Siemens AS 235, AS 235 H, AS 235 K User Manual

s

TELEPERM M

AS 235, AS 235 H and

AS 235 K

Automation Systems

Catalog PLT 111 · 1999

This catalog is no longer available in printed form. However, it can still be used to obtain information and for ordering spare parts.

Certain products from this catalog are no longer available. Your Siemens partner will offer appropriate substitutes wherever possible.

The products and systems described in this catalog are marketed under application of the quality management system certified by DQS in accordance with DIN EN ISO 9001 (certificate register No.: 2613-04). The

DQS certificate is recognized in all EQ Net countries (Reg. No.: 2613).

Introduction

System architecture

Automation systems

I/O modules

Input and output devices

Bus communication

Coupling with other systems

Appendix

REG. NO. 2613-04

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

Brief description

TELEPERM M process control system |

Engineering |

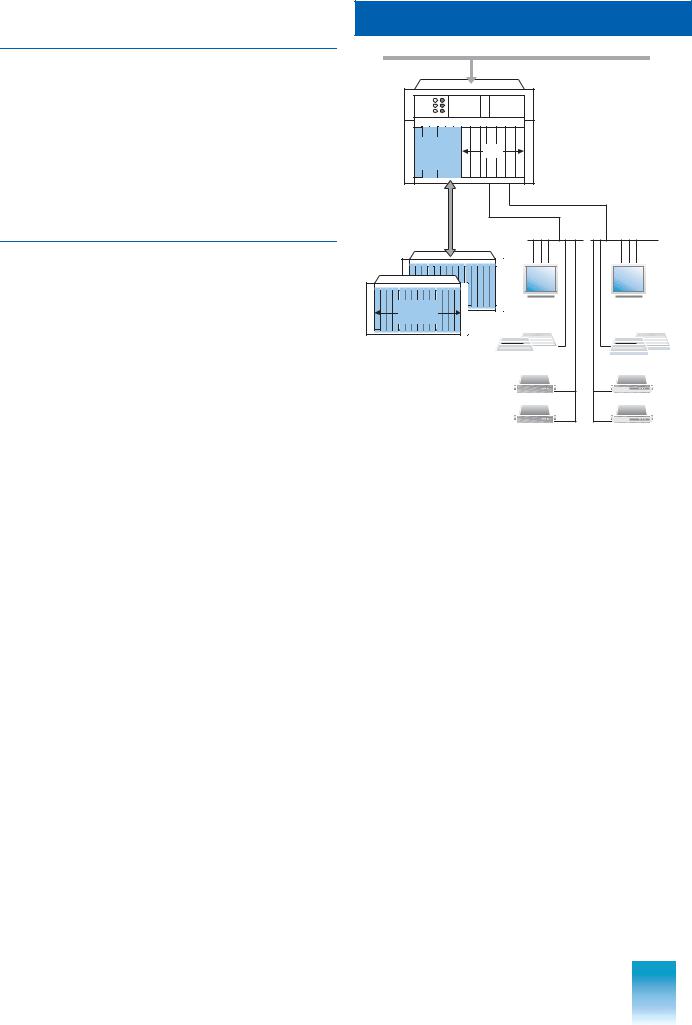

The TELEPERM M process control system provides all functions required for process automation. It is highly suitable for the complete automation of continuous and discontinuous (batch) processes.

The TELEPERM M systems are divided into function units optimized for different tasks associated with process automation:

•AS automation systems

•OS operator systems

•CS and PROFIBUS bus systems

AS automation systems

The various TELEPERM M automation systems have different designs, ranges of functions and performances. The AS 235, AS 235 H and AS 235 K automation systems described in this catalog are proven and reliable. They can be configured within wide limits and coupled to a wide range of subordinate systems. The AS 235 H additionally has a redundant central unit and thus satisfies particularly high availability demands. The AS 235 systems can communicate with one another and with higher-level systems via the TELEPERM M CS 275 plant bus.

A wide range of TELEPERM M input/output modules is available for connection of the process peripherals (sensors and final control elements) to the AS 235, AS 235 H and AS 235 K automation systems. Some modules have their own processing features or can be configured application-specific.

The AS 388/TM and AS 488/TM automation systems (see Catalog PLT 112) use the SIMATIC M7-300 and M7-400 automation computers as the hardware platform and are compatible with the AS 235 system. They are appropriate for the extension of existing TELEPERM M systems or for the design of new systems.

The AS 388/TM and AS 488/TM systems can be operated on the PROFIBUS-TM plant bus. PROFIBUS-TM is based on the standardized PROFIBUS. The AS 488/TM system can additionally be operated on the CS 275 plant bus.

ET 200M distributed I/O systems with a comprehensive range of I/O modules can be connected to the AS 388/TM and AS 488/TM systems via one or two PROFIBUS-DP interfaces.

OS operator systems

The bus-compatible OS 525 (Catalog PLT 122) and WinCC/TMOS (Catalog PLT 123) operator systems are used for process communication. They communicate with the subordinate TELEPERM M automation systems and with SIMATIC S5-155U via the CS 275 plant bus or PROFIBUS-TM.

The operator systems can have a configuration variable from a single-user system up to a multi-user system - where the OS basic unit communicates with several terminals via a terminal bus - and can thus cover the complete range from low-end to high-end applications.

The OS 525 Local system permits the design of a local AS operating console with the complete range of OS 525 functions.

The PROGRAF AS+ configuring software is used for the AS 235, AS 235 H, AS 235 K, AS 388/TM and AS 488/TM automation systems and offers a wide range of support for documentation and configuring by means of a graphic functional diagram editor and an integrated database, amongst others.

Any single-user system WinCC/TM-OS-Single with RC license (Runtime+Configuration) is suitable as the configuring system for WinCC/TM-OS, and an OS 525 single-user system/terminal with OS 525-BIPRO configuring software for OS 525.

Plant bus

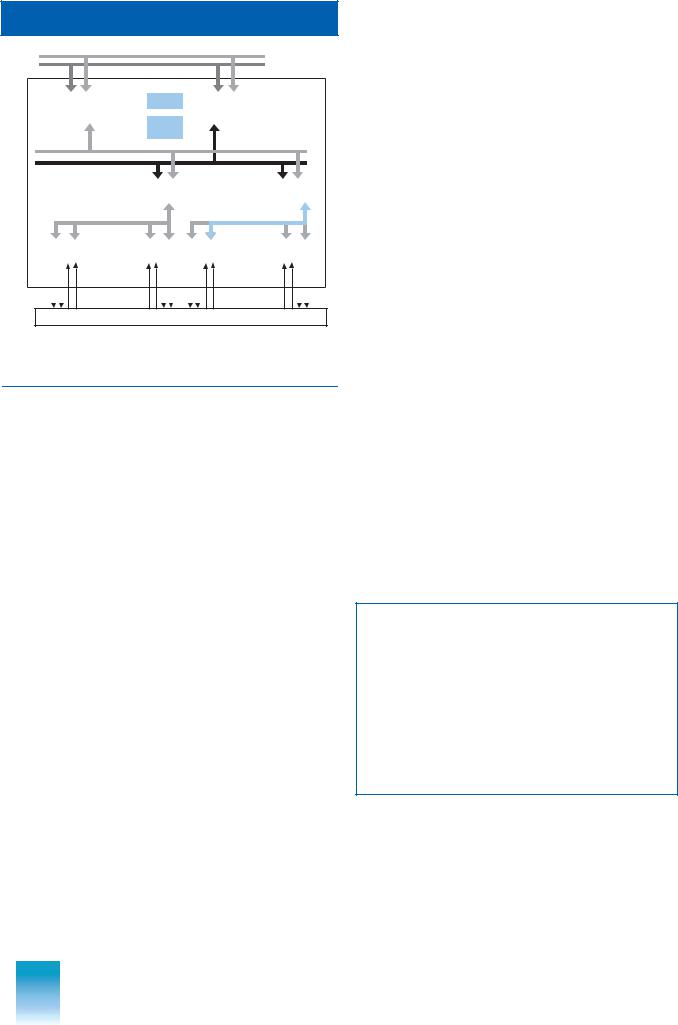

The plant bus is the central communication component of every distributed process control system. Two different bus systems are available for the TELEPERM M process control system, and can also be combined together within a system:

•CS 275

•PROFIBUS-TM

The CS 275 plant bus which has been proven in many automation plants is predestined for communication between the

AS 235, AS 235 H, AS 235 K and AS 488/TM automation systems and the OS 525 and WinCC/TM-OS operator systems. The CS 275 plant bus functions according to the token passing principle and can also have a redundant configuration. Several buses can be combined together using bus couplers such that bus networks are produced corresponding to the plant structure. The bus system is provided with distributed control. The bus interface of each subsystem may take over the master function according to specific criteria.

