Pilz PNOZ m1p base unit User Manual

PNOZmulti Special Applications

Configurable Control System PNOZmulti

Operating Manual — No. 1002337-EN-02

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Contents

Contents |

|

|

Page |

|

|

|

|

Chapter 1 |

Introduction |

|

|

|

1.1 |

Overview of documentation |

1-1 |

|

|

|

|

|

1.2 |

Definition of symbols |

1-2 |

|

|

|

|

|

|

|

|

Chapter 2 |

Muting |

|

|

|

2.1 |

Introduction |

2-1 |

|

|

|

|

|

2.2 |

Safety |

2-2 |

|

|

|

|

|

2.2.1 |

Intended use |

2-2 |

|

|

|

|

|

2.2.2 |

Standards |

2-2 |

|

|

|

|

|

2.2.3 |

Safety guidelines |

2-2 |

|

|

|

|

|

2.3 |

Configuration in the PNOZmulti Configura- 2-4 |

|

|

|

tor |

|

|

|

|

|

|

2.3.1 |

Functions |

2-4 |

|

|

|

|

|

2.3.2 |

Input parameters |

2-4 |

|

|

|

|

|

2.3.3 |

Output parameters |

2-4 |

|

|

|

|

|

2.3.4 |

Monitoring times |

2-5 |

|

|

|

|

|

2.3.5 |

Suspension of muting (override) |

2-5 |

|

|

|

|

|

2.3.6 |

Reset |

2-6 |

|

|

|

|

|

2.3.7 |

Restarting the muting time |

2-6 |

|

|

|

|

|

2.4 |

Operating modes |

2-7 |

|

|

|

|

|

2.4.1 |

Terminology |

2-7 |

|

|

|

|

|

2.4.2 |

Sequential muting |

2-7 |

|

|

|

|

|

2.4.2.1 |

Position of the muting sensors |

2-7 |

|

|

|

|

|

2.4.2.2 |

Switch conditions in sequential mode |

2-8 |

|

|

|

|

|

2.4.2.3 |

Sequence errors |

2-9 |

|

|

|

|

|

2.4.2.4 |

Diagnostic word |

2-10 |

|

|

|

|

|

2.4.2.5 |

Timing diagram (example) |

2-10 |

|

|

|

|

|

2.4.3 |

Parallel muting |

2-11 |

|

|

|

|

|

2.4.3.1 |

Position of the muting sensors |

2-11 |

|

|

|

|

|

2.4.3.2 |

Switch conditions in parallel mode |

2-12 |

|

|

|

|

|

2.4.3.3 |

Diagnostic word |

2-12 |

|

|

|

|

|

2.4.3.4 |

Timing diagram (example) |

2-13 |

|

|

|

|

|

2.4.4 |

Cross muting |

2-14 |

|

|

|

|

|

2.4.4.1 |

Position of the muting sensors |

2-14 |

|

|

|

|

|

2.4.4.2 |

Switch conditions in cross mode |

2-15 |

|

|

|

|

|

2.4.4.3 |

Diagnostic word |

2-16 |

|

|

|

|

|

2.4.4.4 |

Timing diagram (example) |

2-16 |

|

|

||

|

|

|

|

Chapter 3 Safety Mat/Safe Edge |

|

||

|

3.1 |

Introduction |

3-1 |

|

|

|

|

|

3.2 |

Safety |

3-2 |

|

|

|

|

|

3.2.1 |

Intended use |

3-2 |

|

|

|

|

|

3.2.2 |

Safety guidelines |

3-2 |

|

|

|

|

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

1 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

Contents

3.3 |

Function description |

3-3 |

3.4 |

Configuration in the PNOZmulti Configura- 3-4 |

|

|

tor |

|

|

|

|

3.4.1 |

Allocation of test pulses to inputs |

3-4 |

|

|

|

3.5 |

Commissioning the safety system |

3-5 |

|

|

|

3.5.1 |

Preparing for commissioning |

3-5 |

|

|

|

3.5.2 |

Preparing for operation |

3-5 |

|

|

|

3.6 |

Operation |

3-7 |

|

|

|

3.6.1 |

Diagnostic word |

3-7 |

|

|

|

3.7 |

Technical Details |

3-8 |

|

|

|

|

|

|

Chapter 4 Burners |

|

|

4.1 |

Introduction |

4-1 |

|

|

|

4.2 |

Safety |

4-2 |

|

|

|

4.2.1 |

Intended use |

4-2 |

|

|

|

4.3 |

Configuration in the PNOZmulti Configura- 4-3 |

|

|

tor |

|

|

|

|

4.3.1 |

Functions |

4-3 |

|

|

|

4.3.2 |

Monitoring functions/settings for the burn- 4-4 |

|

|

er cycle |

|

|

|

|

4.3.2.1 |

Combustion air pressure monitoring, acti- |

4-4 |

|

vating the combustion air blower, com- |

|

|

pound controller monitoring |

|

|

|

|

4.3.2.2 |

Ignition |

4-5 |

|

|

|

4.3.2.3 |

Flame monitoring |

4-5 |

|

|

|

4.3.2.4 |

Compound controller |

4-6 |

|

|

|

4.3.2.5 |

Tightness control |

4-6 |

|

|

|

4.3.2.6 |

High temperature |

4-7 |

|

|

|

4.3.2.7 |

Plant-dependent monitoring functions |

4-8 |

|

