HEIDENHAIN TNC 620 User Manual

Technical Manual

TNC 620

NC Software 340 56x-02

October 2010

2 |

HEIDENHAIN Technical Manual TNC 620 |

Contents

1 |

Update Information |

|

|

1.1 |

General Information.......................................................................... |

19 |

|

1 |

Update Information No. 1 |

|

|

1.1 |

Overview............................................................................................ |

21 |

|

|

1.1.1 |

Released Service Packs ...................................................... |

21 |

|

1.1.2 |

Released NC Software........................................................ |

21 |

1.2 |

NC Software 340 560-01 ................................................................... |

22 |

|

1.3 |

NC Software 340 551-04 / NC Software 340 560-02 ...................... |

23 |

|

|

1.3.1 Important Notes on Updating Software .............................. |

23 |

|

|

1.3.2 Description of the New Functions....................................... |

28 |

|

1.4 |

NC Software 340 554-xx (TNC 320 Programming Station) ........... |

44 |

|

|

1.4.1 Description of the New Functions....................................... |

44 |

|

1.5 |

Hardware ........................................................................................... |

45 |

|

|

1.5.1 MC 6110 Computer Unit with ProfiBus Interface ............... |

45 |

|

1 |

Update Information No. 2 |

|

|

1.1 |

Overview............................................................................................ |

47 |

|

|

1.1.1 |

Released service packs ....................................................... |

47 |

1.2 |

Hardware ........................................................................................... |

47 |

|

|

1.2.1 MC 6110 main computer of the TNC 620 ........................... |

47 |

|

1 |

Update Information No. 3 |

|

|

1.1 |

Overview............................................................................................ |

49 |

|

|

1.1.1 |

Released service packs ....................................................... |

49 |

1.2 |

NC software 340 56x-02 Service Pack 8 .......................................... |

49 |

|

|

1.2.1 Description of important changes ....................................... |

49 |

|

1.3 |

Hardware ........................................................................................... |

50 |

|

|

1.3.1 UEC 11x controller unit with inverter and PLC I/O .............. |

50 |

|

October 2010 |

3 |

2 |

Introduction |

|

|

2.1 |

Meaning of the Symbols Used in this Manual ............................... |

53 |

|

2.2 |

Proper Operation............................................................................... |

53 |

|

2.3 |

Trained Personnel ............................................................................. |

53 |

|

2.4 |

General Information.......................................................................... |

54 |

|

|

2.4.1 |

HSCI interface ..................................................................... |

57 |

2.5 |

Overview of Components ................................................................ |

58 |

|

|

2.5.1 |

MC main computer, CFR memory card and SIK ................. |

58 |

|

2.5.2 |

CC 6106 controller unit ....................................................... |

60 |

2.5.3UEC 11x controller unit with integrated inverter and

|

|

PLC...................................................................................... |

61 |

|

2.5.4 |

PLC input/output systems with HSCI interface .................. |

63 |

|

2.5.5 |

PSL 130 low-voltage power supply unit.............................. |

67 |

|

2.5.6 |

MB 620 Machine Operating Panel ...................................... |

69 |

|

2.5.7 |

Handwheels ........................................................................ |

70 |

|

2.5.8 |

Key symbols........................................................................ |

73 |

|

2.5.9 |

Touch probes ...................................................................... |

78 |

|

2.5.10 |

Other accessories ............................................................... |

80 |

|

2.5.11 |

Documentation.................................................................... |

80 |

2.6 |

Brief Description................................................................................ |

81 |

|

2.7 |

Software |

............................................................................................ |

93 |

|

2.7.1 |

Designation of the software................................................ |

93 |

|

2.7.2 |

PLC software ...................................................................... |

93 |

|

2.7.3 |

Enabling additional axes or software options...................... |

94 |

|

2.7.4 |

Upgrade functions (Feature Content Level) ........................ |

97 |

|

2.7.5 |

NC software exchange on the TNC 620 ............................. |

98 |

|

2.7.6 |

Installing a service pack .................................................... |

103 |

|

2.7.7 |

Reversing a software update ............................................ |

104 |

|

2.7.8 |

Special features of the software ....................................... |

105 |

|

2.7.9 |

Firmware update on HSCI devices.................................... |

106 |

|

2.7.10 |

Monitoring hardware changes .......................................... |

108 |

|

2.7.11 |

Data backup ...................................................................... |

108 |

2.8 |

Software Releases .......................................................................... |

109 |

|

|

2.8.1 |

NC Software 340 560-xx ................................................... |

109 |

|

2.8.2 |

NC software 340 561-xx ................................................... |

109 |

4 |

HEIDENHAIN Technical Manual TNC 620 |

3 Mounting and Electrical Installation

3.1 General Information........................................................................ |

111 |

|

3.1.1 |

Safety precautions............................................................. |

111 |

3.1.2 |

Degrees of protection ....................................................... |

112 |

3.1.3 |

Electromagnetic compatibility ........................................... |

112 |

3.1.4 |

ESD protection .................................................................. |

113 |

3.2 Environmental Conditions ............................................................. |

115 |

|

3.2.1 |

Heat generation and cooling.............................................. |

115 |

3.2.2 |

Humidity ............................................................................ |

116 |

3.2.3 |

Installation elevation.......................................................... |

116 |

3.2.4 |

Mechanical vibration.......................................................... |

116 |

3.2.5 |

Mounting Attitude with MC 6110 ..................................... |

117 |

3.2.6Mounting Attitude of CC 61xx, UV xxx, UM xxx,

|

|

UE 2xx B ............................................................................ |

118 |

3.3 |

Overview of Hardware.................................................................... |

119 |

|

3.4 |

HSCI |

.................................................................................................. |

120 |

|

3.4.1 |

Introduction ....................................................................... |

120 |

|

3.4.2 |

Topology ............................................................................ |

121 |

|

3.4.3 |

HSCI interface ................................................................... |

122 |

3.5 |

Connection Overview for TNC 620 ............................................... |

124 |

|

|

3.5.1 .................................................. |

MC 6110 main computer |

124 |

|

3.5.2 ........................................ |

CC 6106 modular controller unit |

125 |

3.5.3UEC 11x: Compact Controller Unit with Inverter and

|

|

PLC I/Os ............................................................................ |

126 |

|

3.5.4 |

UEC 11x: Digital PLC inputs/outputs................................. |

133 |

|

3.5.5 |

PLB 62xx and PLB 61xx .................................................... |

136 |

|

3.5.6 |

Switching inputs and outputs 24 V– (PLC) ........................ |

140 |

|

3.5.7 |

PLB 6xxx: Digital PLC Inputs/Outputs............................... |

141 |

|

3.5.8 |

PLB 6xxx: Analog PLC Inputs/Outputs.............................. |

143 |

|

3.5.9 |

X121: PROFIBUS connection ............................................ |

145 |

|

3.5.10 |

Configuring the PLC Inputs/Outputs with IOconfig........... |

146 |

3.6 |

Power Supply for the TNC 620 ...................................................... |