The AS 388/TM and AS 488/TM automation systems and the OS 525 and WinCC/TM-OS operator systems can be connected to the PROFIBUS-TM plant bus. The PROFIBUS-TM is characterized in that it complies with the modern PROFIBUS communication standards to EN 50170 but also uses the TELEPERM M communication mechanisms of the CS 275 (AKS, BKS, MKS and PL/PS telegrams) at the user level (link between bus interface and application).

The PROFIBUS-TM plant bus also operates according to the token passing principle. It can be designed as an electrical or optical network. The two network instructions can also be mixed together. PROFIBUS-TM is preferably used for new systems or partial systems.

The CS 275 and PROFIBUS-TM buses can be connected together by a CS-L2 bridge, thus permitting linking of existing systems and new systems.

Note:

Information systems, computers from other manufacturers, personal computers and gateways can be connected to the CS 275 plant bus. Personal computers with the Win TM software package can also be connected to PROFIBUS-TM.

1/2 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

Brief description

|

|

WinCC/TM-OS |

|

|

WinCC/TM-OS |

|

|

SIMATIC PCS 7 |

||||||||||

|

|

operator |

|

|

operator |

|

|

operator |

||||||||||

|

|

terminals |

|

|

terminals |

|

|

terminals |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terminal bus |

|

|

WinCC/TM- |

PROGRAF AS+ |

WinCC/TM- |

OS server |

OS server |

configuring |

OS server |

SIMATIC |

incl. WinCC/TM-CS 275 |

software |

incl. WinCC/TM- |

PCS 7 |

|

|||

|

Bridge |

PROFIBUS |

|

CS 275 |

|

|

|

|

|

PROFIBUS-TM |

AS 235 |

|

AS |

|

|

488/TM |

|

DP |

ET 200M |

|

- |

|

I/O modules |

PROFIBUS |

|

TELEPERM M |

|

|

AS |

AS |

AS 414/ |

488/TM |

388/TM |

AS 416 / AS 417 |

-DP |

-DP |

-DP |

|

PROFIBUS |

PROFIBUS |

PROFIBUS |

TELEPERM M |

|

|

|

I/O modules |

|

|

|

|

TELEPERM M |

SIMATIC PCS 7 |

||

Fig. 1/1 System configuration for the TELEPERM M process control system, with migration to the SIMATIC PCS 7 process control system

Functions of the AS 235 system

The AS 235, AS 235 H and AS 235 K automation systems provide all I & C functions such as measurement, supervision, calculation, closed-loop control and open-loop control, also particularly taking into account batch processes. The automation systems also handle the tasks for local operation and monitoring, e.g. display, signalling, alarm output, process operation and logging.

The AS 235 and AS 235 K only differ in their design. The AS 235 system is fitted in a cabinet, the AS 235 K system in a wall housing. The AS 235 H system with a redundant central unit is provided for applications with particularly high availability demands.

A large range of dedicated function blocks is available for solving I & C tasks in the AS 235, AS 235 H and AS 235 K automation systems. “Programming” of the automation systems is thus made extremely simple since the function blocks present in the system memory need only be activated by entering configuring instructions and parameters.

In addition, the AS 235, AS 235 H and AS 235 K permit the use of additional languages for special tasks - such as optimization, startup and shutdown of open-loop controls - which are difficult to solve using the existing function blocks or the batch functions. The TML process language (TELEPERM M Language) is available for analog and binary processing operations, as well as the STEP M control language already known from the SIMATIC industrial automation system. TML/STEP M can be used to define new function blocks optimally tailored to the respective task. Despite an extremely high degree of freedom, the clear and transparent “Block technology” is not relinquished. Frequently occurring block combinations can be combined into socalled Typicals and can then be used just like a single block.

A wide range of input and output modules is available for the AS 235, AS 235 H and AS 235 K systems as the interface to the process.

Intelligent I/O modules, e.g. modules which can carry out closed-loop control functions on their own, make it possible to configure a subordinate individual single-loop control level. This increases the availability of the automation system even further.

Further to this, the process interface is supplemented in particular for power applications or distributed small systems by sys- tem-compatible coupling of SIMATIC components.

The AS 235, AS 235 H and AS 235 K systems have either one or two autonomous operation channels for local operation and monitoring. This means that the process operation keyboard, process monitor and printer can be connected to each of the two operation channels and carry out operation and monitoring functions independent of one another.

In addition to the standardized displays which are achieved by addressing the automation function blocks without carrying out any further configuring, the user can also configure free displays. A standardized display is e.g. the loop display for operation of a control loop, a free display is the schematic representation of plant components (flowcharts) in their respective process status.

The local operation devices may be omitted when using central operation and monitoring in a network configuration.

Configuring

Configuring includes the incorporation of the automation structure into the automation system by using configuring instructions, by specifying parameters, by programming with TML and STEP M if applicable, and the feedback documentation.

This is possible either without an additional programming device/personal computer directly on the automation system (direct configuring, input/output using lists) or by using a PROGRAF AS+ engineering tool on a programming device/PC. Both configuring methods can be used

•locally for one automation system or

•centrally from one AS 235 system or one PC with PROGRAF AS+ for bus-coupled systems.

Siemens PLT 111 · 1999 |

1/3 |

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

System data

General system data 1)

Permissible ambient temperature

• Modules |

0 to 70 °C |

|

|

– Operation |

|

||

– |

t/h |

Max. 10 K |

|

– |

t/min |

Max. 0,5 K |

|

– Transport and storage |

-40 to +70 °C |

||

• Cabinet (operation) |

|

|

|

Cabinet ambient temperature at |

|

|

|

1 m above cabinet base |

0 to 40 °C |

|

|

Reduction in specified temperature |

10 K/1000 m |

|

|

above 1000 m above sea level |

|

|

|

Permissible humidity |

Operation |

Storage |

|

– Annual average |

Max. 75 % |

Max. 65 % |

|

– On 30 days/year |

Max. 95 % |

– |

|

– On 60 days/year |

– |

Max. 85 % |

|

Condensation not permissible |

|

|

|

Mechanical ambient conditions |

|

|

|

Operation stress |

|

|

|

|

|

||

(modules in subrack) |

|

|

|

– 10 to 60 Hz |

0.15 mm deflection |

||

– 60 to 500 Hz |

2 g acceleration |

||

System cabinet |

|

|

|

– 10 to 58 Hz |

0.035 mm deflection |

||

– 58 to 500 Hz |

0.5 g acceleration |

||

Transport stress |

|

|

|

|

|

||

(modules in subrack) |

|

|

|

– 5 to 8 Hz |

7.5 mm deflection |

||

– 8 to 500 Hz |

2 g acceleration |

||

Design, earthing conditions |

|

|

|

Potential difference between all |

Max. 7 V |

|

|

ground star points of distributed |

|

|

|

systems |

|

|

|

Insulation |

According to VDE 0160 |

||

Protection class |

Class l |

|

|

Insulation of modules, clearances and |

According to VDE 0110 |

||

creepage distances from pin to pin or |

|

|

|

from conductor to conductor |

|

|

|

Signal data |

|

|

|

(interface to field level) |

|

|

|

• Binary signals |

|

|

|

DC voltage |

Referred to M potential |

||

Signal definition |

|

|

|

Inputs |

Outputs |

||

– L (low) |

-30 to +4.5 V |

0 to 2.5 V |

|

– H (high) |

+13 to +33 V |

L+ to |

|

|

|

|

(L+ - 2.5 V) |

Input currents |

|

|

|

– Electronic transmitters |

0.5 mA |

Typical values for |

|

– Contacts |

4 mA |

configuring |

|

Output currents with DC 24 V |

8.5 mA/100 mA/120 mA |

||

Power signals |

Max. 400 mA |

||

Binary signal outputs |

Short-circuit-proof and |

||

|

|

overload-proof |

|

|

|

|

|

General system data

• Analog signals |

|

DC voltage |

Referred to MZ |

– Rated range of use |

-10 to +10 V |

|

-10 to 0 V |

|

0 to +10 V |

– Overflow range |

|

-10.5 to +10.5 V |

|

– Input resistance |

100 kΩ |

– Output loading capacity |

1 mA |

Direct current |

Referred to M |

– Rated range of use |

0 to 20 mA or 4 to 20 mA |

– Overflow range |

0 to 21 mA or 3.7 to 21 mA |

– Input resistance |

12.5, 50 or 350 Ω |

– Rated output load |

500 or 600 Ω |

Analog signal outputs |

|

Short-circuit-proof and over- |

|

|

load-proof |

Overvoltage resistance of binary and |

Class II |

analog inputs and outputs according |

|

to IEC information 255-4 (Fig. 1/2) |

|

|

|

Fig. 1/2 Overvoltage resistance / dynamic destruction limit

1)Deviations possible in individual cases. Refer to technical data of individual components

