siemens 840D Programming Manual

SINUMERIK 840D sl/840D/840Di sl Cycles

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

_

_____________

Preface

General

1

Drilling cycles and

drilling patterns

2

Milling cycles

3

Turning cycles

4

Error messages and

Error handling

5

List of abbreviations

A

References

B

List of parameters

C

SINUMERIK 840D sl/840D/840Di sl

Cycles

Programming Manual

01/2008

6FC5398-3BP20-1BA0

Valid for

Controls

SINUMERIK 840D sl/840DE sl

SINUMERIK 840D powerline/840DE powerline

SINUMERIK 840Di sl/840DiE sl

Software Version

NCU system software for 840D sl/840DE sl 1.5

HMI Advanced 7.5

each with cycles 7.5

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

This device may only be used for the applications described in the catalog or the technical description and only

in connection with devices or components from other manufacturers which have been approved or

recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage,

positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90327 NÜRNBERG

GERMANY

Ordernumber: 6FC5398-3BP20-1BA0

Ⓟ 11/2007

Copyright © Siemens AG 2008.

Technical data subject to change

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

3

Safety Guidelines

Preface

Preface

Structure of the documentation

The SINUMERIK documentation is organized in 3 parts:

● General documentation

● User documentation

● Manufacturer/service documentation

You can find a publications overview that is updated monthly indicating the currently

available languages on the Internet at:

http://www.siemens.com/motioncontrol

Follow the menu items "Support" → "Technical Documentation" → "Publications Overview".

The Internet version of the DOConCD, the DOConWEB, is available at:

http://www.automation.siemens.com/doconweb

Information about training courses and FAQs (Frequently Asked Questions) can be found at

the following website:

http://www.siemens.com/motioncontrol, under "Support"

Target group

This documentation is intended for machine tool programmers.

Benefits

This Programming manual enables the target group to develop, write, and test programs and

to correct errors.

Standard scope

The functionality of the standard scope (cycles SW 7.3) is described in this Programming

manual. Additions or changes made by the machine tool manufacturer are documented by

the machine tool manufacturer.

It may be possible to execute other functions not described in this documentation in the

control. This does not, however, represent an obligation to supply such functions with a new

control or when servicing.

Preface

Cycles

4 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

Further, for the sake of simplicity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable case of

installation, operation or maintenance.

Technical Support

If you have questions, contact the following hotline:

Europe and Africa time zone

A&D Technical Support

Tel.: +49 (0) 180 / 5050 - 222

Fax: +49 (0) 180 / 5050 - 223

Internet:

http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

Asia and Australia time zone

A&D Technical Support

Tel.: +86 1064 719 990

Fax: +86 1064 747 474

Internet:

http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

America time zone

A&D Technical Support

Tel.: +1 423 262 2522

Fax: +1 423 262 2289

Internet:

http://www.siemens.com/automation/support-request

E-mail: mailto:adsupport@siemens.com

Note

Country telephone numbers for technical support are provided at the following Internet

address:

http://www.siemens.com/automation/service&support

Questions about the Manual

If you have any queries (suggestions, corrections) in relation to this documentation, please

fax or e-mail us:

Fax: +49 (0) 9131 / 98 - 63315

E-mail: mailto:motioncontrol.docu@siemens.com

Preface

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

5

Fax form: See the reply form at the end of this publication

SINUMERIK Internet address

http://www.siemens.com/sinumerik

Validity

This Programming Guide is valid for Cycles Version 7.3.

Structure of descriptions

All cycles and programming options have been described according to the same internal

structure, as far as this is meaningful and practicable. The various levels of information have

been organized such that you can selectively access the information you need for the task in

hand.

Supplementary devices

The applications of SIEMENS controls can be expanded for specific purposes through the

addition of special add-on devices, equipment and expansions supplied by SIEMENS.

Preface

Cycles

6 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

7

Table of contents

Preface ...................................................................................................................................................... 3

1 General....................................................................................................................................................

11

1.1 Overview of cycles .......................................................................................................................

11

1.1.1 Drilling cycles, hole pattern cycles, milling cycles, and turning cycles ........................................

11

1.1.2 Cycle auxiliary subroutines ..........................................................................................................

13

1.2 Programming cycles ....................................................................................................................

14

1.2.1 Call and return conditions ............................................................................................................

14

1.2.2 Messages during execution of a cycle.........................................................................................

15

1.2.3 Cycle call and parameter list........................................................................................................

15

1.2.4 Simulation of cycles .....................................................................................................................

19

1.3 Cycle support in the program editor.............................................................................................

20

1.3.1 Menus, cycle selection.................................................................................................................

20

1.3.2 Functions of the input screen forms.............................................................................................

21

1.4 Cycle support for user cycles.......................................................................................................

30

1.4.1 Overview of necessary files .........................................................................................................

30

1.4.2 Getting started with cycle support................................................................................................

30

1.4.3 Cycle support configuration .........................................................................................................

31

1.4.4 Bitmap size and screen resolution...............................................................................................

32

1.4.5 Bitmap storage in the data management of HMI Advanced ........................................................

32

1.4.6 Bitmap handling for HMI Embedded............................................................................................

33

1.5 Cycle startup ................................................................................................................................

34

1.5.1 Machine data................................................................................................................................

34

1.5.2 Definition files for cycles GUD7.DEF and SMAC.DEF ................................................................

35

1.5.3 New delivery forms for cycles in HMI Advanced..........................................................................

36

1.5.4 Upgrading the cycles with SW 6.4 and higher in HMI Advanced with SW 6.3 and higher..........

37

1.6 Additional functions for cycles......................................................................................................

38

2 Drilling cycles and drilling patterns...........................................................................................................

41

2.1 Drilling cycles ...............................................................................................................................

41

2.1.1 General information .....................................................................................................................

41

2.1.2 Requirements...............................................................................................................................

42

2.1.3 Drilling, centering - CYCLE81......................................................................................................

44

2.1.4 Drilling, counterboring - CYCLE82:..............................................................................................

47

2.1.5 Deep-hole drilling - CYCLE83......................................................................................................

50

2.1.6 Rigid tapping - CYCLE84.............................................................................................................

58

2.1.7 Tapping with compensating chuck - CYCLE840 .........................................................................

65

2.1.8 Boring 1 - CYCLE85 ....................................................................................................................

72

2.1.9 Boring 2 - CYCLE86 ....................................................................................................................

75

2.1.10 Boring 3 - CYCLE87 ....................................................................................................................

79

2.1.11 Boring 4 - CYCLE88 ....................................................................................................................

82

2.1.12 Boring 5 - CYCLE89 ....................................................................................................................

85

2.2 Modal call of drilling cycles ..........................................................................................................

88

Table of contents

Cycles

8 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

2.3 Drilling pattern cycles .................................................................................................................. 91

2.3.1 Requirements..............................................................................................................................

91

2.3.2 Row of holes - HOLES1..............................................................................................................

92

2.3.3 Row of holes - HOLES2..............................................................................................................

95

2.3.4 Dot matrix - CYCLE801...............................................................................................................