147 |

|

|

3.6.1 |

PSL 130 low-voltage power supply unit ............................ |

153 |

3.7 |

Power Supply for PLC Outputs...................................................... |

161 |

|

3.8 |

Power Supply for PLB 6xxx............................................................ |

162 |

|

3.9 |

Power Supply for Control-Is-Ready Signal ................................... |

163 |

|

3.10 |

Drive Controller Enable .................................................................. |

164 |

|

3.11 |

Buffer Battery .................................................................................. |

165 |

|

3.12 |

Encoder Connections ..................................................................... |

166 |

|

|

3.12.1 |

General information........................................................... |

166 |

|

3.12.2 |

Position Encoder Input ..................................................... |

167 |

|

3.12.3 |

Input of speed encoder ................................................... |

169 |

October 2010 |

5 |

3.13 |

Adapters for Encoder Signals ........................................................ |

174 |

|

3.14 |

Connecting the Motor Power Stages (Only CC 61xx) ................. |

178 |

|

3.15 |

Touch Probe Systems..................................................................... |

179 |

|

3.16 |

Data Interfaces ................................................................................ |

182 |

|

|

3.16.1 |

USB Interface.................................................................... |

185 |

3.17 |

MB 620 Machine Operating Panel ................................................. |

186 |

|

3.18 |

Handwheel Input............................................................................. |

190 |

|

|

3.18.1 HR 410 portable handwheel.............................................. |

190 |

|

|

3.18.2 HR 130 panel-mounted handwheel................................... |

192 |

|

|

3.18.3 |

HRA 110 handwheel adapter ............................................ |

193 |

3.19 |

Cable Specifications........................................................................ |

195 |

|

3.20 |

Dimensions ...................................................................................... |

196 |

|

|

3.20.1 |

MC 6110 ........................................................................... |

197 |

|

3.20.2 |

MB 620 ............................................................................. |

198 |

|

3.20.3 |

CC 6106 ............................................................................ |

199 |

|

3.20.4 |

UEC 11x ............................................................................ |

200 |

|

3.20.5 |

PL 6xxx.............................................................................. |

201 |

|

3.20.6 |

PSL 130............................................................................. |

201 |

|

3.20.7 |

Adapter block for the data interface.................................. |

202 |

|

3.20.8 |

USB hub ............................................................................ |

203 |

|

3.20.9 |

Line-drop compensator ..................................................... |

204 |

|

3.20.10 |

Handwheels ...................................................................... |

204 |

|

3.20.11 |

Touch probes .................................................................... |

208 |

3.21 |

HSCI Connection Overview of the TNC 620 with CC 61xx.......... |

215 |

|

3.22 |

HSCI Connection Overview of the TNC 620 with UEC 11xx ....... |

216 |

|

3.23 |

Grounding diagram for TNC 620 with Modular |

|

|

|

HEIDENHAIN Inverter System ....................................................... |

217 |

|

3.24 |

Basic Circuit Diagram for TNC 620 ................................................ |

218 |

|

3.25 |

Cable Overview for TNC 620 with CC 6106 .................................. |

219 |

|

3.26 |

Cable Overview for TNC 620 with UEC 11x.................................. |

220 |

|

3.27 |

Cable Overview for TNC 620—Accessories .................................. |

221 |

|

6 |

HEIDENHAIN Technical Manual TNC 620 |

4 |

Machine Parameters |

|

|

4.1 |

General Information........................................................................ |

223 |

|

4.2 |

The “Machine Parameter” Mode of Operation ............................ |

225 |

|

|

4.2.1 |

Calling the configuration editor.......................................... |

225 |

|

4.2.2 |

Entering and Changing Machine Parameters .................... |

227 |

|

4.2.3 |

Accessing Machine Parameters via MP Numbers ............ |

238 |

|

4.2.4 |

Managing configuration files ............................................. |

241 |

|

4.2.5 |

Sort File Content ............................................................... |

241 |

|

4.2.6 |

Attribute Information......................................................... |

242 |

|

4.2.7 |

Access Protection / Options.............................................. |

244 |

|

4.2.8 |

Update rules ...................................................................... |

245 |

|

4.2.9 |

Remove Syntax Error ........................................................ |

255 |

|

4.2.10 |

Resets the update version ................................................ |

255 |

|

4.2.11 |

Backup of Parameters ....................................................... |

256 |

4.3 |

User Parameters.............................................................................. |

257 |

|

|

4.3.1 |

Configuration of the user parameters ............................... |

258 |

|

4.3.2 |

Example:............................................................................ |

260 |

|

4.3.3 |

XML commands for creating the layout files .................... |

262 |

4.4 |

The KeySynonym function............................................................. |

265 |

|

4.5 |

Allocation of Configuration Data .................................................. |

267 |

|

4.6 |

Structure of a Parameter File......................................................... |

269 |

|

4.7 |

Machine-Parameter Subfiles.......................................................... |

272 |

|

|

4.7.1 |

Syntax of Machine-Parameter Subfile ............................... |

272 |

|

4.7.2 |

Activating the Machine-Parameter Subfile ........................ |

272 |

4.7.3Displaying/Editing Data Records in the Configuration

|

|

Editor ................................................................................. |

275 |

4.8 |

Read or Change Machine Parameters via a PLC Module ............ |

277 |

|

4.9 |

Overview of Machine Parameters ................................................. |

283 |

|

|

4.9.1 |

“System” Group ............................................................... |

283 |

|

4.9.2 |

“Channels” Group............................................................. |

292 |

|

4.9.3 |

“Axes” group .................................................................... |

295 |

|

4.9.4 |

“KeySynonym” group ....................................................... |

300 |

4.10 |

Parameter Overview Sorted by MP Numbers.............................. |

301 |

|

|

4.10.1 |

System configuration and miscellaneous.......................... |

302 |

|

4.10.2 |

Channel-specific parameters ............................................. |

322 |

|

4.10.3 |

Axis-specific parameters ................................................... |

327 |

|

4.10.4 |

Parameters for configuring the parameter sets ................ |

329 |

4.11 |

Overview: iTNC 530 MP Numbers <–> TNC 620 MP |

|

|

|

Numbers |

.......................................................................................... |

336 |

|

4.11.1 |

Measuring systems and machine axes ............................. |

337 |

|

4.11.2 |

Positioning and regulation ................................................. |

339 |

|

4.11.3 |

PWM interface (DSP) ........................................................ |

341 |

|

4.11.4 |

Spindle control (1st spindle) .............................................. |

344 |

|

4.11.5 |

Integrated PLC .................................................................. |

