Texas Instruments UCC3626DW, UCC3626PWTR, UCC3626PW, UCC3626N, UCC3626DWTR Datasheet

...

UCC2626

UCC3626

PRELIMINARY

04/99

FEATURES

•

Two Quadrant and Four Quadrant

Operation

•

Integrated Absolute Value Current

Amplifier

•

Pulse-by-Pulse and Average Current

Sensing

•

Accurate, Variable Duty Cycle

Tachometer Output

•

Trimmed Precision Reference

•

Precision Oscillator

•

Direction Output

Brushless DC Motor Controller

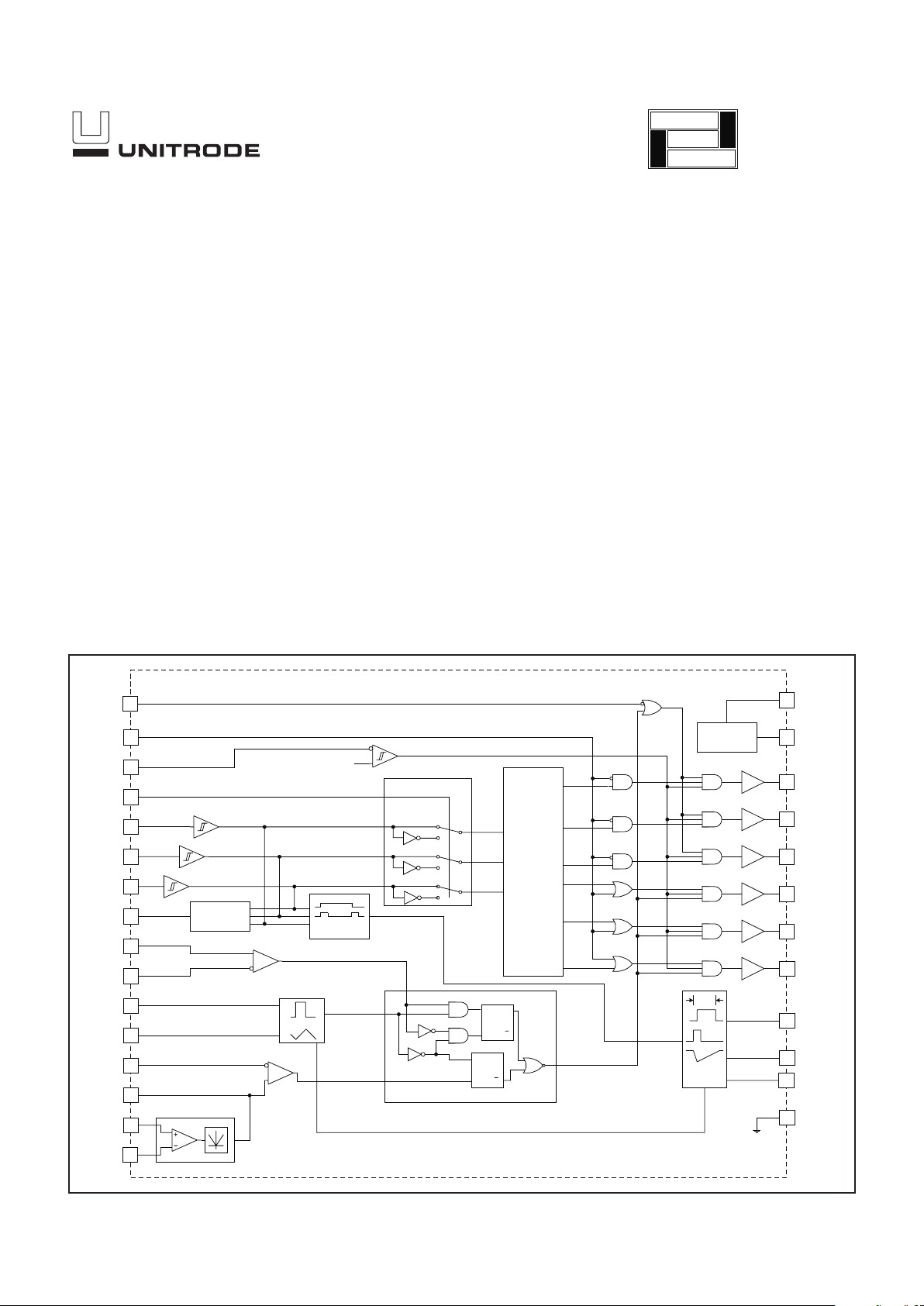

17HALLC

8DIR_OUT

14PWM_NI

13PWM_I

16HALLB

SYNCH

11

OC_REF

9

SNS_I

3

4

1

5

22 CLOW

C_TACH

R_TACH

TACH_OUT

GND

2VREF

27 AHI

25 BHI

23 CHI

26

ALOW

10

SNS_NI

IOUT

7

6

12

CT

18COAST

21DIR_IN

15HALLA

19BRAKE

20QUAD

SENSE AMPLIFIER

OVER-CURRENT

COMPARATOR

OSCILLATOR

DIRECTION

DETECTOR

EDGE

DETECTOR

28 VDD

ONE SHOT

R•C

5VOLT

REFERENCE

QQSR

PWM LOGIC

24 BLOW

1.75V

DIRECTION

SELECT

HALL

DECODER

PWM COMPARATOR

X5

Q

Q

S

R

BLOCK DIAGRAM

UDG-97173

DESCRIPTION

The UCC3626 motor controller IC combines many of the functions re

quired to design a high performance, two or four quadrant, 3-phase,

brushless DC motor controller into one package. Rotor position inputs

are decoded to provide six outputs that control an external power stage.

A precision triangle oscillator and latched comparator provide PWM mo

tor control in either voltage or current mode configurations. The oscilla

tor is easily synchronized to an external master clock source via the

SYNCH input. Additionally, a QUAD select input configures the chip to

modulate either the low side switches only, or both upper and lower

switches, allowing the user to minimize switching losses in less de

manding two quadrant applications.

The chip includes a differential current sense amplifier and absolute

value circuit which provide an accurate reconstruction of motor current,

useful for pulse by pulse over current protection as well as closing a

current control loop. A precision tachometer is also provided for imple

menting closed loop speed control. The TACH_OUT signal is a variable

duty cycle, frequency output which can be used directly for digital control or filtered to provide an analog feedback signal. Other features include COAST, BRAKE, and DIR_IN commands along with a direction

output, DIR_OUT.

application

INFO

available

2

UCC2626

UCC3626

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for VCC = 12V; CT = 1nF,

R

TACH

= 250K, C

TACH

= 100pF, TA=TJ, TA= –40°C to +85°C for the UCC2626, and 0°C to +70°C for the UCC3626.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Overall

