TEXAS INSTRUMENTS UCC1807-1, UCC1807-2, UCC1807-3, UCC2807-1, UCC2807-2 Technical data

...

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

www.ti.com |

SLUS163A – JUNE 1997 – REVISED AUGUST 2007 |

|

PROGRAMMABLE MAXIMUM DUTY CYCLE PWM CONTROLLER

FEATURES

∙User Programmable Maximum PWM Duty Cycle

∙100-A Startup Current

∙Operation to 1 MHz

∙Internal Full Cycle Soft Start

∙Internal Leading Edge Blanking of Current Sense Signal

∙1-A Totem Pole Output

ORDERING INFORMATION

PART |

TURN-ON |

TURN-OFF |

PACKAGES |

|

NUMBER |

THRESHOLD |

THRESHOLD |

||

|

||||

UCCx807-1 |

7.2 V |

6.9 V |

J |

|

UCCx807-2 |

12.5 V |

8.3 V |

N, D |

|

UCCx807-3 |

4.3 V |

4.1 V |

N, D, PW |

DESCRIPTION

The UCC3807 family of high speed, low power integrated circuits contains all of the control and drive circuitry required for off-line and dc-to-dc fixed frequency current mode switching power supplies with minimal external parts count.

These devices are similar to the UCC3800 family, but with the added feature of a user programmable maximum duty cycle. Oscillator frequency and maximum duty cycle are programmed with two resistors and a capacitor. The UCC3807 family also features internal full cycle soft start and internal leading edge blanking of the current sense input.

The UCC3807 family offers a variety of package options, temperature range options, and choice of critical voltage levels. The family has UVLO thresholds and hysteresis levels for off-line and battery powered systems. Thresholds are shown in the table below.