345 |

|

4.11.6 |

Serial interface................................................................... |

346 |

|

4.11.7 |

Touch probe ...................................................................... |

346 |

|

4.11.8 |

Tool touch probe for tool measurement............................ |

347 |

|

4.11.9 |

Tapping.............................................................................. |

347 |

|

4.11.10 |

Display and programming.................................................. |

348 |

|

4.11.11 Machining and Program Run ............................................. |

349 |

|

|

4.11.12 |

Hardware........................................................................... |

350 |

October 2010 |

7 |

5 |

Modules and PLC Operands |

|

|

5.1 |

Overview of Modules...................................................................... |

351 |

|

5.2 |

Overview of the PLC Operands...................................................... |

357 |

|

|

5.2.1 |

PLC Operands of the “General Data” Group .................... |

357 |

|

5.2.2 |

PLC Operands of the “Operating Mode Group” |

|

|

|

Group ................................................................................ |

359 |

|

5.2.3 |

PLC Operands of the “Machining Channels” Group ........ |

360 |

|

5.2.4 |

PLC Operands of the “Axis” Group .................................. |

362 |

|

5.2.5 |

PLC Operands of the “Spindle” Group ............................. |

364 |

6 |

Configuring the Axes and Spindle |

|

|

6.1 |

Machine Structure .......................................................................... |

365 |

|

|

6.1.1 |

Adapting the control to the machine................................. |

365 |

|

6.1.2 |

Definition of axes .............................................................. |

366 |

6.2 Configuration of Machining Channels .......................................... |

368 |

||

|

6.2.1 |

Configuring a machining channel ...................................... |

368 |

|

6.2.2 |

Traversing the reference marks ........................................ |

373 |

|

6.2.3 |

Returning to the contour/block scan ................................. |

374 |

6.3 |

Configuration of Axes..................................................................... |

378 |

|

|

6.3.1 |

Axis designations and coordinates.................................... |

380 |

|

6.3.2 |

Programmable axes .......................................................... |

383 |

|

6.3.3 |

Physical axes..................................................................... |

386 |

|

6.3.4 |

Display of axes on the screen ........................................... |

394 |

|

6.3.5 |

Hirth coupling .................................................................... |

398 |

|

6.3.6 |

Kinematics properties of axes........................................... |

400 |

|

6.3.7 |

Manual axis (counter axis)................................................. |

402 |

|

6.3.8 |

Introducing a new NC axis into the system ...................... |

404 |

6.4 |

Encoders |

.......................................................................................... |

415 |

|

6.4.1 |

Type of the position encoder ............................................ |

415 |

|

6.4.2 |

Signal period of encoders.................................................. |

418 |

|

6.4.3 |

Distance-coded reference marks ...................................... |

422 |

6.4.4Connecting the encoders, PWM output on the

|

CC 61xx............................................................................. |

424 |

6.4.5 |

Connecting the encoders to the UEC 11x......................... |

429 |

6.4.6 |

Defining the traverse direction.......................................... |

431 |

6.4.7 |

Encoder monitoring........................................................... |

433 |

6.4.8 |

Linear and torque motors.................................................. |

437 |

6.5 Reading and Writing Axis Information ......................................... |

439 |

|

6.5.1 |

Reading axis information................................................... |

439 |

6.5.2Writing axis information – activating and deactivating

|

|

axes................................................................................... |

445 |

6.6 |

Traverse Ranges.............................................................................. |

454 |

|

|

6.6.1 |

Overwrite software limit switches.................................... |

455 |

6.7 |

Lubrication Pulse............................................................................. |

456 |

|

6.8 |

Controlling Axes by PLC (PLC Axes) ............................................. |

458 |

|

8 |

HEIDENHAIN Technical Manual TNC 620 |

6.9 Axis Error Compensation ............................................................... |

468 |

|

6.9.1 |

Backlash compensation..................................................... |

470 |

6.9.2 |

Linear axis error compensation ......................................... |

474 |

6.9.3 |

Nonlinear axis error compensation.................................... |

476 |

6.9.4 |

Compensation of thermal expansion................................. |

483 |

6.9.5 |

Compensation of static friction ......................................... |

485 |

6.9.6 |

Compensation of sliding friction........................................ |

486 |

6.10 |

Machine Kinematics........................................................................ |

488 |

|

|

6.10.1 |

Configuring the machine kinematics ................................. |

491 |

|

6.10.2 |

Find/activate kinematics through the PLC......................... |

511 |

6.11 |

Tilting Axes...................................................................................... |

513 |

|

6.11.1“Tilting the working plane” function

|

|

(software option 1) ............................................................ |

513 |

6.12 |

Parallel Axes .................................................................................... |

518 |

|

6.13 |

Synchronized Axes (Option 24) ..................................................... |

520 |

|

|

6.13.1 |

Gantry axes ....................................................................... |

520 |

|

6.13.2 |

Master-slave torque control .............................................. |

530 |

6.14 |

Reference Marks.............................................................................. |

541 |

|

|

6.14.1 |

Definition........................................................................... |

541 |

|

6.14.2 Traversing the reference marks ........................................ |

542 |

|

6.14.3Defining the process of traversing the reference

|

marks................................................................................. |

545 |

6.14.4 |

“Pass Over Reference Point” operating mode ................. |

552 |

6.15 The Control Loop ............................................................................ |

556 |

|

6.15.1 |

Block diagram of control loop............................................ |

556 |

6.15.2Relation between jerk, acceleration, velocity and

|

distance............................................................................. |

557 |

6.15.3 |

Geometry filter .................................................................. |

559 |

6.15.4 |

Look-ahead........................................................................ |

561 |

6.15.5 |

Interpolator........................................................................ |

571 |

6.15.6 Nominal position value filter .............................................. |

572 |

|

6.15.7 Feed-rate smoothing (software option 2) .......................... |

583 |

|

6.15.8 |

Position controller.............................................................. |

585 |

6.15.9 Activating and deactivating position control loops ............ |

594 |

|

6.15.10 |

Feed-rate enable................................................................ |

597 |

6.15.11 |

Speed controller ................................................................ |

599 |

6.15.12Filters in the speed controller and position controller

when using the CC 61xx and CC 424................................ |

603 |

6.15.13CC 61xx/CC 424: filter order for separate low-pass

filter in the speed controller .............................................. |

607 |

6.15.14CC 61xx/CC424: peculiarities in weakened-field

|

operation ........................................................................... |

608 |

6.15.15 Active damping of low-frequency oscillations ................... |

610 |

|

6.15.16 |

Acceleration feedforward control ...................................... |

612 |

6.15.17 |

IPC, holding torque, following error in the jerk phase ....... |

615 |

6.15.18HSCI: switching drives on and off, enabling the drive

controller ........................................................................... |

