HEIDENHAIN iTNC 530 Service Manual

Service Manual

iTNC 530

July 2010

1 How to Use this Service Manual ........................................................................................ |

11 |

|

1.1 |

Target Group ............................................................................................................... ... |

11 |

1.2 |

About this Manual ......................................................................................................... |

11 |

1.3 |

Other Service Manuals .................................................................................................. |

12 |

1.4 |

Other Documentation .................................................................................................... |

12 |

1.5 |

Support .................................................................................................................... ...... |

12 |

1.6 |

Service Training ........................................................................................................... .. |

12 |

1.7 |

Meaning of the Symbols Used in this Manual ............................................................... |

13 |

1.8 |

Safety ..................................................................................................................... ....... |

13 |

2 Safety Precautions............................................................................................................... |

15 |

|

2.1 |

Overview ................................................................................................................... .... |

15 |

3 Code Numbers ..................................................................................................................... |

17 |

|

3.1 |

Introduction ............................................................................................................... .... |

17 |

3.2 |

Overview ................................................................................................................... .... |

17 |

3.3 |

Input of Code Numbers .......................................................................................... ...... |

18 |

4 Error Messages .................................................................................................................... |

21 |

|

4.1 |

Introduction ............................................................................................................... .... |

21 |

4.2 |

HELP Key ................................................................................................................... .... |

25 |

4.3 |

ERR Key ................................................................................................................... ..... |

26 |

4.4 |

CE Key .................................................................................................................... ...... |

28 |

4.5 |

List of NC Error Messages ............................................................................................ |

29 |

5 Errors Patterns ..................................................................................................................... |

55 |

|

5.1 |

Introduction ............................................................................................................... .... |

55 |

5.2 |

Overview of Possible Error Patterns .............. ............................................................... |

55 |

6 Procedures and Tips for Error Diagnosis ........................................................................... |

59 |

|

6.1 |

Introduction ............................................................................................................... .... |

59 |

6.2 |

Power Off and On ......................................................................................................... |

59 |

6.3 |

Sequence for Finding Serious Electrical Errors ........................................................ ...... |

60 |

6.4 |

Sequence for Finding Errors in the Control Loop .................................................... ...... |

62 |

6.5 |

Error Localization by Process of Interchange . ............................................................... |

65 |

6.6 |

Error Localization by Process of Exclusion ... ................................................................. |

66 |

6.7 |

Finding Position Differences of Direct and Indirect Encoder ......................................... |

68 |

6.8 |

Error Localization by Switching from Direct to Indirect Position Measurement ............ |

70 |

6.9 |

Notes and Tips ............................................................................................................. .. |

72 |

7 Creating and Downloading of Service Files ...................................................................... |

77 |

|

7.1 |

Introduction ............................................................................................................... .... |

77 |

7.2 |

Automatic Generation of Service Files .......................................................................... |

78 |

7.3 |

Automatic Generation of Service Files .......................................................................... |

78 |

7.4 |

Downloading of Service Files ....................... ................................................................. |

79 |

8 Log |

......................................................................................................................................... |

81 |

8.1 ................................................................................................................... |

Introduction |

81 |

8.2 ............................................................................................................... |

Calling the Log |

82 |

8.3 ................................................................................................ |

Overview of Log Entries |

83 |

8.4 .............................................................................. |

Log Entries at Program Cancelation |

87 |

9 Integrated ...............................................................Diagnostic Functions and DriveDiag |

89 |

|

9.1 ................................................................................................................... |

Introduction |

89 |

9.2 ............................................................................................... |

Activation and Operation |

90 |

9.3 ........................................................................................................ |

For Error Diagnosis |

98 |

10 Integrated .....................................................................................................Oscilloscope |

99 |

|

10.1 .................................................................................................................Introduction |

99 |

|

10.2 ..............................................................................................Activation and Settings |

100 |

|

10.3 .........................................................................Recording and Adjusting the Signals |

105 |

|

10.4 .................................................................................Saving and Loading Recordings |

110 |

|

July 2010 |

HEIDENHAIN Service Manual iTNC 530 |

10.5 |

For Error Diagnosis.................................................................................................... |

111 |

10.5.1 Triggering on error marker ............................................................................... |

111 |

|

10.5.2 Circular interpolation test ................................................................................. |

113 |

|

10.5.3 Descriptions in this manual ............................................................................. |

114 |

|

11 PLC Diagnosis................................................................................................................... |

115 |

|

11.1 |

Introduction ............................................................................................................... |

115 |

11.2 |

Possible Causes of Errors ......................................................................................... |

118 |

11.3 |

Diagnosis Tools in the PLC Mode ............................................................................. |

119 |

11.3.1 The TABLE function ......................................................................................... |

119 |

|

11.3.2 The LOGIC diagram ......................................................................................... |

125 |

|

11.3.3 The TRACE function ....................................................................................... |

128 |

|

11.3.4 The WATCH LIST function .............................................................................. |

129 |

|

11.3.5 The I / O - FORCE LIST .................................................................................... |

131 |

|

11.3.6 PROFIBUS diagnosis ....................................................................................... |

133 |

|

11.4 |

Non-Volatile PLC Markers and Words ....................................................................... |

136 |

11.5 |

Overviews ................................................................................................................. |

138 |

11.6 |

Specifications ............................................................................................................ |

147 |

11.6.1 PLC inputs ....................................................................................................... |

147 |

|

11.6.2 Analog inputs ................................................................................................... |

148 |

|

11.6.3 Inputs for thermistors ...................................................................................... |

148 |

|

11.6.4 PLC outputs ..................................................................................................... |

149 |

|

12 Hard Disk and File Manager of the iTNC 530 ................................................................ |

151 |

|

12.1 |

Introduction ............................................................................................................... |

151 |

12.2 |

Structure of the Hard Disk......................................................................................... |

152 |

12.3 |

Possible Causes of Error ........................................................................................... |

152 |

12.4 |

Test of Hard Disk ..................................................................................................... |

153 |

12.5 |

Setting the System Time........................................................................................... |

159 |

12.6 |

Setting the Program Manager .................................................................................. |

162 |

12.7 |

File Management of TNC Partition ........................................................................... |

163 |

12.8 |

File Management of PLC Partition ............................................................................ |

165 |

13 Data Backup ..................................................................................................................... |

169 |

|

13.1 |

Introduction ............................................................................................................... |

