siemens 840D Programming Manual

SINUMERIK

SINUMERIK

840D sl/840Di sl/840D/840Di/810D Job planning

Programming Manual

Valid for

Control

SINUMERIK 840D sl/840DE sl SINUMERIK 840Di sl/840DiE sl

SINUMERIK 840D powerline/840DE powerline SINUMERIK 840Di powerline/840DiE powerline SINUMERIK 810D powerline/810DE powerline

Software |

Version |

NCU system software for 840D sl/840DE sl 1.4 |

|

NCU system software for 840Di sl/DiE sl |

1.0 |

NCU system software for 840D/840DE |

7.4 |

NCU system software for 840Di/840DiE |

3.3 |

NCU system software for 810D/810DE |

7.4 |

11/2006 |

|

6FC5398-2BP10-2BA0 |

|

Preface

Flexible NC programming |

1 |

|

|

|

|

Subroutines, Macros |

2 |

|

File and Program |

|

|

3 |

||

Management |

||

|

|

|

Protection zones |

4 |

|

|

|

|

Special Motion Commands |

5 |

|

|

|

|

Frames |

6 |

|

|

|

|

Transformations |

7 |

|

|

|

|

Tool offsets |

8 |

|

|

|

|

Path traversing behavior |

9 |

|

|

|

|

Motion synchronous actions |

10 |

|

|

|

|

Oscillation |

11 |

|

|

|

|

Punching and nibbling |

12 |

|

|

|

|

Additional functions |

13 |

|

User stock removal |

|

|

14 |

||

programs |

||

|

|

|

Tables |

15 |

|

|

|

|

Appendix |

A |

|

|

|

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes in this documentation qualified persons are defined as persons who are authorized to commission, ground and label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in connection with devices or components from other manufacturers which have been approved or recommended by Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

Order No.: 6FC5398-2BP10-2BA0 |

Copyright © Siemens AG 2006. |

Automation and Drives |

11/2006 |

Technical data subject to change |

Postfach 48 48 |

|

|

90437 NÜRNBERG |

|

|

GERMANY |

|

|

Preface

Foreword

SINUMERIK® Documentation

The SINUMERIK documentation is organized in 3 parts:

•General Documentation

•User Documentation

•Manufacturer/service documentation

An overview of publications (updated monthly) indicating the language versions available can be found on the Internet at:

http://www.siemens.com/motioncontrol

Select the menu items "Support" → "Technical Documentation" → "Overview of Publications".

The Internet version of DOConCD (DOConWEB) is available at: http://www.automation.siemens.com/doconweb

Information about training courses and FAQs (Frequently Asked Questions) can be found at the following website:

http://www.siemens.com/motioncontrol under menu option "Support"

Target group

This publication is intended for:

•Programmers

•Project engineers

Benefits

With the programming manual, the target group can develop, write, test, and debug programs and software user interfaces.

Job planning |

3 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Preface

Standard scope

This Programming Guide describes the functionality afforded by standard functions. Extensions or changes made by the machine tool manufacturer are documented by the machine tool manufacturer.

Other functions not described in this documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with a new control or when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information about all types of the product and cannot cover every conceivable case of installation, operation or maintenance.

Technical Support

If you have any technical questions, please contact our hotline:

|

Europe/Africa |

|

Asia/Australia |

America |

Phone |

+49 180 5050 222 |

+86 1064 719 990 |

+1 423 262 2522 |

|

Fax |

+49 180 5050 223 |

+86 1064 747 474 |

+1 423 262 2289 |

|

Internet |

http://www.siemens.com/automation/support-request |

|||

mailto:adsupport@siemens.com |

|

|||

Note

Country telephone numbers for technical support are provided under the following Internet address:

Enter http://www.siemens.com/automation/service&support

Questions about the manual

If you have any queries (suggestions, corrections) in relation to this documentation, please fax or e-mail us:

Fax: |

+49 (0) 9131 / 98 - 63315 |

E-mail: mailto:docu.motioncontrol@siemens.com

Fax form: See the reply form at the end of this publication

SINUMERIK Internet address

http://www.siemens.com/sinumerik

4 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Preface

EC declaration of conformity

The EC Declaration of Conformity for the EMC Directive can be found/obtained from:

•the internet: http://www.ad.siemens.de/csinfo under product/order no. 15257461

•the relevant branch office of the A&D MC group of Siemens AG.

Export version

The following functions are not available in the export version:

Function |

810DE |

840DE sl |

840DE |

840DiE sl |

840DiE |

Helical interpolation 2D+6 |

− |

− |

− |

− |

− |

(Basic version, no options) |

|

|

|

|

|

Milling machining package |

− |

− |

− |

− |

− |

Five axis machining package |

− |

− |

− |

− |

− |

Handling transformation package |

− |

− |

− |

− |

− |

Multi-axis interpolation (> 4 interpolating axes) |

− |

− |

− |

− |

− |

OA NCK compile cycles |

− |

− |

− |

− |

− |

Clearance control 1D/3D in position-control cycle 1) |

− |

− |

− |

− |

− |

Synchronized actions 1) |

# |

# |

# |

# |

# |

(Basic version, no options) |

|

|

|

|

|

Master-value coupling and curve-table interpolation |

# |

# |

# |

# |

# |

Sag compensation, multi-dimensional |

# |

# |

# |

# |

# |

Synchronized actions, stage 2 1) |

− |

− |

# |

− |

# |

Electronic gear 1) |

− |

− |

# |

− |

# |

Electronic transfer |

− |

− |

# |

− |

# |

|

# Restricted functionality |

|

|

|

|

-Function not available

1)The restricted functions for the SINUMERIK 810DE powerline/SINUMERIK 840DE sl/SINUMERIK 840DE powerline/ SINUMERIK 840DiE sl/SINUMERIK 840DiE powerline export versions impose a limit of "max. 4 interpolating axes".

Description

Fundamentals

This Programming Guide "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements which are also defined according to DIN 66025.

Job planning |

5 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Preface

Job planning

The Programming Guide "Job Planning" is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK 840D sl/840Di sl/840D/840Di/810D control enables the user to program complex workpiece programs (e.g., for free-form surfaces, channel coordination, etc.) and greatly facilitates the programming of complicated operations.

The commands and statements described in this Programming Guide are not specific to one particular technology.