Supply Current 310mA

Under-Voltage Lockout

Start Threshold 10.5 V

UVLO Hysteresis 0.5 V

5.0 V Reference

Output Voltage I

VREF

= –2mA 4.9 5 5.1 V

Line Regulation 11V < VCC < 14.5V 10 mV

Load Regulation –1 > I

VREF

> –5mA 30 mV

Short Circuit Current 40 120 mA

Coast Input Comparator

Threshold 1.75 V

Hysteresis 0.1 V

Input Bias Current 0.1 µA

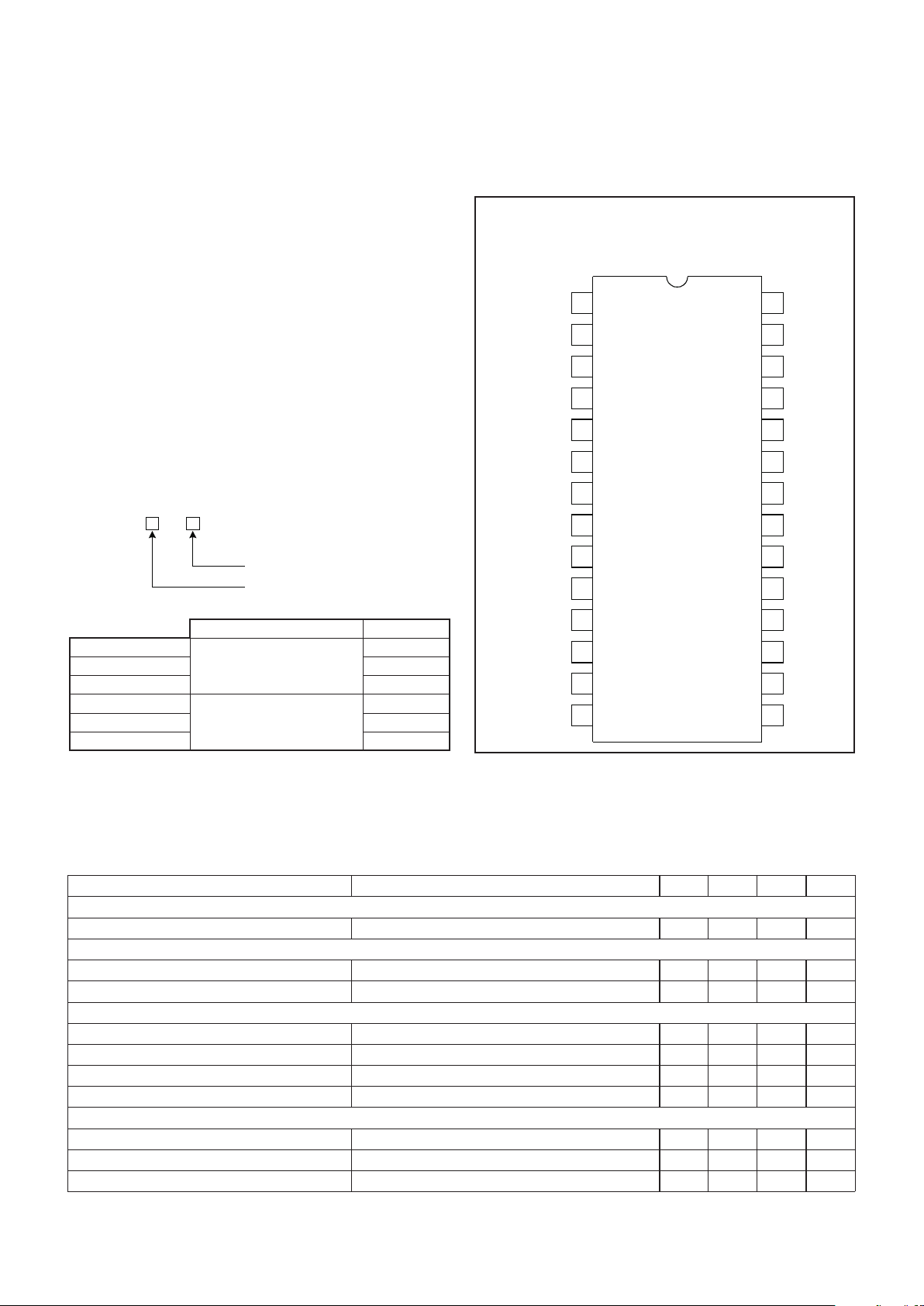

IOUT

BHI

ALO

AHI

BRAKE

BLOW

CHI

CLOW

VDD

TACH_OUT

VREF

SNS_I

SYNCH

SNS_NI

R_TACH

C_TACH

CT

GND

DIR_OUT

OC_REF HALLC

DIR_IN

QUAD

COAST

PWM_NI

PWM_I

HALLA

HALLB

14

13

12

11

10

9

8

7

6

5

4

3

2

1

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CONNECTION DIAGRAMS

ABSOLUTE MAXIMUM RATINGS

Supply Voltage VDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +15V

Inputs

Pins 20, 19, 18, 21, 15, 16, 17, 7, 12, 9, 10 . . . . –0.3V to V

DD

Pins 13, 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 8.0V

Output Current

Pins 22, 23, 24, 25, 26, 27 . . . . . . . . . . . . . . . . . . . . . ±200mA

Pins 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –20mA

Pins 3. 8, 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1mA

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering 10 Seconds). . . . . . . . . . +300°C

Note: Unless otherwise indicated, voltages are referenced to

ground. Currents are positive into, negative out of specified ter

-

minal. Consult packaging section of Databook for thermal limi

-

tations and considerations of package.

DIL-28, SOIC-28, TSSOP-28 (Top View)

N Package, DW Package, PW Package

UCC

PACKAGE

626

TEMPERATURE RANGE

ORDERING INFORMATION

TEMPERATURE RANGE PACKAGE

UCC2626N DIL

UCC2626DW –40° C to +85° C SOIC

UCC2626PW TSSOP

UCC3626N DIL

UCC3626DW 0° C to +70° C SOIC

UCC3626PW TSSOP

3

UCC2626

UCC3626

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for VCC = 12V; CT = 1nF,

R

TACH

= 250K, C

TACH

= 100pF, TA=TJ, TA= –40°C to +85°C for the UCC2626, and 0°C to +70°C for the UCC3626.

