siemens 840Disl User Manual

SINUMERIK 840Di sl

Manual

Commissioning Manual

Valid for

SINUMERIK 840Di sl/840DiE sl control

Software |

Version |

System software for 840Di sl/DiE sl |

1.4 |

05/2008

6FC5397–4CP10–4BA0

Foreword

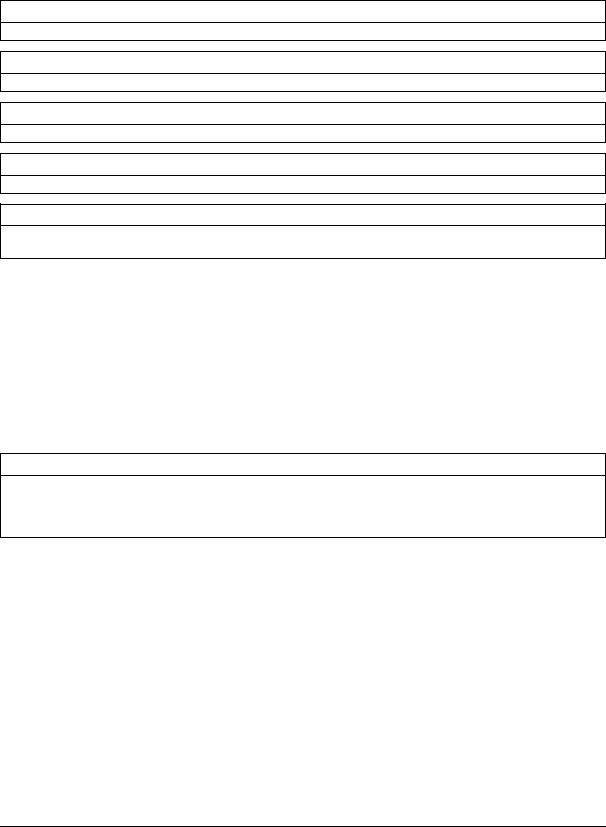

General Information on the |

|

|

1 |

||

SINUMERIK 840Di sl |

||

|

|

|

Hardware Descriptions |

2 |

|

|

|

|

Configuration |

3 |

|

|

|

|

EMC and ESD Measures |

4 |

|

|

|

|

Power-On and Power-Up |

5 |

|

|

|

|

PLC commissioning |

6 |

|

|

|

|

Ethernet communication |

7 |

|

PROFIBUS DP |

|

|

8 |

||

Communication |

||

Drive commissioning |

|

|

9 |

||

(SINAMICS) |

||

Drive commissioning |

|

|

10 |

||

(SIMODRIVE) |

||

NC Commissioning with HMI |

|

|

11 |

||

Advanced |

||

|

|

|

Alarm and message texts |

12 |

|

|

|

|

Axis and Spindle Test Run |

13 |

|

Drive Optimization with HMI |

|

|

14 |

||

Advanced |

||

User data backup/Series |

|

|

15 |

||

commissioning |

||

Software installation/update |

|

|

16 |

||

and data backup |

||

|

|

|

License management |

17 |

|

840Di-specific data and |

|

|

18 |

||

functions |

||

|

|

|

Appendix |

A |

|

|

|

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes in this documentation qualified persons are defined as persons who are authorized to commission, ground and label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

WARNING

WARNING

This device may only be used for the applications described in the catalog or the technical description and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

Ordernumber: 6FC5397–4CP10–4BA0 |

Copyright © Siemens AG 2008. |

Industry Sector |

06/2008 |

Technical data subject to change |

Postfach 48 48 |

|

|

90327 NÜRNBERG |

|

|

GERMANY |

|

|

Foreword

SINUMERIK documentation

The SINUMERIK documentation is organized in 3 parts:

●General documentation

●User documentation

●Manufacturer/Service documentation

An overview of publications, which is updated monthly and also provides information about the language versions available, can be found on the Internet at:

http://www.siemens.com/motioncontrol

Select the menu items "Support" → "Technical Documentation" → "Overview of Publications". The Internet version of DOConCD (DOConWEB) is available at: http://www.automation.siemens.com/doconweb

Information on the range of training courses and FAQs (frequently asked questions) are available on the Internet under:

http://www.siemens.com/motioncontrol under menu item "Support".

