HEIDENHAIN Inverter Systems and Motors Service Manual

Service Manual

Inverter Systems

and Motors

June 2012

1 How to use this service manual ........................................................................................... |

9 |

|

1.1 |

Target group .................................................................................................................... |

9 |

1.2 |

About this manual............................................................................................................ |

9 |

1.3 |

Other service manuals................................................................................................... |

10 |

1.4 |

Other documentation .................................................................................................... |

10 |

1.5 |

Support .......................................................................................................................... |

10 |

1.6 |

Service training .............................................................................................................. |

11 |

1.7 |

Meaning of the symbols used in this manual................................................................ |

11 |

1.8 |

Safety ............................................................................................................................ |

11 |

2 Safety precautions............................................................................................................... |

13 |

|

2.1 |

Introduction ................................................................................................................... |

13 |

2.2 |

Please observe .............................................................................................................. |

13 |

2.3 |

With inverter systems, especially remember:............................................................... |

15 |

2.4 |

With motors, especially remember: .............................................................................. |

16 |

3 Errors and error messages.................................................................................................. |

17 |

|

3.1 |

Introduction ................................................................................................................... |

17 |

3.2 |

Overview of possible errors .......................................................................................... |

18 |

3.3 |

Error messages on the monitor of the control .............................................................. |

21 |

3.4 |

Log of the control .......................................................................................................... |

22 |

4 Explanation of the LEDs ...................................................................................................... |

23 |

|

4.1 |

Introduction ................................................................................................................... |

23 |

4.2 |

Controller unit with integrated inverter.......................................................................... |

24 |

4.3 |

Compact inverters ......................................................................................................... |

25 |

4.4 |

Power supply units ........................................................................................................ |

28 |

4.5 |

Power modules ............................................................................................................. |

30 |

4.6 |

HEIDENHAIN interface cards for the SIMODRIVE system ........................................... |

30 |

|

4.6.1 Boards with Ribbon Cable Connection for the PWM Interface ........................... |

30 |

|

4.6.2 Boards with D-sub Connection for the PWM Interface ....................................... |

30 |

5 Procedures and tips for error diagnosis in the field ......................................................... |

31 |

|

5.1 |

Introduction ................................................................................................................... |

31 |

5.2 |

Sequence for finding errors in digital drives .................................................................. |

31 |

5.3 |

Sequence for finding errors in the control loop ............................................................. |

33 |

5.4 |

Error localization by process of interchange .................................................................. |

35 |

5.5 |

Error localization by process of exclusion...................................................................... |

36 |

5.6 |

Notes and tips for the field service................................................................................ |

37 |

6 Error diagnosis on motors .................................................................................................. |

47 |

|

6.1 |

Safety ............................................................................................................................ |

47 |

6.2 |

Possible causes of error ................................................................................................ |

47 |

6.3 |

Visual inspection............................................................................................................ |

48 |

6.4 |

Inspection for ground fault ............................................................................................ |

49 |

6.5 |

Inspection for winding short circuit or interruption........................................................ |

53 |

6.6 |

Inspection of the motor encoder ................................................................................... |

56 |

6.7 |

Inspection of the fan...................................................................................................... |

64 |

6.8 |

Inspection of the temperature sensor ........................................................................... |

65 |

6.9 |

Inspection of the motor brakes ..................................................................................... |

67 |

6.10 Inspection for unbalance ............................................................................................. |

69 |

|

7 Error diagnosis on the inverter system ............................................................................. |

71 |

|

7.1 |

Safety ............................................................................................................................ |

71 |

7.2 |

Possible causes of error ................................................................................................ |

71 |

7.3 |

Visual inspection............................................................................................................ |

72 |

7.4 |

Checking the criteria for water-cooled iInverters........................................................... |

73 |

7.5 |

Error diagnosis on the UV, UVR power supply unit ....................................................... |

75 |

|

7.5.1 Inspection for ground fault ................................................................................... |

75 |

7.5.2 Inspection for short circuit or interruption ........................................................... |

79 |

7.5.3 Checking thefuses ............................................................................................... |

83 |

7.5.4 Checking the braking resistor switch in the UV 130 (D) ...................................... |

84 |

7.5.5 Checking the LEDs .............................................................................................. |

88 |

7.5.6 Checking the voltages ......................................................................................... |

89 |

7.6 Error diagnosis on UM power module .......................................................................... |

95 |

7.6.1 Inspection for ground fault .................................................................................. |

95 |

7.6.2 Inspection for short circuit or interruption ........................................................... |

99 |

7.6.3 Checking the LEDs ............................................................................................ |

105 |

7.6.4 Checking the voltages ....................................................................................... |

107 |

7.6.5 Interchanging power modules or output stages of the same type ................... |

109 |

7.6.6 Interchange of the PWM outputs ...................................................................... |

112 |

7.7 Error Diagnosis on the UE, UR Compact Inverter ....................................................... |

113 |

7.7.1 Inspection for ground fault ................................................................................ |

113 |

7.7.2 Inspection for short circuit or interruption ......................................................... |

117 |

7.7.3 Checking thefuses ............................................................................................. |

124 |

7.7.4 Checking the internal braking resistor ............................................................... |

125 |

7.7.5 Checking the braking resistor switch ................................................................ |

129 |

7.7.6 Checking the LEDs ............................................................................................ |

133 |

7.7.7 Checking the voltages ....................................................................................... |

136 |

7.7.8 Exchanging output stages of the same type ..................................................... |

142 |

7.7.9 Interchange of the PWM outputs ...................................................................... |

145 |

7.8 Error diagnosis on the controller unit with integrated UEC inverter ............................ |

146 |

7.8.1 Inspection for ground fault ................................................................................ |

146 |

7.8.2 Inspection for short circuit or interruption ......................................................... |

150 |

7.8.3 Checking the internal braking resistor ............................................................... |

150 |

7.8.4 Checking the braking resistor switch ................................................................ |

152 |

7.8.5 Checking the LEDs ............................................................................................ |

153 |

7.8.6 Checking the primary voltage ............................................................................ |

155 |

7.8.7 Exchanging output stages of the same type ..................................................... |

155 |

7.9 Error diagnosis on the controller unit with integrated UMC inverter........................... |

156 |

7.9.1 Inspection for ground fault ................................................................................ |

156 |

7.9.2 Inspection for short circuit or interruption ......................................................... |

160 |

7.9.3 Checking the LEDs ............................................................................................ |

166 |

7.9.4 Checking the voltages ....................................................................................... |

167 |

7.9.5 Exchanging output stages of the same type ..................................................... |

168 |

7.10 Error diagnosis on non-HEIDENHAIN inverter systems ........................................... |

169 |

7.10.1 Inspection for ground fault .............................................................................. |

169 |

7.10.2 Inspection for short circuit or interruption ....................................................... |

169 |

7.10.3 Checking the displays on the infeed/regenerative module |

|

of the non-HEIDENHAIN manufacturer ...................................................................... |