|

|

4.3.2.8 |

Shutdown types |

4-8 |

|

|

|

4.3.2.9 |

Step times |

4-9 |

|

|

|

4.4 |

Burner cycle |

4-11 |

|

|

|

4.4.1 |

Steps |

4-11 |

|

|

|

4.4.2 |

Errors during the burner cycle |

4-11 |

|

|

|

4.4.3 |

Master burner with direct ignition |

4-12 |

|

|

|

4.4.4 |

Master burner with separate flame moni- |

4-14 |

|

toring |

|

|

|

|

4.4.5 |

Master burner with joint flame monitoring |

4-16 |

|

|

|

4.4.6 |

Slave burner with direct ignition |

4-17 |

|

|

|

4.4.7 |

Slave burner with separate flame monitor- |

4-17 |

|

ing |

|

|

|

|

4.4.8 |

Slave burner with joint flame monitoring |

4-18 |

|

|

|

4.4.9 |

Example: Viewing the burner cycle in the |

4-19 |

|

PNOZmulti Configurator |

|

|

|

|

4.5 |

Inputs and outputs |

4-22 |

|

|

|

4.5.1 |

Element's inputs |

4-22 |

|

|

|

2 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

Contents

4.5.1.1 |

Operation |

4-22 |

4.5.1.2 |

Monitoring functions |

4-22 |

|

|

|

4.5.2 |

Element's outputs |

4-24 |

|

|

|

4.6 |

Configuration examples |

4-26 |

|

|

|

4.6.1 |

Burner configuration |

4-26 |

|

|

|

4.6.1.1 |

Burner structure |

4-26 |

|

|

|

4.6.1.2 |

Burner properties |

4-26 |

|

|

|

4.6.1.3 |

Configuration in the PNOZmulti Configura- 4-26 |

|

|

tor |

|

|

|

|

4.6.2 |

Connecting the safety valves |

4-27 |

|

|

|

|

|

|

Chapter 5 Loop formation (LOOP) |

|

|

5.1 |

Introduction |

5-1 |

|

|

|

5.1.1 |

Intended use |

5-1 |

|

|

|

5.2 |

Function description |

5-2 |

|

|

|

5.3 |

Example configurations |

5-3 |

|

|

|

5.3.1 |

Application using one loop |

5-3 |

|

|

|

5.3.2 |

Application using two loops |

5-3 |

|

|

|

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

3 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

Contents

4Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1 Introduction

1.1Overview of documentation

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Muting

This chapter describes the muting function with units from the configurable control system PNOZmulti.

3 Safety Mat/Safe Edge

This chapter describes the use of pressure-sensitive protective devices with the PNOZmulti.

4 Burners

This chapter describes how to control and monitor burners with the configurable control system PNOZmulti.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

1-1 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

1 Introduction

1.2Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses an immediate threat of serious injury and death and indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus material damage, and also provides information on preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also provides information on preventive measures that can be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on special features.

1-2 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.1Introduction

This chapter describes the muting function with units from the configurable control system PNOZmulti. The safe inputs and outputs from base units and expansion modules are suitable.

NOTICE

With a muting application, please refer to the operating manuals provided with the units. Please also refer to the PNOZmulti technical catalogue.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-1 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.2Safety

2.2.1Intended use

The muting logic element is used to temporarily suspend safety functions (ESPE/AOPD) without interrupting the process (muting) in accordance with EN 61496-1. For a limited time period and a specific operational phase (e.g. when feeding materials), it will suspend the effect of safety devices during the working process. Once completed, it will reset the safety function.

