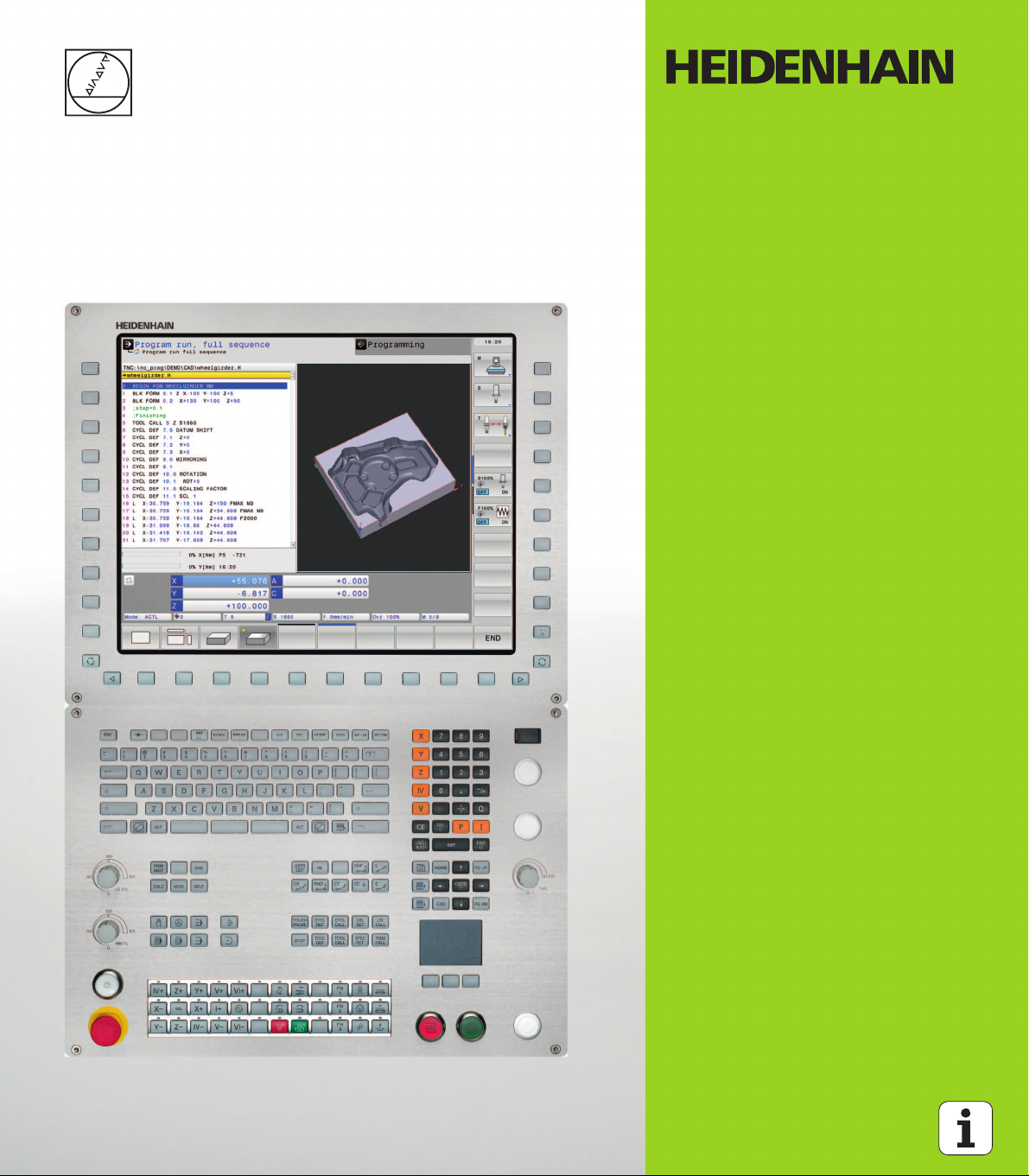

HEIDENHAIN TNC 640 User Manual

User’s Manual

ISO Programming

TNC 640

NC Software

340590-01

340591-01

340594-01

English (en)

