Rockwell Automation FactoryTalk Historian SE 4.0 User Manual

LIVE DATA INTERFACE USER GUIDE

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013

Supersedes Publication HSELD-UM023A-EN-E–May 2012

Contacting Rockwell |

Customer Support Telephone — 1.440.646.3434 |

|

Online Support — http://www.rockwellautomation.com/support/overview.page |

Copyright Notice |

© 2013 Rockwell Automation, Inc. All rights reserved. Printed in the USA. |

|

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation, |

|

Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation, Inc. is |

|

strictly prohibited. Please refer to the license agreement for details. |

Trademark Notices |

FactoryTalk, FactoryTalk Historian Machine Edition (ME), FactoryTalk Historian Site Edition (SE), FactoryTalk |

|

Live Data, FactoryTalk Services Platform, FactoryTalk VantagePoint, FactoryTalk View, FactoryTalk ViewStudio, |

|

Rockwell, Rockwell Automation, Rockwell Software, RSView, RSView Machine Edition, RSView ME Station, |

|

RSView Studio, and RSLinx Enterprise are trademarks of Rockwell Automation, Inc. |

|

Any Rockwell Automation logo, software or hardware not mentioned herein is also a trademark, registered or |

|

otherwise, of Rockwell Automation, Inc. |

|

For a complete list of products and their respective trademarks, go to |

|

http://www.rockwellautomation.com/rockwellautomation/legal-notices/overview.page?%23tab4#/tab4. |

Other Trademarks |

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows, |

|

Windows ME, Windows NT, Windows 2000, Windows Server-, Windows XP, Windows 7, and Vista are either |

|

registered trademarks or trademarks of Microsoft Corporation in the United States and/or other countries. |

|

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in |

|

the United States and/or other countries. |

|

ControlNet is a registered trademark of ControlNet International. |

|

DeviceNet is a trademark of the Open DeviceNet Vendor Association, Inc. (ODVA) |

|

OLE for Process Control (OPC) is a registered trademark of the OPC Foundation. |

|

Oracle, SQL*Net, and SQL*Plus are registered trademarks of Oracle Corporation. |

|

All other trademarks are the property of their respective holders and are hereby acknowledged. |

Warranty |

This product is warranted in accordance with the product license. The product’s performance may be affected |

|

by system configuration, the application being performed, operator control, maintenance, and other related |

|

factors. Rockwell Automation is not responsible for these intervening factors. The instructions in this |

|

document do not cover all the details or variations in the equipment, procedure, or process described, nor do |

|

they provide directions for meeting every possible contingency during installation, operation, or |

|

maintenance. This product’s implementation may vary among users. |

|

This document is current as of the time of release of the product; however, the accompanying software may |

|

have changed since the release. Rockwell Automation, Inc. reserves the right to change any information |

|

contained in this document or the software at any time without prior notice. It is your responsibility to obtain |

|

the most current information available from Rockwell when installing or using this product. |

Table of Contents

Introduction

Principles of Operation

Configuring FactoryTalk

Historian Live Data Interface

Point Source

Point Configuration

Chapter 1

Installation ...................................................................................................... |

7 |

Features............................................................................................................ |

8 |

Related Documentation .............................................................................. |

8 |

Chapter 2

Processing Loops ......................................................................................... |

12 |

FactoryTalk Diagnostics............................................................................ |

13 |

Chapter 3

Configuring the FTLD Interface Using the FactoryTalk |

|

Administration Console............................................................................ |

16 |

Configuring the FTLD Interface Using the Interface Configuration |

|

Utility (ICU)................................................................................................ |

16 |

Adding Remote Servers to Connection Manager .......................... |

19 |

Defining Remote Servers as API Hosts ............................................ |

19 |

Chapter 4

PI 3 Server Node: Reserved Point Sources ............................................ |

21 |

Chapter 5

Point Attributes........................................................................................... |

23 |

|

Length....................................................................................................... |

|

23 |

Point Source ............................................................................................ |

24 |

|

Point Type |

............................................................................................... |

24 |

PI 3 Server Nodes................................................................................... |

24 |

|

Location1 ................................................................................................. |

|

24 |

Location2 ................................................................................................. |

|

25 |

Location3 ................................................................................................. |

|

25 |

Location4 ................................................................................................. |

|

25 |

Advise and Polled Tags.................................................................... |

26 |

|

Output Tags....................................................................................... |

