siemens 840D Programming Manual

SINUMERIK

SINUMERIK 840D sl / 828D Job Planning

Programming Manual

Valid for

Control

SINUMERIK 840D sl / 840DE sl SINUMERIK 828D

Software |

Version |

CNC software |

4.5 SP2 |

03/2013

6FC5398-2BP40-3BA1

Preface

Flexible NC programming |

1 |

|

File and Program |

|

|

2 |

||

Management |

||

|

|

|

Protection zones |

3 |

|

|

|

|

Special motion commands |

4 |

|

Coordinate transformations |

|

|

5 |

||

(frames) |

||

|

|

|

Transformations |

6 |

|

|

|

|

Kinematic chains |

7 |

|

Collision avoidance with |

|

|

8 |

||

kinematic chains |

||

|

|

|

Tool offsets |

9 |

|

|

|

|

Path traversing behavior |

10 |

|

|

|

|

Axis couplings |

11 |

|

|

|

|

Synchronized actions |

12 |

|

|

|

|

Oscillation |

13 |

|

|

|

|

Punching and nibbling |

14 |

|

|

|

|

Grinding |

15 |

|

|

|

|

Additional functions |

16 |

|

User stock removal |

|

|

17 |

||

programs |

||

Programming cycles |

|

|

18 |

||

externally |

||

|

|

|

Tables |

19 |

|

|

|

|

Appendix |

A |

|

|

|

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are graded according to the degree of danger.

DANGER

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified personnel are those who, based on their training and experience, are capable of identifying risks and avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. The permissible ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG |

Order number: 6FC5398-2BP40-3BA1 |

Copyright © Siemens AG 1995 - 2013. |

Industry Sector |

04/2013 Technical data subject to change |

All rights reserved |

Postfach 48 48 |

|

|

90026 NÜRNBERG |

|

|

GERMANY |

|

|

Preface

SINUMERIK documentation

The SINUMERIK documentation is organized in the following categories:

●General documentation

●User documentation

●Manufacturer/service documentation

Additional information

You can find information on the following topics at www.siemens.com/motioncontrol/docu:

●Ordering documentation/overview of documentation

●Additional links to download documents

●Using documentation online (find and search in manuals/information)

Please send any questions about the technical documentation (e.g. suggestions for improvement, corrections) to the following address:

docu.motioncontrol@siemens.com

My Documentation Manager (MDM)

Under the following link you will find information to individually compile OEM-specific machine documentation based on the Siemens content:

www.siemens.com/mdm

Training

For information about the range of training courses, refer under:

●www.siemens.com/sitrain

SITRAIN - Siemens training for products, systems and solutions in automation technology

●www.siemens.com/sinutrain

SinuTrain - training software for SINUMERIK

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

3 |

Preface

FAQs

You can find Frequently Asked Questions in the Service&Support pages under Product Support. http://support.automation.siemens.com

SINUMERIK

You can find information on SINUMERIK under the following link: www.siemens.com/sinumerik

Target group

This publication is intended for:

●Programmers

●Project engineers

Benefits

With the programming manual, the target group can develop, write, test, and debug programs and software user interfaces.

Standard scope

This Programming Manual describes the functionality afforded by standard functions. Extensions or changes made by the machine tool manufacturer are documented by the machine tool manufacturer.

Other functions not described in this documentation might be executable in the control. This does not, however, represent an obligation to supply such functions with a new control or when servicing.

Further, for the sake of simplicity, this documentation does not contain all detailed information about all types of the product and cannot cover every conceivable case of installation, operation or maintenance.

Technical Support

You will find telephone numbers for other countries for technical support in the Internet under http://www.siemens.com/automation/service&support

|

Job Planning |

4 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

Preface

Information on structure and contents

"Fundamentals" and "Job planning" Programming Manual

The description of the NC programming is divided into two manuals:

1.Fundamentals

The "Fundamentals" Programming Manual is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements which are also defined according to DIN 66025.

2.Job planning

This "Job planning" Programming Manual is intended for use by technicians with in-depth, comprehensive programming knowledge. By virtue of a special programming language, the SINUMERIK control enables the user to program complex workpiece programs (e.g. for free-form surfaces, channel coordination, ...) and makes programming of complicated operations easy for technologists.

Availability of the described NC language elements

All NC language elements described in the manual are available for the SINUMERIK 840D sl. The availability regarding SINUMERIK 828D can be found in table "Operations: Availability for SINUMERIK 828D (Page 778)".

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

5 |

Preface

|

Job Planning |

6 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

Table of contents

|

Preface |

...................................................................................................................................................... |

3 |

1 |

Flexible ........................................................................................................................NC programming |

17 |

|

|

1.1 ...................................................................................................................................... |

Variables |

17 |

|

1.1.1 ............................................................................................................................ |

System variable |

17 |

|

1.1.2 ................................................................. |

Predefined user variables: Arithmetic parameters (R) |

20 |

|

1.1.3 .................................................................................... |

Predefined user variables: Link variables |

21 |

|

1.1.4 ................................................................................................ |

Definition of user variables (DEF) |

24 |

|

1.1.5 ......... |

Redefinition of system variables, user variables, and NC language commands (REDEF) |

29 |

|

1.1.6 ......................................................................................................... |

Attribute: Initialization value |

32 |

|

1.1.7 ................................................................................................... |

Attribute: Limit values (LLI, ULI) |

35 |

|

1.1.8 ...................................................................................................... |

Attribute: Physical unit (PHU) |

37 |

|

1.1.9 .......................................... |

Attribute: Access rights (APR, APW, APRP, APWP, APRB, APWB) |

39 |

|

1.1.10 ......................................................................... |

Overview of definable and redefinable attributes |

44 |

|

1.1.11 ................................................. |

Definition and initialization of array variables (DEF, SET, REP) |

45 |

|

1.1.12 ................. |

Definition and initialization of array variables (DEF, SET, REP): Further Information |

49 |

|

1.1.13 .................................................................................................................................... |

Data types |

52 |

|

1.1.14 ................................................................. |

Explicit data type conversions (AXTOINT, INTTOAX) |

53 |

|

1.1.15 ...................................................................................... |

Check availability of a variable (ISVAR) |

54 |

1.1.16Read attribute values / data type (GETVARPHU, GETVARAP, GETVARLIM,

|

GETVARDFT, GETVARTYP)...................................................................................................... |

