siemens 810D User Manual

System Overview

Connection Conditions

Design and Installation

SINUMERIK 810D

Description

Configuration CCU

Axis Expansion

Equipment Manual

I/O Modules

NCU Terminal Block

DMP Compact Modules

Maintenance and Service

Abbreviations

Valid for

Index

Control

SINUMERIK 810D powerline

SINUMERIK 810DE powerline

Edition 03/2006

1

2

3

4

5

6

7

8

9

A

SINUMERIK→ Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A . . . . . New documentation.

B . . . . . Unrevised reprint with new order no.

C . . . . . Revised edition with new status.

Edition |

Order No. |

Remarks |

12.95 |

6FC5297–1AD10–0BP0 |

A |

07.96 |

6FC5297–1AD10–0BP1 |

C |

08.97 |

6FC5297–2AD10–0BP0 |

C |

12.98 |

6FC5297–3AD10–0BP0 |

C |

08.99 |

6FC5297–3AD10–0BP1 |

C |

04.00 |

6FC5297–3AD10–0BP2 |

C |

10.00 |

6FC5297–4AD10–0BP0 |

C |

12.01 |

6FC5297–4AD10–0BP1 |

C |

03.02 |

6FC5297–6AD10–0BP0 |

C |

11.02 |

6FC5297–6AD10–0BP1 |

C |

03.05 |

6FC5297–6AD10–0BP2 |

C |

03.06 |

6FC5297–7AD10–0BP0 |

C |

Trademarks

All product names mentioned may be trademarks or product designations of Siemens AG or their suppliers, whose use by third parties for their own purposes may infringe the rights of the trademark owners.

Further information is available in the Internet under: http://www.siemens.com/motioncontrol

This publication was produced with Interleaf V 7.

Other functions not described in this documentation might be executable in the control. However, no claim can be made regarding the availability of these functions when the equipment is first supplied or in the event of servicing.

We have checked that the contents of this document correspond to the hardware and software described. Nevertheless, differences might exist and therefore we cannot guarantee that they are completely identical. The information given in this publication is reviewed at regular intervals and any corrections that might be necessary are made in the subsequent printings. Suggestions for improvement are also welcome.

Copyright♥ Siemens AG 2006 |

Subject to change without prior notice. |

|

|

Order No. 6FC5297-7AD10-0BP0 |

Siemens Aktiengesellschaft |

Printed in the Federal Republic of Germany |

|

Preface

SINUMERIK |

The SINUMERIK documentation is subdivided into 3 parts: |

||

Documentation |

S |

General Documentation |

|

|

|||

|

S |

User documentation |

|

|

S |

Manufacturer/Service documentation |

|

|

A list of documents with the respective available languages is updated on a |

||

|

monthly basis and is available on the Internet at: |

||

|

http://www.siemens.com/motioncontrol |

||

|

Select “Support” → “Technical Documentation → “Overview of Documents”. |

||

|

The Internet version of the DOConCD (DOConWEB) is available at: |

||

|

http://www.automation.siemens.com/doconweb |

||

|

Information on the training offerings and on FAQs (frequently asked questions) |

||

|

can be found in the Internet under: |

||

|

http://www.siemens.com/motioncontrol and menu item “Support”. |

||

Target group |

This documentation is intended for: |

||

|

S Project engineers, electricians and installers |

||

|

S Maintenance and service personnel |

||

Benefits |

The information in this manual enables installation of the SINUMERIK 810D |

||

|

Numerical Control and measures for maintenance and service. |

||

Standard version |

This documentation only describes the functionality of the standard version. |

||

|

Extensions or changes made by the machine tool manufacturer are documen- |

||

|

ted by the machine tool manufacturer. Other functions not described in this |

||

|

documentation might be executable in the control. This does not, however, |

||

|

represent an obligation to supply such functions with an initial delivery or when |

||

|

servicing. |

||

|

For the sake of simplicity, this documentation does not contain all detailed infor- |

||

|

mation about all types of the product and cannot cover every conceivable case |

||

|

of installation, operation, or maintenance. |

||

Technical Support |

If you have any questions about the control, please contact the hotline: |

||

|

Europe and Africa time zone |

||

|

|

A&D Technical Support |

|

|

|

Tel.: |

+49 (0) 180 / 5050 222 |

|

|

Fax: |

+49 (0) 180 / 5050-223 |

|

|

Internet: http://www.siemens.com/automation/support-request |

|

|

|

E-Mail: mailto:adsupport@siemens.com |

|

Copyright ♥ Siemens AG 2006 |

iii |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Preface

Questions about the manual

Asia and Australia time zone

A&D Technical Support

Tel.: +86 1064 719 990

Fax: +86 1064 747 474

Internet: http://www.siemens.com/automation/support-request E-Mail: mailto:adsupport@siemens.com

America time zone

A&D Technical Support

Tel.: +1 423 262 2522

Fax: +1 423 262 2289

Internet: http://www.siemens.com/automation/support-request E-Mail: mailto:adsupport@siemens.com

Note

Country-specific telephone numbers for technical support are provided under the following internet address:

Enter http://www.siemens.com/automation/service&support

For questions on the documentation (suggestions, corrections), please send a fax or e-mail to the following address:

Fax: +49 (0) 9131 / 98 – 63315

E-Mail: mailto:motioncontrol.docu@siemens.com

Fax form: see the reply form at the end of the brochure

SINUMERIK |

http://www.siemens.com/sinumerik |

Internet address |

|

EC Conformity |

The EC conformity declarations on EMC are to be found at/can be obtained |

Declaration |

from: |

|

S in the Internet: |

|

http://www.ad.siemens.de/csinfo |

|

under the product/order no. 15257461 |

|

S at the relevant branch office of the A&D MC group of Siemens AG. |

Safety instructions |

This manual contains information which you should observe in order to ensure |

|

your own personal safety, as well to avoid material damage. Notices which are |

|

relevant to your own personal safety are highlighted by a safety alert symbol; |

|

notices which are relevant only to equipment and property damage have no |

|

safety alert symbol. The warnings appear in decreasing order of risk as given |

|

below. |

Danger

!indicates that death or serious injury will result if proper precautions are not taken.

iv |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Preface

Qualified personnel

Warning

!indicates that death or serious injury may result if proper precautions are not taken.

Caution

!with a safety alert symbol, indicates that minor personal injury may result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an undesirable event or state may arise if the relevant notes are not observed.

If several hazards of different degrees occur, the hazard with the highest degree must always be given priority. If a warning note with a warning triangle warns of personal injury, the same warning note can also contain a warning of material damage.

Commissioning and operation of the device/equipment/system in question must only be performed using this documentation. Only qualified personnel should be allowed to commission and operate the device/system. Qualified persons are defined as persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accordance with established safety practices and standards.

Intended use |

Please note the following: |

Warning

!The equipment may only be used for single purpose applications explicitly described in the catalog and in the technical description and it may only be used along with third-party devices and components recommended by Siemens. To ensure trouble-free and safe operation of the product, it must be transported, stored and installed as intended and maintained and operated with care.

