HEIDENHAIN TNC 430 Technical Manual

Technical Manual

TNC 426 CB/PB/M TNC 430 CA/PA/M

NC Software |

280 470-12 |

|

280 471-12 |

280 472-14

280 473-14

280 474-19

280 475-19

280 476-21

280 477-21

December 2001

343 734-21 · 10 · 12/2001 · Bi · Printed in Germany · Subject to change without notice (343 734-E6)

Foreword

This Technical Manual has been written for all machine tool manufacturers and distributors. It contains all of the information necessary for the mounting, electrical connection, commissioning and PLC programming of HEIDENHAIN contouring controls.

Every time the hardware or software of HEIDENHAIN's contouring control is updated, you will receive a set of supplementary pages free-of-charge. Always sort these pages into your Technical Manual immediately. In this way, your manual will always be up-to-date.

You can use extracts from this manual to supplement your machine documentation. If you increase the size of the manual format (17 cm x 24 cm) by the factor 1.225, you will have DIN A4 format.

No documentation is perfect. Documentation is alive. It thrives on your comments and suggestions for improvement. Please help us by sending us your ideas.

DR. JOHANNES HEIDENHAIN GmbH

E/P Department

Dr.-Johannes-Heidenhain-Str. 5

83301 Traunreut

1 Update Information No. 6

1.1 Releases

The following NC software was released: |

|

n NC software 280 474-18 and 280 475-18 |

June 2001 |

n NC software 280 474-19 and 280 475-19 |

August 2001 |

n NC software 280 476-15 and 280 477-15 |

November 2000 |

n NC software 280 476-16 and 280 477-16 |

December 2000 |

n NC software 280 476-17 and 280 477-17 |

March 2001 |

n NC software 280 476-18 and 280 477-18 |

April 2001 |

n NC software 280 476-19 and 280 477-19 |

July 2001 |

n NC software 280 476-20 and 280 477-20 |

August 2001 |

n NC software 280 476-21 and 280 476-21 |

November 2001 |

1.2 NC software 280 474-xx

|

NC software |

Setup Disks |

Release |

|

280 474-18 |

286 195-21 |

06/2001 |

|

Export version: |

|

|

|

280 475-18 |

286 195-21 |

06/2001 |

|

NC Software |

Setup Disks |

Release |

|

280 474-19 |

286 195-22 |

08/2001 |

|

Export version: |

|

|

|

280 475-19 |

286 195-22 |

08/2001 |

1.3 NC software 280 476-xx |

|

|

|

|

NC software |

Setup Disks |

Release |

|

280 476-15 |

286 197-17 |

11/2000 |

|

Export version: |

|

|

|

280 477-15 |

286 197-17 |

11/2000 |

Machine |

n MP7441 has been expanded: |

|

|

parameters |

Bit 1: Reserved, enter 0 |

|

|

|

Bit 2: Error message “Enter depth as negative” when a positive depth was |

||

|

programmed in the fixed cycles. |

|

|

=0: Error message is suppressed

=1: Error message is not suppressed

nMP7682 has been expanded: Bit 3: Reserved, enter 0

Bit 4: Reserved, enter 0

Machine |

n Before a probing block, the control checks whether M4501 is set. If it is, the |

integration |

probing block start is delayed by 1 second. |

December 2001 |

Update Information No. 6 |

1 – 1 |

Machine parameters

PLC programming

NC software |

Setup Disks |

Release |

280 476-16 |

286 197-18 |

12/2000 |

Export version: |

|

|

280 477-16 |

286 197-18 |

12/2000 |

nMP2221 has been expanded:

All HEIDENHAIN inverters except the UE 2xx compact inverter provide the error signal ERR-IZ.

Bit 2 = 0: Do not monitor the ERR-IZ signal, or the inverter doesn't supply this signal (SIEMENS and INDRAMAT inverters, and HEIDENHAIN UE 2xx compact inverters).

Bit 2 = 1: Monitor the ERR-IZ signal (HEIDENHAIN inverters except UE 2xx compact inverters).

nThe minimum input value of MP7430 was changed from 0.1 to 0.001.

nFN18: SYSREAD has been expanded:

You can ascertain the angle of misalignment between the spindle and the tilted coordinate system.

ID210

NR8

nFN18: SYSREAD has been expanded:

You can find the measurement results of touch probe cycles 0 and 1 without probe radius and length compensation.

ID360

NR3

Machine parameters

Machine integration

NC Software |

Setup Disks |

Release |

280 476-17 |

286 197-19 |

03/2001 |

Export version: |

|

|

280 477-17 |

286 197-19 |

03/2001 |

nThe PLC can change machine parameter MP2397.x.

nMP7683 has been expanded:

Bit 7: AUTOSTART function of an NC program through the PLC

0:AUTOSTART function of an NC program is performed by the NC.

