siemens 840D Operating Manual

Turning

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

_

_________________

_

SINUMERIK

SINUMERIK 840D sl / 828D

Turning

Operating Manual

Valid for:

Controller

SINUMERIK 840D sl / 840DE sl / 828D

Software version

CNC Software for 840D sl / 840DE sl 4.5 SP2

SINUMERIK Operate for PCU/PC 4.5 SP2

03/2013

6FC5398-8CP40-3BA1

Preface

Introduction

1

Setting up the machine

2

Working in manual mode

3

Machining the workpiece

4

Simulating machining

5

Creating a G code program

6

Creating a ShopTurn

program

7

Programming technology

functions (cycles)

8

Multi-channel machining

(only 840D sl)

9

Collision avoidance (only

840D sl)

10

Tool management

11

Managing programs

12

Alarm, error and system

messages

13

Working with Manual

Machine

14

Working with a B axis (only

840D sl)

15

Working with two tool

carriers

16

Continued on next page

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5398-8CP40-3BA1

Ⓟ 04/2013 Technical data subject to change

Copyright © Siemens AG 2008 - 2013.

All rights reserved

SINUMERIK 840D sl / 828D

Turning

Operating Manual

Continuation

Teaching in a program

17

HT 8

18

Ctrl-Energy

19

Easy Message (828D only)

20

Easy Extend (828D only)

21

Service Planner (828D only)

22

Ladder Viewer and Ladder

add-on (828D only)

23

Appendix

A

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Order number: 6FC5398-8CP40-3BA1

Ⓟ 04/2013 Technical data subject to change

Copyright © Siemens AG 2008 - 2013.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

5

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

● General documentation

● User documentation

● Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

● Ordering documentation/overview of documentation

● Additional links to download documents

● Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for

improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific

machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

● www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

● www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product

Support. http://support.automation.siemens.com

Preface

Turning

6 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

SINUMERIK

You can find information on SINUMERIK under the following link:

www.siemens.com/sinumerik

Target group

This documentation is intended for users of turning machines running the SINUMERIK

Operate software.

Benefits

The operating manual helps users familiarize themselves with the control elements and

commands. Guided by the manual, users are capable of responding to problems and taking

corrective action.

Standard scope

This documentation describes the functionality of the standard scope. Extensions or changes

made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control.

However, no claim can be made regarding the availability of these functions when the

equipment is first supplied or in the event of servicing.

Furthermore, for the sake of clarity, this documentation does not contain all detailed

information about all types of the product and cannot cover every conceivable case of

installation, operation or maintenance.

Terms

The meanings of some basic terms used in this documentation are given below.

Program

A program is a sequence of instructions to the CNC which combine to produce a specific

workpiece on the machine.

Contour

The term contour refers generally to the outline of a workpiece. More specifically, it refers to

the section of the program that defines the outline of a workpiece comprising individual

elements.

Cycle

A cycle, such as the tapping cycle, is a subprogram defined in SINUMERIK Operate for

executing a frequently repeated machining operation.

Preface

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

7

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under

http://www.siemens.com/automation/service&support

Preface

Turning

8 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

9

Table of contents

Preface ......................................................................................................................................................

5

1 Introduction..............................................................................................................................................

23

1.1 Product overview .........................................................................................................................