169 |

13.2 |

Connection Setup...................................................................................................... |

172 |

13.2.1 Via Ethernet ..................................................................................................... |

172 |

|

13.2.2 Via serial interface RS-232-C or RS-422 ........................................................... |

182 |

|

13.2.3 Via USB ............................................................................................................ |

185 |

|

13.3 |

Reading In and Out of Individual Files or Directories ................................................ |

186 |

13.4 |

Backup on an External Data Medium ........................................................................ |

192 |

13.5 |

Extracting Files from the Backup File........................................................................ |

196 |

13.6 |

Restoring Data........................................................................................................... |

197 |

13.7 |

Cable Overview ......................................................................................................... |

200 |

13.7.1 Ethernet interface RJ45 connection ................................................................ |

200 |

|

13.7.2 RS-232-C (V.24) ............................................................................................... |

201 |

|

13.7.3 RS-422 (V.11) .................................................................................................. |

204 |

|

13.8 |

Operating Modes of the Data Interfaces................................................................... |

205 |

13.8.1 Overview of operating modes ......................................................................... |

205 |

|

13.8.2 Interface configuration and assignment of mode ............................................ |

206 |

|

13.9 |

Drive Symbols ........................................................................................................... |

207 |

14 Reloading the NC Software Used .................................................................................. |

209 |

|

14.1 |

Introduction ............................................................................................................... |

209 |

14.2 |

Preparations .............................................................................................................. |

209 |

14.3 |

Proceeding up to NC Software 34049x-02 (Single-Processor Version) ..................... |

210 |

14.4 |

Proceeding as of NC Software 34049x-02 (Single-Processor Version)...................... |

212 |

14.5 |

Proceeding for the Dual-Processor Version............................................................... |

215 |

HEIDENHAIN Service Manual iTNC 530

15 Loading of Service Packs ................................................................................................ |

219 |

|

15.1 |

Introduction ............................................................................................................... |

219 |

15.2 |

Preparations............................................................................................................... |

220 |

15.3 |

Execution up to NC Software 34049x-01 (Single and Dual Processor Version) ........ |

221 |

15.4 |

Execution as of NC Software 34049x-02 (Single-Processor Version)........................ |

223 |

15.5 |

Execution as of NC Software 34049x-02 (Dual-Processor Version) .......................... |

226 |

16 Checking the Enables on the iTNC 530.......................................................................... |

229 |

|

16.1 |

Introduction ............................................................................................................... |

229 |

16.2 |

Examination ............................................................................................................... |

232 |

16.2.1 Checking the "Control is ready" output and input |

|

|

|

(EMERGENCY STOP chain) ....................................................................................... |

233 |

16.2.2 Checking the global drive enable I32, connector X42 / pin 33 ......................... |

239 |

|

16.2.3 Checking the drive enabling for the axis groups via connector |

|

|

|

X150 and X151 (if wired) ............................................................................................ |

242 |

16.2.4 Checking the readiness of the inverter system ............................................... |

243 |

|

16.2.5 Checking PLC modules, markers and words ................................................... |

248 |

|

17 Power Supply ................................................................................................................... |

251 |

|

17.1 |

Power Supply for the iTNC 530 ................................................................................. |

251 |

17.1.1 Introduction ...................................................................................................... |

251 |

|

17.1.2 UV 105, UV 105 B ............................................................................................ |

256 |

|

17.1.3 UV 106, UV 106 B ............................................................................................ |

260 |

|

17.2 |

Power Supply for "Control-Is-Ready Signal" ............................................................... |

262 |

17.3 |

Buffer Battery ............................................................................................................ |

264 |

17.4 |

Information Menu...................................................................................................... |

267 |

17.5 |

Power Supply for PLC Outputs ................................................................................. |

268 |

17.5.1 Introduction ...................................................................................................... |

268 |

|

17.5.2 Supply voltage for PLC outputs on the MC ..................................................... |

269 |

|

17.5.3 Supply voltage for PLC outputs on the PL 4xx B ............................................. |

272 |

|

17.5.4 Supply voltage for PLC outputs on the PL 510 ................................................ |

274 |

|

17.6 |

Power Supply for the Display Units........................................................................... |

276 |

18 Encoder Interface ............................................................................................................. |

277 |

|

18.1 |

Position Encoders...................................................................................................... |

277 |

18.1.1 Introduction ...................................................................................................... |

277 |

|

18.1.2 Possible causes of errors ................................................................................. |

279 |

|

18.1.3 Troubleshooting ............................................................................................... |

280 |

|

18.1.4 Possibilities with the integrated diagnosis or DriveDiag .................................. |

282 |

|

18.1.5 Possibilities with the integrated oscilloscope .................................................. |

283 |

|

18.1.6 Corrective action .............................................................................................. |

286 |

|

18.1.7 Determining the field angle on linear motors, torque motors and |

|

|

|

synchronous spindles ................................................................................................ |

287 |

18.1.8 Resetting the machine datum ......................................................................... |

288 |

|

18.1.9 Restoring the spindle orientation ..................................................................... |

292 |

|

18.2 |

Speed Encoders ........................................................................................................ |

293 |

18.2.1 Introduction ..................................................................................................... |

293 |

|

18.2.2 Possible causes of errors ................................................................................. |

295 |

|

18.2.3 Trouble shooting on the CC 422 ...................................................................... |

296 |

|

18.2.4 Trouble shooting on the CC 424 (B) ................................................................. |

298 |

|

18.2.5 Possibilities with the integrated diagnosis or DriveDiag .................................. |

300 |

|

18.2.6 Possibilities with the integrated oscilloscope .................................................. |

301 |

|

18.2.7 Corrective action .............................................................................................. |

304 |

|

18.2.8 Readjusting the trip dog for reference end position ........................................ |

305 |

|

18.2.9 Resetting the machine datum ......................................................................... |

306 |

|

18.2.10 Restoring the spindle orientation ................................................................... |

306 |

|

18.3 |

Error Codes for Encoders with EnDat Interface ........................................................ |

307 |

18.4 |

Further Examination of Position and Speed Encoders .............................................. |

308 |

July 2010 |

HEIDENHAIN Service Manual iTNC 530 |

18.5 |

Position Measurement via Motor Encoder (Indirect Position Measurement) ........... |

311 |

18.6 |

Switching over the Position Display for Servicing ..................................................... |