1/4 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

System data

Technical data of automation systems |

Technical data of automation systems (continued) |

Central unit |

|

Central processor |

Microprogrammed |

Arithmetic unit processing width |

32 bit |

Process execution levels |

5 |

• Acyclic |

2 (alarm and background levels) |

• Cyclic |

|

2 (125 ms, 1 s) and communica- |

|

|

tion level |

|

|

Memory (EDC) |

1-bit correction when reading |

Interface to central processor |

16 bit wide |

Main memory (RAM) |

4000 kbyte |

Memory for system software (RAM) |

1 Mbyte |

Memory backup time (RAM) Tmin |

480 h |

Input and output devices

Operation unit

•Number of operation units which can be used simultaneously

Process monitor

•Vertical frequency

•Horizontal frequency

•Video signals

Graphic display

•Semi-graphics

•Format

•Colors

•Resolution

•Message line

•Working field

•Input line

Configuring unit

Mini floppy disk unit

•Diskette format

•Max. storage volume per diskette

Logging printer/message printer

•Number of logging/message printers which can be operated simultaneously

•Format

•Printing speed with normal font

1 process monitor

1 process operation keyboard

2

50 Hz non-interlaced

15.625 kHz

RGB with SYNC in green channel

32 lines with 64 characters each

8

High-resolution

1

29 lines

1, for configuring

1 configuring keyboard,

1 mini floppy disk unit

5.25 inch

1 Mbyte

Needle and ink-jet printers

2 / 2

DIN A4 (80 characters/line) or DIN A3 (136 characters/line)

300 characters/s

Power supply for AS

Supply voltage

•Redundant supply

•Permissible range including ripple

Permissible ripple (DC 24 V systems)

Limiting range of use (DC 24 V systems)

Voltage dip with UN=24 V (DC 24 V systems)

External fusing required

Current consumption of basic unit/ basic system (typical value without I/O modules)

Power consumption (basic unit/system)

Permissible thermal load in cabinet (for AS 235 and AS 235 H)

•Without heat exchanger 1)

–Without fan subassembly

–With fan subassemblies

•With heat exchanger and fan subassemblies

Heat to be dissipated from housing (only AS 235 K)

Degree of protection EN 60 529

•Standard cabinet without heat exchanger

•Standard cabinet with heat exchanger

•Sheet-steel housing

•Subrack

Impairment of function by gases

DC 24 V

(AS 235 K also

AC 50/60 Hz, 230 V)

With AS 235 H and AS 235 K, DC 24 V; as option with AS 235

DC 20.8 to 33 V (AS 235 and AS 235 K, DC 24 V)

DC 21.6 to 31 V (AS 235 H)

15 % of mean DC value within the permissible range

35 V ≤ 500 ms

45 V ≤ 10 ms

0 V ≤ 5 ms, recovery time 10 s

–Max. 80 A with I/O modules (AS 235 and AS 235 H)

–25 A (AS 235 K, DC 24 V)

–10 A (AS 235 K, AC 230 V)

5.5 A (AS 235)

8.5 A (AS 235 H)

6.5 A (AS 235 K, DC 24 V)

1.0 A (AS 235 K, AC 230 V)

–Max. 160 W (AS 235, without I/O modules)

–Max. 200 W (AS 235 H, without I/O modules)

–Max. 220 W (AS 235 K, DC 24 V, with I/O modules)

–Max. 330 VA (AS 235 K,

AC 230 V, with I/O modules)

Max. 350 W

Max. 700 W

Max. 1000 W

Max. 200 W |

|

AS 235/235 H |

AS 235 K |

IP 20 |

– |

IP 54 |

– |

– |

IP 21 |

IP 00 |

IP 00 |

Industrial atmospheres for occupied rooms are permissible

1) With cabinet inlet temperature 40 °C

Siemens PLT 111 · 1999 |

1/5 |

This catalog is out of date, see note on page 1

TELEPERM M

Introduction

System data

Technical data of automation systems (continued)

I/O modules |

|

|

Function modules/calculation mod- |

Autonomous closed-loop and |

|

ules |

individual control drive modules |

|

|

or user-configured with own |

|

|

microprocessor |

|

Signal modules |

|

|

Binary and analog |

||

Counter modules |

Metered pulse module, pro- |

|

|

portioning counter module |

|

Coupling modules |

For SIMATIC S5/S7 peripheral |

|

|

I/O modules and devices, and |

|

|

for subordinate devices and sys- |

|

|

tems |

|

Max. number of I/O modules |

90 / 1141) |

(AS 235) |

|

91 / 1031) |

(AS 235 H) |

|

6 / 1081) |

(AS 235 K) |

|

|

|

Typical quantity breakdown |

|

|

Control loops |

30 to 80 |

|

Additional analog-value monitoring |

50 to 120 |

|

Sequential controls |

5 to 15 |

|

Logic controls |

100 to 250 |

|

Any number of flowcharts (up to 8 |

|

|

colors) and individually formatted |

|

|

logs |

|

|

Dimensions / weight |

|

|

Dimensions (H x W x D) in mm |

|

|

• Standard cabinets |

|

|

|

|

|

– With degree of protection IP 20 |

2200 x 900 x 400 |

|

– With degree of protection IP 20 |

2200 x 900 x 600 |

|

and IP 54 |

|

|

• Housing with degree of protection |

820 x 600 x 360 |

|

IP 21 |

|

|

Weight |

|

|

• AS 235 / AS 235 H |

200 to 250 kg 2) |

|

• AS 235 K (DC) |

77 kg 3) |

|

AS 235 K (AC) |

85 kg 3) |

|

|

|

|

1)When used with ES 100 K extension system

2)Typical value, depends on configuration with I/O modules

3)Without I/O modules

1/6 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

System architecture

|

2/2 |

Performance characteristics |

|

2/4 |

Redundancy with AS 235 H |

Configuring |

|

|

|

2/5 |

Standard function blocks |

|

2/10 |

User function blocks |

|

|

|

Siemens PLT 111 · 1999 |

2/1 |

This catalog is out of date, see note on page 1

System architecture

Performance characteristics

Performance characteristics

The AS 235, AS 235 H and AS 235 K systems are programmable automation systems of the TELEPERM M process control system based on function blocks. They have a different design and availability, but the same range of functions. The AS 235 K system is fitted in a wall housing, the AS 235 and AS 235 H systems are fitted in cabinets. The AS 235 H automation system has a redundant central unit to satisfy particularly high demands placed on the availability.

The systems can either be used on their own with local operation and monitoring, or coupled in system networks with central operation and monitoring.

System configuration

The automation systems consist of:

•A basic unit (AS 235, AS 235 H) or a basic system (AS 235 K)

•ES 100 K extension systems (wall housing) or extension units (for fitting in cabinets) as extension for configuring with input/ output modules.

Standard input/output devices enable local communication with the automation system during the configuring and commissioning phases as well as during later operation. The following can be connected:

•54-cm (21-inch) process monitors

•Process operation keyboard and configuring keyboard, max. 2 of each for 2 independent operating consoles

•Max. 4 logging printers

•1 mini floppy disk unit for booting the system memory and for loading/saving the user memory.

Basic system/basic unit

The basic unit (AS 235, AS 235 H) or the basic system (AS 235 K) mainly contains

• the power supply modules,

I/O modules

There are the following groups of I/O modules:

•Signal modules

•Function modules

•Calculation modules

•Coupling modules.

Signal modules are required for input and output of the process signals, usually without further processing (exception: adaptation of characteristic with temperature measurements).

Function modules (closed-loop control modules) and calculation modules have additional performance features which are independent of the central unit of the automation system and which can be used to increase the total processing performance or the availability by transferring backup functions should the central unit of the automation system fail.

The calculation modules enable the configuring of individual user functions.