23

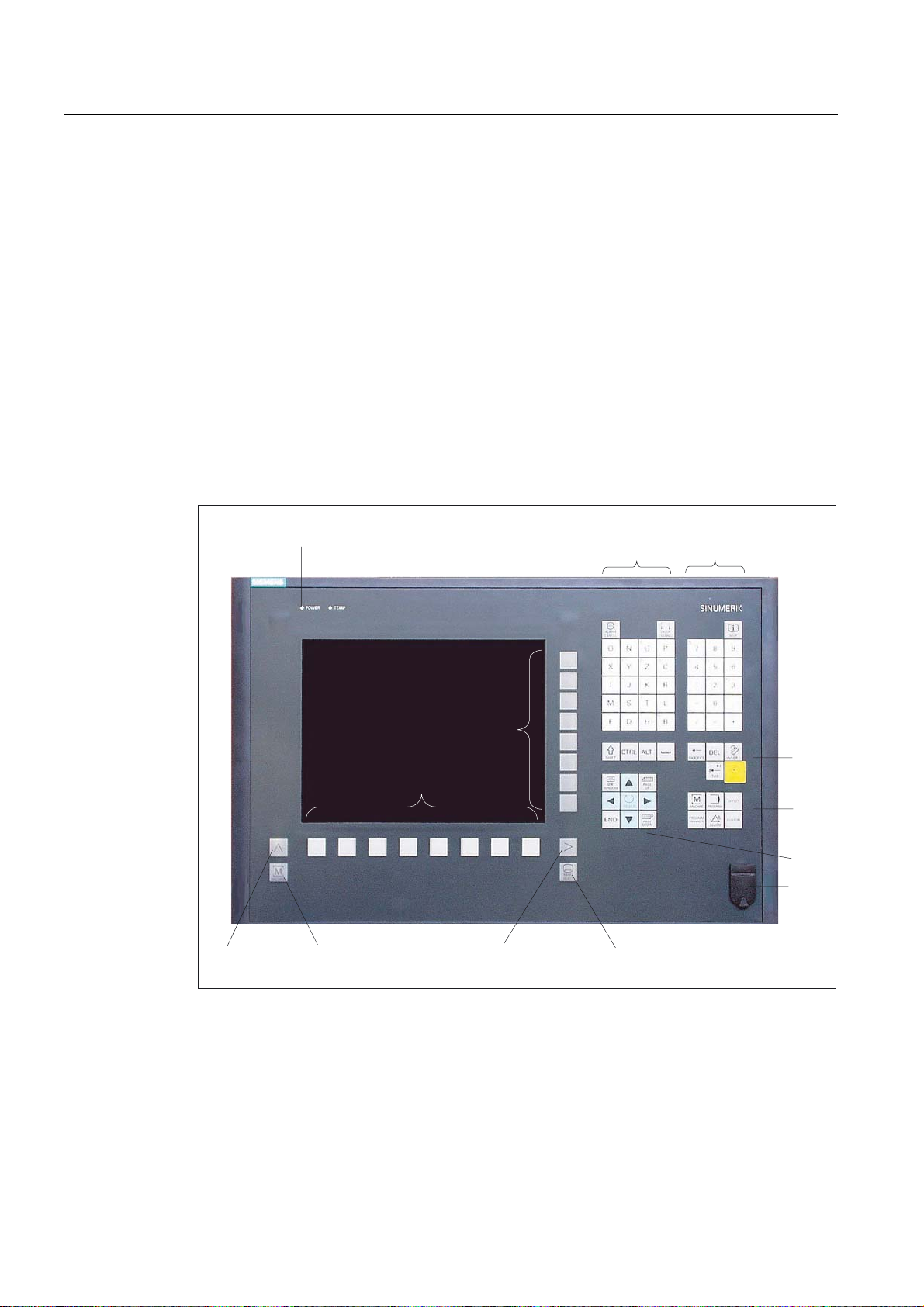

1.2 Operator panel fronts ...................................................................................................................

24

1.2.1 Overview......................................................................................................................................