They can be used for a variety of tasks, such as

•Turning, milling and grinding

•Cyclical machines (packaging, woodworking)

•Laser power controls.

6 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Table of contents

|

Preface...................................................................................................................................................... |

3 |

1 |

Flexible NC programming........................................................................................................................ |

15 |

1.1Variables and arithmetic parameters (user-defined variables, arithmetic parameters,

|

system variables)......................................................................................................................... |

15 |

1.2 |

Variable definition (DEF user-defined variables LUD, GUD, PUD)............................................. |

17 |

1.3 |

Array definitions (DEF, SET, REP).............................................................................................. |

21 |

1.4 |

Indirect programming................................................................................................................... |

28 |

1.4.1 |

Run string as parts program line (EXECSTRING)....................................................................... |

31 |

1.5 |

Assignments................................................................................................................................. |

32 |

1.6 |

Arithmetic operations/functions.................................................................................................... |

33 |

1.7 |

Comparison and logical operations ............................................................................................. |

36 |

1.7.1 |

Precision correction on comparison errors (TRUNC).................................................................. |

39 |

1.7.2 |

Variable minimum, maximum and range (MINVAL, MAXVAL and BOUND) .............................. |

40 |

1.8 |

Priority of the operations.............................................................................................................. |

42 |

1.9 |

Possible type conversions ........................................................................................................... |

43 |

1.10 |

String operations.......................................................................................................................... |

44 |

1.10.1 |

Type conversion to STRING........................................................................................................ |

45 |

1.10.2 |

Type conversion of STRING........................................................................................................ |

46 |

1.10.3 |

Concatenation of strings.............................................................................................................. |

47 |

1.10.4 |

Conversion to lower/upper case.................................................................................................. |

48 |

1.10.5 |

Length of the string...................................................................................................................... |

49 |

1.10.6 |

Look for character/string in the string .......................................................................................... |

49 |

1.10.7 |

Selection of a substring................................................................................................................ |

51 |

1.10.8 |

Selection of a single character..................................................................................................... |

51 |

1.11 |

CASE statement .......................................................................................................................... |

53 |

1.12 |

Control structures......................................................................................................................... |

55 |

1.13 |

Program coordination................................................................................................................... |

59 |

1.14 |

Interrupt routine (SETINT, DISABLE, ENABLE, CLRINT)........................................................... |

64 |

1.15 |

Axis replacement, spindle replacement (RELEASE, GET, GETD) ............................................. |

73 |

1.16 |

Transfer axis to another channel (AXTOCHAN).......................................................................... |

77 |

1.17 |

NEWCONF: Setting machine data effective................................................................................ |

78 |

1.18 |

WRITE: Write file.......................................................................................................................... |

79 |

1.19 |

DELETE: Delete file..................................................................................................................... |

81 |

1.20 |

READ: Read lines in the file......................................................................................................... |

83 |

1.21 |

ISFILE: File present in the NCK user memory............................................................................. |

85 |

Job planning |

|

|

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

7 |

|

Table of contents

|

1.22 |

FILEDATE/TIME/SIZE/STAT/INFO: File information.................................................................. |

86 |

|

1.23 |

CHECKSUM: Form the checksum over an array........................................................................ |

88 |

|

1.24 |

ROUNDUP: Round up ................................................................................................................ |

89 |

2 |

Subroutines, Macros................................................................................................................................ |

91 |

|

|

2.1 |

Using subroutines ....................................................................................................................... |

91 |

|

2.2 |

Subroutines with SAVE mechanism ........................................................................................... |

94 |

|

2.3 |

Subroutines with parameter transfer (PROC, VAR) ................................................................... |

95 |

|

2.4 |

Call subroutines (L or EXTERN)................................................................................................. |

99 |

|

2.5 |

Parameterized subroutine return (RET).................................................................................... |

104 |

|

2.6 |

Subroutine with program repetition (P)..................................................................................... |

108 |

|

2.7 |

Modal subroutine (MCALL)....................................................................................................... |

110 |

|

2.8 |

Indirect subroutine call (CALL).................................................................................................. |

112 |

|

2.9 |

Repeating program sections with indirect programming (CALL).............................................. |

112 |

|

2.10 |

Indirect call of a program programmed in ISO language (ISOCALL) ....................................... |

114 |

|

2.11 |

Calling subroutine with path specification and parameters (PCALL)........................................ |

115 |

|

2.12 |

Extend search path for subroutine calls with CALLPATH......................................................... |

116 |

|

2.13 |

Execute external subroutine (EXTCALL).................................................................................. |

118 |

|

2.14 |

Suppress individual block (SBLOF, SBLON)............................................................................ |

122 |

|

2.15 |

Suppress current block display (DISPLOF).............................................................................. |

126 |

|

2.16 |

Identifying subprograms with preparation (PREPRO).............................................................. |

128 |

|

2.17 |

Cycles: Setting parameters for user cycles............................................................................... |

129 |

|

2.18 |

Macro technique (DEFINE...AS)............................................................................................... |

132 |

3 |

File and Program Management ............................................................................................................. |

135 |

|

|

3.1 |

Program memory ...................................................................................................................... |

135 |

|

3.2 |

Working memory....................................................................................................................... |

140 |

|

3.3 |

Defining user data..................................................................................................................... |

142 |

|

3.4 |

Protection levels for user data, MD, SD and NC commands.................................................... |

145 |

|

3.4.1 |

Defining protection levels for user data (GUD)......................................................................... |

145 |

|

3.4.2 |

Automatic activation of GUDs and MACs................................................................................. |

147 |

|

3.4.3 |

Change the protection data for the machine and setting data (REDEF MD, SD)..................... |

148 |

|

3.4.4 |

Protection levels for NC commands (REDEF).......................................................................... |

150 |

|

3.5 |

REDEF Changing the attributes of the NC language elements................................................ |

152 |

|

3.6 |

SEFORM structuring statement in the Step editor.................................................................... |

158 |

4 |

Protection zones.................................................................................................................................... |

159 |

|

|

4.1 |

Definition of the protection zones (CPROTDEF, NPROTDEF) ................................................ |

159 |

|

4.2 |

Activating, deactivating protection zones (CPROT, NPROT)................................................... |

162 |

|

4.3 |

Checking for protection zone violation, working area limitation and software limits................. |

