HEIDENHAIN TNC 335 User Manual

April 1996

208 793 21 · 3.3 · 4/96 · S · Printed in Germany · Subject to change without notice

(208 793 E1)

Technical Manual

TNC 360

Valid for the NC software types

259 90 up to version 06

260 02 up to version 17

280 49 up to version 17

260 060 up to version 17

280 610 up to version 17

8/95 TNC 360

Preface

This Technical Manual is intended for all manufacturers and distributors of machine tools. It

contains all the necessary information for the assembly, electrical installation, start-up and PLC

programming for the HEIDENHAIN contouring controls TNC 360.

Whenever HEIDENHAIN improves the hardware or software in these controls you will receive a free

delivery of updated information. Please arrange and insert this updated information in your manual

without delay. This will ensure that your manual always remains at the current revision level.

You can use extracts from this manual for your machine documentation. An enlargement of the

manual format (17 cm x 24 cm) by a factor of 1.225 will produce pages in A4 format.

No manual can be perfect. Like all living things it must grow and change. Among other things, it

lives from your impulses and suggestions for improvement. Please help us by giving us your ideas.

DR. JOHANNES HEIDENHAIN GmbH

Department E/P

PO Box 1260

83292 Traunreut

Germany

1

2

3

4

5

6

7

8

9

10

11

Contents Technical Manual TNC 360

Update Information

Introduction

Mounting and Electrical Installation

Machine Integration

Machine Parameters

Markers and Words

PLC Programming

Data interfaces

Original Equipment Manufacturer’s (OEM) Cycles

Positioning Module

Appendix

4/96 TNC 360 Update Information No. 8 1-1

Update Information No. 8

In mid February 1996 software version 17 was released for the NC software types 260 02 and 280

49, and for the newly introduced software types 260 060 (for 1 MB EPROMs) and 280 610 (for 2 MB

EPROMs). The new software types were introduced for the Polish conversational language.

Software version 17 contains the following additions:

• The software now supports the new handwheel HR 410.

The HR 410 is a portable electronic handwheel with:

Keys for selection of five axes

Keys for traverse direction

Keys for three pre-programmed feed rates for latched traverse

One key for actual-position capture

Three keys for machine functions determined by the machine manufacturer

Two permissive buttons

Emergency stop button

Magnetic holding pads

With MP7640 = 6 you can activate the functions for the HR410 handwheel.

MP7645.0 determines whether the keys on the handwheel are assigned to the NC or the PLC.

MP7645.0 = 0

NC key assignment

MP7645.0 = 1

PLC key assignment

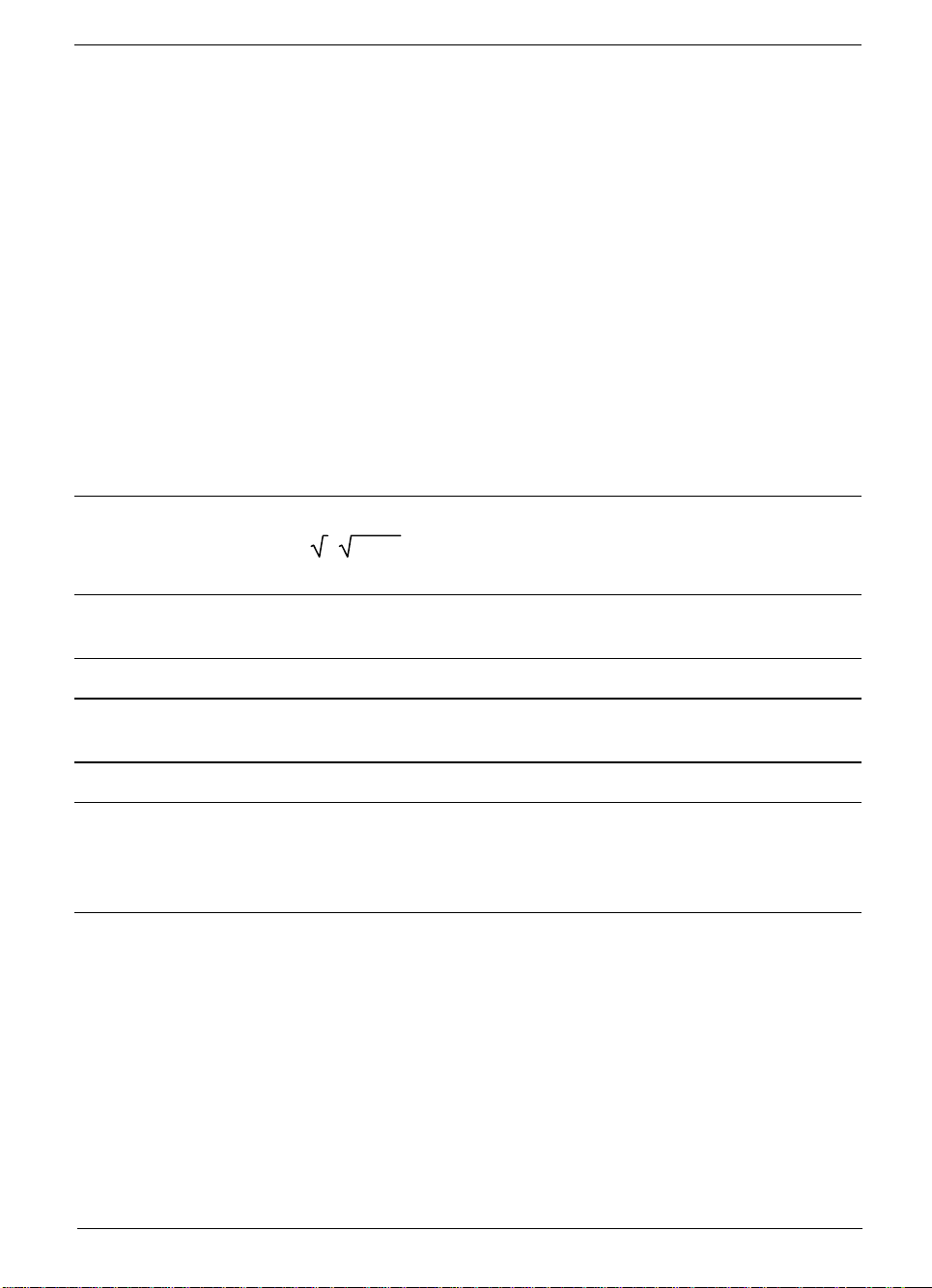

XIV

O96

I160

O97

I161

YV

Handwheel

control panel

O98

I162

O99

I163

Z

ACTUAL

POSITION

CAPTURE

O100

I164

O103

I167

LOW FEED

RATE

MEDIUM

FEED RATE

HIGH FEED

RATE

O104

I168

O105

I169

O106

I170

–+

I171 I172

O109

I173

O110

I174

O111

I175

O109

I173

O110

I174

O111

I175

With the exception of the A, B and C function

keys, all keys are assigned to the NC.

MP7670.x determines the interpolation factor

for low, medium and high speeds. MP7671.x

determines the low, medium and high speed

values. The speed is given as a percentage factor

of the manual feed rate (MP1020.x).

All keys are assigned to the PLC. Handwheel

axis and handwheel interpolation are set by

module 9036. With W766 you can change the

feed rate by pressing the axis direction keys.

1-2 TNC 360 Update Information No. 8 4/96

MP7670 Interpolation factor for handwheel

Input: 0 to 10

MP7670.0 Interpolation factor for low speed

MP7670.1 Interpolation factor for medium speed

MP7670.2 Interpolation factor for high speed

MP7671 Manual feed rate in "handwheel" operating mode with HR 410

Input: 0 to 1000 [% to MP1020]

MP7670.0 Low speed

MP7670.1 Medium speed

MP7670.2 High speed

A dummy plug (Id.-Nr. 271 958 03) is available for an EMERGENCY STOP.