Use of this operating mode and the arrangement of the sensors are machine or plant-specific and depend on the risk assessment of the machine or plant.

Be sure that you observe the warning notes given in the other parts of this configuration guide and in the PNOZmulti technical catalogue. These are highlighted visually through the use of symbols.

CAUTION!

Failure to observe the safety regulations in this configuration guide and in the PNOZmulti technical catalogue will render the warranty invalid.

2.2.2Standards

Knowledge of and compliance with the relevant standards and directives are a prerequisite for using the muting function. The following gives an overview of the most important standards:

EN 61496-1: Safety of machinery – Electrosensitive protective equipment

EN 60947-5-3: Low voltage switchgear and controlgear - Control circuit devices and switching elements

EN 999: Safety of machinery - The positioning of protective equipment

Please note this is not an exhaustive list of safety standards and directives.

2-2 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.2Safety

2.2.3Safety guidelines

WARNING!

The following information must be heeded! Failure to comply with these guidelines could result in serious injury or death.

Refer to EN 61496-1 and EN 60947-5-3 when configuring, setting up and operating the muting device.

Refer to EN 999 with regard to the positioning of the AOPD.

Measures must be taken to exclude common cause failures, e.g. by the use of non-equivalent signals or diverse sensors.

Muting switches should be positioned so that it is impossible for a person to trigger the muting function.

The vehicle should be designed to make it impossible for people to ride on it.

Limit the size of the entry area by applying appropriate safety measures. People must not be able to enter the danger zone during the muting phase.

If various transport speeds are being used, consider the total duration of the muting phase.

Remember that a new muting phase can only be introduced once the previous phase has been completed.

Maintenance gates should be provided if you secure equipment through muting.

Please note that if the maintenance gates are opened, the plant absolutely must be brought to a standstill in accordance with the risk classification.

Use of muting sensors with contacts: Supply the contacts of the muting sensors via test pulse outputs (test pulses).

Use of ESPE as muting sensors: Test pulses cannot be used. For this reason, be sure to use a N/O contact as sensor 1 and a N/C contact as sensor 2 for fault detection (shorts across contacts).

Laying the connection cable to the sensors in a way that is protected against shorts (i.e. separate) may provide an alternative to non-equiv- alent sensors.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-3 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.3Configuration in the PNOZmulti Configurator

2.3.1Functions

Muting via light beam devices or limit switches

Override option in case of fault

Max. muting time can be set

Muting sensors can be monitored for simultaneity

Configuration of bounce time for contact-based muting sensors

Sequence of the muting sensors can be monitored

Operating modes

–Sequential muting

–Parallel muting

–Cross muting

2.3.2Input parameters

Muting sensor 1

N/O contact of muting sensor 1 Muting sensor 1 = 0: Not operated Muting sensor 1 = 1: Operated

Muting sensor 2

N/O contact of muting sensor 2 Muting sensor 2 = 0: Not operated Muting sensor 2 = 1: Operated

Light curtain

Light curtain = 0: Interrupted Light curtain = 1: Not interrupted

Assign the light curtain input parameter to the output of the light curtain function element. The light curtain function element must be configured with an automatic reset.

Muting sensor 3

N/O contact of muting sensor 3 Muting sensor 3 = 0: Not operated Muting sensor 3 = 1: Operated

Muting sensor 4

N/O contact of muting sensor 4 Muting sensor 4 = 0: Not operated Muting sensor 4 = 1: Operated

Muting override

Muting override = 1: Suspend the muting function if a fault occurs (override) to override the muting channel.

Reset = 0/1 pulse edge: Reset muting after an error or start the muting time.

2-4 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.3Configuration in the PNOZmulti Configurator

2.3.3Output parameters

Enable

Enable = 0: Error detected (e.g. simultaneity exceeded)

Enable = 1: The enable is granted if no error has been detected. Muting active

Display of muting status (e.g. for activating a lamp) Muting active = 0: No muting (light curtain not suspended) Muting active = 1: Muting active (light curtain suspended)

2.3.4Monitoring times

Maximum muting time

This setting is used to adjust the maximum permitted muting time. Permitted value range: 1 ... 900s (= 15 minutes)

Simultaneity

This setting is used to define the maximum time (synchronisation time) which is permitted to elapse between the actuation (0/1-pulse edge) of muting sensors 1 and 2 or muting sensors 3 and 4. Permissible value range for parallel muting and cross muting: 1 ... 3 s Permitted value range for sequential muting: 1 ... 30 s

Bounce time

This setting can be used to set the time up to the point at which the muting sensors finally make contact.

