Siemens 8DJ20 User Manual

www.siemens.com/energy

Switchgear Type 8DJ20

up to 24 kV, Gas-Insulated

Medium-Voltage Switchgear

Catalog HA 45.31 · 2008

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

2

8DJ20 switchgear is a factory-

assembled, type-tested, metal-

enclosed switchgear for indoor

installation.

Typ ic al us es

8DJ20 switchgear is used for

power distribution in substations

– even under severe environmen

-

tal conditions, such as:

•

Industrial environments

•

Damp, sandy or dusty areas

•

Simple outdoor substations

Main uses

•

Compact substations

•

Compact transformer substations,

e. g. for wind power stations

•

Garage and vault substations

•

Underground and underfloor

substations

•

Sidewalk substations, e.g.

containing switchgear with a

very small overall width – in

particular the basic versions

of schemes 10, 32 and 71 –

in conurbations

•

Substations with control aisle

Technology

•

Switchgear design with up to

5 feeders

•

Maintenance-free

•

Climate-independent

•

Partition class: PM

(metallic partition)

•

Three-pole primary enclosure,

metal-enclosed

•

Insulating gas SF

6

•

Welded switchgear vessel with-

out seals, made of stainless

steel, with welded-in bushings

for electrical connections and

mechanical components

•

Three-position switch-discon

-

nector with load-break and

make-proof earthing function

•

Cable connection for

bushings with outside cone

•

Connection with cable plugs

– In ring-main feeders with

bolted contact (M16)

– In transformer feeders with

plug-in contact

•

Option: Connection with

conventional sealing ends

– For thermoplastic-insulated

cables via elbow adapter

AKE 20/630 (make Siemens)

– For paper-insulated mass-im-

pregnated cables via commer-

cially available adapter systems

•

Easy installation

Personal safety

•

Safe-to-touch and hermetically-

sealed primary enclosure

•

HV HRC fuses and cable sealing

ends are only accessible when

outgoing feeders are earthed

•

Operation only possible when

enclosure is closed

•

Logical mechanical interlocking

•

Capacitive voltage detecting

system to verify safe isolation

from supply

•

Feeder earthing by means of

make-proof earthing switches

Security of operation

•

Hermetically-sealed primary

enclosure independent of en-

vironmental effects such as

pollution, humidity and small

animals – sealed for life:

– Welded switchgear vessel

– Welded-in bushings and

operating mechanism

•

Operating mechanism parts

maintenance-free

(IEC 62 271-1/VDE 0671-1)

•

Operating mechanisms of

switching devices located out-

side the switchgear vessel

(primary enclosure)

•

Switchgear interlocking system

with logical mechanical inter-

locks

Cost-efficiency

Extremely low “life-cycle costs”

throughout the entire product

service life as a result of:

•

Maintenance-free concept

•

Climatic independence

•

Minimum space requirements

•

Maximum availability

Standards

seepage21

Technical Data

Electrical data, filling pressure, temperature 4

Application, Requirements

Features, typical use 2 and 3

Product Range

Equipment features 4

Product range overview, schemes 5

Design

Panel design 6

Dimensions

Switchgear 10 to 13

Floor openings, fixing points 14 and 15

Examples for cable connection 16

Designs, Special Designs

LV compartment, outdoor enclosures 18 to 20

Standards, Notes

Standards, specifications,

guidelines, classification 21 to 23

Shipping

Types of transport, transport data 17

Components

Three-position switch-disconnector,

operating mechanisms 7

HV HRC fuse assembly, secondary

equipment, pressure absorber system 8

Cable connection 9

For further information, please refer to

•

Catalog HA 40.1:

Switchgear Types 8DJ and 8DH, General Part

•

HA 45.31/41.11:

Supplements to Switchgear Types 8DJ and 8DH

Invalid:

Catalog HA 45.31 · 2006

The products and systems describedin this catalog

are manufactured and sold according to a certified

quality and environmental managementsystem

(acc. to ISO 9001 and ISO 14001).

(DQS Certificate Reg. No. DQS 003473 QM UM).

The certificate is accepted in all IQNet countries.

Contents

Application, Requirements

Features

© Siemens AG 2008

Page

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

3

Our product range extends from

switchgear installed in a radial

transformer panel (individual

panel) to switchgear with 5

feeders, consisting of

•

Ring-main feeders

•

Transformer feeders with

HV HRC fuse assemblies

•

Circuit-breaker feeders (for

thecompleteproductrange

see Supplements to Catalogs

HA 45.31/41.11 – 2006)

The switchgear is available in

three overall heights:

•

1200 mm

(with low subframe)

•

1400 mm and 1760 mm

(with high subframe)

These overall heights cover all

areas of application, from com-

pact substations to switchgear

rooms with control aisle.