166 |

8 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

|

|

|

Table of contents |

5 |

Special Motion Commands.................................................................................................................... |

173 |

|

|

5.1 |

Approaching coded positions (CAC, CIC, CDC, CACP, CACN)............................................... |

173 |

|

5.2 |

Spline interpolation (ASPLINE, BSPLINE, CSPLINE, BAUTO, BNAT, BTAN)......................... |

174 |

|

5.3 |

Spline grouping (SPLINEPATH)................................................................................................ |

183 |

|

5.4 |

Compressor (COMPOF/ON, COMPCURV, COMPCAD).......................................................... |

185 |

|

5.5 |

Polynomial interpolation (POLY, POLYPATH) .......................................................................... |

189 |

|

5.6 |

Settable path reference (SPATH, UPATH)................................................................................ |

195 |

|

5.7 |

Measurements with touch trigger probe (MEAS, MEAW) ......................................................... |

197 |

|

5.8 |

Extended measuring function (MEASA, MEAWA, MEAC) (option)........................................... |

200 |

|

5.9 |

Special functions for OEM users (OEMIPO1, OEMIPO2, G810 to G829)................................ |

209 |

|

5.10 |

Feed reduction with corner deceleration (FENDNORM, G62, G621)........................................ |

209 |

5.11Programmed end-of-motion criterion (FINEA, COARSEA, IPOENDA, IPOBRKA,

|

|

ADISPOSA) ................................................................................................................................ |

210 |

|

5.12 |

Programmable servo parameter set (SCPARA) ........................................................................ |

214 |

6 |

Frames |

.................................................................................................................................................. |

217 |

|

6.1 |

Coordinate transformation via frame variables .......................................................................... |

217 |

|

6.1.1 |

Predefined frame variable ( $ P _ BFRAME, $ P _ IFRAME, $ P _ PFRAME, $ P _ ACTFRAME) ........ |

219 |

|

6.2 ........................................................................... |

Frame variables / assigning values to frames |

224 |

|

6.2.1 ..................................................................... |

Assigning direct values (axis value, angle, scale) |

224 |

|

6.2.2 ............................................... |

Reading and changing frame components (TR, FI, RT, SC, MI) |

226 |

|

6.2.3 ............................................................................................................ |

Linking complete frames |

228 |

|

6.2.4 .......................................................................................... |

Defining new frames (DEF FRAME) |

229 |

|

6.3 ............................................................................... |

Coarse and fine offsets (CFINE; CTRANS) |

230 |

|

6.4 .................................................................................................................................. |

DRF offset |

232 |

|

6.5 .................................................................................................................... |

External zero offset |

233 |

|

6.6 ........................................................................................................ |

Preset offset (PRESETON) |

234 |

|

6.7 .................................. |

Frame calculation from three measuring points in space (MEAFRAME) |

235 |

|

6.8 ..................................................................................................................... |

NCU global frames |

238 |

|

6.8.1 .................................................................... |

Channel - specific frames ( $ P _ CHBFR, $ P _ UBFR) |

239 |

|

6.8.2 ..................................................................................................... |

Frames active in the channel |

241 |

7 |

Transformations..................................................................................................................................... |

247 |

|

|

7.1 .......................................................................... |

General programming of transformation types |

247 |

|

7.1.1 ............................................................................... |

Orientation movements for transformations |

249 |

|

7.1.2 ....................................................................... |

Overview of orientation transformation TRAORI |

253 |

|

7.2 ................................................................... |

Three, four and five axis transformation (TRAORI) |

255 |

|

7.2.1 .............................................................................. |

General relationships of universal tool head |

255 |

|

7.2.2 ................................................................... |

Three, four and five axis transformation (TRAORI) |

258 |

|

7.2.3 ........................................ |

Variants of orientation programming and initial setting (OTIRESET) |

259 |

|

7.2.4 ... ... ... .............................................. |

Programming of the tool orientation (A , B , C , LEAD, TILT) |

261 |

|

7.2.5 ...................................................................... |

Face milling (3D - milling A4, B4, C4, A5, B5, C5) |

267 |

|

7.2.6 ....................................................................... |

Orientation axis reference (ORIWKS, ORIMKS) |

268 |

|

7.2.7 ................... |

Programming the orientation axes (ORIAXES, ORIVECT, ORIEULER, ORIRPY) |

271 |

Job planning |

9 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Table of contents

7.2.8Orientation programming along the peripheral surface of a taper (ORIPLANE,

ORICONxx)............................................................................................................................... |

273 |

7.2.9Specification of orientation for two contact points (ORICURVE, PO[XH]=, PO[YH]=,

|

PO[ZH]=)................................................................................................................................... |

276 |

7.3 |

Orientation polynomials (PO[angle], PO[coordinate])............................................................... |

279 |

7.4 |

Rotations of the tool orientation (ORIROTA, ORIROTR/TT, ORIROTC, THETA).................... |

281 |

7.5 |

Orientations relative to the path................................................................................................ |

283 |

7.5.1 |

Orientation types relative to the path........................................................................................ |

283 |

7.5.2Rotation of the tool orientation relative to the path (ORIPATH, ORIPATHS, angle of

|

|

rotation)..................................................................................................................................... |

285 |

|

7.5.3 |

Interpolation of the tool rotation relative to the path (ORIROTC, THETA)................................ |

286 |

|

7.5.4 |

Smoothing of orientation characteristic (ORIPATHS A8=, B8=, C8=)...................................... |

288 |

|

7.6 |

Compression of the orientation COMPON (A..., B..., C..., THETA).......................................... |

289 |

|

7.7 |

Online tool length compensation (TOFFON, TOFFOF)............................................................ |

293 |

|

7.8 |

Kinematic transformation .......................................................................................................... |

295 |

|

7.8.1 |

Milling on turned parts (TRANSMIT)......................................................................................... |

295 |

|

7.8.2 |

Cylinder surface transformation (TRACYL) .............................................................................. |

299 |

|

7.8.3 |

Inclined axis (TRAANG)............................................................................................................ |

307 |

|

7.8.4 |

Inclined axis programming (G05, G07)..................................................................................... |

310 |

|

7.9 |

Cartesian PTP travel................................................................................................................. |

312 |

|

7.9.1 |

PTP for TRANSMIT................................................................................................................... |