56 |

1.2 |

Indirect programming................................................................................................................... |

61 |

1.2.1 |

Indirectly programming addresses............................................................................................... |

61 |

1.2.2 |

Indirectly programming G codes.................................................................................................. |

64 |

1.2.3 |

Indirectly programming position attributes (GP) .......................................................................... |

65 |

1.2.4 |

Indirectly programming part program lines (EXECSTRING)....................................................... |

68 |

1.3 |

Arithmetic functions...................................................................................................................... |

69 |

1.4 |

Comparison and logic operations................................................................................................ |

71 |

1.5 |

Precision correction on comparison errors (TRUNC).................................................................. |

73 |

1.6 |

Variable minimum, maximum and range (MINVAL, MAXVAL and BOUND) .............................. |

74 |

1.7 |

Priority of the operations.............................................................................................................. |

76 |

1.8 |

Possible type conversions ........................................................................................................... |

77 |

1.9 |

String operations.......................................................................................................................... |

78 |

1.9.1 |

Type conversion to STRING (AXSTRING).................................................................................. |

78 |

1.9.2 |

Type conversion from STRING (NUMBER, ISNUMBER, AXNAME).......................................... |

79 |

1.9.3 |

Concatenation of strings (<<)....................................................................................................... |

81 |

1.9.4 |

Conversion to lower/upper case letters (TOLOWER, TOUPPER).............................................. |

82 |

1.9.5 |

Determine length of string (STRLEN).......................................................................................... |

83 |

1.9.6 |

Search for character/string in the string (INDEX, RINDEX, MINDEX, MATCH).......................... |

83 |

1.9.7 |

Selection of a substring (SUBSTR) ............................................................................................. |

85 |

1.9.8 |

Reading and writing of individual characters............................................................................... |

85 |

1.9.9 |

Formatting a string (SPRINT) ...................................................................................................... |

87 |

Job Planning |

|

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

7 |

|

Table of contents

1.10 |

Program jumps and branches..................................................................................................... |

96 |

|

1.10.1 |

Return jump to the start of the program (GOTOS)...................................................................... |

96 |

|

1.10.2 |

Program jumps to jump markers (GOTOB, GOTOF, GOTO, GOTOC)...................................... |

97 |

|

1.10.3 |

Program branch (CASE |

... OF ... DEFAULT ...)........................................................................ |

100 |

1.11 |

Repeat program section (REPEAT, REPEATB, ENDLABEL, P).............................................. |

102 |

|

1.12 |

Check structures....................................................................................................................... |

|

108 |

1.12.1 |

Conditional statement and branch (IF, ELSE, ENDIF) ............................................................. |

110 |

|

1.12.2 |

Continuous program loop (LOOP, ENDLOOP)......................................................................... |

111 |

|

1.12.3 |

Count loop (FOR ... TO ... |

, ENDFOR) ...................................................................................... |

112 |

1.12.4 |

Program loop with condition at start of loop (WHILE, ENDWHILE).......................................... |

114 |

|

1.12.5 |

Program loop with condition at the end of the loop (REPEAT, UNTIL).................................... |

115 |

|

1.12.6 |

Program example with nested check structures....................................................................... |

115 |

|

1.13 |

Program coordination (INIT, START, WAITM, WAITMC, WAITE, SETM, CLEARM).............. |

116 |

|

1.14 |

Interrupt routine (ASUB)............................................................................................................ |

|

121 |

1.14.1 |

Function of an interrupt routine................................................................................................. |

121 |

|

1.14.2 |

Creating an interrupt routine..................................................................................................... |

123 |

|

1.14.3 |

Assign and start interrupt routine (SETINT, PRIO, BLSYNC) .................................................. |

124 |

|

1.14.4 |

Deactivating/reactivating the assignment of an interrupt routine (DISABLE, ENABLE)........... |

125 |

|

1.14.5 |

Delete assignment of interrupt routine (CLRINT) ..................................................................... |

126 |

|

1.14.6 |

Fast retraction from the contour (SETINT LIFTFAST, ALF)..................................................... |

127 |

|

1.14.7 |

Traversing direction for fast retraction from the contour........................................................... |

129 |

|

1.14.8 |

Motion sequence for interrupt routines ..................................................................................... |

132 |

|

1.15 |

Axis replacement, spindle replacement (RELEASE, GET, GETD)........................................... |

132 |

|

1.16 |

Transfer axis to another channel (AXTOCHAN)....................................................................... |

137 |

|

1.17 |

Activate machine data (NEWCONF)......................................................................................... |

138 |

|

1.18 |

Write file (WRITE)..................................................................................................................... |

|

139 |

1.19 |

Delete file (DELETE)................................................................................................................. |

|

144 |

1.20 |

Read lines in the file (READ).................................................................................................... |

146 |

|

1.21 |

Check for presence of file (ISFILE)........................................................................................... |

148 |

|

1.22 |

Read out file information (FILEDATE, FILETIME, FILESIZE, FILESTAT, FILEINFO)............. |

150 |

|

1.23 |

Roundup (ROUNDUP).............................................................................................................. |

|

153 |

1.24 |

Subprogram technique.............................................................................................................. |

|

154 |

1.24.1 |

General information................................................................................................................... |

|

154 |

1.24.1.1 |

Subprogram .............................................................................................................................. |

|

154 |

1.24.1.2 |

Subprogram names................................................................................................................... |

|

155 |

1.24.1.3 |

Nesting of subprograms............................................................................................................ |

|

156 |

1.24.1.4 |

Search path............................................................................................................................... |

|

157 |

1.24.1.5 |

Formal and actual parameters.................................................................................................. |

158 |

|

1.24.1.6 |

Parameter transfer.................................................................................................................... |

|

159 |

1.24.2 |

Definition of a subprogram........................................................................................................ |

161 |

|

1.24.2.1 |

Subprogram without parameter transfer................................................................................... |

161 |

|

1.24.2.2 |

Subprogram with call-by-value parameter transfer (PROC)..................................................... |

162 |

|

1.24.2.3 |

Subprogram with call-by-reference parameter transfer (PROC, VAR)..................................... |

163 |

|

1.24.2.4 |

Save modal G functions (SAVE)............................................................................................... |

166 |

|

1.24.2.5 |

Suppress single block execution (SBLOF, SBLON)................................................................. |

