HEIDENHAIN TNC 640 User Manual

TNC 640

User’s Manual

DIN/ISO Programming

NC Software 340590-04 340591-04 340595-04

English (en) 3/2014

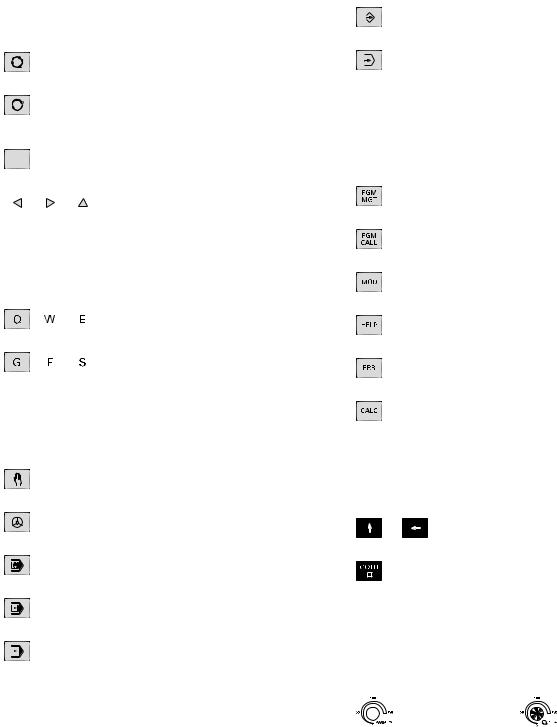

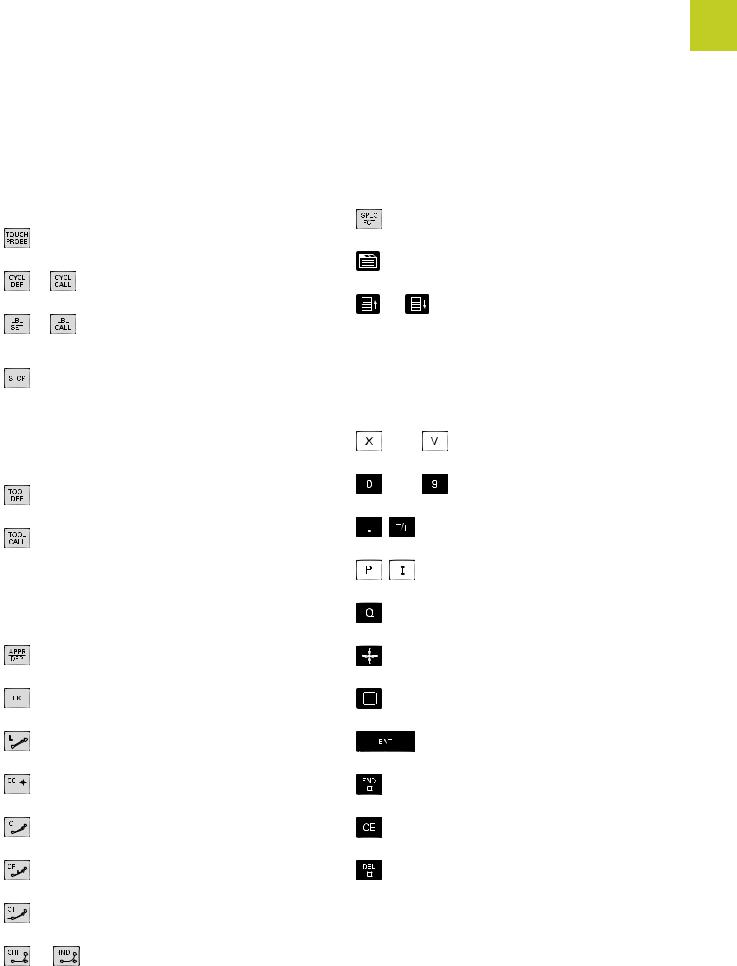

Controls of the TNC

Controls of the TNC

Controls of the TNC

Keys on visual display unit

Key Function

Select split screen layout

Toggle the display between machining and programming modes

Soft keys for selecting functions on screen

Shifting between soft-key rows

Shifting between soft-key rows

Alphanumeric keyboard

Key Function

File names, comments

File names, comments

DIN/ISO programming

DIN/ISO programming

Machine operating modes

Key Function

Manual operation

Electronic handwheel

Positioning with manual data input

Program run, single block

Program run, full sequence

Programming modes

Key Function

Programming

Test run

Program/file management,

TNC functions

Key Function

Select or delete programs and files, external data transfer

Define program call, select datum and point tables

Select MOD functions

Display help text for NC error messages, call TNCguide

Display all current error messages

Show calculator

Navigation keys

Key Function

Move highlight

Go directly to blocks, cycles and parameter functions

Potentiometer for feed rate and spindle speed

Feed rate |

Spindle speed |

|

|

2 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

Cycles, subprograms and program section repeats

Key Function

Define touch probe cycles

Define and call cycles

Enter and call labels for subprogramming and program section repeats

Enter program stop in a program

Tool functions

Key Function

Define tool data in the program

Call tool data

Programming path movements

Key Function

Approach/depart contour

FK free contour programming

Straight line

Circle center/pole for polar coordinates

Circular arc with center

Circle with radius

Circular arc with tangential connection

Chamfer/Corner rounding

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014

Special functions

Key Function

Show special functions

Select the next tab in forms

Up/down one dialog box or button

Entering and editing coordinate axes and numbers

Key Function

Select coordinate axes or enter

. . . them in a program

Numbers

. . .

Decimal point / Reverse algebraic sign

Polar coordinate input /

Incremental values

|

Q-parameter programming/ |

|

Q-parameter status |

|

Save actual position or values from |

|

calculator |

NO |

Skip dialog questions, delete |

ENT |

words |

|

|

|

Confirm entry and resume dialog |

|

Conclude block and exit entry |

Clear numerical entry or TNC error message

Abort dialog, delete program section

3

Controls of the TNC

Controls of the TNC

4 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

Fundamentals

Fundamentals

Fundamentals

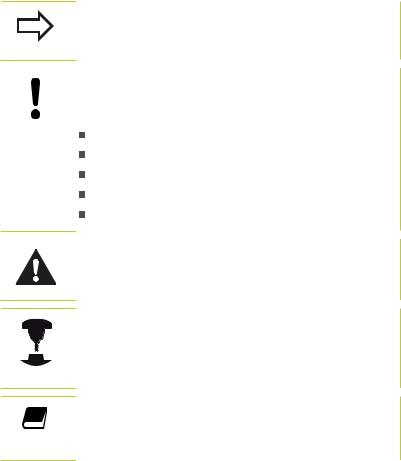

About this manual

About this manual

The symbols used in this manual are described below.

This symbol indicates that important information about the function described must be considered.

This symbol indicates that there is one or more of the following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine Danger to operator