Coupling modules enable the connection of I/O modules over larger distances. They additionally enable use of non-intelligent I/O modules of the SIMATIC S5 programmable controllers, plus the ET 100U distributed I/Os for the automation systems.

Memory, configuring

The memory with battery backup of the automation systems is divided into:

•a system memory and

•a user memory.

The write-protected system memory contains the software which always belongs to the automation system, in the form of basic programs and function blocks. Far more than 100 standardized blocks are available for data acquisition, closed-loop control, open-loop control, calculation, supervision, logging, display and operation/monitoring.

•the central processor module,

•a memory module with user memory with 4,000 Kbyte capacity and battery backup and

•the interface modules for the input and output devices and the CS 275 bus system,

each of which is redundant in the AS 235 H system.

The central processor is microprogrammed and has a maximum processing width of 32 bits. Three basic cycles are present for processing (125 ms, 1 s and background level). An acyclic mode can also be defined.

The basic unit of the AS 235 and the basic system of the

AS 235 K each has 6 slots for I/O modules. No I/O modules can be plugged into the basic unit of the AS 235 H systems.

The following can be fitted into the systems as standard:

• AS 235 |

Max. 90 |

I/O modules |

|

(basic unit + 6 extension units) |

|

• AS 235 |

H Max. 91 |

I/O modules |

|

(7 extension units) |

|

• AS 235 |

K Max. 108 I/O modules |

|

(basic system + eight ES 100 K extension systems)

Instead of programming the system with individual commands and carrying out the required program tests, it is only necessary in the TELEPERM M process control system to configure these complete function blocks in order to obtain a “user program”. In the simplest case, configuring means calling the function blocks with the keyboard, several times if necessary, and then assigning the respective linking instructions and parameters. The resulting application-oriented configuring data are then stored in the user memory.

Configuring is possible before the automation system is started up as well as during operation. It is possible to temporarily switch partial functions of the user system out of operation for this purpose.

Convenient configuring using graphic inputs is possible using the PROGRAF AS+ engineering tool which can be executed in a personal computer connected locally to the AS 235/235 H/235 K automation system or centrally to the CS 275 bus system.

The number of usable I/O slots with the AS 235 and AS 235 H can be increased by additional use of ES 100 K extension systems:

•AS 235 Max. 114 I/O modules

•AS 235 H Max. 103 I/O modules

2/2 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

System architecture

STEP M

In addition to the function blocks for binary processing, the AS 235/235 H/235 K systems can use the STEP M control lan-

guage, without leaving the block configuration, in order to formulate extensive and complex open-loop control tasks.

TML language

The TML process language can be used in addition to the firmware blocks for special tasks. It can be used to format special function blocks and to implement particularly complex functions, e.g. for the mixing of binary value arithmetic and measured value arithmetic.

Operation and monitoring

The AS 235, AS 235 H and AS 235 K systems have either one or two autonomous operation channels for local operation and monitoring. This means that process operation keyboards, printers and process monitors can be connected in duplicate and operated using operation/monitoring functions which are independent of one another. Some of the local operation devices can be omitted in the case of central operation and monitoring with a network configuration.

Scope of performance

The user RAM of the automation systems has a memory capacity of 4,000 Kbytes. This means that even one single system can already implement larger automation tasks. Even the data quantities encountered with extensive batch processes can be handled. If it is taken into account that various tasks occur mixed together, the performance is approximately as follows:

•30 to 80 control loops

•50 to 120 additional analog-value monitoring functions

•5 to 15 sequential controls

•100 to 250 logic controls

•Any number of flow charts (up to 8 colors) and individually designed logs.

Performance characteristics

Summary of system properties

•Automation system for autonomous operation with local communication or for network operation with central communication

•Fitted in wall housing or cabinet

•Configurable within wide limits

(up to 114 I/O modules depending on system)

•User memory up to 4,000 Kbytes on one module

•32-bit processing of analog values

•Optimized data transfer rate resulting from separate processing of analog and binary values

•Central unit redundant as option with synchronous processing of clocks (AS 235 H)

•Operation without fans possible

•Complete range of standard function blocks

•User function blocks with convenient TML programming language, also STEP M programming language for open-loop control tasks

•Configuring/programming either online without programmer (using lists) or with PC (using graphics)

•Local or central configuring (via bus)

Siemens PLT 111 · 1999 |

2/3 |

This catalog is out of date, see note on page 1

System architecture

Redundancy with AS 235 H

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CS 275 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

plant bus |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Central |

|

|

Synchronization |

|

|

Central |

|

|

|

|

|

|||||||

|

processing |

|

|

|

|

|

|

|

processing |

|

|

|

|

|

||||||

|

|

unit I |

|

|

|

|

|

|

|

|

unit II |

|

|

|

|

|

||||

|

|

|

|

Comparison, |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

cross-coupling |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Redundant I/O bus |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Comparison, |