167 |

|

|

|

|

Job Planning |

8 |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

|

Table of contents

|

1.24.2.6 |

Suppress current block display (DISPLOF, DISPLON, ACTBLOCNO)..................................... |

172 |

|

1.24.2.7 |

Identifying subprograms with preparation (PREPRO)............................................................... |

175 |

|

1.24.2.8 |

Subprogram return M17............................................................................................................. |

176 |

|

1.24.2.9 |

RET subprogram return............................................................................................................. |

177 |

|

1.24.2.10 |

Parameterizable subprogram return jump (RET ...) ............................................................. |

178 |

|

1.24.3 |

Subprogram call......................................................................................................................... |

184 |

|

1.24.3.1 |

Subprogram call without parameter transfer.............................................................................. |

184 |

|

1.24.3.2 |

Subprogram call with parameter transfer (EXTERN)................................................................. |

187 |

|

1.24.3.3 |

Number of program repetitions (P)............................................................................................ |

189 |

|

1.24.3.4 |

Modal subprogram call (MCALL)............................................................................................... |

191 |

|

1.24.3.5 |

Indirect subprogram call (CALL)................................................................................................ |

193 |

|

1.24.3.6 |

Indirect subprogram call with specification of the calling program part (CALL BLOCK ... |

|

|

|

TO ...)......................................................................................................................................... |

194 |

|

1.24.3.7 |

Indirect call of a program programmed in ISO language (ISOCALL)........................................ |

195 |

|

1.24.3.8 |

Call subprogram with path specification and parameters (PCALL)........................................... |

196 |

|

1.24.3.9 |

Extend search path for subprogram calls (CALLPATH)............................................................ |

197 |

|

1.24.3.10 Execute external subprogram (840D sl) (EXTCALL)............................................................ |

198 |

|

|

1.24.3.11 Execute external subprogram (828D) (EXTCALL)............................................................... |

202 |

|

|

1.25 |

Macro technique (DEFINE ... AS).............................................................................................. |

205 |

2 |

File and Program Management ............................................................................................................. |

209 |

|

|

2.1 |

Program memory....................................................................................................................... |

209 |

|

2.2 |

Working memory (CHANDATA, COMPLETE, INITIAL)............................................................ |

213 |

3 |

Protection zones.................................................................................................................................... |

217 |

|

|

3.1 |

Defining the protection zones (CPROTDEF, NPROTDEF)....................................................... |

217 |

|

3.2 |

Activating/deactivating protection zones (CPROT, NPROT)..................................................... |

220 |

3.3Checking for protection zone violation, working area limitation and software limit switches

|

|

(CALCPOSI)............................................................................................................................... |

224 |

4 |

Special motion commands..................................................................................................................... |

229 |

|

|

4.1 |

Approaching coded positions (CAC, CIC, CDC, CACP, CACN)............................................... |

229 |

4.2Spline interpolation (ASPLINE, BSPLINE, CSPLINE, BAUTO, BNAT, BTAN, EAUTO,

|

ENAT, ETAN, PW, SD, PL) ....................................................................................................... |

230 |

4.3 |

Spline group (SPLINEPATH)..................................................................................................... |

240 |

4.4 |

NC block compression (COMPON, COMPCURV, COMPCAD, COMPOF).............................. |

241 |

4.5 |

Polynomial interpolation (POLY, POLYPATH, PO, PL)............................................................. |

244 |

4.6 |

Settable path reference (SPATH, UPATH)................................................................................ |

250 |

4.7 |

Measuring with touch-trigger probe (MEAS, MEAW)................................................................ |

253 |

4.8 |

Axial measurement (MEASA, MEAWA, MEAC) (option)........................................................... |

256 |

4.9 |

Special functions for OEM users (OMA1 ... OMA5, OEMIPO1, OEMIPO2, G810 ... G829)..... |

266 |

4.10 |

Feedrate reduction with corner deceleration (FENDNORM, G62, G621)................................. |

267 |

4.11Programmable end of motion criteria (FINEA, COARSEA, IPOENDA, IPOBRKA,

ADISPOSA)................................................................................................................................ |

268 |

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

9 |

Table of contents

5 |

Coordinate transformations (frames) ..................................................................................................... |

271 |

|

|

5.1 |

Coordinate transformation via frame variables......................................................................... |

271 |

|

5.1.1 |

Predefined frame variable ($P_IFRAME, $P_BFRAME, $P_PFRAME, $P_ACTFRAME)....... |

273 |

|

5.2 |

Frame variables / assigning values to frames........................................................................... |

278 |

|

5.2.1 |

Assigning direct values (axis value, angle, scale) .................................................................... |

278 |

|

5.2.2 |

Reading and changing frame components (TR, FI, RT, SC, MI).............................................. |

280 |

|

5.2.3 |

Linking complete frames........................................................................................................... |

282 |

|

5.2.4 |

Defining new frames (DEF FRAME)......................................................................................... |

283 |

|

5.3 |

Coarse and fine offsets (CFINE, CTRANS).............................................................................. |

284 |

|

5.4 |

External zero offset................................................................................................................... |

286 |

|

5.5 |

Preset offset with PRESETON.................................................................................................. |

287 |

|

5.6 |

Frame calculation from three measuring points in space (MEAFRAME)................................. |

288 |

|

5.7 |

NCU global frames.................................................................................................................... |

292 |

|

5.7.1 |

Channel-specific frames ($P_CHBFR, $P_UBFR)................................................................... |

293 |

|

5.7.2 |

Frames active in the channel.................................................................................................... |

294 |

6 |

Transformations..................................................................................................................................... |

299 |

|

|

6.1 |

General programming of transformation types......................................................................... |

299 |

|

6.1.1 |

Orientation movements for transformations.............................................................................. |

301 |

|

6.1.2 |

Overview of orientation transformation TRAORI....................................................................... |

305 |

|

6.2 |

Three, four and five axis transformation (TRAORI).................................................................. |

307 |

|

6.2.1 |

General relationships of universal tool head............................................................................. |

307 |

|

6.2.2 |

Three, four and five axis transformation (TRAORI).................................................................. |

310 |

|

6.2.3 |

Variants of orientation programming and initial setting (ORIRESET)....................................... |

311 |

|

6.2.4 |

Programming the tool orientation (A..., B..., C..., LEAD, TILT)................................................. |

313 |

|

6.2.5 |

Face milling (A4, B4, C4, A5, B5, C5)....................................................................................... |