169 |

7.10.4 Checking the LEDs on the HEIDENHAIN expansion boards ........................... |

170 |

7.10.5 Checking the voltages ..................................................................................... |

171 |

7.10.6 Interchaning the HEIDENHAIN interface boards |

|

for the SIMODRIVE 611 system ................................................................................ |

172 |

7.10.7 Interchanging power stages of the same type ................................................ |

173 |

7.10.8 Interchange of the PWM outputs .................................................................... |

175 |

8 Error diagnosis on accessories ......................................................................................... |

177 |

8.1 Safety .......................................................................................................................... |

177 |

8.2 Possible causes of error .............................................................................................. |

177 |

8.3 Visual inspection.......................................................................................................... |

177 |

8.4 Error diagnosis on the PW braking resistor ................................................................. |

178 |

8.4.1 Inspection for ground fault ................................................................................ |

178 |

8.4.2 Checking the resistance value ........................................................................... |

182 |

8.4.3 Checking the fan ................................................................................................ |

183 |

8.4.4 Checking the temperature switch ..................................................................... |

183 |

|

8.5 Error diagnosis on the braking resistor module UP 1x0 ............................................ |

184 |

|

8.5.1 Inspection for ground fault ................................................................................. |

184 |

|

8.5.2 Inspection for short circuit ................................................................................. |

187 |

|

8.5.3 Checking the resistance value ........................................................................... |

189 |

|

8.5.4 Checking the braking resistor switch ................................................................. |

190 |

|

8.5.5 Checking the temperature switch ..................................................................... |

193 |

|

8.6 Error diagnosis on the SM voltage-protection module ................................................ |

194 |

|

8.6.1 Inspection for short circuit ................................................................................. |

194 |

|

8.6.2 Checking the temperature switch ..................................................................... |

198 |

|

9 Error diagnosis on UV power supply units ..................................................................... |

199 |

|

9.1 Safety .......................................................................................................................... |

199 |

|

9.2 Possible causes of error .............................................................................................. |

199 |

|

9.3 Error diagnosis on UV 101 B........................................................................................ |

200 |

|

9.4 Error diagnosis on UV 102 ........................................................................................... |

203 |

|

9.5 Error diagnosis on UV 105, UV 105 B.......................................................................... |

205 |

|

9.6 Error diagnosis on the UV 106 B ................................................................................. |

211 |

|

9.7 Error diagnosis on the UV 111A, UV 111B .................................................................. |

213 |

|

10 Exchange of HEIDENHAIN components ........................................................................ |

215 |

|

10.1 |

Important notes ......................................................................................................... |

215 |

10.2 |

Replacement of the complete controller unit with integrated inverter...................... |

220 |

10.3 |

Exchanging the complete inverter............................................................................. |

221 |

10.3.1 Inverter without water cooling ......................................................................... |

221 |

|

10.3.2 Inverter with water cooling .............................................................................. |

222 |

|

10.4 |

Exchanging the complete motor ............................................................................... |

224 |

10.4.1 Motor without hollow shaft ............................................................................. |

224 |

|

10.4.2 Motor withn hollow shaft ................................................................................ |

225 |

|

10.5 |

Exchanging the motor encoder of the QAN asynchronous motor ............................ |

227 |

10.6 |

Replacement of scanning head and scale drum of hollow-shaft motor .................... |

231 |

10.6.1 Replacement of the scanning head without signal cable ................................ |

232 |

|

10.6.2 Replacement of the scanning head with signal cable ...................................... |

238 |

|

10.6.3 Replacing the scale drum ................................................................................ |

245 |

|

10.7 |

Exchanging the signal socket of the motor ............................................................... |

250 |

10.8 |

Exchanging the fan of a spindle motor ...................................................................... |

252 |

10.9 |

Exchanging the fan guard of a spindle motor ............................................................ |

257 |

10.10 Changing connections to the reserve temperature sensor ..................................... |

260 |

|

10.11 Exchanging inverter accessories ............................................................................. |

261 |

|

10.12 Exchanging cables and connectors ......................................................................... |

262 |

|

10.13 Exchanging power supply units............................................................................... |

263 |

|

10.13.1 Exchanging the UV 101 B, UV 102, UV 111A, UV 111 B power supply unit . 263 |

||

10.13.2 Exchanging the UV 105 power supply unit .................................................... |

264 |

|

10.13.3 Exchanging the UV 105 B power supply unit ................................................ |

265 |

|

10.13.4 Exchanging the UV 106 B power supply unit ................................................ |

266 |

|

10.14 Exchanging HEIDENHAIN interface boards in the SIMODRIVE system ................. |

267 |

|

11 Overview of components................................................................................................ |

273 |

|

11.1 |

Controller units with integrated inverter.................................................................... |

273 |

11.1.1 Assembly ......................................................................................................... |

273 |

|

11.1.2 Controller units with integrated UEC 1xx inverter ........................................... |

274 |

|

11.1.3 Controller unit with integrated UMC 1xx inverter ............................................ |

274 |

|

11.1.4 Toroidal cores .................................................................................................. |

274 |

|

11.2 |

Compact inverters ..................................................................................................... |

275 |

11.2.1 Compilation ...................................................................................................... |

275 |

|

11.2.2 UE1xx compact inverter .................................................................................. |

276 |

|

11.2.3 UE 2xx compact inverter ................................................................................. |

276 |

|

11.2.4 UE 2xxB compact inverter ............................................................................... |

277 |

|

11.2.5 UR 2xx (D) compact inverter ........................................................................... |

277 |

|

11.2.6 Toroidal cores .................................................................................................. |

278 |

|

11.2.7 Ribbon cables and covers (only for UE 2xxB, UR 2xx(D)) ................................ |

278 |

|

11.3 |

Modular inverters ...................................................................................................... |

279 |

11.3.1 Compilation ...................................................................................................... |

279 |

|

11.3.2 UV 130(D) power supply unit ........................................................................... |

280 |

|

11.3.3 UV(R) 1x0(D) power supply unit ...................................................................... |

280 |

|

11.3.4 UM 1xx(B)(D) power modules ......................................................................... |

281 |

|

11.3.5 Ribbon cables and covers ................................................................................ |

281 |

|

11.4 |

Accessories for compact inverters and modular inverters ........................................ |

