HEIDENHAIN Manualplus 620 Technical Manual

Technical Manual

MANUALplus 620

NC Software 548 328-03

November 2010

1 Update Information No. 1 |

|

|

1.1 |

Overview .............................................................................................. |

17 |

1.2 |

NC Software 548 328-02 ..................................................................... |

17 |

|

1.2.1 Important notes on updating software .................................. |

17 |

|

1.2.2 Description of the new functions .......................................... |

23 |

1 Update Information No. 2 |

|

|

1.1 |

Overview .............................................................................................. |

33 |

1.2 |

NC Software 548 328-03 ..................................................................... |

33 |

|

1.2.1 Important notes on updating software .................................. |

33 |

|

1.2.2 Description of the new functions .......................................... |

35 |

1 Update Information No. 3 |

|

|

1.1 |

Hardware.............................................................................................. |

43 |

|

1.1.1 UEC 11x controller unit with inverter and PLC I/O ................ |

43 |

2 |

Introduction |

|

2.1 |

Meaning of the Symbols Used in this Manual ................................. |

47 |

2.2 |

Proper Operation................................................................................. |

47 |

2.3 |

Trained Personnel ............................................................................... |

47 |

2.4 |

General Information............................................................................ |

48 |

|

2.4.1 HSCI interface........................................................................ |

51 |

2.5 |

Component Overview of MANUALplus 620 .................................... |

52 |

|

2.5.1 MC main computer, CFR memory card and SIK.................... |

52 |

|

2.5.2 SIK (System Identification Key).............................................. |

54 |

|

2.5.3 CC 6106 controller unit .......................................................... |

54 |

|

2.5.4 UEC 11x controller unit with integrated inverter and PLC ..... |

55 |

|

2.5.5 PLC input/output systems with HSCI interface ..................... |

57 |

|

2.5.6 PSL 130 low-voltage power supply unit ................................ |

61 |

|

2.5.7 MB 620T machine operating panel........................................ |

63 |

2.5.8HSCI Adapter for PLB 6001 OEM-Specific

|

Machine Operating Panel ...................................................... |

63 |

2.5.9 |

Handwheels........................................................................... |

64 |

2.5.10 |

Key symbols .......................................................................... |

67 |

2.5.11 |

Touch probes......................................................................... |

71 |

2.5.12 |

Other accessories.................................................................. |

74 |

2.5.13 |

Documentation ...................................................................... |

74 |

2.6 Brief Description.................................................................................. |

75 |

|

2.6.1 |

Specifications of the MANUALplus 620 ................................ |

75 |

2.6.2 |

User functions ....................................................................... |

80 |

2.6.3 |

Software options ................................................................... |

85 |

2.6.4 |

Accessories ........................................................................... |

86 |

November 2010 |

3 |

2.7 Software............................................................................................... |

88 |

|

2.7.1 |

Designation of the software .................................................. |

88 |

2.7.2 |

PLC software......................................................................... |

89 |

2.7.3 |

Enabling additional control loops or software options ........... |

89 |

2.7.4 |

Configurations ....................................................................... |

93 |

2.7.5 |

Coordinate system of the lathe ............................................. |

93 |

2.7.6 |

NC software exchange on the MANUALplus 620................. |

94 |

2.7.7 |

Installing a service pack....................................................... |

100 |

2.7.8 |

Reversing a software update............................................... |

101 |

2.7.9 |

Special features of the software ......................................... |

103 |

2.7.10 |

Firmware update on HSCI devices ...................................... |

104 |

2.7.11 |

Monitoring hardware changes............................................. |

106 |

2.7.12 |

Data backup......................................................................... |

106 |

2.8 Software Releases............................................................................. |

107 |

2.8.1 NC software 548 328-xx...................................................... |

107 |

3 Mounting and Electrical Installation

3.1 General Information.......................................................................... |

109 |

|

3.1.1 |

Safety precautions............................................................... |

109 |

3.1.2 |

Degrees of protection.......................................................... |

110 |

3.1.3 |

Electromagnetic compatibility ............................................. |

110 |

3.1.4 |

ESD protection .................................................................... |

111 |

3.2 Environmental Conditions................................................................ |

113 |

|

3.2.1 Storage and operating temperatures................................... |

113 |

|

3.2.2 Heat generation and cooling................................................ |

115 |

|

3.2.3 Limit values for ambient conditions..................................... |

116 |

|

3.2.4 |

Installation elevation ............................................................ |

116 |

3.2.5 |

MC6110T mounting position ............................................... |

117 |

3.2.6Mounting attitude of CC 61xx, UV xxx, UM xxx, UE 2xx B . 118

3.3 |

Overview of Components................................................................. |

119 |

|

3.4 |

HSCI .................................................................................................... |

|

122 |

|

3.4.1 |

Introduction ......................................................................... |

122 |

|

3.4.2 |

Topology .............................................................................. |

123 |

|

3.4.3 |

HSCI interface ..................................................................... |

124 |

3.5 |

Connection OverviewMANUALplus 620 ........................................ |

125 |

|

|

3.5.1 MC 6110T main computer................................................... |

125 |

|

|

3.5.2 |

CC 6106............................................................................... |

126 |

|

3.5.3 |

CC 6108............................................................................... |

127 |

|

3.5.4 |

UEC 11x............................................................................... |

128 |

|

3.5.5 |

PLB 62xx ............................................................................. |

130 |

|

3.5.6 |

PLB 61xx ............................................................................. |

130 |

|

3.5.7 I/O modules PLD-H and PLA-H............................................ |

131 |

|

3.6 |

Supply Voltages in the HSCI System .............................................. |

133 |

|

|

3.6.1 X90: +24 V NC output of the UxC 11x (FS) ......................... |

135 |

|

|

3.6.2 X101: NC power supply....................................................... |

136 |

|

|

3.6.3 Power supply of the CC61xx ............................................... |

137 |

|

|

3.6.4 PSL 130 low-voltage power supply unit .............................. |

140 |

|

4 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

3.7 UxC 11x (FS): Power Supply and Motor Connection..................... |

149 |

|

3.7.1 |

UEC 11x (FS)........................................................................ |

149 |

3.8 UxC 11x (FS): Meaning of the LEDs................................................. |

155 |

|

3.9 Power supply for PLC outputs ......................................................... |

156 |

|

3.10 Power Supply for PLB 6xxx (FS) ...................................................... |

157 |

|

3.11 Power supply for control-is-ready signal ........................................ |

157 |

|

3.12 Drive Controller Enable..................................................................... |

158 |

|

3.13 Digital PLC Inputs/Outputs .............................................................. |

159 |

|

3.13.1 |

UxC 11x (FS): Digital PLC inputs/outputs ............................ |

164 |

3.14 Analog PLC inputs/outputs.............................................................. |

169 |

|

3.15 PROFIBUS Connection...................................................................... |

171 |

|

3.16 Configuring the PLC Inputs/Outputs with IOconfig....................... |

172 |

|

3.17 Buffer battery..................................................................................... |

173 |

|

3.18 Encoder connections ........................................................................ |

174 |

|

3.18.1 |

General information ............................................................. |