Copyright ♥ Siemens AG 2006 |

v |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Preface

Danger notices |

Should it be necessary to test or take measurements on live equipment, then |

|

the specifications and procedures defined in Accident Prevention Regulation of |

|

the Berufsgenossenschaft BGV A3 (German employer’s liability insurance |

|

association) must be adhered to, in particular § 8 “Permissible deviations when |

|

working with live components”. Suitable electric tools should be used. |

Danger

!Operating electrical equipment has parts and components that are at hazardous voltage levels.

After disconnecting all the supply voltages, a hazardous voltage will be present in the DC link of all SIMODRIVE modules for another 5 minutes!

See Operating Guide

Danger

!S Repairs to devices that have been supplied by our company must only be

carried out by SIEMENS Customer Service or by repair centers authorized by SIEMENS. When replacing parts or components, only use those parts that are included in the spare parts list.

SBefore opening the equipment, always ensure that the power is off.

SEMERGENCY STOP devices complying with EN 60204 (VDE 0113 Part 1) must remain effective in all automation equipment modes. Resetting the EMERGENCY STOP device must not cause an uncontrolled or undefined restart.

SAnywhere in the automation equipment where faults might cause major material damage or even physical injury, in other words, where faults could be dangerous, additional external precautions must be taken, or facilities must be provided, that guarantee or enforce a safe operational state, even when there is a fault (e.g. using an independent limit value switch, mechanical interlocks etc.)

Warning

!Connecting cables and signal cables should be installed so that inductive and capacitive interference does not in any way impair the automation functions.

Warning

The modules contain electrostatically sensitive devices. Discharge yourself of electrostatic energy before touching the components. The easiest way to do this is to touch a conductive, grounded object immediately beforehand (for example, the bare metal part of control cabinet or the protective ground contact of a socket outlet).

vi |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Preface

ESD notices |

Electrostatically Sensitive Devices |

Important

!Handling of modules containing devices sensitive to electrostatic discharge:

SWhen handling components which can be destroyed by electrostatic

discharge, it must be ensured that personnel, the workstation and packaging are well grounded.

SGenerally, electronic modules must not be touched unless work has to be carried out on them. Only touch electronic modules after you have grounded yourself.

STouch components only if:

–you are constantly grounded via an ESD arm band,

–ESD-shoes or ESD-shoe grounding strips if there is an ESD floor.

SModules may be placed only on electrically conductive surfaces (table with ESD top, conductive ESD foam plastic, ESD packing bags, ESD transport containers).

SKeep modules away from visual display units, monitors or TV sets (minimum distance from screen 10 cm).

SDo not bring ESD-sensitive modules into contact with chargeable and highly-insulating materials, such as plastic, insulating table tops or clothing made of synthetic materials.

SMeasurements on modules are allowed only if

–the measuring instrument is properly grounded (e.g. equipment grounding conductor), or

–before measuring with a potential-free measuring instrument, the probe is briefly discharged (e.g. touch the unpainted metal parts of the control housing).

Other information

Important

!This notice indicates important facts that must be taken into consideration.

Note

This note contains additional important information.

Copyright ♥ Siemens AG 2006 |

vii |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Preface

Notes

viii |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Contents

1 |

System overview . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

|

|

1.1 |

SINUMERIK 810D powerline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

|

|

1.2 |

System configuration . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

|

1.3 |

Labels . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-21 |

2 |

Connection Conditions . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

|

|

2.1 |

Supplementary electrical conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

|

|

2.1.1 |

Power supply . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

|

2.1.2 |

Safe isolation to EN 61800-5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-26 |

|

|

2.1.3 |

Grounding Concept . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-28 |

|

2.1.4 |

RI suppression measures . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-29 |

|

2.2 |

Climatic and mechanical environmental conditions . . . . . . . . . . . . . . . |

2-31 |

|

|

2.2.1 |

Transport and storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-31 |

|

|

2.2.2 |

Operating conditions . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-32 |

|

2.3 |

Technical data of the individual components . . . . . . . . . . . . . . . . . . . . . |

2-34 |

|

|

2.4 |

MPI/OPI network rules . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-35 |

3 |

Design and Installation of the 810D |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

|

|

3.1 |

Structure of the SINUMERIK 810D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

|

|

3.2 |

Assembly of the SINUMERIK 810D . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-38 |

|

|

3.2.1 |

Alteration for external heat dissipation, 2-axis CCU box . . . . . . . . . . . |

3-43 |

|

|

3.3 |

Power supply . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-45 |

4 |

Description of the SINUMERIK 810D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-47 |

||

|

4.1 |

Components of the SINUMERIK 810D . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-47 |

|

|

4.1.1 |

Overview . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-47 |

|

4.2 |

Interfaces . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-50 |

|

4.2.1 |

Overview . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-50 |

|

4.2.2 |

Description of the interfaces, operating and display elements . . . . . . |

4-52 |

|

|

4.2.3 |

Cable distributor . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-60 |

|

4.3 |

Measuring system . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-63 |

|

4.3.1 |

Assignment of measuring systems and motor connection . . . . . . . . . |

4-63 |

|

|

4.3.2 |

Encoder systems that can be evaluated . . . . . . . . . . . . . . . . . . . . . . . . . |

4-64 |

|

|

4.3.3 |

Measuring channels, indirect and direct measuring system . . . . . . . . |

4-66 |

|

|

4.4 |

Integrated power modules: |

3-axis CCU box . . . . . . . . . . . . . . . . . . . . . |

4-71 |

|

4.5 |

Integrated power modules: |

2-axis CCU box . . . . . . . . . . . . . . . . . . . . . |

4-74 |

|

4.6 |

PLC module . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-75 |

|

4.7 |

PCMCIA card (memory card) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-76 |

|

Copyright ♥ Siemens AG 2006 |

ix |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

5 |

Axis expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-77 |

|

|

5.1 |

Axis expansion plug-in unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-77 |

|

5.2 |

Axis expansion with SIMODRIVE 611D control plug-in unit . . . . . . . . |

5-80 |

6 |

I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-83 |

|

|

6.1 |

Single I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-83 |

7 |

NCU terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-91 |

|

8 |

DMP compact modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-97 |

|

|

8.1 |

DMP compact module 16I (6FC5111-0CA01-0AA0) . . . . . . . . . . . . . . |

8-97 |

|

8.2 |

DMP compact module 16O (6FC5111-0CA02-0AA2) . . . . . . . . . . . . . |

8-99 |

|

8.3 |

DMP compact module 8O (6FC5111-0CA03-0AA2) . . . . . . . . . . . . . . |

8-101 |

|

8.4 |

DMP compact module 1I analog (6FC5111-0CA04-0AA0) . . . . . . . . . |

8-103 |

|

8.5 |

DMP compact module 1I NC analog (6FC5211-0AA10-0AA0) . . . . . . |

8-106 |

|

8.6 |

DMP compact module 1O analog (6FC5111-0CA05-0AA0) . . . . . . . . |

8-109 |

9 |

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9-111 |

|

|

9.1 |

Battery replacement (6FC5247-0AA18-0AA0) . . . . . . . . . . . . . . . . . . . |

9-111 |

A |

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-113 |

|

B |

Index . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-115 |

x |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

System Overview |

1 |

1.1SINUMERIK 810D powerline

Since 03.2002

SSINUMERIK 810D powerline and

SSINUMERIK 810DE powerline

have been available. The following powerline module with improved performance is now available:

Table 1-1 |

powerline module for SINUMERIK 810D/810DE |

|

|

|

|

Module |

|

Description |

|

|

|

CCU3 |

|

with additional pulse interface and 2 machining channels |

|

|

|

CCU3.4 |

|

like CCU3, but with increased NC performance and PLC 314C-2DP |

|

|

|

Note

SINUMERIK 810D powerline and SINUMERIK 810DE powerline are delivered with software version 6.