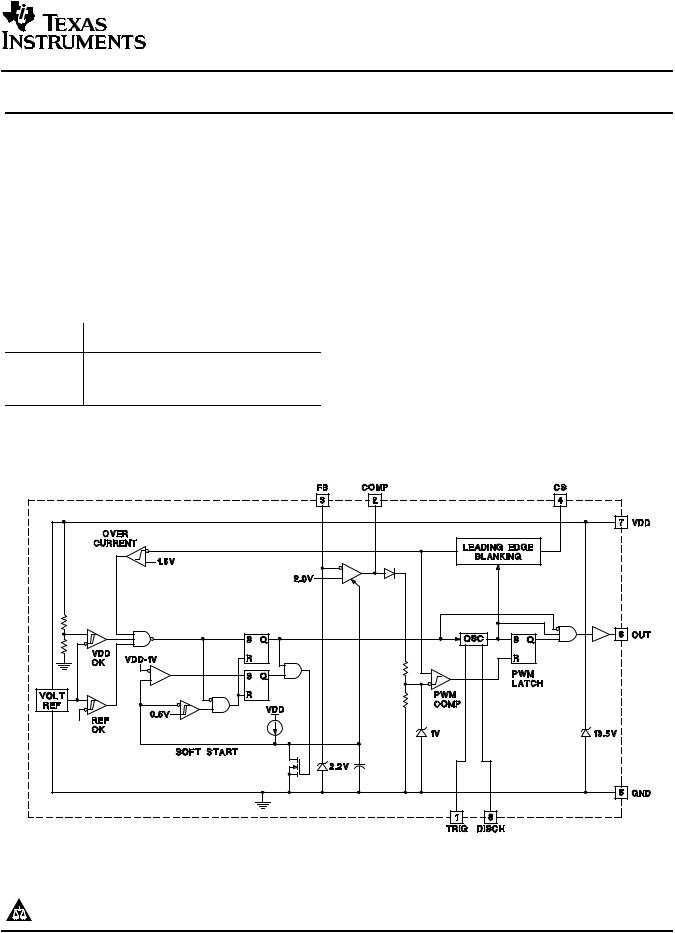

BLOCK DIAGRAM

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date. |

Copyright © 1997–2007, Texas Instruments Incorporated |

Products conform to specifications per the terms of the Texas |

|

Instruments standard warranty. Production processing does not |

|

necessarily include testing of all parameters. |

|

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

www.ti.com

SLUS163A – JUNE 1997 – REVISED AUGUST 2007

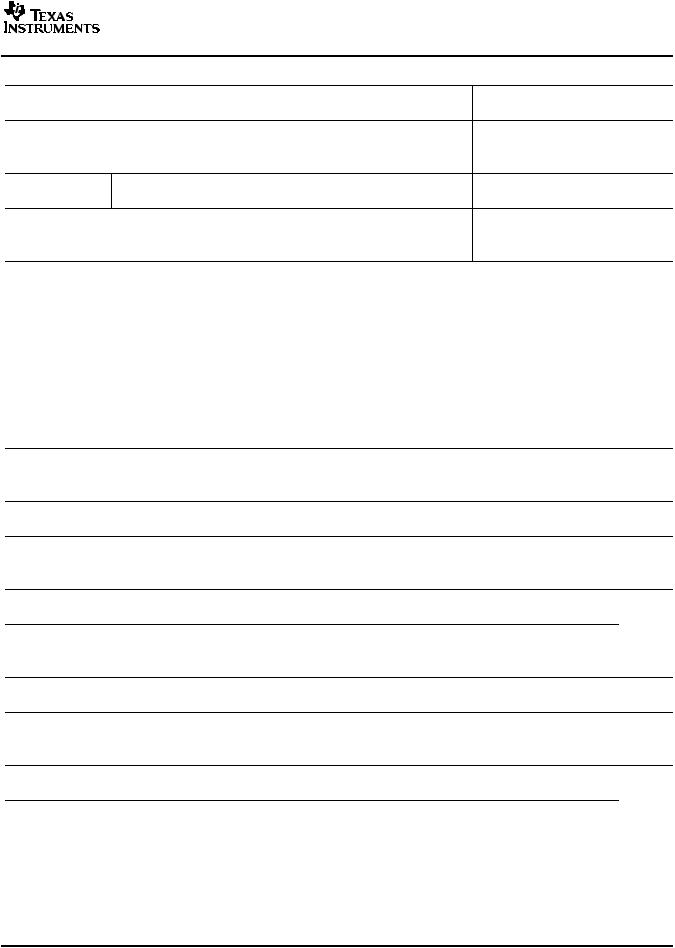

ORDERING INFORMATION

UCC |

|

|

807 |

|

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UVLO Threshold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Package |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature Range |