319 |

|

6.2.6 |

Reference of the orientation axes (ORIWKS, ORIMKS):.......................................................... |

321 |

6.2.7Programming orientation axes (ORIAXES, ORIVECT, ORIEULER, ORIRPY, ORIRPY2,

ORIVIRT1, ORIVIRT2).............................................................................................................. |

323 |

6.2.8Orientation programming along the peripheral surface of a taper (ORIPLANE,

ORICONCW, ORICONCCW, ORICONTO, ORICONIO).......................................................... |

326 |

6.2.9Specification of orientation for two contact points (ORICURVE, PO[XH]=, PO[YH]=,

|

PO[ZH]=)................................................................................................................................... |

329 |

6.3 |

Orientation polynomials (PO[angle], PO[coordinate])............................................................... |

331 |

6.4 |

Rotations of the tool orientation (ORIROTA, ORIROTR, ORIROTT, ORIROTC, THETA)....... |

333 |

6.5 |

Orientations relative to the path................................................................................................ |

336 |

6.5.1 |

Orientation types relative to the path........................................................................................ |

336 |

6.5.2Rotation of the tool orientation relative to the path (ORIPATH, ORIPATHS, angle of

|

rotation)..................................................................................................................................... |

337 |

6.5.3 |

Interpolation of the tool rotation relative to the path (ORIROTC, THETA)................................ |

339 |

6.5.4 |

Smoothing of orientation characteristic (ORIPATHS A8=, B8=, C8=)...................................... |

341 |

6.6 |

Compression of the orientation (COMPON, COMPCURV, COMPCAD).................................. |

342 |

6.7 |

Smoothing the orientation characteristic (ORISON, ORISOF)................................................. |

344 |

6.8 |

Kinematic transformation .......................................................................................................... |

347 |

6.8.1 |

Milling on turned parts (TRANSMIT):........................................................................................ |

347 |

|

|

Job Planning |

10 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

|

Table of contents

|

6.8.2 |

Cylinder surface transformation (TRACYL)............................................................................... |

349 |

|

6.8.3 |

Inclined axis (TRAANG)............................................................................................................. |

357 |

|

6.8.4 |

Inclined axis programming (G5, G7).......................................................................................... |

360 |

|

6.9 |

Cartesian PTP travel.................................................................................................................. |

362 |

|

6.9.1 |

PTP for TRANSMIT ................................................................................................................... |

366 |

|

6.10 |

Constraints when selecting a transformation............................................................................. |

370 |

|

6.11 |

Deselecting a transformation (TRAFOOF) ................................................................................ |

371 |

|

6.12 |

Chained transformations (TRACON, TRAFOOF)...................................................................... |

371 |

7 |

Kinematic chains.................................................................................................................................... |

375 |

|

|

7.1 |

Deletion of components (DELOBJ)............................................................................................ |

375 |

|

7.2 |

Index determination by means of names (NAMETOINT).......................................................... |

377 |

8 |

Collision avoidance with kinematic chains............................................................................................. |

379 |

|

|

8.1 |

Check for collision pair (COLLPAIR) ......................................................................................... |

379 |

|

8.2 |

Requesting a recalculation of the collision model (PROTA)...................................................... |

380 |

|

8.3 |

Setting the protection zone status (PROTS).............................................................................. |

382 |

|

8.4 |

Determining the clearance of two protection zones (PROTD)................................................... |

383 |

9 |

Tool offsets............................................................................................................................................ |

385 |

|

|

9.1 |

Offset memory............................................................................................................................ |

385 |

|

9.2 |

Additive offsets........................................................................................................................... |

388 |

|

9.2.1 |

Selecting additive offsets (DL)................................................................................................... |

388 |

|

9.2.2 |

Specify wear and setup values ($TC_SCPxy[t,d], $TC_ECPxy[t,d])......................................... |

389 |

|

9.2.3 |

Delete additive offsets (DELDL)................................................................................................. |

390 |

|

9.3 |

Special handling of tool offsets.................................................................................................. |

391 |

|

9.3.1 |

Mirroring of tool lengths ............................................................................................................. |

393 |

|

9.3.2 |

Wear sign evaluation ................................................................................................................. |

394 |

9.3.3Coordinate system of the active machining operation (TOWSTD, TOWMCS, TOWWCS,

|

TOWBCS, TOWTCS, TOWKCS)............................................................................................... |

395 |

9.3.4 |

Tool length and plane change.................................................................................................... |

398 |

9.4 |

Online tool offset (PUTFTOCF, FCTDEF, PUTFTOC, FTOCON, FTOCOF)............................ |

399 |

9.5 |

Activate 3D tool offsets (CUT3DC..., CUT3DF...)...................................................................... |

404 |

9.5.1 |

Activating 3D tool offsets (CUT3DC, CUT3DF, CUT3DFS, CUT3DFF, ISD)............................ |

404 |

9.5.2 |

3D tool offset peripheral milling, face milling ............................................................................. |

406 |

9.5.3 |

3D tool offset Tool shapes and tool data for face milling........................................................... |

408 |

9.5.4 |

3D tool offset Offset on the path, path curvature, insertion depth (CUT3DC, ISD)................... |

409 |

9.5.5 |

3D tool offset Inside/outside corners and intersection procedure (G450/G451) ....................... |

412 |

9.5.6 |

3D tool offset 3D circumferential milling with limitation surfaces............................................... |

413 |

9.5.7 |

3D tool offset: Taking into consideration a limitation surface (CUT3DCC, CUT3DCCD).......... |

414 |

9.6 |

Tool orientation (ORIC, ORID, OSOF, OSC, OSS, OSSE, ORIS, OSD, OST)......................... |

418 |

9.7 |

Free assignment of D numbers, cutting edge numbers............................................................. |

424 |

9.7.1 |

Free assignment of D numbers, cutting edge numbers (CE address)...................................... |

424 |

9.7.2 |

Free assignment of D numbers: Checking D numbers (CHKDNO)........................................... |

424 |

9.7.3 |

Free assignment of D numbers: Rename D numbers (GETDNO, SETDNO)........................... |

425 |

Job Planning |

|

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

11 |

|

Table of contents

9.7.4Free assignment of D numbers: Determine T number to the specified D number

|

(GETACTTD) ............................................................................................................................ |

426 |

9.7.5 |

Free assignment of D numbers: Invalidate D numbers (DZERO) ............................................ |

