siemens 810G, 820G User Manual

SINUMERIK 810G

SINUMERIK 820G

Difference Description for Software Version

Operating and Programming |

08.91 Edition |

User Documentation

SINUMERIK 810G

SINUMERIK 820G Difference Description for Software Version 2

Operating and Programming

User Documentation

Valid for: |

|

Control |

Software version |

SINUMERIK 810G |

2 onwards |

SINUMERIK 820G |

2 onwards |

August 1991 Edition

SINUMERIK® documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ºRemarksº column.

Status code in ºRemarksº column:

A. . . New documentation

B. . . Unrevised reprint with new Order No.

C. . . Revised edition with new status

If factual changes have been made on the page since the last edition this is indicated by a new edition coding in the header on that page.

Edition |

Order No. |

Remarks |

08.91 |

6ZB5 410-0FK02-0BA0 |

A |

Other functions not described in this documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with a new control or when servicing.

This publication was produced on the Siemens 5800 Office

System.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration of a utility model or design, are reserved.

© Siemens AG 1991 All Rights Reserved

Preliminary

Notes for the reader

This Difference Description is aimed at machine tool users. It describes any additions or alterations to the UserÂs Guides, ºOperating and Programmingº:

·SINUMERIK 810G, SW1 Edition 09.90 or

·SINUMERIK 820G, SW1 Edition 08.90.

The Difference Description can therefore only be used in conjunction with one of the above mentioned UserÂs Guides.

These two UserÂs Guides will subsequently be referred to as ºStandard Documentationº. Section numbers refer to the sections in the Standard Documentation.

Individual sections have been completely revised and replace the corresponding chapter in the Standard Documentation. Such sections have not been marked in any particular way.

Other sections supplement the Standard Documentation. They are marked with the words ºSupplement to Standard Documentationº.

The Difference Description comprises two distinct parts:

·Part 1: Operating

·Part 2: Programming

Further information regarding other SINUMERIK 810G/820G or general SINUMERIK 810/820 publications or publications valid for all SINUMERIK controls (e.g. ºUniversal Interfaceº and ºMeasuring Cyclesº) can be obtained from your Siemens local branch office.

Technical comments

In parts of this documentation you will see the symbol shown on the left and a comment referring to an ordering data option.

This symbol is intended to point out that the described function is executable only if the control includes the designated option. The ordering data options for SINUMERIK 810G and 820G are listed in the Standard Documentation: Part 1: Operating, Section 7.2.

The symbol shown here appears in this documentation wherever the machine tool manufacturer can influence or modify the described function by changing a machine data (MD).

Other functions which are not described in this documentation can possibly also be performed in the control.

However, the customer is not entitled to demand these functions when new equipment is supplied or when servicing is carried out.

This UserÂs Guide applies to:

SINUMERIK 810G and 820G control, Software Version 2

Difference Description

Part 1: Operating

Operating and Programming

User Documentation

Control Design |

1 |

|

|

|

|

Operating |

2 |

|

|

|

|

Operating Sequences |

3 |

|

|

|

|

Diagnostics |

4 |

|

|

|

|

Maintenance |

5 |

|

|

|

|

Data Interface |

6 |

|

|

|

|

Interfacing to the Machine |

7 |

|

|

|

|

Appendix |

8 |

|

|

|

|

Contents

|

|

Page |

1 |

Control Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±1 |

2 |

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±1 |

3 |

Operating Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.3 |

Influencing the ºAUTOMATICº operation . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.3.1 |

Influencing the program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.3.3 |

ºBlock searchº . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.7 |

ºJOGº mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.8 |

ºINC FEED 1 ... INC FEED 10 000º mode (ºincrementalº) . . . . . . . . . . |

3±2 |

3.2.9 |

Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±2 |

4 |

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±1 |

4.6 |

Listing of the alarms/alarm description . . . . . . . . . . . . . . . . . . . . . . . . |

4±1 |

5 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±1 |

6 |

Data Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±1 |

7 |

Interfacing to the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±1 |

8 |

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8±1 |

08.91 |

1 Control Design |

1 Control Design

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

1±1 |

SINUMERIK 810G/820G (BN)

08.91 |

2 Operating |

2 Operating

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

2±1 |

SINUMERIK 810G/820G (BN)

08.91 |

3 Operating Sequences |

3.2.3 Influencing the ºAUTOMATICº operation

3 Operating Sequences

No changes have been made to the sections that are not mentioned.