282 |

11.4.1 PW 21x, PW 110(B), PW 120 braking resistors ............................................... |

282 |

|

11.4.2 UP 110, UP 120 braking resistor module ........................................................ |

283 |

|

11.4.3 Line filter .......................................................................................................... |

284 |

|

11.4.4 Three-phase capacitor ..................................................................................... |

286 |

|

11.4.5 KDR 1x0(B) commutating reactor .................................................................... |

287 |

|

11.4.6 ZKF 1x0 DC-link filter ....................................................................................... |

288 |

|

11.4.7 SM 1xx voltage protection module .................................................................. |

290 |

|

11.4.8 Adapter module ............................................................................................... |

291 |

|

11.4.9 Axis-enabling module ...................................................................................... |

292 |

|

11.4.10 Capacitor module ........................................................................................... |

293 |

|

11.5 |

HEIDENHAIN interface boards for the SIMODRIVE system..................................... |

294 |

11.5.1 Compilation ...................................................................................................... |

294 |

|

11.5.2 Interface boards ............................................................................................... |

294 |

|

11.6 |

Power supply units.................................................................................................... |

295 |

11.6.1 UV 101 B power supply unit ............................................................................ |

295 |

|

11.6.2 UV 102 power supply unit ............................................................................... |

296 |

|

11.6.3 UV 105 power supply unit ............................................................................... |

297 |

|

11.6.4 UV 105 B power supply unit ............................................................................ |

297 |

|

11.6.5 UV 106 B power supply unit ............................................................................ |

299 |

|

11.6.6 UV 111 A, UV 111 B power supply units ......................................................... |

299 |

|

11.7 |

HEIDENHAIN motors ................................................................................................ |

300 |

12 Connector designations and pin layouts....................................................................... |

301 |

|

12.1 |

Important note........................................................................................................... |

301 |

12.2 |

Controller units with integrated inverter.................................................................... |

301 |

12.2.1 Designation and position of connections ........................................................ |

301 |

|

12.2.2 Pin layouts on the UEC and UMC .................................................................... |

302 |

|

12.3 |

Compact inverters ..................................................................................................... |

318 |

12.3.1 Designation and position of connections ........................................................ |

318 |

|

12.3.2 Pin layout on the compact inverter .................................................................. |

336 |

|

12.4 |

Power supply units.................................................................................................... |

343 |

12.4.1 Designation and position of connections ........................................................ |

343 |

|

12.4.2 Pin Layout on the Power Supply Units ............................................................ |

355 |

|

12.5 |

Braking resistors and braking resistor module .......................................................... |

358 |

12.5.1 Designation and position of connections ........................................................ |

358 |

|

12.5.2 Pin layout of braking resistor or braking resistor module ................................. |

360 |

|

12.6 |

Power modules ......................................................................................................... |

362 |

12.6.1 Designation and position of connections ........................................................ |

362 |

|

12.6.2 Pin layout on the power supply units .............................................................. |

382 |

|

12.7 |

DC-link filter............................................................................................................... |

384 |

12.7.1 Designation and position of connections ........................................................ |

384 |

|

12.7.2 Pin layout on the DC-link filter ......................................................................... |

384 |

|

12.8 |

Adapter module......................................................................................................... |

385 |

12.8.1 Designation and position of connections ........................................................ |

385 |

|

12.8.2 Pin layout on the adapter module .................................................................... |

385 |

|

12.9 |

HEIDENHAIN interface boards for the SIMODRIVE system..................................... |

387 |

12.9.1 Designation and position of connections ........................................................ |

387 |

|

12.9.2 Pin layout on the expansion boards ................................................................. |

388 |

|

12.10 UV 101 (B) power supply unit.................................................................................. |

390 |

|

12.10.1 Designation and Position of Connections ..................................................... |

390 |

|

12.10.2 Error diagnosis on UV 101 B .......................................................................... |

391 |

|

12.11 UV 102 power supply unit ....................................................................................... |

392 |

|

12.11.1 Designation and position of connections ...................................................... |

392 |

|

12.11.2 Pin layouts on UV 102 .................................................................................... |

392 |

|

12.12 UV 105 power supply unit ....................................................................................... |

393 |

|

12.12.1 Designation and position of connections ...................................................... |

393 |

|

12.12.2 Pin layouts on UV 105 .................................................................................... |

394 |

|

12.13 UV 105 B power supply unit.................................................................................... |

395 |

|

12.13.1 Designation and position of connections ...................................................... |

395 |

|

12.13.2 Pin layouts on UV 105 B ................................................................................ |

395 |

|

12.14 UV 106 B power supply unit.................................................................................... |

397 |

|

12.14.1 Designation and position of connections ...................................................... |

397 |

|

12.14.2 Pin layouts on UV 106 B ................................................................................ |

397 |

|

12.15 Error diagnosis on the UV 111A, UV 111B .............................................................. |

399 |

|

12.15.1 Designation and position of connections ....................................................... |

399 |

|

12.15.2 Pin layout on the UV 111A, UV 111B ............................................................. |

400 |

|

13 ID labels ............................................................................................................................ |

401 |

|

13.1 |

ID label for inverters .................................................................................................. |

401 |

13.2 |

Electronic ID label for inverters ................................................................................. |

404 |

13.3 |

ID label for motors..................................................................................................... |

406 |

13.4 |

Electronic ID label for motors .................................................................................... |

407 |

13.5 |

ID Label for HEIDENHAIN Expansion Boards............................................................ |

409 |

13.6 |

ID label for accessories ............................................................................................. |

409 |

14 Measuring, testing and inspection equipment ............................................................. |

411 |

|

14.1 |

Important notes ......................................................................................................... |

411 |

14.2 |

Voltage tester ............................................................................................................ |

412 |

14.3 |

Insulation tester......................................................................................................... |

412 |

14.4 |

Multimeter................................................................................................................. |

413 |

14.5 |

Current probe ............................................................................................................ |

413 |

14.6 |

Test adapter............................................................................................................... |

414 |

14.7 |

PWM 9 encoder diagnostic kit .................................................................................. |

418 |

14.8 |

Testing unit PWT 18 .................................................................................................. |

420 |

14.9 |

IK 215 adjusting and testing package ........................................................................ |

421 |

14.10 PWM 20 encoder diagnostic kit .............................................................................. |

422 |

|

15 Annex: Functional principles .......................................................................................... |

423 |

|

15.1 |

PWM signals ............................................................................................................. |

423 |

15.2 |

HEIDENHAIN inverter systems ................................................................................. |

426 |

15.3 |

HEIDENHAIN motors ................................................................................................ |

429 |

15.3.1 Introduction ...................................................................................................... |

429 |

|

15.3.2 Asynchronous motors ...................................................................................... |

430 |

|

15.3.3 Synchronous motors ........................................................................................ |

431 |

|

15.3.4 Linear motors ................................................................................................... |

