TEXAS INSTRUMENTS UCC1580-1, UCC1580-2, UCC1580-3, UCC1580-4, UCC2580-1 Technical data

...

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

Single Ended Active Clamp/Reset PWM

FEATURES

Provides Auxiliary Switch Activation Complementary to Main Power Switch Drive

Programmable deadtime (Turn-on Delay) Between Activation of Each Switch

Voltage Mode Control with

Feedforward Operation

Programmable Limits for Both Transformer VoltSecond Product and PWM Duty Cycle

High Current Gate Driver for Both Main and Auxiliary Outputs

Multiple Protection Features with Latched Shutdown and Soft Restart

Low Supply Current (100 A Startup,

1.5 mA Operation)

DESCRIPTION

The UCC3580 family of PWM controllers is designed to implement a variety of active clamp/reset and synchronous rectifier switching converter topologies. While containing all the necessary functions for fixed frequency, high performance pulse width modulation, the additional feature of this design is the inclusion of an auxiliary switch driver which complements the main power switch, and with a programmable deadtime or delay between each transition. The active clamp/reset technique allows operation of single ended converters beyond 50% duty cycle while reducing voltage stresses on the switches, and allows a greater flux swing for the power transformer. This approach also allows a reduction in switching losses by recovering energy stored in parasitic elements such as leakage inductance and switch capacitance.

The oscillator is programmed with two resistors and a capacitor to set switching frequency and maximum duty cycle. A separate synchronized ramp provides a voltage feedforward pulse width modulation and a programmed maximum volt-second limit. The generated clock from the oscillator contains both frequency and maximum duty cycle information.

(continued)

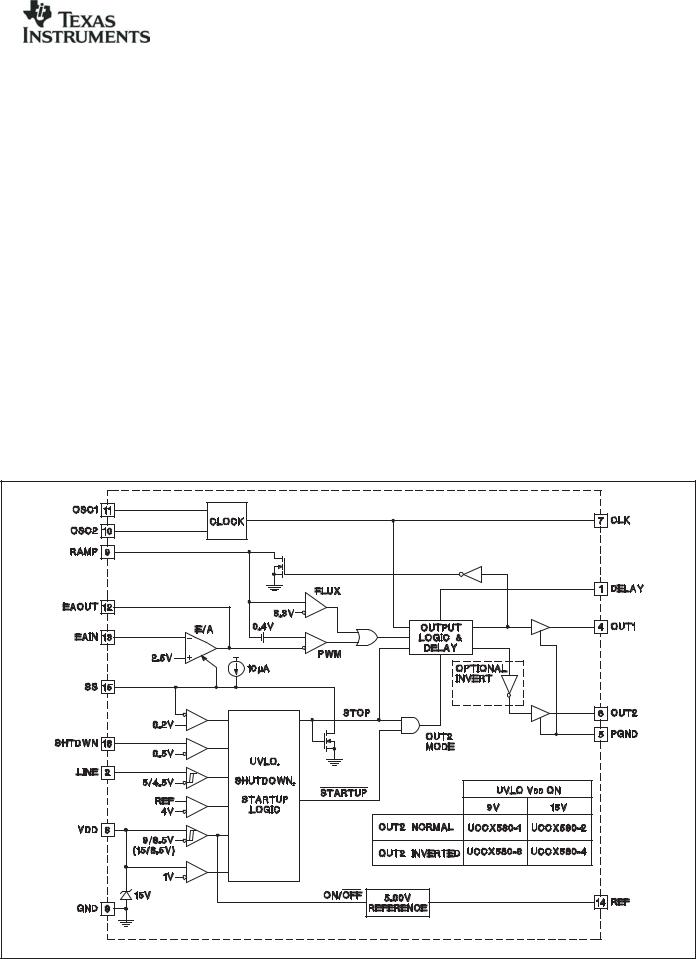

BLOCK DIAGRAM

Pin Numbers refer to DIL-16 and SOIC-16 packages |

UDG-95069-2 |

SLUS292D - FEBRUARY 1999 - REVISED FEBRUARY 2007 |

|

DESCRIPTION (cont.)