98

3 Milling cycles .........................................................................................................................................

101

3.1 General information...................................................................................................................

101

3.2 Requirements............................................................................................................................

101

3.3 Thread milling - CYCLE90 ........................................................................................................

104

3.4 Long holes located on a circle - LONGHOLE ...........................................................................

111

3.5 Slots on a circle - SLOT1 ..........................................................................................................

117

3.6 Circumferential slot - SLOT2.....................................................................................................

125

3.7 Milling rectangular pockets - POCKET1 ...................................................................................

132

3.8 Milling circular pockets - POCKET2..........................................................................................

137

3.9 Milling a rectangular pocket - POCKET3 ..................................................................................

142

3.10 Milling a circular pocket - POCKET4.........................................................................................

150

3.11 Face milling - CYCLE71............................................................................................................

156

3.12 Path milling - CYCLE72 ............................................................................................................

163

3.13 Rectangular spigot milling - CYCLE76......................................................................................

173

3.14 Circular spigot milling - CYCLE77.............................................................................................

179

3.15 Pocket milling with islands - CYCLE73, CYCLE74, CYCLE75.................................................

184

3.15.1 General information...................................................................................................................

184

3.15.2 Transfer pocket edge contour - CYCLE74................................................................................

185

3.15.3 Transfer island contour - CYCLE75 ..........................................................................................

186

3.15.4 Pocket milling with islands - CYCLE73 .....................................................................................

189

3.15.4.1 General information...................................................................................................................

189

3.15.4.2 Examples...................................................................................................................................

192

3.15.4.3 Description of technology in Example 2....................................................................................

202

3.16 Swiveling – CYCLE800 .............................................................................................................

211

3.16.1 General information...................................................................................................................

211

3.16.2 Programming via screen form...................................................................................................

213

3.16.2.1 General information...................................................................................................................

213

3.16.2.2 Parameters of input screen form...............................................................................................

213

3.16.2.3 Operator and programmer instructions .....................................................................................

220

3.16.2.4 Examples of input screen form .................................................................................................

222

3.16.3 Programming using parameters................................................................................................

225

3.16.4 Setting of tools - CYCLE800 .....................................................................................................

228

3.16.5 Alignment of tools - CYCLE800 ................................................................................................

230

3.16.6 Setting up workpieces with swiveled machining planes ...........................................................

233

3.16.6.1 General information...................................................................................................................

233

3.16.6.2 Parameters of input screen form...............................................................................................

234

3.16.6.3 Data transfer of swivel data in “Swiveling in JOG"....................................................................

238

3.16.7 Startup - CYCLE800 .................................................................................................................

239

3.16.7.1 General information...................................................................................................................

239

3.16.7.2 Startup of kinematic chain.........................................................................................................

244

3.16.7.3 Starting up kinematic rotary axes..............................................................................................

252

Table of contents

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

9

3.16.7.4 Startup of fine kinematics...........................................................................................................254

3.16.7.5 Startup examples for machine kinematics .................................................................................

255

3.16.8 Manufacturer Cycle TOOLCARR.SPF - CYCLE800 .................................................................

265

3.17 High speed settings - CYCLE832 ..............................................................................................

270

3.17.1 General information ...................................................................................................................

270

3.17.2 Programming via input screen form...........................................................................................

273

3.17.2.1 General information ...................................................................................................................

273

3.17.2.2 Parameters of input screen form................................................................................................

273

3.17.3 Programming via parameters.....................................................................................................

277

3.17.4 Customizing technology.............................................................................................................

278

3.17.4.1 General information ...................................................................................................................

278

3.17.4.2 Customizing of machine setter/programmer..............................................................................

278

3.17.4.3 Customization by the machine manufacturer ............................................................................

279

3.17.4.4 Customizing additional program parameters CYC_832T ..........................................................

280

3.17.5 Ports...........................................................................................................................................

283

3.18 Engraving cycle CYCLE60.........................................................................................................

285

3.19 Trochoidal milling / plunge cutting - CYCLE899 ........................................................................

298

3.19.1 General information ...................................................................................................................

298

3.19.2 Function .....................................................................................................................................

298

3.19.2.1 Vortex milling..............................................................................................................................

298

3.19.2.2 Plunge cutting ............................................................................................................................

300

3.19.3 Programming via a screen form.................................................................................................

302

3.19.3.1 General information ...................................................................................................................

302

3.19.3.2 Parameters of the screen form ..................................................................................................

303

3.19.4 Programming using parameters.................................................................................................

305

3.19.5 Programming example...............................................................................................................

309

4 Turning cycles .......................................................................................................................................

313

4.1 General information ...................................................................................................................

313

4.2 Conditions ..................................................................................................................................

313

4.3 Grooving cycle - CYCLE93 ........................................................................................................

317

4.4 Undercut cycle - CYCLE94 ........................................................................................................

328

4.5 Stock removal cycle - CYCLE95................................................................................................

333

4.6 Thread undercut - CYCLE96 .....................................................................................................

347

4.7 Thread cutting - CYCLE97.........................................................................................................

351

4.8 Thread chaining - CYCLE98......................................................................................................

359

4.9 Thread recutting.........................................................................................................................

366

4.10 Extended stock removal cycle - CYCLE950..............................................................................

367

5 Error messages and Error handling .......................................................................................................

387

5.1 General information ...................................................................................................................

387

5.2 Error handling in the cycles........................................................................................................

387

5.3 Messages in the cycles..............................................................................................................

388

A List of abbreviations...............................................................................................................................

389

B References ............................................................................................................................................

395

C List of parameters..................................................................................................................................

397

Table of contents

Cycles

10 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

Glossary ................................................................................................................................................ 401

Index......................................................................................................................................................

425

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

11

General

1

The first section provides you with an overview of the available cycles. The following

sections describe the general conditions that apply to all cycles regarding

● Programming the cycles and

● Operator guidance for calling the cycles.

1.1 Overview of cycles

Cycles are generally applicable technology subroutines, with which you can implement

specific machining processes such as tapping a thread or milling a pocket. These cycles are

adapted to individual tasks by parameter assignment.

The system provides you with the technologies

● Drilling

● Milling

● Turning

in various standard cycles.

