KOHLER K-5533, K-5535, K-5546, K-5547, K-5562 Installation Manual

Installation and Care Guide

Steam Generator

K-5533, K-5535, K-5546, |

|

K-5562 |

K-5547

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México (Ej. K-12345M)

Français, page “Français-1” Español, página “Español-1”

1230488-2-B

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS.

IMPORTANT! When installing and using this electrical equipment, basic safety precautions should always be followed, including the following:

WARNING: Risk of explosion. For dual steam generator installations, do not interconnect steam outlets. A separate steam line must be provided for each steam outlet.

CAUTION: Risk of electrocution. Disconnect the electricity to the working area at the main breaker panel before performing these installation steps.

CAUTION: Risk of injury. To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

WARNING: Risk of personal injury.

•The wet surfaces of steam enclosures may be slippery. Use care when entering or leaving.

•The steam head is hot. Do not touch the steam head and avoid the steam near the steam head.

•Prolonged use of the steam system can raise excessively the internal human body temperature and impair the body’s ability to regulate its internal temperature (hyperthermia). Limit your use of steam to 10 - 15 minutes until you are certain of your body’s reaction.

•Excessive temperatures have a high potential for causing fetal damage during the early months of pregnancy. Pregnant or possibly pregnant women should consult a physician regarding correct exposure.

•Obese persons and persons with a history of heart disease, low or high blood pressure, circulatory system problems, or diabetes should consult a physician before using a steambath.

•Persons using medication should consult a physician before using a steambath since some medications may induce drowsiness while other medications may affect heart rate, blood pressure and circulation.

WARNING: Risk of personal injury. If you become uncomfortable while taking a steam bath, you should turn off the unit. Cool off with the shower, open the door, or exit the unit.

WARNING: Risk of personal injury. DO NOT consume alcoholic beverages or take medications/drugs prior to or when using the steam bath. Alcohol and drugs affect mental judgement, greatly increase the risk of hyperthermia, and inhibit bodily functions such as heartbeat and respiration, resulting in potentially dangerous effects.

WARNING: Risk of allergic reaction. Before adding any oils, aromatic therapies, or skin care products to the aromatherapy well, make sure they will not cause an allergic reaction to the user.

CAUTION: Risk of personal injury. Do not plumb a trap in the steam line or plumb the pressure relief valve into the steam line. Plumbing the pressure relief valve into the steam line can be hazardous if the steam outlet is capped.

CAUTION: Risk of personal injury or property damage. Avoid coming in contact with the water tank and/or steam discharge line while the steam generator is operating or shortly after shutdown. Wear eye protection and protective clothing when servicing the steam generator. The steam generator operates at high temperatures.

CAUTION: Do not use for space heating purposes.

IMPORTANT! Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above the normal body temperature of 98.6° F (37° C). The symptoms of hyperthermia include an increase in the internal temperature of the body, dizziness, lethargy, drowsiness, and fainting. The effects of hyperthermia include:

•Failure to perceive heat

•Failure to recognize the need to exit the steambath

1230488-2-B |

2 |

Kohler Co. |

IMPORTANT SAFETY INSTRUCTIONS (cont.)

•Unawareness of impending risk

•Fetal damage in pregnant women

•Physical inability to exit the steambath

•Unconsciousness

IMPORTANT! Recommended feedwater quality should be: Hardness - less than 60 ppm (3.5 gpg); Total Alkalinity - greater than 150 ppm (8.8 gpg). Calcium scale buildup from hard water can prevent proper operation of the steam generator and may cause premature failure. To ensure proper operation, the feedwater supply should be tested prior to operating the steam generator. If feedwater quality is not within the specified limit, contact a reputable water treatment company for treatment options.

IMPORTANT! Maximum inlet water pressure is not to exceed 70 psi (483 kPa).

NOTICE: Use this unit only for its intended use as specified in this manual. DO NOT use attachments not recommended by Kohler Co.