4/2012

Controls of the TNC

1

50

0

50

100

F %

1

50

0

50

100

S %

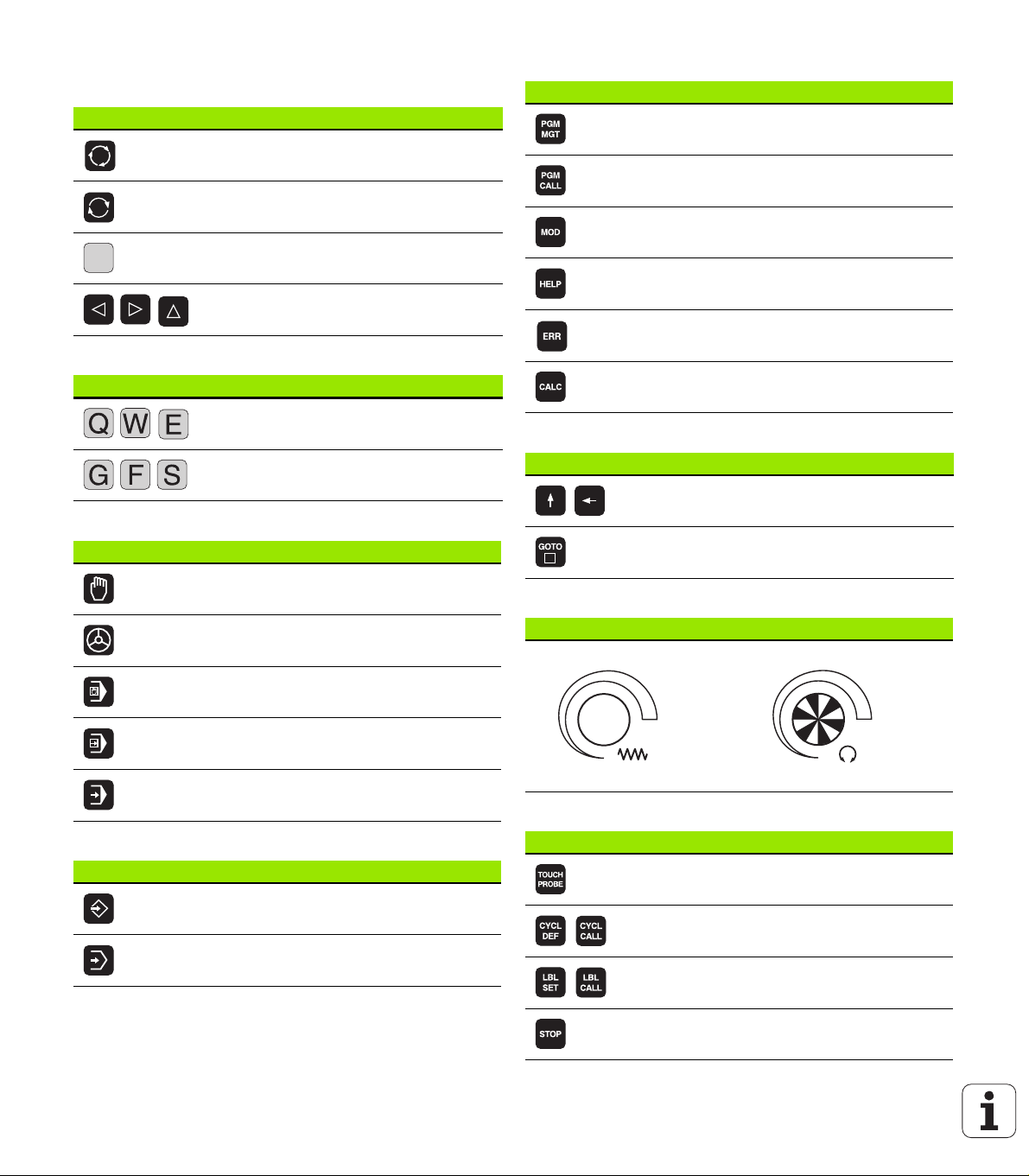

Keys on visual display unit

Key Function

Split screen layout

Toggle the display between machining

and programming modes

Soft keys for selecting functions on

screen

Switch the soft-key rows

Alphanumeric keyboard

Key Function

File names, comments

DIN/ISO programming

Machine operating modes

Key Function

Manual Operation

Electronic Handwheel

Program/file management, TNC functions

Key Function

Select or delete programs and files,

external data transfer

Define program call, select datum and

point tables

Select MOD functions

Display help text for NC error messages,

call TNCguide

Display all current error messages

Show calculator

Navigation keys

Key Function

Move highlight

Go directly to blocks, cycles and

parameter functions

Potentiometer for feed rate and spindle speed

Feed rate Spindle speed

Programming modes

Key Function

Positioning with Manual Data Input

Program Run, Single Block

Program Run, Full Sequence

Cycles, subprograms and program section repeats

Key Function

Define touch probe cycles

Programming and Editing

Define and call cycles

Test Run

Enter and call labels for subprogramming

and program section repeats

Enter program stop in a program

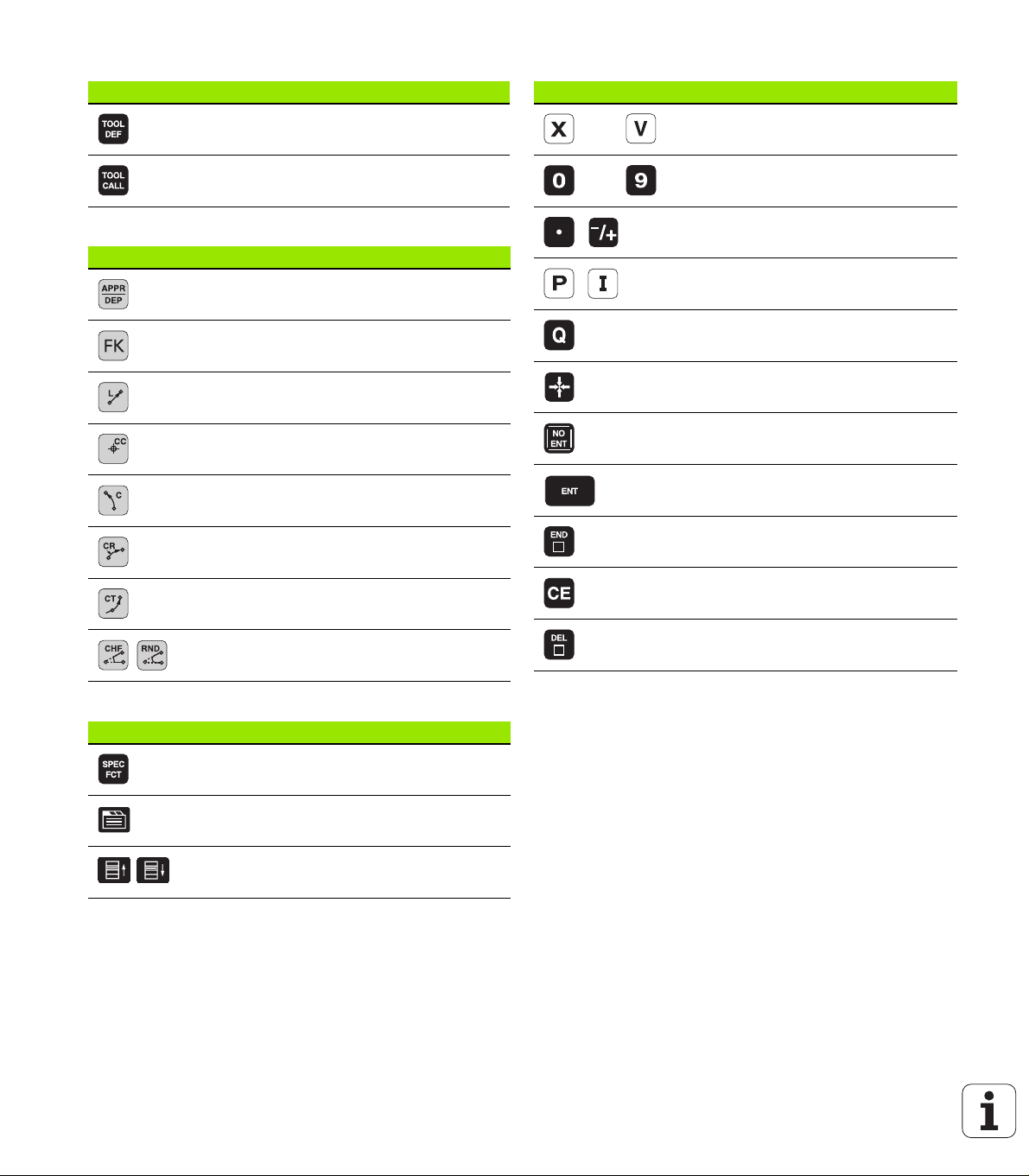

Tool functions

Key Function

Define tool data in the program

Coordinate axes and numbers: Entering and editing

Key Function

Select coordinate axes or

enter them into the program

Call tool data

Programming path movements

Key Function

Approach/depart contour

FK free contour programming

Straight line

Circle center/pole for polar coordinates

Circle with center

Circle with radius

Circular arc with tangential connection

Chamfer/Corner rounding

Numbers

Decimal point / Reverse algebraic sign

Polar coordinate input / Incremental

values

Q parameter programming /

Q parameter status

Save actual position or values from

