siemens 840D User Manual

Description of Functions 03/2004 Edition

SINUMERIK 840D/840Di/810D

Synchronized Actions

Valid for

Control Software Version

SINUMERIK 840D powerline 7

SINUMERIK 840DE powerline 7

SINUMERIK 840Di 3

SINUMERIK 840DiE (export version) 3

SINUMERIK 810D powerline 7

SINUMERIK 810DE powerline 7

03.2004 Edition

SINUMERIK 840D/840Di/810D

Synchronized Actions

Description of Functions

Brief Description 1

Detailed Description 2

Supplementary Conditions 3

Data Descriptions (MD, SD) 4

Signal Descriptions 5

Examples 6

Data Fields, Lists 7

References A

Index B

Further information is available on the Internet under:

http://www.siemens.com/motioncontrol

This publication was produced with Interleaf V7.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for damages. All rights, including those created by patent

grant or registration of a utility model or design, are reserved.

Siemens AG, 1994–2004. All rights reserved

Other functions not described in this documentation might be

executable in the control. However, no claim can be made regarding

the availability of these functions when the equipment is first supplied

or for service cases.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist and therefore we cannot guarantee that they are completely

identical. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

Subject to changes without prior notice

Siemens AktiengesellschaftOrder No. 6FC5 297-7AD40-0BP0

Printed in German

y

SINUMERIK

Documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . . .

B Unrevised reprint with new order no.. . . . .

C Revised edition with new status. . . . . .

If factual changes have been made on the page in relation to the same software

version, this is indicated by a new edition coding in the header on that page.

06.94 6FC5 297–0AC30–0BP0 A

08.94 6FC5 297–0AC30–0BP1 C

02.95 6FC5 297–2AC30–0BP0 C

04.95 6FC5 297–2AC30–0BP1 C

09.95 6FC5 297–3AC30–0BP0 C

03.96 6FC5 297–3AC30–0BP1 C

08.97 6FC5 297–4AD40–0BP0 A

1)

12.97 6FC5 297–4AD40–0BP1 C

12.98 6FC5 297–5AD40–0BP0 C

08.99 6FC5 297–5AD40–0BP1 C

04.00 6FC5 297–5AD40–0BP2 C

10.00 6FC5 297–6AD40–0BP0 C

09.01 6FC5 297–6AD40–0BP1 C

11.02 6FC5 297–6AD40–0BP2 C

03.04 6FC5 297–7AD40–0BP0 C

1)

This

document

replaces

the

S5

function

described

for

older

software

versions

in

the

“Description

of

Functions:

Extended

Functions”

brochure.

This book is part of the documentation on CD-ROM (DOCONCD)

Edition Order No. Remarks

03.04 6FC5 298–7CA00–0BG0 C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are registered

trademarks of Siemens AG. The remaining designations in this brochure may be trademarks, the use of

which by third parties for their own purposes may violate the rights of the respective owners.

3ls

03.04

Synchronized Actions (FBSY)

v

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Preface

The SINUMERIK documentation is organized on three levels:

S General documentation

S User documentation

S Manufacturer/service documentation

This document is designed for machine tool manufacturers. The brochure con-

tains a detailed description of the scope of functions offered by SINUMERIK

840D/810D controllers.

The function descriptions are only valid for the specific software version or up to

the software version specified. You should request valid function descriptions

for new software versions. Old function descriptions are only partly applicable

for new software versions.

For more detailed information on SINUMERIK 840D/840Di/810D publications

and other publications covering all SINUMERIK controls (e.g. universal inter-

face, measuring cycles, etc.) please contact your local Siemens office.

Note

It may be possible to run functions that are not described in this document in your controller.

This does not, however, represent an obligation to supply such functions with a new control

or when servicing.

If you have queries regarding the control system, please contact the following

hotline:

A&D Technical Support Phone: ++49-(0)180-5050-222

Fax: ++49-(0)180-5050-223

Email: adsupport@siemens.com

If you have queries regarding documentation (suggestions, corrections), please

send a fax to the following fax address:

Fax: ++49-(0)9131-98-2176

Email: motioncontrol.docu@erlf.siemens.de

Fax form: See the feedback page at the end of the document

http://www.siemens.com/motioncontrol

Notes for the

reader

Hotline

Internet address

for SINUMERIK

09.01

03.04

Synchronized Actions (FBSY)

vi

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Improved-performance variants

S SINUMERIK 840D powerline and

S SINUMERIK 840DE powerline

will be available from 09.2001 onwards. For a list of available powerline

modules, please refer to Section 1.1 of the Hardware Description /PHD/.

Improved-performance variants

S SINUMERIK 810D powerline and

S SINUMERIK 810DE powerline

will be available from 12.2001 onwards. For a list of available powerline

modules, please refer to Section 1.1 of the Hardware Description /PHC/.

This document describes the synchronized actions function for SINUMERIK

840D SW 4 and later and for SINUMERIK 810D SW 2 and later. It replaces the

S5 function described for older software versions in the “Description of

Functions: Extended Functions” brochure.

The function descriptions provide the information required for configuration and

installation.

The information contained in the function descriptions is designed for:

S Design engineers

S PLC programmers creating the PLC user program with the signals listed

S Start-up engineers once the system has been configured and set up

S Maintenance personnel inspecting and interpreting status signals and

alarms

!