1.1.1 Drilling cycles, hole pattern cycles, milling cycles, and turning cycles

You can run the following cycles with the SINUMERIK 810D, 840D and 840Di controls:

Drilling cycles

CYCLE81

Drilling, centering

CYCLE82

Drilling, counterboring

CYCLE83

Deep-hole drilling

CYCLE84

Rigid tapping

CYCLE840

Tapping with compensating chuck

CYCLE85

Boring 1

CYCLE86

Boring 2

CYCLE87

Boring 3

CYCLE88

Boring 4

CYCLE89

Boring 5

General

1.1 Overview of cycles

Cycles

12 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

Hole pattern cycles

HOLES1

Machining a row of holes

HOLES2

Machining a circle of holes

CYCLE801

Dot matrix

Milling cycles

CYCLE90

Thread milling

LONGHOLE

Milling pattern of elongated holes on a circle

SLOT1

Groove milling pattern on a circle

SLOT2

Circumferential groove milling pattern

POCKET1

Rectangular pocket milling (with face cutter)

POCKET2

Circular pocket milling (with face cutter)

POCKET3

Rectangular pocket milling (with any milling tool)

POCKET4

Circular pocket milling (with any milling tool)

CYCLE71

Face milling

CYCLE72

Contour milling

CYCLE76

Rectangular spigot milling

CYCLE77

Circular spigot milling

CYCLE73

Pocket milling with islands

CYCLE74

Transfer of pocket edge contour

CYCLE75

Transfer of island contour

CYCLE800

Swiveling

CYCLE832

High speed settings

CYCLE60

Engraving cycle

CYCLE899

Trochoidal milling / plunge cutting

Turning cycles

CYCLE93

Recess

CYCLE94

Undercut (DIN form E and F)

CYCLE95

Stock removal with relief cutting

CYCLE96

Thread undercut (DIN forms A, B, C, and D)

CYCLE97

Thread cutting

CYCLE98

Chaining of threads

CYCLE950

Extended stock removal

General

1.1 Overview of cycles

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

13

1.1.2 Cycle auxiliary subroutines

Included in the cycle package is the auxiliary subroutine

● PITCH

This auxiliary subroutine must always be loaded in the control.

General

1.2 Programming cycles

Cycles

14 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

1.2 Programming cycles

A standard cycle is defined as a subroutine with name and parameter list. The conditions

described in the "SINUMERIK Programming Guide Part 1: Fundamentals" are applicable for

calling a cycle.

Note

The cycles are supplied on diskette/CD or with the relevant software version for HMI

Advanced. They are loaded to the part program memory of the control via the V.24 interface

or from the diskette drive (see operator's guide).

1.2.1 Call and return conditions

The G functions active before the cycle is called and the programmable frame remain active

beyond the cycle.

You define the machining plane (G17, G18, G19) before the cycle call. A cycle operates in

the current plane with the

● Abscissa (1st geometry axis)

● Ordinate (2nd geometry axis)

● Applicate (3rd geometry axis of the plane in space)

In the drilling cycles, the drilling is executed in the axis that is vertical on the plane (3rd

geometry plane). In milling, the depth infeed is carried out in this axis.

*

*

*

$SSOLFDWH

=

;

<

$EVFLVVD

2UGLQDWH

General

1.2 Programming cycles

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

15

Plane and axis assignment:

Command Plane Vertical infeed axis

G17

X/Y Z

G18

Z/X Y

G19

Y/Z X

1.2.2 Messages during execution of a cycle

During various cycles, messages that refer to the state of machining are displayed on the

screen of the control system during program execution. These messages do not interrupt the

program execution and remain until the next message appears or the cycle is completed.

The message texts and their meaning are listed together with the cycle to which they refer.

Note

You can find a summary of all messages in Appendix A of this programming guide.

Block display during execution of a cycle

The cycle call is displayed in the current block display for the duration of the cycle.

1.2.3 Cycle call and parameter list

The standard cycles use user-defined variables. The defining parameters for the cycles can

be transferred via the parameter list when the cycle is called.

Note

Cycle calls always require a block for themselves.

Fundamentals of standard cycle parameter assignment

The Programming Guide describes the parameter list of every cycle with the

● order and the

● type.

It is imperative to observe the order of the defining parameters.

General

1.2 Programming cycles

Cycles

16 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

Each defining parameter of a cycle has a certain data type. The parameter being used must

be specified when the cycle is called. In the parameter list,

● variables or

● constants

can be transferred.

If variables are transferred in the parameter list, they must first be defined in the calling

program and assigned values. Cycles can be called

● with an incomplete parameter list or

● by leaving out parameters.

If you want to exclude the last transfer parameters that have to be written in a call, you can

prematurely terminate the parameter list with ")". If any parameters are to be omitted within

the list, a comma "..., ,..." must be written as a placeholder.

Note

No plausibility checks are made of parameter values with a discrete or limited value range

unless an error response has been specifically described for a cycle.

During a cycle call, if the parameter list contains more entries than there are parameters

defined in the cycle, the general NC alarm 12340 "Too many parameters" appears, and the

cycle is not executed.

General

1.2 Programming cycles

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

17

Note

Transfer parameters and calculation resolution of the NCU

The value ranges defined in the Programming Guide Fundamentals apply to the transfer

parameters of standard and measuring cycles. The value range for angle values is defined

as follows (see ROT / AROT in the Programming Guide Fundamentals):

• Rotation around 1st geometry axis: -180 degrees to +180 degrees

• Rotation around 2nd geometry axis: -90 degrees to +90 degrees

• Rotation around 3rd geometry axis: -180 degrees to +180 degrees

When angle values are passed to a standard or measuring cycle, please note that they must

be rounded down to zero if they are lower than the calculation resolution of the NCU. The

calculation resolution for angle positions on the NCU is specified in machine data 10210

$MN_INT_INCR_PER_DEG.

Example of the parameter _OVR[21] of measuring cycle CYCLE998 (measure angle):

_OVR[21]=-0.000345 ;calculation resolution MD $MN_INT_INCR_PER_DEG=1000

IF ((ABS(_OVR[21] * $MN_INT_INCR_PER_DEG)) < 1)

_OVR[21]=0

ENDIF

Explanation:

If the value of parameter _OVR[21] is less than the programmed calculation resolution, it is

rounded down to zero.

Cycle call

The various methods for writing a cycle call are shown in the following example, CYCLE100,

which requires the following input parameters.

Example

FORM char ;Definition of the form to be machined, values: E and F

MID real ;Infeed depth (to be entered without sign)

FFR real ;Feed

VARI integer ;Machining type, values: 0, 1, or 2

FAL real ;Finishing allowance

This cycle is called via the Cycle100 (FORM, MID, FFR, VARI, FAL) command.

1. Parameter list with constant values

Rather than input individual parameters, you can directly enter the concrete values to be

used in the cycle.

Example

CYCLE100 ("E", 5, 0.1, 1, 0) ;Cycle call

General

1.2 Programming cycles

Cycles

18 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

2. Parameter list with variables as transfer parameters

You can transfer the parameters as R variables that you define before calling the cycle and

to which you must assign variables.

Example

DEF CHAR FORM="E" ;Definition of a parameter, value assignment

DEF REAL MID=5, FFR, FAL

DEF INT VARI=1

;Definition of parameters with and without

;value assignments

N10 FFR=0.1 FAL=0 ;Value assignments

N20 CYCLE100 (FORM, MID, FFR, VARI,

FAL)

;Cycle call

3. Use of predefined variables as transfer parameters

To assign parameters to cycles, you can also use variables such as R parameters.

Example

DEF CHAR FORM="E" ;Definition of a parameter, value assignment

N10 R1=5 R2=0.1 R3=1 R4=0 ;Value assignments

N20 CYCLE100 (FORM, R1, R2, R3, R4) ;Cycle call

As R parameters are predefined as type real, it is important to ensure that the type of the

target parameter in the cycle is compatible with the type real.