Target group

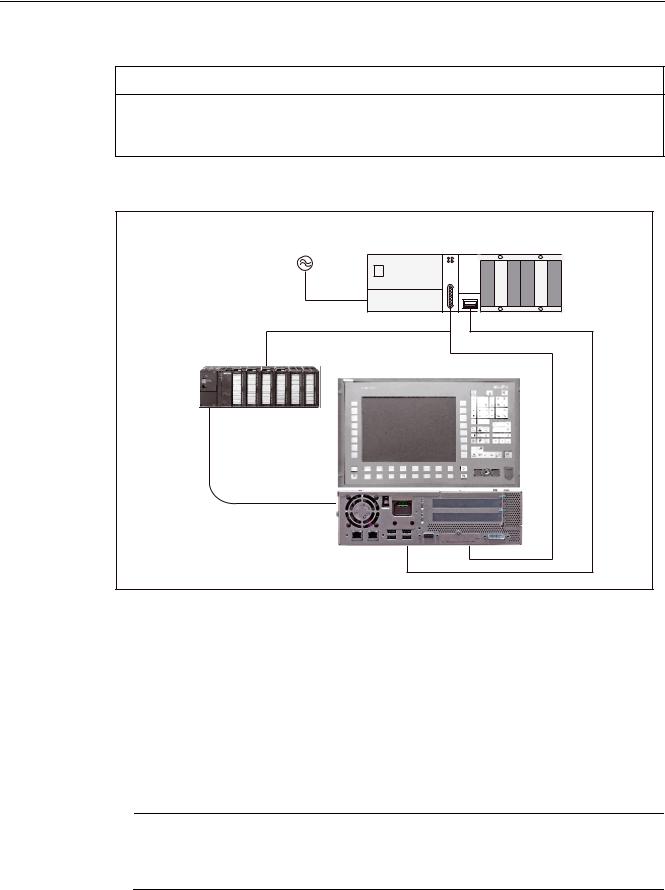

This documentation is intended for manufacturers/end users of machine tools and production machines who use SINUMERIK 840Di sl and SINAMICS S120.

Benefits

This manual provides detailed information required for the configuration and commissioning of a SINUMERIK 840Di sl system.

This manual describes the control system design and the interfaces of the individual components. The commissioning procedure for SINUMERIK 840Di sl (NCK, PLC and drives) is also described.

For detailed information about individual functions, function assignment and performance data of individual components, please refer to the appropriate document for the subject concerned (e.g. manuals, description of functions etc.).

Separate documents are available for user-oriented activities. These include, for example, generating part programs and handling controls.

Separate information is also available for operations that the machine tool manufacturer must carry out. These include, for example, configuring/engineering, installation and programming the PLC.

Manual |

3 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Foreword

Standard scope

This documentation only describes the functionality of the standard version. Additions or revisions made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation might be executable in the control. However, no claim can be made regarding the availability of these functions when the equipment is first supplied or in the event of servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information about all types of the product and cannot cover every conceivable case of installation, operation or maintenance.

Technical support

If you have any technical questions, please contact our hotline:

|

Europe / Africa |

Phone |

+49 180 5050 222 |

Fax |

+49 180 5050 223 |

Internet |

http://www.siemens.com/automation/support-request |

|

|

|

America |

Phone |

+1 423 262 2522 |

Fax |

+1 423 262 2200 |

mailto:techsupport.sea@siemens.com |

|

|

|

|

Asia/Pacific |

Phone |

+86 1064 719 990 |

Fax |

+86 1064 747 474 |

mailto:adsupport.asia@siemens.com |

Note

Country-specific telephone numbers for technical support are provided under the following Internet address:

Enter http://www.siemens.com/automation/service&support

4 |

Manual |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Foreword

Questions about this documentation

If you have any queries (suggestions, corrections) regarding this documentation, please send a fax or email to the following address:

Fax |

+49 913198 63315 |

mailto:docu.motioncontrol@siemens.com |

A fax form is available in the appendix of this document.

Internet address for SINUMERIK 840Di sl

Product information page: http://www.siemens.com/sinumerik > further via the vertical linkbar on the left: Products and systems > Automation systems > CNC SINUMERIK > SINUMERIK 840Di sl

The link-box (vertical link-bar on the right) "Everything about SINUMERIK 840Di sl" gives you direct access to all important product information.

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be viewed/downloaded from the Internet at:

http://support.automation.siemens.com

under the Product Order No. 15257461or at the relevant branch office of the A&D MC group of Siemens AG.

Danger notices

The following notices are intended firstly for your personal safety and secondly to prevent damage occurring to the product described or any connected devices and machines. Nonobservance of the warnings can result in severe personal injury or property damage.

DANGER

DANGER

Only appropriately qualified personnel may commission/start-up SINUMERIK equipment.

The personnel must take into account the information provided in the technical customer documentation for the product, and be familiar with and observe the specified danger and warning notices.

When electrical equipment and motors are operated, the electrical circuits automatically conduct a dangerous voltage.

When the system is operating, dangerous axis movements may occur throughout the entire work area.

A potential fire hazard exists due to the energy being transferred in the equipment and the work materials used.

All work on the electrical system must be performed after the system has been switched off and disconnected from the power supply.

Manual |

5 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Foreword

DANGER

DANGER

Proper transportation, expert storage, installation and mounting, as well as careful operation and maintenance are essential for this SINUMERIK device to operate correctly and reliably.

The details in the catalogs and proposals also apply to the design of special equipment versions.

In addition to the danger and warning information provided in the technical customer documentation, the applicable national, local, and system-specific regulations and requirements must be taken into account.

Only protective extra-low voltages (PELVs) that comply with EN 61800-5-1 can be connected to all connections and terminals between 0 and 48 V.

Should it be necessary to test or take measurements on live equipment, then the specifications and procedural instructions defined in Accident Prevention Regulation VBG A2 must be adhered to, in particular § 8 "Permissible deviations when working on live components". Suitable electric tools should be used.

WARNING

WARNING

Operating the equipment in the immediate vicinity (< 1.5 m) of mobile telephones with a transmitting power of > 1 W may lead to incorrect functioning of the devices.

Connecting cables and signal lines should be installed so that inductive and capacitive interference does not in any way impair the automation and safety functions.

SINAMICS equipment with three-phase motors conforms to EMC Directive 89/336/EEC in the configurations specified in the associated EC Certificate of Conformity.

DANGER

DANGER

Repairs to devices that have been supplied by our company may only be carried out by SIEMENS customer service or by repair centers authorized by SIEMENS.

When replacing parts or components, only use those parts that are included in the spare parts list.