Important

This document is valid for the following controls:

D SINUMERIK 840D powerline,

software version 7

D SINUMERIK 810D powerline,

software version 7

D SINUMERIK 840Di,

software version 3

The SW versions indicated in this document refer to the SINUMERIK 840D and

810D controls. For detailed information about which function is enabled for

which controller, see /BU/, Catalog NC 60 (this information is not provided in this

document). Equivalents are as follows:

SINUMERIK 840D

powerline

SINUMERIK 810D

powerline

Objective

Target groups

Equivalent NC

software versions

10.0009.01

03.04

Synchronized Actions (FBSY)

vii

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

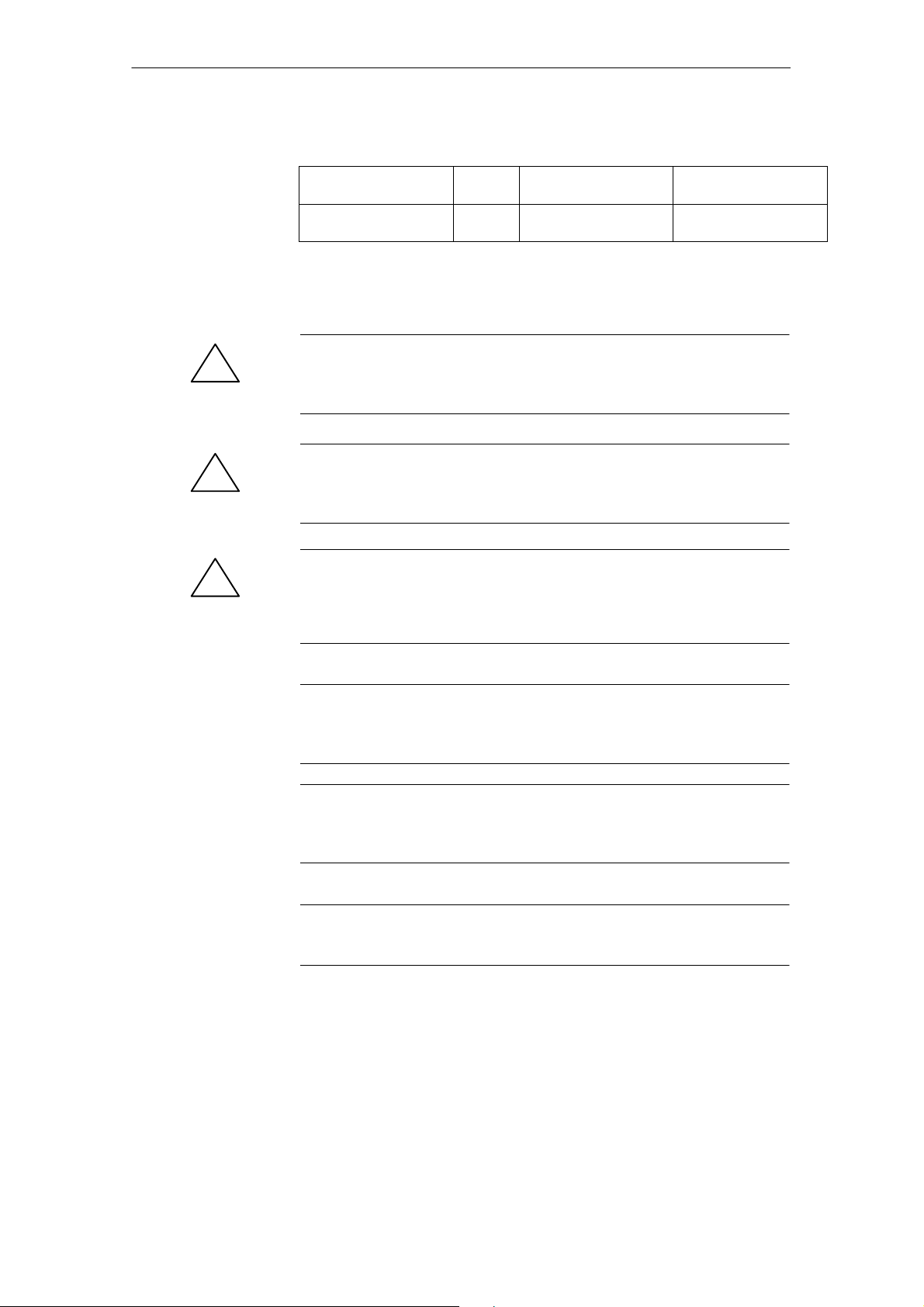

Table 1-1 Equivalent software version

SINUMERIK 840D pow-

erline

SINUMERIK 810D pow-

erline

SINUMERIK 840Di

7.1 Corre-

sponds to

7.1 3.1

!

Danger

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury or in substantial property damage.

!

Warning

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury or in substantial property damage.

!

Caution

Used with the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury or in property dam-

age.

Caution

Used without safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Notice

Used without the safety alert symbol indicates a potential situation which, if not

avoided, may result in an undesirable result or state.

!

Important

Important indicates an important or especially relevant item of information.

Symbols

10.0009.0109.0110.00

03.04

Synchronized Actions (FBSY)

viii

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Note

This note contains additional important information.

10.00

03.04

Synchronized Actions (FBSY)

ix

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Contents

1 Brief Description 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Detailed Description 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Components of synchronized actions 2-15. . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Definition of motion-synchronous actions 2-21. . . . . . . . . . . . . . . . . . . . . .

2.1.2 Execution of synchronized actions 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 List of possible actions 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Real-time evaluations and calculations 2-23. . . . . . . . . . . . . . . . . . . . . . . .

2.3 Special real-time variables for synchronized actions 2-29. . . . . . . . . . . .

2.3.1 Marker/counter variables 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Timers 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Synchronized action parameters 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 R parameters 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Machine and setting data 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 FIFO variables (circulating memory) 2-33. . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.7 System variables saved in SRAM (SW 6.3 and later) 2-36. . . . . . . . . . .

2.3.8 Determining the path tangent in synchronized actions 2-37. . . . . . . . . . .

2.3.9 Determining the current override 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.10 Capacity evaluation using time requirement for synchronized

actions 2-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.11 List of system variables relevant to synchronized actions 2-42. . . . . . . .

