worn. Proceed as follows:

Using the included hexagon socket screw, loosen the 4 screws for the head (see Fig. B). Unscrew the old head using minimal force (see Fig. C).

Properly dispose of the old head.

Screw in the new head hand tight (see Fig. F). tighten the 4 screws on the head (see Fig. G).

Start-up (see Fig. A)

Maintenance

Screw a threaded plug fitting ¼“ (6.35 mm) into the air tool.

Note: We recommend using Teflon tape to achieve maximum leak-tightness. Otherwise the equipment may potentially be unable to produce its full capacity.

To connect the device to the air hose, never point the front end (needle head) of the tool at yourself or others.

Pulling the trigger 6 will start the device. Release the trigger 6 to stop the device.

Following the maintenance information specified here will ensure a long service life for the product and trouble-free operation. Your needle scaler working properly for a long time requires regular lubrication.

You may choose from the following options:

With an oil-fog lubricator

A complete maintenance unit includes an oil-fog lubricator and is attached to the compressor.

10 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 10 |

04.06.14 13:17 |

|

|

… / Cleaning and Care / Information about warranty and service processing

Via in-line oiler

Install an in-line oiler directly adjacent to the tool (approx. 50 cm clearance) to adequately supply the tool with oil.

Manually

Add 3–5 drops of speciality tool oil to the compressed air connection before every use. If the compressed air tool is not being used for several days, add 5–10 drops of oil to the compressed air connection before switching it on.

Always store your compressed air tools in dry rooms.

With frequent use and high contamination, maintenance should be performed every 30 min. The equipment should always be lubricated in the process

Verify the speed and the noise level after every use.

Regularly check the speed.

ATTENTION! Clean the appliance before maintenance from all dangerous substances which (due to work processes) may have accumulated on the appliance. Avoid all skin contact with these substances.

REMARK! The skin coming into contact with dangerous dust may result in severe dermatitis. If dust is produced or dispersed during the maintenance work, it can be inhaled.

Cleaning and Care

Never clean with liquids such as petrol, solvents or water.

Do not allow liquids to enter the tool. Only clean the tool with a dry cloth.

Information about warranty and service processing

Creative Marketing Consulting

GmbH warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you have legal rights against the retailer of this product. Your statutory rights are not limited in any way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase. Please retain the original receipt safely. This document is required as your proof of purchase.

Should this device show any fault in materials or manufacture within three years from date of purchase, it will be repaired or replaced - at our choice - by us free of charge. This warranty is conditional on the defective device and the receipt of purchase being presented within the three year warranty period, and that there is a brief written description of the nature of the defect and of the date it arose.

If the defect is covered by our warranty, we will return the repaired device or replacement thereof. A repair or exchange of the device does not extend a new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality guidelines and meticulously examined before delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product parts subject to normal wear and tear and which can therefore be considered as wear items, or to damage to fragile parts, e.g. switches, storage batteries or glass parts.

This warranty becomes void if the device has been damaged or improperly used or maintained. All instructions provided in the instructions for use must be followed strictly to constitute proper use of the product. Purposes and practices which the operating instructions warn of or advise against must be avoided without fail.

This product is intended for private, non-commercial use only. Any incorrect or improper use of the device,

GB 11

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 11 |

04.06.14 13:17 |

|

|

Loading...

Loading...