315 |

19 Reference Run .................................................................................................................. |

317 |

|

19.1 |

Definition ................................................................................................................... |

317 |

19.2 |

Traversing the Reference Marks ............................................................................... |

318 |

19.3 |

Possible Causes of Errors ......................................................................................... |

318 |

19.4 |

Troubleshooting......................................................................................................... |

319 |

19.5 |

Corrective Action....................................................................................................... |

320 |

19.6 |

Deselecting the Reference Run for Axes.................................................................. |

320 |

19.7 |

Retraction after an Error with Control Reset ............................................................. |

321 |

20 Interface to the Drives ..................................................................................................... |

323 |

|

20.1 |

Digital PWM Interface ............................................................................................... |

323 |

20.1.1 Introduction ..................................................................................................... |

323 |

|

20.1.2 Tables for power supply modules, power stages and motors ........................ |

326 |

|

20.1.3 Possible causes of error .................................................................................. |

332 |

|

20.1.4 Sequence for finding errors in the control loop ............................................... |

332 |

|

20.1.5 Troubleshooting: Interchanging PWM outputs on the CC 422 ........................ |

333 |

|

20.1.6 Troubleshooting: Interchanging PWM outputs on the CC 424 (B) .................. |

336 |

|

20.1.7 Troubleshooting: Interchanging power modules or output stages of |

|

|

the same type ............................................................................................................. |

339 |

|

20.1.8 Troubleshooting: Interchanging the HEIDENHAIN interface boards |

|

|

|

for the SIMODRIVE 611 system ............................................................................... |

342 |

20.1.9 Corrective action .............................................................................................. |

343 |

|

20.2 |

Analog Speed Command Interface ........................................................................... |

344 |

20.2.1 Introduction ..................................................................................................... |

344 |

|

20.2.2 Possible causes of error .................................................................................. |

344 |

|

20.2.3 Sequence for finding errors in the control loop ............................................... |

345 |

|

20.2.4 Checking the analog speed command interface ............................................. |

346 |

|

20.2.5 Adjusting the electrical offset (drift adjustment) ............................................. |

349 |

|

20.2.6 Speed adjustment at the servo amplifier (tachometer adjustment) ................ |

352 |

|

20.2.7 Corrective action .............................................................................................. |

354 |

|

21 Visual Display Unit .......................................................................................................... |

355 |

|

21.1 |

Introduction ............................................................................................................... |

355 |

21.2 |

Possible Causes of Errors ......................................................................................... |

355 |

21.3 |

Troubleshooting......................................................................................................... |

356 |

21.4 |

Corrective Action....................................................................................................... |

358 |

22 Keyboard Unit .................................................................................................................. |

359 |

|

22.1 |

Introduction ............................................................................................................... |

359 |

22.2 |

Front View of the Keyboard Units ............................................................................ |

360 |

22.3 |

Possible Causes of Error ........................................................................................... |

362 |

22.4 |

Checking the Keys..................................................................................................... |

363 |

22.5 |

Checking the Potentiometers.................................................................................... |

367 |

22.6 |

Checking the Touchpads ........................................................................................... |

370 |

22.7 |

Corrective Action....................................................................................................... |

371 |

22.8 |

Key Matrix of the Keyboard Units ............................................................................. |

372 |

22.9 |

Key Matrix of the Keyboard Units ............................................................................. |

388 |

23 Machine Operating Panel................................................................................................ |

389 |

|

23.1 |

Introduction ............................................................................................................... |

389 |

23.2 |

Possible Causes of Errors ......................................................................................... |

390 |

23.3 |

Checking the Power Supply ...................................................................................... |

391 |

23.4 |

Checking the Keys..................................................................................................... |

392 |

23.5 |

Checking the Outputs ............................................................................................... |

397 |

23.6 |

Corrective Action....................................................................................................... |

398 |

HEIDENHAIN Service Manual iTNC 530

24 Handwheel........................................................................................................................ |

399 |

|

24.1 |

Introduction ............................................................................................................... |

399 |

24.2 |

Possible Causes of Errors.......................................................................................... |

400 |

24.3 |

Error Location on Portable Handwheel with HR 420 Display .................................... |

401 |

24.4 |

Error Diagnosis at HR 410 Portable Handwheel........................................................ |

406 |

24.5 |

Deselecting and Disconnecting the Portable Handwheel ......................................... |

409 |

24.6 |

Error Diagnosis at Panel-Mounted Handwheels........................................................ |

410 |

24.7 |

Corrective Action ....................................................................................................... |

412 |

25 Touch Probe ..................................................................................................................... |

413 |

|

25.1 |

Introduction ............................................................................................................... |

413 |

25.2 |

Possible Causes of Errors.......................................................................................... |

417 |

25.3 |

Error Diagnosis on TS Touch Probes ......................................................................... |

418 |

25.4 |

Error Diagnosis on TT Touch Probes ......................................................................... |

422 |

25.5 |

Error Diagnosis on Laser Touch Probe ...................................................................... |

425 |

25.6 |

Deselecting and Disconnecting the Touch Probe...................................................... |

426 |

25.7 |

Corrective Action ....................................................................................................... |

427 |

26 Important Features of HEIDENHAIN Components ....................................................... |

429 |

|

26.1 |

HEIDENHAIN Components in a Machine Tool .......................................................... |

429 |

26.2 Hardware Identification ............................................................................................. |

430 |

|

26.3 |

Display of Important System Information.................................................................. |

443 |

27 Connector Designation and Layout ............................................................................... |

447 |

|||

27.1 |

Important Note .......................................................................................................... |

447 |

||

27.2 MC and CC ................................................................................................................ |

447 |

|||

27.2.1 Designation and position of connectors .......................................................... |

447 |

|||

27.2.2 Pin Layouts on the MC and CC ........................................................................ |

457 |

|||

27.3 |

Power Supply Units ................................................................................................... |

487 |

||

27.3.1 UV 105 power supply unit ............................................................................... |

488 |

|||

27.3.2 UV 105 B power supply unit ............................................................................ |

490 |

|||

27.3.3 UV 106 (B) power supply unit .......................................................................... |

492 |

|||

27.4 |

Monitors .................................................................................................................... |

493 |

||

27.4.1 |

Designation and position of connectors ......................................................... |

493 |

||

27.4.2 |

Pin layouts ...................................................................................................... |