|

|

|

Comparison, |

|

|||||||

|

|

|

|

|

|

|

|

switchover |

|

|

|

switchover |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I/O bus |

|

|

|

|

|

|

I/O bus |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

I/O |

|

|

|

|

|

|

I/O |

|

|

|

|

||

|

|

|

|

|

|

modules |

|

|

|

|

|

modules |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process level

Redundant path

Redundant path

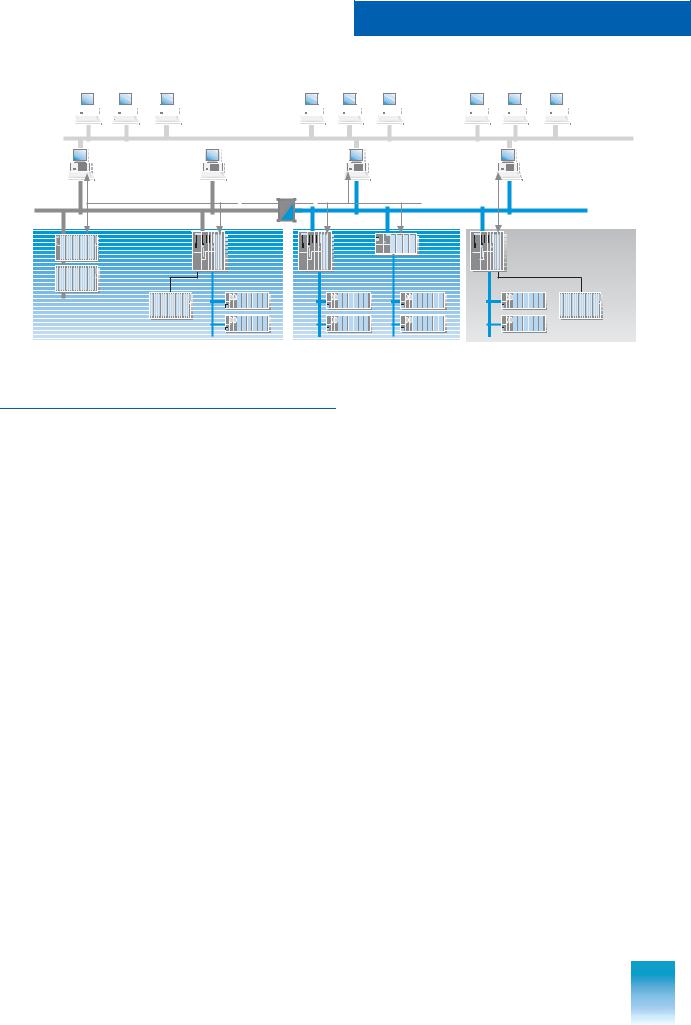

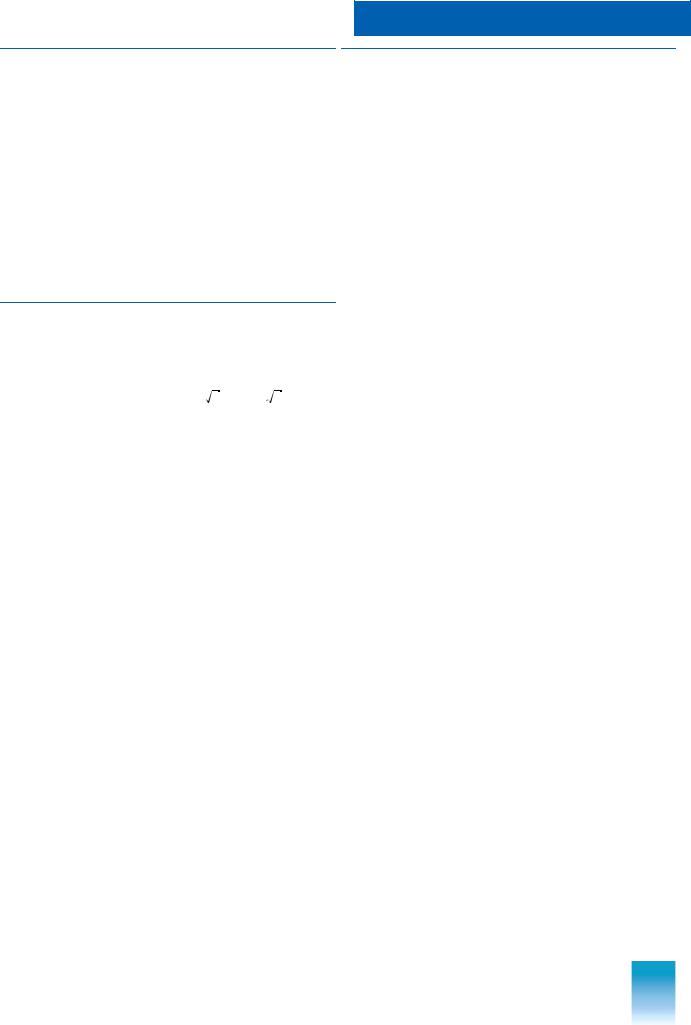

Fig. 2/1 1-out-of-2 redundancy structure with AS 235 H

Redundancy with the AS 235 H automation system

Various system characteristics must be considered with regard to the reliability and availability of a system. The requirements for reliability are met by fault-tolerant (high-availability) systems while those for safety are met by fail-safe systems.

According to VDI/VDE 3542 the following applies:

A system is fault-tolerant if occurring faults have no effect on its function. Fail-safe is the ability of a technical system to remain in a safe mode or to switch immediately to another safe mode in the event of a fault.

The AS 235 H automation system is a high-availability system with redundant central units operating with system clocks where execution of the planned automation functions is not interrupted by system faults.

The system operates according to the fault-tolerant 1-out-of-2 principle. The AS 235 H system is equipped with 2 identical central processing units for this purpose, the master unit and the slave unit (Fig. 2/1). Each of the two CPUs contains a power supply module, central processor, memory module for system software and user program as well as 1 or 2 interface modules for the I/O bus depending on the number of I/O modules connected. The user programs stored in the 2 memory modules are identical.

Process signals are always applied to both CPUs. Only one of these, the master unit, can output commands to the process via the I/O modules. The other operates in hot standby mode and is always able to take over smooth control of the process should the master unit fail.

The fully-synchronous mode of operation of the two partial

AS 235 H systems means that any assignment of the master is possible: master/slave or slave/master. Both partial systems are updated with the same information simultaneously because all input data are applied to both, meaning that online backup data transmission between the two partial systems is superfluous.

Central faults are detected very rapidly using a hardware comparator. This compares the redundant bus signals for each read or write operation of the central processors operating with synchronous clocks. Software test programs are started in the event of a fault in order to established its location.

The synchronous signals of the redundant I/O bus are checked for equality for selective areas of up to 13 I/O modules each and converted to the single-channel I/O bus of the standard I/O modules. Up to 3 selected I/O module areas can be supplied by the redundant I/O bus (A), a further 4 selected I/O module areas can be supplied by extending with a redundant I/O bus 2 (B). A strict division into fault limiting regions thus ensures that single faults can only have an effect within one selective I/O module area.

The AS 235 H system enables maintenance and repair without interfering with process operations. The corresponding partial system, irrespective of whether it is the master or slave, is removed from the synchronous operation. The partner system then retains the master status, or is assigned it automatically, and thus handles the active process operations. The disabled, passive partial system now operates completely independently, but without the I/O modules since these are required by the master.

This simplex operation with 2 independent systems enables new user programs to be configured, loaded or tested and to operate on the process either on a trial basis or permanently. This flexibility prevents undesirable down times in the process when changing the automation structure.

The backup of a passive partial system (transition from simplex to duplex operation with a slave system ready for operation) is initiated by the operator and is executed without influencing the online processing of the master system. It is terminated by automatic synchronization. The second partial system is then the slave and is ready to accept the master status at any time.

When connected to the CS 275 bus system, the redundant AS 235 H system responds like a single participant.

The user software of the AS 235 H automation system is compatible with that of the AS 235 and AS 235 K systems, i.e. user configurations which have been generated on these systems and which function directly can also be used in the AS 235 H system without limitations.

Important note:

The AS 235 automation system has been optimized for high reliability and availability by means of fault tolerance and a non-interacting design. However, it does not belong – just like any other single or redundant programmable system – to the class of special fail-safe systems approved by independent testing authorities (e.g. TÜV).

It is therefore important when automating processes or process sections relevant to safety to ensure that suitable subordinate interlocking circuits or protective systems are provided for these areas in the AS 235 H system as in the

AS 235 / AS 235 K systems which make a dangerous operating state impossible should faults occur in the automation system.

2/4 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

System architecture

Configuring

Standard function blocks

Standard function blocks |

Blocks for binary processing |

Dedicated function blocks are present in the automation systems to solve the control tasks. These are the so-called standard function blocks. The AS 235, AS 235 H and AS 235 K systems have the same standard function blocks for data acquisition, closed-loop and open-loop control, calculation and monitoring.

The standard function blocks present in the system software are activated by engineering tools using configuring instructions. The blocks are combined into an automation structure which is processed cyclically, and sometimes acyclically, by the central processor of the automation system.

The configuration of the automation structure is usually generated graphically using the PROGRAF AS+ configuring tool (see also page 2/9).

The following tables list the standard function blocks divided according to their areas of application.