Basic design

•

Manual operating mechanism

•

Transformer cable connection

at the front (standard)

•

With logical mechanical inter-

locks

•

With ready-for-service indicator

•

With capacitive voltage de-

tecting system at the ring-

main feeders

Options (others on request)

•

Capacitive voltage detecting

system at the transformer

feeders

•

Motor operating mechanisms

for the three-position switch-

disconnectors

•

Auxiliary switch for three-posi-

tion switch-disconnector and

make-proof earthing switch

•

Short-circuit indicator with

built-in housing

•

Surge arresters for ring-main

feeders

•

Shunt releases for transformer

feeders

•

Secondary equipment for

remote operation or remote

indication, e.g. with local-

remote switch in the case of

motor operating mechanisms

or ”tripped signal” in the case

of transformer feeders

•

Locking devices

•

Closing lock-out

•

De-earthing lock-out

•

Cable clamps

Radial transformer

panel

1 transformer feeder

1 radial cable connection

Scheme 01

Ring-main/

transformer block

2 ring-main feeders

1 transformer feeder

Scheme 10

Ring-main/

transformer block

3 ring-main feeders

2 transformer feeders

Scheme 82

R

-

H

A

4

5

-

0

9

9

c

e

p

s

R

-

H

A

4

5

-

1

0

0

b

e

p

s

R

-

H

A

4

5

-

1

0

1

c

e

p

s

R

-

H

A

4

5

-

0

8

6

c

e

p

s

8DJ20 switchgear in

a compact substation

Typical use

Features

Application

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

4

• Basic equipment

°

Additional equipment

(option), further

additional equipment

on request

xNot

applicable

– Not avail-

able

Equipment

Manual operating mechanism for

three-position switch-disconnector:

– As spring-operated mechanism

– As spring-operat./stored-energy mech.

Motor operating mechanism for

three-position switch-disconnector

Interlock for cable compartment

cover

Cable compartment cover locked

in place/screwed on

Cable bracket

2)

in ring-main and cable

feeders, cable routing downwards

Cable bracket in transformer feeder:

For cable routing

– Downwards (standard), f. cable elb. plugs

or

– Downwards, for straight cable plugs

or

– To the rear, for cable elbow plugs

Low-voltage terminals in the

operating mechanism

(option for secondary equipment)

Shunt release

Auxiliary switch for

– Switch-disconnector

CLOSED/OPEN:1NO+2NC

–EARTHINGCLOSED/OPEN:

1NO+1NC

Locking device for

three-position switch-disconnector

Short-circuit or earth-fault indicator

– Wiring at the indicator

(standard)

– Wiring to terminal (option)

De-earthing lock-out for

make-proof earthing switch

in transformer feeder

Closing lock-out for

three-position switch-disconnector

Double cable connection for

– Overall height of switchgear 1200 mm

– Overall height of switchgear 1400 mm

– Overall height of switchgear 1760 mm

Surge arrester for

– Overall height of switchgear 1200 mm

– Overall height of switchgear 1400 mm

– Overall height of switchgear 1760 mm

Cable clamps for cable fixing

– Supplied separately

– Preassembled (option)

Radial cable connection, panel K(E) for scheme 21

(with additional earthing switch)

Radial cable connection,panelKforscheme02

(without earthing switch)

Ring-main feeders

panel RK

Transformer feeder

panel1Tinscheme01

Transformer

feeders

panel T

1) According to some national requirements, higher values of the

rated short-duration power-frequency withstand voltage

available for I

k

=20kAwith:

– 42 kV for phase-to-phase, phase-to-earth and opencontact

gap as well as

– 48 kV across the isolating distance

Higher values of the rated lightning impulse withstand voltage:

– 95 kV for phase-to-phase, phase-to-earth and opencontact

gap as well as

– 110 kV across the isolating distance

2) For overall height of switchgear 1200 mm:

Cable bracket below the feeder

3) Cable fixing by customer

(the switchgear is supplied without cable bracket)

4) In case of scheme 01 the cable compartment cover is bolted.

The transformer connection is effected via the bushings

arranged underneath the switchgear vessel. The transformer

feeder is earthed by the three-position switch

5) Temperature range, reduced normal currents at ambientair

temperatures>+40°C

6) SurgearrestertypeRDAwithRICS(TycoElectronics)not

possible for a height of 1200 mm

o. r. = on request

•

–

x

x

•

–

–

•

–

•

–x

°°°

•

–•••

–•–––

••••

x

x

x

x

x

x

x

x

x

x

x

•

without

3)

•

•

without

3)

•–•••

–––

°°

°

°

x

x

°

°

°

°

°

°

°

x

°°°

°

°

°

°

°

°

–

–

–

–

°

xxx

4)

°

–x

°

––

°

°

°

°

°

°

°

°

°

x

x

x

x

x

x

–

°

°

–

°

°

o. r.

6)

°

°

x

x

x

x

x

x

°

°

°

°

°

°

°

–

°

°

Rated voltage U

r

kV 7.2121517.524

Rated insulation level

Rated short-duration kV

power-frequency

withstand voltage U

d

20 28

1)

36 38 50

Rated lightning impulse kV

withstand voltage U

p

60 75

1)

95 95 125

Rated frequency f

r

50/60 Hz

Rated normal current I

r

for ring-main feeders 400 or 630 A

for transformer feeders

depending on the

HV HRC fuse link

200 A

for schemes 01 and 21

depending on the

HV HRC fuse link

200 A

Rated short-time

withstand current I

k

at 1 s kA

kA

kA

–

20

25

–

20

25

–

20

25

16

20

25

16

20

–

at 3 s (option) kA 20 20 20 20 20

Rated peak kA

withstand current I

p

kA

kA

–

50

63

–

50

63

–

50

63

40

50

63

40

50

–

Rated short-circuit

making current I

ma

fortransformerfeeders kA2525252525

for ring-main feeders kA

kA

kA

–

50

63

–

50

63

–

50

63

40

50

63

40

50

–

Ambient air temperature T

(operating conditions acc. to

IEC 62 271-200/Clause 2 or

IEC 62 271-1

)