The main gate drive output (OUT1) is controlled by the pulse width modulator. The second output (OUT2) is intended to activate an auxiliary switch during the off time of the main switch, except that between each transition there is deadtime where both switches are off, programmed by a single external resistor. This design offers two options for OUT2, normal and inverted. In the -1 and -2 versions, OUT2 is normal and can be used to drive PMOS FETs. In the -3 and -4 versions, OUT2 is inverted and can be used to drive NMOS FETs. In all versions, both the main and auxiliary switches are held off prior to startup and when the PWM command goes to zero duty cycle. During fault conditions, OUT1 is held off while OUT2 operates at maximum duty cycle with a guaranteed off time equal to the sum of the two deadtimes.

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

Undervoltage lockout monitors supply voltage (VDD), the precision reference (REF), input line voltage (LINE), and the shutdown comparator (SHTDWN). If after any of these four have sensed a fault condition, recovery to full operation is initiated with a soft start. VDD thresholds, on and off, are 15V and 8.5V for the -2 and -4 versions, 9V and 8.5V for the -1 and -3 versions.

The UCC1580-x is specified for operation over the military temperature range of -55°C to 125°C. The UCC2580-x is specified from -40°C to 85°C. The UCC3580-x is specified from 0°C to 70°C. Package options include 16-pin surface mount and dual in-line.

ABSOLUTE MAXIMUM RATINGS

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16V

IVDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA LINE, RAMP . . . . . . . . . . . . . . . . . . . . . . . . 0.3V to VDD + 1V

ILINE, IRAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA DELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3V

IDELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA IOUT1 (tpw < 1 s and Duty Cycle < 10%) . . . . . . . 0.6A to 1.2A IOUT2 (tpw < 1 s and Duty Cycle < 10%) . . . . . . . 0.4A to 0.4A ICLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA to 100mA OSC1, OSC2, SS, SHTDWN, EAIN . . . . . 0.3V to REF + 0.3V

IEAOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5mA to 5mA IREF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30mA PGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2V to 0.2V

Storage Temperature . . . . . . . . . . . . . . . . . . -65°C to +150°C Junction Temperature . . . . . . . . . . . . . . . . . . -55°C to +150°C Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

All voltages are with respect to ground unless otherwise stated. Currents are positive into, negative out of the specified terminal. Consult Packaging Section of Databook for thermal limitations and considerations of packages.

ORDER INFORMATION

CONNECTION DIAGRAMS

DIL-16, SOIC-16 (Top View) J, N, or D Packages

2

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

ELECTRICAL CHARACTERISTICSUnless otherwise stated, all specifications are over the full temperature range, VDD =

12V, R1 = 18.2 k , R2 = 4.41 k , CT = 130 pF, R3 = 100 k , COUT1 = 0 F, COUT2 = 0 F. TA = 0°C to 70°C for the UCC3580, -40°C to 85°C for the UCC2580, -55°C to 125°C for the UCC1580, TA = TJ.