NOTICE: Do not apply excessive heat to the steam generator connections when you solder connections. Do not apply flux or acids directly to the steam generator, as damage to the seals, plastic components, and trim finish may result. Do not apply petroleum-based lubricants to the steam generator components, as damage may result.

SAVE THESE INSTRUCTIONS.

Tools and Materials

Plus:

• Drain/spill pan

• 1/2" copper tubing

• Assorted copper fittings

• Wire Cutters or Wire Strippers

• Conventional woodworking tools and materials

• 45 and 90 degree elbows

Hacksaw or Tube Cutter Drill w/ 1-1/4" & |

Sealant Tape |

Solder |

|

|

2-1/2" Hole Bit |

Propane Torch |

|||

|

||||

|

|

|

Before You Begin

NOTE: The instructions in this installation guide cover both single and dual steam generator installations.

IMPORTANT! Provide an access panel of adequate size to permit removal of the steam generator for servicing.

Inspect the product for any shipping damage. Do not install the unit if it is damaged. Contact the Kohler Co. Customer Care Center using the information on the back of this guide.

Follow all local plumbing and electrical codes. All electrical work should be done by a qualified electrician.

Disconnect all power before making any electrical connections.

Kohler Co. |

3 |

1230488-2-B |

Before You Begin (cont.)

Connect the steam generator to water supply lines that meet all applicable plumbing codes.

For custom installations, locate the steam head 6″ (152 mm) from the floor and 4-1/2″ (114 mm) from the inside of the threshold.

1230488-2-B |

4 |

Kohler Co. |

|

19-3/8" (492 mm) |

|

11-11/16" |

14" |

|

(297 mm) |

||

(356 mm) |

||

|

||

3-1/2" |

1-7/8" |

|

(89 mm) |

||

(48 mm) |

||

|

Minimum required access panel is 24" (610 mm) L x 15" (381 mm) H.

Allow for a minimum of 12" (305 mm) of space around all sides of the steam generator.

Allow for the drain/spill pan.

KOHLER® drain pan (shown) sold separately.

|

4-13/16" |

4-3/8" |

|

|

|

Green LED |

(122 mm) |

(111 mm) |

|

|

|

|

|

|

|

6-9/16" |

|

Diagnostic Light |

|

|

3/4" NPT |

Field Wiring |

|

|

17-15/16" (456 mm) |

Service Box |

(167 mm) |

||

3/8" NPT |

Pressure Relief |

|

|||

|

|

||||

Water Inlet |

|

|

|

|

|

2-5/8" |

3-5/8" |

1-3/4" |

|

(92 mm) |

|

||

(67 mm) |

|

(44 mm) |

13-9/16" |

|

|

|

(344 mm) |

Control |

|

9-9/16" |

|

2-1/8" |

|

8-1/4" |

(243 mm) |

|

(54 mm) |

||

Cable Input |

|

||||

(210 mm) |

|

|

|

||

|

|

|

|

||

2" |

|

|

|

|

|

(51 mm) |

|

2-5/8" |

3/4" |

3/4" NPT |

|

3-3/4" |

1/2" NPT |

||||

|

(19 mm) |

Drain Pan Outlet |

|||

(95 mm) |

Steam Outlet (67 mm) |

||||

Roughing-In

NOTE: Use the dimensions in the diagram above for reference when determining the placement and clearance for the steam generator.

NOTE: Unions are supplied for the steam, drain, and water inlet connections.