Earlier software versions of SINUMERIK 810D cannot be run on SINUMERIK 810D powerline and SINUMERIK 810DE powerline.

Copyright ♥ Siemens AG 2006 |

1-11 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

1.2System configuration

Components |

A fully equipped SINUMERIK 810D consists of different components. These are |

||

|

|

listed below. |

|

Table 1-2 |

Components of the 810D in the maximum configuration (without motors) |

||

|

|

|

|

Component |

MLFB |

Description |

|

|

|

|

|

Mains supply module |

See References: |

Power supply module for powering the electronics and drives. |

|

(MS) |

|

/PJU/ Configuration |

Either unstabilized (OI 5 kW to 28 kW) or stablized as infeed/rege- |

|

|

Manual Converters |

nerative feedback module (I/R module) as from 16 kW to 120 kW; |

|

|

|

optional filter modules. |

|

|

|

|

SINUMERIK 810D |

|

|

|

– CCU box |

|

6FC5447-0AA00-0AA1 |

Module racks for CCU integrated power modules: 1 x 18/36A |

(3 axes) |

|

|

(FSD) or 24/32A (MSD) and 2 x 6/12A (FSD), internal heat |

|

|

6FC5447-0AA01-0AA0 |

dissipation only |

– CCU box |

|

|

Module rack for the CCU integrated power modules: 2 x 9/18/A |

(2 axes) |

|

|

(FSD), internal/external heat dissipation |

|

|

|

|

– CCU3.4 |

|

6FC5410-0AY03-1AA0 |

like CCU3 but with PLC 314C-2DP |

|

|

|

|

– CCU3 |

|

6FC5410-0AY03-0AA1 |

CPU of the 810D contains: |

|

|

6FC5410-0AY03-0AA2 |

NCK, PLC 315-2DP, communication functions, digital standard |

|

|

|

control |

|

|

|

Additional functions: |

|

|

|

– 16 MB DRAM, 2.5 MB SRAM |

|

|

|

– Handling with 6 axes |

|

|

|

– 2nd channel with 6 axes |

|

|

|

|

Operator panel front 1) |

|

Display, keyboard and operation of the 810D |

|

PCU 20/50/70 1) |

|

Makes communication between operator and machine possible |

|

Machine control panel 1) |

|

Operation of PLC-controlled machine functions of 810D |

|

ISA adapter 1) |

|

|

Permits use of AT modules in conjunction with the PCU |

Full CNC keyboard 1) |

|

Full keyboard connectable to PCU |

|

Memory card (PCMCIA) |

|

Slot for PCMCIA card on the CCU. |

|

|

|

|

PCMCIA card for software update (not 810DE). |

|

|

|

|

Floppy disk unit 1) |

|

Built-in unit for connection to PCU |

|

Cable distributor |

6FX2006-1BA02 |

Connection of two handwheels and two probes to the CCU |

|

|

|

|

|

Cable |

|

|

References: Catalog NC Z |

|

|

|

|

Axis expansion |

|

6FC5412-0FA12-0AA0 |

For installation in a SIMODRIVE 611 D power module (1-axis) for |

plug-in unit left |

|

|

axis expansion, place between I/R module and 810D |

|

|

|

References: /PJU/, Configuration Manual Converters |

|

|

|

|

Axis expansion |

|

6FC5412-0FA10-0AA0 |

For installation in a SIMODRIVE 611 power module (1-axis or |

plug-in unit |

|

|

2-axis), |

|

|

|

References: /PJU/, Configuration Manual Converters |

|

|

|

|

SIMATIC |

|

|

See http://www.siemens.com/automation/simatic |

components |

|

|

|

|

|

|

|

Single I/O module |

6FC5411-0AA00-0AA0 |

PLC I/O module with 64 inputs and 32 short-circuit-proof outputs |

|

|

|

|

|

NCU terminal block 1) |

6FC5211-0AA00-0AA0 |

Rapid digital and analog NC I/Os on the drive bus of the |

|

|

|

|

SINUMERIK 810D |

|

|

|

|

Handheld unit 1) |

6FX2007-1AC.. |

Handheld unit with handwheel, EMERGENCY STOP button, key- |

|

|

|

|

switch, override, enabling buttons, display, free keys, connection |

|

|

|

via MPI bus and cable distributor |

|

|

|

|

1-12 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

|

|

1 System Overview |

|

|

1.2 System configuration |

|

|

|

Component |

MLFB |

Description |

|

|

|

Handheld terminal |

6FC5403-0AA10-0AA0 |

Handheld unit combining the functions of operator panel front and |

(HT 6) 1) |

|

MCP, with |

|

|

– Display, |

|

|

– Keyboard, enabling buttons, EMERGENCY STOP and override |

|

|

button |

|

|

– RS 232 C interface for archiving programs and data |

|

|

– Connection via cables and distributors to SINUMERIK |

|

|

810D/840Di/840D and FM357-2H |

|

|

|

Distributor box 1) |

6FX2006-1BC00 |

For linking the hand-held unit to the MPI bus. Connection for |

|

|

EMERGENCY STOP circuit, enable keys, handwheel, 24 V DC |

|

|

|

Mini Handheld Unit 1) |

6FX2006-1BG00 |

Small handheld unit for setup and operation on simple machines |

|

|

for job shop or similar applications. |

|

|

Use with 810D, 840C, 840D, and FM-NC possible. |

|

|

|

The components marked with 1) are described in:

References: /BH/, Operator Components Manual

Copyright ♥ Siemens AG 2006 |

1-13 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

|

Diskette |

Handheld unit or mini handheld unit or HT 6 |

|

|

unit |

|

|

PCU |

Handheld |

|

|

unit |

HT 6 |

||

|

|||

* POWER * TEMP |

SINUMERIK |

|

Operator panel front

MPI |

cable |

MCP |

|

|

|

17 |

|

16 |

|

|

|

|

|

||

|

|

|

|

|

|

|

QWERTY |

|

|

Distributor box |

|

||

keyboard |

|

|

|

|

|

|

|

|

|

|

Cable |

|

|

|

|

|

|

distributor |

|

|

Encoder cable |

|

|

|

|

|

|

direct |

|

|

|

|

|

|

measuring system |

|

|

|

|

|

|

14 |

|

|

|

|

|

Measurement (2x) *) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Handwheel (2x) |