This symbol indicates a possibly dangerous situation that may cause light injuries if not avoided.

This symbol indicates that the described function must be adapted by the machine tool builder. The function described may therefore vary depending on the machine.

This symbol indicates that you can find detailed information about a function in another manual.

Would you like any changes, or have you found any errors?

We are continuously striving to improve our documentation for you. Please help us by sending your requests to the following e-mail address: tnc-userdoc@heidenhain.de.

6 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

TNC model, software and features

TNC model, software and features

This manual describes functions and features provided by TNCs as of the following NC software numbers.

TNC model |

NC software number |

|

|

TNC 640 |

340590-04 |

|

|

TNC 640 E |

340591-04 |

|

|

TNC 640 Programming Station |

340595-04 |

The suffix E indicates the export version of the TNC. The export version of the TNC has the following limitations:

Simultaneous linear movement in up to 4 axes

The machine tool builder adapts the usable features of the TNC to his machine by setting machine parameters. Some of the functions described in this manual may therefore not be among the features provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

Tool measurement with the TT

Please contact your machine tool builder to become familiar with the features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer programming courses for the TNCs. We recommend these courses as an effective way of improving your programming skill and sharing information and ideas with other TNC users.

User's Manual for Cycle Programming:

All of the cycle functions (touch probe cycles and fixed cycles) are described in the Cycle Programming User’s Manual. Please contact HEIDENHAIN if you require a copy of this User's Manual. ID: 892905-xx

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

7 |

Fundamentals

Fundamentals

TNC model, software and features

Software options

The TNC 640 features various software options that can be enabled by your machine tool builder. Each option is to be enabled separately and contains the following respective functions:

Software option 1 (option number 08)

Rotary table machining |

■ |

Programming of cylindrical contours as if in two axes |

|

■ |

Feed rate in distance per minute |

|

|

|

Coordinate transformation |

■ |

Working plane, tilting the ... |

|

|

|

Interpolation |

■ |

Circle in 3 axes with tilted working plane (spacial arc) |

Software option 2 (option number 09) |

||

|

|

|

3-D machining |

■ |

Motion control with minimum jerk |

|

■ |

3-D tool compensation through surface normal vectors |

|

■ |

Using the electronic handwheel to change the angle of the swivel head |

|

|

during program run without affecting the position of the tool point. |

|

|

(TCPM = Tool Center Point Management) |

|

■ |

Keeping the tool normal to the contour |

|

■ |

Tool radius compensation perpendicular to traversing and tool direction |

|

|

|

Interpolation |

■ |

Linear in 5 axes (subject to export permit) |

HEIDENHAIN DNC (option number 18)