1:AUTOSTART function of an NC program is performed by the PLC. The NC does not trigger an NC start.

nM4182 is new:

The marker indicates whether the autostart function was activated.

nM4183 is new:

The marker indicates whether the time from the autostart function has expired.

nIf an NC program block is interrupted in Single block mode or by a STOP block and the positions of NC axes are changed, the NC program can be restarted at the changed positions. If STRICTREPOS = YES in OEM.SYS, the function for restoring the position is activated.

1 – 2 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Miscellaneous

Machine parameters

Machine integration

Machine parameters

nWhen the control starts, it checks whether there is enough space on the hard disk for system files. If not, the error message Too many setup files appears. In this event, delete any unnecessary NC software or setup files from the hard disk.

nWhen the control starts, the data of the fixed cycles and touch probe cycles are checked and the resulting information is saved in the log.

NC software |

Setup Disks |

Release |

280 476-17 |

286 197-20 |

03/2001 |

Export version: |

|

|

280 477-17 |

286 197-20 |

03/2001 |

NC Software |

Setup Disks |

Release |

280 476-18 |

286 197-21 |

04/2001 |

Export version: |

|

|

280 477-18 |

286 197-21 |

04/2001 |

nThe maximum input values of MP1060.x and MP1070.x were extended to 30 [m/s2 or 1000°/s2].

nMP7682 has been expanded:

Bit 4: Tolerance of rotary axes with M128

=0: With consideration of head dimensions

=1: Without consideration of head dimensions

nSince no speed encoder is used during volts-per-hertz (U/f) control mode, W322 = 0. Module 9164 supplies the actual speed value while the spindle is active, and not during the acceleration and braking phase.

NC Software |

Setup Disks |

Release |

280 476-18 |

286 197-22 |

05/2001 |

Export version: |

|

|

280 477-18 |

286 197-22 |

05/2001 |

NC Software |

Setup Disks |

Release |

280 476-18 |

286 197-23 |

05/2001 |

Export version: |

|

|

280 477-18 |

286 197-23 |

05/2001 |

NC Software |

Setup Disks |

Release |

280 476-19 |

286 197-24 |

07/2001 |

Export version: |

|

|

280 477-19 |

286 197-24 |

07/2001 |

nMP2180 has been expanded, MP2181 has been added: MP2180 has been expanded into MP2180.0 to MP2180.8.

In MP2180.0 to MP2180.8 and in MP2181, the same value must be entered.

nThe maximum input value of MP2600.x was increased to 30 000 [A/(rev/s2)].

nMP7160 has been expanded:

Bit 3 = 0: IPC and acceleration feedforward control active

Bit 3 = 1: IPC and acceleration feedforward control not active

December 2001 |

Update Information No. 6 |

1 – 3 |

Machine integration

PLC modules

Miscellaneous

Machine parameters

Machine integration

nIf you save the actual position value with Module 9146 and then close the position control loop, or if the position control loop is closed and the actual position value is then saved with Module 9146, the error message Actual position value saved <Axis> appears. The error message triggers an emergency stop.

nA maximum of 16 variables can be used in the MP7530 column and in the TEMPCOMP column of the description tables for the swivel axis geometry.

Module 9120 Starting a PLC axis

Module 9120 was expanded by an error code: 6= Feed rate not permitted

Module 9123 Traversing the reference marks of PLC axes

Module 9123 was expanded by an error code: 6= Feed rate not permitted

nIf REMOTE.PLCPASSWORDFORCED = YES in OEM.SYS, machine backup, full backup and setup are only possible with the code word defined in

PLCPASSWORD =.

NC Software |

Setup Disks |

Release |

280 476-20 |

286 197-25 |

08/2001 |

Export version: |

|

|

280 477-20 |

286 197-25 |

08/2001 |

NC Software |

Setup Disks |

Release |

280 476-20 |

286 197-26 |

09/2001 |

Export version: |

|

|

280 477-20 |

286 197-26 |

09/2001 |

NC software |

Setup disks |

Release |

280 476-21 |

286 197-27 |

11/2001 |

Export version: |

|

|

280 477-21 |

286 197-27 |

11/2001 |

nMP1152 is new:

0:I3 (control-is-ready signal acknowledgement) is passed on directly to the NC

1:I3 is processed by the PLC before being passed on to the NC

nThe machining plane position indication (MP7500 bit 1 = 1) has been expanded by the following swivel-axis combination:

Swivel head and rotary table: axis sequence B variable, A variable (tool axis Z)

nAn internal EMERGENCY STOP can be simulated with the code number FAILTEST in order to check the wiring of the machine. The control-is-ready output is reset. The NC and PLC are no longer operable.

Danger

Hanging axes must be supported before the test in order to prevent damage to the machine in case of error.