432 |

|

15.3.5 Torque motors ................................................................................................. |

432 |

|

1 How to use this service manual

1.1 Target group

|

This Service Manual has been written for specialist electricians for service, maintenance and |

||

|

commissioning. |

|

|

|

Specialists who perform work on the electrical system of a machine tool and its components must |

||

|

have the required technical knowledge and competence! |

||

1.2 About this manual |

|

||

Objective |

This Service Manual assists service personnel in the field in diagnosing and |

||

|

correcting errors on HEIDENHAIN inverter systems and HEIDENHAIN motors. |

||

Products described |

HEIDENHAIN inverter systems are available as regenerative and non-regenerative version. |

||

|

HEIDENHAIN motors fall into the categories of synchronous motors for feed drives and |

||

|

asynchronous motors for main spindles (see brochure HEIDENHAIN Motors). |

||

|

|

Note |

|

|

|

|

|

|

|

If you need information on linear and torque motors, contact the corresponding manufacturer. |

|

|

|

|

|

|

This manual also contains information on HEIDENHAIN interface boards for the SIMODRIVE system. |

||

|

HEIDENHAIN inverter systems and motors are designed for digital axes and spindles and are |

||

|

controlled with PWM signals (pulse width modulation). |

||

|

These drives are mainly operated with HEIDENHAIN controls, e.g.: |

||

|

|

|

|

|

Milling controls: |

TNC 410 M, TNC 426 M, TNC 430 M, iTNC 530 (HSCI), TNC 620 (HSCI) |

|

|

|

|

|

|

Lathe controls: |

MANUALplus 4110, MANUALplus M, MANUALplus 620 (HSCI), |

|

|

|

|

CNC PILOT 4290, CNC PILOT 620 (HSCI) |

|

|

|

|

|

Milling/turning |

TNC 640 (HSCI) |

|

|

controls: |

|

|

|

|

|

|

Contents |

This manual includes: |

|

|

|

Information on possible error causes |

||

|

Descriptions of error diagnosis |

||

|

Information on corrective action |

||

|

Theoretical explanations of functions and their correlations |

||

|

The “Overview of possible errors” on page 3 – 18 includes many references to troubleshooting |

||

|

descriptions. |

|

|

|

You will find these descriptions in the chapters of this Service Manual sorted by topics. |

||

Validity |

It comprises the service possibilities with the current hardware at the editing date of this manual. |

||

|

The servicing possibilities of your equipment may differ from those described here. |

||

|

The descriptions also provide information on any peculiarities regarding service of the units. |

||

Prerequisites |

For the instructions for the field service it is assumed that ... |

||

|

the machine had been working perfectly before the error occurred. |

||

|

only original spare parts are used! |

||

June 2012 |

1 – 9 |

Update service |

This Service Manual is updated at irregular intervals. |

|

You find the current printable version of this SHB Inverter Systems and Motors in |

|

HESIS-Web Including Filebase. |

|

If you are not a registered customer with access to this HEIDENHAIN database, you will receive this |

|

Service Manual either on the occasion of a service training course or from your machine tool builder. |

Print version |

If you take part in a HEIDENHAIN service training, you will receive the Service Manual in printed form. |

1.3Other service manuals

Service Manual MANUALplusM

Service Manual TNC 410

Service Manual TNC 426 CB/PB/M, TNC 430 CA/PA/M

Service Manual iTNC 530

Service Manual iTNC 530 HSCI

Service Manual TNC 620

1.4Other documentation

In the following documents you find further important information:

Machine documentation by the manufacturer

(circuit diagrams of the machine, wiring diagrams, machine operating manual, etc.)

User's Manuals for HEIDENHAIN controls

HEIDENHAIN TNCguide (DVD)

Mounting instructions by HEIDENHAIN

Brochures of the respective HEIDENHAIN products

PWM 9 User's Manual

PWT Operating Instructions

IK215 / PWM 20 Operating Instructions

Note

You can find up-to-date issues of this and other HEIDENHAIN documents quickly on our website --> www.heidenhain.de

1.5 Support

Attention

The machine manufacturer must be contacted first for error diagnosis on your machine tool!

However, support will also be provided by the Service Department of HEIDENHAIN Traunreut or by the HEIDENHAIN agencies.

You will find telephone numbers as well as e-mail addresses on the back cover of this Service Manual, or on the HEIDENHAIN website (www.heidenhain.de).

1 – 10 |

HEIDENHAIN Service Manual Inverter Systems and Motors |

1.6 Service training

HEIDENHAIN Traunreut offers service training courses in German language.

We recommend the HEIDENHAIN Service Training Seminars for the technician who works with this Service Manual.

Please contact HEIDENHAIN Traunreut or visit our website (www.heidenhain.de).

Note

If required, please inquire at the HEIDENHAIN subsidiary in your country whether service training courses are offered in your language.

1.7 Meaning of the symbols used in this manual

Danger

Failure to comply with this information could result in most serious or fatal injuries, and/or in substantial material damage.

Attention

Failure to comply with this information could result in injuries and interruptions of operation, including material damage.

Note

These boxes contain important and useful information.

1.8 Safety

Danger

Before you start servicing:

It is extremely important that you read the safety precautions in this manual!

See “Safety precautions” on page 2 – 13

June 2012 |

1 – 11 |

1 – 12 |

HEIDENHAIN Service Manual Inverter Systems and Motors |

2 Safety precautions

2.1 Introduction

The safety precautions below are provided to ensure your personal safety and the safety of the machine tool.

Please read this information carefully before you start servicing the machine!

2.2 Please observe

Ground

Danger

Ensure that the equipment grounding conductor is continuous!

Any interruption of the protective ground can result in serious injury to persons and or property.

Zero potential

Danger

Ensure that the main switch of the control is switched off and that connected devices are not under power when you engage or disengage any connectors or terminals.

Take precautions against restart!

Use an appropriate voltage test unit to ensure that the unit is not under voltage! Always observe that the DC-link voltage must be reduced completely!

Fundamental knowledge

Danger

In order to be able to judge the behavior of an NC controlled machine, service engineers need to have fundamental knowledge of controls, encoders, drives, electronics and mechanics.

Inappropriate use may cause considerable damage to persons or property.

Know-how and competence

Danger

Technicians who work on the electrical system of the machine must have the required know-how and competence.

June 2012 |

2 – 13 |

Suitable tools

Danger

Use suitable tools, e.g. insulated screwdrivers and pincers!

Suitable voltage test unit

Danger

The voltage test unit used (e.g., moving coil measuring device, multimeter) including the measuring lines used must conform to the safety category Cat III / 1000 V or Cat IV / 600 V at least!