24

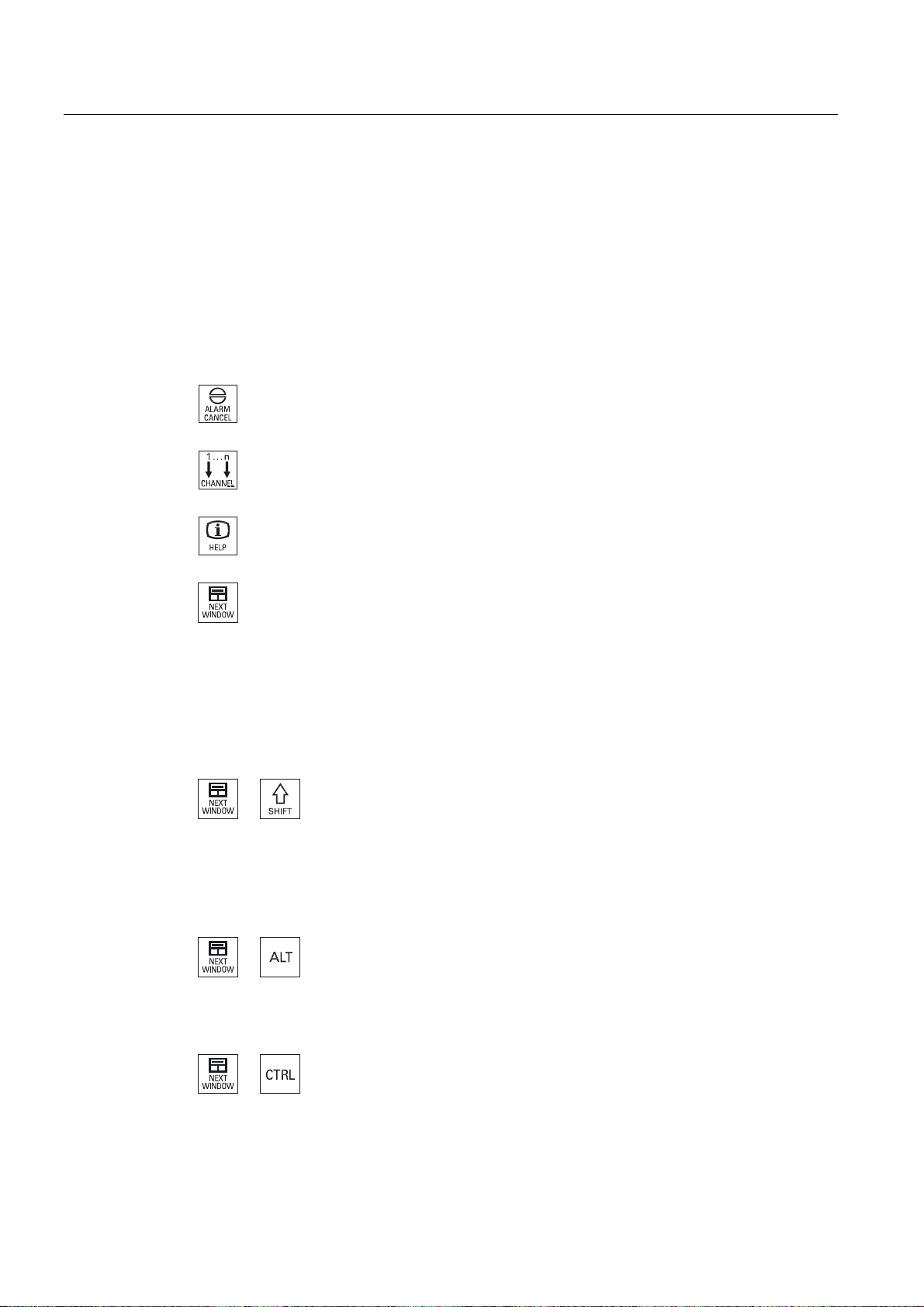

1.2.2 Keys of the operator panel...........................................................................................................

26

1.3 Machine control panels ................................................................................................................

35

1.3.1 Overview......................................................................................................................................

35

1.3.2 Controls on the machine control panel ........................................................................................

35

1.4 User interface...............................................................................................................................

38

1.4.1 Screen layout...............................................................................................................................

38

1.4.2 Status display...............................................................................................................................

39

1.4.3 Actual value window ....................................................................................................................

42

1.4.4 T,F,S window ...............................................................................................................................

43

1.4.5 Current block display ...................................................................................................................

46

1.4.6 Operation via softkeys and buttons .............................................................................................

46

1.4.7 Entering or selecting parameters.................................................................................................

48

1.4.8 Pocket calculator..........................................................................................................................

50

1.4.9 Context menu...............................................................................................................................

52

1.4.10 Touch operation ...........................................................................................................................

52

1.4.11 Changing the user interface language.........................................................................................

53

1.4.12 Entering Asian characters............................................................................................................

54

1.4.13 Protection levels...........................................................................................................................

56

1.4.14 Online help in SINUMERIK Operate............................................................................................

58

2 Setting up the machine............................................................................................................................

61

2.1 Switching on and switching off.....................................................................................................

61

2.2 Approaching a reference point.....................................................................................................

62

2.2.1 Referencing axes.........................................................................................................................

62

2.2.2 User agreement ...........................................................................................................................

63

2.3 Modes and mode groups .............................................................................................................

65

2.3.1 General ........................................................................................................................................

65

2.3.2 Modes groups and channels........................................................................................................

67

2.3.3 Channel switchover......................................................................................................................

68

2.4 Settings for the machine ..............................................................................................................

69

2.4.1 Switching over the coordinate system (MCS/WCS) ....................................................................

69

2.4.2 Switching the unit of measurement..............................................................................................

70

2.4.3 Setting the zero offset..................................................................................................................

71

2.5 Measuring the tool .......................................................................................................................

73

2.5.1 Measuring a tool manually...........................................................................................................

73

2.5.2 Measuring a tool with a tool probe...............................................................................................

75

2.5.3 Calibrating the tool probe.............................................................................................................

77

Table of contents

Turning

10 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

2.5.4 Measuring a tool with a magnifying glass ................................................................................... 78

2.6 Measuring the workpiece zero ....................................................................................................

80

2.7 Zero offsets .................................................................................................................................

82

2.7.1 Display active zero offset ............................................................................................................

83

2.7.2 Displaying the zero offset "overview"..........................................................................................

84

2.7.3 Displaying and editing base zero offset......................................................................................

86

2.7.4 Displaying and editing settable zero offset .................................................................................

87

2.7.5 Displaying and editing details of the zero offsets........................................................................

88

2.7.6 Deleting a zero offset ..................................................................................................................

89

2.7.7 Measuring the workpiece zero....................................................................................................

90

2.8 Monitoring axis and spindle data ................................................................................................

91

2.8.1 Specify working area limitations..................................................................................................

91

2.8.2 Editing spindle data.....................................................................................................................

92

2.8.3 Spindle chuck data......................................................................................................................

93

2.9 Displaying setting data lists.........................................................................................................

95

2.10 Handwheel assignment...............................................................................................................

96

2.11 MDA ............................................................................................................................................

98

2.11.1 Loading an MDA program from the Program Manager ..............................................................

98

2.11.2 Saving an MDA program.............................................................................................................

99

2.11.3 Executing an MDA program......................................................................................................

100

2.11.4 Deleting an MDA program.........................................................................................................

100

3 Working in manual mode .......................................................................................................................

101

3.1 General......................................................................................................................................

101

3.2 Selecting a tool and spindle ......................................................................................................