Note

More detailed information about data types and type conversion and compatibility is given in

the Programming Guide.

In the event of type incompatibilities, the system displays alarm 12330 "Type of parameter ...

incorrect".

4. Incomplete parameter list and omission of parameters

If an assigned parameter for a cycle call is not required or if it should have a value of zero, it

can be omitted from the parameter list. In its place, only the comma "..., ,..." is to be written in

order to ensure the correct assignment of subsequent parameters or if the parameter list is

to be closed early with ")".

Example

CYCLE100 ("F", 3, 0.3, , 1) ;Cycle call, 4th parameter omitted

;(i.e., the value zero)

CYCLE100 ("F", 3, 0.3) ;Cycle call, a value of zero is assigned

;to the last two parameters

;(e.g., they have been omitted)

General

1.2 Programming cycles

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

19

5. Expressions in the parameter list

Expressions, the results of which are assigned to the corresponding parameter in the cycle,

are also permitted in the parameter list.

Example

DEF REAL MID=7, FFR=200 ;Definition of the parameters, value

assignments

CYCLE100 ("E", MID*0.5, FFR+100,1) ;Cycle call infeed depth 3.5, Feed rate 300

1.2.4 Simulation of cycles

Programs with cycle calls can be tested first in simulation.

Function

In HMI Embedded configurations, the program runs normally in the NC and the traversing

motion is traced on screen during simulation.

In HMI Advanced configurations, the program is simulated on the HMI only. This makes it

possible to run cycles without tool data or without prior selection of a tool offset in the MM.

The finished contour is then traversed in the case of cycles that have to include tool offset

data in the calculation of their traversing motion (e.g., milling pockets and grooves, turning

with recess) and a message indicates that simulation without tool is active.

This function can be used, for example, to check the position of the pocket.

General

1.3 Cycle support in the program editor

Cycles

20 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

1.3 Cycle support in the program editor

The program editor provides cycle support for Siemens and user cycles.

Function

The cycle support offers the following functions:

● Cycle selection via soft keys

● Input screen forms for parameter assignment with help displays

● Online help for each parameter (HMI Advanced only)

● Support of contour input

From the individual screen forms, a program code that can be reset is generated.

1.3.1 Menus, cycle selection

Technology-oriented cycle selection is carried out using soft keys:

Geometry input via the geometry processor or contour definition screen forms

Input screen forms for drilling cycles and drilling patterns

Input screen forms for milling cycles

Input screen forms for turning cycles

After confirming the screen form input by clicking OK, the technology selection bar remains

visible. Similar cycles are supplied from shared screen forms.

&RQWRXU

%RUH

0LOOLQJ

7XUQLQJ

General

1.3 Cycle support in the program editor

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

21

Within the screen forms, it is then possible to switch between cycles via soft key, e.g., for

tapping or undercut.

The editor cycle support also contains screen forms that insert a multi-line DIN code in the

program instead of a cycle call, e.g., contour definition screen forms and the input of any

drilling positions.

1.3.2 Functions of the input screen forms

Function

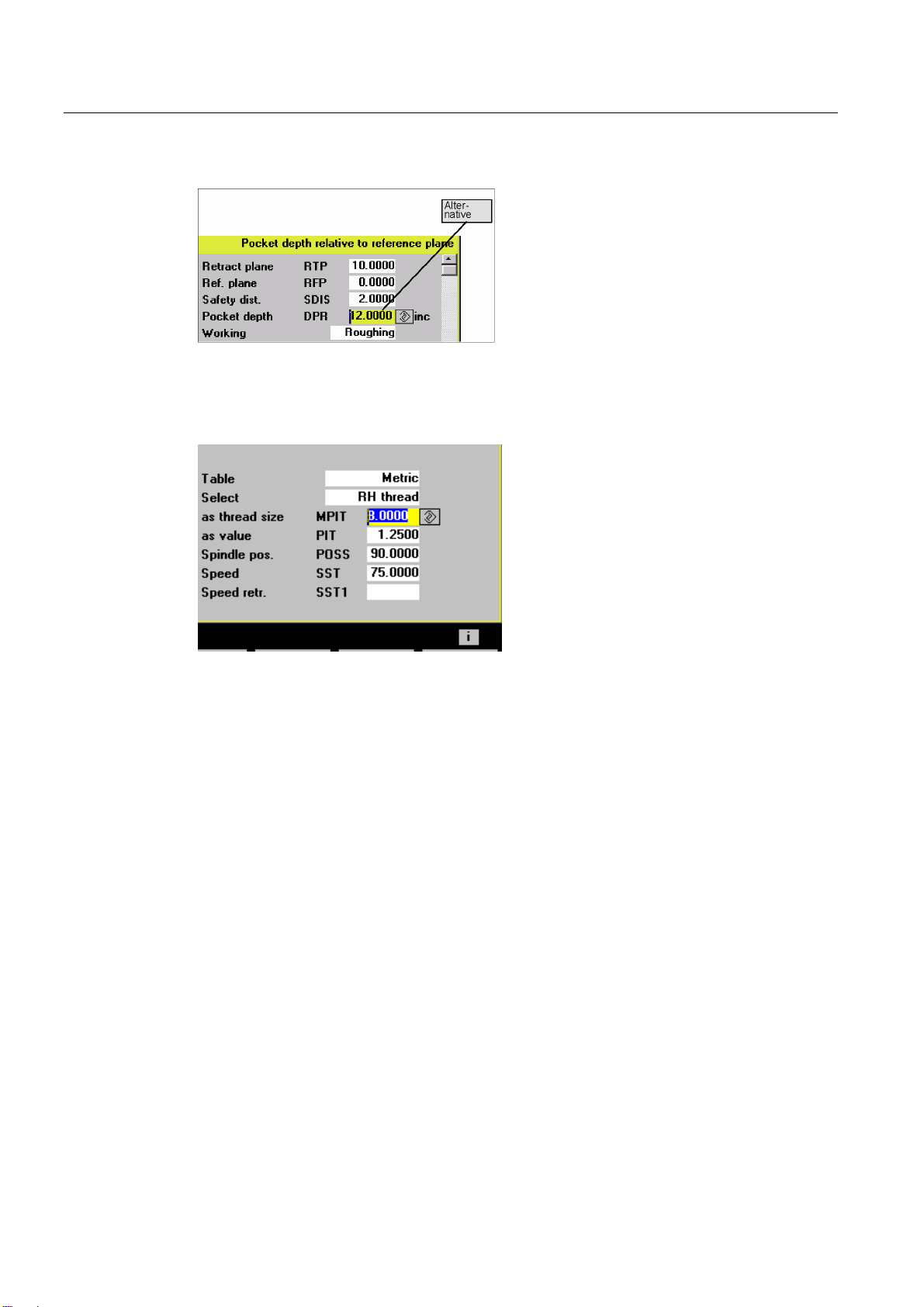

● Many cycles allow you to influence the processing type via the VARI parameter. It often

contains several settings composing one code. In the cycle support screen forms, these

individual settings can be divided among different input fields that can be switched using

the toggle key.