3.2.3 Influencing the ºAUTOMATICº operation

3.2.3.1 Influencing the program

Supplement to Standard Documentation

Note:

If dry run feedrate is active, the reciprocating movement programmed with G181 is executed with the feed value programmed in the part program.

3.2.3.3 ºBlock searchº

Supplement to Standard Documentation

Note:

The target position after block search is approached with the speed set in the machine data.

Reciprocating axes which are programmed with G181 are traversed at the rate programmed in the part program.

3.2.7ºJOGº mode

Supplement to Standard Documentation

The oblique axis and/or the oblique grinding wheel can be traversed in Cartesian coordinates or obliquely. The initial setting is Cartesian. Overstoring G05 switches the machine to oblique plunge grinding. If the machine has an oblique axis, only the oblique axis will be moved, if the machine has an oblique grinding wheel, the infeed axis and the reference axis are moved.

Overstoring G01 deselects G05 and switches the machine back to Cartesian movement.

G01 is automatically activated after program start or program interrupt.

The spindle speed and the T, H, M, D and G functions can be determined using ºOVERSTOREº (see Section 3.2.3.2 of the OperatorÂs Guide).

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

3±1 |

SINUMERIK 810G/820G (BN)

3 Operating Sequences |

08.91 |

3.2.8 ºINC FEED 1 ... INC FEED 10 000º mode (ºincrementalº)

3.2.8ºINC FEED 1 ... INC FEED 10 000º mode (ºincrementalº)

Supplement to Standard Documentation

The oblique axis and/or the oblique grinding wheel can be traversed in Cartesian coordinates or obliquely.

For other operations see Section 3.2.7 ºJOGº mode.

3.2.9Handwheel

Supplement to Standard Documentation

The oblique axis and/or the oblique grinding wheel can be traversed in Cartesian coordinates or obliquely.

For other operations see Section 3.2.7 ºJOGº mode.

3±2 |

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

|

SINUMERIK 810G/820G (BN) |

08.91 |

4 Diagnostics |

4.6 Listing of the alarms/alarm description

4 Diagnostics

4.6Listing of the alarms/alarm description

Supplement to Standard Documentation

Alarm No. |

2062 |

|

|

Alarm Text: |

ºFeed missing/not prog.º |

|

|

Cause: |

· No F value programmed |

|

· F value too small (machine data) |

|

· Feed per rev. G95 too high |

|

· No feed per rev. programmed |

|

· The simultaneous feedrates are active for the interpolating axes, e.g. for |

|

G02 |

Remedy: |

Program feed properly |

|

|

Alarm No. |

2087 |

|

|

AlarmText: |

ºCoordinate rotation not allowedº |

|

|

Cause: |

If coordinate rotation is programmed in the NC program, a circular |

|

movement should be carried out immediately afterwards. |

Remedy: |

Check NC program |

|

|

Alarm No. |

2159 |

|

|

AlarmText: |

ºProgram error surface speedº |

|

|

Cause: |

· Grinding wheel surface speed has been programmed for two spindles |

|

simultaneously |

|

· Spindle number and tool type do not coincide |

|

· Grinding wheel surface speed can only be programmed for one spindle |

Remedy: |

The third decade of the tool type must coincide with the spindle number. |

Explanation: |

Compensation block and current block number not displayed. |

|

|

Alarm No. |

2196 |

|

|

AlarmText: |

ºGeneral reciprocation errorº |

|

|

Cause: |

The programmed target position for the reciprocating axis corresponds to |

|

the present position. |

Remedy: |

The reciprocation path resulting from the programming must not be equal to |

|

zero. |

Explanation: |

Compensation block and current block number not displayed. |

|

|

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

4±1 |

SINUMERIK 810G/820G (BN)