■Communication with external PC applications over COM component

Display step (Option number 23)

Input resolution and display |

■ |

Linear axes down to 0.01 µm |

step |

■ |

Rotary axes to 0.00001° |

|

Dynamic Collision Monitoring (DCM) software option (option number 40)

Collision monitoring in all |

■ |

The machine manufacturer defines objects to be monitored |

machine operating modes |

■ |

Three warning levels in manual operation |

|

||

|

■ |

Program interrupt during automatic operation |

|

■ |

Includes monitoring of 5-axis movements |

8 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

TNC model, software and features

DXF Converter software option (option number 42)

Extracting contour |

■ |

Supported DXF format: AC1009 (AutoCAD R12) |

|

programs and machining |

■ |

For contours and point patterns |

|

positions from DXF data. |

|||

■ |

Simple and convenient specification of reference points |

||

Extracting contour sections |

|||

from plain-language |

■ |

Select graphical features of contour sections from conversational |

|

programs. |

|

programs |

|

|

|

Adaptive Feed Control (AFC) software option (option number 45)

Function for adaptive feedrate control for optimizing the machining conditions during series production

■Recording the actual spindle power by means of a teach-in cut

■Defining the limits of automatic feed rate control

■Fully automatic feed control during program run

KinematicsOpt software option (option number 48)

Touch-probe cycles for automatic testing and optimization of the machine kinematics

■Backup/restore active kinematics

■Test active kinematics

■Optimize active kinematics

Mill-Turning software option (option number 50)

Functions for milling/turning ■ |

Switching between Milling/Turning mode of operation |

|

mode |

■ |

Constant cutting speed |

|

||

|

■ |

Tool-tip radius compensation |

|

■ |

Turning cycles |

Extended Tool Managment software option (option number 93)

■Extended tool management, python-based

Remote Desktop Manager software option (option number 133)

Remote operation of external computer units (e.g. Windows PC) via the TNC user interface

■Windows on a separate computer unit

■Incorporated in the TNC interface

Synchronizing Functions software option (option number 135)

Real Time Coupling (RTC) |

■ |

Coupling of axes |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

9 |

Fundamentals

Fundamentals

TNC model, software and features

Cross Talk Compensation (CTC) software option (option number 141)

Compensation of axis |

■ |

Determination of dynamically caused position deviation through axis |

couplings |

|

acceleration |

|

■ |

Compensation of the TCP |

Position Adaptive Control (PAC) software option (option number 142)

Changing control |

■ |

Changing of the control parameters depending on the position of the |

parameters |

|

axes in the working space |

|

■ |

Changing of the control parameters depending on the speed or |

|

|

acceleration of an axis |

Load Adaptive Control (LAC) software option (option number 143)

Dynamic changing of control |

■ |

Automatic determination of workpiece weight and frictional forces |

parameters |

■ |

Continuous adaptation of the parameters of the adaptive precontrolling |

|

||

|

|

to the actual weight of the workpiece during machining |

Active Chatter Control (ACC) software option (option number 145)

Fully automatic function for chatter control during machining

10 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

TNC model, software and features

Feature Content Level (upgrade functions)

Along with software options, significant further improvements of the TNC software are managed via the Feature Content Level upgrade functions. Functions subject to the FCL are not available simply by updating the software on your TNC.

All upgrade functions are available to you without surcharge when you receive a new machine.

Upgrade functions are identified in the manual with FCL n, where n indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable the FCL functions. For more information, contact your machine tool builder or HEIDENHAIN.

Intended place of operation

The TNC complies with the limits for a Class A device in accordance with the specifications in EN 55022, and is intended for use primarily in industrially-zoned areas.

Legal information

This product uses open source software. Further information is available on the control under

Programming and Editing operating mode

MOD function

License Info soft key

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

11 |

Fundamentals

Fundamentals

TNC model, software and features

New functions

New Functions 34059x-02

DXF files can be opened directly on the TNC in order to extract contours and point patterns ("Programming: Data transfer from DXF files or plain-language contours", page 229).

The active tool-axis direction can now be activated in manual mode and during handwheel superimposition as a virtual tool axis ("Superimposing handwheel positioning during program run: M118 ", page 340).

The machine manufacturer can now define any areas on the machine for collision monitoring ("Dynamic Collision Monitoring (software option)", page 351).

Writing and reading data in freely definable tables ("Freely definable tables", page 377).

The Adaptive Feed Control (AFC) function has been integrated ("Adaptive Feed Control Software Option (AFC)", page 357)

New touch probe cycle 484 for calibrating the wireless TT 449 tool touch probe (see User's Manual for Cycles).