174 |

3.18.2 |

Position encoder input ........................................................ |

175 |

3.18.3 |

Input of speed encoder ...................................................... |

177 |

3.19 Adapters for Encoder Signals .......................................................... |

183 |

|

3.20 Connecting the Motor Power Stages (Only CC 61xx).................... |

187 |

|

3.21 Touch Probe Systems ....................................................................... |

188 |

|

3.22 Data Interfaces................................................................................... |

191 |

|

3.22.1 |

USB interface (USB 2.0) ..................................................... |

194 |

3.23 MB 620T Machine Operating Panel ................................................. |

195 |

|

3.24 HSCI Adapter for PLB 6001 OEM-Specific |

|

|

Machine Operating Panel ................................................................. |

201 |

|

3.25 Handwheel Input ............................................................................... |

206 |

|

3.25.1 |

HR 410 portable handwheel ................................................ |

206 |

3.25.2 |

HR 130 panel-mounted handwheel ..................................... |

209 |

3.25.3 |

HRA 110 handwheel adapter............................................... |

210 |

3.26 CML 110 Capacitor Module .............................................................. |

212 |

|

3.27 Connecting Cable: Specifications .................................................... |

213 |

|

3.28 Dimensions ........................................................................................ |

214 |

|

3.28.1 |

MC 6110T............................................................................ |

215 |

3.28.2 |

MB 620T.............................................................................. |

216 |

3.28.3 |

CC 6106............................................................................... |

217 |

3.28.4 |

CC 6108 / CC 6110 .............................................................. |

218 |

3.28.5 |

UEC 11x (FS)........................................................................ |

219 |

3.28.6 |

PL 6xxx (FS)......................................................................... |

220 |

3.28.7 |

PLB 6001 (FS)...................................................................... |

221 |

3.28.8 |

PSL 130 ............................................................................... |

222 |

3.28.9 |

PSL 135 ............................................................................... |

223 |

3.28.10 Adapter block for the data interface .................................... |

224 |

|

3.28.11 USB hub............................................................................... |

225 |

|

3.28.12 Line-drop compensator........................................................ |

226 |

|

3.28.13 Handwheels......................................................................... |

226 |

|

3.28.14 Touch probes....................................................................... |

229 |

|

3.28.15 CML 110.............................................................................. |

236 |

|

3.28.16 USB hub for operating panel................................................ |

236 |

|

November 2010 |

5 |

3.29 HSCI Connection Overview of the MANUALplus 620 |

|

with CC 61xx...................................................................................... |

237 |

3.30 HSCI Connection Overview of the MANUALplus 620 |

|

with UEC 11x ..................................................................................... |

238 |

3.31 Grounding Diagram for MANUALplus 620 with Modular |

|

HEIDENHAIN Inverter System.......................................................... |

239 |

3.32 Basic Circuit Diagram for MANUALplus 620 .................................. |

240 |

3.33 Cable Overview for MANUALplus 620 with UEC 11x – Basic |

|

Configuration..................................................................................... |

241 |

3.34 Cable Overview for MANUALplus 620 with CC 610x – Basic |

|

Configuration..................................................................................... |

242 |

3.35 Cable Overview for HEIDENHAIN Inverter System........................ |

243 |

3.36 Cable Overview for MANUALplus 620 – Accessories .................... |

244 |

4 |

Machine Parameters |

|

|

4.1 |

General Information.......................................................................... |

245 |

|

4.2 |

The “Machine Parameter” Mode of Operation .............................. |

247 |

|

|

4.2.1 |

Calling the configuration editor............................................ |

247 |

|

4.2.2 Entering and changing machine parameters ....................... |

249 |

|

|

4.2.3 |

Accessing machine parameters via MP numbers ............... |

259 |

|

4.2.4 |

Managing configuration files ............................................... |

261 |

|

4.2.5 |

Sort file content ................................................................... |

261 |

|

4.2.6 |

Attribute information ........................................................... |

262 |

|

4.2.7 |

Access protection / options ................................................. |

264 |

|

4.2.8 |

Update rules ........................................................................ |

265 |

|

4.2.9 |

Remove syntax error ........................................................... |

275 |

|

4.2.10 Resets the update version................................................... |

275 |

|

|

4.2.11 |

Backup of parameters ......................................................... |

276 |

4.3 |

User Parameters................................................................................ |

277 |

|

|

4.3.1 |

Configuration of the user parameters.................................. |

278 |

|

4.3.2 |

Example:.............................................................................. |

284 |

|

4.3.3 |

XML commands for creating the layout files....................... |

286 |

4.4 |

The KeySynonym Function .............................................................. |

289 |

|

4.5 |

Allocation of Configuration Data .................................................... |

291 |

|

4.6 |

Structure of a Parameter File ........................................................... |

292 |

|

4.7 |

Machine-Parameter Subfiles ............................................................ |

295 |

|

|

4.7.1 Syntax of machine parameter subfile .................................. |

295 |

|

|

4.7.2 |

Activating the machine parameter subfile ........................... |

295 |

4.7.3Displaying/editing data records in the configuration editor.. 298

4.8 |

Read or Change Machine Parameters via a PLC Module .............. |

300 |

4.9 |

Switching Parameter Sets................................................................ |

306 |

6 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

4.10 Overview of Machine Parameters ................................................... |

316 |

|

4.10.1 |

"System" Group.................................................................... |

316 |

4.10.2 |

"Channels" group.................................................................. |

323 |

4.10.3 |

"Axes" group......................................................................... |

326 |

4.10.4 |

"KeySynonym" group............................................................ |

332 |

4.10.5 |

"Aggregates" group .............................................................. |

333 |

4.10.6 |

"ProcessingData" group........................................................ |

334 |

4.11 Parameter Overview Sorted by MP Numbers ................................ |

335 |

|

4.11.1 System configuration and miscellaneous ............................ |

336 |

|

4.11.2 |

Channel-specific parameters ............................................... |

356 |

4.11.3 |

Axis-specific parameters...................................................... |

361 |

4.11.4 Parameters for configuring the parameter sets................... |

363 |

|

4.11.5 Parameters for configuring tool carriers and tool holders.... |

370 |

|

4.11.6 |

Other parameters ................................................................ |

372 |

5 Modules and PLC Operands

5.1 |

Overview of Modules....................................................................... |

373 |

5.2 |

Overview of the PLC Operands....................................................... |