There are connecting terminals on the adapter for the contacts from the emergency stop button

and the permissive buttons (maximum load 1.2 A)

Connector layout:

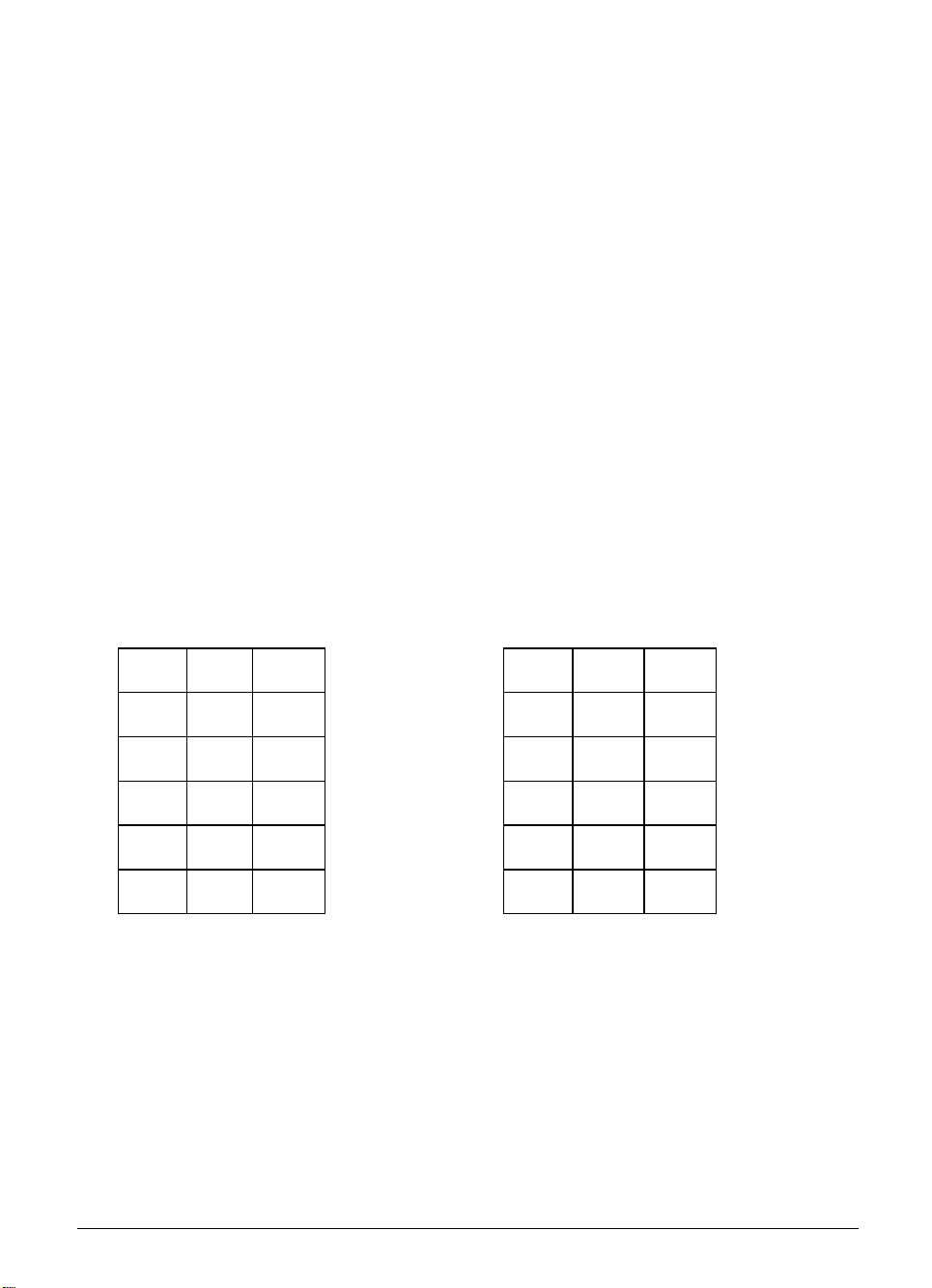

VL ID number 281 429.. KA ID number 296 466.. VB ID number 296 467 05 HR 410

ID number

296 469 01

D-sub

connector

(male

)

9-pin

D-sub

connector

(female

)

9-pin

D-sub

connector

(male

)

9-pin

Coupling on

mounting

base

(female)

18-pin

Connecto

r (male

)

18-pin

Connecto

r (female)

18-pin

Connecto

r (male)

18-pin

Housing Shield Housing Housing Shield Housing Housing Shield Housing Housing Shield