101

3.2.1 T,S,M window............................................................................................................................

101

3.2.2 Selecting a tool..........................................................................................................................

103

3.2.3 Starting and stopping the spindle manually ..............................................................................

104

3.2.4 Positioning the spindle ..............................................................................................................

105

3.3 Traversing axes.........................................................................................................................

106

3.3.1 Traverse axes by a defined increment......................................................................................

106

3.3.2 Traversing axes by a variable increment ..................................................................................

107

3.4 Positioning axes ........................................................................................................................

108

3.5 Manual retraction ......................................................................................................................

109

3.6 Simple stock removal of workpiece...........................................................................................

111

3.7 Thread synchronizing................................................................................................................

114

3.8 Default settings for manual mode .............................................................................................

116

4 Machining the workpiece .......................................................................................................................

117

4.1 Starting and stopping machining...............................................................................................

117

4.2 Selecting a program ..................................................................................................................

118

4.3 Executing a trail program run ....................................................................................................

119

4.4 Displaying the current program block .......................................................................................

120

4.4.1 Current block display.................................................................................................................

120

Table of contents

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

11

4.4.2 Displaying a basic block.............................................................................................................121

4.4.3 Display program level ................................................................................................................

122

4.5 Correcting a program .................................................................................................................

123

4.6 Repositioning axes.....................................................................................................................

124

4.7 Starting machining at a specific point ........................................................................................

125

4.7.1 Use block search .......................................................................................................................

125

4.7.2 Continuing program from search target.....................................................................................

127

4.7.3 Simple search target definition...................................................................................................

128

4.7.4 Defining an interruption point as search target..........................................................................

129

4.7.5 Entering the search target via search pointer............................................................................

130

4.7.6 Parameters for block search in the search pointer ....................................................................

131

4.7.7 Block search mode ....................................................................................................................

132

4.8 Controlling the program run .......................................................................................................

134

4.8.1 Program control..........................................................................................................................

134

4.8.2 Skip blocks.................................................................................................................................

135

4.9 Overstore ...................................................................................................................................

137

4.10 Editing a program.......................................................................................................................

138

4.10.1 Searching in programs...............................................................................................................

139

4.10.2 Replacing program text..............................................................................................................

141

4.10.3 Copying/pasting/deleting a program block.................................................................................

142

4.10.4 Renumbering a program ............................................................................................................

143

4.10.5 Creating a program block...........................................................................................................

144

4.10.6 Opening additional programs.....................................................................................................

146

4.10.7 Editor settings ............................................................................................................................

147

4.11 Display and edit user variables ..................................................................................................

149

4.11.1 Overview ....................................................................................................................................

149

4.11.2 R parameters .............................................................................................................................

150

4.11.3 Displaying global user data (GUD) ............................................................................................

151

4.11.4 Displaying channel GUDs..........................................................................................................

152

4.11.5 Displaying local user data (LUD) ...............................................................................................

153

4.11.6 Displaying program user data (PUD).........................................................................................

154

4.11.7 Searching for user variables ......................................................................................................

155

4.12 Displaying G functions and auxiliary functions ..........................................................................

157

4.12.1 Selected G functions..................................................................................................................

157

4.12.2 All G functions............................................................................................................................

159

4.12.3 G functions for mold making ......................................................................................................

160

4.12.4 Auxiliary functions ......................................................................................................................

162

4.13 Mold making view ......................................................................................................................

165

4.13.1 Mold making view ......................................................................................................................

165

4.13.2 Starting the mold making view...................................................................................................

167

4.13.3 Specifically jump to the program block ......................................................................................

168

4.13.4 Searching for program blocks....................................................................................................

168

4.13.5 Changing the view .....................................................................................................................

169

4.13.5.1 Enlarging or reducing the graphical representation ...................................................................

169

4.13.5.2 Modifying the viewport ...............................................................................................................

170

4.14 Displaying the program runtime and counting workpieces ........................................................

171

4.15 Setting for automatic mode ........................................................................................................

173

Table of contents

Turning

12 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

5 Simulating machining............................................................................................................................. 175

5.1 Overview ...................................................................................................................................

175

5.2 Simulation before machining of the workpiece .........................................................................

181

5.3 Simultaneous recording before machining of the workpiece ....................................................

182

5.4 Simultaneous recording during machining of the workpiece ....................................................

183

5.5 Different views of the workpiece ...............................................................................................

184

5.5.1 Side view...................................................................................................................................

184

5.5.2 Half section ...............................................................................................................................

184

5.5.3 Face view..................................................................................................................................

185

5.5.4 3D view......................................................................................................................................

185

5.5.5 2-window...................................................................................................................................

186

5.6 Graphical display.......................................................................................................................

186

5.7 Editing the simulation display....................................................................................................

187

5.7.1 Blank display.............................................................................................................................

187

5.7.2 Showing and hiding the tool path..............................................................................................

189

5.8 Program control during the simulation ......................................................................................

190

5.8.1 Changing the feedrate...............................................................................................................