378 |

|

5.2.1 PLC operands of the General Data group ........................... |

378 |

|

5.2.2 PLC operands of the Operating Mode Group group........... |

380 |

|

5.2.3 PLC operands of the Machining Channels group ............... |

380 |

|

5.2.4 PLC operands of the Axis group ......................................... |

382 |

|

5.2.5 PLC operands of the Spindle group .................................... |

383 |

6 Configuring the Axes and Spindle

6.1 |

Machine Structure............................................................................. |

385 |

|

|

6.1.1 MANUALplus 620 Adapting to the machine........................ |

385 |

|

|

6.1.2 |

Definition of axes................................................................. |

386 |

6.2 Configuration of Machining Channels............................................. |

388 |

||

|

6.2.1 Configuring a machining channel......................................... |

388 |

|

|

6.2.2 Traversing the reference marks........................................... |

392 |

|

|

6.2.3 Returning to the contour/block scan.................................... |

393 |

|

6.3 |

Configuration of Axes ....................................................................... |

395 |

|

|

6.3.1 Axis designations and coordinates ...................................... |

397 |

|

|

6.3.2 |

Programmable axes ............................................................. |

399 |

|

6.3.3 |

Physical axes ....................................................................... |

402 |

|

6.3.4 |

Hirth coupling....................................................................... |

410 |

|

6.3.5 Kinematic properties of axes ............................................... |

412 |

|

|

6.3.6 Manual axis (counter axis) ................................................... |

414 |

|

6.4 |

Encoders............................................................................................. |

416 |

|

|

6.4.1 Type of position encoder ..................................................... |

416 |

|

|

6.4.2 Signal period of encoders .................................................... |

419 |

|

|

6.4.3 |

Distance-coded reference marks......................................... |

424 |

|

6.4.4 Connecting the encoders, PWM output on the CC 61xx .... |

426 |

|

|

6.4.5 Connecting the encoders to the UEC 11x ........................... |

431 |

|

|

6.4.6 Defining the traverse direction ............................................ |

433 |

|

|

6.4.7 |

Encoder monitoring ............................................................. |

435 |

November 2010 |

7 |

6.5 Reading and Writing Axis Information............................................ |

439 |

6.5.1 Reading axis information ..................................................... |

439 |

6.5.2Writing axis information—activating and deactivating axes. 444

6.6 |

Traverse Ranges ................................................................................ |

453 |

|

6.7 |

Lubrication Pulse............................................................................... |

454 |

|

6.8 |

PLC Axes ............................................................................................ |

457 |

|

6.9 |

Axis Error Compensation ................................................................. |

467 |

|

|

6.9.1 |

Backlash compensation....................................................... |

469 |

|

6.9.2 |

Linear axis error compensation ........................................... |

473 |

|

6.9.3 |

Nonlinear axis error compensation ...................................... |

475 |

|

6.9.4 |

Compensation of thermal expansion................................... |

482 |

|

6.9.5 |

Compensation of static friction............................................ |

484 |

|

6.9.6 |

Compensation of sliding friction .......................................... |

485 |

6.10 Machine kinematics on lathes (as of NC software 548328-03) ..... |

487 |

||

|

6.10.1 |

Configuring the machine kinematics ................................... |

490 |

|

6.10.2 |

Preconfigured subkinematics .............................................. |

497 |

|

6.10.3 |

Standard kinematics models ............................................... |

499 |

|

6.10.4 |

Find/activate kinematics through the PLC ........................... |

500 |

|

6.10.5 |

Axis mirroring on lathes (as of NC software 548328-03)..... |

501 |

6.11 Machine kinematics for lathes (up to NC software 548 328-02) ... |

502 |

||

|

6.11.1 |

Configuration of the machine kinematics ............................ |

503 |

|

6.11.2 |

Definition of the transformation with vectors...................... |

513 |

|

6.11.3 |

Axis mirroring for lathes ...................................................... |

516 |

6.12 Reference Marks................................................................................ |

517 |

||

|

6.12.1 |

Definition ............................................................................. |

517 |

|

6.12.2 |

Traversing the reference marks........................................... |

518 |

|

6.12.3 |

Traversing the reference marks........................................... |

521 |

|

6.12.4 |

Defining the process of traversing the reference marks ..... |

524 |

|

6.12.5 |

"Pass over reference point" operating mode ....................... |

531 |

6.13 The Control Loop............................................................................... |

535 |

||

|

6.13.1 |

Block diagram of control loop .............................................. |

535 |

|

6.13.2 |

Relation between jerk, acceleration, velocity and distance . 536 |

|

|

6.13.3 |

Nominal position value filter ................................................ |

538 |

|

6.13.4 |

Look-ahead .......................................................................... |

547 |

|

6.13.5 |

Interpolator .......................................................................... |

559 |

|

6.13.6 |

Position controller................................................................ |

560 |

|

6.13.7 |

Activating and deactivating position control loops............... |

569 |

|

6.13.8 |

Feed-rate enable.................................................................. |

573 |

|

6.13.9 |

Speed controller .................................................................. |

575 |

|

6.13.10 Filters in the speed controller and position controller |

|

|

|

|

when using the CC 61xx and CC 424.................................. |

579 |

|

6.13.11 CC 61xx/CC 424: filter order for separate low-pass filter |

|

|

|

|

in the speed controller......................................................... |

583 |

|

6.13.12 CC 61xx/CC424: peculiarities in weakened-field operation . 584 |

||

|

6.13.13 Active damping of low-frequency oscillations ..................... |

586 |

|

|

6.13.14 Acceleration feedforward control ........................................ |

588 |

|

|

6.13.15 IPC, holding torque, following error in the jerk phase ......... |

591 |

|

|

6.13.16 HSCI: switching drives on and off, enabling the drive |

|

|

|

|

controller .............................................................................. |

596 |

|

6.13.17 Current controller................................................................. |

605 |

|

|

6.13.18 Braking the drives for an EMERGENCY STOP and a power |

|

|

|

|

failure................................................................................... |

610 |

|

6.13.19 Power and torque limiting ................................................... |

613 |

|

|

|

|

|

8 |

|

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

|

6.13.20 Controller parameters for manual traverse .......................... |

620 |

|

6.13.21 Controller parameters for analog axes................................. |

621 |

|

6.13.22 Synchronous motors in field weakening range.................... |

632 |

|

6.13.23 Motor with wye/delta switchover........................................ |

634 |

|

6.13.24 Speed-dependent switching of the PWM frequency .......... |

636 |

|

6.13.25 TRC – torque ripple compensation ...................................... |

639 |

|

6.13.26 Torsion compensation ......................................................... |

642 |

|

6.14 Monitoring Functions ....................................................................... |

644 |

|

6.14.1 |

Monitoring the drives........................................................... |

644 |

6.14.2 |

Position monitoring.............................................................. |

646 |

6.14.3 |

Movement monitoring ......................................................... |

650 |

6.14.4 |

Standstill monitoring ............................................................ |

652 |

6.14.5 |

Positioning window ............................................................. |