427 |

9.8 |

Toolholder kinematics............................................................................................................... |

427 |

9.9Tool length compensation for orientable toolholders (TCARR, TCOABS, TCOFR,

|

TCOFRX, TCOFRY, TCOFRZ)................................................................................................. |

433 |

9.10 |

Online tool length compensation (TOFFON, TOFFOF)............................................................ |

436 |

9.11 |

Cutting data modification for tools that can be rotated (CUTMOD).......................................... |

439 |

10 Path traversing behavior........................................................................................................................ |

445 |

|

10.1 |

Tangential control (TANG, TANGON, TANGOF, TLIFT, TANGDEL)....................................... |

445 |

10.2 |

Feedrate characteristic (FNORM, FLIN, FCUB, FPO).............................................................. |

452 |

10.3 |

Acceleration behavior................................................................................................................ |

457 |

10.3.1 |

Acceleration mode (BRISK, BRISKA, SOFT, SOFTA, DRIVE, DRIVEA) ................................ |

457 |

10.3.2 |

Influence of acceleration on following axes (VELOLIMA, ACCLIMA, JERKLIMA)................... |

459 |

10.3.3Activation of technology-specific dynamic values (DYNNORM, DYNPOS, DYNROUGH,

|

DYNSEMIFIN, DYNFINISH) ..................................................................................................... |

461 |

10.4 |

Traversing with feedforward control (FFWON, FFWOF).......................................................... |

463 |

10.5 |

Programmable contour accuracy (CPRECON, CPRECOF)..................................................... |

464 |

10.6Program sequence with preprocessing memory (STOPFIFO, STARTFIFO, FIFOCTRL,

|

STOPRE).................................................................................................................................. |

466 |

10.7 |

Program sections that can be conditionally interrupted (DELAYFSTON, DELAYFSTOF)....... |

469 |

10.8 |

Prevent program position for SERUPRO (IPTRLOCK, IPTRUNLOCK)................................... |

474 |

10.9Repositioning to the contour (REPOSA, REPOSL, REPOSQ, REPOSQA, REPOSH,

|

REPOSHA, DISR, DISPR, RMIBL, RMBBL, RMEBL, RMNBL)............................................... |

476 |

10.10 |

Influencing the motion control................................................................................................... |

484 |

10.10.1 |

Percentage jerk correction (JERKLIM) ..................................................................................... |

484 |

10.10.2 |

Percentage velocity correction (VELOLIM)............................................................................... |

486 |

10.10.3 |

Program example for JERKLIM and VELOLIM......................................................................... |

488 |

10.11 |

Programmable contour/orientation tolerance (CTOL, OTOL, ATOL)....................................... |

488 |

10.12 |

Tolerance for G0 motion (STOLF)............................................................................................ |

492 |

10.13 |

Block change behavior with active coupling (CPBC)................................................................ |

494 |

11 Axis couplings........................................................................................................................................ |

495 |

|

11.1 |

Coupled motion (TRAILON, TRAILOF)..................................................................................... |

495 |

11.2 |

Curve tables (CTAB)................................................................................................................. |

500 |

11.2.1 |

Define curve tables (CTABDEF, CATBEND)............................................................................ |

501 |

11.2.2 |

Check for presence of curve table (CTABEXISTS).................................................................. |

507 |

11.2.3 |

Delete curve tables (CTABDEL)............................................................................................... |

507 |

11.2.4 |

Locking curve tables to prevent deletion and overwriting (CTABLOCK, CTABUNLOCK)....... |

509 |

11.2.5Curve tables: Determine table properties (CTABID, CTABISLOCK, CTABMEMTYP,

CTABPERIOD).......................................................................................................................... |

510 |

11.2.6Read curve table values (CTABTSV, CTABTEV, CTABTSP, CTABTEP, CTABSSV,

|

CTABSEV, CTAB, CTABINV, CTABTMIN, CTABTMAX) |

......................................................... 512 |

|

|

Job Planning |

12 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

|

Table of contents

11.2.7Curve tables: Check use of resources (CTABNO, CTABNOMEM, CTABFNO, CTABSEGID, CTABSEG, CTABFSEG, CTABMSEG, CTABPOLID, CTABPOL,

|

CTABFPOL, CTABMPOL)......................................................................................................... |

517 |

11.3 |

Axial master value coupling (LEADON, LEADOF) .................................................................... |

518 |

11.4 |

Electronic gear (EG) .................................................................................................................. |

523 |

11.4.1 |

Defining an electronic gear (EGDEF)........................................................................................ |

524 |

11.4.2 |

Switch-in the electronic gearbox (EGON, EGONSYN, EGONSYNE)....................................... |

525 |

11.4.3 |

Switching-in the electronic gearbox (EGOFS, EGOFC)............................................................ |

529 |

11.4.4 |

Deleting the definition of an electronic gear (EGDEL)............................................................... |

530 |

11.4.5 |

Rotational feedrate (G95) / electronic gear (FPR)..................................................................... |

530 |

11.5 |

Synchronous spindle.................................................................................................................. |

531 |

11.5.1Synchronous spindle: Programming (COUPDEF, COUPDEL, COUPON, COUPONC,

|

|

COUPOF, COUPOFS, COUPRES, WAITC)............................................................................. |

531 |

|

11.6 |

Generic coupling (CP...)............................................................................................................. |

541 |

|

11.7 |

Master/slave coupling (MASLDEF, MASLDEL, MASLON, MASLOF, MASLOFS)................... |

549 |

12 |

Synchronized actions............................................................................................................................. |

553 |

|

|

12.1 |

Definition of a synchronized action............................................................................................ |

553 |

13 |

Oscillation.............................................................................................................................................. |

555 |

|

13.1Asynchronous oscillation (OS, OSP1, OSP2, OST1, OST2, OSCTRL, OSNSC, OSE,

|

|

OSB) .......................................................................................................................................... |

555 |

|

13.2 |

Oscillation controlled by synchronized actions (OSCILL).......................................................... |

560 |

14 |

Punching and nibbling ........................................................................................................................... |

569 |

|

|

14.1 |

Activation, deactivation.............................................................................................................. |

569 |

14.1.1Punching and nibbling on or off (SPOF, SON, PON, SONS, PONS, PDELAYON,

|

|

PDELAYOF, PUNCHACC) ........................................................................................................ |

569 |

|

14.2 |

Automatic path segmentation .................................................................................................... |