2.4 Actions in synchronized actions 2-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Output of M, S and H auxiliary functions to PLC 2-45. . . . . . . . . . . . . . . .

2.4.2 Setting (writing) and reading of real-time variables 2-47. . . . . . . . . . . . . .

2.4.3 Alteration of SW cam positions and times (setting data) 2-48. . . . . . . . .

2.4.4 FCTDEF 2-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Polynomial evaluation SYNFCT 2-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 Overlaid movements $AA_OFF settable (SW 6 and later) 2-56. . . . . . .

2.4.7 Online tool offset FTOC 2-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.8 RDISABLE 2-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.9 STOPREOF 2-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.10 DELDTG 2-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.11 Disabling a programmed axis motion 2-62. . . . . . . . . . . . . . . . . . . . . . . . .

2.4.12 Starting command axes 2-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.13 Axial feedrate from synchronized actions 2-65. . . . . . . . . . . . . . . . . . . . . .

2.4.14 Starting/Stopping axes from synchronized actions 2-66. . . . . . . . . . . . . .

2.4.15 Spindle motions from synchronized actions 2-66. . . . . . . . . . . . . . . . . . . .

2.4.16 Setting actual values from synchronized actions 2-70. . . . . . . . . . . . . . .

2.4.17 Coupled motions and activating/deactivating couplings 2-71. . . . . . . . . .

2.4.18 Measurements from synchronized actions 2-74. . . . . . . . . . . . . . . . . . . . .

2.4.19 Setting and deletion of wait markers for channel synchronization 2-78.

2.4.20 Setting alarm/error reactions 2-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.21 Evaluating data for machine maintenance 2-80. . . . . . . . . . . . . . . . . . . . .

2.5 Calling technology cycles 2-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Coordination of synchronized actions, technology cycles, part

program (and PLC) 2-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Control and protection of synchronized actions 2-87. . . . . . . . . . . . . . . . .

2.6.1 Control via PLC 2-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Protected synchronized actions 2-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03.04

03.04

Synchronized Actions (FBSY)

x

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.7 Control system response for synchronized actions in specific

operational states 2-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 POWER ON 2-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 RESET 2-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 NC STOP 2-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Mode change 2-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.5 End of program 2-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.6 Response of active synchronized actions to end of program and

change in operating mode 2-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.7 Block search 2-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.8 Program interruption by ASUB 2-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.9 REPOS 2-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.10 Response to alarms 2-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Configuration 2-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Configurability 2-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Diagnostics (with MMC 102/MMC 103 only) 2-99. . . . . . . . . . . . . . . . . . .

2.9.1 Display status of synchronized actions 2-100. . . . . . . . . . . . . . . . . . . . . . . .

2.9.2 Display real-time variables 2-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.3 Log real-time variables 2-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Supplementary Conditions 3-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Data Descriptions (MD, SD) 4-105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General machine data 4-105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Channelspecific machine data 4-107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Axis/spindlespecific machine data 4-111. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Setting data 4-113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Signal Descriptions 5-115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Examples 6-117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Examples of conditions in synchronized actions 6-117. . . . . . . . . . . . . . . .

6.2 Reading and writing of SD/MD from synchronized actions 6-118. . . . . . .

6.3 Examples of adaptive control 6-120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Clearance control with variable upper limit 6-120. . . . . . . . . . . . . . . . . . . . .

6.3.2 Feedrate control 6-121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Control velocity as a function of normalized path 6-123. . . . . . . . . . . . . . .

6.4 Monitoring of a safety clearance between two axes 6-124. . . . . . . . . . . . .

6.5 Store execution times in R parameters 6-124. . . . . . . . . . . . . . . . . . . . . . . .

6.6 “Centering” with continuous measurement 6-125. . . . . . . . . . . . . . . . . . . . .

6.7 Axis couplings via synchronized actions 6-128. . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Coupling to leading axis 6-128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 Non-circular grinding via master value coupling 6-129. . . . . . . . . . . . . . . .

6.7.3 On-the-fly parting 6-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Technology cycles position spindle 6-133. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 Synchronized actions in the TCC/MC area 6-134. . . . . . . . . . . . . . . . . . . .

03.04

Synchronized Actions (FBSY)

xi

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

7 Data Fields, Lists 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Interface signals 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Machine data 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Alarms 7-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03.04

Synchronized Actions (FBSY)

xii

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Notes

03.04

Synchronized Actions (FBSY)

1-13

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Brief Description

Motion-synchronous actions (or “synchronized actions” for short) are instruc-

tions programmed by the user, which are evaluated in the interpolation cycle of

the NCK in synchronism with part program execution. If the condition pro-

grammed in the synchronized action is fulfilled or if none is specified, then ac-

tions assigned to the instruction are activated in synchronism with the remain-

der of the part program run.

The following selection from the wide range of possible applications indicates

how actions programmed in synchronized actions can be usefully employed.

S Output of auxiliary functions to PLC

S Writing and reading of real-time variables

S Positioning of axes and spindles

S Activation of synchronous procedures such as:

– Readin disable

– Deletion of distance-to-go

– End preprocessing stop

S Activation of technology cycles

S Online calculation of function values

S Online tool offsets

S Activation/deactivation of couplings/coupled motion

S Take measurements

S Enabling/disabling of synchronized actions

All possible applications of this function are described in the “Detailed Descrip-

tion” chapter.

Definition of

synchronized

actions

Applications

1 Brief Descri

p

tion

1

03.04

Synchronized Actions (FBSY)

1-14

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

In NCK interpolation cycle:

Real-time events and

values:

– Digital inputs/signals

– Values of system

variables

– Measured values

– Drive data

Gating logic

– Evaluation of

conditions

Initiated actions:

– Non-modal

– Modal

– Static modal (across

different operating modes)

Fig. 1-1 Schematic diagram of synchronized actions

For details of how to program synchronized actions, please see

Reference: /PGA/, Programming Guide Advanced

The following chapters describe:

– Functional conditions for synchronized actions (Chapter 2),

– The required machine data (Chapter 4),

– Example applications (Chapter 6).