Kohler Co. |

5 |

1230488-2-B |

Water Inlet |

Install copper |

Single Installation |

|

|

||

|

|

Install copper union as close |

||||

Shut-Off Valve |

union in water |

Water Feed to |

Pressure |

|||

as possible to steam generator. |

||||||

feed line. |

||||||

|

Steam Generator |

Relief Valve |

|

|||

|

|

|

|

Pitch toward |

|

|

|

|

|

|

the generator. |

||

Tee |

Field Service |

|

|

|

|

|

|

|

|

|

|

||

Recommended |

Box |

|

Steam Outlet |

|

||

|

|

|

||||

In-Line Water |

Control Cable |

|

|

Steam |

||

Filter |

|

|

||||

Input |

|

|

|

Head |

||

|

|

|

Drain (install per |

|||

Add tee to the |

|

|

|

|

||

|

Drain Pan |

applicable codes.) |

|

|||

water feed line for |

|

|

|

|

|

|

dual installations |

|

Dual Installation |

|

|

||

(optional). |

|

|

|

|||

Do not run pipes |

|

|

|

|

||

down and then up. |

|

|

|

|

||

Steam Trap

1. Determine the System Layout

WARNING: Risk of property damage. Allow a minimum of 12″ (305 mm) of air space around the steam generator at all times. This provides an area for the heat generated by the unit to dissipate.

IMPORTANT! The minimum required access panel is 24″ (610 mm) L x 15″ (381 mm) H.

NOTICE: The steam generator will perform best when installed as close as possible to the steam head. The unit should be installed within 25’ (7.62 m) of the steam head.

NOTICE: Large drops in the steam line can increase condensation and reduce the amount of steam produced. For optimum performance, do not install the steam generator above the level of the steam head.

IMPORTANT! This steam generator must only be installed in the upright position as shown. The pressure relief valve location must be on top.

IMPORTANT! Contact Kohler Co. Customer Care Center if this steam generator will be installed at an elevation over 6000’ (1829 m) above sea level. For installation at high elevations the Customer Care Center will provide instructions on disconnecting the fast start coil.

NOTE: For optimum performance, use 45° elbows in the steam line when possible.

Determine the location of the steam generator. Allow for a 12″ (305 mm) air gap on all sides of the generator. Allow for a drain pan.

Choose a drain pan appropriate for your installation (KOHLER drain pan is sold separately).

Determine the location of the water supplies and steam lines. Ensure clearance between the steam line and any surrounding surfaces.

Install this steam generator in a heated space to prevent freezing.

1230488-2-B |

6 |

Kohler Co. |

Determine the System Layout (cont.)

Ensure this steam generator is installed level.

Allow for access to the steam generator after installation.

Select the steam generator size based upon the steam room volumes identified below.

NOTE: For every additional foot of ceiling height above 8’ (2.4 m) choose the next largest steam generator.

Steam Generator |

Steam Room Volume - Cubic Feet (Cubic Meters) |

13 kW |

447 (12.7) |

15 kW |

500 (14.2) |

26 kW |

894 (25.3) |

30 kW |

1000 (28.3) |

|

|

Kohler Co. |

7 |

1230488-2-B |

Single Installation |

Dual Installation |

|

2" (51 mm) Min |

|

2" (51 mm) Min |

|

|

|

Provide clearance |

|

Wall Stud |

|

|

|

from wall. |

|

|

Wall Stud |

|

|

|

Provide |

2-1/2" (64 mm) |

|

clearance |

|

|

|

|

6" (152 mm) from Floor |

from wall. |

12-1/2" (318 mm) Min |

|

|

|

2-1/2" (64 mm) |

|

6" (152 mm) from Floor |

2. Determine the Location of the Steam Hardware

WARNING: Risk of personal injury. Do not install the steam control user interface outside the steam enclosure. The user interface must be installed within the enclosure to allow the sensors to regulate the temperature and control the flow of steam.

WARNING: Risk of scalding. Do not block the steam head or locate it near a seat or bench, as the steam head is hot during operation and may scald the user if touched.

IMPORTANT! Do not install the control directly above or in-line with the steam head.

NOTICE: When installing the control kit, allow room in the control cable for a drip loop. The drip loop will discourage moisture from following the control cable to the steam generator.

NOTE: All dimensions should be taken from the inside of the shower. Refer to the Steam Control Kit Installation Guide for more dimensional and installation information.