653 |

6.14.6 Monitoring of the power supply unit .................................. |

656 |

|

6.14.7 |

Temperature monitoring...................................................... |

659 |

6.14.8 |

I2t monitoring....................................................................... |

662 |

6.14.9 Momentary utilization of drive motors................................. |

673 |

|

6.14.10 Status of HEIDENHAIN hardware and software.................. |

675 |

|

6.14.11 Motor brake ......................................................................... |

679 |

|

6.14.12 Emergency stop monitoring ................................................ |

680 |

|

6.14.13 Monitoring functions when using the CC 61xx and CC 424 685 |

||

6.15 Spindles.............................................................................................. |

687 |

|

6.15.1 |

Configuring spindles ............................................................ |

687 |

6.15.2 Position encoder of the spindle ........................................... |

688 |

|

6.15.3 Speed encoder of the spindle.............................................. |

689 |

|

6.15.4 Filtering the acceleration values .......................................... |

691 |

|

6.15.5 |

Controlling the spindle ......................................................... |

692 |

6.15.6 Oriented spindle stop (spindle point stop) ........................... |

703 |

|

6.15.7 Switching the operating modes........................................... |

706 |

|

6.15.8 Stopping/referencing the spindle at trip dog position .......... |

708 |

|

6.15.9 Analog spindle with unipolar motor ..................................... |

712 |

|

6.15.10 Spindle synchronism............................................................ |

713 |

|

6.15.11 Spindle of the kinematics model |

|

|

|

(as of NC software 548 328-03)........................................... |

716 |

6.15.12 Spindle of the kinematics model |

|

|

|

(until NC software 548 328-02)............................................ |

717 |

6.15.13 Gear shifting ........................................................................ |

718 |

|

6.15.14 Tapping ................................................................................ |

718 |

|

6.15.15 C-axis operation ................................................................... |

719 |

|

6.15.16 Volts-per-hertz control mode ............................................... |

721 |

|

6.16 Configuring the Controller Unit and Drive Motors ........................ |

723 |

|

6.16.1 Structure of the CC 61xx and UEC 11x controller units....... |

723 |

|

6.16.2 PWM frequencies with the CC 61xx ................................... |

725 |

|

6.16.3 |

PWM frequency with INDRAMAT "POWER DRIVE" |

|

|

inverters ............................................................................... |

727 |

6.16.4 PWM frequency with SIEMENS "SIMODRIVE" inverters .... |

727 |

|

6.16.5 Comparison of the CC 61xx and CC 424 controller units .... |

730 |

|

6.16.6 Configuring the servo motor................................................ |

732 |

|

6.16.7 Field orientation – fundamentals.......................................... |

735 |

|

6.16.8 Ascertaining the field angle with the CC 61xx or CC 424.... |

737 |

|

November 2010 |

9 |

6.17 Current Controller Adjustment ........................................................ |

745 |

|

6.18 Commissioning.................................................................................. |

747 |

|

6.18.1 Power module table and motor table .................................. |

747 |

|

6.18.2 |

Preparation .......................................................................... |

757 |

6.18.3 Commissioning of digital axes............................................. |

762 |

|

6.18.4 Commissioning of analog axes............................................ |

778 |

|

6.18.5 Commissioning the digital spindle....................................... |

799 |

|

6.19 Integrated Oscilloscope .................................................................... |

803 |

|

6.19.1 |

Fundamentals ...................................................................... |

803 |

6.19.2 |

Preparing a recording........................................................... |

805 |

6.19.3 |

Recording signals ................................................................ |

808 |

6.19.4 |

Analyzing the recording ....................................................... |

811 |

6.19.5 Saving and loading recordings ............................................. |

814 |

|

6.19.6 Circular interpolation test with the integrated oscilloscope. 815 |

||

6.19.7 Configuring the colors of the oscilloscope display .............. |

816 |

|

6.20 Diagnosis with the Online Monitor (OLM)...................................... |

820 |

|

6.20.1 |

Introduction ......................................................................... |

820 |

6.20.2 |

Using the OLM .................................................................... |

821 |

6.20.3 |

Screen layout....................................................................... |

823 |

6.20.4 Group of NC axes ................................................................ |

826 |

|

6.20.5 Group of spindle commands ............................................... |

846 |

|

6.20.6 Group of NC channels ......................................................... |

848 |

|

6.20.7 |

Hardware group................................................................... |

853 |

6.20.8 Group of drive commands ................................................... |

866 |

|

6.20.9 |

Auxiliary group ..................................................................... |

867 |

6.20.10 PLC group............................................................................ |

873 |

|

6.20.11 Queue trace......................................................................... |

876 |

|

6.20.12 Frequent causes of error ..................................................... |

878 |

|

7 |

Machine Interfacing |

|

|

7.1 |

Display and Operation ...................................................................... |

879 |

|

|

7.1.1 Unit of measurement for display and operation .................. |

879 |

|

|

7.1.2 |

Conversational language...................................................... |

881 |

|

7.1.3 |

Expanded menu structure ................................................... |

884 |

|

7.1.4 Access rights to NC files ..................................................... |

886 |

|

|

7.1.5 |

Code numbers ..................................................................... |

886 |

|

7.1.6 |

Programming station mode ................................................. |

887 |

7.1.7Operating modes / control operation in the operating mode

|

|

group ................................................................................... |

890 |

|

7.1.8 Control operation in the machining channel ........................ |

894 |

|

|

7.1.9 Error messages and log files ............................................... |

907 |

|

7.2 |

Machine Display in the Dashboard.................................................. |

931 |

|

|

7.2.1 Assigning dashboards to the operating modes ................... |

933 |

|

|

7.2.2 |

Configuring dashboards....................................................... |

936 |

7.3 |

PLC Soft Keys .................................................................................... |

947 |

|

7.4 |

Switching the Control On/Off.......................................................... |

948 |

|

|

7.4.1 Powering up the control ...................................................... |

948 |

|

|

7.4.2 Shutting down the control ................................................... |

952 |

|

7.5 |

Keystroke Simulation ....................................................................... |

960 |

|

|

7.5.1 |

Control keyboard ................................................................. |

960 |

|

7.5.2 |

Machine operating panel ..................................................... |

966 |

10 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

7.6 Electronic Handwheel ....................................................................... |

967 |

7.6.1 Serial handwheel ................................................................. |

967 |

7.6.2 Handwheel at position encoder input .................................. |

972 |

7.6.3 Traverse per handwheel revolution ..................................... |

977 |

7.6.4 Assigning a handwheel to an axis........................................ |

978 |

7.6.5 HR 410 portable handwheel ................................................ |

981 |

7.6.6HR 150 panel-mounted handwheels with HRA 110

|

|

handwheel adapter .............................................................. |

983 |

7.7 |

Override.............................................................................................. |

985 |

|

|

7.7.1 |

Override devices.................................................................. |

985 |

|

7.7.2 |

Compensation for potentiometers....................................... |

988 |

|

7.7.3 |

Override functions ............................................................... |