494 |

||

27.5 |

Keyboard Units .......................................................................................................... |

495 |

||

27.5.1 Designation and position of connectors .......................................................... |

495 |

|||

27.5.2 Pin layouts ....................................................................................................... |

497 |

|||

27.6 |

BTS 1x0 Monitor/Keyboard Switch............................................................................ |

498 |

||

27.7 |

Machine Operating Panel ....................................................................................... |

499 |

||

27.7.1 Designation and position of connectors .......................................................... |

499 |

|||

27.7.2 Pin Layouts on MB 420 ................................................................................... |

499 |

|||

27.7.3 Pin layouts on MB 520 ..................................................................................... |

500 |

|||

27.8 |

Handwheels............................................................................................................... |

503 |

||

27.8.1 HR 4xx portable handwheel ............................................................................. |

503 |

|||

27.8.2 HR 130 panel-mounted handwheel ................................................................. |

504 |

|||

27.8.3 HRA 110 handwheel adapter ........................................................................... |

505 |

|||

27.9 |

Touch Probes............................................................................................................. |

507 |

||

27.10 |

PLC Input/Output Units ........................................................................................ |

507 |

||

27.10.1 Designation and position of connectors ........................................................ |

507 |

|||

27.10.2 PL 4xxB Pin Layouts ...................................................................................... |

510 |

|||

27.10.3 Pin layouts for PL 510 .................................................................................... |

516 |

|||

27.11 Encoders.................................................................................................................. |

520 |

|||

27.11.1 Position encoders .......................................................................................... |

520 |

|||

27.11.2 Speed encoders ............................................................................................. |

522 |

|||

27.12 |

Inverters and Motors .............................................................................................. |

522 |

||

27.13 Interface Boards for the SIMODRIVE System 611D ............................................. |

522 |

|||

July 2010 |

HEIDENHAIN Service Manual iTNC 530 |

28 Exchange of HEIDENHAIN Components........................................................................ |

523 |

|

28.1 |

Important Information ............................................................................................... |

523 |

28.2 |

Exchange of the MC 422........................................................................................... |

531 |

28.3 |

Exchange of the Drive Assembly .............................................................................. |

537 |

28.4 Exchange of the MC 422 B, MC 422 C, MC 420 ...................................................... |

542 |

|

28.5 |

Exchange of the HDR................................................................................................ |

544 |

28.6 |

Exchange of the CC................................................................................................... |

551 |

28.7 |

Exchange of the Buffer Battery................................................................................. |

552 |

28.8 |

Exchange of Other HEIDENHAIN Components ........................................................ |

553 |

28.9 |

Exchange of HEIDENHAIN Components in the SIMODRIVE System ...................... |

554 |

29 Measuring, Testing and Inspection Equipment ............................................................ |

561 |

|

29.1 |

Important Notes ........................................................................................................ |

561 |

29.2 |

Test Adapter.............................................................................................................. |

562 |

29.3 |

PWM 9 Encoder Diagnostic Set................................................................................ |

566 |

29.4 |

PWT 10/17/18 Testing Unit ....................................................................................... |

568 |

29.5 |

IK 215 Adjusting and Testing Package ...................................................................... |

570 |

30 Machine Parameter ........................................................................................................ |

571 |

|

30.1 |

Explanation ................................................................................................................ |

571 |

30.2 |

The Machine Parameter Editor.................................................................................. |

572 |

30.3 |

Meaning of the Machine Parameters........................................................................ |

579 |

30.4 |

List of Machine Parameters ...................................................................................... |

580 |

30.4.1 Encoders and machines .................................................................................. |

580 |

|

30.4.2 Positioning ....................................................................................................... |

586 |

|

30.4.3 Operation with Velocity Feedforward Control ................................................. |

592 |

|

30.4.4 Operation with following error (servo lag) ....................................................... |

593 |

|

30.4.5 Integrated speed and current control .............................................................. |

594 |

|

30.4.6 Spindle ............................................................................................................. |

603 |

|

30.4.7 Integrated PLC ................................................................................................. |

606 |

|

30.4.8 Configuration of the Data Interface ................................................................. |

609 |

|

30.4.9 3-D touch probe ............................................................................................... |

611 |

|

30.4.10 Tool Measurement with TT ........................................................................... |

613 |

|

30.4.11 Tapping .......................................................................................................... |

616 |

|

30.4.12 Display and operation .................................................................................... |

617 |

|

30.4.13 Color .............................................................................................................. |

624 |

|

30.4.14 Machining and Program Run ......................................................................... |

627 |

|

30.4.15 Hardware ....................................................................................................... |

634 |

|

30.4.16 Second spindle .............................................................................................. |

643 |

|

1 Annex: Principle of Function of the iTNC 530 Control.................................................... |

645 |

|

1.1 Introduction ................................................................................................................. |

645 |

|

1.2 The Control Loop......................................................................................................... |

645 |

|

1.3 PWM Signals............................................................................................................... |

654 |

|

2 Annex: Principle of Function of the iTNC 530 Control.................................................... |

657 |

|

3 Annex: Monitoring Functions ........................................................................................... |

661 |

|

3.1 Introduction ................................................................................................................. |

661 |

|

3.2 During Start-Up............................................................................................................ |

661 |

|

3.3 During Operation ......................................................................................................... |

663 |

|

3.3.1 Position or servo lag monitoring ........................................................................ |

664 |

|

3.3.2 Nominal speed value monitoring ....................................................................... |

666 |

|

3.3.3 Movement monitoring ....................................................................................... |

667 |

|

3.3.4 Standstill monitoring .......................................................................................... |

669 |

|

3.3.5 Positioning window ........................................................................................... |

670 |

|

3.3.6 Monitoring of the power supply unit ................................................................. |

672 |

|

3.3.7 Temperature monitoring .................................................................................... |

674 |

|

3.3.8 Internal power supply and housing fan .............................................................. |

675 |

|

HEIDENHAIN Service Manual iTNC 530

3.3.9 I2t monitoring ..................................................................................................... |

676 |

3.3.10 Actual utilization of drive motors ..................................................................... |

681 |

3.3.11 Status of HEIDENHAIN inverters ..................................................................... |

682 |

3.3.12 Controlling the motor brakes ........................................................................... |

684 |

3.3.13 EMERGENCY STOP monitoring during operation ........................................... |

687 |

July 2010 |

HEIDENHAIN Service Manual iTNC 530 |

HEIDENHAIN Service Manual iTNC 530

1 How to Use this Service Manual

1.1Target Group

This Service Manual has been written for specialist electricians for service, maintenance and commissioning.