calculator

Skip dialog questions, delete words

Confirm entry and resume dialog

Conclude block and exit entry

Clear numerical entry or TNC error

message

Abort dialog, delete program section

Special functions

Key Function

Show special functions

Select the next tab in forms

Up/down one dialog box or button

About this Manual

The symbols used in this manual are described below.

This symbol indicates that important notes about the

function described must be regarded.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

About this Manual

Would you like any changes, or have you found any errors?

We are continuously striving to improve documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

HEIDENHAIN TNC 640 5

TNC Model, Software and Features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

TNC model NC software number

TNC 640 340590-01

TNC 640 E 340591-01

TNC 640 Programming Station 340594-01

The suffix E indicates the export version of the TNC. The export

version of the TNC has the following limitations:

Simultaneous linear movement in up to 4 axes

The machine tool builder adapts the usable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

Tool measurement with the TT

Please contact your machine tool builder to become familiar with the

TNC Model, Software and Features

features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

User’s Manual for Cycle Programming:

All of the cycle functions (touch probe cycles and fixed

cycles) are described in a separate manual. Please contact

HEIDENHAIN if you need a copy of this User’s Manual.

ID: 892905-xx

6

Software options

The TNC 640 features various software options that can be enabled by

your machine tool builder. Each option is to be enabled separately and

contains the following respective functions:

Software option 1 (option number #08)

Cylinder surface interpolation (Cycles 27, 28 and 29)

Feed rate in mm/min for rotary axes: M116