Dual steam heads can be installed on opposite walls to improve steam distribution.

Determine the steam head location. Locate the steam head(s) 6″ (152 mm) above the shower floor and a minimum of 4-1/2″ (114 mm) away from the enclosure door threshold. The steam head location should be within 25’ (7.62 m) of the steam generator.

For single steam head installations, determine the steam control user interface location on the wall opposite the steam head.

For dual steam head installations, determine the steam control user interface location on a different wall than the steam heads. Locate the user interface as far from the steam heads as practical.

Locate the steam control user interface 60″ (1524 mm) above the floor of the shower.

Make sure there is adequate clearance between the steam lines and any surrounding surfaces.

3. Install the Electrical Supply

Model |

K-5533-NA |

K-5535-NA |

K-5546-NA |

K-5547-NA |

|

Generator Size |

13 kW |

15 kW |

26 kW (2 - 13 kW) |

30 kW (2 - 15 kW) |

|

Required Electrical Service |

|

|

|

|

|

Generator Dedicated |

240 V, 80 A, |

240 V, 90 A, |

240 |

V 80 A, |

240 V, 90 A, |

Circuit #1 |

50/60 Hz |

50/60 Hz |

50/60 Hz |

50/60 Hz |

|

Generator Dedicated |

NA |

NA |

240 |

V 80A, |

240 V, 90 A, |

Circuit #2 |

|

|

50/60 Hz |

50/60 Hz |

|

Product Electrical |

240V, 59 A 60 Hz |

240V, 68 A, 60 Hz |

240 |

V, 59 A, 60 Hz |

240V, 68 A, 60 Hz |

Rating |

|

|

|

|

|

|

|

|

|

|

|

1230488-2-B |

8 |

Kohler Co. |

Install the Electrical Supply (cont.)

WARNING: Risk of electrocution. Disconnect the electricity to the working area at the main breaker panel before performing these installation steps.

NOTICE: Each steam generator requires a dedicated circuit. Dual steam generator installations require a second dedicated circuit.

Follow all local electrical codes. All electrical work should be done by a qualified electrician. In the chart above, find the electrical supply requirements for your steam generator.

Install the appropriate electrical supply (install two dedicated supplies for dual steam generator installations).

Kohler Co. |

9 |

1230488-2-B |

Single Installation |

Control |

|

Cable |

|

Input |

Water Inlet |

|

Pressure |

Steam Outlet |

|

Relief Valve |

||

|

||

Drain Pan |

Drain (install per |

|

|

applicable codes.) |

4. Install the Steam Generator

Maintain a 12" (305 mm) |

Dual Installation |

minimum space around |

|

the units. |

|

12" (305 mm) |

|

WARNING: Risk of property damage. Allow a minimum of 12″ (305 mm) of air space around the steam generator at all times. This provides an area for the heat generated by the unit to dissipate.

NOTICE: For optimum performance, install the steam generator as close as possible to the steam head. The steam generator must be installed within 25’ (7.62 m) of the steam head.

Install the desired drain pan at the steam generator location. Kohler Co. recommends using a KOHLER drain pan.