316 |

|

7.10 |

Constraints when selecting a transformation............................................................................ |

320 |

|

7.11 |

Deselect transformation (TRAFOOF) ....................................................................................... |

321 |

|

7.12 |

Chained transformations (TRACON, TRAFOOF)..................................................................... |

321 |

|

7.13 |

Replaceable geometry axes (GEOAX)..................................................................................... |

323 |

8 |

Tool offsets............................................................................................................................................ |

327 |

|

|

8.1 |

Offset memory........................................................................................................................... |

327 |

|

8.2 |

Language commands for tool management ............................................................................. |

330 |

|

8.3 |

Online tool compensation (PUTFTOCF, PUTFTOC, FTOCON, FTOCOF) ............................. |

333 |

|

8.4 |

Keep tool radius compensation constant (CUTCONON).......................................................... |

338 |

|

8.5 |

Activate 3D tool offsets (CUT3DC..., CUT3DF...)..................................................................... |

340 |

|

8.5.1 |

Activate 3D tool offsets (CUT3DC, CUT3DF, CUT3DFS, CUT3DFF)...................................... |

340 |

|

8.5.2 |

3D tool radius compensation: peripheral milling, face milling................................................... |

342 |

|

8.5.3 |

Tool types/tool change with changed dimensions (G40, G41, G42)........................................ |

343 |

8.5.4Compensation on the path, path curvature, and insertion depth ISD and tool status

|

(CUT3DC)................................................................................................................................. |

345 |

8.5.5 |

Inside corners/outside corners and intersection procedure (G450/G451)................................ |

347 |

8.5.6 |

3D circumferential milling with limitation surfaces general use................................................. |

349 |

8.5.7 |

Consideration of a limitation surface (CUT3DCC, CUT3DCCD).............................................. |

349 |

8.6 |

Tool orientation (ORIC, ORID, OSOF, OSC, OSS, OSSE, OSD, OST)................................... |

353 |

8.7 |

Free assignment of D numbers, cutting edge numbers............................................................ |

359 |

8.7.1 |

Free assignment of D numbers, cutting edge numbers (CE address) ..................................... |

359 |

8.7.2 |

Checking D numbers (CHKDNO) ............................................................................................. |

360 |

8.7.3 |

Renaming D numbers (GETDNO, SETDNO)........................................................................... |

360 |

8.7.4 |

Deriving the T number from the specified D number (GETACTTD)......................................... |

361 |

10 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

|

|

|

Table of contents |

|

8.7.5 |

Invalidate D numbers (DZERO)................................................................................................. |

362 |

|

8.8 |

Tool holder kinematics............................................................................................................... |

363 |

9 |

Path traversing behavior........................................................................................................................ |

369 |

|

|

9.1 |

Tangential control (TANG, TANGON, TANGOF, TANGDEL)................................................... |

369 |

|

9.2 |

Coupled motion (TRAILON, TRAILOF) ..................................................................................... |

375 |

|

9.3 |

Curve tables (CTAB).................................................................................................................. |

379 |

|

9.3.1 |

Curve tables: general relationships ........................................................................................... |

379 |

|

9.3.2 |

Principal functions curve tables (CTABDEF, CTABEND, CTABDEL)....................................... |

380 |

9.3.3Curve table forms (CTABDEL, CTABNOMEM, CTABFNO, CTABID, CTABLOCK,

|

CTABUNLOCK)......................................................................................................................... |

385 |

9.3.4 |

Behavior at the edges of curve tables (CTABTSV, CTABTSP, CTABMIN, CTABMAX)........... |

390 |

9.3.5Access to curve table positions and table segments (CTAB, CTABINV, CTABSSV,

|

CTABSEV)................................................................................................................................. |

394 |

9.4 |

Axial leading value coupling (LEADON, LEADOF).................................................................... |

397 |

9.5 |

Feedrate response (FNORM, FLIN, FCUB, FPO)..................................................................... |

403 |

9.6 |

Program run with preprocessing memory (STARTFIFO, STOPFIFO, STOPRE)..................... |

410 |

9.7 |

Conditionally interruptible program sections (DELAYFSTON, DELAYFSTOF) ........................ |

412 |

9.8 |

Preventing program position for SERUPRO (IPTRLOCK, IPTRUNLOCK)............................... |

417 |

9.9 |

Repositioning at contour (REPOSA/L, REPOSQ/H, RMI, RMN, RMB, RME) .......................... |

419 |

10 Motion synchronous actions .................................................................................................................. |

429 |

|

10.1 |

Structure, basic information....................................................................................................... |

429 |

10.1.1 |

Programming and command elements...................................................................................... |

431 |

10.1.2 |

Validity range: Identification number ID..................................................................................... |

432 |

10.1.3 |

Cyclic checking of the condition................................................................................................. |

433 |

10.1.4 |

Actions ....................................................................................................................................... |

435 |

10.2 |

Operators for conditions and actions......................................................................................... |

436 |

10.3 |

Main run variables for synchronized actions.............................................................................. |

437 |

10.3.1 |

General information on system variables .................................................................................. |

437 |

10.3.2 |

Implicit type conversion.............................................................................................................. |

438 |

10.3.3 |

GUD variables for synchronous actions .................................................................................... |

440 |

10.3.4 |

Default axis identifier (NO_AXIS)............................................................................................... |

441 |

10.3.5 |

Synchronized action marker $AC_MARKER[n]......................................................................... |

442 |

10.3.6 |

Synchronized action parameters $AC_PARAM[n]..................................................................... |

443 |

10.3.7 |

Arithmetic parameter $R[n]........................................................................................................ |

444 |

10.3.8 |

Read and write NC machine and NC setting data..................................................................... |

445 |

10.3.9 |

Timer-Variable $AC_Timer[n] .................................................................................................... |

446 |

10.3.10 |

FIFO variable $AC_FIFO1[n] ... $AC_FIFO10[n]....................................................................... |

447 |

10.3.11 |

Information about the block types in the interpolator................................................................. |

449 |

10.4 |

Actions in synchronized actions................................................................................................. |

451 |

10.4.1 |

Overview.................................................................................................................................... |

451 |

10.4.2 |

Output of auxiliary functions....................................................................................................... |

454 |

10.4.3 |

Set read-in disable (RDISABLE)................................................................................................ |