The new HR 520 and HR 550 FS handwheels are supported ("Traverse with electronic handwheels", page 458).

New machining cycle 225 ENGRAVING (see User’s Manual for Cycle Programming)

New Active Chatter Control (ACC) software option ("Active Chatter Control (ACC; software option)", page 370).

New manual probing cycle "Center line as datum" ("Setting a center line as datum ", page 503).

New function for rounding corners ("Rounding corners: M197", page 346).

External access to the TNC can now be blocked with a MOD function ("External access", page 553).

12 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

TNC model, software and features

New Functions 34059x-02

The maximum number of characters for the NAME and DOC fields in the tool table has been increased from 16 to 32 ("Enter tool data into the table", page 164).

The columns AFC and ACC were added to the tool table ("Enter tool data into the table", page 164).

Operation and position behavior of the manual probing cycles has been improved ("Using 3-D touch probes ", page 482).

Predefined values can now be entered into a cycle parameter with the PREDEF function in cycles (see User’s Manual for Cycle Programming).

The status display has been expanded with the AFC tab ("Additional status displays", page 76).

The FUNCTION TURNDATA SPIN turning function has been expanded with an input option for maximum speed ("Program spindle speed", page 432).

A new optimization algorithm is now used with the KinematicsOpt cycles (see User’s Manual for Cycle Programming).

With Cycle 257, circular stud milling, a parameter is now available with which you can determine the approach position on the stud (see User's Manual for Cycle Programming)

With Cycle 256, rectangular stud, a parameter is now available with which you can determine the approach position on the stud (see User's Manual for Cycle Programming).

With the "Basic Rotation" probing cycle, workpiece misalignment can now be compensated for via a table rotation ("Compensation of workpiece misalignment by rotating the table", page 496)

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

13 |

Fundamentals

Fundamentals

TNC model, software and features

New functions 34059x-04

New special operating mode Retraction ("Retraction after a power interruption", page 540).

New graphic simulation ("Graphics ", page 522).

New MOD function "tool usage file" within the machine settings group ("Tool usage file", page 555).

New MOD function "set system time" within the systems settings group ("Set the system time", page 557).

New MOD group "graphic settings" ("Graphic settings", page 552).

With the new syntax for the adaptive feed control (AFC) you can start or end a teach-in step ("Recording a teach-in cut", page 362).

With the new cutting data calculator you can calculate the spindle speed and the feed rate ("Cutting data calculator", page 139).

In the TURNDATA function, you can now define the effect of the tool compensation ("Tool compensation in the program", page 434).

Now you can activate and deactivate the active chatter compensation (ACC) by soft key ("Activating/deactivating ACC", page 371).

New if/then decisions were introduced in the jump commands ("Programming if-then decisions", page 271).

The character set of the fixed cycle 225 Engraving was expanded by more characters and the diameter sign (see User's Manual for Cycle Programming).

New fixed cycle 275 trochoidal milling (see User’s Manual for Cycle Programming)

New fixed cycle 233 ENGRAVING (see User’s Manual for Cycle Programming)

In the drilling cycles 200, 203 and 205 the parameter Q395 BEZUG DEPTH REFERENCE was introduced in order to evaluate the T ANGLE (see User's Manual for Cycle Programming).

The probing cycle 4 MEASURING IN 3-D was introduced (see User's Manual for Cycle Programming).

14 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

TNC model, software and features

Changed functions 34059x-04

The turning tool table was expanded by the column NAME ("Tool data", page 435).

Now up to 4 functions are allowed in an NC block ("Fundamentals", page 328).

New soft keys for value transfer have been introduced in the pocket calculator ("Operation", page 136).

The distance-to-go display can now also be displayed in the input system ("Position Display Types", page 558).

Cycle 241 SINGLE-LIP DEEP HOLE DRILLING was expanded by several input parameters (see User's Manual for Cycle Programming).

Cycle 404 was expanded by the parameter Q305 NUMBER IN TABLE (see User's Manual for Cycle Programming).

In the thread milling cycles 26x an approaching feed rate was introduced (see User's Manual for Cycle Programming).

In Cycle 205 Universal Pecking you can now use parameter Q208 to define a feed rate for retraction (see User's Manual for Cycle Programming).