|

|

|

|

|

|

|

|

|

|

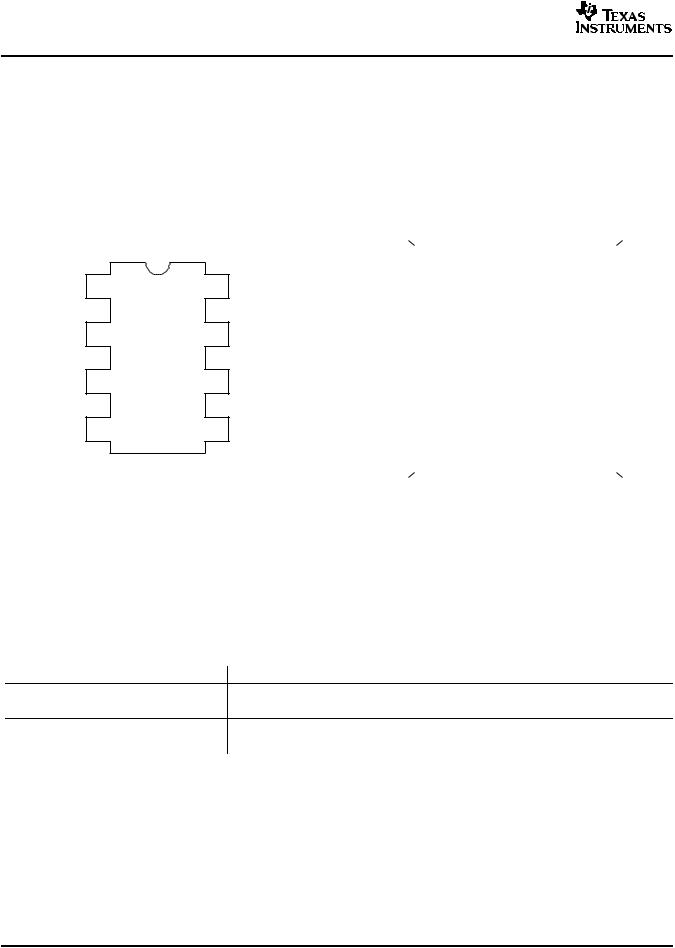

CONNECTION DIAGRAMS |

TSSOP-14 (Top View) PW Package (UCC2807-3 |

|

only) |

||

|

DIL-8, SOIC-8 (Top View) J, N or D Packages

TRIG |

1 |

8 |

DISCH |

COMP |

2 |

7 |

VDD |

FB |

3 |

6 |

OUT |

CS |

4 |

5 |

GND |

|

|

|

|

|

|

|

|

|

|

|

TRIG |

DISCH |

|

|

|

|

1 |

|

|

14 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

N/C |

N/C |

|

13 |

|

|

|

|

COMP |

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

VDD |

|

12 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

OUT |

|

|

|

|

4 |

|

N/C |

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

FB |

N/C |

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

CS |

|

|

|

|

|

6 |

|

GND |

|

9 |

|

|

|

|

|

N/C |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

GND |

|

8 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE

Specified thermal resistance is θJL (junction to lead) on TSSOP-14 pin 8 and 9.

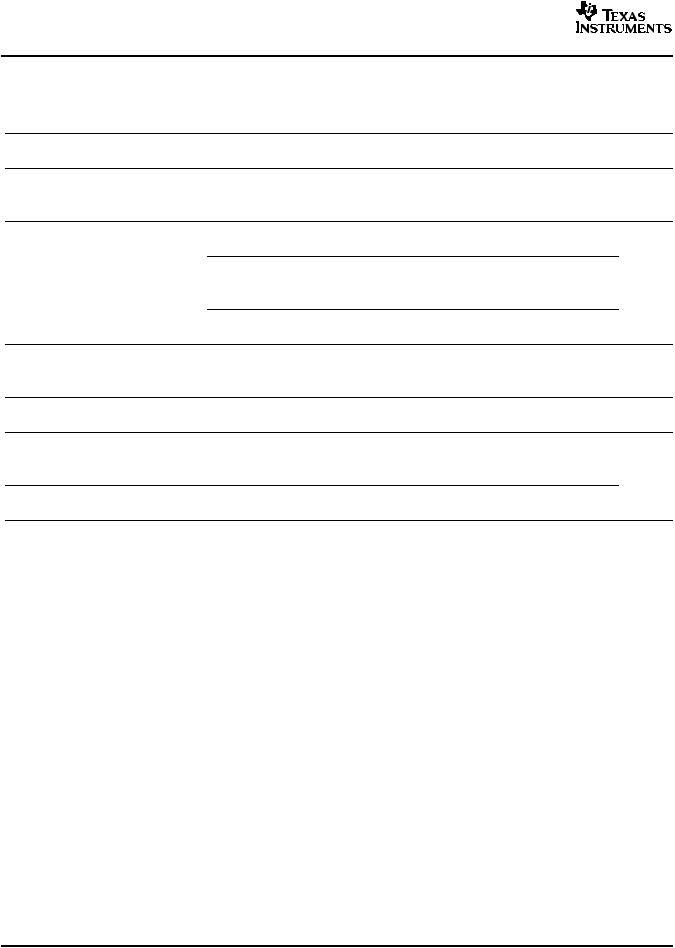

THERMAL CHARACTERISTICS

over operating free-air temperature range (unless otherwise noted)