Blocks for analog and digital processing

Type |

Designation |

Function |

|

SUM |

Adder |

Y = X1 + X2 - X3 - X4 |

|

MUL |

Multiplier |

Y = X1 · X2 |

|

DIV |

Divider |

Y = X1/X2 |

|

|

|

|

|

RAD |

Square-root extractor |

Y = |

X or Y = K X |

LN |

Logarithm extractor |

Y = KF · Ioge | X | |

|

EXP |

Exponential value |

Y = ex |

|

ABS |

Absolute value |

X = | X | |

|

|

|

|

|

INT |

Integrator |

Y = K · X dt, K = 1/T |

|

DIF |

Differentiator |

Y(s)/X(s) = (T·s)/(1 + (T·s/v)) |

|

PT |

|

|

|

Delay |

Y(s)/X(s) = 1/(1 + T·s) |

||

TOZ |

Dead time |

Y(s)/X(s) = e-s·T |

|

MIN |

Minimum-value |

Y = minimum of X1, X2, X3 |

|

|

selector |

|

|

MAX |

Maximum-value |

Y = maximum of X1, X2, X3 |

|

|

selector |

|

|

TOB |

Dead band |

Y = X-TOBU for X < TOBU |

|

|

|

0 |

for TOBU ≤X ≤TOBO |

|

|

X-TOBO for X > TOBO |

|

PLG |

Function generator |

Linear interpolation between 6 |

|

|

|

pairs of turning points |

|

GW |

Limit monitor |

Limit check between two switch- |

|

|

|

ing points |

|

ASL |

Analog-value switch |

Y = X1 for S = “0” |

|

|

|

Y = X2 for S = “1” |

|

SPEI |

Analog-value mem- |

Storage of up to 256 analog val- |

|

|

ory |

ues |

|

|

|

|

|

Type |

Designation |

Function |

||

VU |

AND |

A = E1 E2 E3 |

||

VO |

OR |

A = E1 E2 E3 |

||

VN |

Negation |

A = |

|

|

E |

||||

VM |

Flag |

Flag of binary input signals (flip- |

||

|

|

flop) |

||

VZ |

Time delay |

Switch-on and switch-off delays |

||

VS + STEP |

STEP M block |

Freely programmable in STEP M |

||

MPX |

Multiplexer |

To supply the STEP commands in |

||

|

|

the following VS/KS block |

||

BW |

Binary selection |

Selection of status combination |

||

|

|

from up to 3 binary signals |

||

INKU |

Incremental con- |

Converts analog value into an |

||

|

verter |

open or close pulse |

||

BCE |

BCD input |

Conversion of a BCD signal into |

||

|

|

an analog value |

||

BCA |

BCD output |

Conversion of an analog value |

||

|

|

into a BCD signal |

||

KA |

Sequence start |

Marks the start of an ON/OFF |

||

|

|

branch of a subgroup control |

||

KAK |

|

As KA, but with additional func- |

||

|

|

tions |

||

|

|

|

|

|

KB |

Sequence |

Conditions of a control step, for |

||

|

|

power plants |

||

KBK |

|

As KB, but with additional func- |

||

|

|

tions |

||

KS |

Sequence step |

As KB, for process plants |

||

KV |

|

|

||

Sequence branch |

Branch of a sequence into a max- |

|||

|

|

imum of 6 branches, with process |

||

|

|

plants |

||

KE |

Sequence end |

Last block in a sequence |

||

KEK |

|

As KE, but with additional func- |

||

|

|

tions |

||

HA |

Auxiliary oil auto- |

Controls electric auxiliary oil |

||

|

matic unit |

pumps for oil supply to generator |

||

|

|

sets |

||

HUP |

Horn block |

Triggers signalling equipment |

||

|

|

(optical and audible) |

||

EAR |

Individual analog- |

Allocates analog values from out- |

||

|

value allocation |

puts in GA blocks |

||

EBR |

Single-bit allocation |

Links individual binary outputs to |

||

|

|

GB/GM data blocks |

||

UBR |

Universal binary |

Links 16 binary outputs to GB/ |

||

|

location |

GM data blocks |

||

|

|

|

|

|

Siemens PLT 111 · 1999 |

2/5 |

This catalog is out of date, see note on page 1

System architecture

Configuring

Standard function blocks

Blocks for processing with standardized operation and monitoring

Type |

Designation |

Function |

RClosed-loop controlPID control, e.g. for disturbance

|

ler |

variable feedforward, tracking of |

|

|

setpoint and manipulated vari- |

|

|

able, limit formation |

RN |

|

As R, |

|

|

with additional functions |

|

|

|

M |

Measured-value |

Monitors a measured value for 3 |

|

monitoring |

pairs of limits |

|

|

Extension of a closed-loop con- |

|

|

trol block for limit monitoring |

|

|

Limitation of measured value at |

|

|

the error limits |

V |

Ratio |

Generation of a ratio, e.g. with a |

|

|

ratio control |

|

|

Proportional adjuster, e.g. with |

|

|

synchronization control or to influ- |

|

|

ence the command variable in a |

|

|

cascade |

B |

|

|

Operation block |

Display of analog values (internal |

|

|

|

result of calculations, ...) |

|

|

Access to analog and binary val- |

|

|

ues (input of constants, ...) |

S |

Control unit |

Operation and monitoring of a |

|

|

sequence in process plants |

G |

Subgroup control |

Operation and monitoring of |

|

|

sequences in power plants |

GK |

Group control |

As G, |

|

with additional functions |

|

A |

Output for binary |

Display of and access to a binary |

|

data |

value |

F |

Window block |

Display of 5 measured values; |

|

|

each of the 5 values is monitored |

|

|

for a pair of limits |

FN |

Window block |

Display and limit monitoring of 5 |

|

|

measured values; |

|

|

input of 5 pairs of limits each with |

|

|

hysteresis as well as 5 ranges for |

|

|

the measured value display |

T |

Trend 1) |

Display of the trend of 2 mea- |

|

|

sured values as a bargraph; time |

|

|

base between 1.625 s and 36 h |

SR |

Recorder 1) |

Summary of up to 4 series of |

|

|

measurements, displayed on |

|

|

screen as dashed-line curves; |

|

|

4 pairs of limits for monitoring the |

|

|

measured values |

C |

Selector |

To switch over binary signals, |

|

|

e.g. manual/automatic mode |

PKM |

Alarm acquisition |

Acquires planned alarms from |

|

|

binary input module/GB block |

PKF |

Alarm sequence dis- |

Output of PKM alarms; new |

|

play 1) |

alarms of PKM blocks, display of |

|

|

alarm history |

|

|

|

|

|

|

1) Displays in PROGRAF AS+

Data blocks

Type |

Designation |

Function |

GA |

Data block for global |

Storage of 256 analog values |

|

analog values |

with error 10-9; |

|

|

storage of process image, histor- |

|

|

ical values etc. |

GB |

Data block for global |

Storage and scanning of 256 |

|

binary values |

binary values; |

|

|

especially for binary process |

|

|

inputs and outputs |

GM |

Data block for global |

Storage and scanning of 256 |

|

flags |

internal binary statuses |

GT |

Data block for global |

Storage and generation of times/ |

|

times (timer) |

timers for execution of time- |

|

|

dependent functions |

FA |

Data field block for |

Storage of internal/external ana- |

|

analog values |

log values with error 10-9; |

|

|

especially for internal results |

FSA |

Data field block for |

Storage of internal/external ana- |

|

analog values |

log values with error 10-4; espe- |

|

|

cially for internal results |

FB |

Data field block for |

Storage of internal/external |

|

binary data |

binary values; extension of GB/ |

|

|

GM blocks |

|

|

|

FC |

Data field block for |

Storage of characters (texts) |

|

characters |

|

|

|

|

Blocks for signal exchange via CS 275

Type |

Designation |

Function |

AKS |

Analog coupling and |

Transmission of up to 28 analog |

|

transmitter block |

values and abbreviated time |

|

|

(minutes and seconds) from an |

|

|

AS 235 system to a max. of 6 or |

|

|

32 receivers (AKE blocks) |

|

|

|

AKE |

Analog coupling and |

Reception of up to 28 analog val- |

|

receiver block |

ues via the CS 275 from the data |

|

|

set of an MKS block of another |

|

|

bus participant |

BKS |

Binary coupling and |

Transmission of up to 128 binary |

|

transmitter block |

signals and abbreviated time |

|

|

from an AS 235 to a max. of 6 or |

|

|

32 receivers (BKE blocks) |

BKE |

Binary coupling and |

Reception of up to 128 binary val- |

|

receiver block |

ues via the CS 275 from the data |

|

|

set of a BKS block of another bus |

|

|

participant |

ZKS |

Character coupling |

Transmission of up to four S16 |

|

and transmitter block |

strings from an AS 235 to up to 6 |

|

|

or 32 receivers (ZKE blocks) |

ZKE |

Character coupling |

Reception of up to four S16 |

|

and receiver block |

strings from another AS system |

MKS |

Alarm coupling and |

Transition of 32 binary signals as |

|

transmitter block |

alarms (with the time a signal |

|

|

changes from 0→1 or 1→0) to |

|

|

other bus participants |

MKE |

Alarm coupling and |

Reception of 32 binary signals of |

|

receiver block |

an MKS block and the time of |

|

|

transmission sent by another bus |

|

|

participant via the CS 275 |

SKS |

Status coupling and |

Transfer of status information to |

|

transmitter block |

higher-level systems (operator |

|

|

system, computer) |

|

|

|

PLPS |

Reading and writing |

Reading or writing of up to 20 |

|

of parameters |

parameters from a bus-coupled |

|

|

AS 235 system |

|

|

|

2/6 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

|

|

|

|

|

System architecture |

|||

|

|

|

|

|

|

Configuring |

||

|

|

|

|

|

Standard function blocks |

|||

|

|

|

|

|

|

|

||

Driver blocks for I/O modules |

|

|

|

|

|

|||

Type |

Designation |

Function |

For modules with |

|||||

|

|

|

|

|

|

Order No. |

||

|

|

|

|

|

|

|||

AE |

Analog input |

Acquisition of an analog signal via an analog input module channel (0 to 20 mA, |

6DS1 701-8AA, -8AB |

|||||

|

|

|

4 to 20 mA, 0 to ± 10 V; Pt 100 resistance thermometer, thermocouples) or an |

6DS1 730-8AA |

||||

|

|

|

analog input module of the SIMATIC S5 programmable controllers (instrument |

6DS1 731-8AA/-8BA/ |

||||

|

|

|

range U) |

-8EA/-8FA/-8RR + |

||||

|

|

|

6DS1 703-8AB, -8RR |

|||||

AR |

Analog input allocation |

Acquisition of 8 analog process variables, conversion into physical variables; |

||||||

6DS1 700-... |

||||||||

|

|

|

storage in GA blocks or direct linking |

6DS1 321-8AA 1) |

|

|||

AA |

Analog output |

Output of an analog signal via a channel of an analog output module or an ana- |

6DS1 702-8AA, -8RR |

|||||

|

|

|

log output module of the SIMATIC S5 programmable controllers (instrument |

6DS1 321-8AA 1) |

||||

range U)

BEI |

Binary input |

Acquisition of binary signals via a binary input module; |

|

|

storage of binary signals in GB block |

BRA |

Binary allocation |

Acquisition of 8 binary signals via a binary input module; |

|

|

allocation of signals to specified linking addresses |

6DS1 601-...