620 |

6.15.19 Current controller .............................................................. |

630 |

6.15.20Braking the drives for an EMERGENCY STOP and a

|

power fail........................................................................... |

635 |

6.15.21 Power and torque limiting ................................................. |

638 |

|

6.15.22 |

Controller parameters for manual traverse........................ |

645 |

6.15.23 |

Switching parameter sets ................................................. |

646 |

October 2010 |

9 |

6.15.24 Synchronous motors in field weakening range ................. |

659 |

|

6.15.25 |

Motor with wye/delta switchover ..................................... |

661 |

6.15.26 Speed-dependent switching of the PWM frequency........ |

663 |

|

6.15.27 TRC – torque ripple compensation.................................... |

666 |

|

6.15.28 |

Torsion compensation....................................................... |

669 |

6.16 Monitoring Functions ..................................................................... |

671 |

|

6.16.1 |

Monitoring the drives ........................................................ |

671 |

6.16.2 |

Position monitoring ........................................................... |

673 |

6.16.3 |

Movement monitoring ...................................................... |

677 |

6.16.4 |

Standstill monitoring ......................................................... |

679 |

6.16.5 |

Positioning window........................................................... |

680 |

6.16.6 |

Monitoring of the power supply unit ................................ |

684 |

6.16.7 |

Temperature monitoring ................................................... |

687 |

6.16.8 |

I2t monitoring .................................................................... |

691 |

6.16.9 |

Momentary utilization of drive motors .............................. |

702 |

6.16.10 |

Status of HEIDENHAIN hardware and software ............... |

704 |

6.16.11 |

Motor brake....................................................................... |

708 |

6.16.12 |

Emergency stop monitoring.............................................. |

709 |

6.16.13Monitoring functions when using the CC 61xx and

|

CC 424 .............................................................................. |

714 |

6.17 Spindles |

........................................................................................... |

716 |

6.17.1 |

Configuring spindles .......................................................... |

716 |

6.17.2 .........................................Position encoder of the spindle |

717 |

|

6.17.3 ...................................................... |

Spindle speed encoder |

718 |

6.17.4 ........................................Filtering the acceleration values |

720 |

|

6.17.5 ...................................................... |

Controlling the spindle |

721 |

6.17.6 ........................Oriented spindle stop (spindle point stop) |

732 |

|

6.17.7Tapping with floating tap holder and coded

|

spindle-speed output......................................................... |

736 |

6.17.8 |

Switching the modes of operation .................................... |

738 |

6.17.9 |

Stop spindle at trip dog position........................................ |

740 |

6.17.10 |

Spindle of the kinematics model....................................... |

743 |

6.17.11 |

Gear shifting...................................................................... |

744 |

6.17.12 |

Tapping.............................................................................. |

744 |

6.17.13 |

Operating a second spindle............................................... |

744 |

6.17.14 |

C-axis operation................................................................. |

746 |

6.17.15 |

Volts-per-hertz control mode............................................. |

748 |

6.18 Configuring the Controller Unit and Drive Motors ...................... |

749 |

|

6.18.1Structure of the CC 61xx and UEC 11x controller

units .................................................................................. |

749 |

6.18.2CC61xx: single-speed and double-speed (software

option #49) ........................................................................ |

751 |

6.18.3 PWM frequencies with the CC 61xx................................. |

755 |

6.18.4PWM frequency with INDRAMAT “POWER DRIVE”

inverters ........................................................................... |

757 |

6.18.5PWM frequency with SIEMENS “SIMODRIVE”

inverters ............................................................................ |

757 |

6.18.6Comparison of the CC 61xx and CC 424 controller

|

units .................................................................................. |

760 |

6.18.7 |

Configuring the servo motor ............................................. |

763 |

6.18.8 |

Field orientation – fundamentals ....................................... |

766 |

6.18.9Ascertaining the field angle with the CC 61xx or

CC 424 .............................................................................. |

768 |

10 |

HEIDENHAIN Technical Manual TNC 620 |

6.19 |

Current Controller Adjustment...................................................... |

776 |

|

6.20 |

Integrated Oscilloscope.................................................................. |

778 |

|

|

6.20.1 |

Fundamentals.................................................................... |

778 |

|

6.20.2 |

Prepare recording.............................................................. |

780 |

|

6.20.3 |

Record signals ................................................................... |

784 |

|

6.20.4 |

Analyze recording.............................................................. |

786 |

|

6.20.5 Saving and loading recordings........................................... |

789 |

|

6.20.6Circular interpolation test with the integrated

|

|

oscilloscope....................................................................... |

790 |

|

6.20.7 |

Configure the colors of the oscilloscope display ............... |

791 |

7 |

Machine Integration |

|

|

7.1 |

Display and Operation .................................................................... |

795 |

|

|

7.1.1 |

Position and status display ................................................ |

795 |

|

7.1.2 |

Unit of measurement for display and operation ................ |

803 |

|

7.1.3 |

Conversational language ................................................... |

804 |

|

7.1.4 |

Format of NC programs and cycle display......................... |

809 |

|

7.1.5 |

Settings for the programming mode of operation............. |

811 |

|

7.1.6 |

Binary file management .................................................... |

817 |

|

7.1.7 |

Access rights to drives and directories ............................. |

819 |

|

7.1.8 |

Code numbers................................................................... |

821 |

|

7.1.9 |

Programming station mode............................................... |

822 |

7.1.10Operating modes / control operation in the operating

|

mode group....................................................................... |

825 |

7.1.11 |

Control operation in the machining channel ...................... |

829 |

7.1.12 |

Error messages and log files ............................................. |

846 |

7.1.13TNCguide – context-sensitive help system (user

|

|

documentation) ................................................................. |

871 |

|

7.1.14 |

Table editor........................................................................ |

882 |

|

7.1.15 |

Machine datum ................................................................. |

885 |

|

7.1.16 |

Cycles................................................................................ |

888 |

|

7.1.17 |

Window manager (XFCE) .................................................. |

892 |

7.2 |

Small PLC window.......................................................................... |

896 |

|

7.3 |

PLC Soft Keys .................................................................................. |

900 |

|

7.4 |

Switching the Control On/Off........................................................ |

901 |

|

|

7.4.1 |

Powering up the control.................................................... |

901 |

|

7.4.2 |

Shutting down the control................................................. |

904 |

7.5 |

Keystroke Simulation ..................................................................... |

911 |

|

|

7.5.1 |

Control keyboard ............................................................... |

911 |

|

7.5.2 |

Machine operating panel................................................... |

918 |

7.6 |

Electronic Handwheel..................................................................... |

920 |

|

|

7.6.1 |

Serial handwheel............................................................... |