989 |

7.8 |

PLC Inputs/Outputs .......................................................................... |

994 |

|

|

7.8.1 |

Diagnosis of the external PL................................................ |

994 |

|

7.8.2 |

24 V– switching input/outputs ............................................ |

998 |

|

7.8.3 |

Analog inputs..................................................................... |

1002 |

|

7.8.4 |

Analog outputs................................................................... |

1005 |

7.9 Operating Times and System Times ............................................. |

1007 |

||

|

7.9.1 |

Measuring operating times................................................ |

1007 |

|

7.9.2 |

System time ...................................................................... |

1013 |

7.10 Touch Probe..................................................................................... |

1015 |

||

|

7.10.1 |

Tool measurement ............................................................ |

1017 |

7.11 Additional Parameters for Lathes.................................................. |

1020 |

||

|

7.11.1 |

Coordinate system of the lathe ......................................... |

1020 |

|

7.11.2 |

Linear axes......................................................................... |

1021 |

|

7.11.3 |

Spindles ............................................................................. |

1022 |

|

7.11.4 |

C axis ................................................................................. |

1025 |

|

7.11.5 |

Tool carriers ....................................................................... |

1027 |

|

7.11.6 |

Tool holders ....................................................................... |

1031 |

|

7.11.7 |

Transfer of data to the PLC................................................ |

1035 |

|

7.11.8 |

Conversions....................................................................... |

1038 |

|

7.11.9 |

Global settings ................................................................... |

1038 |

|

7.11.10 Settings for cycles ............................................................. |

1045 |

|

|

7.11.11 Settings for smart.TURN operating mode ......................... |

1047 |

|

|

7.11.12 Settings for the simulation................................................. |

1050 |

|

|

7.11.13 User parameters ................................................................ |

1055 |

|

7.12 Configuration of the Lathe ............................................................. |

1056 |

||

|

7.12.1 |

Coordinate system............................................................. |

1056 |

|

7.12.2 |

Settings for linear axes ...................................................... |

1057 |

|

7.12.3 |

Settings for spindles .......................................................... |

1058 |

|

7.12.4 |

Driven tool ......................................................................... |

1060 |

|

7.12.5 |

Settings for the C axis ....................................................... |

1062 |

|

7.12.6 |

Configuring the Y axis........................................................ |

1066 |

|

7.12.7 |

Configuring the W axis ...................................................... |

1073 |

|

7.12.8 |

Configuring the tool carrier ................................................ |

1080 |

|

7.12.9 |

Expert programs ................................................................ |

1086 |

|

7.12.10 Manual programs............................................................... |

1087 |

|

November 2010 |

11 |

8 |

PLC Programming |

|

|

8.1 |

PLC Functions .................................................................................. |

1089 |

|

|

8.1.1 |

The API 3.0 symbolic memory interface ........................... |

1090 |

|

8.1.2 |

HEIDENHAIN PLC basic program...................................... |

1094 |

|

8.1.3 |

Selecting the PLC programming mode of operation ......... |

1095 |

|

8.1.4 |

PLC main menu ................................................................. |

1096 |

|

8.1.5 |

File management............................................................... |

1098 |

|

8.1.6 |

The API DATA function...................................................... |

1099 |

|

8.1.7 |

The WATCH LIST function ................................................ |

1100 |

|

8.1.8 |

The TABLE function........................................................... |

1102 |

|

8.1.9 |

The TRACE function .......................................................... |

1104 |

|

8.1.10 |

The COMPILE function...................................................... |

1106 |

|

8.1.11 |

The EDIT function.............................................................. |

1107 |

|

8.1.12 |

Diagnostic functions .......................................................... |

1110 |

|

8.1.13 |

Bus diagnosis .................................................................... |

1111 |

8.2 Configuring PLC Input/Output Systems ....................................... |

1118 |

||

8.3 |

Operands.......................................................................................... |

1120 |

|

|

8.3.1 |

Operanden-Übersicht ........................................................ |

1120 |

|

8.3.2 |

Operand addressing (byte, word, double word) ................ |

1123 |

|

8.3.3 |

Timers and counters ......................................................... |

1124 |

|

8.3.4 |

Fast PLC inputs ................................................................. |

1134 |

8.4 |

Data Organization ........................................................................... |

1136 |

|

|

8.4.1 |

Data organization on the CFR memory card...................... |

1136 |

|

8.4.2 |

Data organization on the hard disk .................................... |

1137 |

|

8.4.3 |

Compressing graphic files ................................................. |

1138 |

8.4.4Configuring the displayed drives and directories in the file

|

manager ............................................................................. |

1139 |

8.4.5 |

PLC system files .............................................................. |

1141 |

8.5 M Functions (M Strobe).................................................................. |

1148 |

|

8.5.1 Assigning M functions to the machining channels............ |

1148 |

|

8.5.2 |

Configuration of M functions............................................. |

1149 |

8.5.3 Overview of M Functions of the MANUALplus 620.......... |

1158 |

|

8.6 S Function (S Strobe)...................................................................... |

1160 |

|

8.6.1 Assigning S functions to the machining channels ............. |

1160 |

|

8.6.2 |

Configuration of S function................................................ |

1161 |

8.7 T Functions (T Strobe) .................................................................... |

1173 |

|

8.7.1 Assigning T functions to the machining channels ............. |

1173 |

|

8.7.2 |

Configuration of T functions .............................................. |

1174 |

8.8 Alias Functions (Alias Strobe)....................................................... |

1181 |

|

8.8.1 |

Assigning alias functions to the machining channels ........ |

1181 |

8.8.2 Configuration of alias functions ......................................... |

1182 |

|

8.9 User-Defined Cycles ........................................................................ |

1184 |

|

8.10 Tables ............................................................................................... |

|

1185 |

8.10.1 |

Table Types of the MANUALplus 620 ............................... |

1186 |

8.10.2 |

Creating a new table type.................................................. |

1189 |

8.10.3 |

Defining a table prototype ................................................. |

1200 |

8.10.4 |

Defining the path for OEM tables...................................... |

1202 |

8.10.5 |

Symbolic names for tables ................................................ |

1202 |

8.10.6 |

Editing tables via the PLC ................................................. |

1204 |

8.10.7 |

Access to tables via SQL commands ................................ |

1218 |

8.10.8 |

PLC modules for the SQL statements .............................. |

1232 |

12 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

8.11 Data Transfer NC => PLC, PLC => NC ............................................ |

1251 |

|

8.11.1 |

Introduction........................................................................ |

1251 |

8.11.2 Data Transfer NC program => PLC ................................... |

1252 |

|

8.11.3 Data transfer machine parameters => PLC....................... |

1254 |

|

8.12 Program Creation ............................................................................ |

1256 |

|

8.12.1 |

ASCII editor........................................................................ |