EMERGENCY STOP devices EN 60204-1 (VDE 0113 Part 1) must remain active in all modes of the automation equipment. Resetting the EMERGENCY STOP device must not cause an uncontrolled or undefined restart.

Anywhere in the automation equipment where faults might cause physical injury or major material damage, in other words, where faults could be dangerous, additional external precautions must be taken, or facilities must be provided, that guarantee or enforce a safe operational state, even when there is a fault (e.g. using an independent limit value switch, mechanical locking mechanisms, EMERGENCY STOP devices)

6 |

Manual |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Table of contents

|

Foreword |

................................................................................................................................................... |

3 |

1 |

General Information on the SINUMERIK 840Di sl.................................................................................... |

17 |

|

|

1.1 |

Overview of SINUMERIK 840Di sl............................................................................................... |

17 |

|

1.1.1 |

System components .................................................................................................................... |

18 |

|

1.1.2 |

System software packages and quantity structures.................................................................... |

18 |

|

1.1.3 |

Hardware Components................................................................................................................ |

19 |

|

1.1.4 |

Software components.................................................................................................................. |

21 |

|

1.1.5 |

Real-time properties..................................................................................................................... |

23 |

|

1.1.6 |

System integrity ........................................................................................................................... |

24 |

|

1.1.7 |

Failure safety................................................................................................................................ |

25 |

|

1.1.8 |

Switch off...................................................................................................................................... |

27 |

|

1.1.9 |

UPS system ................................................................................................................................. |

29 |

|

1.2 |

Overview of software components............................................................................................... |

31 |

|

1.3 |

Notes on startup........................................................................................................................... |

34 |

|

1.4 |

Standard/export version............................................................................................................... |

36 |

|

1.5 |

840Di startup................................................................................................................................ |

38 |

|

1.5.1 |

Menu command: Windows........................................................................................................... |

39 |

2 |

Hardware Descriptions ............................................................................................................................ |

43 |

|

|

2.1 |

Overview of hardware components............................................................................................. |

43 |

|

2.2 |

MCI2 board for 840Di sl............................................................................................................... |

47 |

|

2.2.1 |

Assembly...................................................................................................................................... |

47 |

|

2.2.2 |

Interface description..................................................................................................................... |

48 |

|

2.2.3 |

Replace module........................................................................................................................... |

50 |

|

2.2.4 |

Technical data.............................................................................................................................. |

54 |

|

2.3 |

MCI board extension slot variation .............................................................................................. |

56 |

|

2.3.1 |

Assembly...................................................................................................................................... |

56 |

|

2.3.2 |

Installation instructions................................................................................................................. |

58 |

|

2.3.3 |

Interface description..................................................................................................................... |

60 |

|

2.3.4 |

Technical data.............................................................................................................................. |

63 |

|

2.4 |

Cable distributor........................................................................................................................... |

65 |

|

2.5 |

SINUMERIK Industrial PC ........................................................................................................... |

71 |

|

2.5.1 |

SINUMERIK PCU 50.3 ................................................................................................................ |

71 |

|

2.6 |

SINUMERIK operator panel fronts............................................................................................... |

75 |

|

2.6.1 |

Operator panel front OP 012........................................................................................................ |

75 |

|

2.7 |

TCU (Thin Client Unit).................................................................................................................. |

77 |

|

2.8 |

Handheld units............................................................................................................................. |

79 |

|

2.8.1 |

Handheld Terminal HT 8.............................................................................................................. |

79 |

|

2.8.2 |

Handheld Terminal HT 2.............................................................................................................. |

81 |

|

2.9 |

Floppy disk drives........................................................................................................................ |

83 |

Manual |

|

|

7 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

|||

Table of contents

|

2.9.1 |

Floppy disk drive 3.5" (USB)....................................................................................................... |

83 |

|

2.10 |

Power supply............................................................................................................................... |

85 |

|

2.10.1 |

SITOP POWER standard 24V/10A............................................................................................. |

85 |

|

2.11 |

Uninterrupted power supply (UPS)............................................................................................. |

87 |

|

2.11.1 |

SITOP POWER DC UPS MODULE 15....................................................................................... |

87 |

|

2.11.2 |

SITOP POWER ACCUMODULE 24 V DC/10 A/3.2 AH............................................................. |

89 |

|

2.12 |

PP72/48 I/O module.................................................................................................................... |

91 |

|

2.12.1 |

Assembly..................................................................................................................................... |

91 |

|

2.12.2 |

Interface description.................................................................................................................... |

92 |

|

2.12.3 |

Power supply............................................................................................................................. |

100 |

|

2.12.4 |

Grounding.................................................................................................................................. |

101 |

|

2.12.5 |

Dimension drawing.................................................................................................................... |

102 |

|

2.12.6 |

Technical data........................................................................................................................... |

103 |

|

2.13 |

ADI4 (Analog Drive Interface for 4 Axes).................................................................................. |

104 |

|

2.13.1 |

Assembly................................................................................................................................... |

104 |

|

2.14 |

Diagnostic repeater for PROFIBUS DP.................................................................................... |

106 |

|

2.14.1 |

Assembly................................................................................................................................... |

106 |

3 |

Configuration......................................................................................................................................... |

109 |

|

|

3.1 |

System overview....................................................................................................................... |

109 |

|

3.1.1 |

Operator panels and touch panels............................................................................................ |

109 |

|

3.1.2 |

PROFIBUS DP components..................................................................................................... |