1230488-2-B |

10 |

Kohler Co. |

Water Inlet |

Shut-Off Valve |

|

|

|

|

|

Copper Union |

Copper Union |

Pitch toward |

Steam |

|

|

|

|

|

the generator. |

Head |

Tee |

|

|

|

Steam Trap |

|

|

|

|

|

||

Recommended |

|

|

|

|

|

In-Line Water |

To Optional |

|

|

|

|

Filter |

|

|

|

|

|

|

Second Generator |

Do not run pipes |

|

|

|

|

|

|

|

|

|

|

|

|

down and then up. |

|

|

Single Installation |

|

Dual Installation |

|

|

|

|

2" (51 mm) Min |

|

2" (51 mm) Min |

|

|

Provide clearance |

|

|

|

Wall Stud |

|

|

Provide clearance |

|

|

||

from wall. |

|

|

|

|

|

|

|

from wall. |

|

|

|

|

|

|

|

|

|

6" (152 mm) from Floor |

Wall Stud |

|

|

2-1/2" (64 mm) |

|

|

12-1/2" (318 mm) Min |

||||

|

|

|

|

||

|

|

2-1/2" (64 mm) |

|

6" (152 mm) from Floor |

|

|

|

|

|

||

5. Install the Water Supply and Steam Line

WARNING: Risk of personal injury or property damage. Do not plumb the pressure relief valve into the steam line. Plumbing the pressure relief valve into the steam line can create a hazard if the steam line is blocked or obstructed.

WARNING: Risk of scalding. Do not plumb a trap, shut-off valve, or pressure relief valve into the steam line. Plumbing the pressure relief valve into the steam line can be hazardous, if the steam outlet is capped.

WARNING: Risk of scalding. Do not connect the drain valve outlet to the steam line. Ensure there are no valleys or dips in the steam line.

WARNING: Risk of personal injury or property damage. Do not direct the pressure relief valve to the enclosure. In the event the pressure relief valve activates, the hot water may spray causing burns to the user and/or damage to the enclosure. Therefore, the pressure relief valve should be directed to an area where damage will not occur from contact with hot water and should conform to national and local plumbing codes.

Install the Water Supply Line to the Generator

NOTE: For all NPT threaded connections, use pipe tape or pipe sealant. Do not overtighten the fittings.

Connect to an existing cold water line, and run a 3/8″ cold water line to a shut-off valve before the in-line water filter.

Before final connection to the steam generator, flush out the water supply line into a large pail. This removes any debris, silt, sand, or other material that may be in the line. Make sure the filter screen is in place in the water inlet tube.

Install 3/8″ copper tubing with a union fitting (supplied with the steam generator) located as close as possible to the steam generator.

Kohler Co. |

11 |

1230488-2-B |

Install the Water Supply and Steam Line (cont.)

Connect the water supply line to the steam generator.

Turn on the water supply, and fill the steam generator with water. Check for leaks.

Check that the water drain valve on the generator is closed.

NOTICE: Steam generators are equipped with an automatic shut-off. The water will stop after the unit is full. If the water flows out of the steam outlet, shut off the water and consult the ″Troubleshooting″ or contact the Customer Care Center using the information located on the back of this document.

If the water supply line exceeds 10’ (3 m) or is exposed to cold areas, insulate the piping with appropriate insulation.

Install the Steam Line

WARNING: Risk of scalding. Do not locate the steam head near a seat or bench. Scalding may occur upon contact with the steam head.

NOTICE: Never run the steam line down, then up. Running the steam line down and then up will create a steam trap, blocking the flow of steam. The steam line should run up to the steam head from the steam generator, at a pitch of 3/8″ (10 mm) to 1/2″ (13 mm) per 12″ (305 mm) of pipe.

NOTICE: Provide clearance between the back wall and the elbow leading into the steam housing. The elbow must not contact any wall material.

NOTICE: Provide clearance between the steam line and surrounding surfaces.

NOTICE: Do not apply excessive heat to the generator connections when you solder connections. Do not apply flux or acids directly to the steam generator, as damage to the seals, plastic components, and trim finish may result. Do not apply petroleum-based lubricants to the steam generator components, as damage may result.

NOTE: For all the threaded connections, use thread sealant tape or pipe sealant. Do not overtighten the fittings.

NOTE: Use 1/2″ copper tube for the steam line.

NOTE: When possible, use 45° elbows. Performance will be increased when 45° elbows are used.

NOTE: Always install a union fitting (supplied with the steam generator) as close as possible to the steam generator.

Add blocking behind the desired steam head location.

Install and secure a 1/2″ NPT elbow to the blocking directly behind the desired steam head location.