● The input screen forms are changed dynamically. Only the input fields required for the

selected processing type are displayed. Unnecessary input fields are not shown.

● One input may, therefore, automatically assign several dependent parameters. This is the

case for thread cutting, where metric thread tables are currently supported. During the

thread cutting cycle CYCLE97, for example, with input 12 in the input box for the thread

size (parameter MPIT), the thread pitch (parameter PIT) is automatically assigned a value

of 1.75 and the thread depth (parameter TDEP) is automatically assigned a value of

1.074. This function is not active if the metric thread table has not been selected.

● If a screen form is displayed a second time, the most recently entered values are

assigned to all fields. When cycles are called up several times in a row in the same

program (e.g., pocket milling when roughing and finishing), few parameters then have to

be changed.

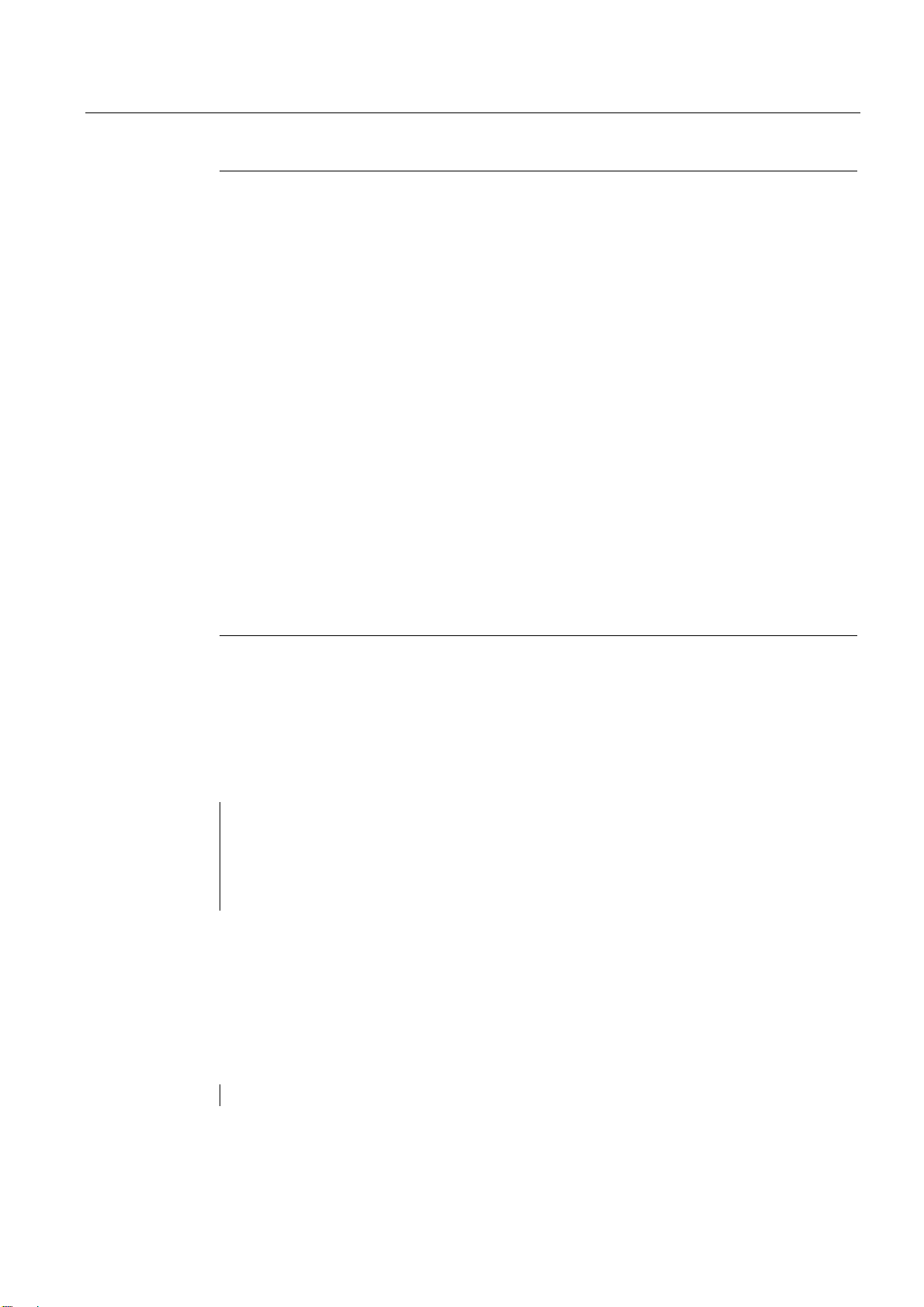

● In screen forms for drilling and milling cycles, certain parameters may be input as

absolute or incremental values. The abbreviation ABS for absolute and INC for

incremental input is displayed behind the input field. This can be toggled with the

"Alternative" soft key. This setting will remain the next time these screen forms are called.