Specialists who perform work on the electrical system of a machine tool and its components must have the required technical knowledge and competence!

1.2About this Manual

This Service Manual assists service personnel in the field in diagnosing and correcting errors on machine tools controlled by iTNC 530.

It includes:

Error messages and types of errors that indicate technical defects

Information on possible error causes

Descriptions of error diagnosis

Application descriptions of the diagnosis tools

Information on corrective action

Data backup instructions

Theoretical explanations of functions and their correlations

The ”List of NC Error Messages” on page 4 – 29 and the ”Overview of Possible Error Patterns” on page 5 – 55 include many references to the descriptions for error diagnosis. You will find these descriptions in the chapters of this Service Manual sorted by topics.

The Service Manual does not provide any commissioning support!

It comprises the service possibilities with the current hardware and software at the editing date of this manual. The service possibilities of your devices may differ from those described here. The descriptions also provide information on any peculiarities of the hardware or software.

This manual is valid for:

iTNC 530, single-processor with NC software 340420 / 421

iTNC 530, single-processor with NC software 340422 / 423

iTNC 530, dual-processor with NC software 340480 / 481

iTNC 530, single-processor with NC software 340490 / 491

iTNC 530, dual-processor with NC software 340492 / 493

For the instructions for the field service it is assumed that ...

the machine had been working perfectly before the error occurred!

only original parts are used!

Note

Basic knowledge in Windows is required for some descriptions in this Service Manual concerning the handling of the dual-processor control iTNC 530 and the use of a service laptop or PC.

July 2010 |

1 – 11 |

Udpate service |

This Service Manual is updated at irregular intervals. |

|

You find the current printable version on our website --> |

|

http://www.heidenhain.de/ ... /SHB iTNC 530 |

|

If you take part in a service training, you receive also a paper version of the Service Manual. |

1.3Other Service Manuals

Service Manual for Inverter Systems and Motors

1.4Other Documentation

For more important information please refer to the following documentation:

Machine documentation by the manufacturer

(circuit diagrams, wiring diagrams, machine operating manual, etc.)

HEIDENHAIN User's Manual for iTNC 530

HEIDENHAIN TNCguide on DVD

Mounting instructions by HEIDENHAIN

Brochures of the respective HEIDENHAIN products

PWM 9 User's Manual

PWT Operating Instructions

IK 215 Operating Instructions

Note

You can find up-to-date issues of this and other HEIDENHAIN documents quickly on our website --> www.heidenhain.de

Note

HEIDENHAIN software tools (e.g. TNCremoNT) feature detailed on-line help.

1.5Support

Caution

The machine manufacturer must be contacted first for error diagnosis on your machine tool!

However, support will also be provided by the Service Department of HEIDENHAIN Traunreut or by the HEIDENHAIN agencies.

You will find telephone numbers as well as e-mail addresses on the back cover of this Service Manual, or on the HEIDENHAIN website (www.heidenhain.de).

1.6Service Training

HEIDENHAIN Traunreut offers service training courses in German language. We recommend the HEIDENHAIN Service Training Seminars for iTNC 530 for the technician who works with this Service Manual.

Please contact HEIDENHAIN Traunreut or visit our website (www.heidenhain.de).

Note

If required, please inquire at the HEIDENHAIN subsidiary in your country whether Service Training Seminars are offered in your language.

1 – 12 |

HEIDENHAIN Service Manual iTNC 530 |

1.7Meaning of the Symbols Used in this Manual

DANGER

Failure to comply with this information could result in most serious or fatal injuries, and/or in substantial material damage.

Caution

Failure to comply with this information could result in injuries and interruptions of operation, including material damage.

Note

These boxes contain important and useful information.

1.8Safety

DANGER

It is extremely important that you read the safety precautions in chapter 2 before you start servicing!

See “Safety Precautions” on page 2 – 15.

July 2010 |

1 – 13 |

1 – 14 |

HEIDENHAIN Service Manual iTNC 530 |

2 Safety Precautions

2.1Overview

Ground

DANGER

Ensure that the equipment grounding conductor is continuous!

Interruptions in the equipment grounding conductor may cause damage to persons or property.

Zero potential

DANGER

Ensure that the main switch of the control is switched off and that connected devices are not under power when you engage or disengage any connectors or terminals.

Take precautions against restart!

Use an appropriate voltage test unit to ensure that the unit is not under voltage!

Fundamental

knowledge

DANGER

In order to be able to judge the behavior of an NC controlled machine, service engineers need to have fundamental knowledge of controls, encoders, drives, electronics and mechanics.

Improper use can result in serious injury to persons and damage to equipment.

Know-how and

competence

DANGER

Technicians who work on the electrical system of the machine must have the required know-how and competence!

Suitable

tools

DANGER

Use suitable tools, e.g. insulated screwdrivers and pincers!

Safety precautions of the machine

manufacturer

Caution

Note the safety precautions on the machine (e.g. labels, signs) and the safety precautions in the documentation of the machine manufacturer (e.g., operating instructions).

Regulations for power installations and instructions for safety and prevention of accidents

DANGER

Observe the national regulations for power installations and the general instructions for safety and prevention of accidents!

July 2010 |

2 – 15 |

Basic insulation

DANGER

The interfaces for the PLC inputs/outputs, machine operating panel and PL expansion cards comply with the basic insulation in accordance with IEC 742 EN 50 178.

Only units that comply with the requirements of IEC 742 EN 50 178 for basic insulation may be connected, otherwise damage to persons or property may be caused.

The maximum dc voltage mean value of the PLC inputs is 31 V.

Vertical axes

DANGER

Always secure vertical axes to prevent them from falling down before you perform tests on these axes!

Changes to entry values

DANGER

Incorrect or non-optimized input values can lead to faulty machine performance and therefore to serious injury to persons and damage to equipment.

Machine parameters may only be changed by the machine manufacturer or after consulting the machine manufacturer!

Uncontrolled axis and spindle movements must be expected.

Settings that have an effect on the control's feedback loops may only be altered when the EMERGENCY STOP button of the machine is pressed.

Liability

Caution

HEIDENHAIN does not accept any responsibility for indirect or direct damage caused to persons or property through incorrect use or operation of the machine!