Note

This Description of Functions applies to the functionality provided in SW 5. The

functions of synchronized actions in SW versions up to and including 3 are

described in:

References: /FB/, S5, “Synchronized Actions”

J

1 Brief Descri

p

tion

12.98

03.04

Synchronized Actions (FBSY)

2.1 Components of synchronized actions

2-15

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Detailed Description

2.1 Components of synchronized actions

Component: Validity,

identifica-

tion number

Frequency G code for

cond. and

action

Condition Action

code word

(fixed)

G code for

action

Action or

technology

cycle

see 2.5

Example: IDS=1 EVERY G70 $AAA_IM[B]

> 15

DO G71 POS[X]= 100

The components of a synchronized action, i.e.:

S Validity:

– With identification number

– Without identification number

S Frequency

S G code for condition and action (SW 5 and later)

S Condition

S G code for actions (SW 5 and later)

S Action(s)/Technology cycle

are explained individually below.

There are three possible for defining the scope of validity of a synchronized

action:

S No status

S ID

S IDS

Structure of a

synchronized

action

Validity, ID number

2

03.04

2.1 Components of synchronized actions

Synchronized Actions (FBSY)

2-16

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Synchronized actions that have no specified validity have a non-modal action,

i.e. they apply only to the next block.

Non-modal synchronized actions are operative only in AUTOMATIC mode.

In SW 6.1 and later, non-modal synchronized actions are active modally for all

preprocessing stop blocks (incl. implicitly generated ones) and for implicitly gen-

erated intermediate blocks.

Synchronized actions with validity identifier ID are modally active in subse-

quently programmed blocks. They are operative only in AUTOMATIC mode.

Limitation:

– ID actions remain operative only until another synchronized action with

the same identification number is programmed

– Until they are canceled with CANCEL(i), see Subsection 2.5.1.

Static synchronized actions that are programmed with keyword “IDS” are active

in all operating modes. They are also referred to as s

tatic synchronized ac-

tions. Option.

Synchronized actions programmed with ID or IDS are deleted from the part pro-

gram.

For modal synchronized actions (ID, IDS) identification numbers between 1 and

255 are allocated. They are important for the functions of mutual coordination of

synchronized actions. See Subsection 2.5.1. Modal/static synchronized actions

with identification numbers between 1 and 64 can be disabled and enabled from

the PLC. See Subsection 2.6.1.

Unique identification numbers must be allocated in the channel.

Applications for static synchronized actions:

– AC grinding (also active in JOG mode)

– Gating logic for Safety Integrated

– Monitoring functions, reaction to machine states in all operating modes

– Optimization of tool change

– Cyclic machines

Examples:

IDS=1 EVERY $A_IN[1]==1 DO POS[X]=100 All operating modes

ID=2 EVERY $A_IN[1]==0 DO POS[X]=0 AUTOMATIC

Note

The following actions are operative only in AUTOMATIC mode when the

program is running:

STOPREOF,

DELDTG

No specified validity

ID

IDS

Identification

numbers

10.00

03.04

Synchronized Actions (FBSY)

2.1 Components of synchronized actions

2-17

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Keywords (see table) are programmed to indicate how often the subsequently

specified condition must be scanned and the associated action executed if the

condition is fulfilled. These keywords are an integral component of the synchro-

nized action condition.

Table 2-1 Effect of frequency keywords

Keyword Scanning frequency

None

If no scanning frequency is programmed, then the action is executed cyclically in every

interpolation cycle.

WHENEVER

The associated action/technology cycle is executed cyclically in every interpolation cycle

provided that the condition is fulfilled.

FROM

If the condition has been fulfilled once, the action/technology cycle is executed cycli-

cally in every interpolation cycle for as long as the synchronized action remains active.

WHEN

As soon as the condition has been fulfilled, the action/technology cycle is executed

once. Once the action has been executed a single time, the condition is no longer

checked.

EVERY

The action/technology cycle is activated once if the condition if fulfilled. The action/

technology cycle is executed every time the condition changes from the “FALSE” to

the “TRUE” state. In contrast to keyword WHEN, checking of the condition continues

after execution of the action/cycle until the synchronized action is deleted or disabled.

For details of technology cycles, please see Section 2.5.

Deselecting (deleting) an active synchronized action from the part program with

CANCEL has no effect on the active action. Positioning motions are completed

as programmed. The CANCEL command can be programmed to delete a

modal or static synchronized action. If a synchronized action is deleted while

the positioning axis motion it has initiated is still in progress, the positioning mo-

tion continues until properly executed. A channel stop also cancels the position-

ing movement from synchronized actions/technology cycles.

In SW 5 and later, G codes can be programmed in synchronized actions. This

allows defined settings to exist for the evaluation of the condition and the action/

technology cycle to be executed, independent of the current part program sta-

tus. It is necessary to separate the synchronized actions from the program envi-

ronment, because synchronized actions are required to execute their actions at

any time from a defined initial state as a result of fulfilled trigger conditions.

Applications:

Definition of the systems of measurement for condition evaluation and action

through G codes G70, G71, G700, G710.

Note

In SW 5, the use of the G codes in synchronized actions is limited to these 4 G

codes.

Frequency

Deletion

G code for

condition and

action

03.04

2.1 Components of synchronized actions

Synchronized Actions (FBSY)

2-18

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

A G code specified for the condition is valid for the evaluation of the condition

and for the action if no separate G code is specified for the action.

Only one G code of the G code group may be programmed for each part of the

condition.

Execution of actions/technology cycles can be made dependent upon a condi-

tion (logical expression).

