Pilz PNOZ s3 User Manual

PNOZ s3

Safety relays

Operating Manual-21395-EN-10

This document is the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made for internal purposes. Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks of Pilz GmbH & Co. KG in some countries.

SD means Secure Digital

SD means Secure Digital

PNOZ s3

PNOZ s3 safety relay

The safety relay provides a safety-related interruption of a safety circuit.

The safety relay meets the requirements of EN 60947-5-1, EN 60204-1 and VDE 0113-1 and may be used in applications with

}E-STOP pushbuttons

}Safety gates

}Light beam devices

For your safety

}Only install and commission the unit if you have read and understood these operating instructions and are familiar with the applicable regulations for health and safety at work and accident prevention.

Ensure VDE and local regulations are met, especially those relating to safety.

}Any guarantee is rendered invalid if the housing is opened or unauthorised modifications are carried out.

Unit features

}Positive-guided relay outputs:

–2 safety contacts (N/O), instantaneous

}1 semiconductor output

}Connection options for:

–E-STOP pushbutton

–Safety gate limit switch

–Start button

–Light beam device

–PSEN

}A connector can be used to connect 1 PNOZsigma contact expansion module

}Operating modes can be set via rotary switch

}LED indicator for:

–Supply voltage

–Input status, channel 1

–Input status, channel 2

–Switch status channel 1/2

–Start circuit

–Error

}Plug-in connection terminals (either spring-loaded terminal or screw terminal)

Operating Manual PNOZ s3 |

3 |

21395-EN-10 |

|

PNOZ s3

Safety features

The relay meets the following safety requirements:

}The circuit is redundant with built-in self-monitoring.

}The safety function remains effective in the case of a component failure.

}The correct opening and closing of the safety function relays is tested automatically in each on-off cycle.

}The unit has an electronic fuse.

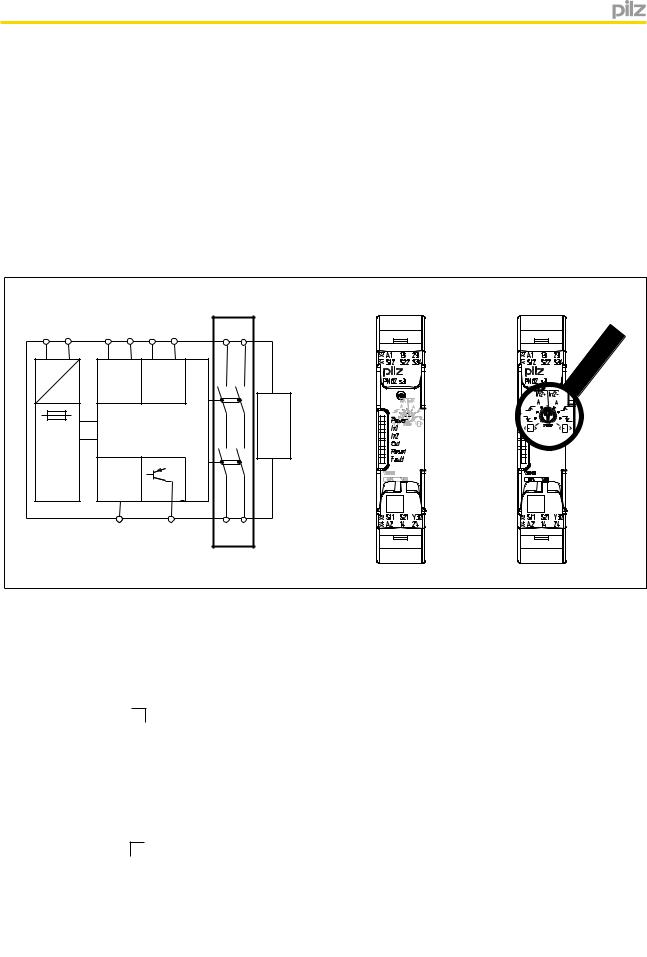

Block diagram/terminal configuration

A1 |

A2 |

S11 S12 S21 S22 |

13 |

23 * |

=

Input |

Input |

= |

K1 |

Power

Interface expansion unit

Reset/ |

|

K2 |

|

|

|

|

|

Start |

|

|

|

S34 |

Y32 |

14 |

24 |

Centre: Front view with cover, right: Front view without cover

*Insulation between the non-marked area and the relay contacts: Basic insulation (overvoltage category III), safe separation (overvoltage category II)

Function description

}In2+ Single-channel operation: no redundancy in the input circuit, earth faults in the start

circuit and input circuit are detected.