Tilting the machining plane (plane functions, Cycle 19 and 3D-ROT

soft key in the Manual Operation mode)

Circle in 3 axes with tilted working plane

Software option 2 (option number #09)

5-axis interpolation

3-D machining:

M128: Maintaining the position of the tool tip when positioning

with tilted axes (TCPM)

FUNCTION TCPM: Maintaining the position of the tool tip when

positioning with tilted axes (TCPM) in selectable modes

M144: Compensating the machine’s kinematic configuration for

ACTUAL/NOMINAL positions at end of block

LN blocks (3-D compensation)

TNC Model, Software and Features

HEIDENHAIN DNC (option number #18)

Communication with external PC applications over COM

component

Additional conversational language (option number #41)

Function for enabling the conversational languages Slovenian,

Slovak, Norwegian, Latvian, Estonian, Korean, Turkish, Romanian,

Lithuanian.

Display step (option number #23)

Input resolution and display step:

Linear axes down to 0.01 µm

Rotary axes to 0.00001°

Double speed (option number #49)

Double-speed control loops are used primarily for high-speed

spindles as well as for linear motors and torque motors

HEIDENHAIN TNC 640 7

KinematicsOpt software option (option number #48)

Touch-probe cycles for inspecting and optimizing the machine

accuracy

Software option Mill-Turning (option number #50)

Functions for milling/turning mode:

Switching between Milling/Turning mode of operation

Constant cutting speed

Tool-tip radius compensation

Turning cycles

Extended Tool Management software option

(option number #93)

Tool management that can be changed by the machine

manufacturer using Python scripts

TNC Model, Software and Features

8

Feature content level (upgrade functions)

Along with software options, significant further improvements of the

TNC software are managed via the Feature Content Level (FCL)

upgrade functions. Functions subject to the FCL are not available

simply by updating the software on your TNC.