PACKAGE |

θJA |

θJC |

DIL-8, J |

125-160 |

28(1) |

DIL-8, N |

110(2) |

50 |

SOIC-8, D |

84-160(2) |

42 |

TSSOP-14 |

132-158(3) |

15(3) |

(1)θJC data values stated were derived from MIL-STD-1835B. MIL-STD-1835B states that "The baseline values shown are worst case

(mean + 2s) for a 60 x 60 mil microcircuit device silicon die and applicable for devices with die sizes up to 14400 square mils. For device die size greater than 14400 square mils use the following values; dual-in-line, 11°C/W; flat pack, 10°C/W; pin grid array, 10°C/W".

(2)Specified θJC (junction to ambient) is for devices mounted to 5 in2 FR4 PC board with one ounce copper where noted. When resistance range is given, lower values are for 5 in2 aluminum PC board. Test PWB was 0.062 inch thick and typically used 0.635 mm trace widths for power packages and 1.3 mm trace widths for non-power packages with 100 x 100 mil probe land area at the end of each trace.

(3)Modeled Data. If value range given for θJA, lower value is for 3 x 3 in., 1 ounce internal copper ground plane, higher value is for 1 x 1 inch ground plane. All model data assumes only one trace for each non-fused lead.

2 |

Submit Documentation Feedback |

|

UCC1807-1/-2/-3 |

|

|

UCC2807-1/-2/-3 |

|

www.ti.com |

UCC3807-1/-2/-3 |

|

SLUS163A – JUNE 1997 – REVISED AUGUST 2007 |

||

|

||

ABSOLUTE MAXIMUM RATINGS(1) (2) |

|

|

|

UNIT |

|

Supply voltage (IDD 10 mA) |

13.5 V |

|

Supply current |

30 mA |

|

OUT current |

±1 A |

|

Analog inputs (FB, CS) |

–0.3 V to (VDD + 0.3 V) |

|

TA +25°C (N or J packages) |

1 W |

|

Power dissipation |

|

|

TA +25°C (D package) |

0.65 W |

|

Storage temperature |

–65°C to 150°C |

|

Junction temperature |

–65°C to 150°C |

|

Lead temperature (soldering, 10 sec.) |

300°C |

(1)All currents are positive into, negative out of the specified terminal.

(2)The UCCx807-2 is designed to be operated in a system that uses as external high voltage source to provide a startup current to a large capacitor from VDD to GND. The worse case current from this source should be less thanthe current needed to run the device in normal operation. The capacitor is needed to provide the reservoir of energy to allow the completion of the startup process before the UVLO voltage is encountered. Once started the converter should be designed so that it is self powered from a controlled voltage source of a lower voltage, one between 9.5 V and 11.5 V. The device is not designed to have the VDD clamp active during normal operation. The VDD voltage is always less than the clamp voltage. The upper limit of the input voltage is applicable to the whole family of UCCx807-1/-2 or -3.

ELECTRICAL CHARACTERISTICS

Unless otherwise stated these specifications apply for TA = –55°C to 125°C for UCC1807-1/-2/-3; –40°C to 85°C for UCC2807-1/-2/-3; and 0°C to 70°C for UCC3807-1/-2/-3; VDD = 10 V(1), RA = 12 kΩ , RB = 4.7 kΩ, CT = 330 pF, 1.0 μF capacitor from VDD to GND, TA = TJ.