PARAMETER |

TEST CONDITIONS |

MIN |

TYP |

MAX |

UNITS |

Oscillator Section |

|

|

|

|

|

Frequency |

|

370 |

400 |

430 |

kHz |

CLK Pulse Width |

|

650 |

750 |

850 |

ns |

CLK VOH |

ICLK = 3 mA |

4.3 |

4.7 |

|

V |

CLK VOL |

ICLK = 3 mA |

|

0.3 |

0.5 |

V |

Ramp Generator Section |

|

|

|

|

|

Ramp VOL |

IRAMP = 100 A |

|

50 |

100 |

mV |

Flux Comparator Vth |

|

3.16 |

3.33 |

3.50 |

V |

Pulse Width Modulator Section |

|

|

|

|

|

Minimum Duty Cycle |

OUT1, EAOUT = VOL |

|

|

0 |

% |

Maximum Duty Cycle |

OUT1, EAIN = 2.6 V |

63 |

66 |

69 |

% |

PWM Comparator Offset |

|

0.1 |

0.4 |

0.9 |

V |

Error Amplifier Section |

|

|

|

|

|

EAIN |

EAOUT = EAIN |

2.44 |

2.5 |

2.56 |

V |

IEAIN |

EAOUT = EAIN |

|

150 |

400 |

nA |

EAOUT, VOL |

EAIN = 2.6 V, IEAOUT = 100 A |

|

0.3 |

0.5 |

V |

EAOUT, VOH |

EAIN = 2.4 V, IEAOUT = 100 A |

4 |

5 |

5.5 |

V |

AVOL |

|

70 |

80 |

|

dB |

Gain Bandwidth Product |

f = 100 kHz (Note 1) |

2 |

6 |

|

MHz |

Softstart/Shutdown Section |

|

|

|

|

|

Start Duty Cycle |

EAIN = 2.4 V |

|

0 |

|

% |

SS VOL |

ISS = 100 A |

|

100 |

350 |

mV |

SS Restart Threshold |

|

|

400 |

550 |

mV |

ISS |

|

|

–20 |

–35 |

A |

SHTDWN VTH |

|

0.4 |

0.5 |

0.6 |

V |

ISHTDWN |

|

|

50 |

150 |

nA |

Undervoltage Lockout Section |

|

|

|

|

|

VDD On |

UCC3580-2,-4 |

14 |

15 |

16 |

V |

|

UCC3580-1,-3 |

8 |

9 |

10 |

V |

VDD Off |

|

7.5 |

8.5 |

9.5 |

V |

LINE On |

|

4.7 |

5 |

5.3 |

V |

LINE Off |

|

4.2 |

4.5 |

4.8 |

V |

ILINE |

LINE = 6 V |

|

50 |

150 |

nA |

Supply Section |

|

|

|

|

|

VDD Clamp |

IVDD = 10 mA |

14 |

15 |

16 |

V |

IVDD Start |

VDD < VDD On |

|

160 |

250 |

A |

IVDD Operating |

No Load |

|

2.5 |

3.5 |

mA |

Output Drivers Section |

|

|

|

|

|

OUT1 VSAT High |

IOUT1 = 50 mA |

|

0.4 |

1.0 |

V |

OUT1 VSAT Low |

IOUT1 =100 mA |

|

0.4 |

1.0 |

V |

OUT2 VSAT High |

IOUT2 = 30 mA |

|

0.4 |

1.0 |

V |

OUT2 VSAT Low |

IOUT2 = 30 mA |

|

0.4 |

1.0 |

V |

OUT1 Fall Time |

COUT1 = 1nF, RS = 3 |

|

20 |

50 |

ns |

OUT1 Rise Time |

COUT1 = 1nF, RS = 3 |

|

40 |

80 |

ns |

OUT2 Fall Time |

COUT2 = 300pF, RS = 10 |

|

20 |

50 |

ns |

OUT2 Rise Time |

COUT2 = 300pF, RS = 10 |

|

20 |

40 |

ns |

3

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

ELECTRICAL CHARACTERISTICSUnless otherwise stated, all specifications are over the full temperature range, VDD =

12V, R1 = 18.2 k , R2 = 4.41 k , CT = 130 pF, R3 = 100 k , COUT1 = 0 F, COUT2 = 0 F. TA = 0°C to 70°C for the UCC3580, -40°C to 85°C for the UCC2580, -55°C to 125°C for the UCC1580, TA = TJ.