574 |

|

14.2.1 |

Path segmentation for path axes ............................................................................................... |

577 |

|

14.2.2 |

Path segmentation for single axes ............................................................................................. |

579 |

15 |

Grinding |

................................................................................................................................................. |

581 |

|

15.1 |

Grinding - specific tool monitoring in the part program (TMON, TMOF) ...................................... |

581 |

16 |

Additional ................................................................................................................................functions |

583 |

|

|

16.1 ................. |

Axis functions (AXNAME, AX, SPI, AXTOSPI, ISAXIS, AXSTRING, MODAXVAL) |

583 |

|

16.2 ...................................................................................... |

Replaceable geometry axes (GEOAX) |

585 |

|

16.3 .......................................................... |

Axis container (AXCTSWE, AXCTSWED, AXCTSWEC) |

590 |

|

16.4 ..................................................................................... |

Wait for valid axis position (WAITENC) |

592 |

|

16.5 .............................................................. |

Programmable parameter set changeover (SCPARA) |

593 |

|

16.6 ................................................................... |

Check scope of NC language present (STRINGIS) |

594 |

|

16.7 ...................................................... |

Interactively call the window from the part program (MMC) |

598 |

|

16.8 .................................................................................................... |

Program runtime/part counter |

600 |

|

16.8.1 .................................................................................. |

Program runtime/part counter (overview) |

600 |

Job Planning |

|

|

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

13 |

||

Table of contents

16.8.2 |

Program runtime ....................................................................................................................... |

600 |

16.8.3 |

Workpiece counter.................................................................................................................... |

604 |

16.9 |

Process DataShare - output to an external device/file (EXTOPEN, WRITE, EXTCLOSE)...... |

605 |

16.10 |

Alarms (SETAL)........................................................................................................................ |

614 |

16.11 |

Extended stop and retract (ESR).............................................................................................. |

616 |

16.11.1 |

NC-controlled ESR.................................................................................................................... |

617 |

16.11.1.1 NC-controlled retraction (POLF, POLFA, POLFMASK, POLFMLIN) .................................. |

617 |

|

16.11.1.2 |

NC-controlled stopping ........................................................................................................ |

621 |

16.11.2 |

Drive-integrated ESR................................................................................................................ |

622 |

16.11.2.1 Configuring drive-integrated stopping (ESRS)..................................................................... |

622 |

|

16.11.2.2 Configuring drive-integrated retraction (ESRS)................................................................... |

623 |

|

17 User stock removal programs................................................................................................................ |

625 |

|

17.1 |

Supporting functions for stock removal..................................................................................... |

625 |

17.2 |

Generate contour table (CONTPRON)..................................................................................... |

626 |

17.3 |

Generate coded contour table (CONTDCON).......................................................................... |

632 |

17.4 |

Determine point of intersection between two contour elements (INTERSEC) ......................... |

635 |

17.5 |

Execute the contour elements of a table block-by-block (EXECTAB)...................................... |

637 |

17.6 |

Calculate circle data (CALCDAT) ............................................................................................. |

638 |

17.7 |

Deactivate contour preparation (EXECUTE) ............................................................................ |

640 |

18 Programming cycles externally.............................................................................................................. |

641 |

|

18.1 |

Technology cycles..................................................................................................................... |

641 |

18.1.1 |

Introduction ............................................................................................................................... |

641 |

18.1.2 |

Drilling, centering - CYCLE81................................................................................................... |

642 |

18.1.3 |

Drilling, counterboring - CYCLE82............................................................................................ |

643 |

18.1.4 |

Reaming - CYCLE85................................................................................................................. |

644 |

18.1.5 |

Deep-hole drilling - CYCLE83................................................................................................... |

645 |

18.1.6 |

Boring - CYCLE86..................................................................................................................... |

648 |

18.1.7 |

Tapping without compensating chuck - CYCLE84 ................................................................... |

649 |

18.1.8 |

Tapping with compensating chuck - CYCLE840....................................................................... |

652 |

18.1.9 |

Thread milling - CYCLE78 ........................................................................................................ |

654 |

18.1.10 |

Freely programmable positions - CYCLE802 ........................................................................... |

656 |

18.1.11 |

Row of holes - HOLES1............................................................................................................ |

657 |

18.1.12 |

Grid or frame - CYCLE801........................................................................................................ |

658 |

18.1.13 |

Circle of holes - HOLES2.......................................................................................................... |

659 |

18.1.14 |

Face milling - CYCLE61............................................................................................................ |

661 |

18.1.15 |

Milling a rectangular pocket - POCKET3.................................................................................. |

662 |

18.1.16 |

Milling a circular pocket - POCKET4......................................................................................... |

665 |

18.1.17 |

Rectangular spigot milling - CYCLE76...................................................................................... |

667 |

18.1.18 |

Circular spigot milling - CYCLE77............................................................................................. |

669 |

18.1.19 |

Multiple-edge - CYCLE79 ......................................................................................................... |

671 |

18.1.20 |

Longitudinal slot - SLOT1.......................................................................................................... |

673 |

18.1.21 |

Circumferential slot - SLOT2..................................................................................................... |

675 |

18.1.22 |

Mill open slot - CYCLE899........................................................................................................ |

677 |

18.1.23 |

Elongated hole - LONGHOLE................................................................................................... |

679 |

18.1.24 |

Thread milling - CYCLE70 ........................................................................................................ |

681 |

18.1.25 |

Engraving cycle - CYCLE60...................................................................................................... |

683 |

|

Job Planning |

|

14 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

|

Table of contents

|

18.1.26 |

Contour call - CYCLE62............................................................................................................. |

685 |

|

18.1.27 |

Path milling - CYCLE72............................................................................................................. |

685 |

|

18.1.28 |

Predrilling a contour pocket - CYCLE64.................................................................................... |

688 |

|

18.1.29 |

Milling a contour pocket - CYCLE63.......................................................................................... |

689 |

|

18.1.30 |

Stock removal - CYCLE951....................................................................................................... |

692 |

|

18.1.31 |

Groove - CYCLE930.................................................................................................................. |

694 |

|

18.1.32 |

Undercut forms - CYCLE940..................................................................................................... |

696 |

|

18.1.33 |

Thread turning - CYCLE99 ........................................................................................................ |

699 |

|

18.1.34 |

Thread chain - CYCLE98........................................................................................................... |