190

5.8.2 Simulating the program block by block .....................................................................................

191

5.9 Editing and adapting a simulation graphic ................................................................................

192

5.9.1 Enlarging or reducing the graphical representation ..................................................................

192

5.9.2 Panning a graphical representation..........................................................................................

193

5.9.3 Rotating the graphical representation.......................................................................................

193

5.9.4 Modifying the viewport ..............................................................................................................

194

5.9.5 Defining cutting planes..............................................................................................................

195

5.10 Displaying simulation alarms.....................................................................................................

196

6 Creating a G code program ...................................................................................................................

197

6.1 Graphical programming.............................................................................................................

197

6.2 Program views ..........................................................................................................................

198

6.3 Program structure .....................................................................................................................

201

6.4 Fundamentals ...........................................................................................................................

201

6.4.1 Machining planes ......................................................................................................................

201

6.4.2 Current planes in cycles and input screens ..............................................................................

202

6.4.3 Programming a tool (T).............................................................................................................

203

6.5 Generating a G code program ..................................................................................................

204

6.6 Blank input ................................................................................................................................

205

6.7 Machining plane, milling direction, retraction plane, safe clearance and feedrate (PL, RP,

SC, F)........................................................................................................................................

208

6.8 Selection of the cycles via softkey ............................................................................................

209

6.9 Calling technology cycles..........................................................................................................

213

6.9.1 Hiding cycle parameters............................................................................................................

213

6.9.2 Setting data for cycles...............................................................................................................

214

6.9.3 Checking cycle parameters.......................................................................................................

214

Table of contents

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

13

6.9.4 Programming variables..............................................................................................................214

6.9.5 Changing a cycle call.................................................................................................................

215

6.9.6 Compatibility for cycle support...................................................................................................

215

6.9.7 Additional functions in the input screens ...................................................................................

216

6.10 Measuring cycle support ............................................................................................................

217

7 Creating a ShopTurn program ...............................................................................................................

219

7.1 Graphic program control, ShopTurn programs ..........................................................................

219

7.2 Program views ...........................................................................................................................

220

7.3 Program structure ......................................................................................................................

224

7.4 Fundamentals ............................................................................................................................

225

7.4.1 Machining planes.......................................................................................................................

225

7.4.2 Machining cycle, approach/retraction ........................................................................................

227

7.4.3 Absolute and incremental dimensions.......................................................................................

229

7.4.4 Polar coordinates.......................................................................................................................

230

7.4.5 Clamping the spindle .................................................................................................................

231

7.5 Creating a ShopTurn program ...................................................................................................

232

7.6 Program header .........................................................................................................................

234

7.7 Generating program blocks........................................................................................................

237

7.8 Tool, offset value, feedrate and spindle speed (T, D, F, S, V)...................................................

238

7.9 Call work offsets.........................................................................................................................

241

7.10 Repeating program blocks .........................................................................................................

242

7.11 Entering the number of workpieces ...........................................................................................

243

7.12 Changing program blocks ..........................................................................................................

244

7.13 Changing program settings........................................................................................................

245

7.14 Selection of the cycles via softkey .............................................................................................

247

7.15 Calling technology functions ......................................................................................................

252

7.15.1 Additional functions in the input screens ...................................................................................

252

7.15.2 Checking cycle parameters........................................................................................................

252

7.15.3 Programming variables ..............................................................................................................

253

7.15.4 Setting data for technological functions .....................................................................................

253

7.15.5 Changing a cycle call .................................................................................................................

254

7.15.6 Compatibility for cycle support...................................................................................................

254

7.16 Programming the approach/retraction cycle ..............................................................................

255

7.17 Measuring cycle support ............................................................................................................

257

7.18 Example: Standard machining ...................................................................................................

258

7.18.1 Workpiece drawing ....................................................................................................................

259

7.18.2 Programming..............................................................................................................................

259

7.18.3 Results/simulation test ...............................................................................................................

272

7.18.4 G code machining program........................................................................................................

274

8 Programming technology functions (cycles) ..........................................................................................

277

8.1 Drilling ........................................................................................................................................

277

Table of contents

Turning

14 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

8.1.1 General...................................................................................................................................... 277

8.1.2 Centering (CYCLE81)...............................................................................................................

278

8.1.3 Drilling (CYCLE82)....................................................................................................................

281

8.1.4 Reaming (CYCLE85) ................................................................................................................

283

8.1.5 Boring (CYCLE86) ....................................................................................................................

285

8.1.6 Deep-hole drilling (CYCLE83)...................................................................................................

289

8.1.7 Tapping (CYCLE84, 840)..........................................................................................................

293

8.1.8 Drill and thread milling (CYCLE78)...........................................................................................

299

8.1.9 Positions and position patterns.................................................................................................

303

8.1.9.1 Approach/retraction...................................................................................................................

303

8.1.10 Arbitrary positions (CYCLE802)................................................................................................

304

8.1.10.1 Function.....................................................................................................................................