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

15 |

Fundamentals

Fundamentals

TNC model, software and features

16 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

Contents |

|

|

1 |

First Steps with the TNC 640....................................................................................................... |

49 |

2 |

Introduction..................................................................................................................................... |

69 |

3 |

Programming: Fundamentals, file management......................................................................... |

89 |

4 |

Programming: Programming aids.............................................................................................. |

131 |

5 |

Programming: Tools..................................................................................................................... |

159 |

6 |

Programming: Programming contours...................................................................................... |

195 |

7 |

Programming: Data transfer from DXF files or plain-language contours............................... |

229 |

8 |

Programming: Subprograms and program section repeats.................................................... |

247 |

9 |

Programming: Q Parameters....................................................................................................... |

263 |

10 |

Programming: Miscellaneous functions..................................................................................... |

327 |

11 |

Programming: Special functions................................................................................................. |

347 |

12 |

Programming: Multiple Axis Machining.................................................................................... |

383 |

13 |

Programming: Pallet editor......................................................................................................... |

421 |

14 |

Programming: Turning Operations............................................................................................. |

427 |

15 |

Manual operation and setup....................................................................................................... |

453 |

16 |

Positioning with Manual Data Input.......................................................................................... |

515 |

17 |

Test run and program run........................................................................................................... |

521 |

18 |

MOD functions.............................................................................................................................. |

549 |

19 |

Tables and overviews................................................................................................................... |

579 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

17 |

Contents

Contents

18 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

1 First Steps with the TNC 640....................................................................................................... |

49 |

|

1.1 |

Overview................................................................................................................................................ |

50 |

1.2 |

Machine switch-on................................................................................................................................ |

50 |

|

Acknowledging the power interruption and moving to the reference points.......................................... |

50 |

1.3 |

Programming the first part.................................................................................................................. |

51 |

|

Selecting the correct operating mode.................................................................................................... |

51 |

|

The most important TNC keys................................................................................................................ |

51 |

|

Creating a new program/file management............................................................................................. |

52 |

|

Defining a workpiece blank.................................................................................................................... |

53 |

|

Program layout........................................................................................................................................ |

54 |

|

Programming a simple contour............................................................................................................... |

55 |

|

Creating a cycle program........................................................................................................................ |

57 |

1.4 |

Graphically testing the first part......................................................................................................... |

59 |

|

Selecting the correct operating mode.................................................................................................... |

59 |

|

Selecting the tool table for the test run................................................................................................. |

59 |

|

Choosing the program you want to test................................................................................................ |

60 |

|

Selecting the screen layout and the view.............................................................................................. |

60 |

|

Starting the test run................................................................................................................................ |

61 |

1.5 |

Setting up tools.................................................................................................................................... |

62 |

|

Selecting the correct operating mode.................................................................................................... |

62 |

|

Preparing and measuring tools............................................................................................................... |

62 |

|

The tool table TOOL.T............................................................................................................................ |

63 |

|

The pocket table TOOL_P.TCH................................................................................................................ |

64 |

1.6 |

Workpiece setup.................................................................................................................................... |

65 |

|

Selecting the correct operating mode.................................................................................................... |

65 |

|

Clamping the workpiece......................................................................................................................... |

65 |

|

Datum setting with 3-D touch probe...................................................................................................... |

66 |

1.7 |

Running the first program................................................................................................................... |

67 |

|

Selecting the correct operating mode.................................................................................................... |

67 |

|

Choosing the program you want to run................................................................................................. |

67 |

|

Start the program.................................................................................................................................... |

67 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

19 |

Contents

Contents

2 Introduction..................................................................................................................................... |

69 |

|

2.1 |

The TNC 640.......................................................................................................................................... |

70 |

|

Programming: HEIDENHAIN conversational and ISO formats............................................................... |

70 |

|

Compatibility............................................................................................................................................ |

70 |

2.2 |

Visual display unit and operating panel............................................................................................ |

71 |

|

Display screen......................................................................................................................................... |

71 |

|

Setting the screen layout........................................................................................................................ |

71 |

|

Control Panel........................................................................................................................................... |

72 |

2.3 |

Modes of Operation.............................................................................................................................. |

73 |

|

Manual Operation and El. Handwheel.................................................................................................... |

73 |

|

Positioning with Manual Data Input........................................................................................................ |

73 |

|

Programming........................................................................................................................................... |

73 |

|

Test Run.................................................................................................................................................. |

74 |

|

Program Run, Full Sequence and Program Run, Single Block................................................................ |

74 |

2.4 |

Status displays...................................................................................................................................... |

75 |

|

"General" status display........................................................................................................................... |

75 |

|

Additional status displays........................................................................................................................ |

76 |

2.5 |

Window Manager.................................................................................................................................. |

83 |

|

Task bar................................................................................................................................................... |

84 |

2.6 |

SELinux security software.................................................................................................................... |

85 |

2.7 |

Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels...................................... |

86 |

|

3-D touch probes.................................................................................................................................... |

86 |

|

HR electronic handwheels...................................................................................................................... |

87 |

20 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

3 Programming: Fundamentals, file management......................................................................... |

89 |

|

3.1 |

Fundamentals........................................................................................................................................ |