Install a temporary 1/2″ copper nipple that extends through the finished wall.

Model Product Information

Model |

K-5533-NA |

K-5535-NA |

K-5546-NA |

K-5547-NA |

Weight |

53 lb (24 kg) |

53 lb (24 kg) |

106 lb (48.1 kg) |

106 lb (48.1 kg) |

Water Supply |

3/8″ copper line |

3/8″ copper line |

3/8″ copper line |

3/8″ copper line |

Steam Line |

1/2″ copper line |

1/2″ copper line |

1/2″ copper line |

1/2″ copper line |

Pressure Relief Valve |

3/4″ NPT female |

3/4″ NPT female |

3/4″ NPT female |

3/4″ NPT female |

(supplied) |

thread |

thread |

thread |

thread |

Drain Line Valve |

3/8″ copper line |

3/8″ copper line |

3/8″ copper line |

3/8″ copper line |

|

|

|

|

|

1230488-2-B |

12 |

Kohler Co. |

240 VAC Source |

|

|||

|

|

|

Typical Two-Pole |

|

N |

L2 |

L1 |

Circuit Breaker |

|

without GFCI |

||||

|

|

|

||

|

|

|

Breaker Box |

|

|

|

|

L1 |

|

|

120V |

|

240V |

|

|

|

L2 |

||

|

|

|

||

|

120V |

|

|

|

|

240V |

|

L1 (Black) |

|

|

|

|

||

|

Equipment Ground |

|

Neutral Bus |

L2 (Black) |

Ground |

|

(Green) |

|

(In Breaker Box) |

|

|

|

|

|

|

|

Electrician to provide |

|

|

suitable strain relief cable. |

6. Connect the Electrical Supply

WARNING: Risk of electrocution. Disconnect all power before performing these installation steps.

NOTICE: All electrical work should be done by a qualified electrician.

NOTICE: All electrical wiring must be done in accordance with local codes.

NOTICE: Each steam generator requires a dedicated circuit. Dual steam generator installations require a second dedicated circuit.

IMPORTANT! Make sure the water supply to the steam generator is turned on before connecting the electrical supply.

Connect the Power

Turn off all electricity to the working area at the main circuit breaker panel.

Connect a 240 VAC electrical line to the wires labeled ″L1,″ ″L2,″ and the green (ground) wire coming out of the steam generator field service box located on top of the steam generator.

Confirm the ground connection has been made in the field service box.

Close the field service box.

Turn on the main power.

The function light should display a green light. If the function light is not green, consult the ″Troubleshooting″ section or contact the Customer Care Center using the number located on the back of this document.