– Without secondary equipment

– With secondary equipment,

class “Minus 5 indoor”

-40to+70°C

5)

-5to55°C

5)

Pressure values at 20 °C

for the insulation:

Rated filling level p

re

1500 hPa (absolute)

Minimum functional level p

me

1300 hPA (absolute)

Technical Data, Product Range

Electrical data, temperature, filling pressure Equipment features of panels

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

5

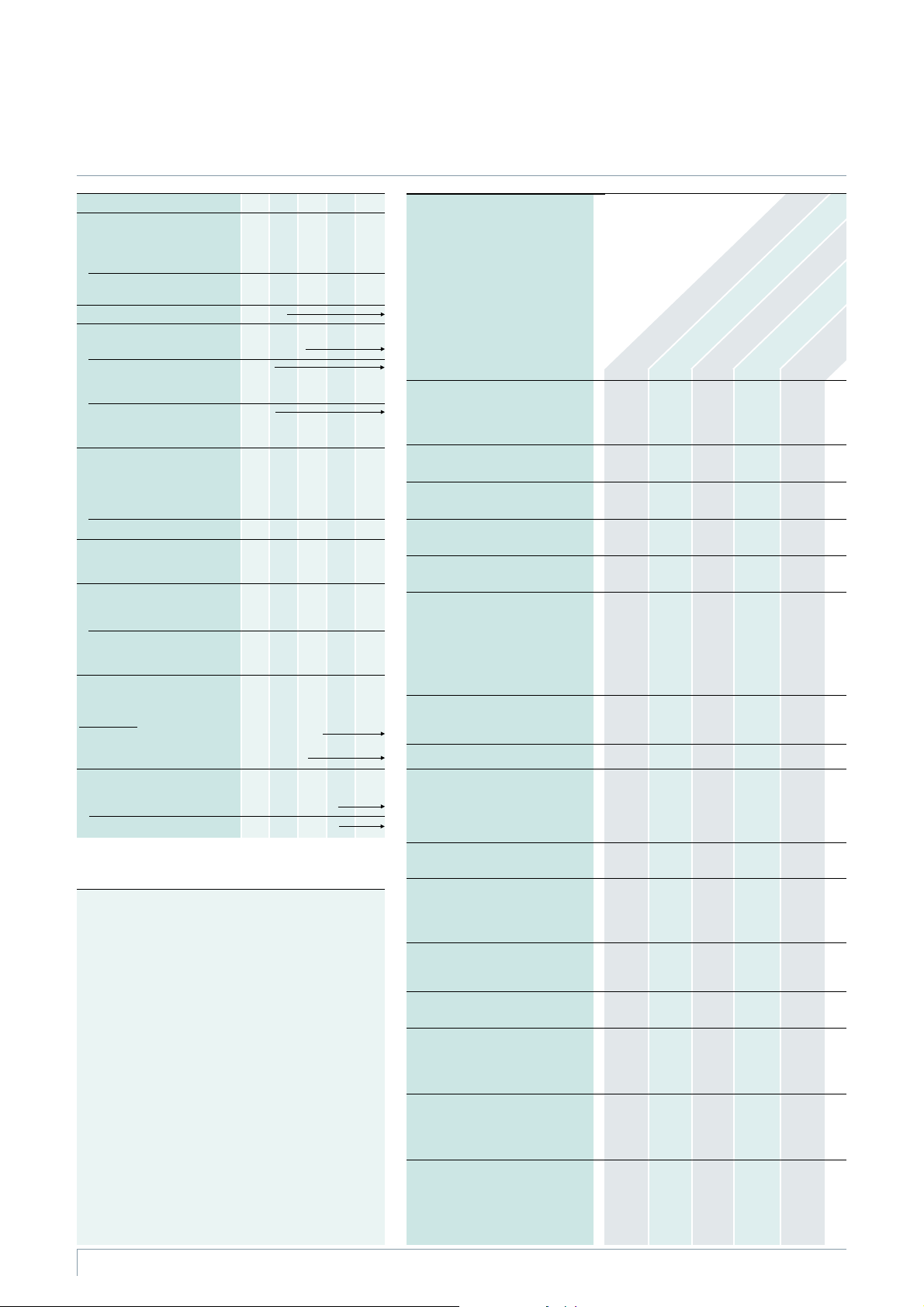

K Radial cable

connection as

infeed

K(E) Radial cable

connection, K as

K(E) with make-proof

earthing switch

Radial transformer panels

Scheme 01 * 1 transformer feeder,

1 radial cable connection

(Abbreviation 1T)

510 775 1200

1400

1760

140

160

200

Radial panel

Scheme 02 1 ring-main feeder with

radial cable connection

(Abbreviation 1RK)

710 775 1200

1400

1760

150

170

210

Block versions, consisting of ring-main andtransformer feeders (with HV HRCfuse assembly)

Scheme 10

* 2 ring-main feeders,

1 transformer feeder

(Abbreviations 2RK+1T)

1060 775 1200

1400

1760

280

300

340

Scheme 71 * 3 ring-main feeders,

1 transformer feeder

(Abbreviations 3RK+1T)

1410 775 1200

1400

1760

340

360

400

Scheme 81 * 2 ring-main feeders,

2 transformer feeders

(Abbreviations 2RK+2T)

1410 775 1200

1400

1760

400

420

460

Block versions, consisting of ring-main feeders (withoutHV HRC fuse assembly)

Scheme 11 2 ring-main feeders

(Abbreviation 2RK)

710 775 1200

1400

1760

160

170

210

Scheme 70 * 4 ring-main feeders

(Abbreviation 4RK)

1410 775 1200

1400

1760

280

300

340

Scheme

Components shown in dotted

lines can be used optionally.