90 |

|

Position encoders and reference marks................................................................................................. |

90 |

|

Reference system................................................................................................................................... |

90 |

|

Reference system on milling machines.................................................................................................. |

91 |

|

Designation of the axes on milling machines......................................................................................... |

91 |

|

Polar coordinates..................................................................................................................................... |

92 |

|

Absolute and incremental workpiece positions...................................................................................... |

93 |

|

Selecting the datum................................................................................................................................ |

94 |

3.2 Opening programs and entering......................................................................................................... |

95 |

|

|

Organization of an NC program in DIN/ISO format................................................................................ |

95 |

|

Define the blank: G30/G31..................................................................................................................... |

96 |

|

Opening a new part program................................................................................................................. |

97 |

|

Programming tool movements in DIN/ISO............................................................................................. |

99 |

|

Actual position capture.......................................................................................................................... |

100 |

|

Editing a program.................................................................................................................................. |

101 |

|

The TNC search function...................................................................................................................... |

104 |

3.3 |

File manager: Fundamentals.............................................................................................................. |

106 |

|

Files....................................................................................................................................................... |

106 |

|

Displaying externally generated files on the TNC................................................................................. |

108 |

|

Data Backup.......................................................................................................................................... |

108 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

21 |

Contents

Contents

3.4 Working with the file manager......................................................................................................... |

109 |

Directories............................................................................................................................................. |

109 |

Paths...................................................................................................................................................... |

109 |

Overview: Functions of the file manager............................................................................................. |

110 |

Calling the file manager........................................................................................................................ |

111 |

Selecting drives, directories and files................................................................................................... |

112 |

Creating a new directory...................................................................................................................... |

113 |

Creating a new file................................................................................................................................ |

113 |

Copying a single file.............................................................................................................................. |

113 |

Copying files into another directory...................................................................................................... |

114 |

Copying a table..................................................................................................................................... |

115 |

Copying a directory............................................................................................................................... |

115 |

Choosing one of the last files selected................................................................................................ |

116 |

Deleting a file........................................................................................................................................ |

117 |

Deleting a directory............................................................................................................................... |

117 |

Tagging files.......................................................................................................................................... |

118 |

Renaming a file..................................................................................................................................... |

119 |

Sorting files........................................................................................................................................... |

119 |

Additional functions............................................................................................................................... |

120 |

Additional tools for management of external file types........................................................................ |

121 |

Data transfer to/from an external data medium................................................................................... |

126 |

The TNC in a network.......................................................................................................................... |

128 |

USB devices on the TNC...................................................................................................................... |

129 |

22 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

4 Programming: Programming aids.............................................................................................. |

131 |

|

4.1 |

Adding comments............................................................................................................................... |

132 |

|

Application............................................................................................................................................. |

132 |

|

Entering comments during programming............................................................................................. |

132 |

|

Inserting comments after program entry............................................................................................. |

132 |

|

Entering a comment in a separate block.............................................................................................. |

132 |

|

Functions for editing of the comment.................................................................................................. |

133 |

4.2 |

Display of NC Programs..................................................................................................................... |

134 |

|

Syntax highlighting................................................................................................................................ |

134 |

|

Scrollbar................................................................................................................................................. |

134 |

4.3 |

Structuring programs.......................................................................................................................... |

135 |

|

Definition and applications.................................................................................................................... |

135 |

|

Displaying the program structure window / Changing the active window............................................ |

135 |

|

Inserting a structuring block in the (left) program window................................................................... |

135 |

|

Selecting blocks in the program structure window.............................................................................. |

135 |

4.4 |

Calculator............................................................................................................................................. |

136 |

|

Operation............................................................................................................................................... |

136 |

4.5 |

Cutting data calculator....................................................................................................................... |

139 |

|

Application............................................................................................................................................. |

139 |

4.6 |

Programming graphics....................................................................................................................... |

142 |

|

Generate/do not generate graphics during programming..................................................................... |

142 |

|

Generating a graphic for an existing program...................................................................................... |

142 |

|

Block number display ON/OFF.............................................................................................................. |

143 |

|

Erasing the graphic............................................................................................................................... |

143 |

|

Showing grid lines................................................................................................................................. |

143 |

|

Magnification or reduction of details.................................................................................................... |

144 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

23 |

Contents

Contents

4.7 Error messages.................................................................................................................................... |

145 |

Display of errors.................................................................................................................................... |

145 |

Open the error window........................................................................................................................ |

145 |

Closing the error window..................................................................................................................... |

145 |

Detailed error messages....................................................................................................................... |

146 |

INTERNAL INFO soft key...................................................................................................................... |

146 |

Clearing errors....................................................................................................................................... |

147 |

Error log................................................................................................................................................. |