110 |

|

3.1.3 |

PCU components...................................................................................................................... |

111 |

|

3.2 |

Electrical design........................................................................................................................ |

112 |

|

3.2.1 |

MCI board and PROFIBUS DP................................................................................................. |

112 |

|

3.2.2 |

MCI board extension................................................................................................................. |

113 |

|

3.2.3 |

PCU 50.3................................................................................................................................... |

114 |

|

3.3 |

Connection overview................................................................................................................. |

115 |

|

3.3.1 |

MCI board and MCI board extension........................................................................................ |

115 |

|

3.3.2 |

PCU50....................................................................................................................................... |

117 |

4 |

EMC and ESD Measures....................................................................................................................... |

119 |

|

|

4.1 |

RI suppression measures ......................................................................................................... |

119 |

|

4.2 |

ESD measures.......................................................................................................................... |

120 |

5 |

Power-On and Power-Up....................................................................................................................... |

121 |

|

|

5.1 |

Preparing for commissioning..................................................................................................... |

121 |

|

5.1.1 |

Checklist.................................................................................................................................... |

121 |

|

5.1.2 |

Recommended sequence for first commissioning.................................................................... |

122 |

|

5.2 |

First power-up........................................................................................................................... |

124 |

|

5.2.1 |

Basic commissioning of the system software ........................................................................... |

124 |

|

5.2.2 |

Basic commissioning of the PLC .............................................................................................. |

126 |

|

5.3 |

Power-up................................................................................................................................... |

127 |

|

5.3.1 |

SRAM handling......................................................................................................................... |

127 |

|

5.3.2 |

Startup after battery replacement (PCU backup battery).......................................................... |

129 |

|

5.3.3 |

Startup after replacement of the MCI board.............................................................................. |

129 |

|

5.3.4 |

Power up after reinstallation/update of the 840Di sl software................................................... |

131 |

|

5.3.5 |

Startup after replacement of the PCU or the MCI board........................................................... |

132 |

|

5.3.6 |

Startup after importing a backup copy...................................................................................... |

132 |

|

5.3.7 |

Startup after power failure/Power Fail....................................................................................... |

133 |

8 |

Manual |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

|

|

|

Table of contents |

|

5.3.8 |

Power-up with shutdown signal ................................................................................................. |

133 |

|

5.4 |

Service Desktop......................................................................................................................... |

135 |

|

5.4.1 |

Activating.................................................................................................................................... |

135 |

|

5.4.2 |

SINUMERIK-specific applications.............................................................................................. |

136 |

|

5.4.3 |

Setting the boot response for the Service Desktop................................................................... |

138 |

|

5.4.4 |

System information after "Fatal exception error"....................................................................... |

138 |

|

5.4.5 |

Starting OEM programs............................................................................................................. |

138 |

|

5.4.6 |

User-specific HMI startup images.............................................................................................. |

139 |

|

5.4.7 |

HMI Explorer.............................................................................................................................. |

140 |

|

5.4.8 |

SW installation/update............................................................................................................... |

141 |

|

5.5 |

ServiceCenter ............................................................................................................................ |

142 |

|

5.5.1 |

Activating.................................................................................................................................... |

142 |

|

5.5.2 |

NC/PLC startup modes.............................................................................................................. |

143 |

|

5.5.3 |

Backup/restore functions ........................................................................................................... |

144 |

|

5.6 |

Configuration of the network connection of the PCU (LAN/WAN)............................................. |

145 |

|

5.7 |

License management................................................................................................................. |

146 |

|

5.7.1 |

License management with the Automation License Manager................................................... |

146 |

|

5.7.2 |

License management with SinuCom NC................................................................................... |

146 |

6 |

PLC commissioning............................................................................................................................... |

149 |

|

|

6.1 |

General ...................................................................................................................................... |

149 |

|

6.1.1 |

Compatibility............................................................................................................................... |

149 |

|

6.1.2 |

Performance Data...................................................................................................................... |

149 |

|

6.1.3 |

PLC program.............................................................................................................................. |

150 |

|

6.1.4 |

Installing the PLC basic program library.................................................................................... |

151 |

|

6.1.5 |

STEP 7 example projects .......................................................................................................... |

151 |

|

6.1.6 |

PLC user program...................................................................................................................... |

153 |

|

6.2 |

Commissioning........................................................................................................................... |

155 |

|

6.2.1 |

Basic requirements.................................................................................................................... |

155 |

|

6.2.2 |

External communications link: Ethernet..................................................................................... |

156 |

|

6.2.3 |

Local communications link: SOFTMC........................................................................................ |

156 |

|

6.2.4 |

Check PLC status and communication interface....................................................................... |

157 |

|

6.2.5 |

First commissioning................................................................................................................... |

157 |

|

6.3 |

Creating a SIMATIC S7 project.................................................................................................. |

160 |

|

6.3.1 |

Create a project.......................................................................................................................... |

161 |

|

6.3.2 |

Inserting Station 300.................................................................................................................. |

161 |

|

6.3.3 |

HW Config.................................................................................................................................. |

163 |

|

6.3.4 |

Inserting the 840Di sl Rack........................................................................................................ |

164 |

|

6.3.5 |

Parameterizing the PROFIBUS interface (X101)....................................................................... |

165 |

|

6.3.6 |

Parameterizing the PROFIBUS interface (X102) (optional) ...................................................... |

167 |

|

6.3.7 |

Parameterizing the MPI interface (X102) (optional)................................................................... |