Kohler Co. |

13 |

1230488-2-B |

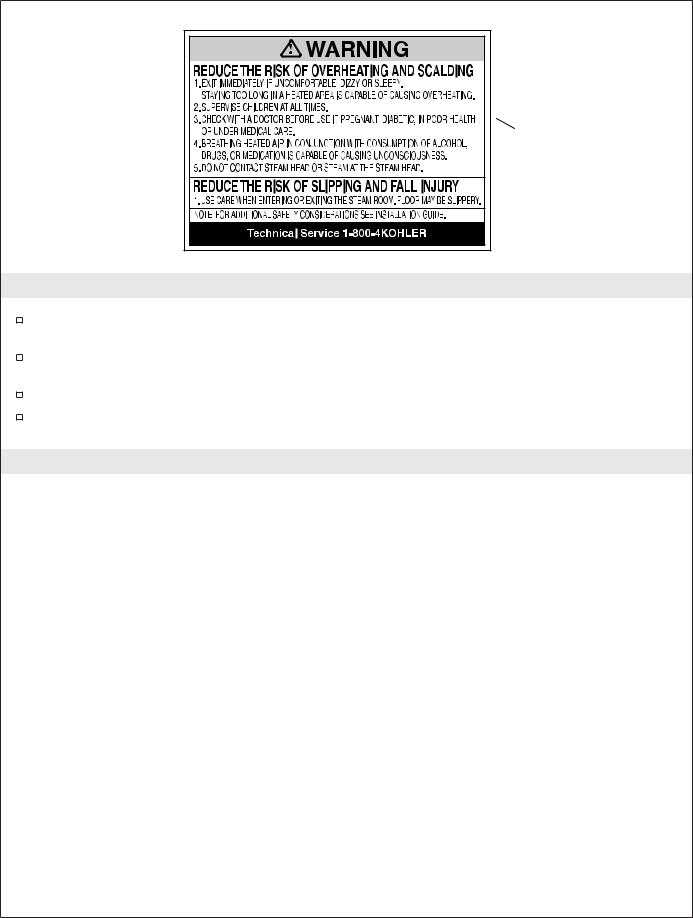

Warning Label

7. Complete the Installation

Remove the adhesive backing from the warning label provided and apply the label to the wall of the shower or steam enclosure.

Install the steam housing and steam head following the instructions packed with the Steam Control Kit.

Install the steam control following the instructions packed with the Steam Control Kit.

To operate the steam control, follow the operating instructions provided with the Steam Control Kit.

Warranty

KOHLER Steam Generator

THREE-YEAR LIMITED WARRANTY

Kohler steam generator units manufactured after September 15, 2001, are warranted to the original consumer purchaser to be free of manufacturing defects in material and workmanship during normal residential usage for three (3) years from the date of installation. This warranty only applies to KOHLER steam generator units installed in the United States of America, Canada or Mexico (″North America″).

If a defect is found in normal residential usage, Kohler Co. will, at its election, repair or replace the unit, or make appropriate adjustment. Damage caused by accident, misuse or abuse is not covered by this warranty. Proof of purchase (original sales receipt) must be provided to Kohler Co. with all warranty claims. Kohler Co. is not responsible for labor charges, removal charges, installation, or other consequential costs. In no event shall the liability of Kohler Co. exceed the purchase price of the unit.

If this unit is used commercially or installed outside of North America, Kohler Co. warrants the unit to be free from defects in material and workmanship for one (1) year from the date of installation with all other terms of this warranty applying except duration.

To obtain warranty service contact Kohler Co., either through your Dealer, Plumbing Contractor, Home Center or E-tailer or by writing Kohler Co., Attn: Customer Care Center, 444 Highland Drive, Kohler, WI 53044, USA, or by calling 1-800-4-KOHLER (1-800-456-4537) from within the USA and Canada, and 001-800-456-4537 from within Mexico, or visit www.kohler.com within the USA, www.ca.kohler.com from within Canada, or www.mx.kohler.com in Mexico.

KOHLER CO. AND/OR SELLER ARE PROVIDING THESE WARRANTIES IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KOHLER CO. AND/OR SELLER DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states/provinces do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of special, incidental or consequential damages, so these limitations and exclusions

1230488-2-B |

14 |

Kohler Co. |

Warranty (cont.)

may not apply to you. This warranty gives you specific legal rights. You may also have other rights, which vary from state/providence to state/providence.

This is Kohler Co.’s exclusive written warranty.

Troubleshooting

CAUTION: Risk of personal injury. Troubleshooting steps involving internal wiring or electrical connections should only be performed by a qualified electrician.

NOTE: The troubleshooting steps below only apply to the steam generator itself. For issues involving the steam control refer to the ″Troubleshooting″ section for the Steam Control Kit.

NOTE: For service parts information, visit your product page at www.kohler.com/serviceparts.

This troubleshooting guide is for general aid only. For service and installation issues and concerns, call 1-800-4KOHLER.