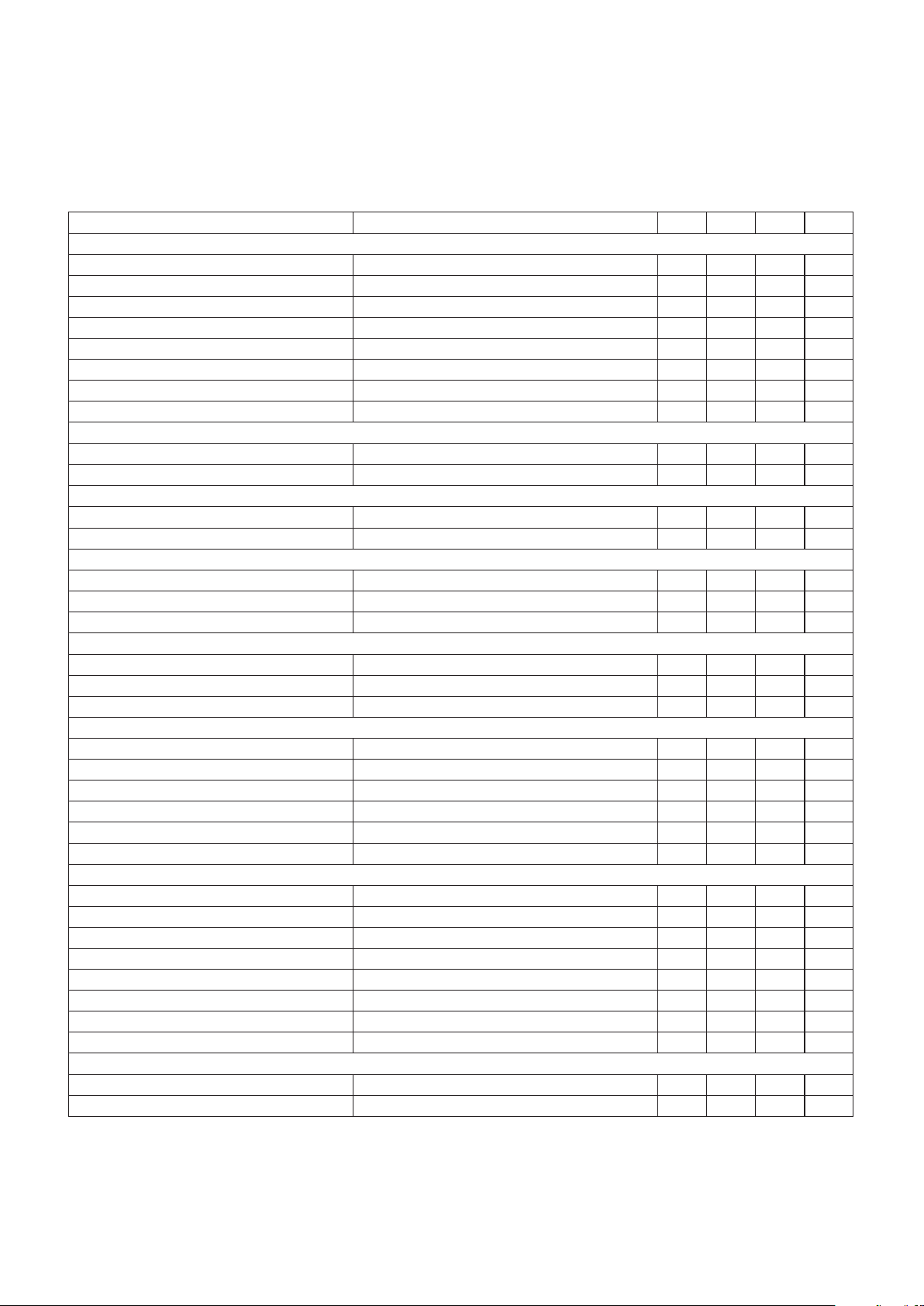

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Sense Amplifier

Input Offset Voltage VCM = 0V 5 mV

Input Bias Current VCM = 0V 10 µA

Gain VCM = 0V 4.9 5 5.1 V/V

CMRR –0.3V < VCM < 0.5 60 dB

PSRR 11V < VCC <14.5V 60 dB

Output High Voltage I

IOUT

= –100µA5V

Output Low Voltage I

IOUT

= 100µA50mV

Output Source Current V

IOUT

= 2V 500 µA

PWM Comparator

Input Common Mode Range 2.0 8.0 V

Propogation Delay 75 nS

Over-Current Comparator

Input Common Mode Range 0.0 5.0 V

Propogation Delay 175 nS

Logic Inputs

Logic High QUAD, BRAKE, DIR 3.5 V

Logic Low QUAD, BRAKE, DIR 1.5 V

Input Current QUAD, BRAKE, DIR 0.1 µA

Hall Buffer Inputs

VIL HALLA, HALLB, HALLC 1 V

VIH HALLA, HALLB, HALLC 1.9 V

Input Current 0V < V

IN

< 5V –25 µA

Oscillator

Frequency R

TACH

= 250k, CT = 1nF 10 KHz

Frequency Change With Voltage 12V < VCC < 14.5V 5 %

CT Peak Voltage 7.5 V

CT Valley Voltage 2.5 V

CT Peak-to-Valley Voltage 5.0 V

SYNCH Pin Minimum Pulse Width –500 ns

Tachometer

V

OH/VREF

I

OUT

= –10µA 99 100 %

Vol I

OUT

= 10µA 0 20 mV

R

ON

High I

OUT

= –100µA1kΩ

R

ON

Low I

OUT

= 100µA1kΩ

Ramp Threshold, Lo 20 mV

Ramp Threshold, Hi 2.52 V

C

TACH

Charge Current R

TACH

= 49.9kΩ 50 µA

T-on Accuracy Note 1 –3 3 %

Direction Output

DIR OUT High Level I

OUT

= –100µA 3.5 5.1 V

DIR OUT Low Level I

OUT

= 100µA01V

4

UCC2626

UCC3626

PIN DESCRIPTIONS

AHI, BHI, CHI: Digital outputs used to control the high

side switches in a three phase inverter. For specific de

-

coding information reference Table I.

ALOW, BLOW, CLOW: Digital outputs used to control

the low side switches in a three phase inverter. For specific decoding information reference Table I.

BRAKE: BRAKE is a digital input which causes the device to enter brake mode. In brake mode all three high

side outputs are turned off, AHI, BHI & CHI, while all

three lowside outputs are turned on, ALOW, BLOW,

CLOW. During brake mode the tachometer output remains operational. The only conditions which can inhibit