2 White 2 2 White E E White E E

4 Brown 4 4 Brown D D Brown D D

6 Yellow 6 6 Yellow B B Yellow B B

7 Gray 7 7 Gray A A Gray A A

8 Green 8 8 Green C C Green C C

66

WH/BK

66

77

YL/BK

77

55

WH/RD

55

44

WH/BL

44

22

WH/GN

22

33

WH/YL

33

11

WH/BR

11

WH/BR

3 Contacts 1 + 2

WH/YL

2 Contact 2 (left) Permissive button

WH/GN

1 Contact 1 (right)

WH/BL

1 Contact

1

WH/RD

2 Contact

1

Emergency stop

YL/BK

3 Contact 2

WH/BK

4 Contact 2

4/96 TNC 360 Update Information No. 8 1-3

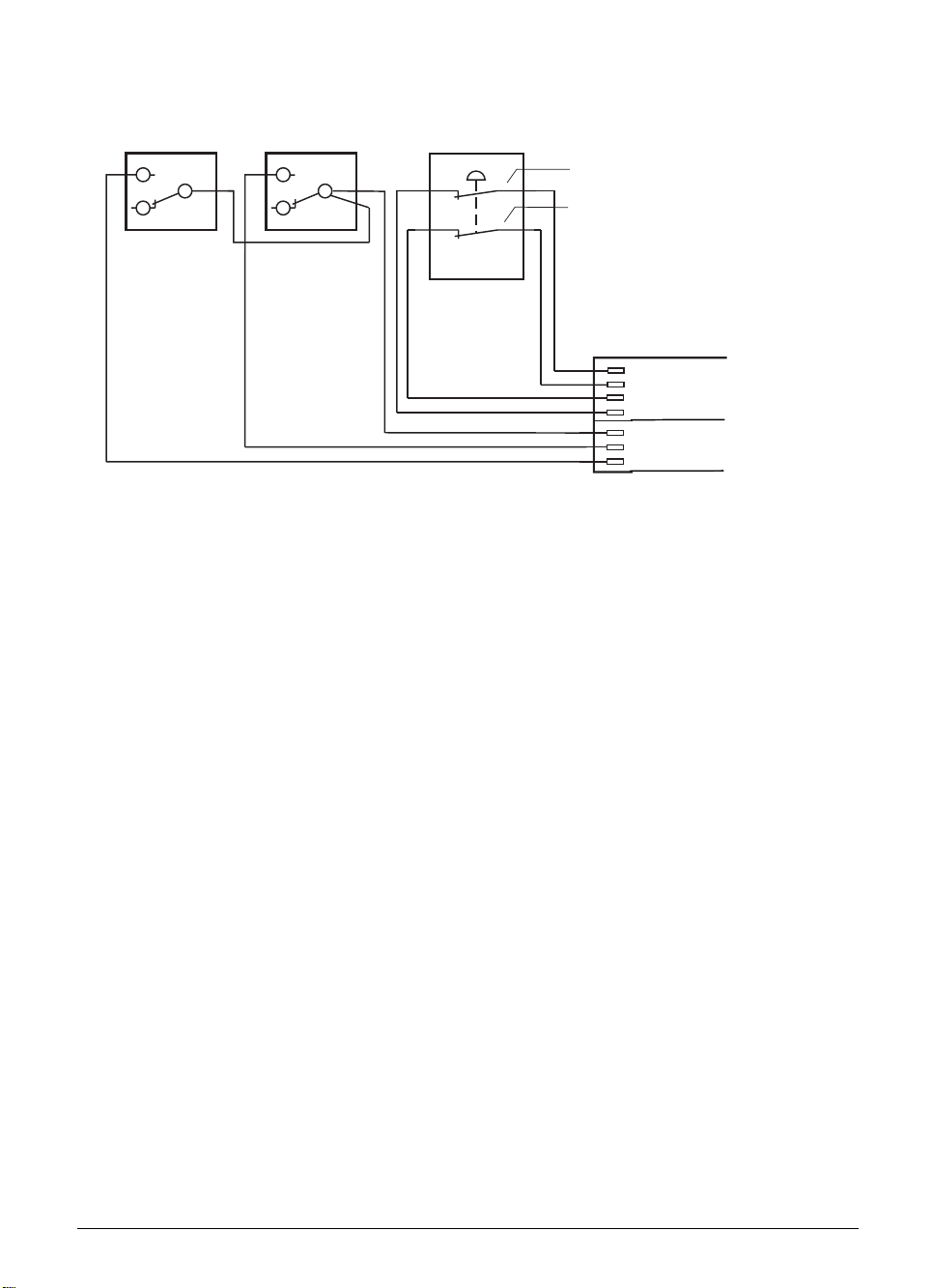

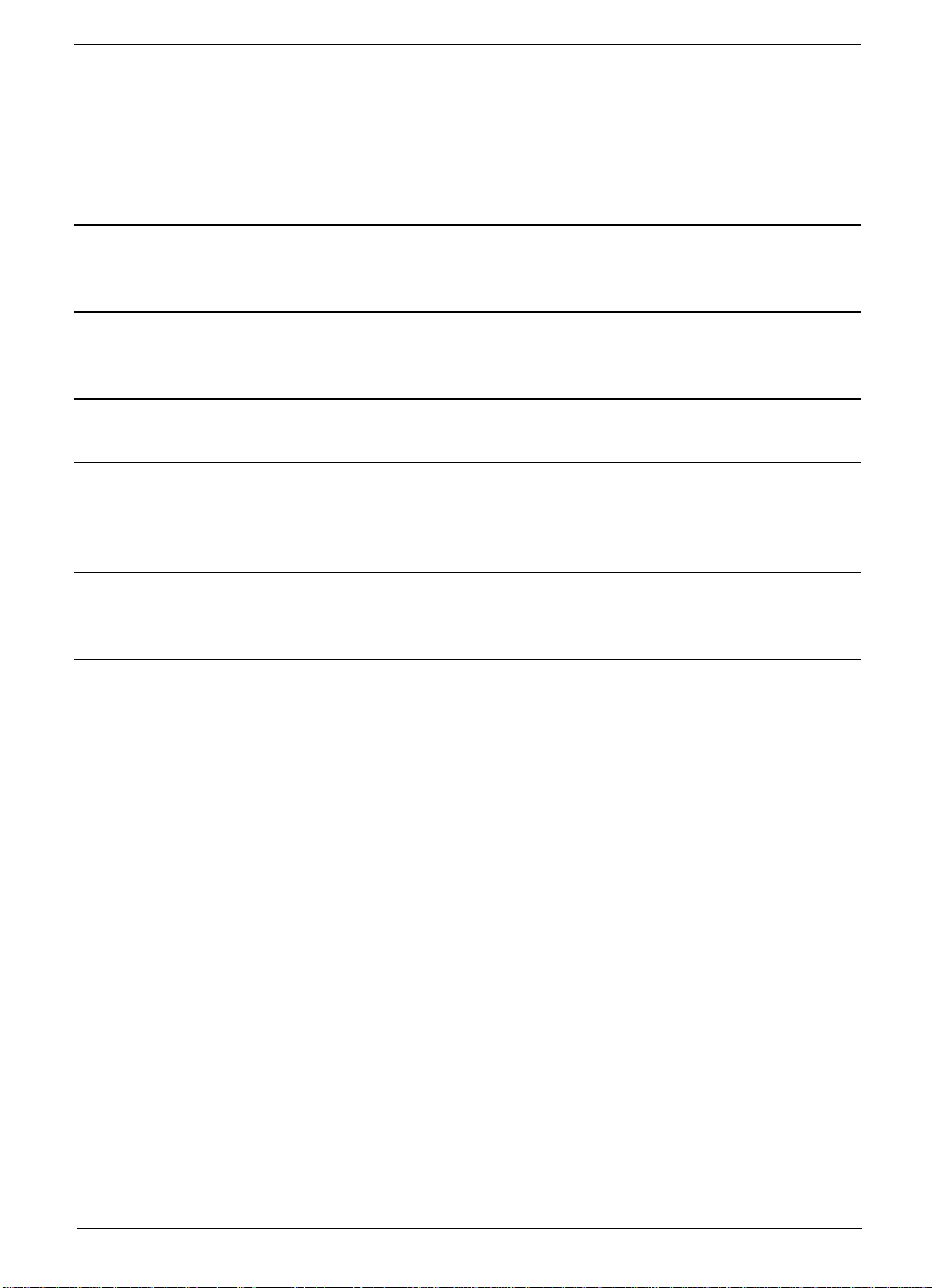

Internal wiring of the contacts for the HR 410 permissive buttons and the EMERGENCY STOP

button:

1

1

2

2

NOT - AUS

Kontakt 2

Kontakt 1

Zustimmtaste 1

Kontakt 1

Kontakt 1

Kontakt 2

Kontakt 2

Kontakt 2

Kontakt 1

Kontakt 1+2

X2

X1

4

2

1

3

1

2

3

Kabeladapter

Zustimmtaste 2

• When machine parameters are being downloaded via the V.24 interface, comments beginning

with the characters ";" or "*" can also be downloaded, either before or after the machine

parameter value.

• Machine parameter MP5020, bit 9 decides whether the control sends the EOT character after

receiving the ETX character.

• The error message "ERROR IN TRANSFERRED VALUE“ is displayed after a timeout is exceeded

during transfer via the V.24 interface.

• PLC Module 9036 expanded

With Module 9036, handwheel interpolation factors of all or of individual axes, and the values for

the jog positioning can be transferred from the PLC to the NC.

Calling the module:

PS B/W/D/K PLC status information type

PS B/W/D/K PLC status value

CM 9036

PL B/W/D Messages that are stored in the STACK:

0: PLC status information was transferred

1: Incorrect PLC status information type

2: Transferred PLC status value incorrect

3: Writing inhibited (e.g. by MP)

The marker M3171 is set if there is an error in transfer.

Permissive button 1 Permissive button 2 EMERGENCY STOP

Contact 2

Contact 1

Cable adapter

Contact 2

Contact 1 X2

Contact 1

Contact 2

Contact 1+2

Contact 2 X1

Contact 1

1-4 TNC 360 Update Information No. 8 4/96

NC status information type: PLC status value:

0: Handwheel interpolation factor for X-axis 0 ... 10

1: Handwheel interpolation factor for Y-axis 0 ... 10

2: Handwheel interpolation factor for Z-axis 0 ... 10

3: Handwheel interpolation factor for 4th axis 0 ... 10

4: Handwheel interpolation factor for all axes 0 ... 10

5: Handwheel interpolation factor for all axes 0 ... 10

6: Select handwheel axis; X-axis 0

Y-axis 1

Z-axis 2

4th axis 3

7 to 9 reserved

10: Limit on jog increment 0 ... 50000 µm

-1 = Remove limit, activate last jog

increment

-2 = Remove limit, activate minimum from

PLC limit on jog increment and jog

increment input via NC

8/95 TNC 360 Update Information No. 7 1-1

Update Information No. 7

The new edition of the Technical Manual for TNC 360 incorporates the data from Update Information

issues No. 1 to 6 in the appropriate chapters and sections. The description of TNC 355 has been

deleted since this unit is no longer in our product program.

Please replace the complete contents of the manual.

We will continue to send new information on the hardware and software of the TNC 360. Please file

the Update Information issues here.

10/94 TNC 360/TNC 335 Update Information No. 6 1-1

Update Information No. 6

New PLC Input/Output Unit PL 410 B

In December the PLC I/O unit PL 410 will be replaced by the PL 410 B.

The PL 410 B provides the same number of switching inputs/output as on the PL 410.

The connector layout is compatible with the PL 410. The dimensions have changed slightly

near the connections X15 to X22.

In contrast to the PL 410, the PL 410 B will be available in two versions. The following version

can be connected to the TNC 360:

PL 410 B Id.-Nr. 263 371 12

64 PLC inputs

31 PLC outputs

1 output “Control is operational“

The logic unit must be connected to the PL 410 B with a new connecting cable.

Connecting cable LE 360C/ PL 410 B: Id.-Nr. 289 111 ..

Max. 20 m

7/94 TNC 360/TNC 335 Update Information No. 5 1-1

Update Information No. 5

For NC software types 260 02 and 280 49, software version 13 was released in mid-June1994,

software version 14 at the end of June, and software version 15 at the beginning of July.

Software version 13 contains the following enhancements:

The input range for machine parameter MP1350 (type of reference mark approach) was

expanded. An input value of 3 selects encoders with distance-coded reference marks, and

thedirection of traverse reverses when the trip dog for the reference end position is crossed.

Data transfer in blockwise mode (ACK/NAK protocol) could be interrupted if the control

characters STX or ETB were transmitted incorrectly. Since the TNC did not know the cause of

the interruption, it sends NAK (after a delay in which no further data are transferred) if a block

was not completely recognized due to a faulty STX or ETB.

If ACK is not received within a certain time, the error message TRANSFERRED DATA

INCORRECT N is generated.

If bit 3 in machine parameter MP7641 is set, the electronic handwheel is selected in each

operating mode (initially before REF traversing) to be able to interrogate the inputs of the

handwheel keys (except axis keys) in the PLC. The axis keys on the handwheel and the

handwheel impulses do not become active until handwheel mode is selected. After an error the

handwheel is not selected again until the handwheel key is pressed.

If the operating voltage of the control is outside the limit values, the blinking error message

PROCESSOR CHECK ERROR M is displayed.

The input range of machine parameter MP4220 has been expanded to 0 ... 65535.

The memory for the executable PLC program has been increased from 28K bytes to 32K bytes.

The value for the analog voltage of the analog input at connector X8 is transferred to word

W392.