Safety precautions of the machine manufacturer

Attention

Note the safety precautions on the machine (e.g. labels, signs) and the safety precautions in the documentation of the machine manufacturer (e.g. operating instructions).

Regulations for power installations and accident prevention

Danger

Observe the national regulations for power installations and the general instructions for safety and prevention of accidents!

Vertical axes

Danger

Always secure vertical axes to prevent them from falling down before you perform tests on these axes!

Liability

Attention

HEIDENHAIN does not accept any responsibility for direct or indirect damage or injury caused to property or persons through improper use or incorrect operation of the machine!

2 – 14 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

2.3 With inverter systems, especially remember

Danger

During operation several parts of the inverter systems may be live and are thus extremely dangerous.

This includes ...

the primary connection with 3 phases, 400 Vac +/- 10 % (may be higher in case of an error)

the conductor bars with 565 Vdc or 650 Vdc (may be higher in case of an error)

the motor outputs

the connecting terminals for the braking resistor

Photo: Example with UV 130 and power modules

Danger

Switch off the machine and wait at least 5 minutes; then ensure that it is not under voltage before removing the conductor bars or disconnecting the braking resistor.

See label on the protective caps!

June 2012 |

2 – 15 |

2.4 With motors, especially remember

Danger

During operation several of the motor parts may be either live or moving and are thus extremely dangerous.

Never perform any kind of work on the motor (e.g., open the terminal box, make or break connections) while it is under power.

Attention

Temperatures of up to 145 °C may occur on the motor surfaces.

When connecting the fan, ensure that the direction of rotation is correct.

The arrow symbol on the fan housing indicates the correct direction.

Attention

After mounting the motor you must verify the trouble-free functioning of the brake.

Danger

On motors that are equipped with a feather key at the shaft end, the feather key must be secured against ejection.

You will find further information on the safe and trouble-free handling of your motor in the operating instructions that accompany each unit.

2 – 16 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

3 Errors and error messages

3.1 Introduction

|

Errors in the drives of machine tools usually lead to an error message on the monitors of the control. |

|

But not all error conditions of the machine generate an error message. |

|

Therefore, here you find an overview of errors with notes and tips on how to proceed. |

Permanent and |

An interruption in the electrical cabinet or a defective device are a permanent error. |

reproducible errors |

If you can generate an error on a machine at any time, the error is reproducible. |

|

By their very nature, permanent and reproducible errors can be located more easily. |

Sporadic and non- |

Sporadic errors may, for example, be caused by a loose connection, shielding problems or |

reproducible errors |

interference. |

|

Non-reproducible errors cannot be generated reliably by certain actions. They "randomly" appear on the |

|

machine. |

|

To investigate sporadic, non-reproducible errors, also integrated diagnosis tools in the control (e.g., an |

|

integrated log, a PLC logic diagram or an integrated oscilloscope) can be used. |

Danger

In case of errors that may lead to very high currents, e.g. ground fault or short circuit in the drive, do not switch on the machine again!

First ensure that there are no defective units, cables, etc.

Then eliminate all ground faults and short circuits in the machine!

June 2012 |

3 – 17 |

3.2 Overview of possible errors

The following table shows an overview of specific errors on the machine or control, possible causes of the errors as well as measures for finding these errors.

The potential measures for finding and correcting the errors are described in more detail in the corresponding chapters.