OI |

|

|

|

|

|

|

or |

|

|

|

|

|

|

I/R |

MSD |

810D |

FSD |

FSD |

|

|

14 |

|

(CCU3) |

|

|

|

|

|

|

|

|

|

|

|

|

Axis |

|

|

Axis |

|

|

|

expansion |

|

Terminal block |

|

||

|

plug-in |

15 |

|

expansion |

|

|

|

unit |

|

plug-in |

|

SIMATIC |

|

|

|

|

|

|||

|

|

|

|

unit |

|

|

|

|

|

|

|

IM cable |

|

|

Motor cable 1x 2x |

2x 1x |

|

|

||

|

|

|

|

|||

Motor encoder |

5x |

|

611 |

|

|

|

cable |

|

|

|

power |

|

|

|

|

|

|

module |

|

|

|

|

|

|

|

SIMATIC |

Single |

|

|

|

|

|

I/O module |

|

Direct measuring |

|

|

|

|

Profibus I/O |

|

|

|

|

|

|

||

|

Motors |

|

|

|

|

|

system |

|

|

*) One measurement input can be replaced by a 3rd handwheel |

|||

(e.g. on the X416) |

|

e.g. 1FNx, 1FEx, 1FKx |

||||

|

|

|

|

|

|

|

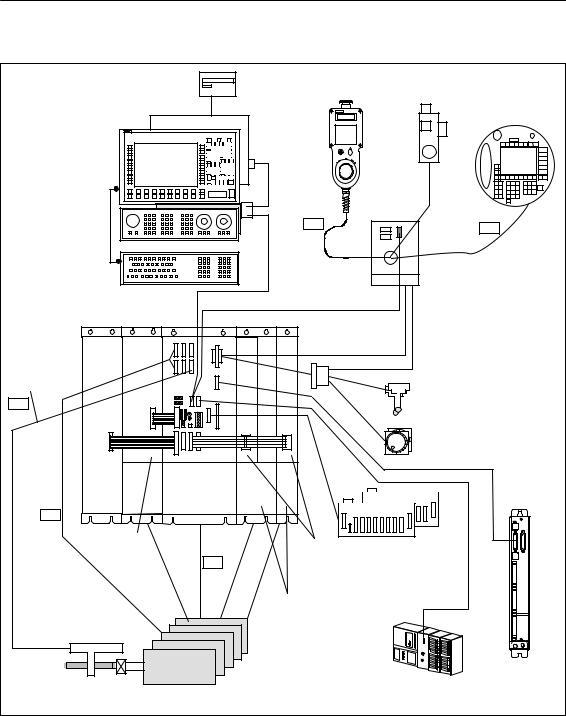

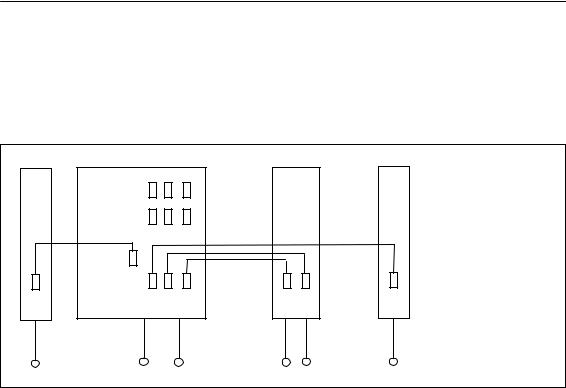

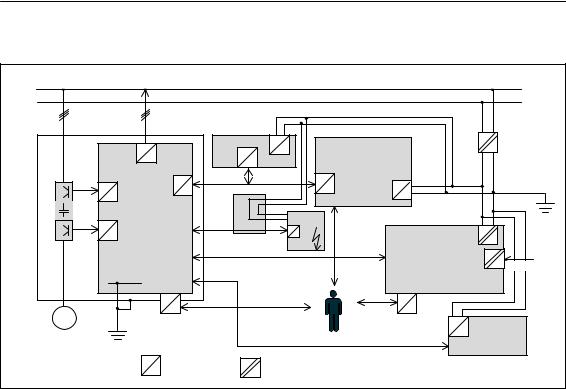

Fig. 1-1 System of the SINUMERIK 810D, for example, the CCU3

1-14 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

|

|

QWERTY |

Floppy/interface |

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Connection on left side of housing |

|||

PS/2 mouse |

24V power supply |

PCI slot |

|

PCI/ISA slot |

|

|

|

||

|

|

|

|

|

|

|

|

PCU50 |

|

|

|

|

|

|

|

|

|

(right side of |

|

COM1/RS232/PLC |

|

|

|

|

|

|

housing) |

|

|

|

|

|

COM2 |

MPI/DP |

|

|

|

|

|

LPT1/PRINTER |

VGA |

USB |

Ethernet |

|

|

PC card |

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

X20 |

|

|

|

MCP |

|

|

|

|

|

|

|

|

(Rear view) |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

HHU |

or |

HT 6 |

|

|

|

|

|

|

|

|

|

|

|

Distributor box |

|

|

|

|

|

|

|

16 |

X1 |

X5 |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

X2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

MPI bus cable |

|

CCU 3 |

|

|

17 |

2 |

|

X4 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measuring probe |

|

X3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cable distributor |

|

|

|

||

|

|

|

|

|

|

5 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Handwheel HHU |

|

||

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

Handwheel |

|

||

|

|

|

|

|

|

Shield |

|

|

|

|

|

–X122 |

–X102 |

|

|

|

MPI bus cable |

2 |

|

|

–X307 |

|

|

|

|

PG740 programming device |

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

MPI cable |

|

|

|

|

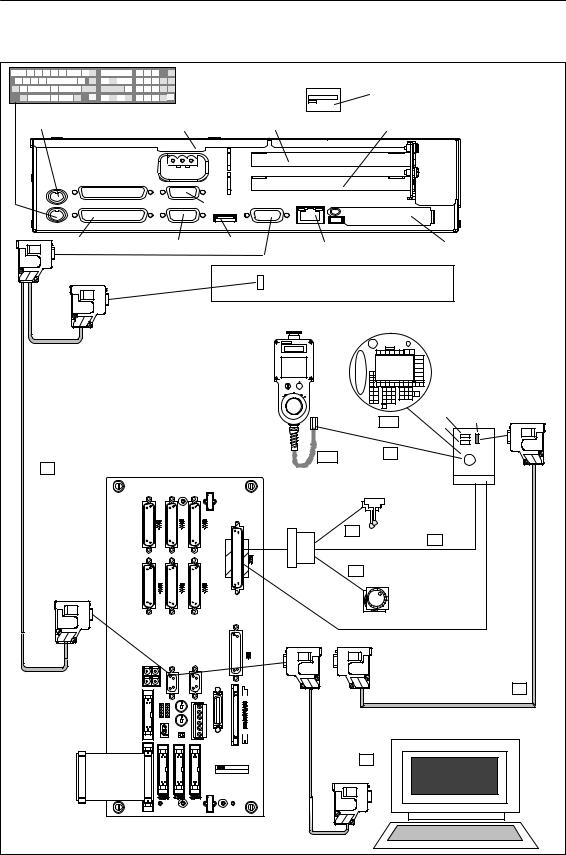

Fig. 1-2 Interface configuration of the SINUMERIK 810D for the MPI bus, HHU, HT 6 and cable distributor

Copyright ♥ Siemens AG 2006 |

1-15 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

SIMATIC S7-300 I/O

X2

PS IM |

SMs |

|

SIMATIC S7-300 IM connecting cable |

8 |

|

||

|

|

CCU3

–X411 |

–X412 |

–X413 |

|

|

|

|

–X121 |

–X414 |

–X415 |

–X416 |

|

|

|

|

–X111 |

|

–X122 |

–X102 |

|

|

–X431 |

MEMORY CARD |

|

–X307 |

|

–X130 |

|

–X306–X305 |

–X304 |

|

Drive bus cable |

7 |

|

|

|

Terminal block |

8

Single I/O module

1)