169 |

|

6.3.8 |

Parameterization of the communications processor (CP 840D sl) (Ethernet)........................... |

170 |

|

6.3.9 |

Networking PG/PC and PCU (Ethernet).................................................................................... |

172 |

|

6.4 |

Creating a PLC program............................................................................................................ |

177 |

|

6.4.1 |

PLC basic program.................................................................................................................... |

177 |

|

6.4.2 |

PLC user program...................................................................................................................... |

178 |

|

6.5 |

Creating a PROFIBUS configuration......................................................................................... |

178 |

|

6.6 |

Load configuration (STEP 7 -> PLC)......................................................................................... |

179 |

|

6.6.1 |

Requirements............................................................................................................................. |

179 |

|

6.6.2 |

Uploading the configuration....................................................................................................... |

179 |

|

6.6.3 |

Series startup file....................................................................................................................... |

180 |

Manual |

9 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Table of contents

|

6.7 |

Testing the PLC program.......................................................................................................... |

181 |

|

6.7.1 |

Startup characteristics............................................................................................................... |

181 |

|

6.7.2 |

Cyclic operation......................................................................................................................... |

182 |

|

6.7.3 |

Monitor/control using the SIMATIC Manager............................................................................ |

182 |

|

6.7.4 |

Monitor/control using HMI Advanced........................................................................................ |

183 |

|

6.8 |

Load configuration in PG (PLC -> STEP 7).............................................................................. |

185 |

7 |

Ethernet communication........................................................................................................................ |

187 |

|

|

7.1 |

General information................................................................................................................... |

187 |

|

7.1.1 |

Ethernet connections of the PCU 50.3...................................................................................... |

187 |

|

7.1.2 |

Determine Ethernet communication partners of the PCU......................................................... |

188 |

|

7.1.3 |

Check Ethernet connection....................................................................................................... |

188 |

|

7.2 |

SINUMERIK 840Di sl commissioning tool SinuCom NC.......................................................... |

188 |

|

7.3 |

STARTER SINAMICS drive commissioning tool...................................................................... |

189 |

|

7.4 |

External HMI Advanced ............................................................................................................ |

189 |

|

7.5 |

MCP 483C IE............................................................................................................................ |

191 |

|

7.5.1 |

Conditions for general commissioning...................................................................................... |

191 |

|

7.5.2 |

Parameterization of the MCP.................................................................................................... |

192 |

|

7.5.3 |

MCP functions........................................................................................................................... |

195 |

|

7.5.4 |

Linking to the basic PLC and user program.............................................................................. |

196 |

|

7.5.5 |

Input/output image .................................................................................................................... |

198 |

|

7.6 |

HT 8........................................................................................................................................... |

201 |

|

7.6.1 |

Conditions for general commissioning...................................................................................... |

201 |

|

7.6.2 |

Parameterization of the power supply unit................................................................................ |

202 |

|

7.6.3 |

Parameterization of the HT 8 via the TCU firmware................................................................. |

203 |

|

7.6.4 |

Parameterization of the HT 8 via the system network center................................................... |

204 |

|

7.6.5 |

Linking to the basic PLC and user program.............................................................................. |

206 |

|

7.6.5.1 |

Linking to the basic PLC program (FB1)................................................................................... |

206 |

|

7.6.5.2 |

Signal transmission from/to NC/PLC interface (FC26)............................................................. |

208 |

|

7.6.5.3 |

Overview of traversing keys...................................................................................................... |

210 |

|

7.6.5.4 |

Activate traversing keys............................................................................................................ |

212 |

|

7.6.5.5 |

Display traversing keys............................................................................................................. |

214 |

|

7.6.5.6 |

Activating user softkeys ............................................................................................................ |

216 |

|

7.6.5.7 |

Displaying user softkeys ........................................................................................................... |

217 |

|

7.6.5.8 |

MCS/WCS coordinate system switchover ................................................................................ |

218 |

|

7.6.5.9 |

Instructions on the evaluation of input signals.......................................................................... |

219 |

|

7.6.5.10 |

Input/output image .................................................................................................................... |

220 |

|

7.7 |

HT 2........................................................................................................................................... |

222 |

|

7.7.1 |

Conditions for general commissioning...................................................................................... |

222 |

|

7.7.2 |

Linking to the basic PLC and user program.............................................................................. |

223 |

|

7.7.2.1 |

Interface signals........................................................................................................................ |

223 |

|

7.7.2.2 |

Rotary coding switch................................................................................................................. |

225 |

|

7.7.2.3 |

Write display-line....................................................................................................................... |

226 |

|

7.7.2.4 |

Character Map .......................................................................................................................... |

227 |

8 |

PROFIBUS DP Communication............................................................................................................. |

229 |

|

|

8.1 |

General information................................................................................................................... |

229 |

|

8.1.1 |

PROFIBUS DP interfaces of the MCI board............................................................................. |

229 |

|

8.1.2 |

PROFIBUS DP with Motion Control option............................................................................... |

229 |

|

8.1.3 |

Message format for cyclic DP communication.......................................................................... |

231 |

|

8.1.4 |

Description of a DP cycle.......................................................................................................... |

232 |

|

8.1.5 |

Networking rules ....................................................................................................................... |

234 |

10 |

Manual |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

|

|

|

Table of contents |

|

8.2 |

Requirements............................................................................................................................. |

235 |

|

8.3 |

Creating a PROFIBUS configuration......................................................................................... |