Error |

Possible error cause |

Measures for error diagnosis and/or corrective |

|

|

|

action |

|

The machine, for example, has |

Ground fault or short circuit on a |

Check the fuses |

|

failed with a loud noise and |

device, cable, etc. |

Visual inspection |

|

cannot be switched on again. |

Grave defect of the motors or in |

(scorch marks, humidity, severe contamination, |

|

|

the inverter system |

damaged cable, etc.) |

|

|

|

Is there a burnt smell? |

|

|

|

Measure ground faults and short circuits, see |

|

|

|

respective descriptions in this manual |

|

|

|

Replace inverters, motors, cables, accessories |

|

|

|

that are defective |

|

|

|

|

|

When hooking up axes, an |

Short circuit in windings of motor |

Check the motor for an interturn fault --> See |

|

"overcurrent" error message is |

Short circuit in the motor power |

“Inspection for winding short circuit or |

|

generated |

cable |

interruption” on page 6 – 53 |

|

|

Short circuit in the voltage |

Check the motor for a short circuit |

|

|

protection module |

Check the voltage protection module for a short |

|

|

Short circuit in the power module |

circuit--> See “Inspection for short circuit” on |

|

|

page 8 – 194 |

||

|

or in the end stage |

||

|

Check power modules and end stages for short |

||

|

|

||

|

|

circuits |

|

|

|

Replace inverters, motors, cables, accessories |

|

|

|

that are defective |

|

|

|

|

|

The control generates error |

Motor defective |

Check the motor --> See “Error diagnosis on |

|

messages regarding the motor |

Motor power cable defective |

motors” on page 6 – 47 |

|

current (e.g., No motor current, |

Inverter defective |

Check the motor cable for a short circuit |

|

Motor current too high) |

Check power modules and end stages |

||

Conductor bars for the DC-link |

|||

|

|||

|

not tightened sufficiently |

Check the voltage protection module for a short |

|

|

|

circuit--> See “Inspection for short circuit” on |

|

|

|

page 8 – 194 |

|

|

|

Tighten conductor bars with 3.5 Nm |

|

|

|

Replace inverters, motors, cables, accessories |

|

|

|

that are defective |

|

|

|

|

|

The machine is switched on but |

Phase in the primary supply is |

Check the phases in the primary supply |

|

the screen of the control remains |

missing |

Check the function of the supply unit or the |

|

dark. |

Defective switch-mode power |

compact inverter |

|

|

supply in the power supply unit |

Check the function of the UV 105 B |

|

|

(UV, UVR) or compact inverter |

Check the function of the PSL 13x |

|

|

(UE, UR) |

Check the ribbon cable X69 |

|

|

Defective power supply unit |

||

|

Check the 5V supply via terminal X74 |

||

|

UV 105 B |

||

|

Defective PSL13x low-voltage |

Disconnect suspicious units from the control and |

|

|

power supply unit |

deselect it in the machine parameters |

|

|

Ribbon cable X69 defective |

--> See service manual of the respective control |

|

|

|

||

|

Defective 5V supply via terminal |

|

|

|

X74 |

|

|

|

Defective unit that is connected |

|

|

|

to the control impairs the low |

|

|

|

voltages |

|

|

|

|

|

3 – 18 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

Error |

Possible error cause |

Measures for error diagnosis and/or corrective |

|

|

|

action |

|

The DC-link voltage Uz is not built |

Phase in the primary supply is |

Check the phases in the primary supply |

|

up |

missing |

Check the releases for the safety relays |

|

(the screen of the control |

Interruption in the electrical |

Check the function of the supply unit or the |

|

functions). |

cabinet, safety relays are not |

||

compact inverter |

|||

|

released |

||

|

Replace the capacitor module |

||

|

Defective power supply unit (UV, |

||

|

Measure short circuits, see respective |

||

|

UVR) or compact inverter (UE, |

||

|

UR) |

descriptions in this manual |

|

|

|

||

|

Defective capacitor module |

|

|

|

DC-link short-circuit in the UM |

|

|

|

|

|

|

The message RELAY EXTERNAL DC |

EMERGENCY STOP chain |

Check the EMERGENCY STOP chain in the range |

|

VOLTAGE MISSING does not |

interrupted |

of the inverter connectors X70, X71, X72 |

|

disappear, although the key |

24 Vdc supply for controls is |

See service manual of the respective control |

|

"Control voltage ON" is pressed. |

missing |

|

|

|

Control defective |

|

|

|

|

|

|

Axes cannot be traversed |

Drive enabling is missing |

See service manual of the respective control |

|

|

Inverter system is not ready for |

Check whether the inverter system is ready |

|

|

operation |

Feed rate not programmed |

|

|

Feed rate set to zero |

||

|

Feed rate set to zero by PLC |

||

|

|

||

|

|

|

|

Axes that are enabled via an axis- |

Drive enable via axis group |

Measure 24 V at X150, 151 |

|

release module, cannot be |

connector X150, 151 on the CC is |

Replace axis-release module |

|

traversed. |

missing |

|

|

|

Axis-release module defective |

|

|

|

|

|

|

The monitor of an iTNC 530 is |

Power failure |

Check the primary voltage |

|

frozen. |

Failure of one or several phases |

Check the fuses |

|

The control is inoperable. |

in the supply line |

Check the wiring of the inverter system |

|

The main switch must be |

|

||

Supply voltage has fallen below |

--> See circuit diagrams of the machine |

||

switched off and on again. |

|||

minimum |

manufacturer |

||

After reset of the control "Power |

Interruption in the electrical |

Check the function of the supply unit or the |

|

fail Interrupt!" is entered in |

cabinet |

compact inverter |

|

the log. |

Defective power supply unit (UV, |

|

|

|

|

||

|

UVR) or compact inverter (UE, |

|

|

|

UR) |

|

|

|

|

|

|

"Oscillating" axes, sometimes |

Poor shielding or grounding |

Check the grounding of your machine --> Consult |

|

involving loud noise. |

Connection (short circuit) of |

your machine manufacturer. |

|

and/or |

shield potential (chassis, cable |

Ensure that all grounding clamps are secure |

|

Various error messages are |

shielding) with 0 V potential of |

Check the cables for damage |

|

generated which, however, are |

the NC power supply |

Check shieldings, covers, etc. |

|

not substantive. |

Connectors on grounding |

||

Check the grounding in connection with the |

|||

|

terminal X131 of infeed/ |

||

|

HEIDENHAIN expansion boards used --> See |

||

|

regenerative module (Simodrive |

||

|

“Error diagnosis on the inverter system” on page |

||

|

611D) not properly wired |

||

|

7 – 71 |

||

|

|

||

|

|

|

|

When braking axes and spindles, |

Defective braking resistor |

Measure braking resistor --> See “Error diagnosis |

|

the motors suddenly coast out of |

(conversion of electrical energy |

on the PW braking resistor” on page 8 – 178 |

|

loop to a stop. |

into heat energy not possible) |

Check the fuses |

|

|

Defective infeed/regenerative |

Wiring interrupted |

|

|

feedback module (energy |

||

|

--> See circuit diagrams of the machine |

||

|

recovery not possible) |

||

|

manufacturer |

||

|

Interruption in the primary supply |

||

|

Check the function of the supply unit or the |

||

|

(fuses, wires, etc.; energy |

compact inverter |

|

|

recovery not possible) |

||

|

|

||

|

|

|

|

An axis is traversed and the error |

Motor brake not released. |

Check whether the brake is released |

|

message I2T value of motor is |

Mechanical stiffness occurs |

Check the wiring of the motor system --> See |

|

too high ... is displayed (or a |

|

circuit diagrams of the machine manufacturer. |

|

similar error message that |

|

If the motor brake is connected to the inverter |

|

indicates an excessive load of the |

|

||

|

module --> Check whether the brake output is |

||

drive). |

|

supplied and triggered correctly. |

|

There is no mechanical damage! |

|

Move the axis while the machine was switched |

|

|

|

||

|

|

off |

|

|

|

|

June 2012 |

3 – 19 |

Error |

Possible error cause |

Measures for error diagnosis and/or corrective |

|

|

action |

SIMODRIVE system used with |

"Old" HEIDENHAIN expansion |

Check the constellation HEIDENHAIN expansion |

CC 422: |

board in modified SIMODRIVE |

board and SIMODRIVE power module --> See |

The control can be switched on. |

power module |

“Compatibility of HEIDENHAIN expansion boards |

During operation the power |

|

to SIMODRIVE power modules” on page 10 – 272 |

|

|

|

module always transmits the |

|

|

Ready signal. |

|

|

The signal reporting that the |

|

|

power module is no longer ready |

|

|

is not detected in some cases. |

|

|

|

|

|

SIMODRIVE system used with |

"Old" HEIDENHAIN expansion |

Check the constellation HEIDENHAIN expansion |

CC 424 (B): |

board in modified SIMODRIVE |

board and SIMODRIVE power module --> See |

After power on, the power |

power module |

“Compatibility of HEIDENHAIN expansion boards |

module transmits a "Ready" signal |

|

to SIMODRIVE power modules” on page 10 – 272 |

|

|

|

to the control although the power |

|

|

module is not ready yet. The |

|

|

control reports the error C510 |

|

|

Impermissible drive enable and |

|

|

cannot be put into operation. |

|

|

|

|

|

SIMODRIVE system used with |

"Old" HEIDENHAIN expansion |

Check the constellation HEIDENHAIN expansion |

TNC 426 PB and TNC 430 PA: |

board in modified SIMODRIVE |

board and SIMODRIVE power module --> See |

After the power module has been |

power module |

“Compatibility of HEIDENHAIN expansion boards |

switched on, it constantly reports |

|

to SIMODRIVE power modules” on page 10 – 272 |

|

|

|

that it is ready, even if this is not |

|

|

the case. In certain situations the |

|

|

“Drives not ready” message can |

|

|

appear, even though it may no |

|

|

longer even be possible to switch |

|

|

the drives on. |

|

|

|

|

|

3 – 20 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

3.3 Error messages on the monitor of the control

HEIDENHAIN inverter systems and HEIDENHAIN motors are usually operated with HEIDENHAIN controls.