Permitted value range: 50 ..0.800 ms

2.3.5Suspension of muting (override)

If there are faults, the muting station can be overridden via the muting override input parameter.

Start-up condition

Muting override can be switched on if at least one of the muting sensors is active. The enable output and muting active output parameter are set during the override. The override is monitored and has a maximum duration that corresponds to the set muting time.

Switch-off condition

Muting override is switched off if

–the muting time has elapsed or

–no muting sensor is active and the light curtain is clear or

–muting override is reset to 0 (release override button).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-5 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.3Configuration in the PNOZmulti Configurator

CAUTION!

The following additional safety requirements apply to the muting override:

–The override switch must have a hold-to-run control device (touch-operated switch).

–The override switch must be installed in a fixed position outside the danger zone.

–The danger zone and the muting station must be visible from the override switch position.

–The danger zone must be identified as clear before the override switch is operated and while it is operated.

2.3.6Reset

Reset resets the muting element after a fault or during start-up if

no muting sensor is operated and

the light curtain is clear.

CAUTION!

The following additional safety requirements apply for the reset button:

–The danger zone and the muting station must be visible from the reset button position.

–The reset button may not be operated until the danger zone has been viewed and has been identified as clear.

2.3.7Restarting the muting time

Reset resumes muting and restarts the muting time if

muting was ended as a result of the muting time having elapsed (e.g. by the conveyor feed stopping)

and

the muting sensors are returning feasible signals and the light curtain has not been interrupted.

2-6 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

The following operating modes can be implemented:

Sequential muting

Parallel muting

Cross muting

WARNING!

"During muting safe conditions shall be provided by other means" (EN 954-1). For example, this may be achieved by the conveyed item blocking access to the danger zone. Even openings in or between the individual parts of the conveyor flow must never enable access.

2.4.1Terminology

Muting On

"Muting On" is the switch condition for switching on the muting function. When muting is switched on, the Muting active output parameter has a 1 signal and time monitoring runs.

Muting Off

"Muting Off" is the switch condition for ending the muting function. When the muting function is ended, output parameter Muting active has a 0 signal.

INFORMATION

You will find important additional information on the use of sensors or contacts in the section entitled "Safety".

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-7 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.2Sequential muting

2.4.2.1Position of the muting sensors

The distance between the muting sensors MS1 and MS2 / MS3 and MS4 should be as large as possible.

Vehicle length W must be greater than the distance between MS1 and MS3 or MS2 and MS4 (W > A and W > B).

MS2 and MS3 must be positioned as close as possible in front of/behind the AOPD.

A

B

MS1 MS2 AOPD

MS3 |

MS4 |

W

AOPD

2-8 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.2.2Switch conditions in sequential mode

Muting On

Entering the danger zone:

1.Muting sensors MS1 and MS2 must be operated consecutively (first MS1, then MS2) within the configured simultaneity period. Muting is activated by operating MS2.

2.Muting sensors MS3 and MS4 must be operated consecutively (first MS3, then MS4) within the configured simultaneity period.

3.MS1 and MS2 must be cleared consecutively (first MS1, then MS2).

4.MS3 and MS4 must be cleared consecutively (first MS3, then MS4).

Leaving the danger zone:

1.Muting sensors MS4 and MS3 must be operated consecutively (first MS4, then MS3) within the configured simultaneity period. Muting is activated by operating MS3.

2.MS2 and MS1 must be operated consecutively (first MS2, then MS1).

3.MS4 and MS3 must be cleared consecutively (first MS4, then MS3).

4.MS2 and MS1 must be cleared consecutively (first MS2, then MS1).

Muting Off

Suspension of the safety function is cancelled as soon as the penultimate muting sensor, MS2 or MS3, is no longer operated, i.e. only one muting sensor remains operated.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-9 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.2.3Sequence errors

The muting sensors must be operated in a specific sequence in sequential mode. Once a particular directional movement has started (entry or exit), it must be fully completed. Any deviation from the sequence shown causes the enable output (enable = 0) and the output parameter Muting active to reset.