6DS1 602-...

6DS1 615-8AA

BAU |

Binary output |

Output of up to 32 binary signals to a binary output module |

6DS1 603-... |

|

|||

|

|

|

6DS1 604-8AA |

|

|

|

6DS1 605-8BA |

RZ |

Input block for two-channel |

Acquisition of analog and binary signals from a channel of a two-channel con- |

6DS1 402-... |

|

controller |

troller module |

6DS1 403-... |

RZA |

Output block for two-chan- |

Transfer of the manipulated variable increment Y or setpoint increment W |

|

|

nel controller |

from a closed-loop control block R or RN to a channel of a controller module |

|

BU8 |

Binary transmitter monitor- |

Acquisition and monitoring of 8 binary signals via a binary input module |

6DS1 620-8AA |

|

ing block |

|

6DS1 621-8AA |

BU16 |

Binary transmitter monitor- |

Acquisition and monitoring of 16 binary signals via a binary input module |

6DS1 600-8AA |

|

ing block |

|

|

ZE |

Metered pulse input |

Acquisition of a channel of a metered pulse input module |

6DS1 607-8AB |

DR |

Input/output for speed con- |

Acquisition of signals from the interface module, and transfer of signals to the |

6DS1 303-8AA 2) |

|

trollers |

interface module |

|

E110 |

Binary input for SIMATIC |

Reading in of 16 binary values from an interface module for input modules of |

6DS1 310-8AA/8AB 1) |

|

S5 input modules |

the SIMATIC S5-110 programmable controllers or for input modules of the |

6DS1 321-8AA 1) |

|

|

SIMATIC S5 programmable controllers (instrument range U) or for standard |

6DS1 600-8AA |

|

|

binary input modules |

6DS1 601-8BA |

|

|

|

6DS1 602-8.. |

|

|

|

6DS1 615-8AA |

A110 |

Binary output for SIMATIC |

Output of 16 binary values from an interface module for output modules of the |

6DS1 310-8AA/8AB 1) |

|

S5 output modules |

SIMATIC S5-110 programmable controllers or for output modules of the |

6DS1 321-8AA 1) |

|

|

SIMATIC S5 programmable controllers (instrument range U) or for standard |

6DS1 603-8.. |

|

|

binary output modules |

6DS1 604-8AA |

|

|

|

6DS1 605-8BA |

S5KE |

Coupling to S5 |

Acquisition of signals from the interface module via telegrams with point-to- |

6DS1 333-8AB 1) |

|

- receive |

point coupling |

|

S5KS |

Coupling to S5 |

Transfer of signals to the interface modules via telegrams with point-to-point |

6DS1 333-8AB 1) |

|

- transmit |

coupling |

|

AEF |

Analog input (field multi- |

Driver for acquisition of analog signals via the field multiplexer analog input |

6DS1 706-8AA |

|

plexer) |

modules 2) |

6DS1 710-8AA |

AAF |

Analog output (field multi- |

Driver for acquisition of analog signals via the field multiplexer analog output |

6DS1 711-8AA |

|

plexer) |

modules 2) |

6DS1 406-8AA/407-8AA |

BEF |

Binary input (field multi- |

Driver for acquisition of binary signals via the binary signal input modules of the |

6DS1 610-8AA |

|

plexer) |

field multiplexer and for acquisition of fault signals from the binary I/O modules |

6DS1 611-8AA |

|

|

of the field multiplexer 2) |

|

BAF |

Binary output (field multi- |

Driver for output of binary signals via the binary signal output modules of the |

6DS1 612-8AA |

|

plexer) |

field multiplexer 2) |

|

PRA |

Testable relay module |

Driver for output of 16 binary signals to a testable relay output module |

6DS1 606-8BA |

PBE |

Testable binary input |

Acquisition of binary signals via a testable binary input module, and transfer of |

6DS1 618-8CA |

|

|

the binary signals to binary-value fields |

|

|

|

|

|

1)Coupling module

2)No longer available

Siemens PLT 111 · 1999 |

2/7 |

This catalog is out of date, see note on page 1

System architecture

Configuring

Standard function blocks

Driver blocks for configurable TELEPERM ME I/O modules

Type |

Designation |

Function |

For modules with |

|

|

|

|

Order No. |

|

MSB |

Motor/valve and actuator |

Acquisition and transfer of binary signals to the binary generation module |

6DS1 717-8AA/-8RR |

|

|

control |

|

+ 6DS1 719-8AA/-8RR |

|

TVB |

Preselection and subloop |

Acquisition and transfer of binary signals to the binary calculation module for |

6DS1 717-8AA/-8RR |

|

|

control |

operation and monitoring of a preselection or subloop control |

|

|

BRBK |

Organization and binary |

Acquisition of binary signals from the flag area of the binary calculation module, |

6DS1 717-8AA/-8RR |

|

|

input/output block |

coordination together with ABR, MSB or TVB |

|

|

ABR |

Analog input and output |

Acquisition and transfer of analog signals to the analog extension module via |

6DS1 717-8AA/-8RR |

|

|

|

the binary calculation module |

+ 6DS1 720-8AA |

|

REN |

Analog/binary inputs and |

Acquisition and transfer of analog and binary signals of the analog calculation |

6DS1 715-8BB |

|

|

output |

module |

|

|

RSK |

Closed-loop control mod- |

Acquisition of signals from single-channel and two-channel configurable |

6DS1 408-8BB |

|

RSKB |

ule driver |

closed-loop control modules |

6DS1 410-8BB |

|

Operation block for RSK |

For operation and monitoring of configurable closed-loop control modules, |

6DS1 411-8AA/-8RR |

||

|

||||

|

6DS1 412-8AA/-8RR |

|||

|

block |

together with RSK block |

|

|

|

|

|

|

Driver blocks for I/O modules with standardized display

Type |

Designation |

Function |

For modules with |

|

|

|

Order No. |

RE |

Closed-loop controller, |

Acquisition of signals from single-channel closed-loop control modules; |

6DS1 400-8BA |

|

single-channel |

transfer of commands and standardized increments to the closed-loop control |

(S controller) |

RK |

|

modules |

6DS1 401-8BA |

|

As RE, with additional functions |

(K controller) |

|

|

|

|

|

EM |

Individual control drive, |

Acquisition of signals from individual control drive modules and application of |

6DS1 500-8BA |

|

motor |

signals to the binary outputs, e.g. for a subgroup control; transfer of commands |