PARAMETER |

TEST CONDITIONS |

MIN |

TYP |

MAX |

UNIT |

|

Oscillator |

|

|

|

|

|

|

Frequency |

|

175 |

202 |

228 |

kHz |

|

Temperature stability |

See (2) |

|

2.5% |

|

|

|

Amplitude |

See (3) |

|

1/3VDD |

|

V |

|

Error Amplifier |

|

|

|

|

|

|

Input voltage |

COMP = 2.0 V |

1.95 |

2.00 |

2.05 |

V |

|

Input bias current |

|

–1 |

|

1 |

A |

|

Open loop voltage gain |

|

60 |

80 |

|

dB |

|

COMP sink current |

FB = 2.2 V, COMP = 1.0 V |

0.3 |

2.5 |

|

mA |

|

COMP source current |

FB = 1.3 V, COMP = 4.0 V |

–0.2 |

–0.5 |

|

||

|

|

|||||

PWM |

|

|

|

|

|

|

Maximum duty cycle |

|

75% |

78% |

81% |

|

|

Minimum duty cycle |

COMP = 0 V |

|

|

0% |

|

|

Current Sense |

|

|

|

|

|

|

Gain |

See (4) |

1.1 |

1.65 |

1.8 |

V/V |

|

Maximum input signal |

COMP = 5.0 V (5) |

0.9 |

1.0 |

1.1 |

V |

|

Input bias current |

|

–200 |

|

200 |

nA |

|

CS blank time |

|

50 |

100 |

150 |

ns |

|

Overcurrent threshold |

|

1.4 |

1.5 |

1.6 |

V |

|

COMP to CS offset |

CS = 0 V |

0.55 |

1.1 |

1.65 |

||

|

(1)Adjust VDD above the start threshold before setting at 10 V for UCC3807-2.

(2)Ensured by design. Not 100% tested in production.

(3)Measured at TRIG; signal minimum = 1/3 VDD, maximum = 2/3 VDD.

A |

VCOMP |

, 0 VCS 0.8 V |

|

||

(4) Gain is defined by: |

VCS |

|

(5)Parameter measured at trip point of latch with FB at 0 V.

Submit Documentation Feedback |

3 |

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

www.ti.com

SLUS163A – JUNE 1997 – REVISED AUGUST 2007

ELECTRICAL CHARACTERISTICS (continued)

Unless otherwise stated these specifications apply for TA = –55°C to 125°C for UCC1807-1/-2/-3; –40°C to 85°C for

UCC2807-1/-2/-3; and 0°C to 70°C for UCC3807-1/-2/-3; VDD = 10 V, RA = 12 kΩ , RB = 4.7 kΩ, CT = 330 pF, 1.0 μF capacitor from VDD to GND, TA = TJ.