8

Connecting cable shielded

9

|

Single I/O module Single I/O module |

|

Terminator |

|

1) Pay attention to maximum configuration !! |

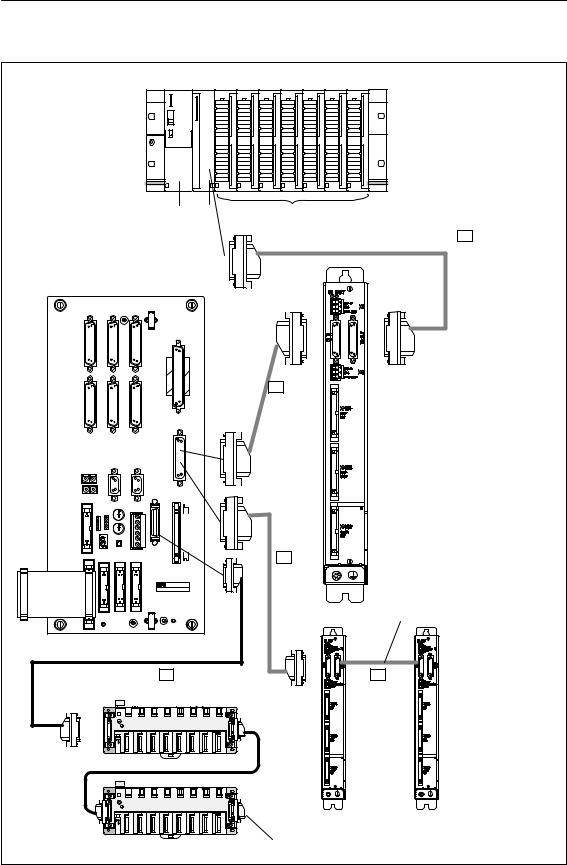

Fig. 1-3 |

Interface configuration of the SINUMERIK 810D for PLC I/Os and NCU terminal block |

1-16 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

|

|

|

|

|

|

|

1 System Overview |

|

|

|

|

|

|

|

1.2 System configuration |

Connecting |

|

The following connecting cables are used for the SINUMERIK 810D |

|||||

cables |

|

|

|

|

|

|

|

Table 1-3 |

|

Connecting cables for SINUMERIK 810D |

|

||||

|

|

|

|

|

|

|

|

No. |

|

|

MLFB |

|

Description |

||

|

|

|

|

|

|||

1 |

|

6FX2002-4EA0V-1VV0 1) |

MPI bus cable from the operator panel front to the MCP and to the |

||||

|

|

|

|

|

|

CCU |

|

|

|

|

|

|

|||

2 |

|

6ES7901-0BF00-0AA0 |

MPI bus cable from the distributor box (HHU) to the CCU |

||||

|

|

|

|

|

|||

3 |

|

6FX2002-4AA21-1VV0 1) |

Connecting cable from distributor box to cable distributor on the CCU |

||||

|

|

|

|

|

|

(for the handwheel pulses from the HHU) |

|

|

|

|

|

|

|||

4 |

|

Included in the scope of |

MPI bus cable to the PG |

||||

|

|

supply of the PG740 |

|

|

|||

|

|

|

|

|

|||

5 |

|

6FX2002-4AA41-1AB0 |

Probe connection cable to cable distributor, length: 5 m |

||||

|

|

|

|

|

|||

6 |

|

6FX2002-4AA21-1VV0 1) |

Connecting cable for the electronic handwheel to the cable distributor |

||||

|

|

|

|

|

|

on the CCU |

|

|

|

|

|

|

|||

7 |

|

6FX2002-1CB01-1AB0 |

Drive bus cable (1 m) for connection of the NCU terminal block |

||||

|

|

|

|

|

|||

8 |

|

6ES7368-3VVV0-0AA0 1) |

Connecting cable for the Step7-300 I/Os (IM361 or single I/O module) |

||||

9 |

|

6FC5411-0AA80-0AA0 |

Connecting cable shield for single-tier configuration with several single |

||||

|

|

|

|

|

|

I/O modules |

|

|

|

|

|

|

|||

10 |

|

6FC5412-0FA80-0AA0 |

Cable set for external SIMODRIVE 611 control, for connecting the |

||||

|

|

|

|

|

|

device bus and drive bus |

|

|

|

|

|

|

|||

11 |

|

6FX2003-0DA00-0AA0 |

Terminator for drive bus (only if the drive bus is used) |

||||

|

|

|

|

|

|

|

|

12 |

|

1) |

|

|

|

Ribbon cable for terminal strip converter |

|

|

|

|

|

|

|

|

|

13 |

|

2) |

|

|

|

Motor encoder cable |

– incremental |

|

|

|

|

|

|

|

– absolute |

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

Cable for connection of direct measuring system to the CCU |

|

|

|

6FX2002-2CG00-1AA0 |

|

– incremental |

|||

|

|

6FX2002-2CH00-1AA0 |

|

– absolute |

|||

|

|

|

|

|

|

|

|

15 |

|

2) |

|

|

|

Power cables for motor |

|

|

|

|

|

|

|||

16 |

|

6FX2002-1AAV3-1VVV |

Round cable from HT6 to the distributor box |

||||

|

|

|

|

|

|

|

|

17 |

|

2) |

|

|

|

Round cable from HHU to the distributor box |

|

|

|

|

|

|

|

||

|

|

|

A number is assigned to each cable. |

||||

|

|

|

You will find these numbers (1 to 17) in the figures above. |

||||

|

|

|

|

|

|

||

1) |

For length code, |

see Reference: |

Catalog NC Z |

|

|||

2) |

|

|

see References: /PJU/, Configuration Manual Converters |

||||

PCU 50/70, MCP |

There are 4 possible variants: |

|

|||||

and HHU/HT 6 |

S HHU/HT 6 without PCU 50/70/MCP |

||||||

|

|

|

|||||

|

|

|

S PCU 50/70/20 + MCP |

MPI bus cable with cable no. 1 |

|||

|

|

|

S |

PCU 50/70/20 |

MPI bus cable with cable no. 2 |

||

|

|

|

S |

MCP |

|

MPI bus cable with cable no. 2 |

|

Copyright ♥ Siemens AG 2006 |

1-17 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

Axis expansion on 810D

On the SINUMERIK 810D, the number of axes can be expanded to six axes, including spindles.

There are two possibilities:

either Connect axis expansion plug-in unit and SIMODRIVE 611 power module at axis expansion interface,

or Connect SIMODRIVE 611D control plug-in unit with SIMODRIVE 611 power module on drive bus/device bus.

Axis expansion plug-in unit

Axis expansion control

plug-in unit

Power modules

Combinations

The axis expansion plug-in units are used whenever no more than six measuring channels are required for the SINUMERIK 810D. This plug-in unit is plugged into a SIMODRIVE 611 power module. The axis expansion plug-in units are designed for 1-axis and 2-axis power modules. The ribbon cables are part of the plug-in unit.

If the six measuring channels of the SINUMERIK 810D are insufficient, SIMODRIVE 611 controller plug-ins must be inserted into the SIMODRIVE 611 power modules to connect further measuring systems (connection via drive bus with drive bus terminator). If 611D control modules are used, it may be necessary to connect the NCU terminal block to the free drive bus connector of the 611D control.