147 |

Keystroke log......................................................................................................................................... |

148 |

Informational texts................................................................................................................................ |

149 |

Saving service files............................................................................................................................... |

149 |

Calling the TNCguide help system....................................................................................................... |

150 |

4.8 TNCguide context-sensitive help system......................................................................................... |

151 |

Application............................................................................................................................................. |

151 |

Working with the TNCguide................................................................................................................. |

152 |

Downloading current help files............................................................................................................. |

156 |

24 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

5 Programming: Tools..................................................................................................................... |

159 |

|

5.1 |

Entering tool-related data.................................................................................................................. |

160 |

|

Feed rate F............................................................................................................................................ |

160 |

|

Spindle speed S.................................................................................................................................... |

161 |

5.2 |

Tool data............................................................................................................................................... |

162 |

|

Requirements for tool compensation................................................................................................... |

162 |

|

Tool number, tool name........................................................................................................................ |

162 |

|

Tool length L......................................................................................................................................... |

162 |

|

Tool radius R......................................................................................................................................... |

162 |

|

Delta values for lengths and radii......................................................................................................... |

163 |

|

Entering tool data into the program..................................................................................................... |

163 |

|

Enter tool data into the table............................................................................................................... |

164 |

|

Importing tool tables............................................................................................................................. |

172 |

|

Pocket table for tool changer................................................................................................................ |

173 |

|

Call tool data......................................................................................................................................... |

176 |

|

Tool change........................................................................................................................................... |

178 |

|

Tool usage test...................................................................................................................................... |

181 |

|

Tool management (software option)..................................................................................................... |

183 |

5.3 |

Tool compensation.............................................................................................................................. |

190 |

|

Introduction........................................................................................................................................... |

190 |

|

Tool length compensation..................................................................................................................... |

190 |

|

Tool radius compensation..................................................................................................................... |

191 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

25 |

Contents

Contents

6 Programming: Programming contours...................................................................................... |

195 |

|

6.1 |

Tool movements.................................................................................................................................. |

196 |

|

Path functions....................................................................................................................................... |

196 |

|

Miscellaneous functions M................................................................................................................... |

196 |

|

Subprograms and program section repeats......................................................................................... |

196 |

|

Programming with Q parameters......................................................................................................... |

196 |

6.2 Fundamentals of Path Functions....................................................................................................... |

197 |

|

|

Programming tool movements for workpiece machining..................................................................... |

197 |

6.3 Approaching and departing a contour............................................................................................. |

200 |

|

|

Starting point and end point................................................................................................................. |

200 |

|

Tangential approach and departure....................................................................................................... |

202 |

|

Overview: Types of paths for contour approach and departure............................................................ |

203 |

|

Important positions for approach and departure................................................................................... |

204 |

|

Approaching on a straight line with tangential connection: APPR LT................................................... |

205 |

|

Approaching on a straight line perpendicular to the first contour point: APPR LN............................... |

205 |

|

Approaching on a circular path with tangential connection: APPR CT.................................................. |

206 |

|

Approaching on a circular path with tangential connection from a straight line to the contour: |

|

|

APPR LCT.............................................................................................................................................. |

206 |

|

Departing in a straight line with tangential connection: DEP LT.......................................................... |

207 |

|

Departing in a straight line perpendicular to the last contour point: DEP LN....................................... |

207 |

|

Departing on a circular path with tangential connection: DEP CT........................................................ |

207 |

|

Departing on a circular arc tangentially connecting the contour and a straight line: DEP LCT.............. |

208 |

6.4 |

Path contours - Cartesian coordinates............................................................................................. |

209 |

|

Overview of path functions.................................................................................................................. |

209 |

|

Programming path functions................................................................................................................. |

209 |

|

Straight line in rapid traverse G00 Straight line with feed rate G01 F.................................................. |

210 |

|

Inserting a chamfer between two straight lines................................................................................... |

211 |

|

Corner rounding G25............................................................................................................................ |

212 |

|

Circle center I, J................................................................................................................................... |

213 |

|

Circular path C around circle center CC............................................................................................... |

214 |

|

CircleG02/G03/G05 with defined radius............................................................................................... |

215 |

|

Circle G06 with tangential connection.................................................................................................. |

217 |

|

Example: Linear movements and chamfers with Cartesian coordinates.............................................. |

218 |

|

Example: Circular movements with Cartesian coordinates.................................................................. |

219 |

|

Example: Full circle with Cartesian coordinates................................................................................... |

220 |

26 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

6.5 Path contours – Polar coordinates.................................................................................................... |

221 |

Overview............................................................................................................................................... |

221 |

Zero point for polar coordinates: pole I, J............................................................................................ |

222 |

Straight line in rapid traverse G10 Straight line with feed rate G11 F................................................... |