The meaning of machine parameter MP7225 (automatic block generation with the capture

actual position key or with PLC marker M2829) has been changed as follows:

MP7225 = 1 : Block generation with the capture actual position key

MP7225 = 2 : Block generation with PLC marker M2829

MP7225 = 0 : No block generation

The resolution of the feed rate display depends on the programmed feed rate:

Feed rate ≤ 31 999 mm/min (previously 29 999 mm/min): display step 2 mm/min

Feed rate > 31 999 mm/min (previously 29 999 mm/min): display step 20 mm/min

Software version 14 was released to correct the following error:

If a STOP and an M function for PLC positioning were executed in one NC block, in the

following block an M function that becomes effective at the beginning of the block (e.g., M3)

was not executed!

1-2 TNC 360/TNC 335 Update Information No. 5 7/94

Software version 15 was released to correct the following error:

### If, in an OEM cycle that was run from the EPROM, the feed rate was defined via Q parameter,

a greatly excessive feed rate was ouput.

2/94 TNC 360/TNC 335 Update Information No. 4 1-1

Update Information No. 4

In late February 1994, software version 12 was released for the NC software 260 02 and 280 49.

Note:

In software version 11, the deceleration ramp is too flat when the feed rate is changed at constant

contour transitions during operation with feed precontrol. This error was corrected in software

version 12.

Software version 11 must be replaced by software version 12!

No new features were introduce in software version 12.

1/94 TNC 360/TNC 335 Update information No. 3 1-1

Update Information No. 3

Software version 11 for software types 260 02 and 280 49 was released at the end of January 1994.

Software version 10 was not released for general distribution.

The following improvements were made since version 9:

•

Machine parameter 7411 defines whether during execution of the TOUCH-PROBE block the

current compensation values for probe length and radius should be taken from the central tool

file or from the calibration process.

MP7411 = 1 : Probe length and radius values from the tool file

MP7411 = 0 : Probe length and radius values from the calibration process

MP 7411 is also effective for tool length compensation in the digitizing cycles. This machine

parameter was already available in version 08, but it was not documented.

•

Machine parameter MP7225 was introduced for automatic generation of NC blocks in the

PROGRAMMING AND EDITING mode. With the "actual position capture" key (teach-in) it is now

possible to generate a positioning block in plain language dialog (not in ISO mode) with a

maximum of 3 axes and without feed rate, radius compensation or M-functions. This positioning

block is inserted below the currently addressed block in the selected NC part program. The

current actual position values become the nominal position values. The axis is selected in the

dialog "AXIS SELECTION =" in the MOD operating mode. Here up to 3 out of 4 axes can be

selected by pressing the corresponding axis keys.

MP7225 = 1 : Block generation with the actual-position-capture key (teach-in)

MP7225 = 2 : Block generation with the actual-position-capture key or with the PLC marker

M2829 (the marker is reset by the NC)

MP7225 = 0 : No block generation or axis selection possible.

•

If the machine parameters are erased, the RS-232-C/V.24 interface is now preset to FE mode.

•

PLC inputs I160 to I175 (HR 332 handwheel) now generate signal edges. The positive edge is

assigned to markers M1660 to M1675, the negative flank to markers M1860 to M1875.

•

If machine parameter MP7641, Bit 2 = 1, the interpolation factor for the handwheel can be set

both from the keyboard as well as from PLC module 9036. If Bit 2 = 0, the machine parameter

functions as before (input either from the keyboard or from PLC module 9036).

•

The NC saves the code number entered in the MOD mode in Doubleword D276.

•

Machine parameter MP810 defines the modulo value for reducing the position values of the

auxiliary axes. Machine parameter MP7470 has no effect on auxiliary axes. Rotary axes as NC

axes are always reduced to the range 0° to 359.999°. Machine parameter MP810 was already

available in version 08, but it was not documented.

1-2 TNC 360/TNC 335 Update information No. 3 1/94

•

The new PLC module 9124 makes it possible to set a feed rate override value for secondary

axes. The override value can lie between 0% and 100% (resolution 0.01 %) and must be

transferred as a whole number (0 to 10 000). It can be set before the beginning of a movement

or during the movement of an auxiliary axis. If the control is reset, the NC presets an override

value of 100%.

Call :

PS B/W/D/K <Axis> (0..3 for X/Y/Z/4)

PS B/W/D/K <Override value> (0..10 000)

CM 9124

PL B/W/D <Error code>

0: Override was set

1: Invalid axis was entered

2: Axis is not defined as auxiliary axis

3: Override value is invalid

Error status after call: M3171 = 0 : Override was set

= 1 : Error condition see above

If more than one of the PLC modules 9120/9121/9123 for controlling the movement of auxiliary

axes is called within one PLC scan, only the last called PLC module is executed. The module

9124 can be called in addition to the above modules within one PLC scan, but it will always

become effective after the other module.

•

In PLC module 9036 (transferring PLC status information to the NC) the interpolation factor can

be set for all axes by transferring the value 4 or 5.

•

The PLC can inhibit the reference pulse for specific axes through Word W608 (bit-

coded,....4zyx).

Bit = 1 : Reference pulse is not evaluated

Bit = 0 : The next reference pulse is evaluated

•

By setting marker M2615 the reference mark of the spindle is evaluated again. The marker is

reset by the NC.

•

Marker 2510 fixes the spindle potentiometer setting at 100%. Marker M2511 has the same

effect on the feed rate potentiometer.

•

CC blocks in OEM cycles are effective only locally and are not transferred into the calling

program.

9/93 TNC 360/TNC 335 Update information No. 2 1-1

Update Information No. 2

In earl September 1993 the software version 09 was released for the software types 260 02 and

280 49.

The new version contains the following changes:

•

If marker M2612 (Suppress position exchange in the tool table) is set before a T strobe is set

(M2046), the position numbers are not exchanged. The PLC acknowledges the T strobe without

having exchanged in the tool magazine and resets the PLC marker M2612. The new tool

number is shown inverted and the associated tool data (length and radius) are activated. The

tool number is shown inverted in the status display until the tool has physically been changed. If

the control is switched off and on in this condition, the last exchanged tool becomes active

again.

•

During execution of cycle 13 (spindle orientation) the NC sets the new marker M2408. This

marker can be evaluated by the PLC for the spindle orientation and should afterwards be reset

by the PLC.

9/93 TNC 360/TNC 335 Update information No. 1 1-1

Update Information No. 1

1 Software

In July 1993 the following software was released:

260 02x 08 for insertion of 1M byte EPROMs

and 280 49x 08 for insertion of 2M byte EPROMs

The software numbers 280 49x 01 to 07 were not delivered. The new software version became

necessary because new logic units can also accommodate 2M byte EPROMs (see below in Section

2 "Hardware").

The new software version contains the following changes:

•

The PLC can limit the maximum feed rate through the doubleword D596. In order to ensure

compatibility to previous PLC programs the doubleword D596 is preset with the value

300 000 mm/min after control switch-on or after interruption of the PLC run.

The new feed rate is effective immediately!

The doubleword D596 has no effect with the new cycles "Tapping" (Cycle 2) and "Rigid Tapping"

(Cycle 17).

•

In the newly introduced machine parameter MP60, axes can be defined as auxiliary axes.

These axes cannot be moved by an NC program. They are controlled exclusively by the PLC.

All auxiliary axes work independently of each other. Auxiliary axes always move in trailing

mode. The following modules are available for the PLC to control the axes:

Module 9120: Positioning of auxiliary axes

Module 9121: Stopping the auxiliary axes

Module 9122: Status inquiry of auxiliary axes

Module 9123: Traversing the reference point of an auxiliary axes

•

Spindle orientation can be suppressed at the beginning of Cycle 17 "Rigid Tapping" with

machine parameter MP7160. At the beginning of the cycle, the spindle voltage is decelerated

with the ramp from MP3410.1 to the value 0 volts.

In this case it is not possible to cut into the same thread several times!

•

Up to 20 NC "tool def" blocks can be read-in during blockwise transfer without central tool

memory, whereby the tool def block must be read-in before the associated "tool call". When a

"PGM call" NC block is read-in or when a user cycle is called, the NC blocks with "tool def" are

considered up to the above mentioned limit and provided that the proper order is followed. A

violation of these preconditions releases the error message "TOO MANY TOOLS".

1-2 TNC 360/TNC 335 Update information No. 1 9/93

•

If bit 2 is set in machine parameter MP7300, the last inserted (programmed) tool is

automatically activated during switch-on.

•

By setting the static PLC marker M2612 the PLC can now prevent the exchange of pocket

numbers in the central tool memory during a P output.

•

Function FN19 was introduced, with which two numerical or Q parameter values with an

accuracy of 1/1000 (i.e., three places after the decimal point) are transferred into the PLC

doublewords D280 and D284. A value of 2.5, for example, is filed in the doublewords as 2500.

The unit of measure of the calling NC program is set in marker M2150 (millimeter=0/inch=1).