26 |

|

Location5 ................................................................................................. |

|

26 |

InstrumentTag........................................................................................ |

26 |

|

Length |

26 |

|

ExDesc ...................................................................................................... |

|

27 |

Length |

27 |

|

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

3 |

Table of Contents

I/O Rates Tag Configuration

Performance Point

Configuration

Startup Command File

Interface Node Clock

Security

Starting and Stopping the

Interface

Error and Informational

Messages

SourceTag ................................................................................................ |

27 |

Compression Testing............................................................................ |

27 |

Exception Reporting ............................................................................. |

28 |

Output Points......................................................................................... |

29 |

Trigger Method 1 (Recommended)............................................. |

29 |

Trigger Method 2 ............................................................................. |

30 |

Sample Tag Configurations ...................................................................... |

30 |

Scan Classes ............................................................................................. |

30 |

Polled Tags............................................................................................... |

31 |

Advise Tags.............................................................................................. |

31 |

Event Tags ............................................................................................... |

31 |

Chapter 6 |

|

Monitoring I/O Rates Tag on the Interface Node.............................. |

33 |

Configuring I/O Rates Tag with ICU ................................................... |

33 |

Chapter 7 |

|

Chapter 8 |

|

Command-line Parameters ....................................................................... |

39 |

Sample FTLDInt.bat File.......................................................................... |

43 |

Setting File .................................................................................................... |

43 |

Chapter 9 |

|

Chapter 10 |

|

Chapter 11 |

|

Using the Interface Configuration Utility ............................................ |

49 |

Using the Administrative Tools .............................................................. |

50 |

Chapter 12 |

|

System Errors and PI Errors...................................................................... |

52 |

Error Descriptions ................................................................................. |

52 |

Appendix A |

|

4 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

|

|

Table of Contents |

Technical Support and |

Before You Call or Write for Help ......................................................... |

53 |

Resources |

Find the Version and Build Numbers .................................................... |

53 |

|

View Computer Platform Information ................................................. |

54 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

5 |

Table of Contents

6 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Chapter 1

Introduction

Installation

The FactoryTalk Historian system uses the PI system as a back end to store tag data. The FactoryTalk Historian Live Data Interface (FTLD) allows FactoryTalk Historian to connect with Rockwell data sources. The FTLD interface provides buffering capability before the data is permanently stored in the Historian archive.

The FTLD Interface is integrated with the FactoryTalk Live Data service provided by FactoryTalk Services Platform. It is a FactoryTalk Live Data client that relies on FactoryTalk Live Data service to talk to FactoryTalk data servers such as FactoryTalk View SE, RSLinx Enterprise, and OPC servers that are part of a FactoryTalk application.

|

The FactoryTalk Historian documentation uses the terms tag and point |

|

NOTE |

||

to mean the same thing. An example of a tag name is: |

||

|

||

|

||

|

FTLDEnt:rc:RSLinxC.secondArray000. |

The FTLD Interface is configured using the FactoryTalk Administration Console or Interface Configuration Utility. See "Configuring FactoryTalk Historian Live Data Interface (page 15)" for more information.

The steps to install the FactoryTalk Historian Live Data Interface are explained in the FactoryTalk Historian SE Installation and Configuration Guide, available from Start > All Programs > Rockwell Software > FactoryTalk Historian SE > Help.

|

The complete user documentation on FactoryTalk Historian SE is |

|

NOTE |

||

available in the Common Files\Rockwell\Help folder in your |

||

|

||

|

||

|

Program Files directory, and in the Redist\Docs folder on your |

|

|

FactoryTalk Historian SE installation DVD. |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

7 |

Chapter 1 Introduction

Features

Related Documentation

The features of the FTLD Interface include:

Item |

Description |

|

|

PI SDK |

The PI SDK and the PI API are bundled together and must be |

|

installed on each PI Interface node. The FTLD Interface does not |

|

specifically make PI SDK calls. It uses the PI API calls to support |

|

longer instrument tag fields and multiple-character point sources. |

|

The PI SDK cannot be used if the interface will be set up to use |

|

Disconnected Startup because it is based on API calls only. |

Source of Time |

The FTLD Interface can accept time stamps from the FactoryTalk |

Stamps |

Live Data server, or it can provide time stamps from the FactoryTalk |

|

Historian server. This is controlled by a command-line parameter. |

|

See "Startup Command File (page 39)" for more information on |

|

using the command line to control time stamps. |

UniInt-based |

UniInt stands for Universal Interface. UniInt is not a separate |

|

product or file; it is an OSIsoft-developed framework used by |

|

developers, and it is integrated into many interfaces, including this |

|

interface. The purpose of UniInt is to keep a consistent feature set |

|

and behavior across as many Rockwell interfaces as possible. It also |

|

allows for a rapid development of new interfaces. In any |

|

UniInt-based interface, the interface uses some of the |

|

UniInt-supplied configuration parameters and some |

|

interface-specific parameters. |

Platforms |

The FTLD Interface is designed to run on the Microsoft Windows |

|

operating systems. |

|

Due to its dependency on FactoryTalk Services Platform, the |

|

FactoryTalk Historian Live Data Interface is not supported on |

|

non-Windows platforms. To see a list of operating systems |

|

supported, refer to the FactoryTalk Historian SE Release Notes. |

The following documentation provides additional information related to the FTLD Interface:

•FactoryTalk Historian SE Installation and Configuration Guide

•FactoryTalk Historian SE Release Notes

8 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

IntroductionChapter 1

Both documents are available from Start > Programs > Rockwell Software > FactoryTalk Historian SE > Help.

•FactoryTalk Help, which is available from Start > Programs > Rockwell Software > FactoryTalk Tools > FactoryTalk Help.

|

To access other documents on FactoryTalk Historian SE, go to the |

|

NOTE |

||

Common Files > Rockwell > Help folder in your Program |

||

|

||

|

||

|

Files directory. |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

9 |

Chapter 1 Introduction

10 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Chapter 2

Principles of Operation

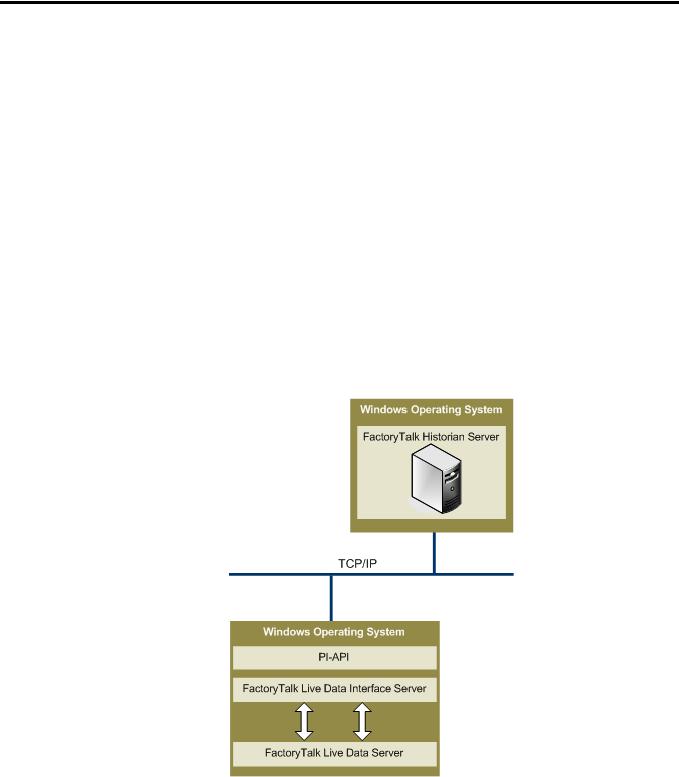

The FactoryTalk Live Data (FTLD) Interface is a FactoryTalk Live Data client that enables process data to be passed between a FactoryTalk Live Data server (for example, RSLinx Enterprise) and a FactoryTalk Historian server. Each instance of the FTLD Interface can provide data to a single FactoryTalk Historian SE server or collective. Multiple instances of the interface may be configured, if required, if API buffering is used.

The figure below shows the basic workflow of the FactoryTalk Historian Live Data Interface.

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

11 |

Chapter 2 Principles of Operation

Processing Loops

At startup, the FTLD Interface tries to establish a connection to both the FactoryTalk Live Data server and the FactoryTalk Historian server.

Once the startup is complete, the Interface enters the processing loop, which includes:

•Servicing scheduled input points. Each Scan Class is processed in turn.

•Servicing output points as events arrive.

•Servicing triggered input points as events arrive.