2 – 16 |

HEIDENHAIN Service Manual iTNC 530 |

3 Code Numbers

3.1Introduction

With code numbers …

certain areas of the hard disk

certain file types

certain functions

... can be called.

DANGER

Code numbers may only be passed on to and be used by trained service technicians. Keep the code numbers confidential!

Inexpert handling may result in a loss of important data, in faulty machine performance and thus lead to damage or injury to property or persons.

3.2Overview

Code number |

Brief description |

Description in |

|

|

this manual |

|

|

|

0 |

Delete the code numbers entered so far --> Code-number |

In this chapter |

|

softkeys, such as MP EDIT or PLC EDIT are deleted. |

|

|

|

|

123 |

Edit subset of machine parameters for the machine operator |

See page 30 - 571 |

|

|

|

75368 |

Offset adjustment for analog axes |

See page 20 – 349 |

|

|

|

79513 |

Info menu (U[BATT], U[ACCU], U[VCC], TEMP, T[CPU1]), |

See page 17 – 267 |

|

|

|

95148 |

Call the active machine parameter list |

See page 30 – 572 |

|

|

|

531210 |

Reset non-volatile PLC markers and PLC words in the RAM |

See page 11 – 133 |

|

|

|

688379 |

Integrated oscilloscope |

See page 10 – 99 |

|

|

|

807667 |

Call the PLC area |

See page 11 – 115 |

|

|

|

857282 |

Reset the operating times |

- |

|

|

|

LOGBOOK |

Call and save the internal log of the TNC |

See page 8 – 81 |

|

|

|

NET123 |

Network settings for the single-processor control |

See page 13 – 172 |

|

|

|

SETUP |

Call for loading of service packs and NC software for the single- |

See page 15 – 219 |

|

processor control |

|

|

|

|

SIK |

Display of the number of the system identification key and of the |

See page 28 – 525 |

|

enabled options |

|

|

|

|

VERSION |

Create the file TNC:\Version.a |

- |

|

System data is saved in this file for diagnostic purposes. The file |

|

|

can be read out for diagnosis. |

|

|

|

|

|

Note |

|

The machine manufacturer can define own MP and PLC code numbers.

In this event the HEIDENHAIN code numbers do not function any longer, or only function to a limited extent. --> Contact your machine manufacturer!

July 2010 |

3 – 17 |

3.3Input of Code Numbers

8 Select the Programming and Editing operating mode.

8 If open: Close the program management by pressing the END button.

Note

Pressing the MOD key while the program manager is open calls the interface settings.

8 Call the code number window.

8 Enter the code number and press ENT to confirm.

Note

When certain code numbers are entered, new soft keys are displayed, MP EDIT, PLC EDIT, OSCI.

With these soft keys you can also change to the corresponding areas without having to enter the code number again.

When you have finished your work, reset all previously entered code numbers:

8Enter the code number 0 and press ENT to confirm.

8Press END to exit the code-number page.

Note

All key codes are reset when the control is restarted.

3 – 18 |

HEIDENHAIN Service Manual iTNC 530 |

Additional notes

As long as the machine parameter list is in the editor, no further code number can be entered. First close the MP editor if you want to enter a new code number

After you have entered the code number for the machine parameters the PLC tree can be seen in the program manager.

Only files with the extension .MP are displayed.

After entering the PLC code number all files in the PLC tree can be seen and loaded in the editor.

However, to edit machine parameters, the soft key MP EDIT needs to be pressed first.

July 2010 |

3 – 19 |

3 – 20 |

HEIDENHAIN Service Manual iTNC 530 |

4 Error Messages

4.1Introduction

Type of error message

iTNC features a comprehensive integral monitoring system for the prevention of input or operation errors, as well as for identification and diagnosis of technical defects on the control and the connected devices. The monitoring system is an integral component of the iTNC hardware and software and is active as long as the control is switched on. The presence of a technical fault or an operation error is made known through a plain-language message.

The effect of the monitoring functions is described in the annex -- .> See “Annex: Monitoring Functions” on page 3 – 661.

Moreover, the machine manufacturer can define specific PLC error messages.

PLC error messages

Machine-specific error messages

Are defined by the machine manufacturer (e.g., coolant pump defective, protective door open).

The machine manufacturer defines how the control reacts to a PLC error message (NC Stop, EMERGENCY STOP, etc.).

The machine manufacturer defines whether the control can still be operated or has to be rebooted after a PLC error message.

If you have any questions, please contact your machine manufacturer.

NC error messages

Are part of the HEIDENHAIN NC software.

Can be subdivided into error messages that result from operation, programming and machine applications and those that indicate a technical defect (devices, electronic and mechanical components, etc.)

HEIDENHAIN defines how the control reacts to an NC error message (NC Stop, EMERGENCY STOP, etc.)

HEIDENHAIN defines whether the control can still be operated or has to be rebooted after an NC error message.

If you have any questions, please contact your machine manufacturer and/or HEIDENHAIN.

Is the displayed error message an NC or PLC error message?

Display |

PLC error message |

NC error message |

|

|

|

ERR window in the column |

PLC |

GENERAL |

"Group". |

|

or |

Call --> |

|

OPERATION |

See “ERR Key” on page 4 – 26. |

|

or |

|

|

PROGRAMMING |

|

|

|

Log |

P- (number and text of |

N- (number and text of |

Call --> |

error message) |

error message) |

See “Log” on page 8 – 81. |

|

|

|

|

|

Note

There are no error numbers assigned to NC error messages that begin with N-1.

Operating-system error messages

Often contain the note CHILD PROCESS ERROR.

The control cannot be operated any more and has to be rebooted.

If you have any questions, please contact your machine manufacturer and/or HEIDENHAIN.

July 2010 |

4 – 21 |

Display of the error message

All error messages that can be acknowledged with the CE key are …

Displayed in the screen header (at the top of the screen) usually in red color.

As a plain-language message.

Figure: Error message in the header

The machine manufacturer can display additional information on PLC error messages in the small PLC window (above the soft-key row).

Figure: Additional information in the small PLC window

Error messages that require a rebooting of the control ...

are displayed in a red or gray window (depending on the NC software version) in the center of the screen.

are made known through a plain-language message.