During transfer the NC sets the strobe marker M2149. The transfer must be acknowledged by

the PLC with the marker M2611.

•

The number of PLC labels was increased to 1024.

•

Marker M2614 was introduced. Setting this marker blocks the output of PLC functions

(M/S/T/Q output) by the NC. The marker is set and reset by the PLC; it is read by the NC.

•

Marker M2827 was introduced. It is set by the PLC and causes the following behavior in case

of an external EMERGENCY STOP and erasable positioning error:

Machining is not aborted ("control in operation" symbol off, strobe signal reset). Instead,

machining is merely interrupted as in an NC STOP (control-in-operation symbol blinks). This

permits machining to be resumed with NC START after the error has been corrected. This

marker functions only for the output of M/S/T/Q strobes.

•

Now a maximum of 32 Q parameters can be transferred for user cycles. To do this, the 'DLG-

DEF' or 'DLG-CALL' blocks must be programmed several times in the user cycle, whereby in

the third DLG block only the first five entries can be evaluated.

•

The following Q parameters were introduced:

Q114 current tool length

Q115 to Q118 measured values of the 4th axis after a programmed probing cycle

•

The type of tool compensation (R0/RR/RL/R+/R-) is stored in Q parameter Q123:

Q123 = 0 means R0

= 1 means RR

= 2 means RL

= 3 means R+

= 4 means R-

•

Application as positioning module:

If machine parameter MP 4010 = 1 is programmed (PLC program from RAM), no machine

parameters will be taken from the PLC EPROM when the positioning module is switched on. If

the CRC sum of the machine parameters is incorrect they will be taken from the PLC EPROM.

9/93 TNC 360/TNC 335 Update information No. 1 1-3

•

The software now supports PLC subprograms stored in the PLC-EPROM (translated PLC

code). With the PLC.EXE programming software from HEIDENHAIN such programs can be

written and on an external computer and filed in the PLC EPROM.

•

The incremental jog positioning can be activated or deactivated (dialog "JOG-INCREMENT: ...")

in the 'ELECTRONIC HANDWHEEL' operating mode by pressing the 'ELECTRONIC

HANDWHEEL' key, provided that marker M2498 is set.

•

In the 'PROGRAMMING AND EDITING' operating mode the electronic handwheel can be used

to move the axes, provided that in machine parameter MP7641 bit 1 = 1. The interpolation

factor (regardless of handwheel model) and the handwheel axis (for HR130) can be change

only in the 'ELECTRONIC HANDWHEEL' operating mode. A handwheel axis, once chosen,

remains in effect even when the operating mode is changed.

Simultaneous operation of the handwheel interface and the RS-232-C interface at differing

baud rates (38 400 and 19 200 baud) results in the error message "BAUD RATE NOT

POSSIBLE".

•

The current feed rate in mm/min is now available in the PLC.

•

Module 9150

During an active M/S/T output the PLC can use module 9150 to define an NC block, which is

then executed after the M/S/T strobe is acknowledged, before the control continues the NC

program. An NC block can also be defined if no program is being run. The block is then

executed immediately.

Call:

PS B/W/D/K <Instruction code>

PS B/W/D/K <Address of the parameter block in the B/W/D range>

CM 9150

PL B/W/D <Error code>

Error code: 0 = NC block was inserted

1 = NC program started, but no M/S/T strobe

2 = Unknown instruction code

3 = Incorrect address in B/W/D range

Error status after call: M3171 = 0 NC block was inserted

= 1 error condition see above

At present the instruction code <0> is implemented for TOOL CALL

Parameters :

B<Adr+0> active elements bit-coded

Bit 0 =1: Tool number, otherwise modal

Bit 1 =1: Tool axis, otherwise modal

Bit 2 =1: Spindle speed, otherwise modal

Bit 3 =0

Bit 4 =0

B<Adr+1> Tool axis (0/1/2/3 = X/Y/Z/IV)

W<Adr+2> Tool number

D <Adr+ 4> Spindle speed (Format 0.001 rpm)

1-4 TNC 360/TNC 335 Update information No. 1 9/93

•

Module 9120

Positioning an auxiliary axis

The positioning of an axis is started by presetting a target position (in the reference system), a

feed rate and a flag register. The axis is positioned without regard to other processes in the

control. There is no contour interpolation with other axes.

Conditions:

The given axis must be activated via MP10 and configured as an auxiliary axis via MP60.

The values for rapid traverse, analog voltage for rapid traverse, acceleration, etc., must be

properly set in the machine parameters.

For axes with automatic reduction (modulo value in MP810.x) the axis is always moved in the

shortest direction to the target position, unless the target position is entered as an incremental

value.

There is no checking for violations of the limit switch ranges!

The axis must be stationary. If the axis is already moving, the positioning must be terminated

beforehand with module 9121.

If the axis was in the reference point traversing mode, this state is canceled. The positioning

always builds on the momentary counter contents.

If the modules 9120, 9121 and 9122 are called several times during a PLC scan, only the last

instruction is executed.

If a "positioning error" status was set in this axis it is erased.

Potential errors:

A non-existent axis was transferred.

An axis was transferred that was not identified as an auxiliary axis in MP10 and MP60.

The axis is already moving.

Call:

PS B/W/D/K <Axis> (0 to 3 for X/Y/Z/4)

PS B/W/D/K <Target position> (in the reference system, Format 0.001mm)

PS B/W/D/K <Feed rate> (mm/min)

PS B/W/D/K <Flag register> Bit 0 = 1: incremental target position

= 0: absolute target position

CM9120

PL B/W/D <Error code>

0: Positioning was started

1: A non-existent axis was transferred

2: Axis is not configured as an auxiliary axis

3: The axis is already moving

4: Absolute position outside of the modulo range

Error status after call: M3171 = 0: Positioning was started correctly

= 1: Positioning was faulty

9/93 TNC 360/TNC 335 Update information No. 1 1-5

•

PLC MODULE 9121

Stopping a positioning with an auxiliary axis

A positioning started beforehand with modules 9120 or 9123 can be canceled at any time with

module 9121.

Conditions:

The given axis must be activated via MP10 and configured in MP60 as an auxiliary axis.

If modules 9120, 9121 and 9122 are called several times for the same axis during a PLC-scan,

only the last instruction will be executed.

Potential errors:

A non-existent axis was transferred.

An axis was transferred that was not configured in MP10 and MP60 as an auxiliary axis.

The given axis is already stationary.

Call:

PS B/W/D/K <Axis> (0 to 3 for X/Y/Z/4)

CM9121

PL B/W/D <Error code>

0: Positioning is canceled

1: A non-existent axis was transferred

2: Axis is not configured as an auxiliary axis

3: Axis was already stationary

Error status after call: M3171 = 0: Positioning was stopped

= 1: Faulty execution

•

PLC MODULE 9122

Inquiring the status of an auxiliary axis

For a certain axis a bit-coded status word is transferred that contains information on the

momentary operating state of this axis.

Conditions:

Status changes causes by commands that the PLC sends to control the auxiliary axes

(modules 9120, 9121, 9123) are not recognized until the next PLC scan.

After switch-on, bit 1 (axis over reference point) is erased.

It is possible to position the axis without traversing the reference point first.

1-6 TNC 360/TNC 335 Update information No. 1 9/93

Potential errors:

A non-existent axis was transferred.

Call:

PS B/W/D/K <Axis> (0 to 3 for X/Y/Z/4)

CM9122

PL B/W/D <Status>

Bit 0: 1= Axis is auxiliary axis

Bit 1: 1= Axis has traversed the reference point

Bit 2: 1= Axis is positioned

Bit 3: 1= Direction of motion is negative

Bit 4: 1= A positioning error has occurred

Error status after call: M3171 = 0: Status was transferred

= 1: Faulty execution

•

PLC MODULE 9123

Passing over the reference point of an auxiliary axis

The module starts positioning in a preset direction, which continues until a reference point is

found or the positioning is canceled with module 9121.

Conditions:

The given axis must be activated via MP10 and configured as an auxiliary axis via MP60.

The values for rapid traverse, analog voltage for rapid traverse, acceleration, etc., must be set

in the machine parameters.

There is no checking for violations of the limit switch ranges!

The axis must be stationary. If the axis is already moving, the positioning must be canceled

beforehand with module 9121.

The feed rate override is not included in the calculation.

The state "reference point not yet traversed" is set for the axis.

A reference point that already exists in this axis is erased, but not the numerical value of the

axis. This is not reinitialized until the reference point is found.

If modules 9120, 9121 and 9122 are called several times during a PLC scan, only the last

instruction is executed.

If a "positioning error" status was set in this axis it is erased.

The positioning is stopped as soon as the reference point is reached. Since the axis must

decelerate before it can stop, it comes to rest behind the reference point in the direction of

motion.