920 |

|

7.6.2 |

Handwheel at position encoder input................................ |

925 |

|

7.6.3 |

Traverse per handwheel revolution................................... |

930 |

|

7.6.4 |

Assigning a handwheel to an axis ..................................... |

931 |

|

7.6.5 |

HR 410 portable handwheel.............................................. |

935 |

7.6.6HR 150 panel-mounted handwheels with HRA 110

handwheel adapter............................................................ |

937 |

October 2010 |

11 |

7.7 Override |

........................................................................................... |

939 |

7.7.1 |

Override devices ............................................................... |

939 |

7.7.2 |

Compensation for potentiometers .................................... |

941 |

7.7.3 ............................................................. |

Override functions |

942 |

7.8 |

PLC Inputs/Outputs ........................................................................ |

946 |

|

|

7.8.1 |

Diagnosis of the external PL ............................................. |

946 |

|

7.8.2 |

24 V– switching input/outputs .......................................... |

950 |

|

7.8.3 |

Analog inputs .................................................................... |

954 |

|

7.8.4 |

Analog outputs .................................................................. |

957 |

7.9 |

Incremental Jog Positioning .......................................................... |

959 |

|

7.10 |

Operating Times and System Times............................................. |

961 |

|

|

7.10.1 |

Measuring operating times ............................................... |

961 |

|

7.10.2 |

System time...................................................................... |

967 |

7.11 |

Tool Changer ................................................................................... |

969 |

|

|

7.11.1 |

Tool and pocket number ................................................... |

969 |

|

7.11.2 |

Automatic Tool Recognition ............................................ |

1000 |

|

7.11.3 |

Controlling the Tool Changer........................................... |

1001 |

7.12 |

Touch Probe................................................................................... |

1007 |

|

|

7.12.1 |

Using the Touch Probes.................................................. |

1010 |

|

7.12.2 |

Touch Probe Cycles ........................................................ |

1015 |

|

7.12.3 |

Tool measurement .......................................................... |

1022 |

7.13 |

Commissioning ............................................................................. |

1035 |

|

|

7.13.1 |

Power Module Table and Motor Table............................ |

1035 |

|

7.13.2 |

Preparation ...................................................................... |

1044 |

|

7.13.3 |

Commissioning of Digital Axes ....................................... |

1047 |

|

7.13.4 |

Commissioning the Spindle ............................................ |

1064 |

7.14 |

Diagnosis with the Online Monitor (OLM) ................................. |

1068 |

|

|

7.14.1 |

Introduction ..................................................................... |

1068 |

|

7.14.2 |

Using the OLM................................................................ |

1069 |

|

7.14.3 |

Screen Layout ................................................................. |

1071 |

|

7.14.4 |

Group of NC Axes ........................................................... |

1074 |

|

7.14.5 |

Group of Spindle Commands .......................................... |

1094 |

|

7.14.6 |

Group of NC Channels .................................................... |

1096 |

|

7.14.7 |

Hardware Group.............................................................. |

1101 |

|

7.14.8 |

Group of Drive Commands ............................................. |

1114 |

|

7.14.9 |

Auxiliary Group ................................................................ |

1115 |

|

7.14.10 |

PLC Group....................................................................... |

1121 |

|

7.14.11 |

Queue-Trace.................................................................... |

1124 |

|

7.14.12 Frequent Causes of Error ................................................ |

1126 |

|

12 |

HEIDENHAIN Technical Manual TNC 620 |

8 |

PLC Programming |

|

|

8.1 |

PLC functions................................................................................. |

1127 |

|

|

8.1.1 |

The API 3.0 symbolic memory interface ......................... |

1128 |

|

8.1.2 |

HEIDENHAIN PLC basic program ................................... |

1134 |

|

8.1.3 |

Selecting the plc programming mode of operation ......... |

1135 |

|

8.1.4 |

PLC main menu............................................................... |

1136 |

|

8.1.5 |

File management............................................................. |

1138 |

|

8.1.6 |

The API DATA function ................................................... |

1139 |

|

8.1.7 |

The WATCH LIST function .............................................. |

1141 |

|

8.1.8 |

The TABLE function ........................................................ |

1143 |

|

8.1.9 |

The TRACE function ........................................................ |

1145 |

|

8.1.10 |

The COMPILE function ................................................... |

1147 |

|

8.1.11 |

The EDIT function............................................................ |

1148 |

|

8.1.12 |

Diagnostic functions........................................................ |

1151 |

|

8.1.13 |

BUS diagnostics .............................................................. |

1171 |

8.2 Configure PLC input/output systems ......................................... |

1176 |

||

8.3 |

Operands........................................................................................ |

1178 |

|

|

8.3.1 |

Overview of operands..................................................... |

1178 |

|

8.3.2 |

Operand addressing (byte, word, double word) .............. |

1181 |

|

8.3.3 |

Timers and counters ....................................................... |

1182 |

|

8.3.4 |

Fast PLC inputs ............................................................... |

1192 |

8.4 |

Data Organization ......................................................................... |

1194 |

|

|

8.4.1 |

Data organization on the CFR memory card.................... |

1194 |

|

8.4.2 |

Compressing graphic files............................................... |

1196 |

8.4.3Configuring the displayed drives and directories in

|

|

the file manager .............................................................. |

1197 |

|

8.4.4 |

PLC system files ........................................................... |

1199 |

8.5 |

M Functions (M Strobe)................................................................ |

1207 |

|

|

8.5.1 |

Assigning M functions to the machining channels.......... |

1207 |

|

8.5.2 |

Configuration of M functions........................................... |

1208 |

|

8.5.3 |

Overview of M functions of the TNC .............................. |

1216 |

8.6 |

S Function (S Strobe) ................................................................... |

1222 |

|

|

8.6.1 |

Assigning S functions to the machining channels........... |

1222 |

|

8.6.2 |

Configuration of S function.............................................. |

1223 |

8.7 |

T Functions (T Strobe) .................................................................. |

1233 |

|

|

8.7.1 |

Assigning T functions to the machining channels ........... |

1233 |

|

8.7.2 |

Configuration of T functions ............................................ |

1234 |

8.8 |

Alias Functions (Alias Strobe)..................................................... |

1241 |

|

8.8.1Assigning alias functions to the machining

|

channels .......................................................................... |

1241 |

8.8.2 |

Configuration of alias functions ....................................... |

1242 |

8.9 Options for the PLC Run-Time System ....................................... |

1244 |

|

October 2010 |

13 |

8.10 Tables ............................................................................................. |

|

1247 |

8.10.1 |

Creating a new table type ............................................... |

1248 |

8.10.2 |

Defining a table prototype............................................... |

1259 |

8.10.3 |

Creating a new table with the file manager .................... |

1260 |

8.10.4 |

Inserting additional columns in an existing table............. |

1261 |

8.10.5 |

Deleting columns from an existing table......................... |

1262 |

8.10.6 |

Removing column names and column descriptions ....... |

1263 |

8.10.7 |

Defining the path for OEM tables ................................... |

1264 |

8.10.8 |

Symbolic names for tables.............................................. |

1264 |

8.10.9 |

Editing tables via the PLC .............................................. |

1266 |

8.10.10 Access to tables via SQL commands.............................. |

1277 |

|

8.10.11 |

PLC modules for the SQL statements ............................ |

1290 |

8.11 Data Transfer NC => PLC, PLC => NC .......................................... |

1309 |

|

8.11.1 |

Introduction ..................................................................... |