Figure: Red error window

4 – 22 |

HEIDENHAIN Service Manual iTNC 530 |

Figure: Gray error window

July 2010 |

4 – 23 |

Reaction of control and machine

Automatic generation of service files

Display only

A message (info, warning, error) is only displayed.

The machine does not react. Programs are not stopped.

The error message can be acknowledged anytime.

Feed stop

The feed-rate enable is reset. The "F"symbol for the feed rate is highlighted.

The axes are braked at the nominal-value characteristic. The contour of the workpiece is usually not damaged.

Once the error message is acknowledged, the machine continues to operate at the set feed rate.

Program cancellation

The running NC progam is canceled.

The axes are braked at the nominal-value characteristic. The contour of the workpiece is usually not damaged.

After the error message was acknowledged, the NC program needs to be restarted (GOTO 0, NC-START).

NC stop

The running NC progam is stopped. The star "*" (STIB) flashes.

The axes are braked at the nominal-value characteristic. The contour of the workpiece is usually not damaged.

After the error message was acknowledged, the NC program can be restarted at the position where it was interrupted (NC-START key).

EMERGENCY STOP

An EMERGENCY STOP is triggered at the machine.

Axes and spindles decelerate at the current limit; the machine must be brought to a standstill as quickly as possible.

The contour of the workpiece is not taken into account and may be damaged.

After the error message was acknowledged, the machine must be switched on completely. Now, the PLC program can be restarted (GOTO 0, NC START).

RESET

An EMERGENCY STOP is triggered at the machine.

Axes and spindles decelerate at the current limit; the machine must be brought to a standstill as quickly as possible.

The contour of the workpiece is not taken into account and may be damaged.

The error message cannot be acknowledged. The control must be shut down and restarted. Now, the PLC program can be restarted (GOTO 0, NC START).

As of NC software version 340 49x-04:

In the event of serious NC software errors or PLC error messages especially defined for this purpose service files are generated automatically.

See “Creating and Downloading of Service Files” on page 7 – 77.

4 – 24 |

HEIDENHAIN Service Manual iTNC 530 |

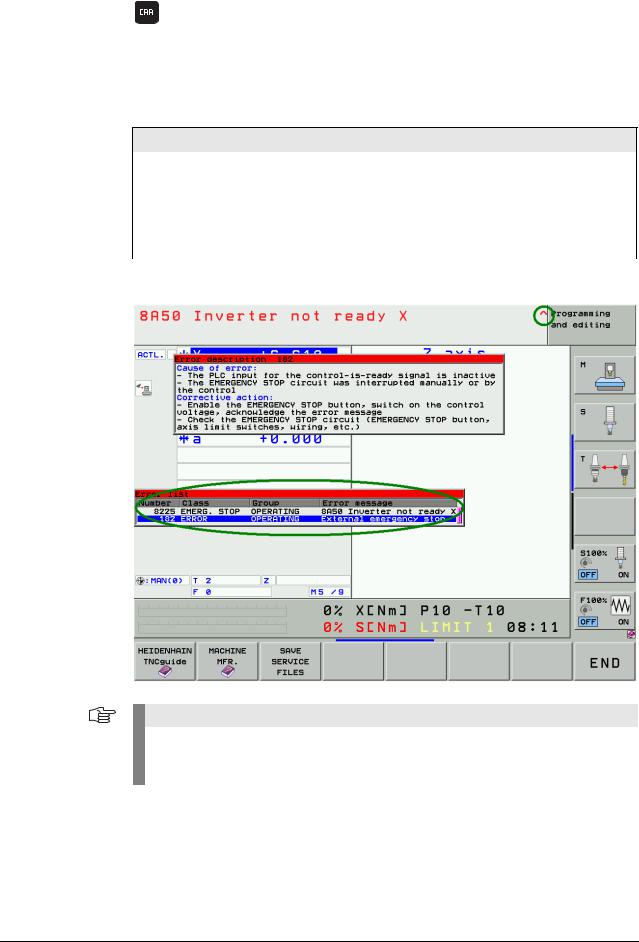

4.2HELP Key

8 Display help texts for error messages

(If you press this key again, the window will close.)

If the service technician presses the HELP key a window is shown that describes the cause of error and possibilities of corrective action in addition to the displayed error message. This support can also be realized for PLC error messages by the machine manufacturer!

Figure: HELP window

Note

HELP texts cannot be displayed for error messages in red or gray windows. The control must be rebooted.

Information on these errors can be found in the list of NC error messages, See “List of NC Error Messages” on page 4 – 29.

July 2010 |

4 – 25 |

4.3ERR Key

8 Display all pending error messages in a list

(If you press this key again, the window will close.)

If there is an AND symbol (little red roof) in the header in addition to the error message, there is more than one pending error message.

The ERR key (ERROR) is located directly over the HELP key. When this key is pressed all pending NC and PLC error messages of the control are displayed in an own window.

List of error messages

In the ERR window |

In the log |

|

|

In order of priority |

In chronological order |

|

|

Errors with a higher priority are at the top of |

The log is written from top to bottom, i.e., |

the list. |

older errors are at the top, younger errors at |

|

the bottom. |

|

|

In addition, the help window can be called with the HELP key.

Note

If your machine still features an old keyboard without an ERR key over the HELP key, press the respective "space key" over the HELP key. --> If the NC software of the iTNC 530 supports the function of the ERR key, it can also be used to call the ERR list!

4 – 26 |

HEIDENHAIN Service Manual iTNC 530 |

The columns in the ERR window have the following meanings:

Column |

Description |

Number |

Error number (–1: no error number defined), issued by HEIDENHAIN or your |

|

machine tool builder |

|

|

Class |

Error class. Defines the reaction of the control: |

|

ERROR |

|

Program run is interrupted by the iTNC |

|

FEED HOLD |

|

The feed-rate release is canceled |

|

PGM HOLD |

|

The program run is interrupted (the control-in-operation symbol blinks) |

|

PGM ABORT |

|

The program run is interrupted (INTERNAL STOP) |

|

EMERG. STOP |

|

EMERGENCY STOP is set off |

|

RESET |

|

iTNC executes a system restart |

|

WARNING |

|

Warning message, program run resumes |

|

INFO |

|

Info message, program run resumes |

|

|

Group |

Error source. |

|

GENERAL |

|

General error |

|

OPERATING |

|

Error during machining and machine traverse |

|

PROGRAMMING |

|

Error during programming |

|

PLC |

|

PLC error message of the machine manufacturer |

|

|

Error |

Displayed error text |

message |

|

|

|

The individual error messages can be selected with the cursor; the open help window shows the appertaining text.