1 – 4 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

n The power module table was expanded by the following columns: I-N-DC,

|

T-DC, F-DC, T-AC, F-AC, T-IGBT, I-N-AC-3333, I-N-AC-4000, I-N-AC-5000, |

|

I-N-AC-6666, I-N-AC-8000 and I-N-AC-10000. The columns currently have no |

|

function. |

|

n The motor table was expanded by the following columns T-DC, F-DC, T-AC |

|

and F-AC. The columns currently have no function. |

Miscellaneous |

n In the Machine-parameter programming mode, the DELETE ALL and SELECT |

|

soft keys after the DEL/SEL SETUP soft key were switched. |

1.4 Use of Speed Encoders with EnDat Interface

Regardless of the Type of encoder in the motor table, the control attempted to communicate with a speed encoder with EnDat interface. If this did not succeed, a speed encoder with Z1 track was assumed.

If an error occurred during communication with the EnDat encoder, the control assumed that it was dealing with an encoder with a Z1 track. This was not the case, however, since encoders with EnDat interface do not have a Z1 track.

This resulted in the error message C310 Z1 track error.

As of NC software 280 476-18 (in conjunction with the setup 286 197-22), the control uses the Type of encoder entry in the motor table. If an encoder with Z1 track is entered in the motor table, the message C310 Z1 track error appears in the event of an error. If an encoder with EnDat interface is entered in the motor table, the control attempts to communicate with the encoder. If this fails, the error message C3F0 EnDat not found <axis> appears.

Warning

If you use the HEIDENHAIN standard motor table motor.mot and motors with EnDat encoders, you might have to change the entry for the motor in the SYS column (type of encoder) of the motor table or enter a new motor.

nSYS = 1: Incremental rotary encoder with Z1 track

nSYS = 2: Absolute speed encoder with EnDat interface

If you use the motor table motor.sn instead of motor.mot, the control attempts to communicate with an encoder with EnDat interface. If this fails, due to an error or because no EnDat encoder is connected, the control assumes that it is dealing with an encoder with Z1 track and tries to read it. If this fails, the error message C310 Z1 track error appears.

December 2001 |

Update Information No. 6 |

1 – 5 |

1.5 Tool-Oriented Machining

As of NC software 280 476-17, “tool-oriented” pallet table machining is also possible. For more information, please refer to the User's Manual.

A special tool-change macro is required for tool-oriented pallet machining. This is defined through the keyword TCTOOLMODE= in NCMACRO.SYS.

This macro is called for tool oriented machining instead of the tool-change macro. If this macro is not defined in NCMACRO.SYS, a HEIDENHAIN standard macro is run.

The HEIDENHAIN standard macro performs the following functions:

nPositioning to clearance height

nExecution of M146

nTool change through TOOL CALL. The existing tool-change macro is called.

The following new functions are available for interrogating whether a clearance height was programmed in the pallet table:

nFN18: SYSREAD ID510 NR5 IDX(axis)

This function can ascertain whether a clearance height was programmed for the corresponding axis.

nFN18: SYSREAD ID510 NR6 IDX(axis)

This function can ascertain the clearance height for the corresponding axis.

With the M function M146 the current geometry information is saved in a temporary file.

An NC macro can be defined through the keyword CLAMP= in NCMACRO.SYS. The macro is called when a loaded fixture (FIX) is called.

In addition to the standard prototype for pallet tables, the COPY SAMPLE FILES soft key copies the prototype for tool-oriented pallet table machining into the PLC:\PROTO directory. Both prototypes are offered when you create a new pallet table. If you do not want this, delete a prototype from the PLC:\PROTO directory. The existing prototype is then used automatically.

nPrototyp.P = standard prototype

nProto_to.P = prototype for tool-oriented machining

1 – 6 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

1.6 Field Orientation

If a synchronous spindle is used along with an encoder without Z1 track or a nonaligned encoder with EnDat interface, there is no assignment between the encoder and rotor magnets. This is remedied by NC software 280 476-13 with the new FIELD ORIENTATION function on the LE 426 M/30 000 rpm and the LE 430 M. When put into service, the control automatically finds the assignment between the encoder and the rotor magnets and saves this information on the hard disk. From this time on the assignment is available to the servo controller.

1.7 New Motor Table

As of NC software 280 476-13, the motor table motor.mot is used as the standard table instead of the previous standard motor tables motor.asn and motor.sn. Synchronous and asynchronous motors are registered in motor.mot. If the new motor table motor.mot is not available, the control looks for motor.asn and motor.sn.

You can transfer asynchronous motors from motor.asn into motor.mot. To transfer synchronous motors into motor.mot, please contact HEIDENHAIN.

1.8 Hardware

New receiver units The EA 550 and EA 552 receiver units and the APE 511 interface electronics for the connection of two EA 552 to the LE have been superseded by new units.

Old units |

New units |

EA 550 (Id. Nr. 262 904-xx) |

EA 632 (Id. Nr. 346 322-xx) |

|

|

EA 552 (Id. Nr. 339 317-xx) |

EA 652 (Id. Nr. 346 323-xx) |

|

|

APE 511 (Id. Nr. 275 759-xx) |

APE 652 (Id. Nr. 354 656-01) |

|

|

LE 430 M/9 axes On the LE 430/9 axes with flash EPROMs, only the speed encoder inputs and with flash EPROMs the position encoder inputs X1 to X6 (but not X35 to X38) are equipped with

EnDat interface.