Errors on inverters and/or motors that occur when the machine is switched on or during operation are ideally shown as errors on the monitor. The operator or the service engineer obtains information on the possible causes of the error and on corrective action. In case of axis-specific errors, there is an axis symbol (e.g. X) in the error text!

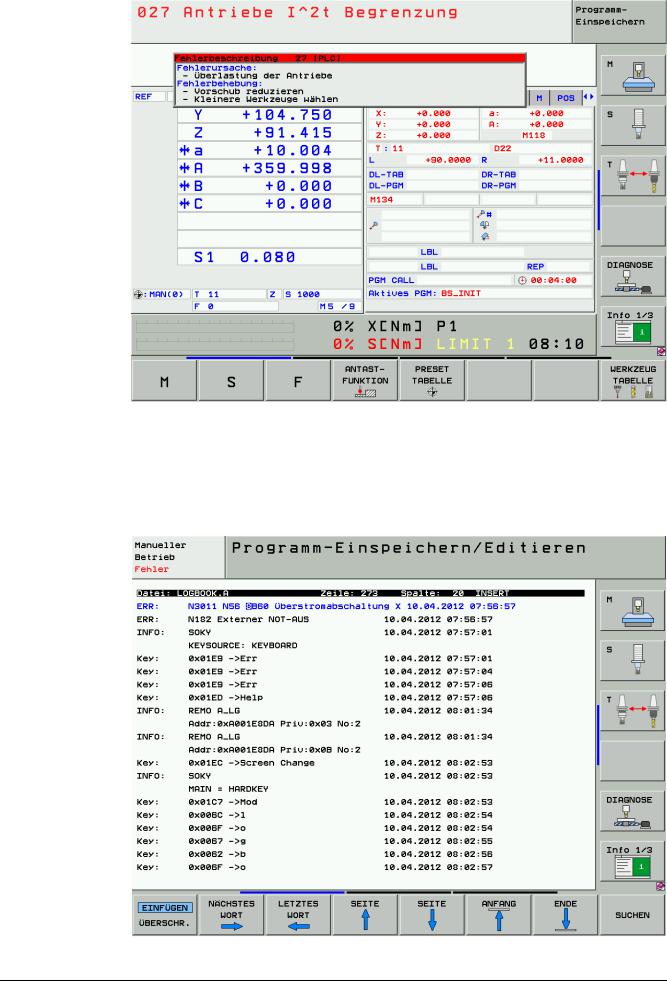

Example of an NC error message on the monitor of an iTNC 530:

|

|

Note |

|

|

If it is possible and makes sense, you may switch the control off and on again to observe |

|

|

whether the error message is generated again afterwards. |

|

|

|

List of NC error |

HEIDENHAIN has defined NC error messages. You can find the complete list of all NC error messages |

|

messages |

for TNC controls on the TNCguide DVD in several languages and sorted by error numbers. |

|

|

This TNCguide information is also available on our website www.heidenhain.de. |

|

PLC error messages |

In addition to the NC error messages defined by HEIDENHAIN, the machine manufacturer can define |

|

|

PLC error messages. |

|

|

The manufacturer can define the machine behavior in case of a PLC error (NC stop, EMERGENCY |

|

|

STOP, etc.). The machine can thus be protected additionally. The operator or the service engineer |

|

|

obtains machine-specific information on the possible causes of the error and on corrective action |

|

|

together with PLC error messages. |

|

June 2012 |

3 – 21 |

Example of an PLC error message on the monitor of an iTNC 530:

3.4 Log of the control

HEIDENHAIN controls feature a log. In these logs information, key strokes, error messages etc. are recorded.

You will find information in the respective service manuals of the controls (e.g. SHB iTNC 530)! Example of NC error messages in the log of an iTNC 530:

3 – 22 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

4 Explanation of the LEDs

4.1 Introduction

Red LED

SH 1 / STO A

Red LED

SH 2 / STO B

On the front of the compact inverters there are several LEDs for functional control. Their meaning is described in this chapter.

The two red LEDs SH 1 or STO A and SH 2 or STO B (located at every axis and spindle output stage) will be explained in detail:

Note

Within the framework of standardization and adaptation to the machine directives 2006/42/EC binding as of January 1, 2010, the designation of the enabling signals SH 1 (Safe Stop 1) and SH 2 (Safe Stop 2) was changed for inverter models from the current production program.

The signal "SH 1“ was renamed to "STO A“ (Safe Torque Off - channel A) and the signal "SH 2“ to "STO B“ (Safe-Torque Off - channel B).

The old red SH 1 LED has been superseded by the red STO.A LED.

SH 1 means "Safe Stop 1" (Sicherer Halt)

STO A means "Safe Torque Off cutout channel A“

SH 1 / STO A is indicated by a red LED on the inverter system

SH 1 / STO A is created by the processor of the HEIDENHAIN control.

SH 1 / STO A is low-active, i.e. line-break proof

If the processor is not ready for operation or if an error is active, SH 1 / STO A is output.

The red SH 1 / STO A LED and the green READY LED at the inverter can not be lit a the same time. They are mutually locked.

The old red SH 2 LED has been superseded by the red STO.B LED.

SH 2 means "Safe Stop 2" (Sicherer Halt 2)

STO B means "Safe Torque Off cutout channel B“

SH 2 / STO B is indicated by a red LED on the inverter system

SH 2 / STO B is created by the controller of the HEIDENHAIN control.

SH 2 / STO B is low-active, i.e. line-break proof

If an axis or spindle is not controlled, SH 2 / STO B is active and the red LED is on. This is, for example, the case with clamped axes or if a spindle is not controlled. SH 2 / STO B and READY are then lit at the same time.