304

8.1.11 Position pattern line (HOLES1), grid or frame (CYCLE801).....................................................

307

8.1.12 Circle position pattern (HOLES2)..............................................................................................

309

8.1.13 Displaying and hiding positions.................................................................................................

313

8.1.14 Repeating positions...................................................................................................................

315

8.1.14.1 Function.....................................................................................................................................

315

8.2 Rotate........................................................................................................................................

316

8.2.1 General......................................................................................................................................

316

8.2.2 Stock removal (CYCLE951)......................................................................................................

316

8.2.3 Groove (CYCLE930).................................................................................................................

319

8.2.4 Undercut form E and F (CYCLE940) ........................................................................................

322

8.2.5 Thread undercuts (CYCLE940) ................................................................................................

324

8.2.6 Thread turning (CYCLE99) .......................................................................................................

327

8.2.7 Thread chain (CYCLE98)..........................................................................................................

336

8.2.7.1 Parameters................................................................................................................................

338

8.2.8 Cut-off (CYCLE92)....................................................................................................................

340

8.3 Contour turning .........................................................................................................................

342

8.3.1 General information...................................................................................................................

342

8.3.2 Representation of the contour...................................................................................................

343

8.3.3 Creating a new contour.............................................................................................................

345

8.3.4 Creating contour elements........................................................................................................

347

8.3.5 Entering the master dimension .................................................................................................

352

8.3.6 Changing the contour................................................................................................................

354

8.3.7 Contour call (CYCLE62) - only for G code program .................................................................

355

8.3.8 Stock removal (CYCLE952)......................................................................................................

356

8.3.9 Stock removal rest (CYCLE952)...............................................................................................

362

8.3.10 Plunge-cutting (CYCLE952)......................................................................................................

365

8.3.11 Plunge-cutting rest (CYCLE952)...............................................................................................

368

8.3.12 Plunge-turning (CYCLE952) .....................................................................................................

370

8.3.13 Plunge-turning rest (CYCLE952) ..............................................................................................

374

8.4 Milling ........................................................................................................................................

377

8.4.1 Face milling (CYCLE61)............................................................................................................

377

8.4.2 Rectangular pocket (POCKET3)...............................................................................................

381

8.4.3 Circular pocket (POCKET4)......................................................................................................

387

8.4.4 Rectangular spigot (CYCLE76).................................................................................................

393

8.4.5 Circular spigot (CYCLE77)........................................................................................................

397

8.4.6 Multi-edge (CYCLE79)..............................................................................................................

401

8.4.7 Longitudinal groove (SLOT1)....................................................................................................

404

8.4.8 Circumferential groove (SLOT2)...............................................................................................

410

8.4.9 Open groove (CYCLE899)........................................................................................................

415

Table of contents

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

15

8.4.10 Long hole (LONGHOLE) - only for G code program..................................................................424

8.4.11 Thread milling (CYCLE70).........................................................................................................

426

8.4.12 Engraving (CYCLE60) ...............................................................................................................

430

8.5 Contour milling ...........................................................................................................................

437

8.5.1 General information ...................................................................................................................

437

8.5.2 Representation of the contour....................................................................................................

437

8.5.3 Creating a new contour..............................................................................................................

439

8.5.4 Creating contour elements.........................................................................................................

441

8.5.5 Changing the contour.................................................................................................................

447

8.5.6 Contour call (CYCLE62) - only for G code program ..................................................................

448

8.5.7 Path milling (CYCLE72).............................................................................................................

449

8.5.8 Contour pocket/contour spigot (CYCLE63/64) ..........................................................................

454

8.5.9 Predrilling contour pocket (CYCLE64).......................................................................................

456

8.5.10 Milling contour pocket (CYCLE63).............................................................................................

461

8.5.11 Contour pocket residual material (CYCLE63, option)................................................................

464

8.5.12 Milling contour spigot (CYCLE63)..............................................................................................

467

8.5.13 Contour spigot residual material (CYCLE63, option).................................................................

470

8.6 Further cycles and functions ......................................................................................................

473

8.6.1 Swiveling plane / aligning tool (CYCLE800)..............................................................................

473

8.6.2 Swiveling tool (CYCLE800)........................................................................................................

482

8.6.2.1 Aligning turning tools - only for G code program (CYCLE800)..................................................

482

8.6.2.2 Aligning milling tools - only for G code program (CYCLE800)...................................................

483

8.6.2.3 Preloading milling tools - only for G code program (CYCLE800) ..............................................

484

8.6.3 High-speed settings (CYCLE832)..............................................................................................

486

8.6.4 Subroutines................................................................................................................................

489

8.7 Additional cycles and functions in ShopTurn .............................................................................

491

8.7.1 Drilling centric.............................................................................................................................

491

8.7.2 Thread centered.........................................................................................................................

493

8.7.3 Transformations.........................................................................................................................

496

8.7.4 Translation .................................................................................................................................

498

8.7.5 Rotation......................................................................................................................................