9/93 TNC 360/TNC 335 Update information No. 1 1-7

Potential errors:

A non-existent axis was transferred.

An axis was transferred that was not configured in MP10 and MP60 as an auxiliary axis.

The axis is already moving.

Call:

PS B/W/D/K <Axis> (0 to 3 for X/Y/Z/4)

PS B/W/D/K <Feed rate> (mm/min)

PS B/W/D/K <Flag register> Bit 0 = 1: negative traverse direction

= 0: positive traverse direction

CM9123

PL B/W/D <Error code>

0: Positioning was started

1: A non-existent axis was transferred

2: The axis is not configured as an auxiliary axis

3: The axis is already moving

Error status after call: M3171 = 0: Positioning was started

= 1: Faulty execution

2 Hardware

The part numbers of the LE 360C logic units that can accommodate 2M byte EPROMs are:

Id.-Nr. 270 641 3x for BE 212

Id.-Nr. 270 642 3x for BF 110

The 2-M byte EPROMs occupy only the sockets IC-P1 and IC-P2. IC-P3 and IC-P4 remain vacant.

The jumper located next to IC-P1 should then be inserted in the setting 2M!

You will receive Update Information issues on the TNC 360/TNC 335 hardware and software

whenever developments warrant. This information will then be included in Supplementary Issues

that you can integrate into the appropriate chapters of the Technical Manual.

8/95 TNC 360 2-1

Introduction – Contents 2

1 Hardware Concept 2-2

2 Features and Specifications 2-3

2.1 TNC 360 2-3

3 Software 2-6

3.1 NC Software 2-6

3.1.1 Software and hardware versions 2-7

3.1.2 Software option 2-8

3.2 PLC Software 2-8

3.3 EPROM sockets 2-9

2-2 TNC 360 1 Hardware Concept 8/95

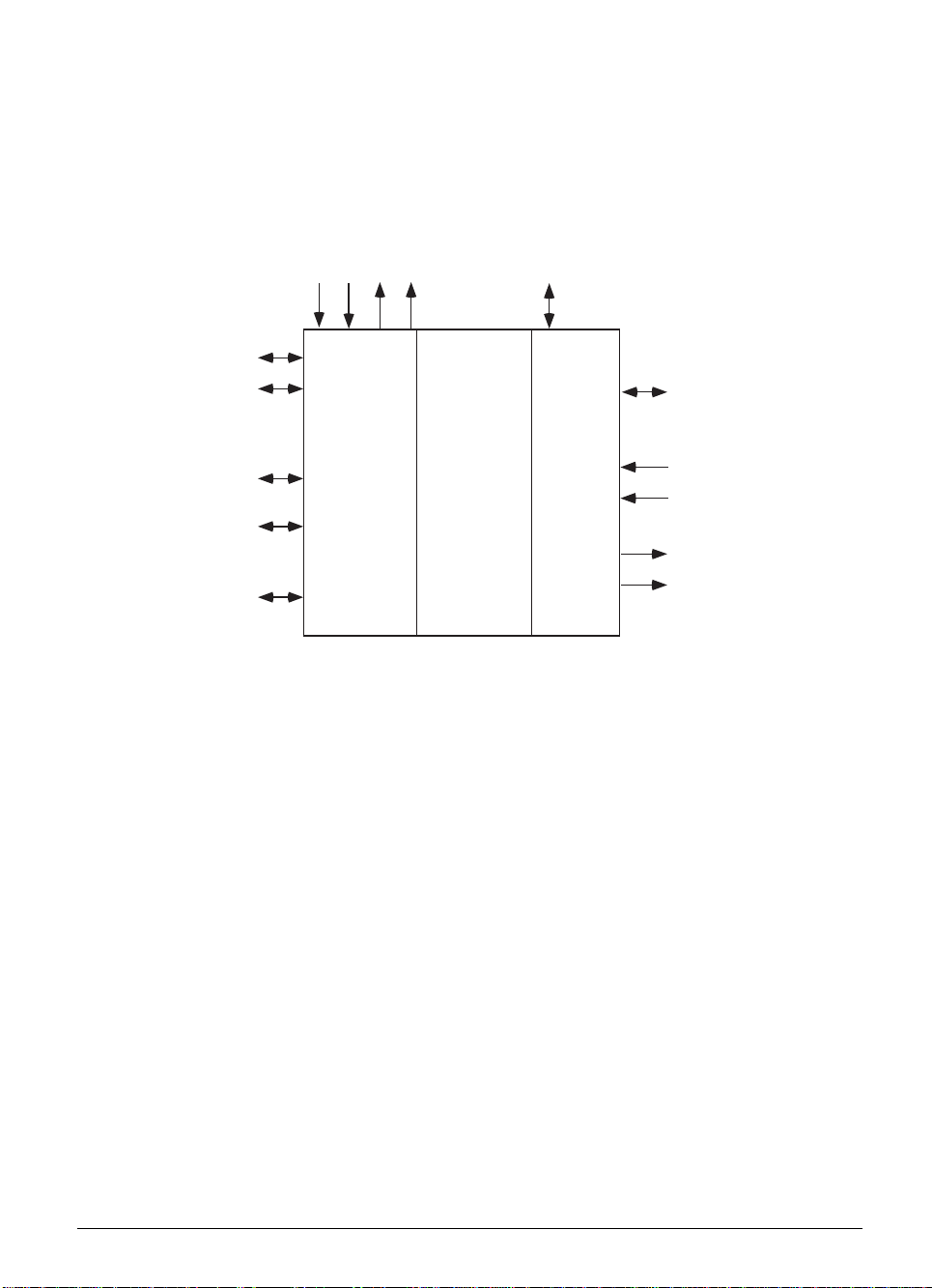

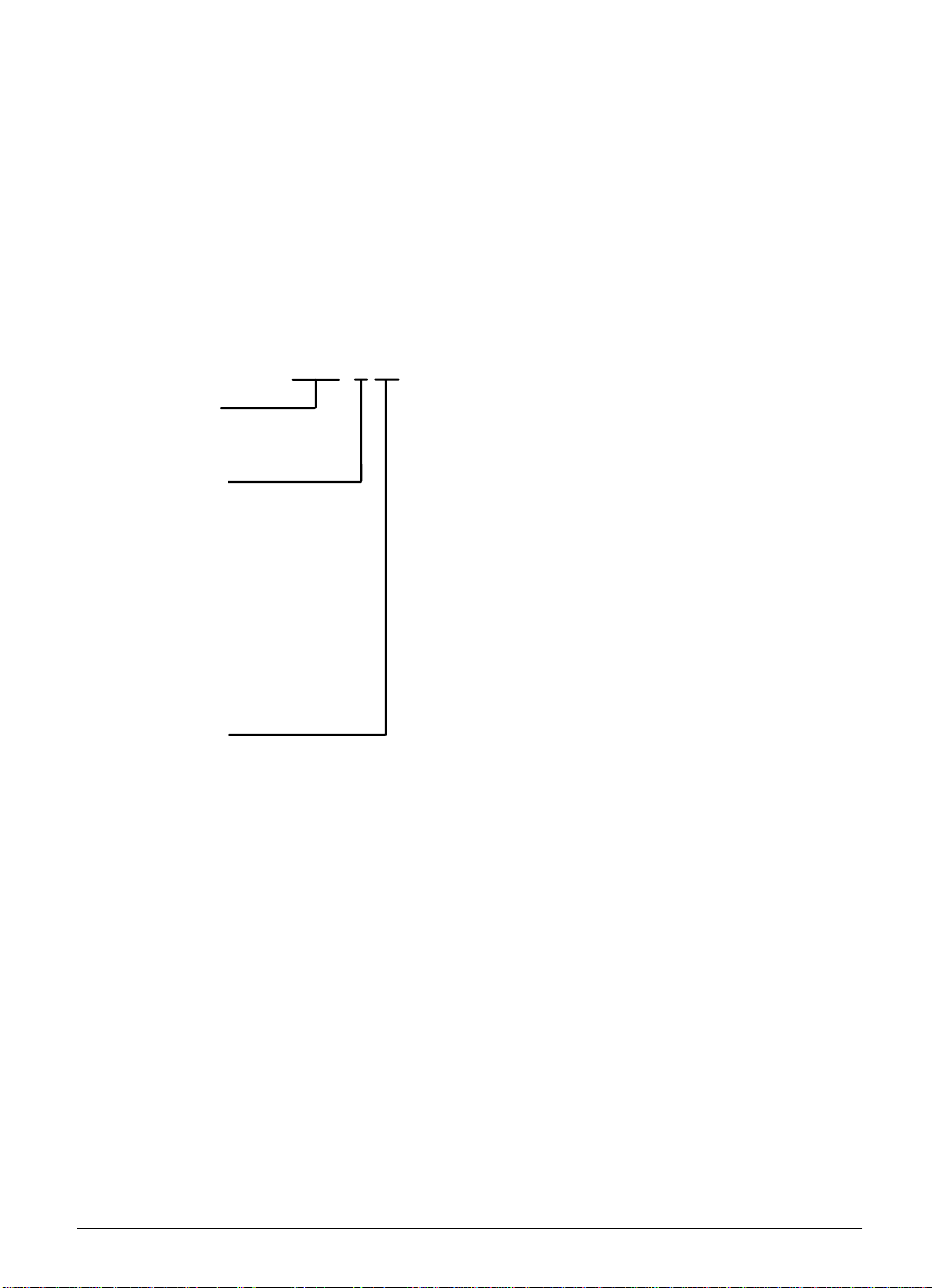

1 Hardware Concept

The HEIDENHAIN TNC 360 contouring control is designed for use with drilling and milling machines.