1309 |

8.11.2 Data transfer NC program => PLC ("FN19: PLC =" or |

|

|

|

"FN29: PLC =")................................................................. |

1310 |

8.11.3 |

Q parameters .................................................................. |

1312 |

8.11.4 Data transfer NC program => NC (FN17: |

|

|

|

SYSWRITE) ..................................................................... |

1314 |

8.11.5 Data transfer NC => NC program (FN18: SYSREAD)....... |

1326 |

|

8.11.6 Data transfer machine parameters => PLC .................... |

1339 |

|

8.11.7 Interrogate PLC operands in the NC program (FN20: |

|

|

|

WAIT FOR) ...................................................................... |

1341 |

8.12 Program Creation.......................................................................... |

1342 |

|

8.12.1 |

ASCII editor ..................................................................... |

1342 |

8.12.2 |

Program format ............................................................... |

1342 |

8.12.3 |

Program structure ........................................................... |

1343 |

8.13 Command Set................................................................................ |

1344 |

|

8.13.1 |

Overview......................................................................... |

1344 |

8.13.2 |

LOAD (L) ......................................................................... |

1347 |

8.13.3 |

LOAD NOT (LN) .............................................................. |

1349 |

8.13.4 |

LOAD TWO’S COMPLEMENT (L–)................................. |

1351 |

8.13.5 |

LOAD BYTE (LB) ............................................................. |

1352 |

8.13.6 |

LOAD WORD (LW) ......................................................... |

1352 |

8.13.7 |

LOAD DOUBLE WORD (LD)........................................... |

1353 |

8.13.8 |

ASSIGN (=)...................................................................... |

1353 |

8.13.9 |

ASSIGN BYTE (B=).......................................................... |

1354 |

8.13.10 |

ASSIGN WORD (W=)...................................................... |

1355 |

8.13.11 |

ASSIGN DOUBLE WORD (D=) ....................................... |

1355 |

8.13.12 |

ASSIGN NOT (=N)........................................................... |

1356 |

8.13.13 |

ASSIGN TWO’S COMPLEMENT (=–) ............................. |

1356 |

8.13.14 |

SET (S)............................................................................. |

1357 |

8.13.15 |

RESET (R)........................................................................ |

1358 |

8.13.16 |

SET NOT (SN).................................................................. |

1359 |

8.13.17 |

RESET NOT (RN)............................................................. |

1360 |

8.13.18 |

AND (A) ........................................................................... |

1361 |

8.13.19 |

AND NOT (AN) ................................................................ |

1363 |

8.13.20 |

OR (O) ............................................................................. |

1365 |

8.13.21 |

OR NOT (ON) .................................................................. |

1367 |

8.13.22 |

EXCLUSIVE OR (XO) ....................................................... |

1369 |

8.13.23 |

EXCLUSIVE OR NOT (XON) ............................................ |

1371 |

8.13.24 |

ADDITION (+).................................................................. |

1373 |

8.13.25 |

SUBTRACTION (–)........................................................... |

1374 |

8.13.26 |

MULTIPLICATION (X)...................................................... |

1375 |

8.13.27 |

DIVISION (/)..................................................................... |

1376 |

|

|

|

14 |

HEIDENHAIN Technical Manual TNC 620 |

|

8.13.28 |

REMAINDER (MOD) ....................................................... |

1377 |

8.13.29 |

INCREMENT (INC)........................................................... |

1377 |

8.13.30 |

DECREMENT (DEC) ........................................................ |

1378 |

8.13.31 |

EQUAL TO (==)............................................................... |

1378 |

8.13.32 |

LESS THAN (<)................................................................ |

1379 |

8.13.33 |

GREATER THAN (>) ........................................................ |

1380 |

8.13.34 LESS THAN OR EQUAL TO (<=) .................................... |

1381 |

|

8.13.35 GREATER THAN OR EQUAL TO (>=)............................. |

1382 |

|

8.13.36 |

NOT EQUAL (<>) ............................................................ |

1383 |

8.13.37 AND [ ] (A[ ]) .................................................................... |

1384 |

|

8.13.38 AND NOT [ ] (AN[ ]) ......................................................... |

1385 |

|

8.13.39 OR [ ] (O[ ]) ...................................................................... |

1385 |

|

8.13.40 OR NOT [ ] (ON[ ]) ........................................................... |

1386 |

|

8.13.41 EXCLUSIVE OR [ ] (XO[ ]) ................................................ |

1386 |

|

8.13.42 EXCLUSIVE OR NOT [ ] (XON[ ]) ..................................... |

1386 |

|

8.13.43 ADDITION [ ] (+[ ]) ........................................................... |

1386 |

|

8.13.44 SUBTRACT [ ] (–[ ]) .......................................................... |

1387 |

|

8.13.45 MULTIPLY [ ] (x[ ]) ........................................................... |

1387 |

|

8.13.46 DIVIDE [ ] (/[ ]).................................................................. |

1388 |

|

8.13.47 REMAINDER [ ] (MOD[ ]) ................................................ |

1388 |

|

8.13.48 EQUAL TO [ ] (==[ ])........................................................ |

1388 |

|

8.13.49 LESS THAN [ ] (<[ ])......................................................... |

1389 |

|

8.13.50 GREATER THAN [ ] (>[ ]) ................................................. |

1390 |

|

8.13.51 LESS THAN OR EQUAL TO [ ] (<=[ ]) ............................. |

1390 |

|

8.13.52 GREATER THAN OR EQUAL TO [ ] (>=[ ])...................... |

1390 |

|

8.13.53 NOT EQUAL [ ] (<>[ ]) ..................................................... |

1390 |

|

8.13.54 |

SHIFT LEFT (<<).............................................................. |

1391 |

8.13.55 |

SHIFT RIGHT (>>) ........................................................... |

1392 |

8.13.56 |

BIT SET (BS).................................................................... |

1393 |

8.13.57 |

BIT CLEAR (BC)............................................................... |

1394 |

8.13.58 |

BIT TEST (BT) .................................................................. |

1395 |

8.13.59 PUSH DATA ONTO THE DATA STACK (PS) ................... |

1396 |

|

8.13.60 PULL DATA FROM THE DATA STACK (PL) .................... |

1397 |

|

8.13.61PUSH LOGIC ACCUMULATOR ONTO THE DATA

STACK (PSL).................................................................... |

1397 |

8.13.62PUSH WORD ACCUMULATOR ONTO THE DATA

STACK (PSW) .................................................................. |

1398 |

8.13.63PULL LOGIC ACCUMULATOR FROM THE DATA

STACK (PLL).................................................................... |

1398 |

8.13.64PULL WORD ACCUMULATOR FROM THE DATA

|

STACK (PLW) .................................................................. |