1256 |

8.12.2 |

Program format.................................................................. |

1256 |

8.12.3 |

Program structure.............................................................. |

1257 |

8.13 Command Set.................................................................................. |

1258 |

|

8.13.1 |

Overview ........................................................................... |

1258 |

8.13.2 |

LOAD (L)............................................................................ |

1261 |

8.13.3 |

LOAD NOT (LN) ................................................................. |

1263 |

8.13.4 LOAD TWO’S COMPLEMENT (L–) ................................... |

1265 |

|

8.13.5 |

LOAD BYTE (LB)................................................................ |

1266 |

8.13.6 |

LOAD WORD (LW)............................................................ |

1266 |

8.13.7 LOAD DOUBLE WORD (LD) ............................................. |

1267 |

|

8.13.8 |

ASSIGN (=) ........................................................................ |

1267 |

8.13.9 |

ASSIGN BYTE (B=) ............................................................ |

1268 |

8.13.10 ASSIGN WORD (W=) ........................................................ |

1269 |

|

8.13.11 ASSIGN DOUBLE WORD (D=).......................................... |

1269 |

|

8.13.12 ASSIGN NOT (=N) ............................................................. |

1270 |

|

8.13.13 ASSIGN TWO’S COMPLEMENT (=–)................................ |

1270 |

|

8.13.14 SET (S) ............................................................................... |

1271 |

|

8.13.15 RESET (R) .......................................................................... |

1272 |

|

8.13.16 SET NOT (SN) .................................................................... |

1273 |

|

8.13.17 RESET NOT (RN) ............................................................... |

1274 |

|

8.13.18 AND (A).............................................................................. |

1275 |

|

8.13.19 AND NOT (AN)................................................................... |

1276 |

|

8.13.20 OR (O)................................................................................ |

1278 |

|

8.13.21 OR NOT (ON)..................................................................... |

1279 |

|

8.13.22 EXCLUSIVE OR (XO).......................................................... |

1280 |

|

8.13.23 EXCLUSIVE OR NOT (XON)............................................... |

1282 |

|

8.13.24 ADDITION (+) .................................................................... |

1283 |

|

8.13.25 SUBTRACTION (–) ............................................................. |

1284 |

|

8.13.26 MULTIPLICATION (X) ........................................................ |

1284 |

|

8.13.27 DIVISION (/) ....................................................................... |

1285 |

|

8.13.28 REMAINDER (MOD).......................................................... |

1286 |

|

8.13.29 INCREMENT (INC) ............................................................. |

1286 |

|

8.13.30 DECREMENT (DEC)........................................................... |

1287 |

|

8.13.31 EQUAL TO (==) ................................................................. |

1287 |

|

8.13.32 LESS THAN (<) .................................................................. |

1288 |

|

8.13.33 GREATER THAN (>)........................................................... |

1288 |

|

8.13.34 LESS THAN OR EQUAL TO (<=)....................................... |

1289 |

|

8.13.35 GREATER THAN OR EQUAL TO (>=) ............................... |

1290 |

|

8.13.36 NOT EQUAL (<>)............................................................... |

1291 |

|

8.13.37 AND [ ] (A[ ])....................................................................... |

1292 |

|

8.13.38 AND NOT [ ] (AN[ ])............................................................ |

1293 |

|

8.13.39 OR [ ] (O[ ])......................................................................... |

1293 |

|

8.13.40 OR NOT [ ] (ON[ ]).............................................................. |

1294 |

|

8.13.41 EXCLUSIVE OR [ ] (XO[ ])................................................... |

1294 |

|

8.13.42 EXCLUSIVE OR NOT [ ] (XON[ ])........................................ |

1294 |

|

8.13.43 ADDITION [ ] (+[ ]) ............................................................. |

1294 |

|

8.13.44 SUBTRACT [ ] (–[ ])............................................................. |

1295 |

|

8.13.45 MULTIPLY [ ] (x[ ]).............................................................. |

1295 |

|

8.13.46 DIVIDE [ ] (/[ ]) .................................................................... |

1296 |

|

November 2010 |

13 |

8.13.47 REMAINDER [ ] (MOD[ ])................................................... |

1296 |

8.13.48 EQUAL TO [ ] (==[ ]) .......................................................... |

1296 |

8.13.49 LESS THAN [ ] (<[ ]) ........................................................... |

1297 |

8.13.50 GREATER THAN [ ] (>[ ]) ................................................... |

1297 |

8.13.51 LESS THAN OR EQUAL TO [ ] (<=[ ])................................ |

1298 |

8.13.52 GREATER THAN OR EQUAL TO [ ] (>=[ ]) ........................ |

1298 |

8.13.53 NOT EQUAL [ ] (<>[ ])........................................................ |

1298 |

8.13.54 SHIFT LEFT (<<) ................................................................ |

1298 |

8.13.55 SHIFT RIGHT (>>).............................................................. |

1300 |

8.13.56 BIT SET (BS) ...................................................................... |

1300 |

8.13.57 BIT CLEAR (BC) ................................................................. |

1301 |

8.13.58 BIT TEST (BT) .................................................................... |

1302 |

8.13.59 PUSH DATA ONTO THE DATA STACK (PS)...................... |

1303 |

8.13.60 PULL DATA FROM THE DATA STACK (PL) ...................... |

1304 |

8.13.61 PUSH LOGIC ACCUMULATOR ONTO THE |

|

DATA STACK (PSL)............................................................. |

1304 |

8.13.62 PUSH WORD ACCUMULATOR ONTO THE |

|

DATA STACK (PSW) .......................................................... |

1305 |

8.13.63 PULL LOGIC ACCUMULATOR FROM THE |

|

DATA STACK (PLL) ............................................................ |

1305 |

8.13.64 PULL WORD ACCUMULATOR FROM THE |

|

DATA STACK (PLW) .......................................................... |

1306 |

8.13.65 UNCONDITIONAL JUMP (JP) ........................................... |

1306 |

8.13.66 JUMP IF LOGIC ACCUMULATOR = 1 (JPT) ..................... |

1307 |

8.13.67 JUMP IF LOGIC ACCUMULATOR = 0 (JPF) ..................... |

1308 |

8.13.68 CALL MODULE (CM) ........................................................ |

1308 |

8.13.69 CALL MODULE IF LOGIC ACCUMULATOR = 1 (CMT).... |

1308 |

8.13.70 CALL MODULE IF LOGIC ACCUMULATOR = 0 (CMF).... |

1309 |

8.13.71 END OF MODULE, END OF PROGRAM (EM).................. |

1310 |

8.13.72END OF MODULE IF LOGIC ACCUMULATOR = 1 (EMT) 1310

8.13.73END OF MODULE IF LOGIC ACCUMULATOR = 0 (EMF) 1310

8.13.74 LABEL (LBL) ...................................................................... |

1310 |

8.14 INDEX Register (X Register)........................................................... |

1311 |

8.15 Commands for String Processing.................................................. |

1313 |

8.16 LOAD String (L) ............................................................................... |

1315 |

8.17 ADD String (+).................................................................................. |

1315 |

8.18 STORE String (=) ............................................................................. |

1315 |

8.19 OVERWRITE String (OVWR)........................................................... |

1316 |

8.20 EQUAL TO Command for String Processing (==)......................... |

1317 |

8.21 LESS THAN Command for String Processing (<) ......................... |

1317 |

8.22 GREATER THAN Command for String Processing (>) ................. |

1317 |

8.23 LESS THAN OR EQUAL TO Command for |

|

String Processing (<=)..................................................................... |