455 |

10.4.4 |

Cancel preprocessing stop (STOPREOF)................................................................................. |

456 |

10.4.5 |

Delete distance-to-go (DELDTG)............................................................................................... |

456 |

10.4.6 |

Polynomial definition (FCTDEF) ................................................................................................ |

458 |

Job planning |

11 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Table of contents

|

10.4.7 |

Synchronized function (SYNFCT)............................................................................................. |

460 |

|

10.4.8 |

Clearance control with limited compensation $AA_OFF_MODE.............................................. |

463 |

|

10.4.9 |

Online tool offset (FTOC).......................................................................................................... |

465 |

|

10.4.10 |

Online tool length offset ($AA_TOFF[tool direction])................................................................ |

467 |

|

10.4.11 |

Positioning movements............................................................................................................. |

468 |

|

10.4.12 |

Position axis (POS)................................................................................................................... |

469 |

|

10.4.13 |

Position in specified reference range (POSRANGE)................................................................ |

470 |

|

10.4.14 |

Start/stop axis (MOV)................................................................................................................ |

471 |

|

10.4.15 |

Axis replacement (RELEASE, GET)......................................................................................... |

472 |

|

10.4.16 |

Axial feed (FA) .......................................................................................................................... |

476 |

|

10.4.17 |

Software limit switch.................................................................................................................. |

476 |

|

10.4.18 |

Axis coordination....................................................................................................................... |

476 |

|

10.4.19 |

Set actual values (PRESETON) ............................................................................................... |

477 |

|

10.4.20 |

Spindle motions......................................................................................................................... |

478 |

|

10.4.21 |

Coupled motion (TRAILON, TRAILOF)..................................................................................... |

479 |

|

10.4.22 |

Leading value coupling (LEADON, LEADOF)........................................................................... |

481 |

|

10.4.23 |

Measuring (MEAWA, MEAC).................................................................................................... |

483 |

|

10.4.24 |

Initialization of array variables with SET, REP.......................................................................... |

484 |

|

10.4.25 |

Set/delete wait markers with SETM, CLEARM......................................................................... |

485 |

|

10.4.26 |

Error responses during SETAL cycle alarms............................................................................ |

485 |

|

10.4.27 |

Travel to fixed stop (FXS and FOCON/FOCOF)....................................................................... |

486 |

|

10.4.28 |

Determining the path tangent in synchronized actions............................................................. |

488 |

|

10.4.29 |

Determining the current override .............................................................................................. |

488 |

|

10.4.30 |

Time use evaluation of synchronized actions........................................................................... |

489 |

|

10.5 |

Technology cycles..................................................................................................................... |

491 |

|

10.5.1 |

Context variable ($P_TECCYCLE)........................................................................................... |

493 |

|

10.5.2 |

Call by value parameters .......................................................................................................... |

494 |

|

10.5.3 |

Default parameter initialization.................................................................................................. |

495 |

|

10.5.4 |

Control processing of technology cycles (ICYCOF, ICYCON) ................................................. |

495 |

|

10.5.5 |

Cascading technology cycles.................................................................................................... |

496 |

|

10.5.6 |

Technology cycles in non-modal synchronized actions............................................................ |

497 |

|

10.5.7 |

IF check structures.................................................................................................................... |

497 |

|

10.5.8 |

Jump instructions (GOTO, GOTOF, GOTOB).......................................................................... |

497 |

|

10.5.9 |

Lock, unlock, reset (LOCK, UNLOCK, RESET)........................................................................ |

498 |

|

10.6 |

Delete synchronized action (CANCEL)..................................................................................... |

499 |

|

10.7 |

Restrictions ............................................................................................................................... |

500 |

11 |

Oscillation.............................................................................................................................................. |

505 |

|

|

11.1 |

Asynchronous oscillation........................................................................................................... |

505 |

|

11.2 |

Control oscillation via synchronized actions ............................................................................. |

510 |

12 |

Punching and nibbling ........................................................................................................................... |

519 |

|

|

12.1 |

Activation, deactivation ............................................................................................................. |

519 |

|

12.1.1 |

Punching and nibbling On or Off (SPOF, SON, PON, SONS, PONS, PDELAYON/OF) ......... |

519 |

|

12.2 |

Automatic path segmentation.................................................................................................... |

522 |

|

12.2.1 |

Path segmentation for path axes.............................................................................................. |

525 |

|

12.2.2 |

Path segmentation for single axes............................................................................................ |

527 |

12 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

|

|

Table of contents |

13 Additional functions................................................................................................................................ |

529 |

|

13.1 |

Axis functions (AXNAME, AX, SPI, AXTOSPI, ISAXIS, AXSTRING)........................................ |

529 |

13.2 |

Check scope of NC language present (STRINGIS)................................................................... |

531 |

13.3 |

ISVAR ( ) function call and read machine array index............................................................... |

535 |

13.4 |

Learn compensation characteristics (QECLRNON, QECLRNOF)............................................ |

538 |

13.5 |

Synchronous spindle.................................................................................................................. |

540 |

13.5.1Synchronous spindle (COUPDEF, COUPDEL, COUPON/ONC, COUPOF/OFS,

|

COUPRES)................................................................................................................................ |

540 |

13.6 |

Electronic gear (EG) .................................................................................................................. |

552 |

13.6.1 |

Defining an electronic gear (EGDEF)........................................................................................ |

552 |

13.6.2 |

Activate electronic gear (EGON)................................................................................................ |

553 |

13.6.3 |

Deactivate electronic gear (EGOFS)......................................................................................... |

557 |

13.6.4 |

Revolutional feedrate (G95)/electronic gear (FPR) ................................................................... |

558 |

13.7 |

Extended stop and retract.......................................................................................................... |

558 |

13.7.1 |

Drive-independent responses to ESR ....................................................................................... |

560 |

13.7.2 |

NC-controlled reactions to retraction......................................................................................... |

562 |

13.7.3 |

NC-controlled reactions to stoppage ......................................................................................... |

566 |

13.7.4 |

Generator operation/DC link backup ......................................................................................... |

566 |

13.7.5 |

Drive-independent stopping....................................................................................................... |

567 |

13.7.6 |

Drive-independent retraction...................................................................................................... |

568 |

13.8 |

Link communication................................................................................................................... |