1399 |

8.13.65 |

UNCONDITIONAL JUMP (JP) ......................................... |

1399 |

8.13.66 JUMP IF LOGIC ACCUMULATOR = 1 (JPT)................... |

1400 |

|

8.13.67 JUMP IF LOGIC ACCUMULATOR = 0 (JPF)................... |

1401 |

|

8.13.68 |

CALL MODULE (CM) ...................................................... |

1401 |

8.13.69CALL MODULE IF LOGIC ACCUMULATOR = 1

(CMT)............................................................................... |

1401 |

8.13.70CALL MODULE IF LOGIC ACCUMULATOR = 0

(CMF)............................................................................... |

1402 |

8.13.71 END OF MODULE, END OF PROGRAM (EM)................ |

1403 |

8.13.72END OF MODULE IF LOGIC ACCUMULATOR = 1

(EMT)............................................................................... |

1403 |

8.13.73END OF MODULE IF LOGIC ACCUMULATOR = 0

(EMF)............................................................................... |

1403 |

8.13.74 LABEL (LBL).................................................................... |

1403 |

October 2010 |

15 |

8.14 |

INDEX Register (X Register)......................................................... |

1404 |

||

8.15 |

Commands for String Processing................................................ |

1406 |

||

8.16 |

LOAD STRING (L) .......................................................................... |

|

1408 |

|

8.17 |

ADD STRING (+) ............................................................................ |

|

1408 |

|

8.18 |

STORE STRING (=) ........................................................................ |

|

1408 |

|

8.19 |

OVERWRITE STRING (OVWR) ..................................................... |

1409 |

||

8.20 |

EQUAL TO Command for String Processing (==) ...................... |

1410 |

||

8.21 |

LESS THAN Command for String Processing (<)....................... |

1410 |

||

8.22 |

GREATER THAN Command for String Processing (>)............... |

1410 |

||

8.23 |

LESS THAN OR EQUAL TO Command for String |

|

||

|

Processing (<=) .............................................................................. |

|

1411 |

|

8.24 |

GREATER THAN OR EQUAL TO Command for String |

|

||

|

Processing (>=) .............................................................................. |

|

1411 |

|

8.25 |

NOT EQUAL Command for String Processing (<>).................... |

1412 |

||

8.26 |

Modules for String Processing .................................................... |

1413 |

||

8.27 |

Submit programs .......................................................................... |

|

1416 |

|

8.28 |

Calling the Submit Program (SUBM) .......................................... |

1417 |

||

8.29 |

Interrogating the Status of a Submit Program (RPLY).............. |

1417 |

||

8.30 |

Canceling a Submit Program (CAN)............................................ |

1418 |

||

8.31 |

Cooperative Multitasking............................................................. |

1420 |

||

|

8.31.1 Starting a Parallel Process (SPAWN)............................... |

1420 |

||

|

8.31.2 |

Control of events............................................................. |

1421 |

|

8.32 |

Constants Field (KF)...................................................................... |

1427 |

||

8.33 |

Program Structures |

...................................................................... |

1428 |

|

|

8.33.1 |

IF ... ELSE ... |

ENDI structure........................................... |

1429 |

|

8.33.2 |

REPEAT ... |

UNTIL Structure............................................ |

1429 |

|

8.33.3 |

WHILE ... ENDW structure ............................................. |

1430 |

|

8.34 |

CASE branch.................................................................................. |

|

1430 |

|

8.35 |

Linking Files................................................................................... |

|

1432 |

|

8.36 |

USES STATEMENT (USES) .......................................................... |

1432 |

||

8.37 |

GLOBAL Statement (GLOBAL) .................................................... |

1434 |

||

8.38 |

EXTERN STATEMENT (EXTERN)................................................. |

1434 |

||

8.39 |

PLC Modules.................................................................................. |

|

1435 |

|

|

8.39.1 Markers, Bytes, Words, and Double Words ................... |

1435 |

||

|

8.39.2 |

Number conversion......................................................... |

1438 |

|

16 |

HEIDENHAIN Technical Manual TNC 620 |

9 |

Data Interfaces |

|

|

9.1 |

Introduction ................................................................................... |

1443 |

|

9.2 |

The Ethernet Interface .................................................................. |

1444 |

|

9.3 |

Connecting the Control to the Network ..................................... |

1445 |

|

|

9.3.1 |

Configuring the control’s network address ..................... |

1445 |

9.3.2Configuring network access to other devices

|

|

(mount)............................................................................ |

1447 |

|

9.3.3 |

Overview of functions for configuring the network ........ |

1449 |

9.4 |

HSCI Interface................................................................................ |

1451 |

|

9.5 |

The USB Interface of the Control (USB 1.1) ............................... |

1453 |

|

9.6 |

The Serial Interface of the Control .............................................. |

1456 |

|

|

9.6.1 |

RS-232-C/V.24 interface .................................................. |

1456 |

9.7 |

Configuring the Serial Interface................................................... |

1459 |

|

|

9.7.1 |

Control characters ........................................................... |

1459 |

|

9.7.2 |

Configuration of interfaces .............................................. |

1460 |

9.8 |

Data Transmission Protocols ....................................................... |

1472 |

|

|

9.8.1 |

Standard communications protocol................................. |

1472 |

9.8.2Communications protocol with block check

|

|

character.......................................................................... |

1474 |

|

9.8.3 |

LSV2 transmission protocol............................................. |

1477 |

9.9 |

Saving and Loading Files ............................................................. |

1478 |

|

9.10 |

Configuring the Control for TeleService 2.0 ............................... |

1479 |

|

9.11 |

Data Transfer by PLC .................................................................... |

1482 |

|

|

9.11.1 |

PLC modules................................................................... |

1482 |

10 |

Index |

|

|

October 2010 |

17 |

18 |

HEIDENHAIN Technical Manual TNC 620 |

1 Update Information

1.1 General Information

Update Information for the TNC 620 appears at irregular intervals, often as part of a new software version. This is preliminary information in PDF format, containing brief descriptions of new software functions as well as new hardware components. After the Update Information has been published, the new items are included in the TNC 620 Technical Manual.

Each Update Information is saved in the HEIDENHAIN FileBase on the Internet, where registered users can access it under http:// filebase.heidenhain.de.