December 2001 |

Update Information No. 6 |

1 – 7 |

1.9 Replacing Instructions

Page |

Change |

Remove |

Insert |

|

|

Page |

Page |

Title |

New software |

December 2000 |

December 2001 |

|

|

|

|

Chapter 1 |

Update information |

– |

Update Info. 6 |

|

|

|

|

Chapter 2 |

Errors corrected, some descriptions |

Entire chapter |

Entire chapter |

|

changed and updated |

|

|

|

|

|

|

Chapter 3 |

Errors corrected, some descriptions |

Entire chapter |

Entire chapter |

|

changed and updated |

|

|

|

|

|

|

Chapter 4 |

Machine parameter list updated |

Entire chapter |

Entire chapter |

|

|

|

|

Chapter 5 |

Module, marker and word lists updated |

Entire chapter |

Entire chapter |

|

|

|

|

Chapter 6 |

Errors corrected, some descriptions |

Entire chapter |

Entire chapter |

|

changed, updated and expanded |

|

|

|

|

|

|

Chapter 7 |

Errors corrected, some descriptions |

Entire chapter |

Entire chapter |

|

changed and updated |

|

|

|

|

|

|

Chapter 8 |

Errors corrected, some descriptions |

Entire chapter |

Entire chapter |

|

changed and updated, new descriptions |

|

|

|

added |

|

|

|

|

|

|

Chapter 9 |

No changes |

Entire chapter |

Entire chapter |

|

|

|

|

Chapter 10 |

Errors corrected |

Entire chapter |

Entire chapter |

|

|

|

|

Chapter 11 |

Index updated |

Entire chapter |

Entire chapter |

|

|

|

|

1 – 8 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

2 Introduction

2.1 |

General Information ........................................................................ |

2 – 3 |

2.2 Overview of Components ............................................................... |

2 – 5 |

|

2.3 |

Brief Description ............................................................................ |

2 – 22 |

2.4 |

Hardware ........................................................................................ |

2 – 29 |

|

2.4.1 Designation of the Logic Unit .................................................. |

2 – 29 |

2.5 |

Software ......................................................................................... |

2 – 30 |

|

2.5.1 Designation of the Software ................................................... |

2 – 30 |

|

2.5.2 Software Option ...................................................................... |

2 – 32 |

|

2.5.3 PLC Software .......................................................................... |

2 – 32 |

|

2.5.4 NC Software Exchange ........................................................... |

2 – 33 |

|

2.5.5 Data Backup ............................................................................ |

2 – 40 |

2.6 |

Software Releases ......................................................................... |

2 – 42 |

|

2.6.1 NC Software 280 470-xx and 280 471-xx ................................ |

2 – 42 |

|

2.6.2 NC Software 280 472-xx and 280 473-xx ................................ |

2 – 45 |

|

2.6.3 NC Software 280 474-xx and 280 475-xx ................................ |

2 – 52 |

|

2.6.4 NC Software 280 476-xx and 280 477-xx ................................ |

2 – 61 |

December 2001 |

2 – 1 |

2 – 2 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

2 Introduction

2.1 General Information

HEIDENHAIN contouring controls are designed for use with milling, drilling and boring machines as well as machining centers.

The TNC 426 PB/M, TNC 430 PA/M features integral digital drive control and controls the power stages via PWM signals.

Integration of the drive controller in the TNC 426 PB/M, TNC 430 PA/M offers the following advantages:

nAll the software is contained centrally in the NC; this means that the individual components of the NC such as feed axes, spindle, NC or PLC are optimally matched.

nHigh control quality, because the position controller, speed controller and current controller are combined into one unit.

nThe same functions are available for commissioning, optimizing and diagnosing feed drives as well as spindles.

With the TNC 426 PB, up to five axes and spindle speeds of up to 12 000 rpm can be controlled digitally (option: 30 000 rpm).

The TNC 430 PA supports up to 6 digitally controlled NC axes, 3 analog controlled secondary axes, and digitally controlled spindle speeds up to 30 000 rpm.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

December 2001 |

|

|

|

|

General Information |

|

|

|

|

|

|

|

|

2 – 3 |

|||||||||||||

The TNC 426 M offers digital control for up to 5 axes and spindle speeds up to 12 000 rpm (option: 30 000 rpm). The TNC 430 M offers digital control for up to six or nine axes and spindle speeds up to 30 000 rpm.

The TNC 426 M, TNC 430 M is designed for connection of a compact or modular inverter system. Thus, together with HEIDENHAIN motors, a complete control package including servo drive can be offered (see Technical Manual “Inverter Systems and Motors”).