568 |

13.8.1 |

Access to a global NCU memory area....................................................................................... |

569 |

13.9 |

Axis container (AXCTWE, AXCTWED) ..................................................................................... |

570 |

13.10 |

Program runtime/Workpiece counter......................................................................................... |

573 |

13.10.1 |

General ...................................................................................................................................... |

573 |

13.10.2 |

Program runtime........................................................................................................................ |

573 |

13.10.3 |

Workpiece counter..................................................................................................................... |

574 |

13.11 |

Interactive window call from parts program, command:............................................................ |

576 |

13.12 |

Influencing the motion control.................................................................................................... |

577 |

13.12.1 |

Percentage jerk correction (JERKLIM)...................................................................................... |

577 |

13.12.2 |

Percentage velocity correction (VELOLIM)................................................................................ |

578 |

13.13 |

Master/slave grouping (MASLDEF, MASLDEL, MASLOF, MASLOF, MASLOFS)................... |

579 |

14 User stock removal programs................................................................................................................ |

583 |

|

14.1 |

Supporting function for stock removal ....................................................................................... |

583 |

14.2 |

Contour preparation (CONTPRON)........................................................................................... |

584 |

14.3 |

Contour decoding (CONTDCON).............................................................................................. |

591 |

14.4 |

Intersection of two contour elements (INTERSEC) ................................................................... |

595 |

14.5 |

Traversing a contour element from the table (EXECTAB)......................................................... |

597 |

14.6 |

Calculate circle data (CALCDAT) .............................................................................................. |

597 |

15 Tables.................................................................................................................................................... |

|

599 |

15.1 |

List of statements....................................................................................................................... |

599 |

Job planning |

13 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Table of contents

A |

Appendix |

................................................................................................................................................ |

641 |

|

A.1 |

List of abbreviations .................................................................................................................. |

642 |

|

A.2 |

Publication - specific information ................................................................................................ |

647 |

|

A.2.1 ................................................................................................. |

Correction sheet - fax template |

647 |

|

A.2.2 ................................................................................................................................... |

Overview |

649 |

|

Glossary ................................................................................................................................................ |

|

651 |

|

Index...................................................................................................................................................... |

|

675 |

14 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming |

1 |

1.1Variables and arithmetic parameters (user-defined variables, arithmetic parameters, system variables)

Function

Using variables in place of constant values makes a program more flexible. You can respond to signals such as measured values or, by storing setpoints in the variables, you can use the same program for different geometries.

With variable calculation and jump instructions a skilled programmer is able to create a very flexible program archive and save a lot of programming work.

Variable types

The control uses 3 classes of variable:

User-defined variables |

Name and type of variable defined by the user, e.g., arithmetic |

|

parameter. |

Arithmetic variables |

Special, predefined arithmetic variable whose address is R plus a |

|

number. The predefined arithmetic variables are of the REAL type. |

System variables |

Variable provided by the control that can be processed in the |

|

program (write, read). System variables provide access to zero |

|

offsets, tool offsets, actual values, measured values on the axes, |

|

control states, etc. |

|

(See Appendix for the meaning of the system variables). |

Variable types

Type |

Meaning |

Value range |

INT |

Integers with leading sign |

±(231 - 1) |

REAL |

Real numbers (fractions with decimal |

±(10-300 … 10+300) |

|

point, LONG REAL in acc. with IEEE) |

|

Job planning |

15 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming

1.1 Variables and arithmetic parameters (user-defined variables,arithmetic parameters, system variables)

BOOL |

Boolean values: TRUE (1) and |

1.0 |

|

FALSE (0) |

|

CHAR |

ASCII character specified by the |

0 … 255 |

|

code |

|

STRING |

Character string, number of |

Sequence of values with 0 ... 255 |

|

characters in [...], maximum of |

|

|

200 characters |

|

AXIS |

Axis identifiers only (axis addresses) |

Any axis identifiers in the channel |

FRAME |

Geometric data for translation, |

|

|

rotation, scaling, mirroring, see the |

|

|

"Frames" Chapter |

|

Arithmetic variables

Address R provides 100 arithmetic variables of type REAL by default.

The exact number of arithmetic variables (up to 32535) is defined in machine data.

Example: R10=5

System variables

The control provides system variables that can be contained and processed in all running programs.

System variables provide machine and control states. Some system variables cannot be assigned values.

Summary of system variables

Special identifiers of system variables always begin with a "$" sign. The specific names then follow.

1st letter |

Meaning |

$M |

Machine data |

$S |

Setting data |

$T |

Tool management data |

$P |

Programmed values |

$A |

Current values |

$V |

Service data |

|

|

2nd letter |

Meaning |

N |

NCK global |

C |

Channel-specific |

A |

Axis-specific |

Example: $AA_IM

Meaning: Current axis-specific value in the machine coordinate system.

16 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming

1.2Variable definition (DEF user-defined variables LUD, GUD, PUD)

1.2Variable definition (DEF user-defined variables LUD, GUD, PUD)

Function

In addition to the predefined variables, programmers can define and initialize their own variables.

Local variables (LUD) are only valid in the program where they are defined. Global variables (GUD) are valid in all programs.

Machine data are used to redefine the local user variables (LUD) defined in the main program as program-global user variables (PUD).

Machine manufacturer

See machine manufacturer's specifications.

Programming

Variable type INT

DEF INT name or

DEF INT name=value

Variable type REAL

DEF REAL name or

DEF REAL name1,name2=3,name4 or

DEF REAL name[array_index1,array_index2]

Variable type BOOL

DEF BOOL name

Variable type CHAR

DEF CHAR name or

DEF CHAR name[array_index]=("A","B",…)

Variable type STRING

DEF STRING[string_length] name

Variable type AXIS

DEF AXIS name or

DEF AXIS name[array_index]

Variable type FRAME

DEF FRAME name

Job planning |

17 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming

1.2 Variable definition (DEF user-defined variables LUD, GUD, PUD)

Note

If a variable is not assigned a value on definition, the system sets zero as the default.

Variables must be defined at the beginning of the program before they are used. The definition must be made in a separate block; only one variable type can be defined per block.