Vehicle length W greater than distance C between MS1 and MS4

All sensors are temporarily operated as the vehicle passes through. The first muting sensor (MS1 upon entering, MS4 upon exiting) only becomes clear once all muting sensors have been operated.

|

|

C |

|

|

|

|

A |

|

|

|

|

B |

|

|

MS1 |

MS2 |

AOPD |

MS3 |

MS4 |

W > C

2-10 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

Vehicle length W less than distance C between MS1 and MS4

As the vehicle passes through, the first muting sensor becomes clear (MS1 upon entering, MS4 upon exiting) before the last muting sensor has been operated.

|

|

C |

|

|

|

|

A |

|

|

|

|

B |

|

|

MS1 |

MS2 |

AOPD |

MS3 |

MS4 |

W < C

MS1 |

MS2 |

MS3 |

MS4 |

Travel direction |

|||||

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

1 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/0 |

1 |

1 |

1/0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

1 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-11 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.2.4Diagnostic word

Messages can be queried in the PNOZmulti Configurator in bit mode and linked further within the program.

Bit 1: Light curtain, interrupted (without active muting)

Bit 2: Waiting for reset (reset)

Bit 3: Sensor status unfeasible, override required

Bit 8: Muting time exceeded

Bit 9: Feasibility error, simultaneity period exceeded on muting sensors 1 and 2, only one sensor operated

Bit 10: Feasibility error, simultaneity period exceeded on muting sensors 3 and 4, only one sensor operated

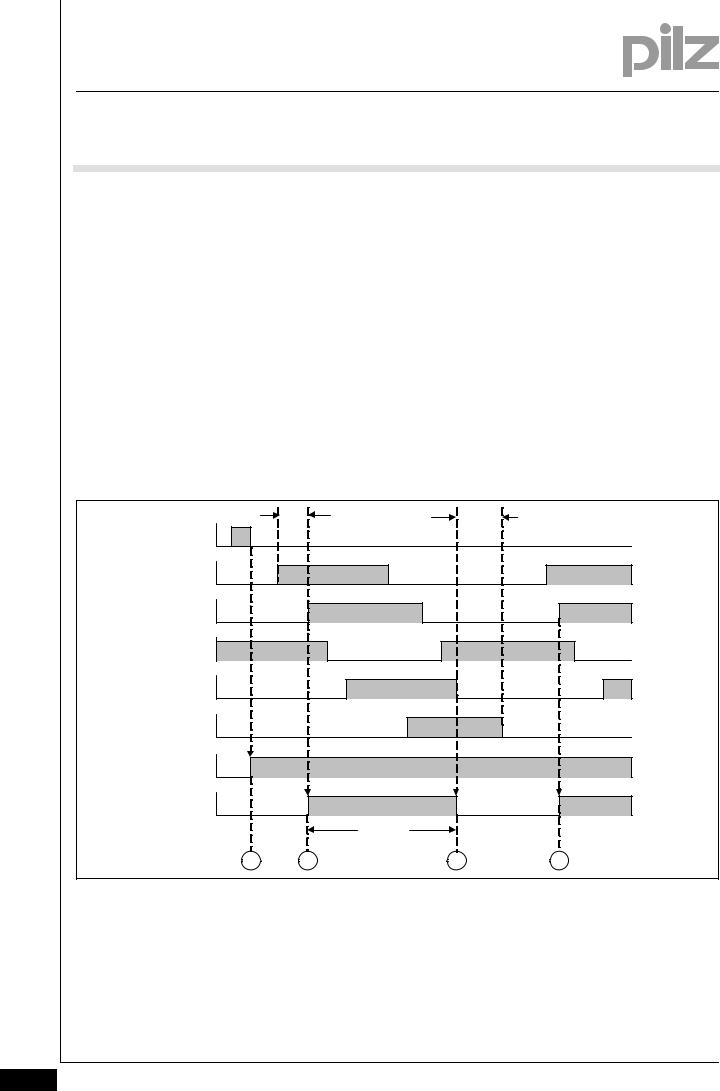

2.4.2.5Timing diagram (example)

Vehicle length W less than distance C between MS1 and MS4

tsync |

t |

1 |

sync |

|

|

Reset 0 |

|

1

MS1 0

1

MS2 0

1

AOPD 0

1

MS3 0

1

MS4 0

1

Enable 0

1

Muting 0

tMUT

1 |

2 |

3 |

4 |

Key:

tsync = Simultaneity tMUT = Muting time

: Set enable with reset

: Start muting via MS1/MS2 : End muting by clearing MS3 : Restart muting via MS1/MS2