1318 |

8.24 GREATER THAN OR EQUAL TO Command for |

|

String Processing (>=)..................................................................... |

1318 |

8.25 NOT EQUAL Command for String Processing (<>)...................... |

1319 |

8.26 Modules for String Processing....................................................... |

1320 |

14 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

8.27 Submit programs ............................................................................ |

|

1323 |

|

8.28 Calling the Submit Program (SUBM) ............................................ |

1324 |

||

8.29 Interrogating the Status of a Submit Program (RPLY)................ |

1324 |

||

8.30 Canceling a Submit Program (CAN) .............................................. |

1325 |

||

8.31 Cooperative Multitasking ............................................................... |

1327 |

||

8.31.1 Starting a parallel process (SPAWN).................................. |

1327 |

||

8.31.2 |

Control of events ............................................................... |

1328 |

|

8.32 Constants Field (KF) ........................................................................ |

1334 |

||

8.33 Program Structures......................................................................... |

1335 |

||

8.33.1 |

IF ... ELSE ... |

ENDI structure ............................................. |

1336 |

8.33.2 |

REPEAT ... |

UNTIL structure............................................... |

1336 |

8.33.3 |

WHILE ... ENDW structure ................................................ |

1337 |

|

8.34 CASE branch .................................................................................... |

|

1338 |

|

8.35 Linking Files ..................................................................................... |

|

1339 |

|

8.36 USES Statement (USES) ................................................................ |

1339 |

||

8.37 GLOBAL Statement (GLOBAL)....................................................... |

1341 |

||

8.38 EXTERN Statement (EXTERN) ....................................................... |

1341 |

||

8.39 PLC Modules .................................................................................... |

|

1342 |

|

8.39.1 Markers, bytes, words, and double words ........................ |

1342 |

||

8.39.2 |

Number conversion ........................................................... |

1345 |

|

9 |

Data Interfaces |

|

|

9.1 |

Introduction ..................................................................................... |

1349 |

|

9.2 |

The Ethernet Interface .................................................................... |

1350 |

|

9.3 |

HSCI interface .................................................................................. |

1351 |

|

9.4 |

The USB Interface of the Control (USB 1.1).................................. |

1353 |

|

9.5 |

The Serial Interface of the Control ................................................ |

1356 |

|

|

9.5.1 |

RS-232-C/V.24 interface..................................................... |

1356 |

|

9.5.2 |

RS-422/V.11 interface ........................................................ |

1359 |

9.6 |

Configuring the Serial Interface..................................................... |

1361 |

|

|

9.6.1 |

Control characters.............................................................. |

1361 |

|

9.6.2 |

Configuration of interfaces ................................................ |

1362 |

9.7 |

Data Transmission Protocols ......................................................... |

1373 |

|

|

9.7.1 |

Standard communications protocol ................................... |

1373 |

|

9.7.2 |

Communications protocol with block check character ...... |

1375 |

|

9.7.3 |

LSV2 transmission protocol ............................................... |

1378 |

9.8 |

Saving and Loading Files................................................................ |

1379 |

|

9.9 |

Configuring the Control for TeleService 2.0 ................................. |

1380 |

|

9.10 The Transfer Mode of Operation ................................................... |

1383 |

||

9.11 Data Transfer by PLC ...................................................................... |

1384 |

||

|

9.11.1 |

PLC Modules ..................................................................... |

1384 |

10 Index

November 2010 |

15 |

16 |

HEIDENHAIN Technisches Handbuch MANUALplus 620 |

1 Update Information No. 1

1.1Overview

1.2NC Software 548 328-02

1.2.1 Important notes on updating software

Please remember the following important information when updating the software versions listed below:

MANUALplus 620: 548 328-01 to 548 328-02

Note

If you are using linear encoders with EnDat interface or motor encoders with EnDat interface for position measurement on your machine, you must carry out the following step.

Move the EnDat axes to known positions before the update:

A function for monitoring the SRAM contents for consistency is introduced with the new NC software. After the software update, all EnDat axes will therefore display the error message S-RAM contents of axis are invalid. At the same time, the control will display a dialog box for confirmation, in which the current (the displayed) position of the axis is compared with the physical (switch-off) position.

Move the axes to known positions before the update.

Write down the switch-off positions.

After the control has booted with the new software for the first time, confirm the positions of the EnDat axes.

Note

HEIDENHAIN recommends:

Making a backup of the control (e.g. with TNCbackup), before updating the

NC software.

Saving your current machine configuration. The configuration editor (DATA

BACKUP soft key) can be used for this purpose.

If you later want to undo the software update and return to the previous software version, you need the saved configuration data of the old version!

Note

Please perform the update of the NC software as described in the Technical

Manual in Chapter 2 "NC Software Exchange".

Note

Be sure to remember the important information about the software update, which is provided on the following pages.

November 2010 |

1.2 NC Software 548 328-02 |

17 |

Checking and saving new machine parameters:

After having installed the new NC software and rebooted the control, you must check and confirm the new machine parameters. The code number dialog box appears on the screen:

Enter the MP code number 95148 and confirm your entry with the ENT key.

Press the UPDATE RULES soft key.

Check the listed update rules. Each entry in the list stands for a new parameter that was added to the system by the update.

Exit the UPDATE RULES with the END soft key.

Press the CONFIG DATA soft key.

Before the configuration editor opens, an informational window is displayed, reporting the removal of the CfgRestorePosition machine parameter. Press the NEXT soft key.

All new machine parameters are marked with a red exclamation point in the configuration editor. The control indicates if certain machine parameters are faulty. Please ignore these messages for the time being.

Important step: Press the SAVE soft key.

The Configuration data changed dialog box opens. Press the SAVE soft key again. The new machine parameters are now automatically saved in the *.cfg files.

Press the END soft key and exit the Machine Parameter operating mode by pressing the END soft key again.

The control then continues booting.

Note

The definition file of the symbolic programming interface API 3.0 has been expanded. You must perform the step described below in order for the PLC program to be compiled successfully after the update.

Replace the apimarker.def file:

During the update of the NC software, a new version of the apimarker.def file was automatically copied to the PLC partition of the control. Proceed as follows:

Switch to the Organization mode of operation.