All upgrade functions are available to you without

surcharge when you receive a new machine.

Upgrade functions are identified in the manual with FCL n, where n

indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable the

FCL functions. For more information, contact your machine tool

builder or HEIDENHAIN.

Intended place of operation

The TNC complies with the limits for a Class A device in accordance with the specifications in EN 55022, and is intended for use primarily in industrially-zoned areas.

Legal information

This product uses open source software. Further information is

available on the control under

U Programming and Editing operating mode

U MOD function

U LICENSE INFO soft key

TNC Model, Software and Features

HEIDENHAIN TNC 640 9

TNC Model, Software and Features

10

Contents

First Steps with the TNC 640

1

Introduction

2

Programming: Fundamentals,

File Management

3

Programming: Programming Aids

4

Programming: Tools

5

Programming: Programming Contours

6

Programming: Subprograms and

Program Section Repeats

7

Programming: Q Parameters

8

Programming: Miscellaneous Functions

9

Programming: Special Functions

10

Programming: Multiple Axis Machining

11

Programming: Pallet Editor

12

Manual Operation and Setup

13

Positioning with Manual Data Input

14

Test Run and Program Run

15

MOD Functions

16

Tables and Overviews

17

HEIDENHAIN TNC 640 11

1 First Steps with the TNC 640 ..... 33

1.1 Overview ..... 34

1.2 Machine Switch-On ..... 35

Acknowledging the power interruption and moving to the reference points ..... 35

1.3 Programming the First Part ..... 36

Selecting the correct operating mode ..... 36

The most important TNC keys ..... 36

Creating a new program/file management ..... 37

Defining a workpiece blank ..... 38

Program layout ..... 39

Programming a simple contour ..... 40

Creating a cycle program ..... 43

1.4 Graphically Testing the First Program ..... 45

Selecting the correct operating mode ..... 45

Selecting the tool table for the test run ..... 45

Choosing the program you want to test ..... 46

Selecting the screen layout and the view ..... 46

Starting the program test ..... 46

1.5 Tool Setup ..... 47

Selecting the correct operating mode ..... 47

Preparing and measuring tools ..... 47

The tool table TOOL.T ..... 47

The pocket table TOOL_P.TCH ..... 48

1.6 Workpiece Setup ..... 49

Selecting the correct operating mode ..... 49

Clamping the workpiece ..... 49

Aligning the workpiece with a 3-D touch probe system ..... 50

Datum setting with a 3-D touch probe ..... 51

1.7 Running the First Program ..... 52

Selecting the correct operating mode ..... 52

Choosing the program you want to run ..... 52

Starting the program ..... 52

HEIDENHAIN TNC 640 13

2 Introduction ..... 53

2.1 The TNC 640 ..... 54

Programming: HEIDENHAIN conversational and ISO formats ..... 54

Compatibility ..... 54

2.2 Visual Display Unit and Keyboard ..... 55

Visual display unit ..... 55

Setting the screen layout ..... 56

Operating panel ..... 57

2.3 Operating Modes ..... 58

Manual Operation and El. Handwheel ..... 58

Positioning with Manual Data Input ..... 58

Programming and Editing ..... 59

Test Run ..... 59

Program Run, Full Sequence and Program Run, Single Block ..... 60

2.4 Status Displays ..... 61

"General" status display ..... 61

Additional status displays ..... 63

2.5 Window Manager ..... 70

Soft-key row ..... 71

2.6 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels ..... 72

3-D touch probes ..... 72

HR electronic handwheels ..... 73

14

3 Programming: Fundamentals, File Management ..... 75

3.1 Fundamentals ..... 76

Position encoders and reference marks ..... 76

Reference system ..... 76

Reference system on milling machines ..... 77

Designation of the axes on milling machines ..... 77

Polar coordinates ..... 78

Absolute and incremental workpiece positions ..... 79

Setting the datum ..... 80

3.2 Creating and Writing Programs ..... 81