The HEIDENHAIN TNCs consist of several units. The principle subassembly is the logic unit. The

logic unit is joined to the other units and the TNC accessories by connecting cables.

Encoders

Noml. value outputs

PLC I/0 unit

Visual display unit

TNC keyboard unit

Touch probe

Electronic handwheel

Data interfaces

NC

PLC

Common

data area

Machine operating panel

PLC outputs

PLC inputs

• • •• • •

• • •• • •

The logic unit contains the electronics for both the NC and the PLC sections of the control.

The common data area contains the machine parameters and the PLC markers and words. The

machine parameters define the hardware-configuration of the machine (ranges of travel,

acceleration, number of axes etc.). The PLC markers and words are used for the exchange of

information between the NC and the PLC.

8/95 TNC 360 2 Features and Specifications 2-3

2 Features and Specifications

2.1 TNC 360

Components • Logic unit LE 360

• Keyboard TE 355 A, TE 355 B

• Color graphics VDU BE 212 (12 inch, 512 x 256 pixels)

• Flat luminescent screen BF 110 (192 mm x 120 mm, 640 x 400 pixels)

Control modes • Contouring control for 4 axes and spindle orientation

• Linear interpolation in 3 of 4 axes

• Circular interpolation in 2 of 4 axes

Program memory Buffered RAM memory (approx. 70 KB) for 32 NC programs,

central tool file, PLC program (if not filed in EPROM),

EPROM memory (128 KB) for PLC program, OEM cycles,

dialogues for OEM cycles, PLC error messages

Tool memory 99 tools

Operating modes • Manual operation

• Electronic handwheel /jog positioning

• Positioning by manual data input

• Program run, single block

• Program run, full sequence

• Programming and editing

• Test run (logical and graphical)

Programming In HEIDENHAIN conversational mode and according to ISO

Entry and display 1 µm, 5 µm, 10 µm, 50 µm, 100 µm

resolution

2-4 TNC 360 2 Features and Specifications 8/95

Programmable • Nominal position (absolute or incremental dimensions) in Cartesian or

functions polar coordinates

• Straight lines

• Circular arcs

• Helical interpolation

• Corner rounding, chamfering

• Tangential approach and departure from a contour

• Tool number, tool length and radius compensation

• Spindle speed

• Rapid traverse

• Feed-rate

• Program call from inside other programs

• Subprograms and repetition of program sections

• Fixed cycles for peck drilling, tapping (without floating tap holder),

slot milling, rectangular pocket milling, circular pocket milling

• Cycles for milling pockets with a free contour (SL cycles)

• Shifting and rotation of the coordinate system, mirroring, scaling,

dwell time, miscellaneous functions M, program stop

• Spindle orientation (to be implemented by the machine manufacturer)

• OEM specific cycles (to be defined by the manufacturer of the machine)

Parameter- Mathematical functions (=, +, −, x, :, sin, cos, angle α of r sin α and

programming r cos α,

, a² + b²), parameter comparison (=, ≠, >, <),

output of parameter values via the data interface

Digitizing • With TS 120 and TNC software expansion option

• Optional evaluation software for PCs

Maximum traverse ± 30 000 mm (1181 in.)

Maximum 300 m/min (11 810 ipm)

traversing speed

Data interfaces • RS-232-C/V.24; data transfer rates up to 38 400 baud

Cycle times Block processing time: 40 ms (for 3D straight lines without radius com-

pensation and with 100% PLC utilization)

Control loop cycle time: 6 ms

PLC cycle time: 24 ms

Position feedback Incremental HEIDENHAIN linear and angular encoders, preferably with

distance-coded reference marks, or incremental HEIDENHAIN rotary

encoders

8/95 TNC 360 2 Features and Specifications 2-5

Control • 4 inputs for position measuring systems (4 sinusoidal inputs)

inputs • 1 measuring system input for spindle orientation (square-wave input

signal)

• 1 input for electronic handwheel

• 1 input for 3D-touch probe system

• 55 PLC inputs + 1 control-is-ready input

• Additionally 64 PLC inputs on optional PLC I/O board PL 410 B

Control • 5 analogue outputs for the spindle and axes

outputs • 31 PLC outputs + 1 control-is-ready output

• Additionally 31 PLC outputs on optional PLC I/O board PL 410 B

Integrated PLC • Programming in the form of a list of instructions, max. 4000 PLC

commands

• Entry by HEIDENHAIN keyboard or data interface

Supply NC: 24 Vdc (See Chapter 3, Section 4.1)

voltage PLC: 24 Vdc

Power NC: approx. 27 W (with BE 212 connected)

consumption PLC: approx. 48 W (See Chapter 3, Section 4.1)

PL 410 B: approx. 480 W (See Chapter 3, Section 4.1)

BF 110: approx. 33 W

Environmental • Operating: LE/BE 0 to 45° C (32 to 113° F)

temperature BF 110: 0 to 40° C (32 to 104° F)

• Storage: –30 to 70° C (–22 to 158° F)

Approximate LE 360 C: 8.0 kg

weight TE 355: 1.6 kg

BE 212: 11.0 kg

BF 110: 1.7 kg

PL 410 B: 1.5 kg

HRA 110: 0.7 kg

2-6 TNC 360 3 Software 8/95

3 Software

The logic unit contains separate software for the NC section and the PLC section. The software is

identified by an 8-digit number.

After switching on the control, the NC and PLC software numbers are displayed on the screen. The

software number can also be directly requested with the aid of the MOD function.

3.1 NC Software

The 8-digit NC software number identifies the type of software, the dialogue language (language of

the country) and the software version.

Software-Typ

Landessprache

0 = deutsch

1 = tschechisch

2 = französisch

3 = italienisch

4 = spanisch

6 = schwedisch

7 = dänisch

8 = finnisch

9 = niederländisch

Software-Version

260 02 0 15

5 = portugiesisch

In addition to the above-listed languages, the TNC can always display English, which may be

selected via the machine parameter MP7230.