Overall dimensions Net

1)

weight

approx.

kg

Width

mm

Depth

2) 3)

mm

Height

mm

Scheme

Components shown in dotted

lines can be used optionally.

Overall dimensions Net

1)

weight

approx.

kg

Width

mm

Depth

2) 3)

mm

Height

mm

Scheme 21 1 radial cable connection,

1 transformer feeder

(Abbreviations 1K(E)+1T)

710 775 1200

1400

1760

200

210

250

Scheme 20 1 ring-main feeder,

1 transformer feeder

(Abbreviations 1RK+1T)

710 775 1200

1400

1760

200

210

250

Scheme 72 4 ring-main feeders,

1 transformer feeder

(Abbreviations 4RK+1T)

1760 775 1200

1400

1760

420

440

480

Scheme 82 3 ring-main feeders,

2 transformer feeders

(Abbreviations 3RK+2T)

1760 775 1200

1400

1760

470

500

540

Scheme 84 5 ring-main feeders

(Abbreviation 5RK)

1760 775 1200

1400

1760

350

380

420

Scheme 32

* 3 ring-main feeders

(Abbreviation 3RK)

1060 775 1200

1400

1760

210

230

270

1) Depending on the relevant equipment, e.g. motor operating mechanism

2) Additional wall distance required: W 15 mm

3) For cable routing of transformer cables downwards

* Scheme is also suitable for outdoor enclosure (see pages 18 and 19)

Abbreviations:

RK = Ring-main feeder K = Cable feeder T = Transformer feeder

K(E) = Cable feeder forradial cable connection with make-proofearthing switch

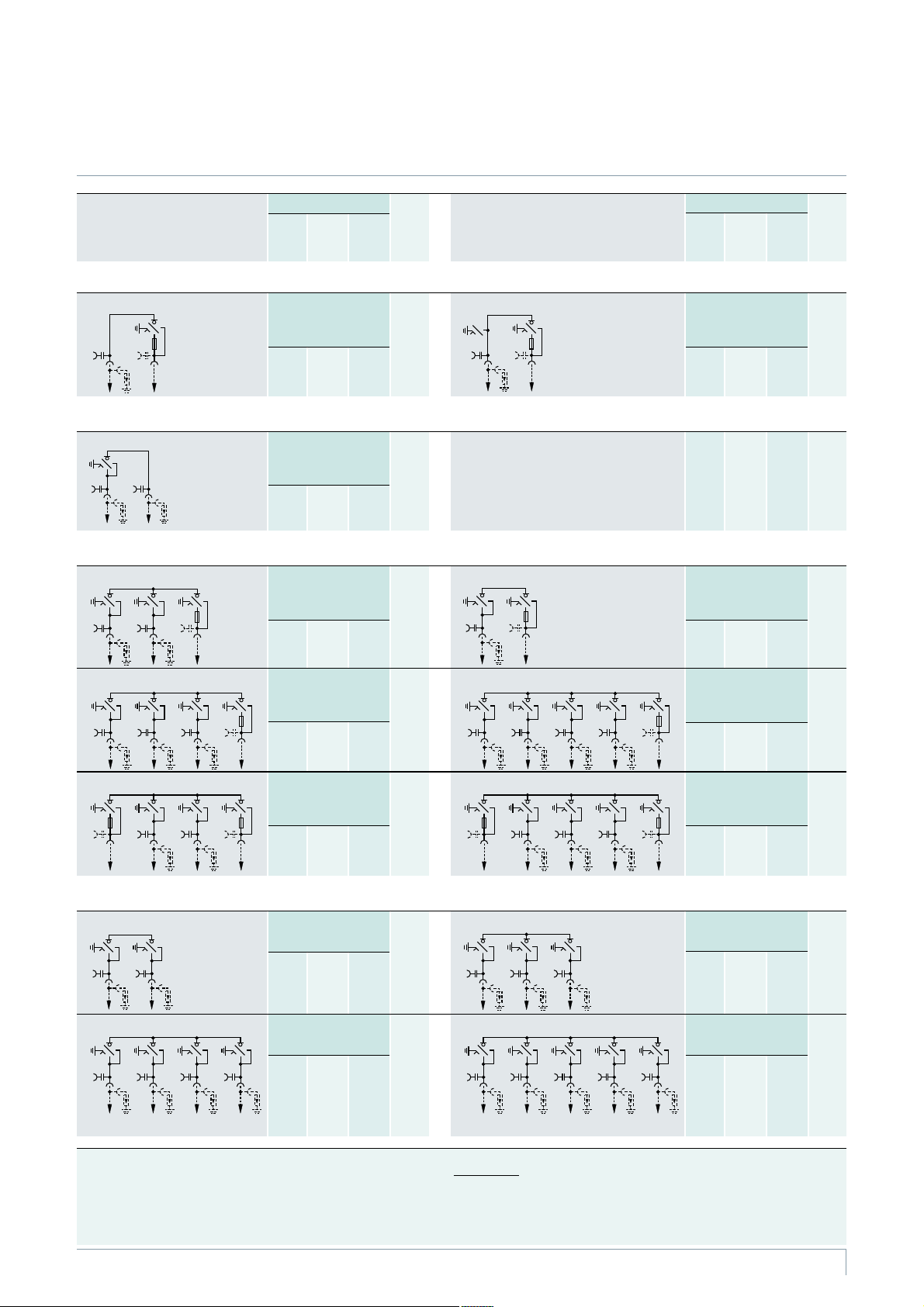

T

HA45-2294d eps

K

HA45-2295c eps

RK K

HA45-2296c eps

RK TRK

HA45-2302c eps

RK TRK RK

HA45-2304c eps

RK TRKT

HA45-2297c eps

RK RK

HA45-2301c eps

RK RKRK RK

RK RKRK RK RK

HA45-2306c eps

HA45-2300c eps

RK RKRK

HA45-2305c eps

RK TRKT RK

HA45-2303c eps

RK TRK RK RK

HA45-2298c eps

TRK

HA45-2299c eps

TK(E)

Product range overview, schemes

Product Range

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

6

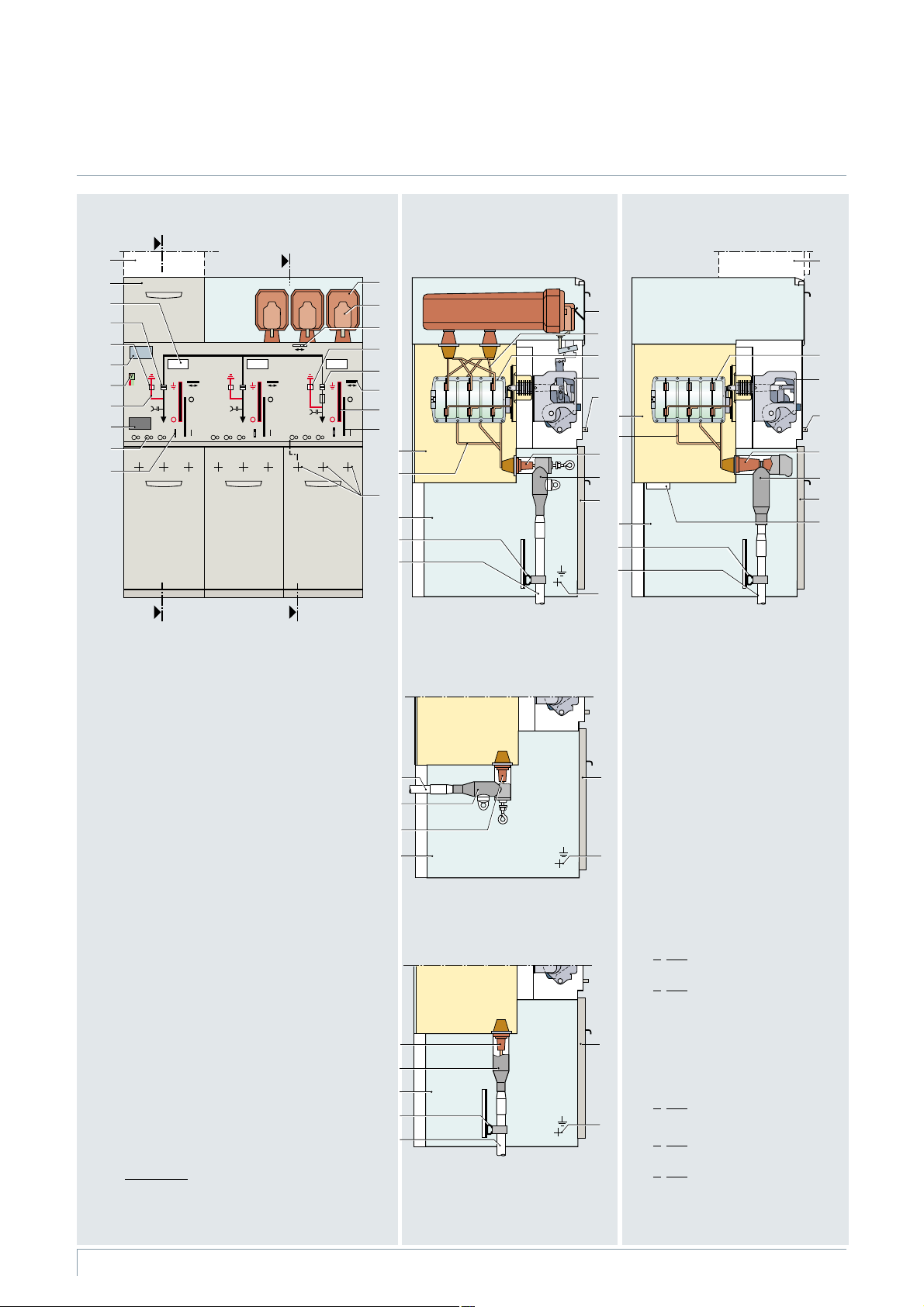

1 Niche for customer-side low-voltage equipment

2 Feeder designation label

Position indicators

in the ring-main feeder:

3 Load-break function ”CLOSED – OPEN”

4 Earthing function ”OPEN – EARTHED”

5 Rating and type plate

6 Ready-for-service indicator

7 Mimic diagram

8 Short-circuit/earth-fault indicator (option)

9 Sockets for voltage detecting system

10 Interlock of the cable compartment cover

11 HV HRC fuse assembly, cover removed

12 Handle for replacing the HV HRC fuse link

13 Interlock for HV HRC fuse assembly

Position indicators

in the transformer feeder:

14 Earthing function ”OPEN – EARTHED”

15 Load-break function ”CLOSED – OPEN”

with ”HV HRC fuse tripped” or”shunt release

tripped”, where applicable

16 Locking device

(option for three-position switch-disconnector)

17 Manual operation for the mechanism of

the earthing function

Option

Cable connection for cable elbow

plugs, cable routing tothe rear

(cable fixing by customer)

18 Manual operation for the mechanism of

the load-break function

19 Switchgear vessel, filled with gas

20 Connecting bar to cable connection

21 Arrangement of cable connections

22 Cable compartment

23 Cable bracket

24 Cable (not included in the scope ofsupply)

25 Cover of the HV HRC fuse compartment

26 Connecting bar to the bushings

for the HV HRC fuse

27 Three-position switch-disconnector

28 Spring-operated/stored-energy mechanism

29 Bushing as interface type “A” for

cable plug with plug-in contact

O

ption: Bushing as interface type “C”

for cable plug with bolted contact (M16)

30 O

ption: Cable elbow plug with

plug-in contact

31 Cable compartment cover

32 M12 earthing connection

33 Spring-operated mechanism

34 Bushing as interface type “C“ for cable

plug with bolted contact (M16)

35 O

ption: Cable T-plug with bolted contact

36 Pressure relief device

37 O

ption: Straight cable plug with

plug-in contact

38 O

ption: Low-voltage compartment

HA45-2337d eps

L1 L2 L3

5

3

2

1

4

B

A

B

A

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

25

26

27

28

10

19

20

31

22

23

32

24

27

33

31

36

10

16

30

29

34

35

38

38

HA45-2308e eps

31

32

29

24

30

22

HA45-2309e eps

31

32

29

22

23

24

37

Ring-main/transformer block

Standard

Cable connection for cable elbowplugs

(option: for cable T-plugs),

cable routing downwards

Scheme 10

Transformer feeder

Section A-A

Cable connection with bolted contact (M16):

– For cable T-plug or cable elbow plug

– For conventional cable sealing ends via

elbow adapter AKE 20/630

Option

Cable connection for

straight cable plugs,

cable routing downwards

Ring-main feeder

Section B-B

Personal safety

All feeder-related covers can only be

opened if the associated three-position

switch-disconnector has been switched to

the “EARTHED” position.

Design

Panel design (example)

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

7

Three-position

switch-disconnector

The switching device used

is the proven three-position

switch-disconnector

Functions

•

Load-break function

•

Earthing function with

short-circuit making capacity

•

Switch positions

CLOSED – OPEN – EARTHED

Operating mechanisms

The three-position switch-

disconnector is operated from

the switchgear front via

Detachable lever mechanism

(standard)

• Spring-operated mechanism

– With ”spring-operated

CLOSED” and ”spring-oper-

ated OPEN” for installation

in ring-main feeders

•

Spring-operated/stored-

energy mechanism

– With ”spring-operated

CLOSED” and ”spring-oper-

ated OPEN” for installation

in transformer feeders

–Withanadditionalenergy

store for the function ”stored-

energy OPEN” after tripping

by the HV HRC fuse (striker

tripping) or by the shunt

release

O

ptions

•

Motor operating mechanism

for switch-disconnector

•

Rotary operating mechanism

•

Locking devices

•

Auxiliary contacts for three

-

position switch-disconnector

and make-proof earthing

switch

•

Shunt release for transformer

feeders

•

Closing lock-out for ring-

main feeders

•

De-earthing lock-out for

transformer feeders

•

Different operating levers

1)