239 |

|

8.3.1 |

Requirement............................................................................................................................... |

239 |

|

8.3.2 |

Inserting DP slaves.................................................................................................................... |

240 |

|

8.3.3 |

Parameterizing the equidistant DP-Slaves finally...................................................................... |

242 |

|

8.3.4 |

Generating system data blocks (SDB)....................................................................................... |

248 |

|

8.3.5 |

Load the configuration in the PLC ............................................................................................. |

249 |

|

8.3.6 |

PROFIBUS diagnosis ................................................................................................................ |

249 |

|

8.4 |

SIMATIC I/O devices (ET200...) ................................................................................................ |

249 |

|

8.5 |

DP slave I/O Module PP72/48................................................................................................... |

250 |

|

8.5.1 |

Parameterization of I/O Module PP72/48.................................................................................. |

250 |

|

8.5.2 |

Inserting the DP slave................................................................................................................ |

250 |

|

8.5.3 |

Setting PROFIBUS parameters................................................................................................. |

251 |

|

8.5.4 |

Setting the I/O addresses .......................................................................................................... |

252 |

|

8.6 |

DP slave MCP 310..................................................................................................................... |

253 |

|

8.6.1 |

General commissioning requirements....................................................................................... |

253 |

|

8.6.2 |

Parameterization of the MCP..................................................................................................... |

255 |

|

8.6.3 |

Functions of the machine control panel..................................................................................... |

258 |

|

8.6.4 |

Configure MCP 310 DP slave.................................................................................................... |

259 |

|

8.6.5 |

Linking to the basic PLC and user program............................................................................... |

264 |

|

8.6.6 |

Input/Output image .................................................................................................................... |

267 |

|

8.7 |

DP slave MCP 483..................................................................................................................... |

270 |

|

8.7.1 |

Conditions for general commissioning....................................................................................... |

270 |

|

8.7.2 |

Parameterization of the MCP..................................................................................................... |

272 |

|

8.7.3 |

Functions of the machine control panel..................................................................................... |

274 |

|

8.7.4 |

Configure MCP 483 DP slave.................................................................................................... |

275 |

|

8.7.5 |

Linking to the basic PLC and user program............................................................................... |

280 |

|

8.7.6 |

Input/Output image .................................................................................................................... |

283 |

|

8.8 |

ADI4 DP slave............................................................................................................................ |

286 |

|

8.8.1 |

SlaveOM .................................................................................................................................... |

286 |

|

8.8.2 |

Inserting the DP slave................................................................................................................ |

286 |

|

8.9 |

DP slave SINAMICS S120......................................................................................................... |

287 |

|

8.9.1 |

SlaveOM for SINAMICS............................................................................................................. |

287 |

|

8.9.2 |

Inserting the DP slave................................................................................................................ |

287 |

|

8.9.3 |

Parameterizing DP slaves.......................................................................................................... |

288 |

|

8.9.4 |

Dependencies of PROFIBUS DP communication..................................................................... |

294 |

|

8.10 |

DP slave SIMODRIVE drives..................................................................................................... |

297 |

|

8.10.1 |

SlaveOM .................................................................................................................................... |

297 |

|

8.10.2 |

Inserting the DP slave................................................................................................................ |

297 |

|

8.10.3 |

Parameterizing DP slaves.......................................................................................................... |

298 |

|

8.10.4 |

Dependencies of PROFIBUS DP communication..................................................................... |

303 |

|

8.11 |

DP slave diagnostic repeater for PROFIBUS DP...................................................................... |

305 |

|

8.11.1 |

Function ..................................................................................................................................... |

305 |

|

8.11.2 |

Area of application..................................................................................................................... |

306 |

|

8.11.3 |

Connection and commissioning................................................................................................. |

306 |

9 |

Drive commissioning (SINAMICS)......................................................................................................... |

307 |

|

|

9.1 |

Requirements............................................................................................................................. |

307 |

|

9.1.1 |

Basic requirements.................................................................................................................... |

307 |

|

9.1.2 |

Safety information...................................................................................................................... |

308 |

Manual |

11 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Table of contents

|

9.2 |

ONLINE commissioning............................................................................................................ |

309 |

|

9.2.1 |

Create new project without Project Wizard............................................................................... |

310 |

|

9.2.2 |

Create new project with Project Wizard.................................................................................... |

313 |

|

9.2.3 |

Drive unit: Enter component topology and configuration automatically.................................... |

316 |

|

9.2.4 |

Drive: Configuring motors and encoders .................................................................................. |

318 |

|

9.2.5 |

Control Unit: Selecting the PROFIBUS meassage frame......................................................... |

321 |

|

9.2.6 |

Infeed: Selecting the PROFIBUS meassage frame.................................................................. |

321 |

|

9.2.7 |

Drive unit: Check configuration................................................................................................. |

322 |

|

9.2.8 |

Drive unit: Configuring PROFIBUS message frames............................................................... |

324 |

|

9.2.9 |

Control Unit: Acknowledge error (BICO interconnection) ........................................................ |

325 |

|

9.2.10 |

Control Unit: Output "Infeed operation" (BICO interconnection) signal ................................... |

326 |

|

9.2.11 |

Control Unit: Output "Infeed ready for activation" (BICO interconnection) signal .................... |

327 |

|

9.2.12 |

Infeed: Acknowledge error (BICO interconnection) ................................................................. |

328 |

|

9.2.13 |

Infeed: Enable/disable drives via ON/OFF1 (BICO interconnection)........................................ |