6DS1 502-8BA |

|

|

to the individual control drive modules |

|

EU |

|

As EM, with additional functions |

|

EV |

Individual control drive, |

As EM, for the corresponding modules |

6DS1 501-8BA/-8BB |

EK |

valve |

As EV, with additional functions |

6DS1 503-8BA |

|

|

||

DZ |

Proportioning counter |

Acquisition of signals from proportioning counter modules (2/4 channels); |

6DS1 613-8BB |

|

|

connection of these signals to the block outputs; |

|

|

|

transfer of commands and standardized analog values |

|

EG |

Individual control drives |

Acquisition of signals from modules; |

6DS1 504-8AA |

|

(4 to 8 channels) |

connection of these signals to the binary outputs; |

6DS1 505-8AA |

|

|

transfer of commands |

|

FM |

Field multiplexer |

Acquisition of signals from a channel of the interface module for FM 100 field |

6DS1 304-8AA |

|

|

multiplexer 1); transfer of signals to the module |

6DS1 304-8BB |

1) No longer available

2/8 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

System architecture

Configuring

|

|

|

|

|

|

|

Standard function blocks |

|

|

|

|

|

|

|

|||

Output blocks for printer and process monitor |

Test blocks |

|

|

|

||||

Type |

Designation |

Function |

|

|

Type |

Designation |

Function |

|

GP |

Group display |

MEL |

Alarm output |

BILD |

|

Display output |

|

+LAYO |

|

PROT |

Log output |

+LAYO |

|

PKF |

Process coupling/ |

|

alarm sequence dis- |

|

play |

|

|

Design of display hierarchy: |

TANZ |

Test display |

Monitoring of binary and analog |

area display and group display |

|

|

variables; |

Output of planned plain text |

|

|

selective access to variables |

|

|

possible (max. 16 analog and 16 |

|

alarms with time (resolution 1 s); |

|

|

|

|

|

binary within a standard display) |

|

also standard blocks, such as M, |

|

|

|

TUEB |

|

|

|

generate alarms |

Test monitoring |

For sequence monitoring of TML |

|

Output of plant-specific displays |

|

|

programs for: |

|

|

• Cyclic sequence monitoring |

|

|

|

|

|

Output of plant-specific logs on |

|

|

• Non-recurring monitoring of a |

|

|

program run |

|

printers |

|

|

|

|

|

(up to 248 TML programs can be |

|

Output of PKM alarms |

|

|

|

|

|

monitored) |

|

|

|

|

|

|

SYST. |

Test and mainte- |

Menu-controlled calling of main- |

|

WART |

nance |

tenance programs: |

Organization blocks

Type |

Designation |

Function |

|

|

XB |

Processing, cyclic |

To inhibit/release a group of func- |

|

|

|

|

tion blocks and to release each |

|

|

|

|

n-th cycle |

|

|

XA |

Processing, acyclic |

To inhibit/non-recurring release a |

|

|

|

|

sequence of function blocks. |

|

|

|

|

When installed in the alarm level |

|

|

|

|

(ZYK 1) as an ALARM block: |

|

|

|

|

1 x execution of subsequent |

|

|

|

|

block sequence |

|

|

XZ |

|

|

|

|

Time start |

For time-dependent switching- |

|

|

|

FUTA |

|

on/off of XB blocks |

|

|

|

|

|

||

Function keys |

For switching-on/off of XA/XB |

|

|

|

|

|

blocks by operator input |

|

|

RNAM |

|

|

|

|

Rename |

Modification of type name or |

|

|

|

|

|

block name |

|

|

APRO+ |

TML connection |

To insert a user-specific TML pro- |

|

|

PROB |

(of PROBLEM |

gram into the execution list |

|

|

|

blocks) |

|

|

|

|

|

|

|

|

•XB switchover

•CS 275 coupling status

•Activate error messages

•TML

•Reloading and selective archiving

•System settings

Siemens PLT 111 · 1999 |

2/9 |

This catalog is out of date, see note on page 1

System architecture

|

2/2 |

Performance characteristics |

|

2/4 |

Redundancy with AS 235 H |

Configuring |

|

|

|

2/5 |

Standard function blocks |

|

2/10 |

User function blocks |

|

|

|

Siemens PLT 111 · 1999 |

2/1 |

This catalog is out of date, see note on page 1

System architecture

Performance characteristics

Performance characteristics

The AS 235, AS 235 H and AS 235 K systems are programmable automation systems of the TELEPERM M process control system based on function blocks. They have a different design and availability, but the same range of functions. The AS 235 K system is fitted in a wall housing, the AS 235 and AS 235 H systems are fitted in cabinets. The AS 235 H automation system has a redundant central unit to satisfy particularly high demands placed on the availability.

The systems can either be used on their own with local operation and monitoring, or coupled in system networks with central operation and monitoring.

System configuration

The automation systems consist of:

•A basic unit (AS 235, AS 235 H) or a basic system (AS 235 K)

•ES 100 K extension systems (wall housing) or extension units (for fitting in cabinets) as extension for configuring with input/ output modules.

Standard input/output devices enable local communication with the automation system during the configuring and commissioning phases as well as during later operation. The following can be connected:

•54-cm (21-inch) process monitors

•Process operation keyboard and configuring keyboard, max. 2 of each for 2 independent operating consoles

•Max. 4 logging printers

•1 mini floppy disk unit for booting the system memory and for loading/saving the user memory.

Basic system/basic unit

The basic unit (AS 235, AS 235 H) or the basic system (AS 235 K) mainly contains

• the power supply modules,

I/O modules

There are the following groups of I/O modules:

•Signal modules

•Function modules

•Calculation modules

•Coupling modules.

Signal modules are required for input and output of the process signals, usually without further processing (exception: adaptation of characteristic with temperature measurements).

Function modules (closed-loop control modules) and calculation modules have additional performance features which are independent of the central unit of the automation system and which can be used to increase the total processing performance or the availability by transferring backup functions should the central unit of the automation system fail.

The calculation modules enable the configuring of individual user functions.

Coupling modules enable the connection of I/O modules over larger distances. They additionally enable use of non-intelligent I/O modules of the SIMATIC S5 programmable controllers, plus the ET 100U distributed I/Os for the automation systems.

Memory, configuring

The memory with battery backup of the automation systems is divided into:

•a system memory and

•a user memory.

The write-protected system memory contains the software which always belongs to the automation system, in the form of basic programs and function blocks. Far more than 100 standardized blocks are available for data acquisition, closed-loop control, open-loop control, calculation, supervision, logging, display and operation/monitoring.

•the central processor module,

•a memory module with user memory with 4,000 Kbyte capacity and battery backup and

•the interface modules for the input and output devices and the CS 275 bus system,

each of which is redundant in the AS 235 H system.

The central processor is microprogrammed and has a maximum processing width of 32 bits. Three basic cycles are present for processing (125 ms, 1 s and background level). An acyclic mode can also be defined.

The basic unit of the AS 235 and the basic system of the

AS 235 K each has 6 slots for I/O modules. No I/O modules can be plugged into the basic unit of the AS 235 H systems.

The following can be fitted into the systems as standard:

• AS 235 |

Max. 90 |

I/O modules |

|

(basic unit + 6 extension units) |

|

• AS 235 |

H Max. 91 |

I/O modules |

|

(7 extension units) |

|

• AS 235 |

K Max. 108 I/O modules |

|

(basic system + eight ES 100 K extension systems)

Instead of programming the system with individual commands and carrying out the required program tests, it is only necessary in the TELEPERM M process control system to configure these complete function blocks in order to obtain a “user program”. In the simplest case, configuring means calling the function blocks with the keyboard, several times if necessary, and then assigning the respective linking instructions and parameters. The resulting application-oriented configuring data are then stored in the user memory.

Configuring is possible before the automation system is started up as well as during operation. It is possible to temporarily switch partial functions of the user system out of operation for this purpose.

Convenient configuring using graphic inputs is possible using the PROGRAF AS+ engineering tool which can be executed in a personal computer connected locally to the AS 235/235 H/235 K automation system or centrally to the CS 275 bus system.

The number of usable I/O slots with the AS 235 and AS 235 H can be increased by additional use of ES 100 K extension systems:

•AS 235 Max. 114 I/O modules

•AS 235 H Max. 103 I/O modules

2/2 |

Siemens PLT 111 · 1999 |

This catalog is out of date, see note on page 1

System architecture

STEP M

In addition to the function blocks for binary processing, the AS 235/235 H/235 K systems can use the STEP M control lan-

guage, without leaving the block configuration, in order to formulate extensive and complex open-loop control tasks.

TML language

The TML process language can be used in addition to the firmware blocks for special tasks. It can be used to format special function blocks and to implement particularly complex functions, e.g. for the mixing of binary value arithmetic and measured value arithmetic.

Operation and monitoring

The AS 235, AS 235 H and AS 235 K systems have either one or two autonomous operation channels for local operation and monitoring. This means that process operation keyboards, printers and process monitors can be connected in duplicate and operated using operation/monitoring functions which are independent of one another. Some of the local operation devices can be omitted in the case of central operation and monitoring with a network configuration.

Scope of performance

The user RAM of the automation systems has a memory capacity of 4,000 Kbytes. This means that even one single system can already implement larger automation tasks. Even the data quantities encountered with extensive batch processes can be handled. If it is taken into account that various tasks occur mixed together, the performance is approximately as follows:

•30 to 80 control loops

•50 to 120 additional analog-value monitoring functions

•5 to 15 sequential controls

•100 to 250 logic controls

•Any number of flow charts (up to 8 colors) and individually designed logs.

Performance characteristics

Summary of system properties

•Automation system for autonomous operation with local communication or for network operation with central communication

•Fitted in wall housing or cabinet

•Configurable within wide limits

(up to 114 I/O modules depending on system)

•User memory up to 4,000 Kbytes on one module

•32-bit processing of analog values

•Optimized data transfer rate resulting from separate processing of analog and binary values

•Central unit redundant as option with synchronous processing of clocks (AS 235 H)

•Operation without fans possible

•Complete range of standard function blocks

•User function blocks with convenient TML programming language, also STEP M programming language for open-loop control tasks

•Configuring/programming either online without programmer (using lists) or with PC (using graphics)

•Local or central configuring (via bus)

Siemens PLT 111 · 1999 |

2/3 |

This catalog is out of date, see note on page 1

System architecture

Redundancy with AS 235 H

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|