The TNC 426 CB is the version of the TNC 426 that is equipped with analog speed command interface and can control machines with up to five axes plus spindle. The TNC 430 CA also has an analog speed command interface for machines with up to eight axes plus spindle. A ninth axis can be controlled with an additional PCB.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 – 4 |

|

|

|

|

|

|

|

|

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

||||||||||||||||||||||

2.2 Overview of Components

LE 426 CB, LE 430 CA Logic Unit

Logic unit |

Signal inputs |

ID numbers of LE for |

ID numbers of LE for |

||

|

|

|

|

BC 120 display unit |

BF 120 display unit |

LE 426 CB |

|

|

|

|

|

|

|

|

|

|

|

|

5 position inputs |

1 |

VPP (350 kHz) |

312 001-xx |

313 524-xx |

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

5 position inputs |

1 |

VPP (50 kHz) |

326 415-xx |

326 419-xx |

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

5 position inputs |

11 µAPP (50 kHz) |

312 002-xx |

313 525-xx |

|

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

LE 430 CA |

|

|

|

|

|

|

|

|

|

|

|

|

8 position inputs |

1 |

VPP (350 kHz) |

311 050-xx |

313 523-xx |

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

5 position inputs |

1 |

VPP (50 kHz) |

326 418-xx |

326 424-xx |

|

3 position inputs |

1 |

VPP (350 kHz) |

|

|

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

December 2001 |

Overview of Components |

2 – 5 |

LE 426 PB, LE 430 PA Logic Unit

Logic unit |

Signal inputs |

ID numbers of LE for |

ID numbers of LE for |

||

|

|

|

|

BC 120 display unit |

BF 120 display unit |

LE 426 PB |

|

|

|

|

|

|

|

|

|

|

|

|

5 position inputs |

1 |

VPP (350 kHz) |

|

|

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

6 speed inputs |

1 |

VPP |

|

|

|

Spindle |

|

|

312 000-xx |

313 527-xx |

|

up to 12 000 rpm |

|

|

|

|

|

|

|

|

|

|

|

Spindle |

|

|

315 475-xx |

318 178-xx |

|

up to 30 000 rpm |

|

|

|

|

|

|

|

|

|

|

|

5 position inputs |

1 |

VPP (50 kHz) |

|

|

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

6 speed inputs |

1 |

VPP |

|

|

|

Spindle |

|

|

326 414-xx |

326 421-xx |

|

up to 12 000 rpm |

|

|

|

|

|

|

|

|

|

|

|

Spindle |

|

|

326 416-xx |

326 420-xx |

|

up to 30 000 rpm |

|

|

|

|

|

|

|

|

|

|

|

5 position inputs |

11 µAPP (50 kHz) |

|

|

|

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

6 speed inputs |

1 |

VPP |

|

|

|

Spindle |

|

|

311 999-xx |

313 526-xx |

|

up to 12 000 rpm |

|

|

|

|

|

|

|

|

|

|

|

Spindle |

|

|

317 349-xx |

318 177-xx |

|

up to 30 000 rpm |

|

|

|

|

|

|

|

|

|

|

2 – 6 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Logic unit |

Signal inputs |

ID numbers of LE for |

ID numbers of LE for |

||

|

|

|

|

BC 120 display unit |

BF 120 display unit |

LE 430 PA |

|

|

|

|

|

|

|

|

|

|

|

|

5 position inputs |

1 |

VPP (350 kHz) |

311 049-xx |

313 521-xx |

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

7 speed inputs |

1 |

VPP |

|

|

|

5 position inputs |

1 |

VPP (50 kHz) |

326 417-xx |

325 716-xx |

|

1 spindle position input |

1 |

VPP (350 kHz) |

|

|

|

7 speed inputs |

1 |

VPP |

|

|

December 2001 |

Overview of Components |

2 – 7 |

LE 426 M, LE 430 M Logic Unit

Logic unit |

Signal inputs |

ID numbers of LE for |

ID numbers of LE for |

|

|

|

|

BC 120 display unit |

BF 120 display unit |

LE 426 M with EPROMs |

|

|

|

|

|

|

|

|

|

|

6 position inputs |

11 µAPP/1 VPP |

|

|

|

|

(2 EnDats) |

|

|

|

6 speed inputs |

1 VPP (2 EnDats) |

|

|

|

Spindle |

|

324 990-xx |

324 991-xx |

|

up to 12 000 rpm |

|

|

|

|

|

|

|

|

|

Spindle |

|

324 994-xx |

324 995-xx |

|

up to 30 000 rpm |

|

|

|

|

|

|

|

|

LE 430 M with EPROMs |

|

|

|

|

|

|

|

|

|

|

6 position inputs |

11 µAPP/1 VPP |

324 992-xx |

324 993-xx |

|

|

(2 EnDats) |

|

|

|

7 speed inputs |

1 VPP (2 EnDats) |

|

|

|

10 position inputs |

11 µAPP/1 VPP |

324 996-xx |

324 997-xx |

|

|

(6 EnDats) |

|

|

|

10 speed inputs |

1 VPP (10 EnDats) |

|

|

Note

A BC 120 can also be attached to the LE for the BF 120 at the same time.