PARAMETER |

TEST CONDITIONS |

MIN |

TYP |

MAX |

UNITS |

Output Drivers Section (cont.) |

|

|

|

|

|

Delay 1 OUT2 to OUT1 |

R3 = 100 k , COUT1 = COUT2 = 15 pF |

90 |

120 |

160 |

ns |

|

TA = TJ = 25°C |

100 |

120 |

140 |

ns |

Delay 2 OUT1 to OUT2 |

R3 = 100 k , COUT1 = COUT2 = 15 pF |

110 |

170 |

250 |

ns |

|

TA = TJ = 25°C |

140 |

170 |

200 |

ns |

Reference Section |

|

|

|

|

|

REF |

IREF = 0 |

4.875 |

5 |

5.125 |

V |

Load Regulation |

IREF = 0 mA to 1 mA |

|

1 |

20 |

mV |

Line Regulation |

VDD = 10 V to 14 V |

|

1 |

20 |

mV |

Note 1: Guaranteed by design. Not 100% tested in production.

PIN DESCRIPTIONS

CLK: Oscillator clock output pin from a low impedance CMOS driver. CLK is high during guaranteed off time. CLK can be used to synchronized up to five other UCC3580 PWMs.

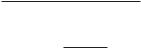

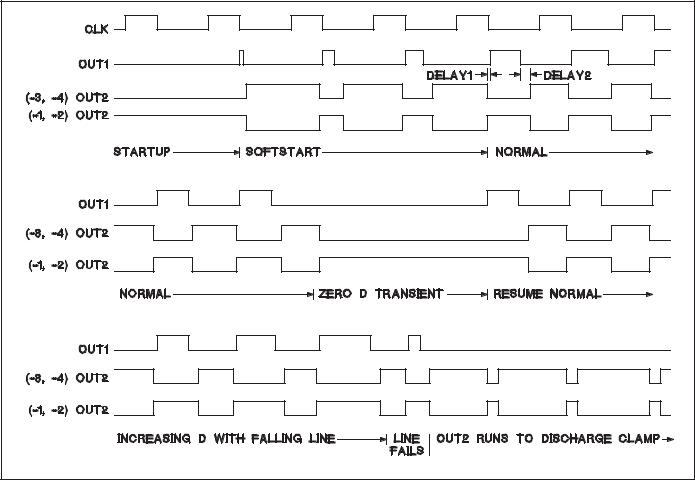

DELAY: A resistor from DELAY to GND programs the nonoverlap delay between OUT1 and OUT2. The delay times, Delay1 and Delay2, are shown in Figure 1 and are as follows:

Delay 1 1.1pF R 3

Delay2 is designed to be larger than Delay1 by a ratio shown in Figure 2.

EAIN: Inverting input to the error amplifier. The noninverting input of the error amplifier is internally set to 2.5V. EAIN is used for feedback and loop compensation.

EAOUT: Output of the error amplifier and input to the PWM comparator. Loop compensation components connect from EAOUT to EAIN.

GND: Signal Ground.

LINE: Hysteretic comparator input. Thresholds are 5.0V and 4.5V. Used to sense input line voltage and turn off OUT1 when the line is low.

OSC1 & OSC2: Oscillator programming pins. A resistor connects each pin to a timing capacitor. The resistor connected to OSC1 sets maximum on time. The resistor connected to OSC2 controls guaranteed off time. The combined total sets frequency with the timing capacitor. Frequency and maximum duty cycle are approximately given by:

1.44

Fre que ncy R1 R2 CT 27 pF

R1

Ma ximum Duty Cycle

R1 R2

Maximum Duty Cycle for OUT1 is slightly less due to Delay1 which is programmed by R3.

OUT1: Gate drive output for the main switch capable of sourcing up to 0.5A and sinking 1A.

OUT2: Gate drive output for the auxiliary switch with 0.3A drive current capability.

PGND: Ground connection for the gate drivers. Connect PGND to GND at a single point so that no high frequency components of the output switching currents are in the ground plane on the circuit board.