499

8.7.6 Scaling .......................................................................................................................................

500

8.7.7 Mirroring.....................................................................................................................................

501

8.7.8 Rotation C..................................................................................................................................

502

8.7.9 Straight and circular machining..................................................................................................

503

8.7.10 Selecting a tool and machining plane ........................................................................................

504

8.7.11 Programming a straight line .......................................................................................................

505

8.7.12 Programming a circle with known center point ..........................................................................

507

8.7.13 Programming a circle with known radius ...................................................................................

509

8.7.14 Polar coordinates .......................................................................................................................

511

8.7.15 Straight line polar .......................................................................................................................

513

8.7.16 Circle polar.................................................................................................................................

515

8.7.17 Machining with movable counterspindle ....................................................................................

517

8.7.17.1 Programming example: Machining main spindle – Transfer workpiece – Machining

counterspindle............................................................................................................................

518

8.7.17.2 Programming example: Machining, counterspindle - without previous transfer ........................

518

8.7.17.3 Programming example: Machining bar material ........................................................................

519

8.7.18 Machining with fixed counterspindle ..........................................................................................

524

Table of contents

Turning

16 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

9 Multi-channel machining (only 840D sl) ................................................................................................. 527

9.1 Multi-channel view (only 840D sl) .............................................................................................

527

9.1.1 Multi-channel view in the "Machine" operating area.................................................................

527

9.1.2 Multi-channel view for large operator panels............................................................................

530

9.1.3 Setting the multi-channel view ..................................................................................................

531

9.2 Multi-channel support (only 840D sl) ........................................................................................

533

9.2.1 Working with several channels .................................................................................................

533

9.2.2 Creating a multi-channel program.............................................................................................

534

9.2.3 Entering multi-channel data ......................................................................................................

535

9.2.4 Multi-channel functionality for large operator panels ................................................................

539

9.2.5 Editing the multi-channel program ............................................................................................

542

9.2.5.1 Changing the job list..................................................................................................................

542

9.2.5.2 Editing a G code multi-channel program...................................................................................

543

9.2.5.3 Editing a ShopTurn multi-channel program ..............................................................................

546

9.2.5.4 Creating a program block..........................................................................................................

554

9.2.6 Setting the multi-channel function.............................................................................................

556

9.2.7 Synchronizing programs ...........................................................................................................

558

9.2.8 Insert WAIT marks ....................................................................................................................

561

9.2.9 Optimizing the machining time..................................................................................................

562

9.2.10 Simulating machining ................................................................................................................

564

9.2.10.1 Simulation..................................................................................................................................

564

9.2.10.2 Different workpiece views for multi-channel support ................................................................

565

9.2.11 Display/edit the multi-channel functionality in the "Machine" operating area ...........................

566

9.2.11.1 Running-in a program ...............................................................................................................

566

9.2.11.2 Block search and program control ............................................................................................

567

9.2.12 Synchronizing a counterspindle ................................................................................................

569

10 Collision avoidance (only 840D sl).........................................................................................................

575

10.1 Collision monitoring in the machine operator area: ..................................................................

575

10.2 Switching the collision avoidance on and off ............................................................................

576

11 Tool management..................................................................................................................................

579

11.1 Lists for the tool management...................................................................................................

579

11.2 Magazine management.............................................................................................................

580

11.3 Tool types..................................................................................................................................

581

11.4 Tool dimensioning .....................................................................................................................

584

11.5 Tool list ......................................................................................................................................

589

11.5.1 Additional data ..........................................................................................................................

593

11.5.2 Creating a new tool ...................................................................................................................

594

11.5.3 Measuring the tool.....................................................................................................................

596

11.5.4 Managing several cutting edges ...............................................................................................

597

11.5.5 Delete tool .................................................................................................................................

597

11.5.6 Loading and unloading tools .....................................................................................................

598

11.5.7 Selecting a magazine................................................................................................................

600

11.5.8 Code carrier connection (only 840D sl).....................................................................................

601

11.5.8.1 Overview ...................................................................................................................................

601

11.6 Tool wear...................................................................................................................................

604

11.6.1 Reactivate tool ..........................................................................................................................

607

Table of contents

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

17

11.7 Tool data OEM ...........................................................................................................................608

11.8 Magazine....................................................................................................................................

610

11.8.1 Positioning a magazine..............................................................................................................

612

11.8.2 Relocating a tool ........................................................................................................................

613

11.8.3 Unload all tools...........................................................................................................................

614

11.9 Sorting tool management lists....................................................................................................

615

11.10 Filtering the tool management lists ............................................................................................

616

11.11 Specific search in the tool management lists.............................................................................

618

11.12 Displaying tool details ................................................................................................................

620

11.13 Displaying all tool details............................................................................................................

621

11.14 Changing the cutting edge position or tool type.........................................................................

622

11.15 Settings for tool lists ...................................................................................................................

623

11.16 Working with multitool (only 840D sl).........................................................................................

625

11.16.1 Tool list for multitool ...................................................................................................................