702 |

|

18.1.35 |

Cut-off - CYCLE92..................................................................................................................... |

705 |

|

18.1.36 |

Contour cutting - CYCLE95 ....................................................................................................... |

706 |

|

18.1.37 |

Contour grooving - CYCLE952.................................................................................................. |

708 |

|

18.1.38 |

Swiveling - CYCLE800............................................................................................................... |

712 |

|

18.1.39 |

High Speed Settings - CYCLE832............................................................................................. |

714 |

19 |

Tables.................................................................................................................................................... |

|

717 |

|

19.1 |

Operations.................................................................................................................................. |

717 |

|

19.2 |

Operations: Availability for SINUMERIK 828D .......................................................................... |

778 |

|

19.3 |

Currently set language in the HMI............................................................................................. |

802 |

A |

Appendix..................................................... |

........................................................................................... |

803 |

|

A.1 |

List of abbreviations................................................................................................................... |

803 |

|

A.2 |

Documentation overview............................................................................................................ |

812 |

|

Glossary ................................................................................................................................................ |

|

813 |

|

Index...................................................................................................................................................... |

|

835 |

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

15 |

Table of contents

|

Job Planning |

16 |

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

Flexible NC programming |

1 |

1.1Variables

The use of variables, especially in conjunction with arithmetic functions and check structures, enables part programs and cycles to be set up with extremely high levels of flexibility. The system provides three different types of variables.

●System variables

System variables are variables with a fixed predefined meaning; they are defined in the system and made available to the user. They are also read and written by the system software. Example: Machine data

The meaning of a system variable is permanently set by the system. However, minor modifications can be made to the properties by the user in the form of redefinition. See "Redefinition of system variables, user variables, and NC language commands (REDEF) (Page 29)"

●User variables

User variables are variables whose meaning is not known to the system; they are not evaluated by the system. The meaning is defined exclusively by the user.

User variables are subdivided into:

–Predefined user variables

Predefined user variables are variables which have already been defined in the system and whose number simply has to be parameterized by the user via specific machine data. The user can make significant changes to the properties of these variables. See "Redefinition of system variables, user variables, and NC language commands (REDEF) (Page 29)".

–User-defined variables

User-defined variables are variables which are defined exclusively by the user and are not created by the system until runtime. Their number, data type, visibility, and all other properties are defined exclusively by the user.

See "Definition of user variables (DEF) (Page 24)"

1.1.1System variable

System variables are variables which are predefined in the system and enable access to the current parameter settings of the control, as well as to machine, control, and process states, in part programs and cycles.

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

17 |

Flexible NC programming

1.1 Variables

Preprocessing variables

Preprocessing variables are system variables that are read and written in the context of preprocessing; in other words, at the point in time at which the part program block in which the system variable is programmed is interpreted. Preprocessing variables do not trigger preprocessing stops.

Main run variables

Main run variables are system variables which are read and written in the context of the main run; in other words at the point in time at which the part program block in which the system variable is programmed is executed. The following are main run variables:

●System variables which can be programmed in synchronized actions (read/write)

●System variables which can be programmed in the part program and trigger preprocessing stops (read/write)

●System variables which can be programmed in the part program and whose value is calculated during preprocessing but not written until the main run (main run synchronized: write only)

Prefix system

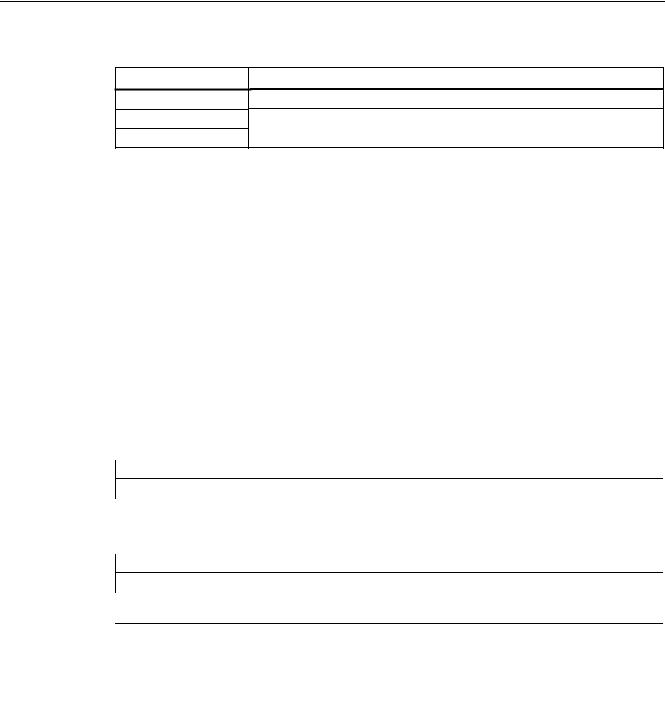

In order that they can be specifically identified, the names of system variables are usually preceded by a prefix comprising the $ sign followed by one or two letters and an underscore.

|

$ + 1st letter |

Meaning: Data type |

|

System variables which are read/written during preprocessing |

|

|

$M |

Machine data 1) |

|

$S |

Setting data, protection zones 1) |

|

$T |

Tool management data |

|

$P |

Programmed values |

|

$C |

Cycle variables of ISO envelope cycles |

|

$O |

Option data |

|

R |

R-parameters (arithmetic parameters) 2) |

|

System variables which are read/written during the main run |

|

|

$$M |

Machine data 1) |

|

$$S |

Setting data 1) |

|

$A |

Current main run data |

|

$V |

Servo data |

|

$R |

R-parameters (arithmetic parameters) 2) |

|

1) Whether machine and setting data is treated as preprocessing or main run variables depends on |

|

|

whether they are written with one or two $ characters. The notation is freely selectable for the specific |

|

|

application. |

|

|

2) When an R-parameter is used in the part program/cycle as a preprocessing variable, the prefix is |

|

|

omitted, e.g. R10. When it is used in a synchronized action as a main run variable, a $ sign is written |

|

|

as a prefix, e.g. $R10. |

|

|

|

Job Planning |

18 |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

Flexible NC programming

1.1 Variables

2nd letter |

Meaning: Visibility |

NNCK-global variable (NCK)

CChannel-specific variable (Channel)

AAxis-specific variable (Axis)

Supplementary conditions

Exceptions in the prefix system

The following system of variables deviate from the prefix system specified above:

●$TC_...: Here, the 2nd letter C does not refer to channel-specific system variables but to toolholder-specific system variables (TC= tool carrier).