4 Diagnostics |

08.91 |

4.6 Listing of the alarms/alarm description |

|

Alarm No. |

3000 |

|

|

Alarm Text: |

ºGeneral programming errorº |

|

|

Cause: |

In one block of the program, a general, not precisely definable, programming |

|

error was made. |

|

Example: · An axis was programmed that is not present on the machine |

|

· An incorrect interpolation parameter was programmed |

|

· G33, G34 or G35 has been programmed with simultaneous |

|

feed. |

Remedy: |

Check the faulty block in ºCompensation blockº. |

|

If possible, the cursor should be positioned in front of the word containing |

|

the error. |

|

The number of the block containing the error is displayed in the alarm line |

|

after the alarm number. |

|

|

Alarm No. |

3009 |

|

|

Alarm Text: |

ºProgram disabledº |

|

|

Cause: |

Subroutine has not been activated for softkey start. |

Remedy: |

Program @00f in first program block. |

|

|

Alarm No. |

3085 |

|

|

Alarm Text: |

ºProgram error G5/G7º |

|

|

Cause: |

· A tool offset or zero offset has been programmed in the G07 block. |

|

· A tool offset or zero offset has been programmed in front of the G07 |

|

block without programming STOP DEC (@714) or the oblique axis. |

Remedy: |

Correct program |

|

|

4±2 |

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

SINUMERIK 810G/820G (BN)

08.91 |

5 Maintenance |

5 Maintenance

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

5±1 |

SINUMERIK 810G/820G (BN)

08.91 |

6 Data Interface |

6 Data Interface

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

6±1 |

SINUMERIK 810G/820G (BN)

08.91 |

7 Interfacing to the Machine |

7 Interfacing to the Machine

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

7±1 |

SINUMERIK 810G/820G (BN)

08.91 |

8 Appendix |

8 Appendix

The standard documentation applies.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

8±1 |

SINUMERIK 810G/820G (BN)

Difference Description

Part 2: Programming

User©s Guide

User Documentation

Fundamentals of Programming |

1 |

|

|

|

|

|

|

|

Directions of Movement, Dimensional Notation |

2 |

|

|

|

|

|

|

|

Programming of Motion Blocks |

3 |

|

|

|

|

|

|

|

Switching, Auxiliary and Miscellaneous Functions |

4 |

|

|

|

|

|

|

|

Subroutines |

5 |

|

|

|

|

|

|

|

Parameters |

6 |

|

|

|

|

|

|

|

Contour Definition |

7 |

|

|

|

|

|

|

|

Tool Offsets |

8 |

|

|

|

|

|

|

|

Wheel Radius Compensation |

9 |

|

|

|

|

|

|

|

Cycles |

10 |

|

|

|

|

|

|

|

Programming of Cycles |

11 |

|

|

|

|

|

|

|

Program Key |

12 |

|

|

|

|

Contents

|

|

Page |

1 |

Fundamentals of Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±1 |

1.11 |

Channel structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1±1 |

2 |

Directions of Movement, Dimensional Notation . . . . . . . . . . . . . . . |

2±1 |

2.3 |

Dimension systems: absolute and incremental position data, G90/G91 . |

2±1 |

2.5 |

Zero offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±1 |

2.9 |

Programmable working area limitation, G25/G26 . . . . . . . . . . . . . . . . . |

2±1 |

2.10 |

Coordinate rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2±4 |

3 |

Programming of Motion Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2 |

Axis motions with machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.4 |

Cylindrical interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.5 |

Feedrate F, G94/G95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±1 |

3.2.10 |

Polar coordinates, G10/G11/G12/G13 . . . . . . . . . . . . . . . . . . . . . . . . . |

3±2 |

3.2.11 |

Thread grinding, G33/G34/G35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±6 |

3.2.11.1 |

Thread with constant lead, G33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±7 |

3.2.11.2 |

Thread with variable lead, G34/G35 . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±10 |

3.2.11.3 |

Infeed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±11 |

3.2.11.4 |

Multiple threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±13 |

3.2.12 |

Plane selection, G16/G17/G18/G19 . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±15 |

3.3 |

Point-to-point control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±21 |

3.4.1 |

Switch off simultaneous oscillation . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±24 |

3.6.1 |

Several feedrates in one block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±24 |

3.7 |

Oblique plunge-cut grinding, G05/G07 . . . . . . . . . . . . . . . . . . . . . . . . |

3±25 |

3.7.1 |

Linear interpolation, G00/G01 (Cartesian movement) . . . . . . . . . . . . . . |

3±27 |

3.7.2 |

Oblique plunge-cut grinding, G05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±28 |

3.7.3 |

Compensating movement, G07 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±29 |