July 2010 |

4 – 27 |

4.4CE Key

8 Clear error message (Clear Error)

Acknowledge error messages displayed by pressing the CE key.

If the error cause is still existing, the corresponding error message is displayed again. --> Eliminate the error!

Note

Messages regarding very fatal errors, cannot be confirmed with the CE key. The control must be rebooted.--> Press the END key.

If this does not work --> Switch the power switch of the machine off and wait for several seconds before you switch it on again.

4 – 28 |

HEIDENHAIN Service Manual iTNC 530 |

4.5List of NC Error Messages

Complete list |

You can find the complete list of all NC error messages (including operator errors) on the |

|

|

TNCguide DVD in several languages and sorted by error numbers. |

|

|

This TNCguide information is also available on our website --> www.heidenhain.de/... |

|

|

This is the official list of NC error messages which contains all possible errors of HEIDENHAIN |

|

|

controls that operate with the HeROS operating system. |

|

|

It consists primarily of error messages related to operation and handling as well as technical error |

|

|

messages. |

|

Filtered list |

The list below contains the most important error messages that indicate a technical defect |

|

|

in numerical and subsequently in alphabetical order. |

|

|

A reference is made, if there are additional descriptions in this Service Manual. |

|

|

|

|

Error message |

Possible cause of error |

Measures for error diagnosis and/or |

|

|

corrective action |

|

|

|

|

Additional information and descriptions in |

Additional information and descriptions in |

|

the manual |

the manual |

|

|

|

8040 Heat-sink |

Heat-sink temperature of UV 1xx power |

Stop the machine and let it cool down. |

temp. UV 1xx |

supply unit is too high. |

Continue working with lower power (reduce |

|

If the heat-sink temperature continues to |

the feed rate). |

|

increase, the unit will be switched off. |

|

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See Service Manual Inverter Systems and |

|

page 3 – 682. |

Motors |

|

|

|

8041 Excessive Iz |

DC-link current of UV 1xx power supply unit |

Continue working with lower power (reduce |

in UV 1xx |

too high |

the feed rate). |

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See Service Manual Inverter Systems and |

|

page 3 – 682. |

Motors |

|

|

|

8043 No inverter- |

Readiness signal of the inverter (supply unit) |

Try to restart. |

ready signal |

is inactive after the feedback control starts. |

Check the wiring (master contactor). |

|

Master contactor has opened. |

Check the PLC program. |

|

Error in PLC program |

|

|

Exchange the inverter (supply unit). |

|

|

Inverter defective |

|

|

|

|

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See “Checking the readiness of the inverter |

|

page 3 – 682. |

system” on page 16 – 243. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

8060 Leakage |

Insulation problem (e.g. defective motor). |

Check the motor. |

current in UV 1xx |

|

Check the wiring. |

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See Service Manual Inverter Systems and |

|

page 3 – 682. |

Motors. |

|

|

|

8061 No inverter- |

Readiness signal of the inverter (supply unit) |

Try to restart. |

ready signal |

is inactive after the feedback control starts. |

Check the wiring (master contactor). |

|

Master contactor has opened. |

Check the PLC program. |

|

Error in PLC program |

|

|

Exchange the inverter (supply unit). |

|

|

Inverter defective |

|

|

|

|

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See “Checking the readiness of the inverter |

|

page 3 – 682. |

system” on page 16 – 243. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

July 2010 |

4 – 29 |

Error message |

Possible cause of error |

Measures for error diagnosis and/or |

|

|

corrective action |

|

|

|

|

Additional information and descriptions in |

Additional information and descriptions in |

|

the manual |

the manual |

|

|

|

8080 Uz UV 1xx |

DC-link voltage of the power supply unit too |

Check the configuration datum (braking of |

too high |

high. |

the spindle). |

|

|

Check the braking resistor. |

|

|

Replace the power supply unit. |

|

|

|

|

See “Status of HEIDENHAIN inverters” on |

See Service Manual Inverter Systems and |

|

page 3 – 682. |

Motors. |

|

|

|

8092 Pos. contr. |

MC is outputting erroneous cycle time for |

Check machine parameter 7600.x. |

cyc. time error |

CC position controller. |

Exchange the drive control board. |

|

Hardware error |

|

|

|

|

8130 Motor brake |

Motor brake defective. |

Traverse the axis to a safe position before |

defective <axis> |

|

power-off. |

|

|

Check controls for motor brakes. |

|

|

Exchange the motor. |

|

|

|

|

|

See “Controlling the motor brakes” on page |

|

|

3 – 684. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

8140 Error <axis> |

Field orientation impossible for mechanical |

Check the machine parameters for number |

field orientation |

reasons. |

of signal periods and distance for the |

|

Incorrect relation between electrical field |

number of signal periods. |

|

and mechanical motor motion. |

Check the machine parameter for the linear |

|

Incorrect motor encoder signal. |

distance of one motor revolution. |

|

For linear motors: Check STR column of the |

|

|

Incorrect motor connection. |

|

|

motor table. |

|

|

Mechanical brakes not released. |

|

|

Check the speed encoder connection. |

|

|

|

|

|

|

Check the motor connection. |

|

|

Release brakes during orientation. |

|

|

|

|

See “Speed Encoders” on page 18 – 293. |

See “Sequence for Finding Errors in the |

|

|

Control Loop” on page 6 – 62. |

|

|

See “Speed Encoders” on page 18 – 293. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

8300 Motor brake |

Motor brake defective. |

Traverse the axis to a safe position before |

defective <axis> |

|

power-off. |

|

|

Check controls for motor brakes. |

|

|

Exchange the motor. |

|

|

|

|

|

See “Controlling the motor brakes” on page |

|

|

3 – 684. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

8310 No current in |

Motor connected incorrectly |

Check the wiring of motor and inverter. |

brake test <axis> |

Inverter connected incorrectly |

Check the inverter. |

|

Inverter defective |

Check the motor. |

|

Motor defective |

|

|

|

|

|

|

See “Controlling the motor brakes” on page |

|

|

3 – 684. |

|

|

See Service Manual Inverter Systems and |

|

|

Motors. |

|

|

|

4 – 30 |

HEIDENHAIN Service Manual iTNC 530 |

Loading...

Loading...