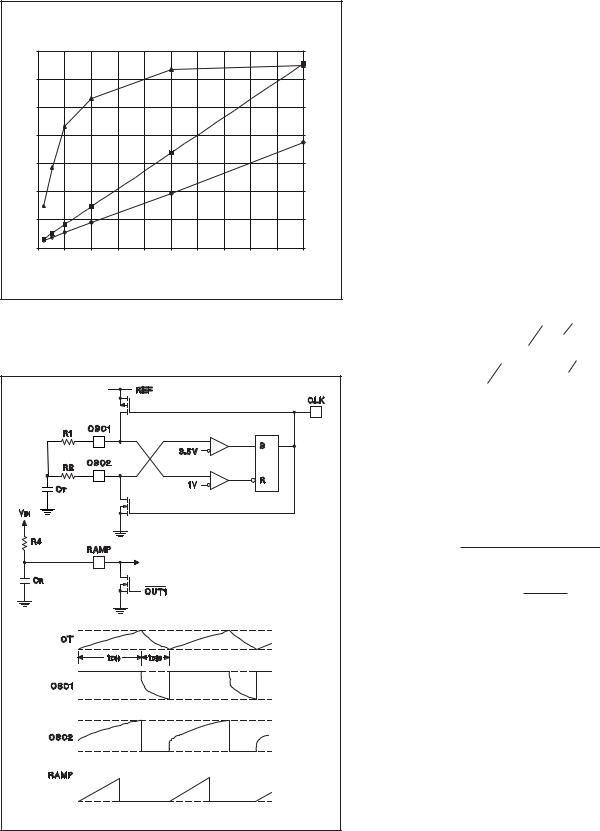

RAMP: A resistor (R4) from RAMP to the input voltage and a capacitor (CR) from RAMP to GND programs the feedforward ramp signal. RAMP is discharged to GND when CLK is high and allowed to charge when CLK is low. RAMP is the line feedforward sawtooth signal for the PWM comparator. Assuming the input voltage is much greater than 3.3V, the ramp is very linear. A flux comparator compares the ramp signal to 3.3V to limit the maximum allowable volt-second product:

Volt-Second Product Clamp = 3.3 • R4 • CR.

REF: Precision 5.0V reference pin. REF can supply up to 5mA to external circuits. REF is off until VDD exceeds 9V (–1 and –3 versions) or activates the 15V clamp (–2 and –4 versions) and turns off again when VDD droops below 8.5V. Bypass REF to GND with a 1 F capacitor.

SHTDWN: Comparator input to stop the chip. The threshold is 0.5V. When the chip is stopped, OUT1 is low and OUT2 continues to oscillate with guaranteed off time equal to two non-overlap delay times. OUT2 continues to switch after SHTDWN is asserted until the voltage on VDD falls below VCS (typically 4 V) in order to discharge the clamp capacitor.

4

PIN DESCRIPTIONS (cont.)

SS: A capacitor from SS to ground programs the soft start time. During soft start, EAOUT follows the amplitude of SS’s slowly increasing waveform until regulation is achieved.

APPLICATION INFORMATION

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

VDD: Chip power supply pin. VDD should be bypassed to PGND. The –1 and –3 versions require VDD to exceed 9V to start and remain above 8.5V to continue running. A shunt clamp from VDD to GND limits the supply voltage to 15V. The –2 and –4 versions do not start until

UDG-95070-2

Note: Waveforms are not to scale.

Figure 1. Output time relationships.

UVLO and Startup

For self biased off-line applications, -2 and -4 versions (UVLO on and off thresholds of 15V and 8.5V typical) are recommended. For all other applications, -1 and -3 versions provide the lower on threshold of 9V. The IC requires a low startup current of only 160 A when VDD is under the UVLO threshold, enabling use of a large trickle charge resistor (with corresponding low power dissipation) from the input voltage. VDD has an internal clamp at 15V which can sink up to 10mA. Measures should be taken not to exceed this current. For -2 and -4 versions,

this clamp must be activated as an indication of reaching the UVLO on threshold. The internal reference (REF) is brought up when the UVLO on threshold is crossed. The startup logic ensures that LINE and REF are above and SHTDWN is below their respective thresholds before outputs are asserted. LINE input is useful for monitoring actual input voltage and shutting off the IC if it falls below a programmed value. A resistive divider should be used to connect the input voltage to the LINE input. This feature can protect the power supply from excessive currents at low line voltages.