Software type

National language

Software version

0 = German

1 = Czech

2 = French

3 = Italian

4 = Spanish

6 = Swedish

7 = Danish

8 = Finnish

9 = Dutch

8/95 TNC 360 3 Software 2-7

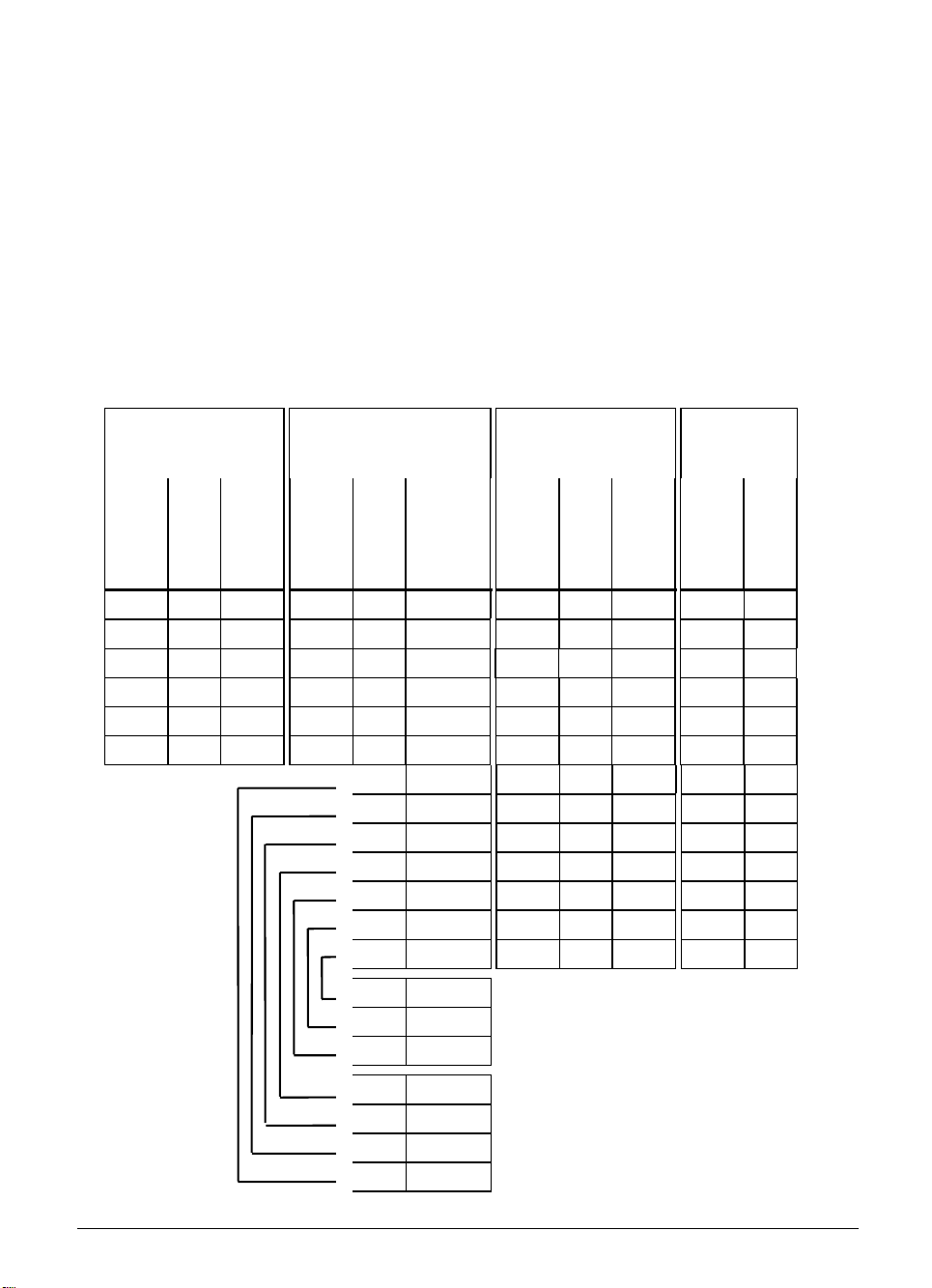

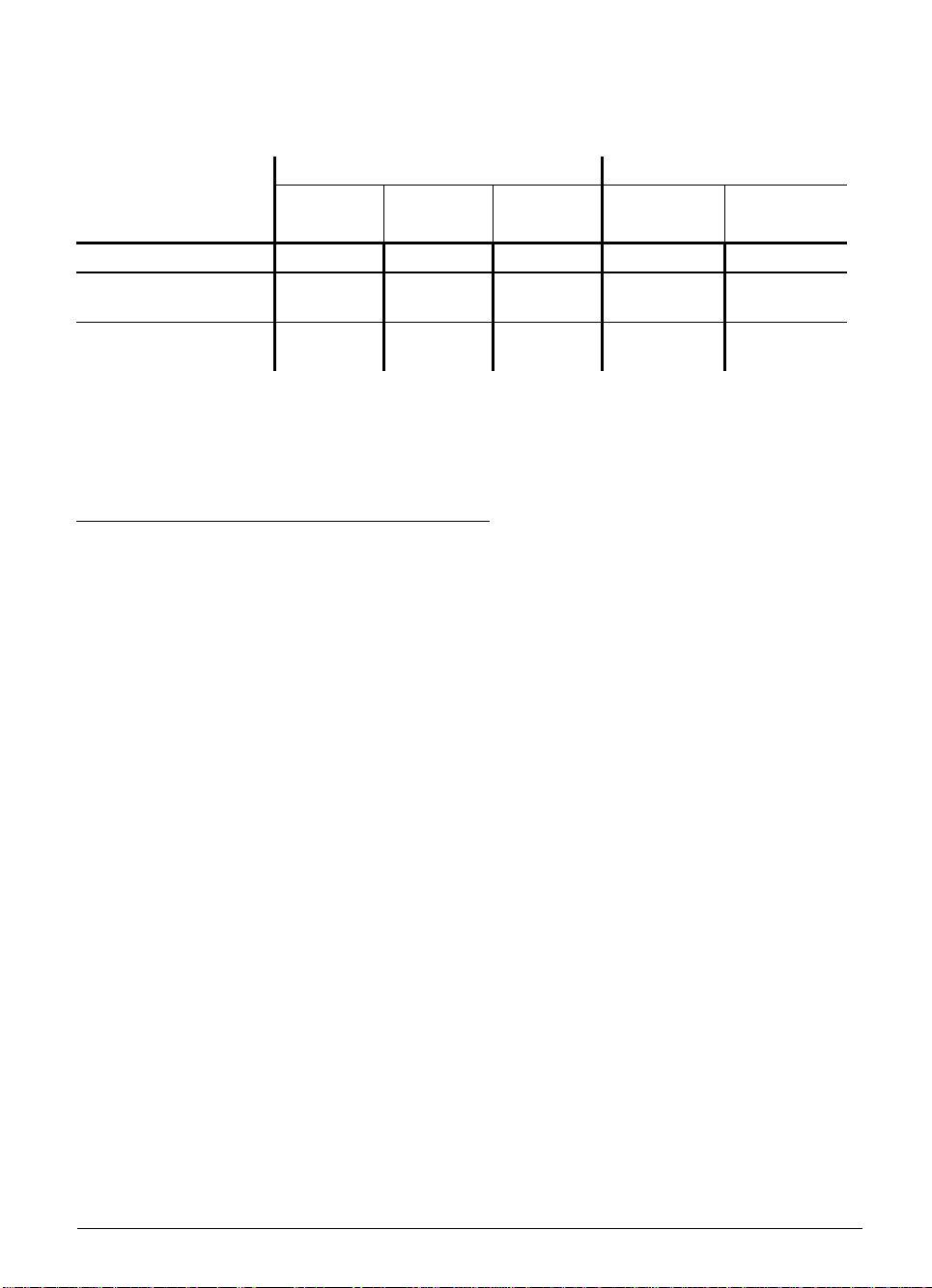

3.1.1. Software and hardware versions

HEIDENHAIN has manufactured several different hardware versions of the logic units LE 360 and LE

360 C. The following table shows which software is compatible with which hardware version:

Id.-Nr. LE 360 Id.-Nr. LE 360 C

Software Type

/Version

258 991 99 264 660 99 264 085 99 270 641 39

(BE 212)

270 642 39

(BF 110)

259 90x 02 to 05 02 to 05 02 to 05 06 -

260 02x (1-MB

EPROM)

- - from 07 from 07 from 07

280 49x (2-MB

EPROM)

- - - from 08 from 08

Only the software types 260 02 and 280 49 will continue to be developed.

Software Releases

HEIDENHAIN releases new versions of NC software in irregular intervals.

NC Software Version Release

259 90x 02 1/91 (Introduction)

259 90x 03 7/91

259 90x 04 3/92

259 90x 05 3/92

259 90x 06 7/92

260 02x 04 3/92 (Introduction)

260 02x 05 3/92

260 02x 06 7/92

260 02x 07 10/92

260 02x 08 7/93

260 02x 09 9/93

260 02x 10 Never released

260 02x 11 1/94

260 02x 12 2/94

260 02x 13 6/94

260 02x 14 6/94

260 02x 15 7/94

260 02x 16 3/95

280 49x 08 7/93 (Introduction)

280 49x 09 9/93

280 49x 10 Never released

280 49x 11 1/94

280 49x 12 2/94

280 49x 13 6/94

280 49x 14 6/94

280 49x 15 7/94

280 49x 16 3/95

2-8 TNC 360 3 Software 8/95

3.1.2 Software option

HEIDENHAIN offers the "Digitizing with TS 120" function as a software option (see Chapter "Machine

integration"). An additional software protection module is installed in controls supplied with this

software option. The Id.-Nr. of the LE 360 logic unit has the variant xxx xxx 79, while the LE 360 has

xxx xxx 34. If the software module is installed, the option number 262 351 01 is indicated on the

screen under the NC and PLC software numbers.

The “Digitizing with TS 120“ software option can be retrofitted. The kit is available under Id. Nr.

265 310 01.

The kit contains:

Software module (EPROM Id.-Nr. 262 351 01)

Printed circuit board

Sponge rubber

ID label

Mounting Instructions

3.2 PLC Software

The PLC software is produced by the manufacturer of the machine. Either HEIDENHAIN or the

manufacturer of the machine can store this software in EPROMs. HEIDENHAIN assigns PLC

software numbers to the machine manufacturers on request. HEIDENHAIN can archive the specific

PLC programs in a data bank, so that the installation of the correct PLC program is assured if a

control has to be exchanged.

Loading...

Loading...