General

1.3 Cycle support in the program editor

Cycles

22 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

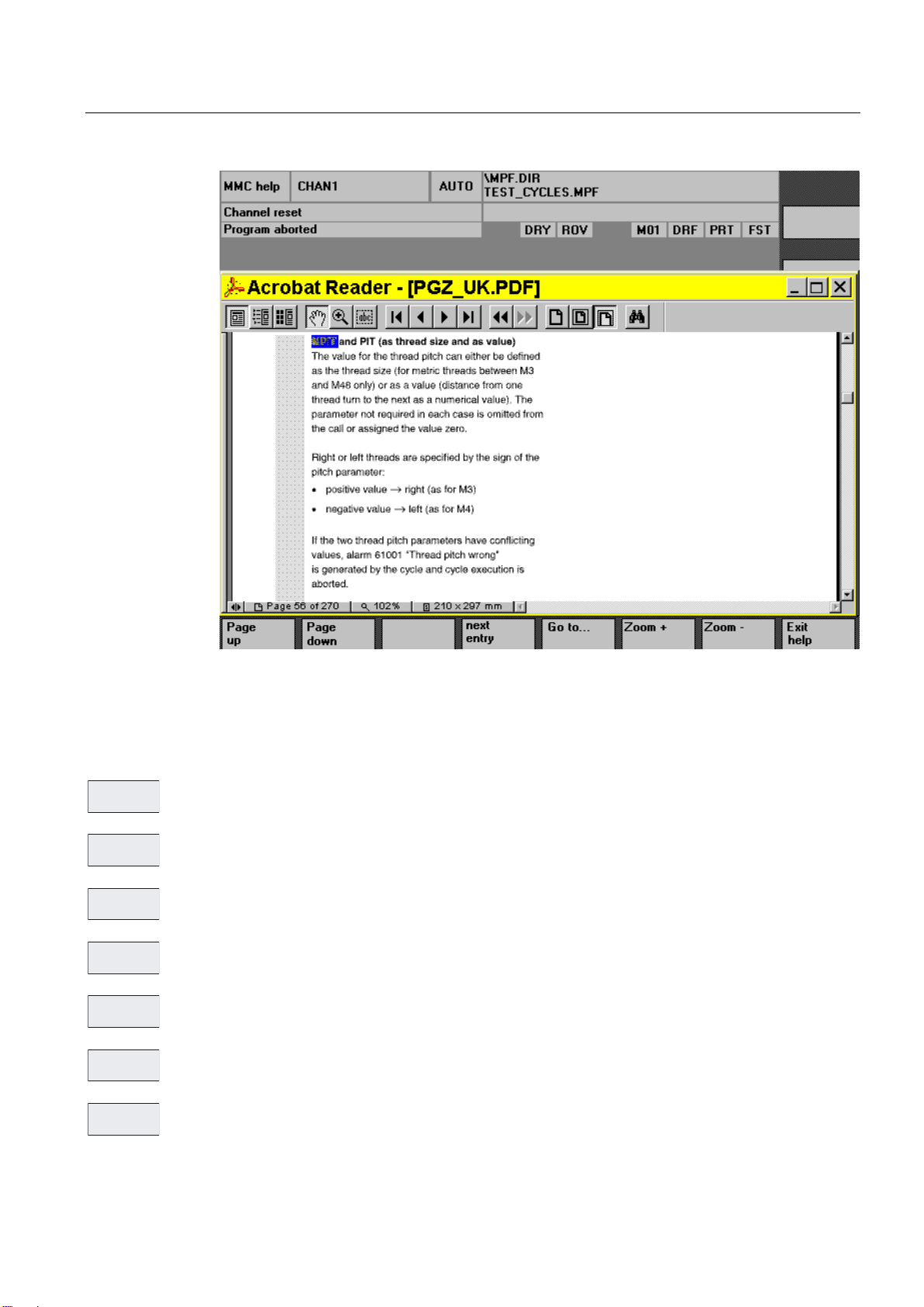

● HMI Advanced allows you to view additional information on each cycle parameter in the

online help. If the cursor is positioned on a parameter and the help icon appears in the

lower right corner, the help function can be activated.

By pressing the info key, the parameter explanation is displayed from the Cycle

Programming Guide.

General

1.3 Cycle support in the program editor

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

23

Operating the help display

Paging backward in the documentation

Paging forward in the documentation

Enables the user to jump to another piece of text included in the help display

Enables the user to jump to a selected piece of text

Zoom the text in the help window

Reduce the text in the help window

Return to the cycle screen form

3DJH

XS

3DJH

GRZQ

1H[WHQWU\

*RWR

=RRP

=RRP

([LW

KHOS

General

1.3 Cycle support in the program editor

Cycles

24 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

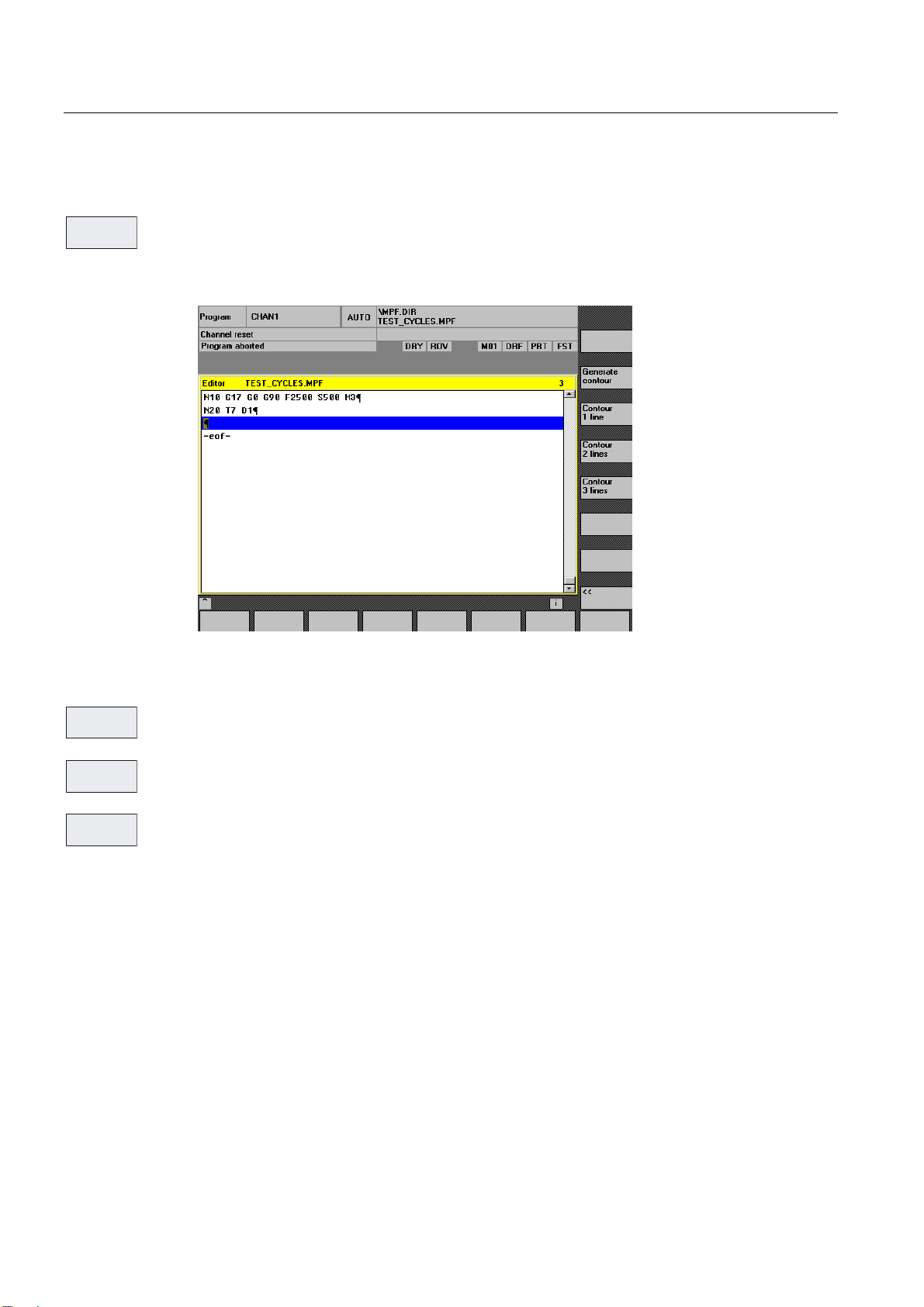

Contour input support

Free contour programming

Starts the free contour programming, which can be used to enter contiguous contour

sections.

References: /BA/, Operator's Guide

Contour definition programming

These soft keys support the contour definitions that are possible.

These consist of one or more straight lines with intermediary contour transition elements

(radii, chamfers). Each contour element may be preassigned by means of end points or point

and angle and supplemented by a free DIN code.