the low side commands during brake are UVLO, ex

-

ceeding peak current, the output of the PWM compara

-

tor, or the COAST command.

COAST: The COAST input consists of a hysteretic com

parator which disables the outputs. The input is useful in

implementing an overvoltage bus clamp in four quadrant

applications. The outputs will be disabled when the input

is above 1.75V.

CT: This pin is used in conjunction with the R_TACH pin

to set the frequency of the oscillator. A timing capacitor

is normally connected between this point and ground

and is alternately charged and discharged between 2.5V

and 7.5V.

C_TACH: A timing capacitor is connected between this

pin and ground to set the width of the TACH_OUT pulse.

The capacitor is charged with a current set by the resis

tor on pin RT.

DIR_IN: DIR_IN is a digital input which determines the

order in which the HALLA,B & C inputs are decoded. For

specific decode information reference Table I.

DIR_OUT: DIR_OUT represents the actual direction of

the rotor as decoded from the HALLA,B&Cinputs. For

any valid combination of HALLA, B &C inputs there are

two valid transitions, one which translates to a clockwise

rotation and another which translates to a counterclockwise rotation. The polarity of DIR_OUT is the same as

DIR_IN while motoring, i.e. sequencing from top to bottom in Table 1.

GND: GND is the reference ground for all functions of the

part. Bypass and timing capacitors should be terminated

as close to this point as possible.

HALLA, HALLB, HALLC: These three inputs are de

signed to accept rotor position information positioned

120° apart. For specific decode information reference Ta

ble I. These inputs should be externally pulled-up to

VREF or another appropriate external supply.

IOUT: IOUT represents the output of the current sense

and absolute value amplifiers. The output signal appear

ing is a representation of the following expression:

I ABS ISENS I ISENS NI

OUT

=−•(_ _)5

This output can be used to close a current control loop as

well as provide additional filtering of the current sense

signal.