The condition is checked in the interpolation cycle. If no condition is pro-

grammed, the action is performed once in every IPO cycle. In SW version 3 and

earlier, two conditions are permitted, i.e. the comparison of a real-time variable

with an expression calculated during preprocessing or the comparison of two

real-time variables.

Examples:

WHENEVER $AA_IM[X] > 10.5*SIN(45) DO .... or

WHENEVER $AA_IM[X] > $$AA_IM[X1] DO ...

An additional condition is available in SW 4 and later, i.e. the linking of compari-

sons using Boolean operations. Boolean operators in NC language may be

used for this purpose:

NOT, AND, OR, XOR, B_OR, B_AND, B_XOR, B_NOT.

Examples:

WHENEVER ($A_IN[1]==1) OR ($A_IN[3]==0) DO ...

; while input 1 is applied or input 3 is not applied ...

Two or more real-time expressions may be compared with one another within

one condition.

Comparisons may be made between variables of the same type or between

partial expressions.

Example:

WHEN $AA_IM[X2] <= $AA_IM[X1] +.5 DO $AA_OVR[X1]=0

; Stop when safety clearance is exceeded

The options for applying real-time expressions are described in the “Calcula-

tions in real time” chapter. When conditions are programmed, all the system

variables listed in Subsection 2.3.11 can be addressed. In addition:

S Machine data, e.g. $$MN_..., $$MC_..., $$MA_...

S Setting data, e.g. $$SN_..., $$SC_..., $$SA_...

Note

S GUD variables cannot be used

S R parameters are addressed with $R....

S Setting and machine data whose value may vary during

machining must be programmed with $$S._... / $$M._...

Further examples of conditions can be found in Section 6.1.

Conditions

03.04

Synchronized Actions (FBSY)

2.1 Components of synchronized actions

2-19

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

This G code may specify a G code for all actions in the block and technology

cycles, which differs from the one set in the condition. If technology cycles are

contained in the action part, the G code remains modally active for all actions

until the next G code, even after the technology cycle has been completed.

Only one G code of the G code group may be programmed for each action part.

Every synchronized action contains one or more programmed actions or one

technology cycle. These are executed when the appropriate condition is ful-

filled. If several actions are programmed in one synchronized action, they are

executed within the same interpolation cycle.

Example: WHEN $AA_IM[Y] >= 35.7 DO M135 $A_OUT[1]=1

If the actual value of the Y axis is greater than or equal to

35.7, then M135 is output to the PLC and output 1 set at the

same time.

A program (name) can also be specified as an action. This program may con-

tain any of the actions, which can be programmed individually in synchronized

actions. Such programs are also referred to as technology cycles below. A

technology cycle is a sequence of actions that are processed sequentially in the

interpolation cycle. See Section 2.5.

Application: Single axis programs, cyclic machines.

The blocks of a part program are prepared at the program preprocessing stage,

stored and then executed sequentially on the interpolation level (main run). Vari-

ables are accessed during block preparation. When real-time variables (e.g.

actual values) are used, block preparation is interrupted to allow current real-

time values up to the preceding block to be supplied. Synchronized actions are

transported to the interpolator in preprocessed form together with the prepared

block. The real-time variables used are evaluated in the interpolation cycle.

Block preparation is not interrupted.

G code for the

action

Actions

Program/technology

cycle

Machining process

03.04

2.1 Components of synchronized actions

Synchronized Actions (FBSY)