See Chapter 5, Axis expansion

The CCU can control up to 6 axes onboard. For this purpose there is a new expansion plug-in in addition to the existing axis expansion plug-in modules.

All power modules of the 611D series can be connected as external power modules for axis expansion.

As from SW 6.3, the limitation to six drives applies.

Expansion levels 1 to 6 can be achieved by many combinations. To operate the spindle to the internal power module, connect it to the 24A/32A power module (A1).

1-18 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

Table 1-4 Possible combinations for 1 to 6 drives on SINUMERIK 810D

Number of |

|

Internal drives |

Drives via axis |

|

drives |

|

1 x 18/36A (FSD) |

expansion |

|

|

|

*or 24/32A (MSD) |

|

|

|

|

2x9/18 / 2 x 6/12A |

|

|

|

3 power modules |

2 power modules |

|

|

|

|

|

|

|

1 |

1 |

|

1 |

0 |

|

|

|

|

|

|

0 |

|

0 |

1 |

|

|

|

|

|

2 |

2 |

|

2 |

0 |

|

|

|

|

|

|

1 |

|

1 |

1 |

|

|

|

|

|

|

0 |

|

0 |

2 |

|

|

|

|

|

3 |

3 |

|

– |

0 |

|

|

|

|

|

|

2 |

|

2 |

1 |

|

|

|

|

|

|

1 |

|

1 |

2 |

|

|

|

|

|

|

0 |

|

0 |

3 |

|

|

|

|

|

4 |

3 |

|

– |

1 |

|

|

|

|

|

|

2 |

|

2 |

2 |

|

|

|

|

|

|

1 |

|

1 |

3 |

|

|

|

|

|

5 |

3 |

|

– |

2 |

|

|

|

|

|

|

2 |

|

2 |

3 |

|

|

|

|

|

6 |

3 |

|

– |

3 |

|

|

|

|

|

|

2 |

|

2 |

4 |

|

|

|

|

|

CCU 3 with 3 axis CCU box plus

2 axis power module to right of CCU

1 axis power module to right of CCU

CCU 3

6x encoder { connection

internal/ external

X307 |

|

|

|

|

|

X306 |

X305 |

X304 |

|||

50 A 15 A 15 A

If no external power module is connected on connector -X307 (internal/external pulse interface 3rd power module) to the left of the CCU3 =>

CCU3 with 3 axis CCU box plus 2 axis CCU box plus

1 axis CCU box

{ |

{ |

|

3 axes |

2 axes |

1 axis |

Fig. 1-4 First way of operating 6 axes on CCU3 with internal 3 axis CCU box

Copyright ♥ Siemens AG 2006 |

1-19 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.2 System configuration

CCU 3 with 3 axis CCU box or 2 axis CCU box plus 2 axis power module to the right of CCU 1 axis power module to the right of CCU 1 axis power module to the left of CCU

CCU 3 |

{ |

|

|

6x encoder |

|

|

|

connection |

|

|

|

internal/ |

|

|

|

external |

|

|

|

X307 |

X305 |

X304 |

|

|

X306 |

||

25 A |

25 A |

|

|

If an external power module is connected to connector -X307, then the 3rd internal power module will be switched to the external power module. On a 3-axis CCU box, the 3rd internal power module A3 (6/12 A) cannot be used.

Fig. 1-5 Second way of operating 6 axes on CCU 3 with 2 axis CCU box

Restrictions

SPower supply: 120 kW.

SThe DC link busbar of the 810D is capable of an effective load of 200 A.

SThe length of the ribbon cable of the axis expansion plug-in unit left for connecting the SIMODRIVE 611 power module is 300 mm.

SThe length of the ribbon cable of the axis expansion plug-in unit right is sufficient for a module width of 150 mm.

SThe length of the cable set for the axis expansion with 611D control plug-in unit is:

62 mm for the drive bus and 150 mm for the device bus.

1-20 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.3 Labels

1.3Labels

In case of technical queries or service, please quote all data on the rating plate to the local SIEMENS office responsible for your equipment.

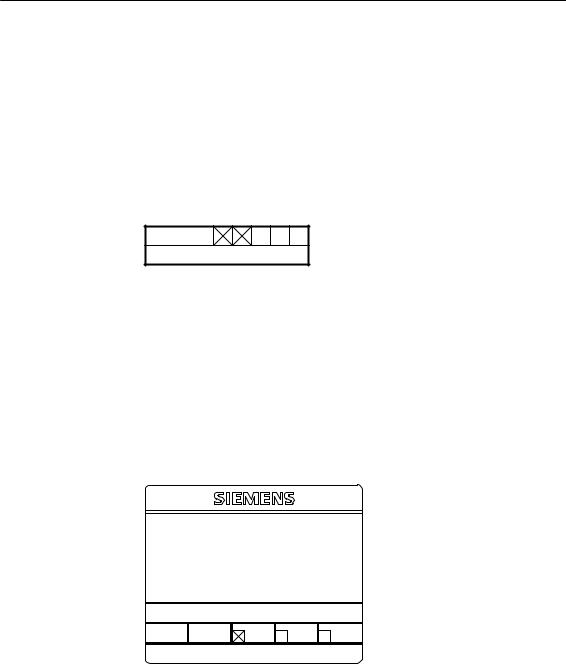

One of the following labels is attached to the components and modules:

PCBs with screen |

Example: |

Component number: 570 573.9001.00 |

printing |

|

Product version: B (last cross) |

SIEMENS A B C D E

570 573.9001.00

CCU3.4 module |

Example: |

Component name: CCU3.4 |

|

|

|

|

|

MLFB: 6FC5410-0AY03-1AA0 |

|

|

|

|

Component number: A5E00377496 |

|

|

|

|

|

|

CCU3.4 |

6FC5410 0AY03 1AA0 |

A5E00377496 |

A B C |

|

|

|

|

|

|

CCU box |

|

Example: |

Component name: SINUMERIK 810D |

|

|

|

|

Power module 2x15A+1x50A |

|

MLFB: 6FC5447-0AA00-0AA1

Product version: A (last cross)

SINUMERIK 810D

Power module 2x15A + 1x50A 6FC5 447-0AA00-0AA1

Made in Germany

A B C

J

Copyright ♥ Siemens AG 2006 |

1-21 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

1 System Overview

1.3 Labels

Notes

1-22 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Connection Conditions |

2 |

2.1Supplementary electrical conditions

Compliance with the connection conditions

The controller is tested for compliance with the ambient conditions specified below. Fault-free operation is only ensured if:

SThese environmental conditions are maintained when storing, transporting and operating the equipment.

SOriginal components and spare parts are used. This applies in particular to the use of specified cables and plug connectors.

SThe equipment has been correctly mounted/installed.

Danger

!The equipment may not be commissioned until it has been clearly identified that the machine in which the controller is installed is in full conformance with the specifications in EC Machinery Directive 98/37/EC.

Assistance and |

The connection conditions must be carefully maintained for the complete |

support |

system. Please contact your local Siemens office or representative for any |

|

assistance. |

Copyright ♥ Siemens AG 2006 |

2-23 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

2.1.1Power supply

Demands on DC power supplies

Warning

!S The DC power supply is always referenced to ground and must be

generated by a safety transformer.