}Dual-channel operation without detection of shorts across contacts: redundant input circuit, detects

–earth faults in the start and input circuit,

–short circuits in the input circuit and, with a monitored start, in the start circuit too.

}In2- Dual-channel operation with detection of shorts across contacts: redundant input circuit, detects

–earth faults in the start and input circuit,

–short circuits in the input circuit and, with a monitored start, in the start circuit too,

–shorts between contacts in the input circuit.

} Automatic start: Unit is active once the input circuit has been closed.

Automatic start: Unit is active once the input circuit has been closed.

Operating Manual PNOZ s3 |

4 |

21395-EN-10 |

|

PNOZ s3

}Manual start: Unit is active once the input circuit is closed and then the start circuit is closed.

} Monitored start with falling edge: Unit is active once

Monitored start with falling edge: Unit is active once

–the input circuit is closed and then the start circuit is closed and opened again.

–the start circuit is closed and then opened again once the input circuit is closed.

} Monitored start with rising edge: Unit is active once the input circuit is closed and once the start circuit is closed after the waiting period has elapsed (see technical details).

Monitored start with rising edge: Unit is active once the input circuit is closed and once the start circuit is closed after the waiting period has elapsed (see technical details).

} Start with start-up test: The unit checks whether safety gates that are closed are opened and then closed again when supply voltage is applied.

Start with start-up test: The unit checks whether safety gates that are closed are opened and then closed again when supply voltage is applied.

}Increase in the number of available instantaneous safety contacts by connecting contact expander modules or external contactors/relays;

A connector can be used to connect 1 PNOZsigma contact expander module.

Installation

Install base unit without contact expansion module:

}Ensure that the plug terminator is inserted at the side of the unit.

Connect base unit and PNOZsigma contact expansion module:

}Remove the plug terminator at the side of the base unit and at the contact expansion module.

}Connect the base unit and the contact expansion module to the supplied connector before mounting the units to the DIN rail.

Installation in control cabinet

}The safety relay should be installed in a control cabinet with a protection type of at least IP54.

}Use the notch on the rear of the unit to attach it to a DIN rail (35 mm).

}When installed vertically: Secure the unit by using a fixing element (e.g. retaining bracket or end angle).

}Push the device upwards or downwards before lifting it from the DIN rail.

Wiring

Please note:

}Information given in the "Technical details" must be followed.

}The outputs 13-14, 23-24 are safety contacts.

}Semiconductor output Y32 should not be used for safety circuits!

}To prevent contact welding, a fuse should be connected before the output contacts (see technical details).

Operating Manual PNOZ s3 |

5 |

21395-EN-10 |

|

PNOZ s3

}Calculation of the max. cable length lmax in the input circuit:

Imax = Rlmax

Rl / km

Rlmax = max. overall cable resistance (see technical details)

Rl / km = cable resistance/km

}Use copper wire that can withstand 60/75 °C.

}Sufficient fuse protection must be provided on all output contacts with capacitive and inductive loads.

}When connecting magnetically operated, reed proximity switches, ensure that the max. peak inrush current (on the input circuit) does not overload the proximity switch.

Preparing for operation

Operating modes

The operating mode is set via the rotary switch on the unit. You can do this by opening the cover on the front of the unit.

CAUTION!

Do not adjust the rotary switch during operation, otherwise an error message will appear, the safety contacts will open and the unit will not be ready for operation until the supply voltage has been switched off and then on again.

Set operating modes

}Switch off supply voltage.

}Select operating mode via the operating mode selector switch "mode".

}If the operating mode selector switch "mode" is in its start position (vertical position), an error message will appear.

Operating mode |

Automatic/man- |

Monitored start |

Monitored start |

Automatic start |

selector switch |

ual start |

rising edge |

falling edge |

with start-up test |

"mode" |

|

|

|

|

Without detec- |

In2+ In2- |

In2+ In2- |

In2+ In2- |

In2+ In2- |

tion of shorts |

|

|

|

|

across contacts |

|

|

|

|

With detection of |

In2+ In2- |

In2+ In2- |

In2+ In2- |

In2+ In2- |

shorts across |

|

|

|

|

contacts |

|

|

|

|

Operating Manual PNOZ s3 |

6 |

21395-EN-10 |

|

Loading...

Loading...