Parameter

INT |

Variable type integer, i.e., whole number |

REAL |

Variable type real, i.e., factional number with decimal point |

BOOL |

Variable type Boolean, i.e., 1 or 0 (TRUE or FALSE) |

CHAR |

Variable type char, i.e., ASCII-coded character |

|

(0 to 255) |

STRING |

Variable type string, i.e., character string |

AXIS |

Variable type axis, i.e., axis addresses and spindles |

FRAME |

Variable type frame, i.e., geometric data |

Example:

Variable type |

Description |

INT |

|

DEF INT NUMBER |

This creates a variable of type integer with the |

|

name NUMBER. |

|

System initializes with zero. |

DEF INT NUMBER=7 |

This creates a variable of type integer with the |

|

name NUMBER. The system initializes the |

|

variable with 7. |

REAL |

|

DEF REAL DEPTH |

This creates a variable of type real with the name |

|

DEPTH. |

|

System initializes with zero (0.0). |

DEF REAL DEPTH=6.25 |

This creates a variable of type real with the name |

|

DEPTH. The variable is initialized with 6.25. |

DEF REAL DEPTH=3.1,LENGTH=2,NUMBER |

More than one variable can be defined in a line. |

BOOL |

|

DEF BOOL IF_TOO_MUCH |

This creates a variable of type BOOL with the |

|

name IF_TOO_MUCH. |

|

System initializes with zero (FALSE). |

DEF BOOL IF_TOO_MUCH=1 or |

This creates a variable of type BOOL with the |

DEF BOOL IF_TOO_MUCH=TRUE or |

name IF_TOO_MUCH. |

DEF BOOL IF_TOO_MUCH=FALSE |

|

CHAR |

|

18 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming 1.2 Variable definition (DEF user-defined variables LUD, GUD, PUD)

DEF CHAR GUSTAV_1=65 |

A code value for the corresponding ASCII |

|

character or the ASCII character itself |

DEF CHAR GUSTAV_1="A" |

can be assigned to a variable of type CHAR |

|

(code value 65 corresponds to letter "A"). |

STRING |

|

DEF STRING[6] MUSTER_1="BEGIN" |

Variables of type string can contain a string |

|

(sequence of characters). The maximum number |

|

of characters is enclosed in square brackets after |

|

the variable type. |

AXIS |

|

DEF AXIS AXIS_NAME=(X1) |

Variables of type AXIS have the name |

|

AXIS_NAME and are assigned the axis identifier |

|

of a channel - X1 in this case. |

|

(Axis names with an extended address must be |

|

enclosed in parentheses.) |

FRAME |

|

DEF FRAME BEVEL_1 |

Variables of type FRAME have names like |

|

BEVEL_1. |

Note

A variable of type AXIS can contain an axis identifier and a spindle identifier of a channel.

Note

Axis names with an extended address must be enclosed in parentheses.

Example Redefine local (LUD) and program-global user variables (PUD)

If they are defined in the main program, they will also be valid at all levels of the subprograms called. They are created with part-program start and deleted with part-program end or RESET.

If machine data $MN_LUD_EXTENDED_SCOPE is set, it is not possible to define a variable with the same name in the main and subprograms.

|

$MN_LUD_EXTENDED_SCOPE=1 |

;Main program |

|

PROC MAIN |

|

|

DEF INT VAR1 |

;PUD definition |

|

... |

;Subprogram call |

|

SUB2 |

|

|

... |

|

|

M30 |

|

|

PROC SUB2 |

;Subprogram SUB2 |

|

DEF INT VAR2 |

;LUD DEFINITION |

|

... |

;Read PUD |

|

IF (VAR1==1) |

|

Job planning |

19 |

|

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

||

Flexible NC programming

1.2 Variable definition (DEF user-defined variables LUD, GUD, PUD)

VAR1=VAR1+1 |

;Read & write PUD |

VAR2=1 |

;Write LUD |

ENDIF |

;Subprogram call |

SUB3 |

|

... |

|

M17 |

|

PROC SUB3 |

;Subprogram SUB3 |

... |

;Read PUD |

IF (VAR1==1) |

|

VAR1=VAR1+1 |

;Read & write PUD |

VAR2=1 |

;Error: LUD from SUB2 not known |

ENDIF |

|

... |

|

M17

Variable names

A variable name consists of up to 31 characters. The first two characters must be a letter or an underscore.

The "$" sign can not be used for user-defined variables because it is used for system variables.

Example: Program-local variables

DEF INT COUNTER |

;Loop |

LOOP: G0 X… |

|

COUNT=COUNT+1 |

|

IF COUNT<50 GOTOB LOOP |

|

M30 |

|

20 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

|

|

Flexible NC programming |

|

|

1.3 Array definitions (DEF, SET, REP) |

Example: Querying existing geometry axes |

|

|

|

DEF AXIS ABSCISSA; |

;1. Geometry axis |

|

||

|

IF ISAXIS(1) == FALSE GOTOF CONTINUE |

|

|

ABSCISSA = $P_AXN1 |

|

|

CONTINUE: |

|

Example: Indirect spindle programming |

|

|

|

DEF AXIS SPINDLE |

|

|

|

|

|

SPINDLE=(S1) |

;Spindle override = 80% |

|

OVRA[SPINDLE]=80 |

|

|

SPINDLE=(S3) |

|

|

… |

|

1.3Array definitions (DEF, SET, REP)

Function

An array is a memory area defined using the variable type with name and size. Arrays with up to two dimensions can be defined.

Note

Maximum array size

When defining arrays, the maximum array size of the 1st and 2nd dimension is 32767 for the array index [n, m].

Initialization of arrays

Initialization values can be assigned to the array elements:

•during the program execution

or

•already with the array definition.

In 2-dimensional arrays, the right array index is incremented first.

Job planning |

21 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming

1.3 Array definitions (DEF, SET, REP)

Programming

DEF CHAR NAME[n,m] or

DEF INT NAME[n,m] or

DEF REAL NAME[n,m] or

DEF AXIS NAME[n,m] or

DEF FRAME NAME[n,m] or

DEF STRING[string_length] NAME[m] or

DEF BOOL[n,m]

• Initialization with value lists; SET Array definition options

DEF Type VARIABLE = SET(VALUE)

DEF Type ARRAY[n,m] = SET(VALUE, value, …) or

DEF Type VARIABLE = Value

DEF Type ARRAY[n,m] = (value, value, …)

Note

SET is optional in the array definition.