SFinal user interfaces are powered via a DC power supply with protective separation per EN 61800-5-1.

SIn the case of supply cables > 10 m, protective elements must be fitted at the device input in order to protect against lightning (surge voltage).

SThe DC power supply must be connected to the ground/shield of the NC for EMC and/or functional reasons. For EMC reasons, this connection should only be made at one point. As a rule, the connection is provided as standard in the S7-300 I/Os. If this is not the case in exceptional circumstances, the ground connection should be made to the grounding rail of the NC cabinet; also refer to /EMC/ EMC Configuring Guidelines.

Table 2-1 |

Requirements of the DC supply |

|

||

|

|

|

|

|

Rated voltage |

|

In accordance with EN 61131-2 |

24 V DC |

|

|

|

S Voltage range (average value) |

20.4 V DC to 28.8 V DC |

|

|

|

S |

Voltage ripple peak-to-peak |

5 % (unfiltered 6-pulse rectification) |

|

|

S Ramp-up time at power-on |

Any |

|

|

|

|

|

|

Non-cyclic overvoltages |

|

|

35 V |

|

|

|

S |

Duration |

500 ms |

|

|

S |

Restoration time |

50 s |

|

|

S |

Events per hour |

10 |

|

|

|

|

|

Transient voltage interruptions |

S |

Outage time |

3 ms |

|

|

|

S |

Restoration time |

10 s |

|

|

S |

Events per hour |

10 |

|

|

|

|

|

Configuration 810D power consumption

The EP and CP points for the power modules only apply in conjunction with the SINUMERIK 810D (axis expansion). The EP and CP points from Catalog NC 60 apply when SIMODRIVE 611D modules with control plug-in units are used.

2-24 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

Table 2-2 |

EP and CP points for 810D components |

|

|

|

|

|

|

|

Component |

Electronics points (EP) |

Control points (CP) |

|

|

|

|

810D |

|

2 |

4.5 |

|

|

|

|

EnDat encoder |

0 |

0.3 |

|

|

|

|

|

Power module 50 A |

0.6 |

0.5 |

|

|

|

|

|

Power module > 50 A 80 A |

0.75 |

1.0 |

|

|

|

|

|

Power module > 80 A, 120 A |

1.5 |

1.5 |

|

|

|

|

|

611D module MSD or FSD |

See Catalog NC 60 |

See Catalog NC 60 |

|

|

|

|

|

Table 2-3 |

Example of calculation of the supply power for 4 axes/1 spindle for 810D |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electronics points (EP) |

|

|

Control points (CP) |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Module |

|

Assessment |

|

Number of |

|

Product |

Assessment |

|

Number of |

|

Product |

|

|

factor, indivi- |

|

modules |

|

|

factor, indivi- |

|

modules |

|

|

|

|

dual module |

|

|

|

|

dual module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

810D |

|

2 |

|

1 |

|

2 |

4.5 |

|

1 |

|

4.5 |

|

|

|

|

|

|

|

|

|

|

|

|

EnDat encoder |

|

0 |

|

2 |

|

0 |

0.3 |

|

2 |

|

0.6 |

|

|

|

|

|

|

|

|

|

|

|

|

LTM 50A |

|

0.6 |

|

1 |

|

0.6 |

0.5 |

|

1 |

|

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

LTM 80A |

|

0.75 |

|

1 |

|

0.75 |

1 |

|

1 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total for |

|

3.35 |

|

|

Total for |

|

6.6 |

|

|

|

|

products |

|

|

|

|

products |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

For I/R unit 16 kW |

|

7.5 |

For I/R unit 16 kW |

|

16.50 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Copyright ♥ Siemens AG 2006 |

2-25 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

2.1.2Safe isolation to EN 61800-5-1

End user interfaces (UI)

Interfaces for servicing, commissioning and maintenance

The complete system includes end user interfaces (UIs) and interfaces for servicing, commissioning and maintenance.

UIs are all the interfaces that are freely accessible to the machine operator without the need for tools or aids. These user interfaces are designed with safe isolation to EN 61800-5-1.

Danger

!The interfaces for servicing, commissioning and maintenance purposes are provided without safe isolation.

If necessary, these interfaces can be isolated safely using a supplementary adapter (insulation voltage 230 V AC). These adapters are not included in the Siemens scope of delivery. You can buy these parts from your local dealer who will help you to make the proper choice.

Table 2-4 |

Service interfaces |

|

|

|

|

|

|

Component |

Interface name |

Function |

|

|

|

|

|

CCU module |

|

X341, X342, X351, X352 |

DAC socket for analog signals |

|

|

|

|

Danger

!Safe isolation can only be ensured if the system configuration specified below is strictly adhered to. When mounting additional components (e.g. S7-300 FM, IP) with an end user interface, please make sure that the end user interface has a basic insulation for at least 230 V AC.