329 |

|

9.2.14 |

Drive: Enable/disable drives via 2nd OFF3 (BICO interconnection)......................................... |

330 |

|

9.2.15 |

Drive unit: Backing up parameters............................................................................................ |

331 |

|

9.2.16 |

Drive: Testing motor rotation..................................................................................................... |

331 |

|

9.2.17 |

Settings of specific parameters................................................................................................. |

332 |

|

9.3 |

Example for systems with more than 6 drives.......................................................................... |

333 |

|

9.3.1 |

Configuration............................................................................................................................. |

333 |

|

9.3.2 |

Basic commissioning................................................................................................................. |

334 |

|

9.3.3 |

Drives of Control Unit 2: Additional BICO interconnection........................................................ |

335 |

|

9.4 |

Further terminal assignments.................................................................................................... |

337 |

|

9.4.1 |

Advice on terminal assignment: 1. CU (X122).......................................................................... |

337 |

|

9.4.2 |

Advice on terminal assignment: 1. CU (X132).......................................................................... |

338 |

|

9.4.3 |

Advice on terminal assignment: 2. up to nth CU (X122)........................................................... |

338 |

|

9.4.4 |

Advice on interconnection: 1. CU with 2nd to nth CU............................................................... |

340 |

|

9.4.5 |

Example: CU interconnection with line contactor...................................................................... |

341 |

|

9.5 |

Basic principles......................................................................................................................... |

342 |

|

9.5.1 |

Drive unit: Upgrade firmware.................................................................................................... |

342 |

10 |

Drive commissioning (SIMODRIVE) ...................................................................................................... |

345 |

|

|

10.1 |

SIMODRIVE 611 universal/E, POSMO CD/CA and SI............................................................. |

346 |

|

10.1.1 |

Commissioning variants............................................................................................................ |

346 |

|

10.1.2 |

Preconditions for an online connection..................................................................................... |

347 |

|

10.1.3 |

Setting a PROFIBUS address (SIMODRIVE 611 universal/E)................................................. |

348 |

|

10.1.4 |

Setting PROFIBUS address (SIMODRIVE POSMO SI/CD/CA)............................................... |

349 |

|

10.1.5 |

Setting the access interface...................................................................................................... |

350 |

|

10.1.6 |

Setting the routing information.................................................................................................. |

351 |

|

10.1.7 |

Starting online operation........................................................................................................... |

353 |

|

10.2 |

Installing SimoCom U................................................................................................................ |

354 |

11 |

NC Commissioning with HMI Advanced ................................................................................................ |

355 |

|

|

11.1 |

General procedure.................................................................................................................... |

355 |

|

11.2 |

Machine and setting data.......................................................................................................... |

356 |

|

11.2.1 |

Display and input....................................................................................................................... |

359 |

|

11.2.2 |

Protection levels........................................................................................................................ |

360 |

|

11.2.3 |

Machine data display filter......................................................................................................... |

363 |

|

11.3 |

System data.............................................................................................................................. |

365 |

|

11.3.1 |

Resolutions ............................................................................................................................... |

365 |

|

11.3.2 |

Standardization of physical units of machine data and setting data......................................... |

367 |

|

11.3.3 |

Changing scaling machine data................................................................................................ |

370 |

12 |

Manual |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

|

|

Table of contents |

11.3.4 |

Loading default machine data.................................................................................................... |

371 |

11.3.5 |

Switching over the measuring system....................................................................................... |

372 |

11.3.6 |

Traversing ranges...................................................................................................................... |

374 |

11.3.7 |

Positioning accuracy of the control system................................................................................ |

374 |

11.3.8 |

Cycle times................................................................................................................................. |

375 |

11.3.9 |

Velocities.................................................................................................................................... |

379 |

11.4 |

Memory configuration ................................................................................................................ |

381 |

11.4.1 |

DRAM memory........................................................................................................................... |

382 |

11.4.2 |

SRAM memory........................................................................................................................... |

383 |

11.5 |

Axes and spindles...................................................................................................................... |

385 |

11.5.1 |

Axis configuration....................................................................................................................... |

385 |

11.5.2 |

Axis names................................................................................................................................. |

388 |

11.5.3 |

Drive configuration..................................................................................................................... |

389 |

11.5.4 |

Setpoint/actual value channels.................................................................................................. |

393 |

11.5.5 |

Incremental measuring system settings .................................................................................... |

396 |

11.5.6 |

Parameterization of absolute measuring systems..................................................................... |

399 |

11.5.7 |

Parameterization of a 2nd measuring system with ADI4........................................................... |

402 |

11.5.8 |

DSC (Dynamic Servo Control)................................................................................................... |

405 |

11.5.9 |

Drive Optimization...................................................................................................................... |

407 |

11.5.10 |

Rotary axes................................................................................................................................ |

407 |

11.5.11 |

Positioning axes......................................................................................................................... |

409 |

11.5.12 |

Indexing axes............................................................................................................................. |

410 |

11.5.13 |

Parameter sets of axis/spindle................................................................................................... |

411 |

11.5.14 |

Position controller ...................................................................................................................... |

413 |

11.5.15 |

Speed setpoint matching ........................................................................................................... |

417 |

11.5.16 |

Drift compensation..................................................................................................................... |

420 |

11.5.17 |

Axis velocity matching................................................................................................................ |

421 |

11.5.18 |

Axis monitoring........................................................................................................................... |

423 |

11.5.19 |

Axis homing................................................................................................................................ |