The Historian Point Database is checked every 2 minutes for points that are added, edited, and deleted. When point updates are detected, the points are loaded (or reloaded) by the Interface as appropriate. The 2-minute update interval can be adjusted with the /updateinterval command-line parameter discussed in the UniInt Interface User Manual.

The manual is located in the UniInt folder (c:\Program Files\Rockwell Software\FactoryTalk Historian\Server\PIPC\Interfaces\UniInt).

The Interface processes a maximum of 25 point updates at a time. If more than 25 points are added, edited, or deleted at one time, the Interface will process the first 25 points, wait 30 seconds (or the length of time specified by the /updateinterval parameter, whichever is lower), process the next 25 points, and so on. After all points have been processed, the Interface will resume checking for updates every 2 minutes (or the length of time specified by the /updateinterval parameter).

All tag edits are performed in the following way: old versions of edited tags are deleted from the interface, new versions are added.

12 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Principles of Operation Chapter 2

FactoryTalk Diagnostics

Therefore, it is more efficient to stop and then start the interface if a large number of tags are edited.

The FTLD Interface sends messages about its operation to FactoryTalk Diagnostics.

FactoryTalk Diagnostics provides the following information about the FTLD Interface:

•Informational messages on the interface startup and shutdown.

•The scan rate of each scan class.

•The count of points loaded by the interface.

•Error messages for points rejected by the interface because they were configured incorrectly.

•Error messages for points rejected by the FTLD server, or error messages sent from the FTLD server.

Because the FTLD Interface is based on the PI-UniInt framework, a few messages are sent to the PIPC log by the PI-UniInt. These error messages are produced by the standard OSIsoft interface routines or by the PI API.

|

The FactoryTalk Diagnostics Setup and Viewer are available from the |

|

NOTE |

||

Tools menu of FactoryTalk Administration Console. |

||

|

||

|

To learn more about viewing error messages and accessing the log file, refer to the help files for FactoryTalk Diagnostics Setup and FactoryTalk Diagnostics Viewer.

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

13 |

Chapter 2 Principles of Operation

14 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Chapter 3

Configuring FactoryTalk Historian Live

Data Interface

To configure a FactoryTalk Historian Live Data Interface (FTLD), we recommend that you use FactoryTalk Administration Console.

However, you must use the Interface Configuration Utility (ICU) to configure an FTLD Interface in the following cases:

•If you are configuring redundant FTLD Interfaces.

For more information, refer to the Rockwell Automation KB 59932 (https://rockwellautomation.custhelp.com/app/answers/detai l/a_id/59932) article.

•If you are configuring the buffer subsystem on an FTLD Interface.

For more information, refer to "Enable Buffering" in the

FactoryTalk Historian SE Installation and Configuration Guide.

|

Enabling the buffer subsystem is a recommended step during |

|

NOTE |

||

the installation of the FactoryTalk Historian Live Data Interface. |

||

|

||

|

||

|

To take advantage of this feature, you must install the FTLD |

|

|

Interface on a separate machine than the FactoryTalk Historian |

|

|

SE. |

•If you are configuring the Disconnected Startup option.

For more information, refer to "(Unint) Disconnected Startup" in the Interface Configuration Utility Help.

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

15 |

Chapter 3 Configuring FactoryTalk Historian Live Data Interface

Configuring the FTLD

Interface Using the

FactoryTalk Administration

Console

|

To open the Interface Configuration Utility (ICU) online help, go |

|

NOTE |

||

to Start > All Programs > Rockwell Software > FactoryTalk |

||

|

||

|

||

|

Historian SE > Interface Configuration Utility, and select Help > |

|

|

Contents and Index from the main menu. |

|

|

If you create an FTLD Interface using the Interface Configuration |

|

NOTE |

||

Utility, it will not appear in the list of interfaces in the |

||

|

||

|

||

|

FactoryTalk Administration Console. As a result, you will not be |

|

|

able to configure the interface from the FactoryTalk |

|

|

Administration Console. |

Refer to "Configuring FactoryTalk Historian Live Data Interface" in the FactoryTalk Historian SE Installation and Configuration Guide for information on configuring an FTLD Interface using the FactoryTalk Administration Console. This section also includes steps on how to enable buffering on the remote interface.

You can configure the FTLD Interface on your local computer (the computer on which the FactoryTalk Historian SE server is installed); however, we recommend that you always install the FTLD Interface on the computer that has the data server installed. Refer to "Verifying the FactoryTalk Historian Live Data Local Interface" in the FactoryTalk Historian SE Installation and Configuration Guide for more information.