2 – 8 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Logic unit |

Signal inputs |

ID numbers of LE for |

ID numbers of LE for |

|

|

|

|

BC 120 display unit |

BF 120 display unit |

LE 426 M with flash EPROMs |

|

|

|

|

|

|

|

|

|

|

6 position inputs |

11 µAPP /1 VPP |

|

|

|

|

(6 EnDats) |

|

|

|

6 speed inputs |

1 VPP/EnDat |

|

|

|

Spindle |

|

344 958-xx |

344 959-xx |

|

up to 12 000 rpm |

|

|

|

|

|

|

|

|

|

Spindle |

|

344 962-xx |

344 963-xx |

|

up to 30 000 rpm |

|

|

|

|

|

|

|

|

LE 430 M with flash EPROMs |

|

|

|

|

|

|

|

|

|

|

6 position inputs |

11 µAPP /1 VPP |

344 960-xx |

344 961-xx |

|

|

(6 EnDats) |

|

|

|

7 speed inputs |

1 VPP/EnDat |

|

|

|

10 position inputs |

11 µAPP /1 VPP |

344 964-xx |

344 965-xx |

|

|

(6 EnDats) |

|

|

|

10 speed inputs |

1 VPP/EnDat |

|

|

Note

A BC 120 can also be attached to the LE for the BF 120 at the same time.

December 2001 |

Overview of Components |

2 – 9 |

TE 420 Operating Panel

The IV and V keys are snap-ons, and can be switched.

Id. Nr. 313 038-11

You can find an overview of the available key symbols on Page 2 – 15.

Horizontal rows to match the design of the flatpanel display

Id. Nr. 316 343-01

BC 120 Visual Display Unit

15-inch color screen (640 x 480 pixels) Id. Nr. 313 037-02

BF 120 Visual Display Unit

10.4-inch color flat panel display (640 x 480 pixels) Id. Nr. 313 506-02

2 – 10 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

BTS 1x0 Monitor/Keyboard Switch

With the BTS 1x0, it is possible to connect two monitors and two operating panels to an LE.

Id. Nr. 317 292-01 |

BTS 110 |

(2 x BC 120) |

|

(see figure at right) |

|

Id. Nr. 329 965-02 |

BTS 120 |

(2 x BF 120) |

MB 420 Machine Operating Panel

Machine operating panel with snap-on (switchable) keys. You can find an overview of the available key symbols on Page 2 – 15.

Key assignment:

nEmergency stop

nMachine control voltage

nNC start, NC stop

nFive axis keys

nRapid traverse

nCoolant

nSpindle start, spindle stop

n7 keys for machine functions

•Standard assignment: FN 1 to FN 5

•Assignment for HEIDENHAIN basic PLC

program: Retract axis, Tool change, Unlock tool, Menu selection →, Unlock door, Rinse water jet, Chip removal

Id. Nr. 293 757-33 |

Standard |

Id. Nr. 293 757-45 |

Basic PLC program |

December 2001 |

Overview of Components |

2 – 11 |

PL 410 B PLC Input/Output Unit

For the expansion of PLC inputs and outputs

Id. Nr. 263 371-12 |

64 inputs |

|

31 outputs |

Id. Nr. 263 371-02 |

64 inputs |

|

31 outputs |

|

4 analog inputs ± 10 V |

|

4 inputs for |

|

Pt 100 |

|

thermistors |

PL 405 B PLC Input/Output Unit |

|

Id. Nr. 263 371-22 |

32 inputs |

|

15 outputs |

HR 410 Handwheel

Portable handwheel with snap-on (switchable) keys. You can find an overview of the available key symbols on Page 2 – 15.

Assignment:

nKeys for selection of 5 axes

nKeys for traverse direction

nKeys for preset feeds

nKey for actual value position capture

nThree keys for machine functions (definable with PLC)

•Spindle right, Spindle left, Spindle stop

•NC start, NC stop, Spindle start

(for HEIDENHAIN basic PLC program)

nTwo permissive buttons

nEmergency stop

nMagnetic holding pads

Id. Nr. 296 469-44 HR 410 handwheel (Spindle right, Spindle left, Spindle stop) Id. Nr. 296 469-45 HR 410 handwheel (NC start, NC stop, Spindle start)

Id. Nr. 312 879-01 |

Connecting cable for cable adapter (spiral cable 3 m) |

Id. Nr. 296 467-xx |

Connecting cable for cable adapter (normal cable) |

Id. Nr. 296 687-xx |

Connecting cable for cable adapter (metal armor) |

Id. Nr. 296 466-xx |

Adapter cable to LE |

Id. Nr. 281 429-xx |

Extension to adapter cable |

Id. Nr. 271 958-03 |

Dummy plug for emergency-stop circuit |

2 – 12 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

HR 130 Handwheel

Panel-mounted handwheel

Id. Nr. 254 040-05 With ergonomic control knob, radial cable outlet

December 2001 |

Overview of Components |

2 – 13 |

HRA 110 Handwheel Adapter

For connecting up to three HR 150 handwheels with the TNC.