2-20

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

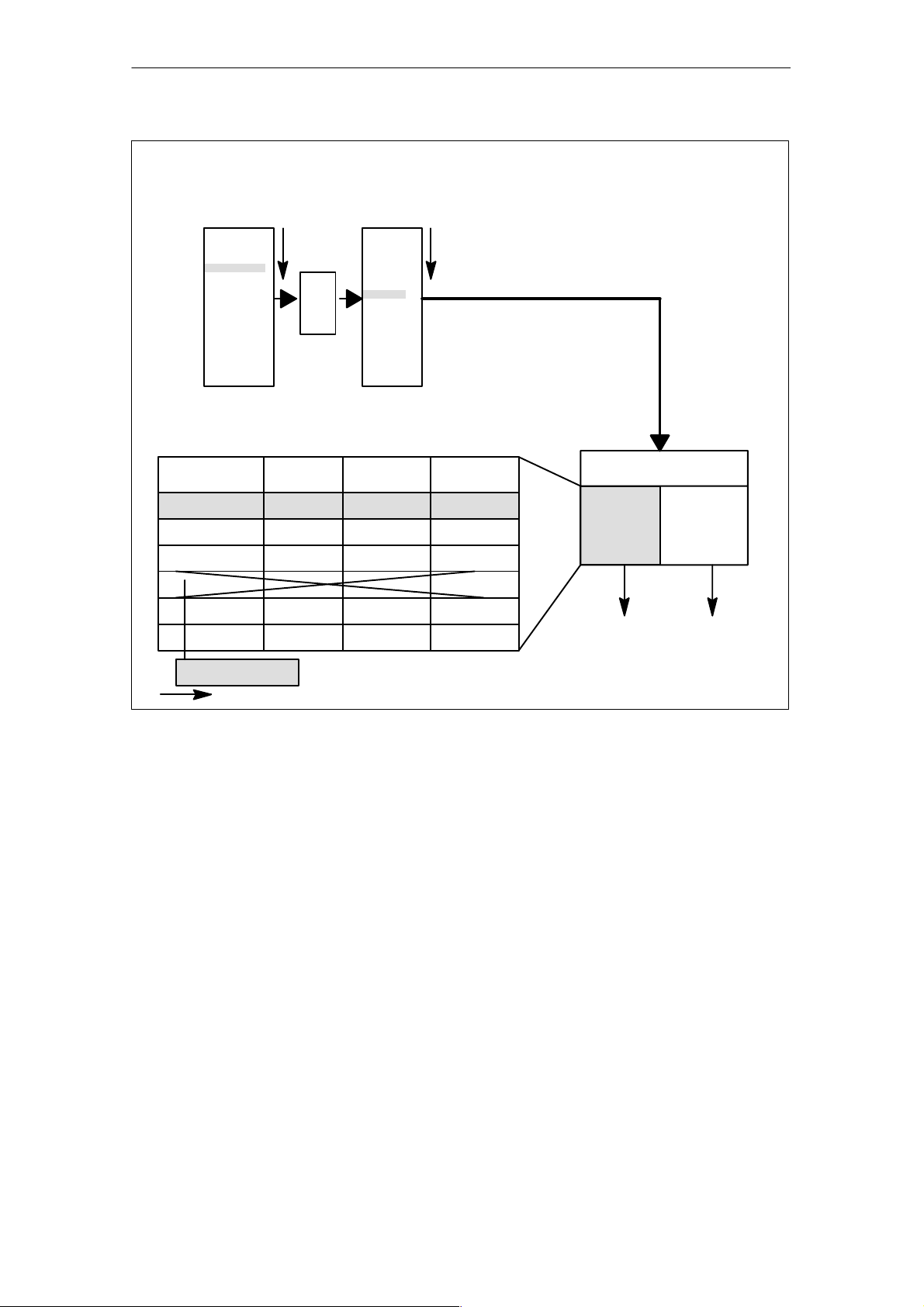

Validity, ID,

IDS

Fre-

quency

Condition

Action(s)

techn. cycles

Stored, preprocessed synchronized actions

Memory size: MD 28250: $MC_MM_NUM_SYNC_ELEMENTS

Part program

Program

preprocessing

Prepared

PP blocks

N5 block1

N10 block2

N15 ID=1

N20 block4

N25 block5

...

block1’

block2’

[ – ]

block4’

block5’

...

ID 1 WHENEVER $A_..< $A_.. M130

Main run

Movement of

axes, ...

Synchroni-

zed

action

processing

Sequence of synchronized action interpretation

SetpointsActions,

technology cycles

Deletion

Fig. 2-1 Schematic diagram illustrating processing of synchronized actions

Synchronized actions are checked in the interpolation cycle to determine

whether they contain actions to be activated. Action(s) are executed in synchro-

nism with path control if the preconditions programmed on the left of the ac-

tion(s) are fulfilled.

Within an interpolation cycle, modal synchronized action instructions are pro-

cessed in order of their ID number (i.e. block with ID number 1 before block with

ID number 2, etc.). Once the modal synchronized action instructions have been

executed, non-modal synchronized action instructions are processed in the or-

der in which they are programmed.

Processing of

synchronized

actions

Order of execution

03.04

Synchronized Actions (FBSY)

2.1 Components of synchronized actions

2-21

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.1.1 Definition of motion-synchronous actions

Motion-synchronous actions can be defined in the following ways:

S In the part program

S Static synchronized actions in an asynchronous subprogram activated by

the PLC

2.1.2 Execution of synchronized actions

The actions programmed in motion-synchronous actions are executed if

S The synchronized action exists and has not been deselected with CAN-

CEL(ID) (see Subsection 2.5.1)

S The synchronized action is not disabled, i.e. no LOCK(ID) (see Subsection

2.5.1)

S Evaluation of the action is due as a result of the programmed frequency key-

word or

S The appropriate condition is fulfilled

For further details, please see the following subsections.

Defining programs

Conditions for

execution

03.04

2.1 Components of synchronized actions

Synchronized Actions (FBSY)

2-22

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.1.3 List of possible actions

S Output of M, S and H auxiliary functions to the PLC

S Real-time variables can be set (written) to obtain the following functionality:

– Overlaid movement ($AA_OFF), option.

– Feedrate control ($AC_OVR, $AA_OVR),

disabling of a programmed axis motion

– ...

S Changes to SW cam positions and times (setting data) and alteration of

other setting data

S Modification of coefficients and limits from FCTDEF

S SYNFCT (polynomial evaluation)

S FTOC (online tool offsets)

S RDISABLE (read-in disable)

S STOPREOF (preprocessing stop cancellation)

S DELDTG (delete distance-to-go)

S Calculation of curve table values

S Axial feedrate from synchronized actions

S Axial frames

S Moving/positioning axes from synchronized actions

S Spindle motions from synchronized actions

S Actual-value setting from synchronized actions (Preset)

S Activation/deactivation of couplings and coupled motion

S Measurements from synchronized actions

S Setting and deletion of wait markers for channel synchronization

S Set alarm/error reactions

S Travel to fixed stop FXS (FXST, FXSW)

S Travel with limited torque FOC (FOCON/FOCOF)

S Extended stop and retract (Description of Functions M3)

S Reading and, if tagged accordingly, writing of system variables from the list

in Subsection 2.3.11.

These actions are described in detail in Section 2.4.

12.9712.9710.0012.9810.00

03.04

Synchronized Actions (FBSY)

2.2 Real-time evaluations and calculations

2-23

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.2 Real-time evaluations and calculations

Calculations carried out in real time represent a subset of those calculations that

can be performed in the NC language. It is restricted to data types REAL, INT,

CHAR and BOOL.

Implicit type conversions, such as in the part program, do not take place. See

data type below.

The term “Real-time expression” refers below to all calculations that can be car-

ried out in the interpolation cycle. Real-time expressions are used in conditions

and in assignments to NC addresses and variables.

All real-time variables are evaluated (read) in the interpolation cycle and can be

written as part of an action.

Real-time variables are all variables that begin with:

$A... (main run variable) or

$V... (servo values).

So that they can be clearly identified, these variables can be programmed with

$$ in synchronized actions.