Example

The following DIN code is generated from the following input screen form for a contour

definition with two straight lines:

*HQHUDWH

FRQWRXU

&RQWRXU

OLQH

&RQWRXU

OLQH

&RQWRXU

OLQH

General

1.3 Cycle support in the program editor

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

25

X=AC(20) ANG=87.3 RND=2.5 F2000 S500 M3

X=IC(10) Y=IC(-20); incremental end point

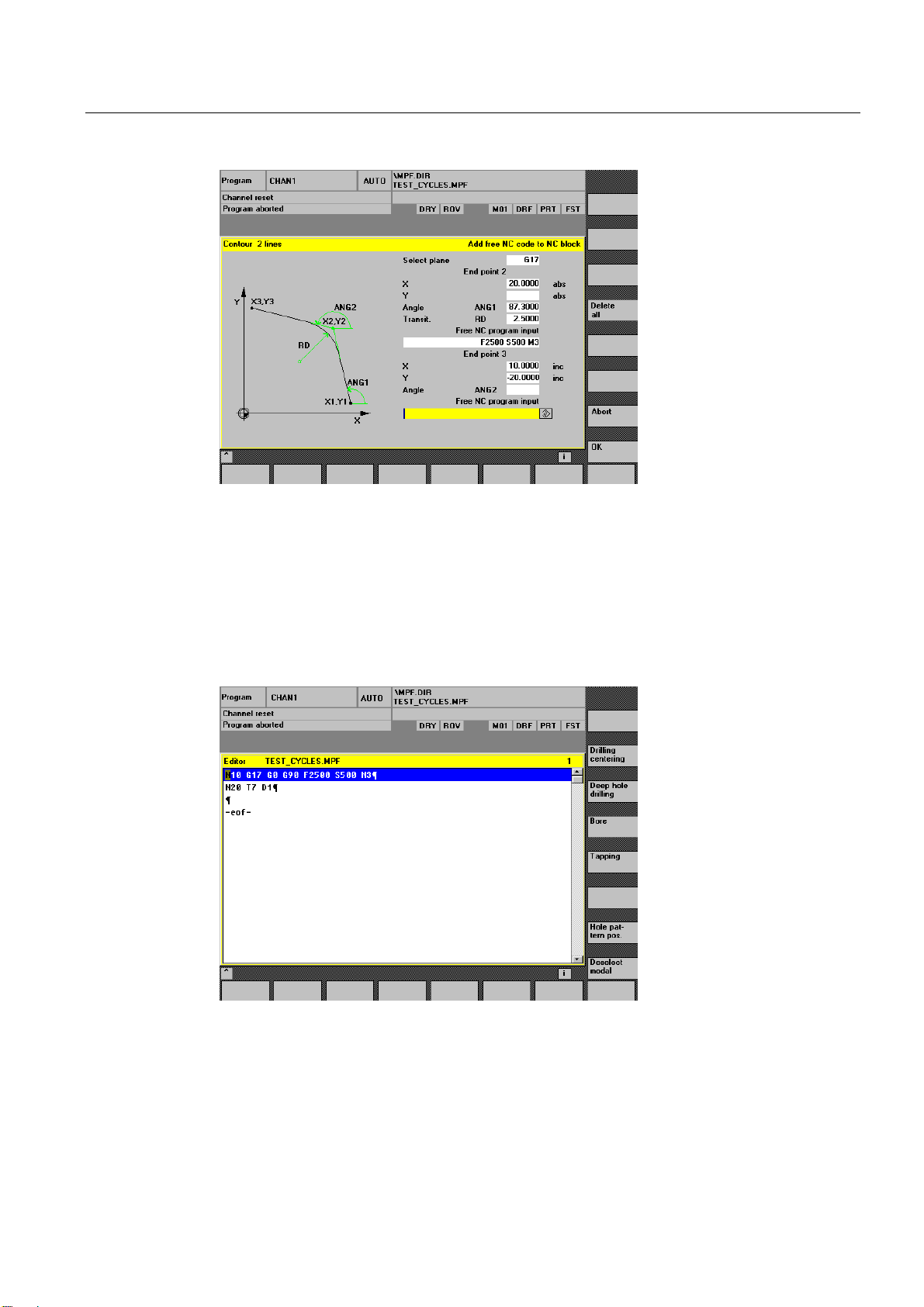

Drilling support

The drilling support includes a selection of drilling cycles and drilling patterns.

General

1.3 Cycle support in the program editor

Cycles

26 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

The "Drilling pattern position" soft key branches into a submenu with a selection of several

drilling patterns.

Selection of drilling patterns

Note

Cycles CYCLE81, CYCLE87 and CYCLE89 cannot be parameterized with this support. The

function of CYCLE81 is covered by CYCLE82 ("Drilling, centering" soft key), as is the

function of CYCLE89. The CYCLE87 function is covered by the function of CYCLE88 (soft

keys “Drilling center.” -> “Drilling with stop").

Drilling patterns may be repeated if, for example, drilling and tapping are to be executed in

succession. To this end, a name for the drilling pattern, which is later entered in the "Repeat

Position" screen form, is assigned in the drilling pattern.

Example with cycle support generated

N100 G17 G0 G90 Z20 F2000 S500 M3 ;Main block

N110 T7 M6 ;Change drilling machine

N120 G0 G90 X50 Y50 ;Initial drilling position

N130 MCALL CYCLE82(10,0,2,0,30,5) ;Modal drilling cycle call

N140 Circle of holes 1: ;Label – name of drilling pattern

N150 HOLES2(50,50,37,20,20,9) ;Call drilling pattern cycle

N160 ENDLABEL:

N170 MCALL ;Deselect modal call

N180 T8 M6 ;Change tap

N190 S400 M3

N200 MCALL CYCLE84(10,0,2,0,30,,→ ;Modal call of tapping cycle

→3,5,0.8,180,300,500)

N210 REPEAT Circle of holes 1 ;Repeat drilling pattern

N220 MCALL ;Deselect modal call

'ULOOLQJ

FHQWHULQJ

'HHSKROH

GULOOLQJ

%RUH

7DSSLQJ

+ROH

SDWWHUQSRV

'HVHOHFW

PRGDO

General

1.3 Cycle support in the program editor

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

27

Moreover, any drilling position may be entered as a repeatable drilling pattern by means of

screen forms.

Up to 5 positions can be programmed in the plane; all values are optionally absolute or

incremental (can be toggled with "Alternative" soft key). The "Delete all" soft key generates

an empty screen form.

Milling support

Milling support includes the following selection possibilities:

General

1.3 Cycle support in the program editor

Cycles

28 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

The "Standard pockets", "Grooves", and "Spigot" soft keys each branch into submenus with

a selection of several pocket, groove, or spigot cycles.

)DFH

PLOOLQJ

6SLJRW

*URRYHV

6WDQGDUG

PLOOLQJ

3DWK

PLOOLQJ

7KUHDG

PLOOLQJ

6ZLYHOLQJ

F\FOHV

!!

Note

Pocket milling cycles POCKET1 and POCKET2 cannot be parameterized with this support.

Turning support

Turning support includes the following selection possibilities:

The undercut cycles for forms E and F (CYCLE94) as well as for the thread undercuts of

forms A to D (CYCLE96) are grouped together under the "Undercut" soft key.