OC_REF: OC_REF is an analog input which sets the trip

voltage of the overcurrent comparator. The sense input of

the comparator is internally connected to the output of the

current sense amplifier and absolute value circuit.

PWM_NI: PWM_NI is the noninverting input to the PWM

comparator.

PWM_I: PWM_I is the inverting input to the PWM com

parator.

ELECTRICAL CHARACTERISTICS: Unless otherwise stated, these specifications apply for VCC = 12V; CT = 1nF,

R

TACH

= 250K, C

TACH

= 100pF, TA=TJ, TA= –40°C to +85°C for the UCC2626, and 0°C to +70°C for the UCC3626.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output Section

Maximum Duty Cycle 100 %

Output Low Voltage I

OUT

= 10mA 0.4 V

Output High Voltage I

OUT

= –10mA 4.0 5.1 V

Output Low Voltage I

OUT

= 1mA 1 V

Output High Voltage I

OUT

= –1mA 4.0 5.1 V

Rise/Fall Time CI = 100pF 100 nS

Note 1: T(on) is calculated using the formula: T(on) = C

TAC H

(VHI–VLO)/I

CHARGE

. This number is compared to the formula T(on) =

R

TAC H

C

TAC H

.

5

UCC2626

UCC3626

Table 1 provides the decode logic for the six outputs,

AHI, BHI, CHI, ALOW, BLOW, and CLOW as a function

of the BRAKE, COAST, DIR_IN, HALLA, HALLB, and

HALLC inputs.

The UCC3626 is designed to operate with 120° position

sensor encoding. In this format, the three position sensor

signals are never simultaneously high or low. Motor's

whose sensors provide 60° encoding can be converted

to 120° using the circuit shown in Fig. 1.

In order to prevent noise from commanding improper

commutation states, some form of low pass filtering on

HALLA, HALLB, and HALLC is recommended. Passive

APPLICATION INFORMATION

QUAD: The QUAD input selects between “two” QUAD =

0 and “four” QUAD = 1 quadrant operation. When in

“two-quadrant” mode only the low side devices are ef

fected by the output of the PWM comparator. In

“four-quadrant” mode both high and low side devices are

controlled by the PWM comparator.

SYNCH: The SYNCH input is used to synchronize the

PWM oscillator with an external digital clock. When using

the SYNCH feature, a resistor equal to R

TA CH

must be

placed in parallel with CT. When not used, ground

SYNCH.

SNS_NI, SNS_I: These inputs are the noninverting and

inverting inputs to the current sense amplifier, respec

tively. The integrated amplifier is configured for a gain of

five. An absolute value function is also incorporated into

the output in order to provide a representation of actual

motor current when operating in four quadrant mode.

TACH_OUT: TACH_OUT is the output of a monostable

triggered by a change in the commutation state, thus pro

viding a variable duty cycle, frequency output. The

on-time of the monostable is set by the timing capacitor

connected to C_TACH. The monostable is capable of be

ing retriggered if a commutation occurs during it's

on-time.

R_TACH: A resistor connected between R_TACH and

ground programs the current for both the oscillator and

tachometer.

VDD: VDD is the input supply connection for this device.

Undervoltage lockout keeps the outputs off for inputs be

low 10.5V. The input should be bypassed with a 0.1µFce

ramic capacitor, minimum.

VREF: VREF is a 5V, 2% trimmed reference output with

5mA of maximum available output current. This pin

should be bypassed to ground with a 0.1µF ceramic ca

pacitor, minimum.

PIN DESCRIPTIONS (cont.)

B

R

A

K

E

C

O

A

S

T

D

I

R

_

IN

HALL

INPUTS

HIGH SIDE

OUTPUTS

LOW SIDE

OUTPUTS

ABCABCABC

001101100010

001100100001

001110010001

001010010100

001011001100

001001001010

000101010100

000001010001

000011100001

000010100010

000110001010

000100001100

X1XXXX000000

10XXXX000111

00X111000000

00X000000000

Table 1. Commutation truth table.

1kΩ

2N2222A

1kΩ

1kΩ

1kΩ

VREF

VREF

VREF

HALLB

HALLA

HALLC

HALLA

HALLB

HALLC

2.2nF

2.2nF

2.2nF

499Ω

499Ω

Figure 1. Circuit to convert 60° hall code to 120°

code.

Loading...

Loading...