E.g. $AA_IM[X] or $$AA_IM[Y]: Actual value for X axis or Y axis in the machine

coordinate system.

Note

Setting data and machine data must be programmed with $$S... / $$M... if its

value changes during machining.

Only real-time variables of the same data type may be linked by a logic opera-

tion within the same expression. However, in order to process various types of

data, you can use the conversion routines provided for type matching (SW 5.2,

see conversion routines). In contrast to full expressions in the NC language,

calculations are performed in the data type of the real-time variables involved.

... DO $R10 = $AC_PARAM[0] ; permissible REAL, REAL

... DO $R10 = $AC_MARKER[0] ; not permissible: REAL, INT

The following examples of real-time evaluations were already available in SW

version 3.2 (they employ only real-time variables of this SW version):

On the left of the comparison, there is a comparison variable calculated in real

time and, on the right, an expression, which is none of the permitted real-time

processing variables that begin with $$.

WHEN $AA_IM[X] > $A_INA[1] DO M120

Restriction

Scope of

application

Real-time variables

Real-time variable

identifiers

Data type

Example 1 for

SW 3.2

01.00

03.04

2.2 Real-time evaluations and calculations

Synchronized Actions (FBSY)

2-24

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

M120 is output during execution of the motion programmed in the following

block if the X axis actual value exceeds the value applied at analog input 1.

With this programming, the actual value is re-evaluated in every interpolation

cycle while the value of the analog input is generated at the instant of interpreta-

tion.

On the left of the comparison, there is a comparison variable calculated in real

time and, on the right, an expression, which is one of those permitted for the

synchronized action (beginning with $$).

WHEN $AA_IM[X] > $$A_INA[1] DO M120

The current actual value of the X axis is compared in the IPO cycle with analog

input 1 because an $$ variable is programmed on the right.

Both variables are compared to one another in the interpolation cycle.

$$ variables may also be programmed on the left of the comparison.

WHEN $$AA_IM[X] > $$A_INA[1] DO M120

Identical to example 2. The left-hand and right-hand sides are always compared

in real time.

The real-time variables available in synchronized actions are listed in Subsec-

tion 2.3.11. New system variables, which have been added in subsequent soft-

ware versions are indicated in the table.

S Machine and setting data

In the case of machine and setting data, $$S... or $$M... must be programmed

for online access. The access instruction to be evaluated during interpretation/

decoding must be preceded by a $ sign. Real-time variables that may legally be

accessed from synchronized actions are addressed preceded only by a $ sign.

There is no implicit type conversion from REAL to INT and vice versa for syn-

chronized actions. However, the user may explicitly call two conversion routines

RTOI( ) and ITOR( ) for type conversion. The functions can be called

S In the part program and

S From the synchronized action.

REAL ITOR( INT ) – Converting integer to real

The function converts the integer value transferred to a real value and returns

this value. The transferred variable is not changed.

Example:

$AC_MARKER[1] = 561

ID=1 WHEN TRUE DO $AC_PARAM[1] = ITOR( $AC_MARKER[1] )

INT RTOI( REAL ) – Converting from real to integer

Example 2 for

SW 3.2

Example 3 for

SW 3.2

Extensions in

SW 4

Conversion

routines (SW 5.2)

ITOR

RTOI

01.00

03.04

Synchronized Actions (FBSY)

2.2 Real-time evaluations and calculations

2-25

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

The function RTOI() converts the Real value presented to a rounded INT value

and returns this integer value. If the value transferred lies outside the range that

can be unambiguously represented as an integer value, alarm 20145 “Motion-

synchronous action: Arithmetic error” is output and no conversion is performed.

The transferred variable is not changed.

Note

The function RTOI() does not produce an unambiguous result when inverted,

i.e. it is not possible to determine the original Real value from the value

returned as the decimal places are lost during conversion!

Example RTOI:

$AC_PARAM[1] = 561.4378

ID=1 WHEN TRUE DO $AC_MARKER[1] = RTOI( $AC_PARAM[1] )

; Result: 561

...

$AC_PARAM[1] = –63.867

ID=1 WHEN TRUE DO $AC_MARKER[1] = RTOI( $AC_PARAM[1] )

; Result:–64

...

$AC_MARKER[1]= 10 $AC_PARAM[1] = –6386798797.29

ID=1 WHEN TRUE DO $AC_MARKER[1] = RTOI( $AC_PARAM[1] )

;Result: Alarm 20145

;$AC_MARKER[1] = 10 (unchanged due to alarm)

In SW 6.4 and later, variables of various data types can be assigned to one

another in synchronized actions without having to call the RTOI or ITOR func-

tion, e.g. REAL to INT and vice versa.

If values outside of the interval [INT_MIN, INT_MAX] would result from the con-

version from REAL to INTEGER, alarm 20145 “Motion-synchronous action:

Arithmetic error” is output and no conversion is performed.

Examples:

Previously

$AC_MARKER[1] = 561

ID=1 WHEN TRUE DO $AC_PARAM[1] = ITOR( $AC_MARKER[1] )

In software version 6.4 and later

$AC_MARKER[1] = 561

ID=1 WHEN TRUE DO $AC_PARAM[1] = $AC_MARKER[1]

Previously

$AC_PARAM[1] = 561.4378

ID=1 WHEN TRUE DO $AC_MARKER[1] = RTOI( $AC_PARAM[1] ) ; 561

In software version 6.4 and later

$AC_PARAM[1] = 561.4378

ID=1 WHEN TRUE DO $AC_MARKER[1] = $AC_PARAM[1] : 561

Implicit type

conversion

(SW 6.4)

01.0003.02

03.04

2.2 Real-time evaluations and calculations

Synchronized Actions (FBSY)

2-26

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Real-time variables of the REAL and INT type can be linked logically by the fol-

lowing basic arithmetic operations:

– Addition

– Subtraction

– Multiplication

– Division

– Integer division

– Modulo division

Only variables of the same type may be linked by these operations.