222 |

Circular path G12/G13/G15 around pole I, J......................................................................................... |

223 |

Circle G16 with tangential connection.................................................................................................. |

223 |

Helix....................................................................................................................................................... |

224 |

Example: Linear movement with polar coordinates............................................................................. |

226 |

Example: Helix...................................................................................................................................... |

227 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

27 |

Contents

Contents

7 Programming: Data transfer from DXF files or plain-language contours............................... |

229 |

7.1 Processing DXF Files (Software Option).......................................................................................... |

230 |

Application............................................................................................................................................. |

230 |

Opening a DXF file............................................................................................................................... |

231 |

Working with the DXF converter.......................................................................................................... |

231 |

Basic settings........................................................................................................................................ |

232 |

Setting layers......................................................................................................................................... |

234 |

Defining the datum............................................................................................................................... |

235 |

Selecting and saving a contour............................................................................................................. |

237 |

Selecting and saving machining positions............................................................................................ |

241 |

28 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

8 Programming: Subprograms and program section repeats.................................................... |

247 |

|

8.1 |

Labeling Subprograms and Program Section Repeats................................................................... |

248 |

|

Label...................................................................................................................................................... |

248 |

8.2 |

Subprograms....................................................................................................................................... |

249 |

|

Operating sequence.............................................................................................................................. |

249 |

|

Programming notes............................................................................................................................... |

249 |

|

Programming a subprogram................................................................................................................. |

249 |

|

Calling a subprogram............................................................................................................................ |

250 |

8.3 |

Program-section repeats.................................................................................................................... |

251 |

|

Label G98.............................................................................................................................................. |

251 |

|

Operating sequence.............................................................................................................................. |

251 |

|

Programming notes............................................................................................................................... |

251 |

|

Programming a program section repeat............................................................................................... |

251 |

|

Calling a program section repeat.......................................................................................................... |

252 |

8.4 |

Any desired program as subprogram............................................................................................... |

253 |

|

Operating sequence.............................................................................................................................. |

253 |

|

Programming notes............................................................................................................................... |

253 |

|

Calling any program as a subprogram.................................................................................................. |

254 |

8.5 |

Nesting................................................................................................................................................. |

255 |

|

Types of nesting.................................................................................................................................... |

255 |

|

Nesting depth........................................................................................................................................ |

255 |

|

Subprogram within a subprogram........................................................................................................ |

256 |

|

Repeating program section repeats...................................................................................................... |

257 |

|

Repeating a subprogram....................................................................................................................... |

258 |

8.6 |

Programming examples..................................................................................................................... |

259 |

|

Example: Milling a contour in several infeeds...................................................................................... |

259 |

|

Example: Groups of holes.................................................................................................................... |

260 |

|

Example: Group of holes with several tools......................................................................................... |

261 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

29 |

Contents

Contents

9 Programming: Q Parameters....................................................................................................... |

263 |

|

9.1 |

Principle and overview of functions................................................................................................. |

264 |

|

Programming notes............................................................................................................................... |

265 |

|

Calling Q parameter functions.............................................................................................................. |

266 |

9.2 |

Part families—Q parameters in place of numerical values............................................................. |

267 |

|

Application............................................................................................................................................. |

267 |

9.3 |

Describing contours with mathematical functions......................................................................... |

268 |

|

Application............................................................................................................................................. |

268 |

|

Overview............................................................................................................................................... |

268 |

|

Programming fundamental operations.................................................................................................. |

269 |

9.4 |

Angle functions (trigonometry)......................................................................................................... |

270 |

|

Definitions............................................................................................................................................. |

270 |

|

Programming trigonometric functions.................................................................................................. |

270 |

9.5 |

If-then decisions with Q parameters................................................................................................ |

271 |

|

Application............................................................................................................................................. |

271 |

|

Unconditional jumps.............................................................................................................................. |

271 |

|

Programming if-then decisions............................................................................................................. |

271 |

9.6 |

Checking and changing Q parameters............................................................................................. |

272 |

|

Procedure.............................................................................................................................................. |

272 |

9.7 |

Additional functions............................................................................................................................ |

274 |

|

Overview............................................................................................................................................... |

274 |

|

D14: Displaying error messages........................................................................................................... |

275 |

|

D18: Reading system data.................................................................................................................... |

279 |

|

D19: Transfer values to PLC................................................................................................................. |

288 |

|

D20: NC and PLC synchronization........................................................................................................ |

288 |

|

D29: Transfer values to the PLC........................................................................................................... |

290 |

|

D37 EXPORT......................................................................................................................................... |

290 |

30 |

TNC 640 | User's Manual for DIN/ISO Programming | 3/2014 |

Loading...

Loading...