5

APPLICATION INFORMATION (cont.)

Delay Times

|

1400 |

|

|

|

|

|

|

|

|

|

1.80 |

|

|

|

Delay Ratio |

|

|

|

|

|

|

|

|

|

|

|

1200 |

|

|

|

|

|

|

|

|

|

1.70 |

|

|

1000 |

|

|

|

|

|

|

|

|

|

1.60 |

Ratio |

|

|

|

|

|

|

Delay2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Delayns |

800 |

|

|

|

|

|

|

|

|

|

1.50 |

Delay2/Delay1 |

600 |

|

|

|

|

|

|

|

Delay1 |

1.40 |

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

|

400 |

|

|

|

|

|

|

|

|

|

1.30 |

|

|

200 |

|

|

|

|

|

|

|

|

|

1.20 |

|

|

0 |

|

|

|

|

|

|

|

|

|

1.10 |

|

|

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

|

|

|

|

|

R3 ProgrammingResistor k |

|

|

|

|

||||

Figure 2. Delay times.

UDG-96016-1 |

Figure 3. Oscillator and ramp circuits.

UCC1580-1,-2,-3,-4

UCC2580-1,-2,-3,-4

UCC3580-1,-2,-3,-4

The soft start pin provides an effective means to start the IC in a controlled manner. An internal current of 20 A begins charging a capacitor connected to SS once the startup conditions listed above have been met. The voltage on SS effectively controls maximum duty cycle on OUT1 during the charging period. OUT2 is also controlled during this period (see Figure 1). Negation of any of the startup conditions causes SS to be immediately discharged. Internal circuitry ensures full discharge of SS (to 0.3V) before allowing charging to begin again, provided all the startup conditions are again met.

Oscillator

Simplified oscillator block diagram and waveforms are shown in Figure 3. OSC1 and OSC2 pins are used to program the frequency and maximum duty cycle. Capacitor CT is alternately charged through R1 and discharged through R2 between levels of 1.67 V and 3.3 V. The charging and discharging equations for CT are given by

VC(cha rge ) = V |

|

|

• e |

- t |

|

|

• 1 2 |

|

|

1 |

|

||

REF |

|

3 |

|

|

|

|

|

|

|

|

3 VREF e - t 2

where 1 = R1 • CT and 2 = R2 • CT. The charge time and discharge time are given by

tCH = 0.69 • R1 • C T and tDIS = 0.69 • R2 • C T

The CLK output is high during the discharge period. It blanks the output to limit the maximum duty cycle of OUT1. The frequency and maximum duty cycle are given by

Fre que ncy =

1.44

(R1+ R2) • CT + 27 pF

R1

Ma ximum Duty Cycle =

R1+ R2

Maximum Duty Cycle for OUT1 will be slightly less due to Delay1 which is programmed by R3.

Voltage Feedforward and Volt-Second Clamp

UCC3580 has a provision for input voltage feedforward. As shown in Figure 3, the ramp slope is made proportional to input line voltage by converting it into a charging current for CR. This provides a first order cancellation of the effects of line voltage changes on converter performance. The maximum volt-second clamp is provided to protect against transient saturation of the transformer core. It terminates the OUT1 pulse when the RAMP voltage exceeds 3.3V. If the feedforward feature is not used, the ramp can be generated by tying R4 to REF. However, the linearity of ramp suffers and in this case the maximum volt-second clamp is no longer available.

6

Loading...

Loading...