Expressions from basic arithmetic operations can be bracketed and nested.

See priorities for operators on the next page.

The following relational operators may be used:

== Equal to

<> Not equal to

< Less than

> Greater than

<= Less than or equal to

>= Greater than or equal to

The following Boolean operators may be used:

NOT NOT,

AND AND,

OR OR,

XOR Exclusive OR

The following bit operators may be used:

B_OR Bit-serial OR

B_AND Bit-serial AND

B_XOR Bit-serial exclusive OR

B_NOT Bit-serial negation

Operands are variables and constants of the INT type.

Basic arithmetic

operations

Expressions

Comparisons

Boolean operators

Bit operators

03.04

Synchronized Actions (FBSY)

2.2 Real-time evaluations and calculations

2-27

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

In order to produce the desired logical result in multiple expressions, the follow-

ing operator priorities should be observed in calculations and conditions:

1. NOT, B_NOT Negation, bit-serial negation

2. *, /, DIV, MOD Multiplication, division

3. +, – Addition, subtraction

4. B_AND Bit-serial AND

5. B_XOR Bit-serial exclusive OR

6. B_OR Bit-serial OR

7. AND AND

8. XOR Exclusive OR

9. OR OR

10. Not used

11. Relational operators

== Equal to

<> Not equal to

> Greater than

< Less than

>= Greater than or equal to

<= Less than or equal to

and parentheses should be used where necessary. The logic operation result

for a condition must be a BOOL data type.

Example of a multiple expression:

WHEN ($AA_IM[X] > VALUE) AND ($AA_IM[Y] > VALUE1) DO ...

A real-time variable of the REAL type can be used to create function values

sine, cosine, etc.

The following functions are possible:

SIN, COS, ABS, ASIN, ACOS, TAN, ATAN2,

TRUNC, ROUND, LN, EXP, ATAN, POT, SQRT,

CTAB, CTABINV

Example:

... DO $AC_PARAM[3]=COS($AA_IM[X])

For a description of how to use these functions, please see:

References: /PG/, Programming Guide

/PGA/, Programming Guide Advanced

The index of a real-time field variable can in turn be a real-time variable.

Example:

WHEN ... DO $AC_PARAM[ $AC_MARKER[1] ] = 3

The current value of the index $AC_MARKER[1] is evaluated in each interpola-

tion cycle.

Priority of

operators

Functions

Indexing

03.04

2.2 Real-time evaluations and calculations

Synchronized Actions (FBSY)

2-28

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

Restrictions:

– It is not permissible to nest indices with real-time variables.

– A real-time index cannot be generated by a variable that is not gener-

ated itself in real time. The following programming would lead to errors:

$AC_PARAM[1]=$P_EP[$AC_MARKER[0]]

03.04

Synchronized Actions (FBSY)

2.3 Special real-time variables for synchronized actions

2-29

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.3 Special real-time variables for synchronized actions

A complete list of system variables that may be addressed in synchronized

actions can be found in Subsection 2.3.11. The characteristics of a few special

real-time variables are described below:

S Marker/counter variables

– Channel-specific markers

S Timers

S Synchronized action parameters

S R parameters

S Machine and setting data

S FIFO variables (circulating memory)

Special real-time variables, i.e. timers, R parameters, machine and setting data

and FIFO variables are available in SW 4 and later.

2.3.1 Marker/counter variables

The $AC_MARKER[n] variable serves as a marker or counter in the INTEGER

data type.

n: Number of marker: 0-n

The number of markers per channel is set via machine data

MD 28256: NUM_AC_MARKER.

Markers exist once in each channel under the same name. They are stored in

the dynamic memory and reset to 0 on POWER ON, NC RESET and End of

Program, ensuring identical start conditions for every program run.

Marker variables can be read and written in synchronized actions.

In software version 6.3 and later, it is possible to select the memory location for

$AC_MARKER[n] between DRAM and SRAM using

MD 28257: MM_BUFFERED_AC_MARKER.

0: Dynamic memory DRAM, (default)

1: Static memory SRAM

A maximum value of 2000 can be assigned to machine data 28256:

NUM_AC_MARKER. One element requires 4 bytes. You must ensure that suffi-

cient memory of the correct type is available.

Markers saved in SRAM can be included in the data backup. See Subsec-

tion 2.3.7

SW 4

Channel-specific

markers

Also available in

SW 6.3 and later

06.01

03.04

2.3 Special real-time variables for synchronized actions

Synchronized Actions (FBSY)

2-30

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Descr. of Functions Synchronized Actions (FBSY) – 03.04 Edition

2.3.2 Timers

System variable $AC_TIMER[n] permits actions to be started after defined wait-

ing times.

n: Number of timer variable

Unit: Seconds

Data type: REAL

The number of available timer variables is programmed in machine data

MD 28258: MM_NUM_AC_TIMER.

Incrementation of a timer variable is started by means of value assignment:

$AC_TIMER[n]=value

n: Number of timer variable

Value: Start value (normally 0)

Incrementation of a timer variable can be stopped by assigning a negative

value:

$AC_TIMER[n]=–1

The current timer value can be read whether the timer variable is running or has

been stopped. Once a timer variable has been stopped by assigning –1, the

current timer value remains stored and can be read.

Output of an actual value via analog output 500 ms after detection of a digital

input:

WHEN $A_IN[1]==1 DO $AC_TIMER[1]=0 ;Reset and start timer

WHEN $AC_TIMER[1]>=0.5 DO $A_OUTA[3]=$AA_IM[X] $AC_TIMER[1]=–1

Setting timers

Stopping timers

Reading timers

Example

Loading...

Loading...