Initializing during the program run

ARRAY[n,m]= SET(value, value, value,…)

ARRAY[n,m]= SET(expression, expression, expression,…)

• Initialization with the same values, REP Array definition options

When "Array" variables are created,

DEF Type ARRAY[n,m] = REP(value) initializes all elements. With

DEF Type ARRAY[n,m] = REP(value, no.arrayElements), only the number of array elements defined in "No.arrayElements" is initialized with "Value".

Initialization begins at array index 0. The remaining variable elements are initialized with zero. If "No.arrayElements" = 0, the entire variable array is initialized with zero, as, for example, for all 30 array elements of varName:

DEF REAL varName[30] =REP(3.5, 0)

22 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming 1.3 Array definitions (DEF, SET, REP)

Note

Variables of type FRAME cannot be initialized.

If a value smaller than zero or larger than the number of array elements is programmed as the range, a "Value range exceeded" alarm is output.

Initializing during the program run

ARRAY[n,m] = REP(value) ARRAY[n,m] = REP(expression)

ARRAY[n,m] = REP(value, no.arrayElements) ARRAY[n,m] = REP(expression, no.arrayElements)

If the range definition "No.arrayElements" = 0, the current values of all array variables remain unchanged, e.g.:

varName [12] =REP(44.5, 0)

Note

Variables of type FRAME are permissible and can be initialized very simply in this way.

Parameters

DEF |

Variable |

type |

Array definition |

SET |

VALUE or |

expression |

Initialization with value lists for the array definition or in the |

|

|

|

program execution |

REP VALUE or expression

REP VALUE, no.arrayElem.

CHAR NAME[n,m]

INT NAME[n,m]

REAL NAME[n,m]

AXIS NAME[n,m]

FRAME NAME[n,m]

BOOL[n,m]

STRING[string_length] NAME[m]

NAME

Type VARIABLE

Initialization with the same values for the array definition or in the program execution

Initialization with the same values for a certain number of array elements that are to be overwritten. A value of zero for the second parameter, e.g., REP(10,0) means that initialization values are not overwritten.

Variable type

(CHAR, INTEGER, REAL, AXIS, FRAME, BOOL)

Data type STRING can only be defined for 1-dimensional arrays. The string length is specified after the data type String.

Variable name

Variable type

(CHAR, INTEGER, REAL, AXIS, FRAME, BOOL)

ARRAY[n,m]= SET(value, value,…)

TYPE ARRAY[n,m] = REP(value)

Initialization of all elements of an array with the listed values for the array definition

Initialization of all elements of an array with the same value for the array definition

Job planning |

23 |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

Flexible NC programming

1.3 Array definitions (DEF, SET, REP)

ARRAY[n,m]= SET(value, value,

..) ARRAY[n,m] = SET(expression, ...)

Initialization of all elements of an array with the listed values in the program execution

ARRAY[n,m]= REP(value)

ARRAY[n,m]= REP(expression)

ARRAY[n, m]

n

m

Maximum array size

No.arrayElem.

Initialization of all elements of an array with the same value in the program execution

Array index

Array size for 1st dimension Array size for 2nd dimension e.g. DEF INT NAME[32767]

Number of array elements to be overwritten by the REP command with "Value". All array elements are overwritten with "Value".

Arrays with variables of type STRING can only be 1-dimensional. Array_index [n,m]

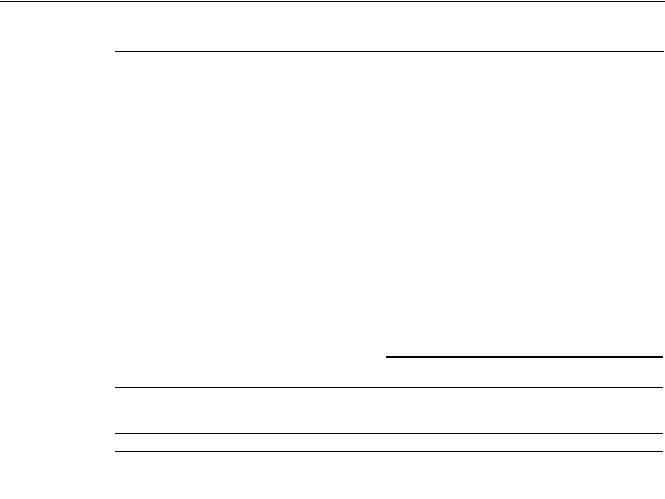

Elements of an array are accessed via the array index. The array elements can either be read or assigned values using this array index.

The first array element starts with index [0,0]; for example, for array size [3,4] the maximum possible array index is [2,3].

$UUD\ LQGH[

>Q P@

P

P

|

|

|

|

P |

|

|

|

|

|

||

|

|

||||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q |

|

|

|

|

|

|

|

|

|

|

|

|

Q |

Q |

Q |

|

Q P |

|

|

|

|

|

|

|

|

|

|

|

|

24 |

Job planning |

Programming Manual, 11/2006, 6FC5398-2BP10-2BA0 |

|

Flexible NC programming |

|

1.3 Array definitions (DEF, SET, REP) |

Memory requirements |

|

Variable type |

Memory requirement per element |

BOOL |

1 byte |

CHAR |

1 byte |

INT |

4 bytes |

REAL |

8 bytes |

STRING |

String length + 1 |

FRAME |

400 bytes, depending on the number of axes |

AXIS |

4 bytes |

Note

The maximum array size determines the size of the memory areas in which the variable memory is managed. It should not be set higher than actually required.

Default: 812 bytes

If no large arrays are defined, select: 256 bytes.

Example: Definition of BOOL arrays

Global user data must contain PLC machine data for switching the control on/off.

Example Definition of arrays with maximum array size for the 1st and 2nd dimension

DEF INT NAME[32767,32767]

Example: Initialization of complete variable arrays

The current assignment is shown in the drawing.

N10 DEF REAL ARRAY1[10,3] = SET(0, 0, 0, 10, 11, 12, 20, 20, 20, 30, 30, 30, 40, 40, 40,)

N20 ARRAY1[0,0] = REP(100)

N30 ARRAY1[5,0] = REP(-100)

N40 ARRAY1[0,0] = SET(0, 1, 2, -10, -11, -12, -20, -20, -20, -30, , , ,

-40, -40, -50, -60, -70)