The axes and the subdivision factor are selected via rotary switch.

Id. Nr. 261 097-03 |

HRA 110 |

Id. Nr. 257 061-09 |

HR 150, radial cable |

|

outlet |

Id. Nr. 270 908-01 |

Handwheel selection |

|

switch |

2 – 14 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Key symbols for the spindle

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

Spindle stop |

|

Spindle start |

|

White/Red |

|

White/Green |

|

330 816-08 |

|

330 816-09 |

|

Spindle direction left |

|

Spindle direction right |

|

Black/Gray |

|

Black/Gray |

|

330 816-40 |

|

330 816-41 |

|

Spindle stop |

|

Spindle start |

|

White/Red |

|

White/Green |

|

330 816-47 |

|

330 816-46 |

|

Clamp the axis |

|

|

|

Black/Gray |

|

|

|

330 816-48 |

|

|

Key symbols with axis designations

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

X |

|

Y |

|

Black/Orange |

|

Black/Orange |

|

330 816-24 |

|

330 816-36 |

|

Z |

|

A |

|

Black/Orange |

|

Black/Orange |

|

330 816-25 |

|

330 816-42 |

|

B |

|

C |

|

Black/Orange |

|

Black/Orange |

|

330 816-26 |

|

330 816-23 |

|

U |

|

V |

|

Black/Orange |

|

Black/Orange |

|

330 816-43 |

|

330 816-38 |

|

W |

|

IV |

|

Black/Orange |

|

Black/Orange |

|

330 816-45 |

|

330 816-37 |

December 2001 |

Overview of Components |

2 – 15 |

Axis direction keys for the principle axes

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

X – |

|

X + |

|

Black/Gray |

|

Black/Gray |

|

330 816-63 |

|

330 816-64 |

|

X– <– |

|

X+ –> |

|

Black/Gray |

|

Black/Gray |

|

330 816-18 |

|

330 816-17 |

|

X’– –> |

|

X’+ <– |

|

Black/Gray |

|

Black/Gray |

|

330 816-0W |

|

330 816-0V |

|

X– <– |

|

X+ –> |

|

Black/Gray |

|

Black/Gray |

|

330 816-0N |

|

330 816-0M |

|

Y – |

|

Y + |

|

Black/Gray |

|

Black/Gray |

|

330 816-67 |

|

330 816-68 |

|

Y’– –> |

|

Y’+ <– |

|

Black/Gray |

|

Black/Gray |

|

330 816-21 |

|

330 816-20 |

|

Y– <– |

|

Y+ –> |

|

Black/Gray |

|

Black/Gray |

|

330 816-0P |

|

330 816-0R |

Y |

Y– –> |

Y |

Y+ <– |

Black/Gray |

Black/Gray |

||

|

330 816-0D |

|

330 816-0E |

|

Z – |

|

Z + |

|

Black/Gray |

|

Black/Gray |

|

330 816-65 |

|

330 816-66 |

|

Z– <– |

|

Z+ –> |

|

Black/Gray |

|

Black/Gray |

|

330 816-19 |

|

330 816-16 |

|

Z’– –> |

|

Z’– <– |

|

Black/Gray |

|

Black/Gray |

|

330 816-0L |

|

330 816-0K |

2 – 16 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Key symbols for axis direction keys for rotary and secondary linear axes