for

the operating mechanisms of

the switch-disconnector and of

the make-proof earthing switch

Three-position switch-disconnector

R

-

H

A

4

5

-

1

0

2

e

p

s

Operating mechanisms

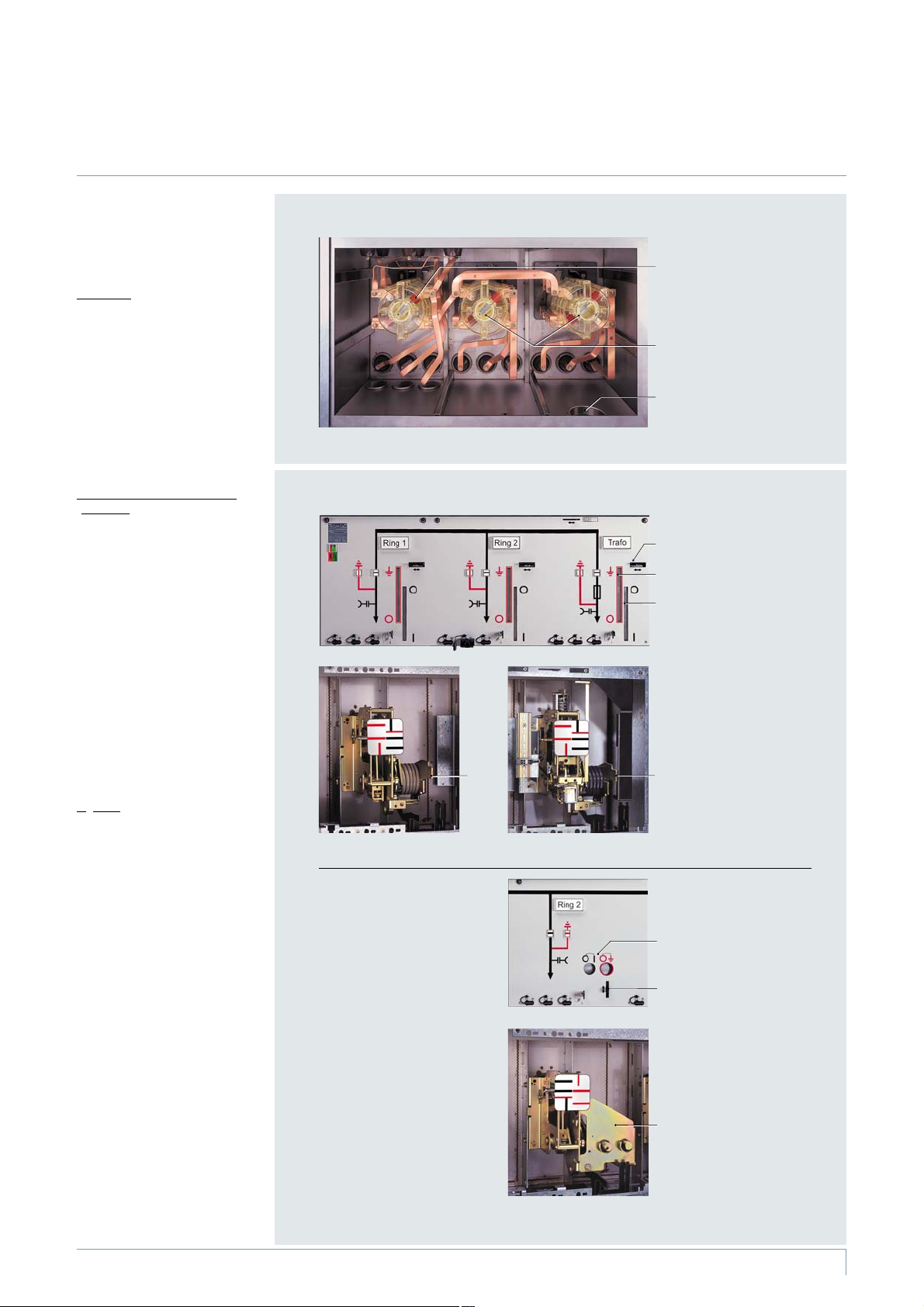

Switchgear vessel of a

ring-main/transformer

block, scheme 10

(rear view)

1 Three-position switch-

disconnector in the

transformer feeder

2 Three-position switch-

disconnector in the

ring-main feeders

3 Pressure relief device

Control board for detach-

able lever mechanisms

(standard)

Example:

Ring-main/transformer block,

scheme 10

4 Locking device (option)

for the detachable lever

mechanism

5 Detachable lever

operation for the

earthing function

6 Detachable lever

operation for the

load-break function

7 Detachable lever

mechanism for the

ring-main feeder

8 Detachable lever

mechanism for the

transformer feeder

Control board for rotary

operating mechanisms

(option)

Example: Ring-main feeder

9 Symbols for the actuating

direction of the rotary

operating mechanism

10 Locking device for the ro-

tary operating mechanism

R

-

H

A

4

5

-

1

0

3

a

e

p

s

R

-

H

A

4

5

-

1

0

4

e

p

s

R

-

H

A

4

5

-

1

0

5

e

p

s

R

-

H

A

4

5

-

1

0

6

a

e

p

s

R

-

H

A

4

5

-

1

0

7

e

p

s

11 Rotary operating

mechanism (option)

10

1

11

2

3

9

4

5

6

8

7

1) According to VDN */VDEW**

recommendation

* AssociationofGermanNetwork

Operators VDN e.V. at the VDEW in

Germany (as of 2003)

** Association of German

Power Stations – VDEW e.V.

Three-position switch-disconnector, operating mechanisms

Components

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

8

HV HRC fuse assembly

The HV HRC fuse boxes are

single-phase insulated and lo-

cated above the transformer

feeder outside the switchgear

vessel.

Standards

(see page 21)

HV HRC fuse links with striker in

“medium” version according to

•

IEC 60 282-1

•

VDE 0670 Parts 4 and 402

•

DIN 43 625 main dimensions

Features

•

Requirements fulfilled as HV

alternating current switch-

fuse combination

•

Selection of HV HRC fuses for

transformers

•

For further features

see Catalog HA 40.1

Secondary equipment (option)

•

Auxiliary switches, motor

operating mechanisms or

shunt releases wired to a

terminal strip

•

Location of the terminal strip

next to the operating mecha-

nism module of the feeder

concerned

•

Customer-side cable routing

to the terminal strip from the

side or rear

Pressure absorber system

(option)

•

Maintenance-free

•

For all schemes (except radial

transformer panel, scheme 01)

•

For rated short-time with

-

stand current I

k

w 16 kA,

with IAC (internal arc

classification, see page 22)

•

With 105 mm deep pressure

relief duct for pressure relief

upwards

•

For overall height of switch-

gear:

–Standard:

1400 mm

–O

ption: 1760 mm

•

For wall-standing arrangement

•

Transformer cable routing:

–Standard:

Downwards

–O

ption: To th e r ear for

schemes 10, 71 and 72

•

Weight approx. 110 kg

HV HRC fuse compartment

HV HRC fuse compartment

with cable compartment

cover removed

Phase L1:

HV HRC fuse box with

HV HRC fuse slide removed

Phase L2:

HV HRC fuse box closed

Phase L3:

Replacement of HV HRC fuses

Auxiliary switch, motor

operating mechanism and

shunt release

Example: Transformer feeder

1 Wiring duct

2 Te rm ina l str ip

3 Auxiliary switch at spring-

operated mechanism of a

ring-main feeder

4 Auxiliary contactors

(standard for motor

operating mechanism)

5 Motor operating mechanism

at spring-operated/

stored-energy mechanism

6 Locking device

(standard for motor

operating mechanism)

7 Shunt release at spring-

operated/stored-energy

mechanism

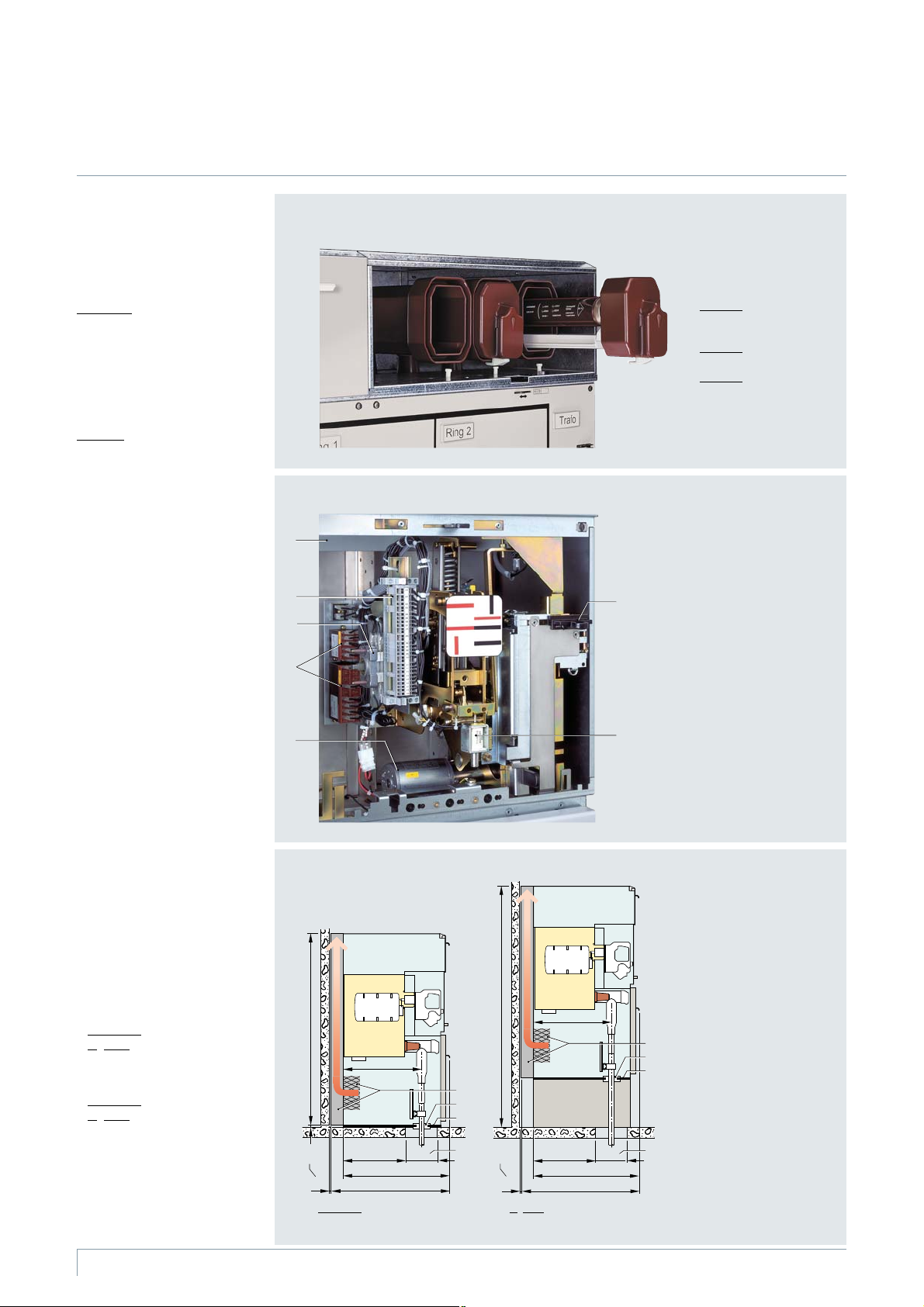

Sectional views of the

pressure absorber system

1 Wall distance

2 Pressure absorber system

with rear pressure relief

duct directed upwards

3 Cable bushing

4 Divided floor plate for

cable entry for on-site

installation

5 Floor opening for the

cable feeder

HA45-2364 eps

1400

~2

880

³

15

775

240

435

~560

2

3

5

1

4

7

1

2

6

HA45-2363 eps

~1762

880

³

15

775

240

435

~560

5

1

2

3

4

R

-

H

A

4

5

-

1

0

8

e

p

s

R

-

H

A

4

5

-

1

3

3

e

p

s

3

4

5

Pressure absorber system

(option)

Standard: Overall height 1400 mm

O

ption: Overall height 1760 mm

Secondary equipment (option)

Components

HV HRC fuse assembly, secondary equipment, pressure absorber system

Loading...

Loading...