Figure: The LEDs SH 1 / SH 2 or STO A / STO B on HEIDENHAIN UM units

June 2012 |

4 – 23 |

4.2 Controller unit with integrated inverter

UEC 11x and

UMC 11x

LED |

Meaning |

Signal direction |

Signal |

||||||||

SH 1 or |

Safe Stop 1 or Safe Torque Off; |

MC UxC |

|

|

|

or |

|||||

SH1B |

|||||||||||

STO A |

no enable from control (main contactor not |

|

STO.A.x |

|

|

|

|||||

|

active, DSP error, PLC error with emergency |

|

|

|

|

|

|

|

|

|

|

|

stop, hardware or software error of MC, CC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

RDY |

Axis/Spindle enabled |

UxC MC |

RDY |

||||||||

|

|

|

|

|

|||||||

SH 2 or |

Safe Stop 2 or Safe Torque Off; |

MC UxC |

|

or |

|||||||

SH2 |

|||||||||||

STO B |

no drive enable from control (e.g. by the |

|

STO.B.x |

|

|

|

|||||

|

PLC, active via external signal or SH 1 or |

|

|

|

|

|

|

|

|

|

|

|

STO A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

PWR RES. |

Reset signal from UxC to the MC |

UxC MC |

|

|

|

|

|

|

|

|

|

RES.PS |

|||||||||||

|

|

|

|

||||||||

READY |

Inverter ready |

UxC MC |

RDY |

||||||||

|

|

|

|

|

|

|

|

||||

UDC-LINK >> |

UZ too high (> approx. 850 V); |

UxC MC |

|

|

|

|

|

|

|

|

|

ERR.UZ.GR |

|||||||||||

|

power modules are switched off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

PWR FAIL |

UZ too low, UZ < 410 V (e.g. failure of a |

UxC MC |

|

|

|

|

|

|

|||

PF.PS |

|||||||||||

|

phase under load, power < 290 V) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

NC RESET |

Reset signal from the MC to the UxC |

MC UxC |

|

|

|

|

|

|

|||

RES.LE |

|||||||||||

|

|

|

|

|

|||||||

TEMP >> |

Temperature of heat sink too high (> 100 °C) |

UxC MC |

|

|

|

|

|

|

|

|

|

ERR.TEMP |

|||||||||||

|

|

|

|

||||||||

X 71 SPINDLE |

Safety relay for spindle triggered |

– |

– |

||||||||

|

|

|

|

||||||||

X 72 AXES |

Safety relay for axes triggered |

– |

– |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Note

On the UEC and UMC, the signals SH 1 (or STO A) and RDY are displayed with two LEDs (red and green) or by means of a multicolored LED, which changes from red to green.

4 – 24 |

HEIDENHAIN Service Manual for Inverter Systems and Motors |

4.3 Compact inverters

UE 1xx

LED |

Meaning |

Signal direction |

|

Signal |

||||||||

UDC LINK ON |

Main contactor triggered |

– |

|

– |

||||||||

SH 1 or |

Safe Stop 1 or Safe Torque Off; |

MC, CC UE |

|

|

|

|

or |

|||||

SH1B |

||||||||||||

STO A |

no enable from control (main contactor not |

|

|

STO.A.x |

|

|

|

|||||

|

active, DSP error, PLC error with emergency |

|

|

|

|

|

|

|

|

|

|

|

|

stop, hardware or software error of MC, CC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

RDY |

Axis/Spindle enabled |

UE MC, CC |

|

RDY |

||||||||

|

|

|

|

|

|

|||||||

SH 2 or |

Safe Stop 2 or Safe Torque Off; |

MC, CC UE |

|

|

or |

|||||||

SH2 |

||||||||||||

STO B |

no drive enable from control (e.g. by the |

|

|

STO.B.x |

|

|

|

|||||

|

PLC, active via external signal or SH 1 or |

|

|

|

|

|

|

|

|

|

|

|

|

STO A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

PWR RES |

Reset signal from UE to the MC, CC |

UE MC, CC |

|

|

|

|

|

|

|

|

|

|

|

RES.PS |

|||||||||||

|

|

|

|

|

||||||||

READY |

Inverter ready |

UE MC, CC |

|

RDY |

||||||||

|

|

|

|

|

|

|

|

|

||||

UDC LINK >> |

UZ too high (> approx. 850 V); |

UE MC, CC |

|

|

|

|

|

|

|

|

|

|

|

ERR.UZ.GR |

|||||||||||

|

power modules are switched off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

PWR FAIL |

UZ too low, UZ < 410 V (e.g. failure of a |

UE MC, CC |

|

|

|

|

|

|

|

|||

|

PF.PS |

|||||||||||

|

phase under load, power < 290 V) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

NC RESET |

Reset signal from MC, CC to UE |

MC, CC UE |

|

|

|

|

|

|

|

|||

|

RES.LE |

|||||||||||

|

|

|

|

|

|

|||||||

TEMP >> |

Temperature of heat sink too high (> 100 °C) |

UE MC, CC |

|

|

|

|

|

|

|

|

|

|

ERR.TEMP |

||||||||||||

|

|

|

|

|||||||||

X 71 SP. |

Safety relay for spindle triggered |

– |

– |

|||||||||

|

|

|

|

|

||||||||

X 72 AXES |

Safety relay for axes triggered |

– |

|

– |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Note |

|

|

|

|

|

|

|

|

|

|

|

|

On the UE 1xx compact inverters, the signals SH 1 and RDY are displayed with two LEDs (red and green) or by means of a multicolored LED, which changes from red to green.

UE 2xx

LED |

Meaning |

Signal direction |

|

Signal |

|||||||

UDC LINK ON |

Main contactor triggered |

– |

|

– |

|||||||

+ 5 V |

+ 5 V power supply available |

– |

|

– |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

UDC LINK >> |

UZ too high (> approx. 800 V); |

UE MC, CC |

|

|

|

|

|

|

|

|

|

|

ERR.UZ.GR |

||||||||||

|

power modules are switched off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEMP >> |

Temperature of heat sink too high (> 100 °C) |

UE MC, CC |

|

|

|

|

|

|

|

|

|

ERR.TEMP |

|||||||||||

|

|

|

|

|

|

|

|

|

|

||

AXIS FAULT |

Short circuit between a phase of the motor |

UE MC, CC |

|

|

|

|

|

|

|

|

|

|

AXISFAULT |

||||||||||

|

output and UZ (axes only) |

|

|

|

|

|

|

|

|

|

|

POWER FAIL |

UZ too low, UZ < 410 V (e.g. failure of a |

UE MC, CC |

|

|

|

|

|

|

|||

|

PF.PS |

||||||||||

|

phase under load, power < 290 V) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

POWER RESET |

Reset signal from UE to the MC |

UE MC, CC |

|

|

|

|

|

|

|||

|

RES.PS |

||||||||||

|

|

|

|

|

|

|

|||||

AXIS/SPINDLE |

Axes/spindle disabled by the MC |

MC, CC UE |

|

|

|

|

|||||

|

SH2 |

||||||||||

RESET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

AXIS/SPINDLE |

Inverter ready |

UE MC, CC |

|

|

|

|

|||||

|

RDY |

||||||||||

READY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

PULSE RELEASE |

Safety relay for spindle triggered |

– |

|

– |

|||||||

SPINDLE |

|

|