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

A– |

|

A+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-95 |

|

330 816-96 |

|

B– |

|

B+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-97 |

|

330 816-98 |

|

C– |

|

C+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-99 |

|

330 816-0A |

|

U– |

|

U+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-0B |

|

330 816-0C |

|

V– |

|

V+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-70 |

|

330 816-69 |

|

W– |

|

W+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-0G |

|

330 816-0H |

|

IV– |

|

IV+ |

|

Black/Gray |

|

Black/Gray |

|

330 816-71 |

|

330 816-72 |

December 2001 |

Overview of Components |

2 – 17 |

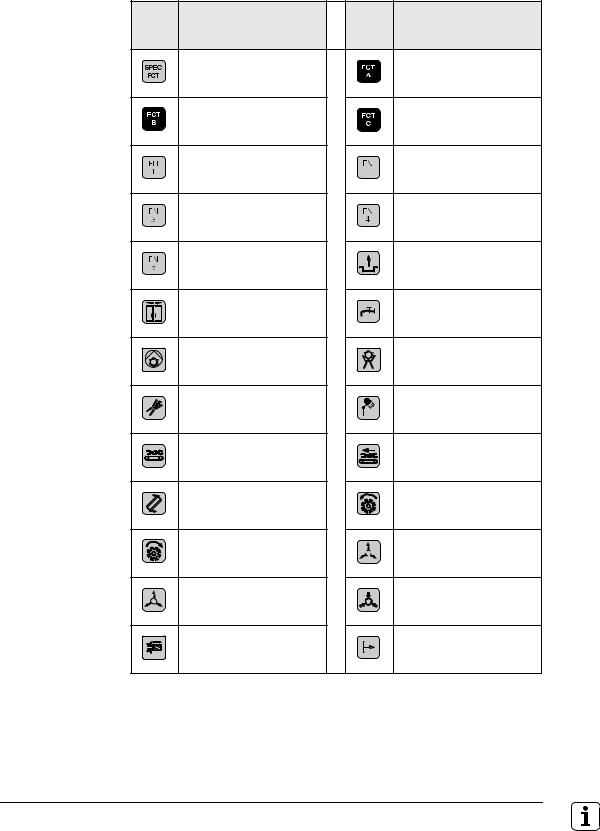

Key symbols for machine functions

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

Special function |

|

Function A |

|

Black/Gray |

|

White/Black |

|

330 816-0X |

|

330 816-30 |

|

Function B |

|

Function C |

|

White/Black |

|

White/Black |

|

330 816-31 |

|

330 816-32 |

|

Function 1 |

|

Function 2 |

|

Black/Gray |

|

Black/Gray |

|

330 816-73 |

|

330 816-74 |

|

Function 3 |

|

Function 4 |

|

Black/Gray |

|

Black/Gray |

|

330 816-75 |

|

330 816-76 |

|

Function 5 |

|

Unlock door |

|

Black/Gray |

|

Black/Gray |

|

330 816-77 |

|

330 816-78 |

|

Unlock door |

|

Coolant |

|

Black/Gray |

|

Black/Gray |

|

330 816-79 |

|

330 816-80 |

|

Coolant (internal) |

|

Coolant (external) |

|

Black/Gray |

|

Black/Gray |

|

330 816-0S |

|

330 816-0T |

|

Rinse water jet |

|

Spotlight |

|

Black/Gray |

|

Black/Gray |

|

330 816-81 |

|

330 816-82 |

|

Chip removal |

|

Chip conveyor |

|

Black/Gray |

|

Black/Gray |

|

330 816-83 |

|

330 816-84 |

|

Tool change |

|

Tool changer left |

|

Black/Gray |

|

Black/Gray |

|

330 816-89 |

|

330 816-85 |

|

Tool changer right |

|

Unlock tool |

|

Black/Gray |

|

Black/Gray |

|

330 816-86 |

|

330 816-87 |

|

Unlock tool |

|

Lock tool |

|

Black/Gray |

|

Black/Gray |

|

330 816-88 |

|

330 816-94 |

|

Lock tool |

|

Retract axis |

|

Black/Gray |

|

Black/Gray |

|

330 816-0U |

|

330 816-91 |

2 – 18 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Other key symbols

Key |

Designation |

Key |

Designation |

|

Print/Background |

|

Print/Background |

|

Id. Nr. |

|

Id. Nr. |

|

No symbol |

|

No symbol |

|

–/Black |

|

–/Gray |

|

330 816-01 |

|

330 816-61 |

|

NC start |

|

NC stop |

|

White/Green |

|

White/Red |

|

330 816-11 |

|

330 816-12 |

|

NC start |

|

NC stop |

|

White/Green |

|

White/Red |

|

330 816-49 |

|

330 816-50 |

|

Feed rate 1 |

|

Feed rate 2 |

|

Black/Gray |

|

Black/Gray |

|

330 816-33 |

|

330 816-34 |

|

Rapid traverse |

|

Permissive key |

|

Black/Gray |

|

White/Green |

|

330 816-35 |

|

330 816-22 |

|

Permissive key |

|

Actual position capture |

|

Black/Gray |

|

White/Black |

|

330 816-90 |

|

330 816-27 |

|

– |

|

+ |

|

White/Black |

|

White/Black |

|

330 816-28 |

|

330 816-29 |

|

Menu selection –> |

|

Menu selection <– |

|

Black/Gray |

|

Black/Gray |

|

330 816-92 |

|

330 816-93 |

|

0 |

|

|

|

Black/Gray |

|

|

|

330 816-0Y |

|

|

December 2001 |

Overview of Components |

2 – 19 |

TS 220 Touch Probe

Touch-trigger probe with cable connection for workpiece setup, measurement during machining, and digitizing.

Id. Nr. 293 488-xx |

TS 220 |

Id. Nr. 274 543-xx |

Adapter cable for |

|

connection to the LE |

TS 632 Touch Probe

Touch-trigger probe with infrared transmission, for workpiece setup and measurement during machining.

Id. Nr. 331 397-xx |

TS 632 |

Id. Nr. 346 322-xx |

EA 632 receiver unit |

Id. Nr. 346 323-xx |

EA 652 receiver unit |

Id. Nr. 354 656-xx |

APE 652 interface |

|

electronics for connecting |

|

two EA 652 to the LE |

Id. Nr. 310 197-xx |

Adapter cable for |

|

connecting the EA 632 or |

|

the APE 652 with the LE |

2 – 20 |

HEIDENHAIN Technical Manual TNC 426, TNC 430 |

Loading...

Loading...