626

11.16.2 Create multitool..........................................................................................................................

627

11.16.3 Equipping multitool with tools.....................................................................................................

629

11.16.4 Removing a tool from multitool ..................................................................................................

630

11.16.5 Delete multitool ..........................................................................................................................

630

11.16.6 Loading and unloading multitool ................................................................................................

631

11.16.7 Reactivating the multitool...........................................................................................................

631

11.16.8 Relocating a multitool.................................................................................................................

633

11.16.9 Positioning multitool ...................................................................................................................

634

12 Managing programs...............................................................................................................................

635

12.1 Overview ....................................................................................................................................

635

12.1.1 Program management ...............................................................................................................

635

12.1.2 NC memory................................................................................................................................

638

12.1.3 Local drive..................................................................................................................................

638

12.1.4 USB drives .................................................................................................................................

639

12.1.5 FTP drive....................................................................................................................................

640

12.2 Opening and closing the program..............................................................................................

641

12.3 Executing a program..................................................................................................................

643

12.4 Creating a directory / program / job list / program list ................................................................

644

12.4.1 Creating a new directory............................................................................................................

644

12.4.2 Creating a new workpiece..........................................................................................................

645

12.4.3 Creating a new G code program................................................................................................

646

12.4.4 New ShopTurn program.............................................................................................................

647

12.4.5 Storing any new file....................................................................................................................

648

12.4.6 Creating a job list .......................................................................................................................

649

12.4.7 Creating a program list...............................................................................................................

651

12.5 Creating templates .....................................................................................................................

652

12.6 Searching directories and files...................................................................................................

653

12.7 Displaying the program in the Preview. .....................................................................................

654

12.8 Selecting several directories/programs......................................................................................

655

Table of contents

Turning

18 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

12.9 Copying and pasting a directory/program ................................................................................. 657

12.10 Deleting a directory/program.....................................................................................................

659

12.11 Changing file and directory properties ......................................................................................

660

12.12 Set up drives .............................................................................................................................

661

12.12.1 Overview ...................................................................................................................................

661

12.12.2 Setting up drives .......................................................................................................................

662

12.13 Viewing PDF documents...........................................................................................................

665

12.14 EXTCALL ..................................................................................................................................

666

12.15 Backing up data ........................................................................................................................

669

12.15.1 Generating an archive in the Program Manager.......................................................................

669

12.15.2 Generating an archive via the system data...............................................................................

670

12.15.3 Reading in an archive in the Program Manager .......................................................................

672

12.15.4 Read in archive from system data ............................................................................................

674

12.16 Setup data .................................................................................................................................

675

12.16.1 Backing up setup data...............................................................................................................

675

12.16.2 Reading-in set-up data..............................................................................................................

678

12.17 RS-232-C ..................................................................................................................................

680

12.17.1 Reading-in and reading-out archives ........................................................................................

680

12.17.2 Setting V24 in the program manager ........................................................................................

682

13 Alarm, error and system messages .......................................................................................................

685

13.1 Displaying alarms......................................................................................................................

685

13.2 Displaying an alarm log.............................................................................................................

687

13.3 Displaying messages ................................................................................................................

688

13.4 Sorting, alarms, faults and messages .......................................................................................

689

13.5 PLC and NC variables...............................................................................................................

690

13.5.1 Displaying and editing PLC and NC variables ..........................................................................

690

13.5.2 Saving and loading screen forms..............................................................................................

694

13.5.3 Load symbols ............................................................................................................................

695

13.6 Version ......................................................................................................................................

696

13.6.1 Displaying version data.............................................................................................................

696

13.6.2 Save information .......................................................................................................................

697

13.7 Logbook.....................................................................................................................................

698

13.7.1 Displaying and editing the logbook ...........................................................................................

699

13.7.2 Making a logbook entry .............................................................................................................

700

13.8 Creating screenshots ................................................................................................................

702

13.9 Remote diagnostics...................................................................................................................

703

13.9.1 Setting remote access...............................................................................................................

703

13.9.2 Permit modem...........................................................................................................................

705

13.9.3 Request remote diagnostics......................................................................................................

705

13.9.4 Exit remote diagnostics.............................................................................................................

706

14 Working with Manual Machine...............................................................................................................

707

14.1 Manual Machine........................................................................................................................

707

Table of contents

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

19

14.2 Measuring the tool .....................................................................................................................709

14.3 Setting the zero offset ................................................................................................................

709

14.4 Set limit stop...............................................................................................................................

710

14.5 Simple workpiece machining .....................................................................................................

711

14.5.1 Traversing axes .........................................................................................................................

711

14.5.2 Taper turning..............................................................................................................................

712

14.5.3 Straight and circular machining..................................................................................................

713

14.5.3.1 Straight turning...........................................................................................................................

713

14.5.3.2 Circular turning...........................................................................................................................

714

14.6 More complex machining ...........................................................................................................

716

14.6.1 Drilling with Manual Machine .....................................................................................................

718