Registered users of the HEIDENHAIN FileBase on the Internet receive an e-mail notification when a new Update Information appears.

November 2009 |

1.1 General Information |

19 |

|

|

|

|

|

|

|

|

20 |

HEIDENHAIN Technical Manual TNC 620 |

||

1 Update Information No. 1

1.1 Overview

1.1.1 Released Service Packs

The following service packs have been released for NC software 340 56x-01:

Service pack 1: 340 56x-01 SP1 |

First release: September 2008 |

Service pack 2: 340 56x-01 SP2 |

October 2008 |

Service pack 3: 340 56x-01 SP3 |

December 2008 |

1.1.2 Released NC Software

The following NC software has been released:

NC software 340 560-02

NC software 340 561-02

NC software 340 564-02

November 2009 |

1.1 Overview |

21 |

1.2 NC Software 340 560-01

Service packs

Warning

When needed, HEIDENHAIN prepares service packs for the various versions of the NC software. Registered customers can download these service packs from the HEIDENHAIN FileBase on the Internet. Installation of a service pack in addition to the already installed NC software implements important error fixes. Please ensure that the NC software always contains the latest service pack before you ship the machine. Perform all tests required of the machine or the NC software again after having installed the service pack.

The following service packs have been released for NC software 340 560-01:

Service pack 1 |

NC software |

Release |

340 560-01 SP1 |

340 560-01 |

First release in |

|

|

September 2008 |

|

|

|

|

|

|

Service pack 2 |

NC software |

Release |

340 560-01 SP2 |

340 560-01 |

October 2008 |

|

|

|

|

|

|

Service pack 3 |

NC software |

Release |

340 560-01 SP3 |

340 560-01 |

December 2008 |

|

|

|

22 |

HEIDENHAIN Technical Manual TNC 620 |

1.3 NC Software 340 551-04 / NC Software 340 560-02

1.3.1 Important Notes on Updating Software

Please remember the following important information when updating the software versions listed below:

TNC 320: 340 551-03 to 340 551-04 or

TNC 620: 340 560-01 to 340 560-02

Note

If you are using linear encoders with EnDat interface or motor encoders with EnDat interface for position measurement on your machine, you must carry out the following step.

Move the EnDat axes to known positions before the update:

A function for monitoring the SRAM contents for consistency will be introduced with new NC software. After the software update, all EnDat axes will therefore display the error message S-RAM contents of axis are invalid. At the same time, the control will display a dialog box for confirmation, in which the current (the displayed) position of the axis is compared with the physical (switch-off) position.

Move the axes to known positions before the update.

Write down the switch-off positions.

After the control has booted with the new software for the first time, confirm the positions of the EnDat axes.

Note

HEIDENHAIN recommends:

Making a backup of the control (e.g. with TNCbackup), before updating the

NC software.

Saving your current machine configuration. The configuration editor (DATA

BACKUP soft key) can be used for this purpose.

If you later want to undo the software update and return to the previous software version, you need the saved configuration data of the old version!

Note

Please perform the update of the NC software as described in the Technical

Manual in Chapter 2 "NC Software Exchange".

Note

Be sure to remember the important information about the software update, which is provided on the following pages.

November 2009 |

1.3 NC Software 340 551-04 / NC Software 340 560-02 |

23 |

Checking and saving new machine parameters:

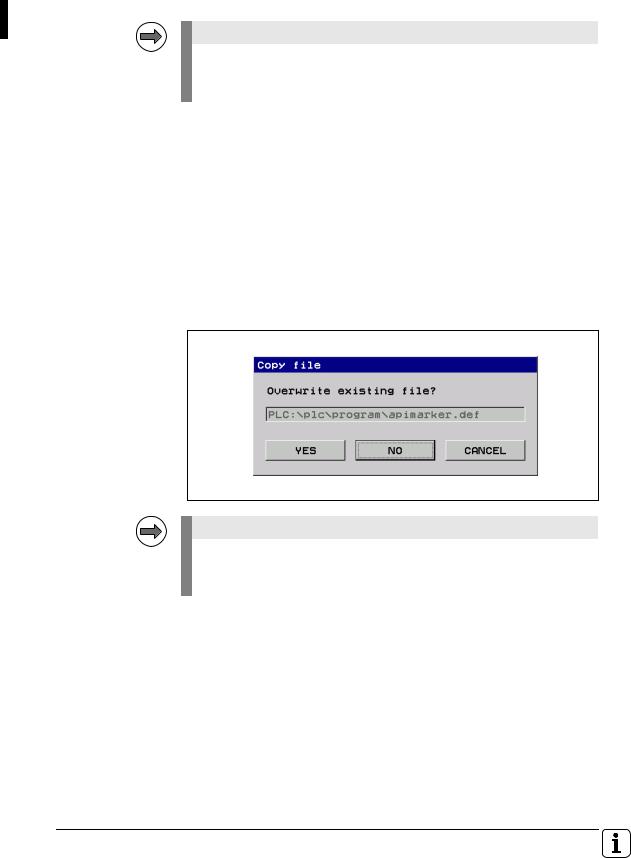

After having installed the new NC software and rebooted the control, you must check and confirm the new machine parameters. The MOD dialog box appears on the screen:

Enter the MP code number 95148 and confirm your entry with the ENT key.

Press the MORE FUNCTIONS soft key.

Press the UPDATE RULES soft key.

Check the listed update rules. Each entry in the list stands for a new parameter that was added to the system by the update.

Exit the UPDATE RULES with the END soft key.

Press the CONFIG DATA soft key.

Before the configuration editor opens, an informational window is displayed, reporting the removal of the CfgRestorePosition machine parameter. Press the NEXT soft key.

All new machine parameters are marked with a red exclamation point in the configuration editor. The control indicates if certain machine parameters are faulty. Please ignore these messages for the time being.

Important step: Press the SAVE soft key.

The Configuration data changed dialog box opens. Press the SAVE soft key again. The new machine parameters are now automatically saved in the *.cfg files.

Press the END soft key and exit the Machine Parameter Programming operating mode by pressing the END soft key again.

The control then continues booting.

Warning

When the control has booted up for the first time after the software update, the internal firmware of HSCI components must be updated.The control displays the error message Firmware update required.

After you have acknowledged the displayed error message, the control will start the update process automatically.

Never shut down the control while the firmware is being updated – otherwise the control will need servicing!

After the update is finished, the control displays another message on the screen. After you have acknowledged the message, the control will shut down automatically. Switch off the machines and restart the control.

24 |

HEIDENHAIN Technical Manual TNC 620 |

Note

Due to a software update regarding the evaluation of parameter MP_signCorrNominalVal (400002), you must check whether the spindle turns in the correct direction:

Check the direction of spindle rotation, and correct it if required:

After the booting process, the control displays the error message Check the parameter for the direction of spindle rotation!.