Symptoms |

Probable Causes |

Recommended Action |

||

1. The green LED light is |

A. |

No electrical power at the steam |

A1. |

Reset the electrical power at the |

not on, and there is no |

|

generator. |

|

circuit breaker. |

steam from the steam |

|

|

|

|

head. |

|

|

|

|

|

|

|

A2. |

Have a qualified electrician verify |

|

|

|

|

that 240 V of power is present at |

|

|

|

|

the steam generator. |

|

B. |

Circuit breaker is in the ″Off″ |

B. |

Turn on the electrical power at the |

|

|

position. |

|

breaker. |

|

C. |

Circuit breaker is not the correct |

C. |

Verify the circuit breaker is the |

|

|

size. |

|

correct size. Replace the circuit |

|

|

|

|

breaker if it is the wrong size. |

|

D. Electrical connection in the |

D. Turn off all electrical power to the |

||

|

|

steam generator field service |

|

steam generator. Have a qualified |

|

|

box is loose. |

|

electrician open the steam |

|

|

|

|

generator field service box and |

|

|

|

|

check/repair the connections. |

2. The green LED light is on, |

A. |

The water is turned off. |

A. |

Turn on the water supply. |

but there is no steam from |

|

|

|

|

the steam head. |

|

|

|

|

|

B. |

The inlet screen is plugged. |

B. |

Remove and clean the inlet screen. |

|

C. |

Excessive back pressure caused |

C. |

Move the steam generator closer to |

|

|

by too long a run of piping or |

|

the steam head or use 45° elbows. |

|

|

too many 90° elbows. |

|

|

|

D. Water blockage due to a steam |

D. Change the steam pipe to slope |

||

|

|

trap in the steam line. A steam |

|

down from the steam head to the |

|

|

trap is caused by steam line |

|

steam generator. |

|

|

piping running down from the |

|

|

|

|

steam generator and then back |

|

|

|

|

up to the steam head. |

|

|

|

E. |

The steam control is not |

E1. |

Check the wiring connections |

|

|

connected. |

|

according to the steam control |

|

|

|

|

installation and care guide. |

|

|

|

E2. |

Use the troubleshooting kit |

|

|

|

|

attached to the steam generator to |

|

|

|

|

troubleshoot connection problems. |

3. There is a continuous |

A. |

Internal steam generator |

A1. |

Shut off the water supply, and |

flow of water from the |

|

components are not working. |

|

drain the water from the steam |

steam head. Water flow |

|

|

|

generator. Close the drain valve. |

during the power clean |

|

|

|

|

cycle is normal. |

|

|

|

|

|

|

|

|

|

Kohler Co. |

15 |

1230488-2-B |

Troubleshooting (cont.)

Symptoms |

Probable Causes |

Recommended Action |

|

|

|

A2. |

Partially open the water supply |

|

|

|

shut-off valve. |

|

|

A3. |

Allow the water to gradually fill |

|

|

|

the steam generator tank (may take |

|

|

|

several minutes). If the water |

|

|

|

continues to flow from the steam |

|

|

|

head, repeat A1 above. |

|

|

A4. |

Fully open the water supply |

|

|

|

shut-off valve. |

|

|

A5. On models with power clean |

|

|

|

|

option only: If water continues to |

|

|

|

flow from the steam head, run the |

|

|

|

power clean cycle. |

|

|

A6. |

If water continues to flow from the |

|

|

|

steam head, contact the Customer |

|

|

|

Care Center using the information |

|

|

|

on the back of this guide. |

|

B. The water supply is incorrectly |

B. |

Review this manual, and if |

|

connected to the steam |

|

necessary reconnect the water |

|

generator. |

|

supply to the proper location. |

4. Steam is coming out of |

A. Elevations over 6000’ (1829 m) |

A. |

At elevations over 6000’ (1829 m) |

the steam head and the |

above sea level can cause water |

|

above sea level contact Kohler Co. |

control is shut off. |

to boil at lower temperatures. |

|

Customer Care Center for |

|

|

|

instructions on disconnecting the |

|

|

|

fast start coil. |

|

|

|

|

1230488-2-B |

16 |

Kohler Co. |

Loading...

Loading...