●$P_ ...: Channel-specific system variables

Use of machine and setting data in synchronized actions

When machine and setting data is used in synchronized actions, the prefix can be used to define whether the machine or setting data will be read/written synchronous to the preprocessing run or the main run.

If the data remains unchanged during machining, it can be read synchronous to the preprocessing run. For this purpose, the machine or setting data prefix is written with a $ sign:

ID=1 WHENEVER $AA_IM[z] < $SA_OSCILL_REVERSE_POS2[Z]–6 DO $AA_OVR[X]=0

If the data changes during machining, it must be read/written synchronous to the main run. For this purpose, the machine or setting data prefix is written with two $ signs:

ID=1 WHENEVER $AA_IM[z] < $$SA_OSCILL_REVERSE_POS2[Z]–6 DO $AA_OVR[X]=0

Note

Writing machine data

When writing an item of machine or setting data, it is important to ensure that the access level which is active when the part program/cycle is executed permits write access and that the data is set to take "IMMEDIATE" effect.

References

A list of the properties of all system variables appears in:

Parameter Manual, System Variables

See also

Variables (Page 17)

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

19 |

Flexible NC programming

1.1 Variables

1.1.2Predefined user variables: Arithmetic parameters (R)

Function

Arithmetic parameters or R parameters are predefined user variables with the designation R, defined as an array of the REAL data type. For historical reasons, notation both with array index, e.g. R[10], and without array index, e.g. R10, is permitted for R parameters.

When using synchronized actions, the $ sign must be included as a prefix, e.g. $R10.

Syntax

When used as a preprocessing variable:

R<n>

R[<expression>]

When used as a main run variable: $R<n>

$R[<expression>]

Meaning

R: |

Identifier when used as a preprocessing variable, e.g. in the part program |

|

$R: |

Identifier when used as a main run variable, e.g. in synchronized actions |

|

|

Type: |

REAL |

|

Range of values: For a non-exponential notation: |

|

|

|

± (0.000 0001 ... 9999 9999) |

|

|

Note: |

|

|

A maximum of 8 decimal places are permitted. |

|

|

For an exponential notation: |

|

|

± (1*10-300 ... 1*10+300) |

|

|

Note: |

|

|

Notation: <Mantisse>EX<exponent> e.g. 8.2EX-3 |

|

|

A maximum of 10 characters are permitted including |

|

|

sign and decimal point. |

<n>: |

Number of the R parameter |

|

|

Type: |

INT |

|

Range of values: 0 - MAX_INDEX |

|

|

|

Note |

|

|

MAX_INDEX is calculated from the parameterized number |

|

|

of R-parameters: |

|

|

MAX_INDEX = (MD28050 $MN_MM_NUM_R_PARAM) - 1 |

<expression>: |

Array index |

|

|

Any expression can be used as an array index, as long as the result of the |

|

|

expression can be converted to the INT data type (INT, REAL, BOOL, |

|

|

CHAR). |

|

|

|

Job Planning |

20 |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

Flexible NC programming

1.1 Variables

Example

Assignments to R-parameters and use of R-parameters in mathematical functions:

Program code |

Comment |

|

|

R0=3.5678 |

; |

Assignment in |

preprocessing |

R[1]=-37.3 |

; |

Assignment in |

preprocessing |

R3=-7 |

; |

Assignment in |

preprocessing |

$R4=-0.1EX-5 |

; |

Assignment in |

main run: R4 = -0.1 * 10^-5 |

$R[6]=1.874EX8 |

; |

Assignment in |

main run: R6 = 1.874 * 10^8 |

R7=SIN(25.3) |

; |

Assignment in |

preprocessing |

R[R2]=R10 |

; |

Indirect addressing using R-parameter |

|

R[(R1+R2)*R3]=5 |

; Indirect addressing using math. expression |

||

X=(R1+R2) |

; |

Traverse axis |

X to the position resulting from the |

|

|

sum of R1 and |

R2 |

Z=SQRT(R1*R1+R2*R2) |

; |

Traverse axis |

Z to the square root position (R1^2 + |

|

|

R2^2) |

|

See also

Variables (Page 17)

1.1.3Predefined user variables: Link variables

Function

Link variables can be used in the context of the "NCU-Link" function for cyclic data exchange between NCUs which are linked on a network. They facilitate data-format-specific access to the link variables memory. The link variables memory is defined both in terms of size and data structure on a system-specific basis by the user/machine manufacturer.

Link variables are system-global user variables which can be read and written in part programs and cycles by all NCUs involved in a link if link communication has been configured. Unlike global user variables (GUD), link variables can also be used in synchronized actions.

On systems without an active NCU link, link variables can be used locally on the controller as additional global user variables alongside global user variables (GUD).

Job Planning |

|

Programming Manual, 03/2013, 6FC5398-2BP40-3BA1 |

21 |

Flexible NC programming

1.1 Variables

Syntax

$A_DLB[<index>] $A_DLW[<index>] $A_DLD[<index>] $A_DLR[<index>]

Meaning

$A_DLB: Link variable for BYTE data format (1 byte)

Data type: |

UINT |

Range of values: 0 ... 255

$A_DLW: Link variable for WORD data format (2 bytes)

Data type: |

INT |

Range of values: -32768 ... 32767

$A_DLD: Link variable for DWORD data format (4 bytes)

Data type: |

INT |

Range of values: -2147483648 ... 2147483647 $A_DLR: Link variable for REAL data format (8 bytes)

Data type: |

REAL |

Range of values: ±(2.2*10-308 … 1.8*10+308)

<index>: Address index in bytes, counted from the start of the link variable memory

Data type: |

INT |

Range of values: 0 - MAX_INDEX

Note

MAX_INDEX is calculated from the parameterized size of the link variables memory: MAX_INDEX = (MD18700 $MN_MM_SIZEOF_LINKVAR_DATA) - 1

Only indices may be programmed, so that the bytes addressed in the link variables memory are located on a data format limit

Index = n * bytes, where n = 0, 1, 2, etc.

–$A_DLB[i]: i = 0, 1, 2, ...

–$A_DLW[i]: i = 0, 2, 4, ...

–$A_DLD[i]: i = 0, 4, 8, ...

–$A_DLR[i]: i = 0, 8, 16, ...

Example