Configuring the FTLD

Interface Using the Interface

Configuration Utility (ICU)

|

For more information on the Interface Configuration Utility, refer to the |

|

NOTE |

||

FT Historian SE Interface Configuration Utility guide available in the |

||

|

||

|

||

|

Common Files > Rockwell > Help folder in your Program Files directory. |

If you configure an interface in the ICU, the batch file of the interface (FTLDInt.bat) will be maintained by the ICU, and all configuration changes will be kept in that file.

16 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Configuring FactoryTalk Historian Live Data Interface Chapter 3

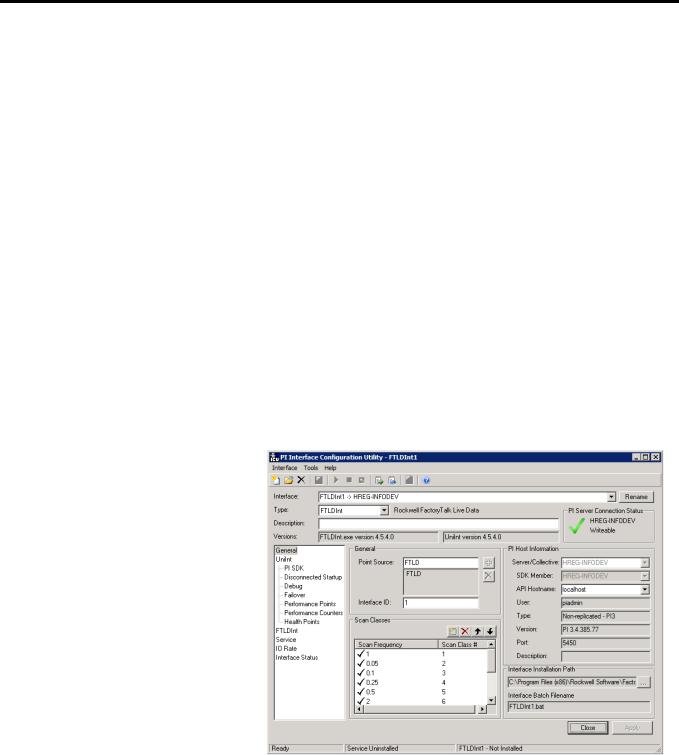

To configure an FTLD Interface with the ICU:

1.Go to Start > All Programs > Rockwell Software > FactoryTalk Historian SE > Interface Configuration Utility. The Interface Configuration Utility dialog box appears.

2.On the Interface menu, click New Windows Interface Instance from BAT File. The Open Interface Configuration File dialog box appears.

3.Navigate to C:\Program Files\Rockwell Software\FactoryTalk Historian\Server\PIPC\Interfaces\LDInterface.

4.Select the FTLDInt_FTLD.bat.bak file and click Open.

5.Click OK in the Interface Configuration Utility message box to acknowledge the information on duplicated point sources and ID combinations.

The FTLD Interface configuration is displayed on the General page of the ICU.

6.From the Type list, select FTLDInt, if it has not been chosen automatically.

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

17 |

Chapter 3 Configuring FactoryTalk Historian Live Data Interface

7. If necessary, edit the Scan Frequency and Scan Class values.

Item |

Description |

|

|

Scan Frequency |

Indicates the frequency at which the interface reads values |

|

from the FactoryTalk Live Data server. |

Scan Class # |

Associated with the Scan Frequency value. If there is no |

|

interface defined, the Scan Class # will be displayed without |

|

a time period. |

8. Click Apply.

Note that in this example the API Hostname is localhost, which means that the interface will be configured to communicate with the local FactoryTalk Historian SE server.

If you want the interface to communicate with a remote FactoryTalk Historian server, you need to:

1.Add the remote server to the Connection Manager (page 19).

2.Define the remote server as the API host (page 19).

|

This step is required to ensure connection to the correct remote |

|

NOTE |

||

server. |

||

|

||

|

Once you have added the server to the Connection Manager and defined it as the API host, you can select the server from the API Hostname list on the General page in the ICU.

There are additional parameters available for configuring the interface:

•/MultiCOM

•/uiDll

•/FTDirectory

•/FTContext

To view them, click FTLDInt in the left pane of the dialog box.

18 |

Rockwell Automation Publication HSELD-UM024A-EN-E–September 2013 |

Loading...

Loading...