431 |

11.5.20 |

Spindle basic data...................................................................................................................... |

441 |

11.5.21 |

Setpoint/actual value channels of spindle.................................................................................. |

444 |

11.5.22 |

Gear stages................................................................................................................................ |

444 |

11.5.23 |

Spindle measuring systems....................................................................................................... |

445 |

11.5.24 |

Speeds and setpoint adjustment for spindle.............................................................................. |

447 |

11.5.25 |

Positioning the spindle............................................................................................................... |

450 |

11.5.26 |

Synchronizing spindle................................................................................................................ |

451 |

11.5.27 |

Spindle monitoring..................................................................................................................... |

453 |

11.5.28 |

Spindle data............................................................................................................................... |

456 |

11.6 |

Handwheels ............................................................................................................................... |

460 |

11.6.1 |

General information ................................................................................................................... |

460 |

11.6.2 |

Connection via cable distributor................................................................................................. |

460 |

11.6.3 |

Connection via PROFIBUS........................................................................................................ |

461 |

11.6.4 |

Connection via Ethernet............................................................................................................. |

464 |

11.7 |

Digital and analog I/O devices................................................................................................... |

467 |

11.7.1 |

Parameterization of the number of inputs/outputs used............................................................ |

468 |

11.7.2 |

Assignment of inputs/outputs to the signal modules ................................................................. |

469 |

11.7.3 |

System variable $A_...[n]........................................................................................................... |

470 |

11.7.4 |

Digital input/output bytes and system variables......................................................................... |

471 |

11.7.5 |

Dynamic response..................................................................................................................... |

472 |

11.7.6 |

Configuration example............................................................................................................... |

473 |

11.8 |

Loadable compile cycles............................................................................................................ |

478 |

11.8.1 |

Load a compile cycle ................................................................................................................. |

479 |

11.8.2 |

Interface version compatibility.................................................................................................... |

479 |

Manual |

13 |

Commissioning Manual, 05/2008, 6FC5397–4CP10–4BA0 |

Table of contents

|

11.8.3 |

Software version of a compile cycle.......................................................................................... |

481 |

|

11.8.4 |

Constraints................................................................................................................................ |

481 |

|

11.8.5 |

Activating and licensing technology functions........................................................................... |

482 |

|

11.8.6 |

Data descriptions (MD) ............................................................................................................. |

483 |

|

11.9 |

PROFIBUS DP.......................................................................................................................... |

484 |

|

11.9.1 |

Setting the parameters for the shut-down behavior.................................................................. |

484 |

|

11.9.2 |

Data descriptions (MD) ............................................................................................................. |

484 |

|

11.10 |

Initial settings ............................................................................................................................ |

485 |

|

11.11 |

NC/PLC Diagnosis.................................................................................................................... |

486 |

|

11.11.1 |

Menu: Diagnostics..................................................................................................................... |

486 |

|

11.11.2 |

Menu: settings........................................................................................................................... |

490 |

12 |

Alarm and message texts ...................................................................................................................... |

493 |

|

|

12.1 |

Configuration file MBDDE.INI.................................................................................................... |

493 |

|

12.2 |

Standard text files ..................................................................................................................... |

494 |

|

12.3 |

User text files ............................................................................................................................ |

494 |

|

12.4 |

Syntax for alarm text files.......................................................................................................... |

497 |

|

12.5 |

Setting the alarm log properties................................................................................................ |

500 |

13 |

Axis and Spindle Test Run..................................................................................................................... |

501 |

|

|

13.1 |

Requirements............................................................................................................................ |

501 |

|

13.1.1 |

Drives: SINAMICS S120........................................................................................................... |

501 |

|

13.1.2 |

Drives: SIMODRIVE.................................................................................................................. |

502 |

|

13.1.3 |

NC/PLC interface signals.......................................................................................................... |

502 |

|

13.2 |

Axis dry run............................................................................................................................... |

504 |

|

13.3 |

Spindle dry run.......................................................................................................................... |

505 |

14 |

Drive Optimization with HMI Advanced.................................................................................................. |

507 |

|

|

14.1 |

Overview................................................................................................................................... |

507 |

|

14.2 |

Measuring functions.................................................................................................................. |

508 |

|

14.3 |

Special functions....................................................................................................................... |

510 |

|

14.4 |

Frequency response measurements ........................................................................................ |

512 |

|

14.4.1 |

Measurement of current control loop........................................................................................ |

513 |

|

14.4.2 |

Speed control loop measurement............................................................................................. |

514 |

|

14.4.3 |

Position control measurement .................................................................................................. |

518 |

|

14.5 |

Graphic display ......................................................................................................................... |

522 |

|

14.6 |

Trace function ........................................................................................................................... |

525 |

|

14.6.1 |

Trace function properties .......................................................................................................... |

525 |

|

14.6.2 |

Main screen and operation........................................................................................................ |

526 |

|

14.6.3 |

Parameter assignment.............................................................................................................. |

527 |

|

14.6.4 |

Performing the measurement.................................................................................................... |

530 |

|

14.6.5 |

Display function......................................................................................................................... |

531 |

|

14.7 |

File Function.............................................................................................................................. |

533 |

|

14.8 |

Print graphic.............................................................................................................................. |

535 |

|

14.9 |

Automatic controller setting....................................................................................................... |

538 |

|

14.9.1 |

Drives: SINAMICS S120........................................................................................................... |

538 |

|

14.9.2 |