Enter the code number 95148 to call the Machine Parameter mode of operation.

Press the END soft key and switch the soft-key row.

Press the PGMMGT  soft key to open the file manager.

soft key to open the file manager.

Switch to the PLC:\proto\plc directory.

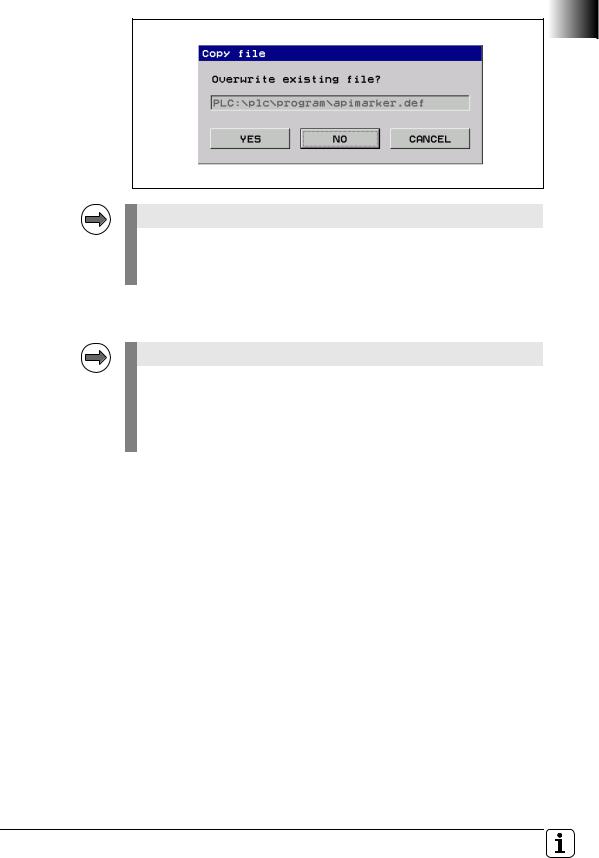

Copy the apimarker.def file to the program directory of your PLC program. Overwrite the existing apimarker.def file:

18 |

HEIDENHAIN Technical Manual MANUALplus 620 |

Note

Please also copy the apimarker.def file to your PC as well, and add it to the PLCdesignNT project. Otherwise, during the next transfer of PLC project files to the control, the file might be overwritten by the old version.

Note

After an update, please modify the previous file oem_turning.mcg as described below, and add it to the PLCdesignNT project. Otherwise, during the next transfer of PLC project files to the control, the file oem_turning.mcg might be overwritten by the old version, which leads to an error.

Modify the max. number of spindles in the file oem.mcg or oem_turning.mcg:

To modify the max. number of spindles in the PLC file oem.mcg or oem_turning.mcg, proceed as follows:

...

DEFINE SPINDLE_COUNT |

= 6 |

; (old: =4) |

...

November 2010 |

1.2 NC Software 548 328-02 |

19 |

Note

After an update, please modify the previous file plc.cfg as described below, and add it to the PLCdesignNT project. Otherwise, during the next transfer of PLC project files to the control, the file plc.cfg might be overwritten by the old version, which leads to an error (Fatal Error Syntax).

Modify the plc.cfg file:

The current plc.cfg file is located in the control in the directory PLC:\config\lathe\manplus\plc.cfg. You can use TNCremoNT to copy the file from the control to the PLC project, or you can use PLCdesignNT to modify the previous file in the PLC project.

Make the following changes to the plc.cfg file:

CfgPlcOverrideDev ( |

|

key:="PotentiometerF", |

|

source:=OVR1, |

|

mop:="MB", |

; This line must be added. |

mode:=LINEAR, |

|

values:=[] |

|

) |

|

CfgPlcOverrideDev ( |

|

key:="PotentiometerS", |

|

source:=OVR2, |

|

mop:="MB", |

; This line must be added. |

mode:=LINEAR, |

|

values:=[] |

|

) |

|

CfgPlcStrobes ( |

|

... |

|

sStrobe:=[ |

; Add an opening bracket |

"S1" |

|

], |

; Add a closing bracket |

... |

|

) |

|

20 |

HEIDENHAIN Technical Manual MANUALplus 620 |

CfgPlcOverrideS (

key:="S1", |

|

minimal:=0.5, |

|

maximal:=1.5, |

|

source:= [ |

; Add an opening bracket |

"PotentiometerS" |

|

] |

; Add a closing bracket |

)

CfgPlcOverrideS (

key:="S2", |

|

minimal:=1, |

|

maximal:=1, |

|

source:= [ |

; Add an opening bracket |

"PotentiometerS" |

|

] |

; Add a closing bracket |

)

CfgPlcOverrideF (

key:="CH_NC1", |

|

minimal:=0, |

|

maximal:=1.5, |

|

source:= [ |

; Add an opening bracket |

"PotentiometerF" |

|

] |

; Add a closing bracket |

) |

|

CfgPlcMop ( |

; Add this and all the following data |

key:="MB", |

|

type:=MB, |

|

primary:=FALSE,

omg:=0,

spindle:=0

)

CfgPlcMop ( key:="HR", type:=HR, primary:=FALSE, omg:=0, spindle:=0

)

November 2010 |

1.2 NC Software 548 328-02 |

21 |

Note

Please observe the following note if you

are using the HEIDENHAIN PLC Basic Program!

It is essential that you check and modify the PLC program:

The behavior of the symbolic API marker NN_ChnProgCancel (NC program cancelation) has been changed: NN_ChnProgCancel will now be set every time the NC program is canceled. For a normal end of program,

NN_ChnProgEnd will be set. The NN_ChnProgCancel marker remains set during the complete Cancel cycle and beyond the program end until the next NC program is started.

When a program is canceled, the NN_ChnProgEnd marker will not be set. The end of program run, including the execution of a Cancel cycle, has been reached when NN_ChnControlInOperation is reset. NN_ChnProgCancel and NN_ChnProgEnd will be reset when NN_ChnControlInOperation is set again.

If both NN_ChnProgCancel and NN_ChnControlInOperation are set, this indicates that the Cancel cycle is being executed.

Module 9429 or 9320 can be used to inquire the reason for the program cancelation.

Please check the following lines in the PLC basic program and modify them if required:

German: Biblioth.src

;External/Internal STOP

L |

ApiChn.NN_ChnProgCancel |

AN |

ML_Internal_STOP |

=MG_Impuls_Internal_STOP

L ApiChn.NN_ChnProgCancel

=ML_Internal_STOP

English: Library.src

;External/Internal STOP

L |

ApiChn.NN_ChnProgCancel |

AN |

ML_Internal_STOP |

=MG_pulse_internal_stop

L ApiChn.NN_ChnProgCancel

=ML_Internal_STOP

22 |

HEIDENHAIN Technical Manual MANUALplus 620 |

1.2.2 Description of the new functions |

|

||

New software |