The "Thread" soft key contains a submenu for selection between single thread cutting or

thread chaining.

7KUHDG

8QGHUFXW

*URRYH

&XW

General

1.3 Cycle support in the program editor

Cycles

Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

29

Recompiling

Retranslating program codes serves to change an existing program with the help of cycle

support. The cursor is placed on the line to be changed, and the "Recompile" soft key is

pressed.

This reopens the corresponding input screen form, which created the program piece, and

values may be modified.

Entering modifications directly into the created DIN code may prevent recompilation.

Therefore, consistent use of the cycle support is required and modifications are to be carried

out with the help of recompilation.

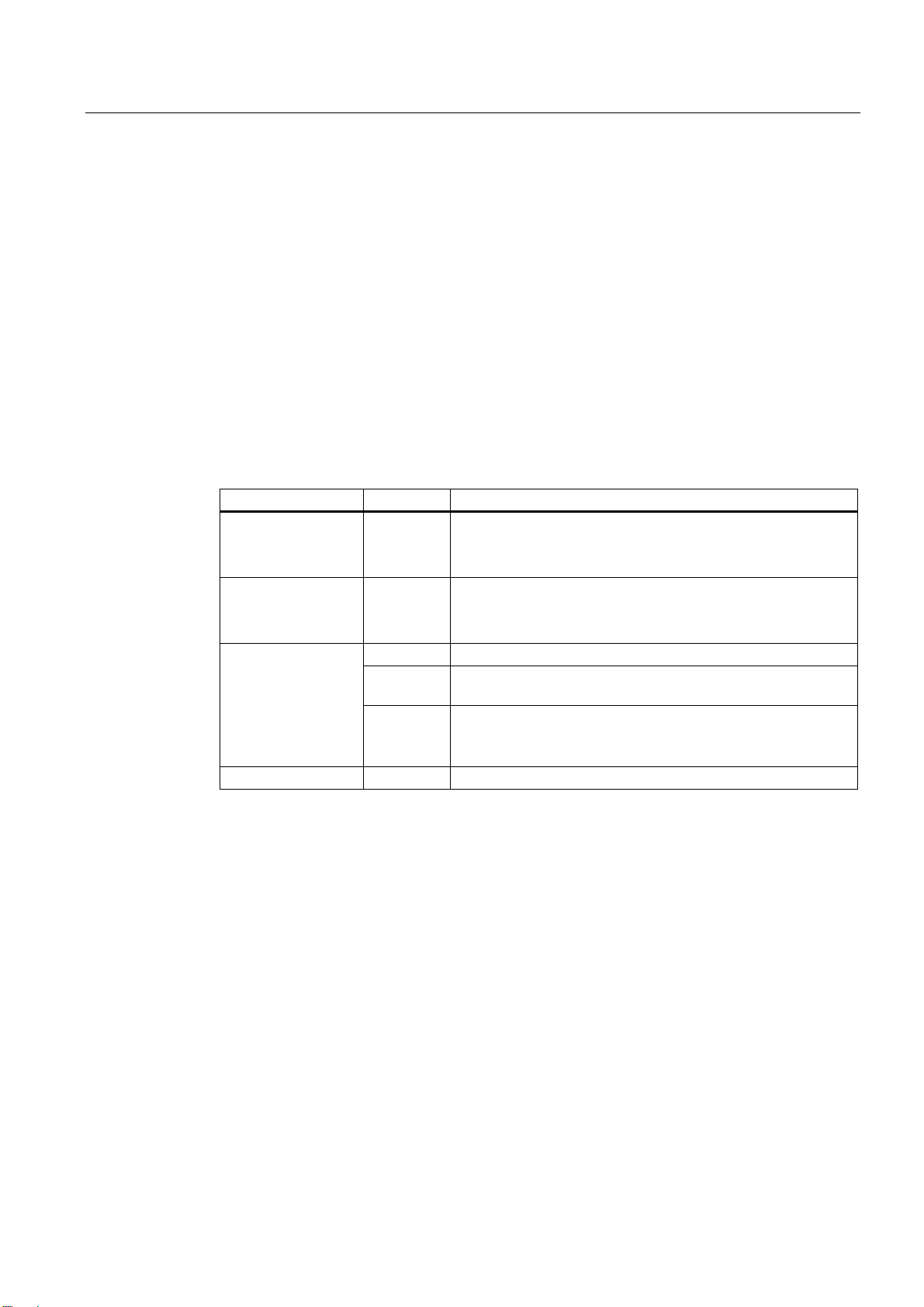

Default settings for cycle support

Cycles SW 6.4 and higher includes a field for setting data _SC_MASK[10] for cycle support.

These are integer type data and are created as NCK global data in the GUD7_SC.DEF.

Date Value Meaning

_SC_MASK [0] - CYCLE84:

Default settings for the _TECHNO parameter

(set by the machine tool manufacturer during commissioning)

_SC_MASK [1] - CYCLE840:

Default settings for the _TECHNO parameter

(set by the machine tool manufacturer during commissioning)

CYCLE97:

0 Suggested values when using a metric thread table according

to DIN13-1 version 11.1999

_SC_MASK [2]

1 Suggested values when using a metric thread table according

to DIN13-1 version prior to 1999

(for backward compatibility of existing programs)

_SC_MASK [3 to 9] internal

Support for programming user cycles

References: /IAM/, HMI Installation and Startup Guide

BE1 "Expanding the User Interface"

IM2 "Startup of HMI Embedded"

IM4 "Startup of HMI Advanced"

General

1.4 Cycle support for user cycles

Cycles

30 Programming Manual, 01/2008, 6FC5398-3BP20-1BA0

1.4 Cycle support for user cycles

1.4.1 Overview of necessary files

The following files constitute the basis for cycle support:

Assignment File Application File type

aeditor.com Standard and user cycles Text file Cycle selection

common.com

(HMI Embedded only)

Standard and user cycles Text file

Input screen form for

parameter assignment

*.com Standard or user cycles Text file

Help screens *.bmp Standard or user cycles Bitmap

Online help

(HMI Advanced only)

pgz_<language>.pdf and

pgz_<language>.txt

Standard cycles only pdf file

Note

Any names can be chosen for the cycle support configuration files (*.com ).

1.4.2 Getting started with cycle support

Function

The horizontal soft key HS6 in the program editor is designated as the Entry soft key for user

cycles. Its function must be configured in file aeditor.com. Assign a text to the soft key and

configure a function in the press block for soft key operation.

Example

//S(Start)

...

HS5=($80270,,se1)

PRESS(HS5)

LS("Turning",,1)

END_PRESS

HS6=("Usercycle",,se1) ;HS6 is configured with the "Usercycle" text

PRESS(HS6)

LS("SK_Cycles1","cycproj1") ;When the soft key is pressed, a soft key bar is

;loaded from the file cycproj1.com

END_PRESS

A detailed description of the configuration is given in:

References: /IAM/, HMI Installation and Startup Guide: BE1 "Expanding the User Interface"

Loading...

Loading...