2-12 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.3Parallel muting

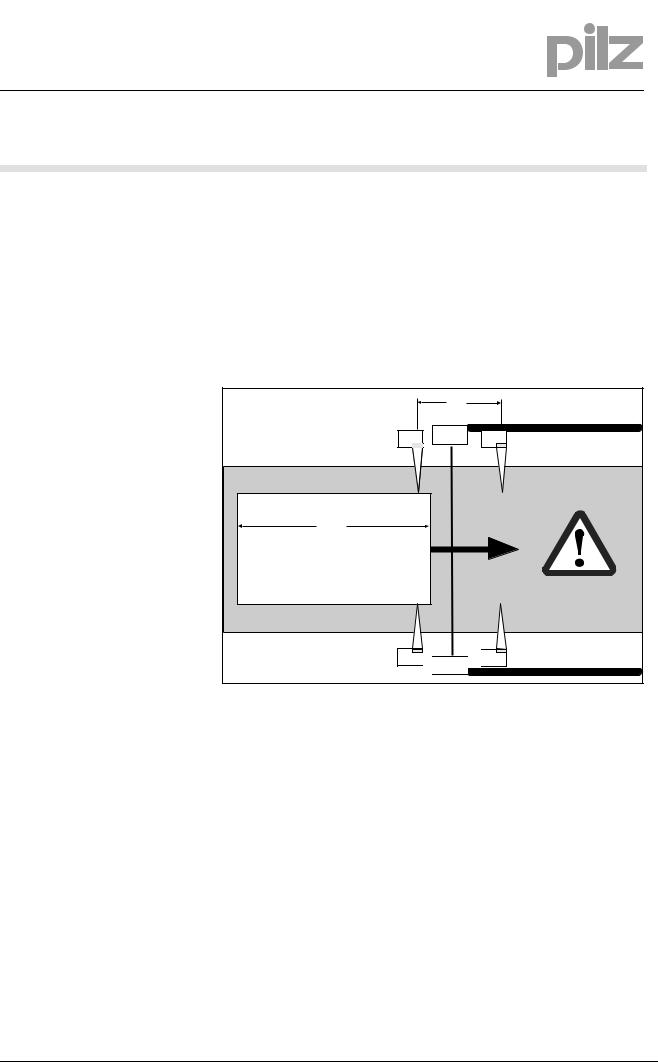

2.4.3.1Position of the muting sensors

Muting sensors MS1 and MS2/MS3 and MS4 must be positioned at the same height to the left and right of the vehicle.

The vehicle length W must be greater than distance A between MS1 and MS3/MS2 and MS4.

The distance between the light curtain and the muting sensor must be as short as possible.

|

A |

|

MS1 |

AOPD |

MS3 |

W

MS2

AOPD

AOPD

MS4

MS4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

2-13 |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

2 Muting

2.4Operating modes

2.4.3.2Switch conditions in parallel mode

Muting On

Entering the danger zone:

1.Muting sensors MS1 and MS2 must be operated within the configured simultaneity period. Muting is activated.

2.Muting sensors MS3 and MS4 must be operated within the configured simultaneity period, before MS1 and MS2 are cleared.

Leaving the danger zone:

1.Muting sensors MS3 and MS4 must be operated within the configured simultaneity period. Muting is activated.

2.Muting sensors MS1 and MS2 must be operated before MS3 and MS4 are cleared.

Muting Off

Suspension of the safety function is cancelled as soon as the penultimate muting sensor, MS3/MS4 upon entering or MS1/MS2 upon exiting, is no longer operated. In other words, only one muting sensor remains operated.

2.4.3.3Diagnostic word

Messages can be queried in the PNOZmulti Configurator in bit mode and linked further within the program.

Bit 1: Light curtain, interrupted (without active muting)

Bit 2: Waiting for reset (reset)

Bit 3: Sensor status unfeasible, override required

Bit 8: Muting time exceeded

Bit 9: Feasibility error, simultaneity period exceeded on muting sensors 1 and 2, only one sensor operated

Bit 10: Feasibility error, simultaneity period exceeded on muting sensors 3 and 4, only one sensor operated

2-14 |

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany |

|

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de |

||

|

Loading...

Loading...