PARAMETER |

TEST CONDITIONS |

MIN |

TYP |

MAX |

UNIT |

Output |

|

|

|

|

|

OUT low level |

I = 100 mA |

|

0.4 |

1 |

V |

OUT high level |

I = 100 mA, VDD – OUT |

|

0.4 |

1 |

|

|

|

||||

Rise/fall time |

|

|

20 |

100 |

ns |

Undervoltage Lockout |

|

|

|

|

|

|

UCCx807-1(6) |

6.6 |

7.2 |

7.8 |

|

Start threshold |

UCCx807-2 |

11.5 |

12.5 |

13.5 |

V |

|

UCCx807-3 |

4.1 |

4.3 |

4.5 |

|

|

UCCx807-1(6) |

6.3 |

6.9 |

7.5 |

|

Minimum operating voltage after start |

UCCx807-2 |

7.6 |

8.3 |

9.0 |

V |

|

UCCx807-3 |

3.9 |

4.1 |

4.3 |

|

|

UCCx807-1 |

0.1 |

0.3 |

0.5 |

|

Hysteresis |

UCCx807-2 |

3.5 |

4.2 |

5.1 |

V |

|

UCCx807-3 |

0.1 |

0.2 |

0.3 |

|

Soft Start |

|

|

|

|

|

COMP rise time |

FB = 1.8 V, From 0.5 V to 4.0 V |

|

4 |

|

|

Overall |

|

|

|

|

|

Startup current |

VDD < Start Threshold (UCCx807-1,-3) |

|

0.1 |

0.2 |

|

VDD < Start Threshold (UCCx807-2) |

|

0.15 |

0.25 |

mA |

|

|

|

||||

Operating supply current |

FB = 0 V, CS = 0 V, No Load(7) |

|

1.3 |

2.1 |

|

VDD zener shunt voltage |

IDD = 10 mA |

12.0 |

13.5 |

15.0 |

V |

Shunt to start difference |

|

0.5 |

10 |

|

V |

(6)Start Threshold and Zener Shunt thresholds track one another.

(7)Does not include current in external timing RC network.

4 |

Submit Documentation Feedback |

UCC1807-1/-2/-3 UCC2807-1/-2/-3

UCC3807-1/-2/-3

www.ti.com

SLUS163A – JUNE 1997 – REVISED AUGUST 2007

PIN DESCRIPTIONS

COMP: COMP is the output of the error amplifier and the input of the PWM comparator. The error amplifier in the UCC3807 is a low output impedance, 2 MHz operational amplifier. COMP can both source and sink current. The error amplifier is internally current limited, which allows zero duty cycle by externally forcing COMP to GND.

The UCC3807 family features built-in full cycle soft start. Soft start is implemented as a clamp on the maximum COMP voltage.

CS: Current sense input. There are two current sense comparators on the chip, the PWM comparator and an overcurrent comparator.

The UCC3807 also contains a leading edge blanking circuit, which disconnects the external CS signal from the current sense comparator during the 100 ns interval immediately following the rising edge of the signal at the OUT pin. In most applications, no analog filtering is required on CS. Compared to an external RC filtering technique, leading edge blanking provides a smaller effective CS to OUT propagation delay. Note, however, that the minimum non-zero on-time of the OUT signal is directly affected by the leading edge blanking and the CS to OUT propagation delay.

The overcurrent comparator is only intended for fault sensing. Exceeding the overcurrent threshold causes a soft start cycle.

FB: The inverting input to the error amplifier. For best stability, keep connections to FB as short as possible and stray capacitance as small as possible.

GND: Reference ground and power ground for all functions of the part.

OUT: The output of a high current power driver capable of driving the gate of a power MOSFET with peak currents exceeding 1A. OUT is actively held low when VDD is below the UVLO threshold.

The high current power driver consists of MOSFET output devices in a totem pole configuration. This allows the output to switch from VDD to GND. The output stage also provides a very low impedance which minimizes overshoot and undershoot. In most cases, external Schottky clamp diodes are not required.

TRIG/DISCH: Oscillator control pins. Trig is the oscillator timing input, which has an RC-type charge/discharge signal controlling the chip’s internal oscillator. DISCH is the pin which provides the low impedance discharge path for the external RC network during normal operation. Oscillator frequency and maximum duty cycle are computed as follows:

frequency |

1.4 |

|

|

|

RA 2RB CT |

|

|||

duty cycle |

RA RB |

|

||

RA 2RB |

|

(1) |

||

as shown in Figure 1.

For best performance, keep the lead from CT to GND as short as possible. A separate ground connection for CT is desirable. The minimum value of RA is 10 kΩ , the minimum value of RB is 2.2 kΩ, and the minimum value of CT is 47 pF.

VDD: The power input connection for this device. Total VDD current is the sum of quiescent current and the average OUT current. Knowing the operating frequency and the MOSFET gate charge (Qg), average OUT current can be calculated from

IOUT = Qg F, where F is frequency.

To prevent noise problems, bypass VDD to GND with a ceramic capacitor as close to the chip as possible in parallel with an electrolytic capacitor. Once started and operating properly the VDD voltage should be below the clamp voltage of the device.

Submit Documentation Feedback |

5 |

Loading...

Loading...