2-26 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

3 x 400 V AC |

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

Housing/shield |

|

|

|

8 |

|

|

|

MSTT/MCP |

|

PCU |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

4 |

11 |

|

24V |

M (GND) |

|

|

|

4 |

4 |

||||

|

|

|

|

11 |

|

||

|

|

2 |

|

|

|

|

|

|

|

3 |

|

|

HHU/ |

|

|

|

|

|

|

|

HT 6 |

|

|

|

|

Distributor box |

4 |

6 |

7 |

|

|

|

|

5 |

|

|

|

|

|

|

|

810D/611 digital |

|

|

|

|

Machine |

|

|

|

|

|

|

|

9 |

|

|

10 |

|

|

|

S7-300 I/Os |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

M |

(GND) |

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

Person |

Terminal |

|

|

|

|

|

block |

|||

|

|

|

|

|

|

||

|

|

Basic insulation |

Protective separation |

|

|

||

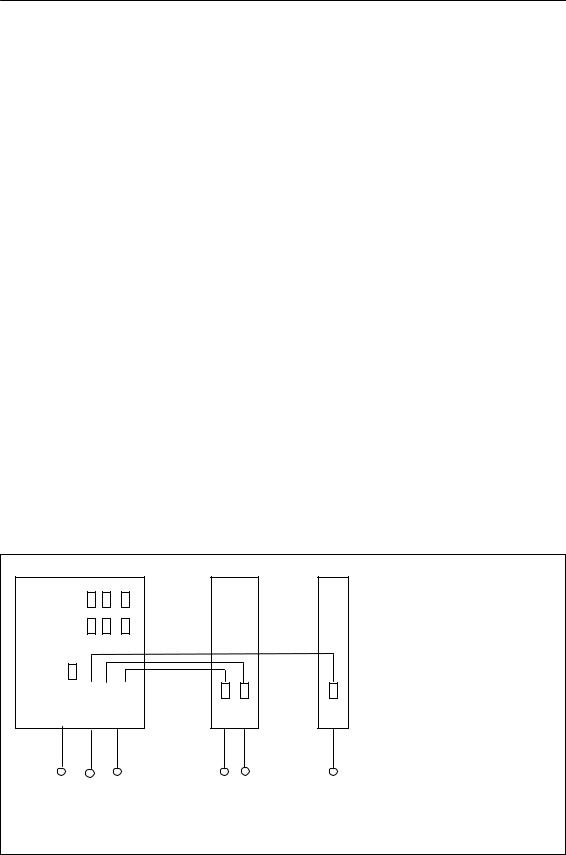

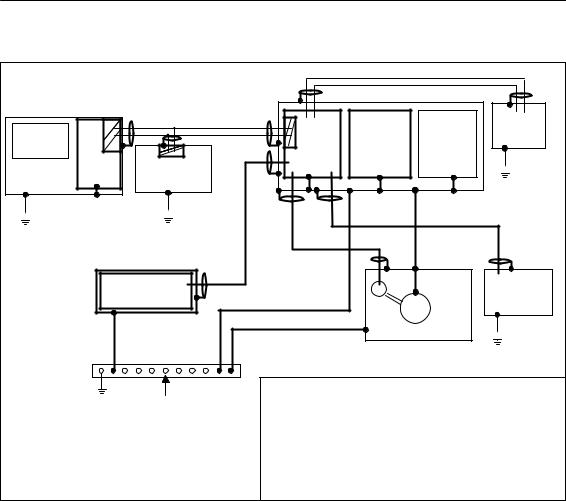

Fig. 2-1 |

Protective separation as per EN 61800-5-1 |

|

|

|

|

|

|

Fig. 2-1 shows the potential balance of the 810D/611D/S7-300 system. Legend:

1.Floating power supply of the SIMODRIVE electronics unit with 230 V AC basic insulation.

2.Floating transistor triggers for the three-phase rectifier bridge with 230 V AC basic insulation.

3.Floating transistor triggers for each axis of the three-phase inverter bridge with 230 V AC basic insulation.

4.Floating signal connection from the CCU to the PCU or HHU/HT 6 with 230 V AC basic insulation.

5.Non-floating signal line between CCU and I/O devices.

6.Non-floating end user interface with protective separation for 230 VAC through interfaces 1 to 4 and 7.

7.Protectively separated 5 V DC power supply, fed from a protectively separated 24 V DC supply.

8.24 V DC power supply unit for external devices and for the machine adaptation control according to applicable standards in the form of a PELV (Protective Extra Low Voltage) circuit featuring safe isolation.

9.Floating interfaces to the machine (not accessible to the end user).

10.Floating signal interfaces directly accessible to the end user (e.g. V.24). For these interfaces, you must always make sure that there is either safe isolation with respect to the line supply voltage or that there are two basic insulation levels, for 230 V AC each.

11.5 V DC power supply with basic insulation, fed from a safely-isolated 24 V DC supply.

Copyright ♥ Siemens AG 2006 |

2-27 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

2.1.3Grounding Concept

The SINUMERIK 810D system consists of a number of individual components, each of which must comply with the appropriate EMC and safety standards. The individual system components are:

SCCU box

SMachine control panel MCP

SKeyboard

SOperator panels (operator panel front + PCU/TCU)

SNCU terminal block

SDistributor box and handheld unit

SS7-300 I/O with IM 361 interface module

SSingle I/O module

CCU box and SIMODRIVE components are fixed to a metal cabinet plate with screws. Make sure that near the screws a low-impedance contact of the CCU box with the cabinet panel can be made. Insulating varnishes must be removed where possible. The connection must be kept free of corrosion.

The electronics grounds of the modules are interconnected via the unit and control bus and also routed to terminal X151 of the NE module.

The ground and module ground M should be connected at the power supply terminal of the IM 361. Further, for the EFP, “SHIELD” and “M24” must be connected in connector X1.

2-28 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

Operator |

PCU/ |

Machine |

|

TCU |

control panel |

||

panel front |

|||

|

|

SL |

SL |

|

– Ground (frame) – |

IM 361

S7-300 peripherals/ single I/O module

PA

Grounding bar

Central ground connection conductor/protective conductor

|

Gating |

Power |

Distributor |

|

electronics |

electronics |

box |

|

CCU |

|

|

|

|

|

SL |

|

|

SL in the motor cable |

|

MB |

MB |

|

|

|

MB |

|

|

|

G |

|

Terminal |

|

M |

(GND) |

block |

|

|

||

|

PA |

|

SL |

|

|

|

|

|

PA |

|

|

Machine bed

MB: Shielded signal cable with reference ground

M:Motor

G:Encoder

PA: |

Equipotential bonding conductor |

|

|||

SL: |

Protective conductor |

|

Cross-sections (mm2) |

||

|

w10 |

|

|||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Line supply connection S |

|

SL minimum |

|

|

|

S v 16 |

|

S |

|

|

|

16 < S v 35 |

|

16 |

|

|

|

S > 35 |

|

|

|

|

|

|

S/2 |

|

|

|

|

|

|

|

Fig. 2-2 Grounding concept

References: /EMV/, EMC Configuring Guidelines

2.1.4RI suppression measures

Shielded signal cables

In addition to the protective grounding of system components, special precautions must be taken to ensure safe, fault-free operation of the system. These measures include shielded signal cables, special equipotential bonding, isolation, and shielding measures.

To ensure safe, interference-free operation of the installation, it is essential to use the cables specified in the individual diagrams.

For digital signal transmission, the shield must have a conductive connection at both sides of the housing.

Exception:

Standard shielded cables grounded on only one side can be used for devices from other manufacturers (printers, programming devices, etc.).

Copyright ♥ Siemens AG 2006 |

2-29 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

2 Connection Conditions

2.1 Supplementary electrical conditions

These external devices may not be connected to the control during normal operation. However, if the system cannot be operated without them, then the cable shields must be connected at both ends. Furthermore, the external device must be connected to the control via an equipotential bonding cable.

Cable |

Definition: |

|

definitions |

S |

Signal cables (e.g.) |

|

||

|

|

– Data cables (MPI, sensor cables, etc.) |

|

|

– Binary inputs and outputs |

|

|

– Emergency Stop cables |

|

S |

Load cables (e.g.) |

|

|

– Low-voltage supply cables (230 V AC, +24 V DC etc.) |

|

|

– Supply cables to contactors (primary and secondary circuit) |

Rules for routing cables

In order to achieve the best possible noise immunity of the complete system (control, power module, machine), the following EMC measures must be carefully observed:

SSignal cables and load cables must be routed at the greatest possible distance from one another.

SIf necessary, signal and load cables may cross one another (if possible, at an angle of 90°), but must never be laid close or parallel to one another.

SOnly cables provided by the manufacturer should be used as signal cables from and to the CCU.

SSignal cables may not be routed close to strong external magnetic fields (e.g. motors and transformers).

SPulse-carrying HC/HV cables must always be laid completely separately from all other cables.

SIf signal lines cannot be routed a sufficient distance away from other cables, they must be installed in grounded cable ducts (metal).

SThe clearance (surface through which interference can be coupled-in) between the following cables must be kept to a minimum:

–Signal cable and electrical circuit signal cable (twisted)

–Signal cable and associated equipotential bonding conductor

–Equipotential bonding conductor and PE conductor (routed together)

Important

!For further notes on interference suppression measures and the connection of shielded cables, please refer to

References: /EMV/, EMC Configuring Guidelines.

2-30 |

Copyright ♥ Siemens AG 2006 |

SINUMERIK 810D Equipment Manual Configuration CCU (PHC) – 03/2006 Edition |

Loading...

Loading...