3.7.4 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3±32 |

4 |

Switching, Auxiliary and Miscellaneous Functions . . . . . . . . . . . . . |

4±1 |

4.2 |

Miscellaneous function M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4±1 |

5 |

Subroutines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5±1 |

6 |

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6±1 |

7 |

Contour Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 7±1 |

7.1 |

Blueprint programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7±1 |

8 |

Tool Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8±1 |

8.3 |

Tool compensation without using the wheel radius compensation . . . . . |

8±1 |

8.4 |

Tool offset using wheel radius compensation . . . . . . . . . . . . . . . . . . . . |

8±1 |

9 |

Wheel Radius Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9±1 |

9.1 |

Selection of wheel radius compensation . . . . . . . . . . . . . . . . . . . . . . . |

9±1 |

10 |

Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10±1 |

10.2 |

Cycle call via G function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10±1 |

11 |

Programming of Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11±1 |

11.9 |

NC-specific functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11±1 |

11.11 |

Operator guidance macro (OGM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11±2 |

12 |

Program Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12±1 |

12.1 |

Internal breakdown of G groups with @ 36b . . . . . . . . . . . . . . . . . . . . |

12±1 |

12.2 |

Program key SINUMERIK 810G/820G . . . . . . . . . . . . . . . . . . . . . . . . |

12±2 |

08.91 |

1 Fundamentals of Programming |

1.11 Channel structure

1 Fundamentals of Programming

Sections that are not mentioned apply unchanged.

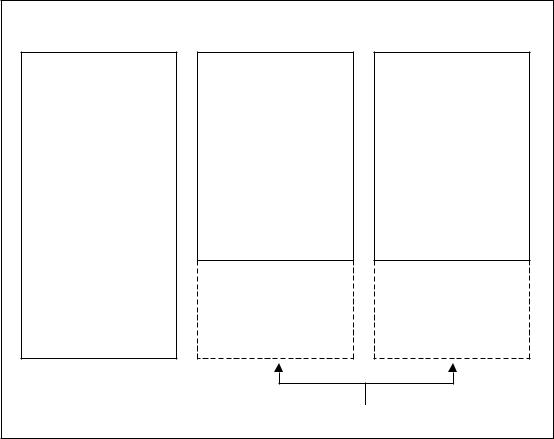

1.11Channel structure

Supplement to Standard Documentation

Functional scope of channels:

Channel 1 |

Channel 2 |

Channel 3 |

||

|

· |

Blueprint |

· |

Display of auxiliary |

|

|

programming |

|

functions |

|

· |

Grinding wheel |

· |

NC-PLC data |

|

|

radius compensation |

|

transfer |

|

· H, T auxil. functions |

|

|

|

|

|

Functions not implemented |

||

Different zero offsets and tool offsets can be programmed in channels 1 and 2 which are channel-specific. Grinding wheel radius compensation cannot be implemented in channel 2.

The active tool offset and zero offset values are used to calculate the actual value display for each axis and each channel.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

1±1 |

SINUMERIK 810G/820G (BN)

08.91 |

2 Directions of Movement, Dimensional Notation |

2.3 Dimension systems: absolute and incremental position data G90/G91

2Directions of Movement, Dimensional Notation

Sections that are not mentioned apply unchanged.

2.3Dimension systems: absolute and incremental position data G90/G91

Supplement to Standard

Mixed programming with G90 and G91 in one block

is not possible.

2.5Zero offset

Supplement to Standard Documentation

Different zero offsets can be programmed in channel 1 and channel 2. The active zero offset value for each channel is used to calculate the actual value display.

2.9Programmable working area limitation, G25/G26

Programming area limitation provides machine protection in the event of operating and programming errors. It can be specified in Cartesian coordinates or axis related

Machine data is used to define whether the programming area limitation is defined in Cartesian coordinates

or axis related.

The tool reference point F must only move in the limited range (framed field). As soon as the tool leaves this limited area or is located outside this area on program start, or as soon as a position outside the working area limitation is programmed, the path setting is terminated or a travel command is not accepted (program stop, no program start, alarm). The current following error is eliminated. Programmable working area limitation is active in AUTOMATIC mode with the values in the setting data.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0FK02 |

2±1 |

SINUMERIK 810G/820G (BN)

Loading...

Loading...