Organization of an NC program in DIN/ISO ..... 81

Define the blank: G30/G31 ..... 81

Creating a new part program ..... 82

Programming tool movements in DIN/ISO format ..... 84

Actual position capture ..... 85

Editing a program ..... 86

The TNC search function ..... 90

3.3 File Management: Fundamentals ..... 92

Files ..... 92

Showing externally created files on the TNC ..... 94

Data backup ..... 94

3.4 Working with the File Manager ..... 95

Directories ..... 95

Paths ..... 95

Overview: Functions of the file manager ..... 96

Calling the file manager ..... 97

Selecting drives, directories and files ..... 98

Creating a new directory ..... 100

Creating a new file ..... 100

Copying a single file ..... 101

Copying files into another directory ..... 102

Copying a table ..... 103

Copying a directory ..... 104

Choosing one of the last files selected ..... 105

Deleting a file ..... 105

Deleting a directory ..... 106

Marking files ..... 107

Renaming a file ..... 108

File sorting ..... 108

Additional functions ..... 109

Additional tools for management of external file types ..... 110

Data transfer to or from an external data medium ..... 115

The TNC in a network ..... 117

USB devices on the TNC ..... 118

HEIDENHAIN TNC 640 15

4 Programming: Programming Aids ..... 119

4.1 Adding Comments ..... 120

Application ..... 120

Entering comments during programming ..... 120

Inserting comments after program entry ..... 120

Entering a comment in a separate block ..... 120

Functions for editing of the comment ..... 121

4.2 Display of NC Programs ..... 122

Syntax highlighting ..... 122

Scrollbar ..... 122

4.3 Structuring Programs ..... 123

Definition and applications ..... 123

Displaying the program structure window / Changing the active window ..... 123

Inserting a structuring block in the (left) program window ..... 123

Selecting blocks in the program structure window ..... 123

4.4 On-Line Calculator ..... 124

Operation ..... 124

4.5 Programming Graphics ..... 126

Generating / not generating graphics during programming ..... 126

Generating a graphic for an existing program ..... 126

Block number display ON/OFF ..... 127

Erasing the graphic ..... 127

Showing grid lines ..... 127

Magnifying or reducing a detail ..... 127

4.6 Error Messages ..... 128

Display of errors ..... 128

Open the error window ..... 128

Closing the error window ..... 128

Detailed error messages ..... 129

INTERNAL INFO soft key ..... 129

Clearing errors ..... 130

Error log ..... 130

Keystroke log ..... 131

Informational texts ..... 132

Saving service files ..... 132

Calling the TNCguide help system ..... 132

4.7 Context-Sensitive Help System ..... 133

Application ..... 133

Working with the TNCguide ..... 134

Downloading current help files ..... 138

16

5 Programming: Tools ..... 141

5.1 Entering Tool-Related Data ..... 142

Feed rate F ..... 142

Spindle speed S ..... 142

5.2 Tool Data ..... 143

Requirements for tool compensation ..... 143

Tool numbers and tool names ..... 143

Tool length L ..... 143

Tool radius R ..... 143

Delta values for lengths and radii ..... 144

Entering tool data into the program ..... 144

Entering tool data in the table ..... 145

Pocket table for tool changer ..... 152

Calling tool data ..... 155

Tool change ..... 156

Tool management (software option) ..... 161

5.3 Tool Compensation ..... 168

Introduction ..... 168

Tool length compensation ..... 168

Tool radius compensation ..... 169

HEIDENHAIN TNC 640 17

6 Programming: Programming Contours ..... 173

6.1 Tool Movements ..... 174

Path functions ..... 174

Miscellaneous functions M ..... 174

Subprograms and program section repeats ..... 174

Programming with Q parameters ..... 174

6.2 Fundamentals of Path Functions ..... 175

Programming tool movements for workpiece machining ..... 175

6.3 Contour Approach and Departure ..... 178

Starting point and end point ..... 178

Tangential approach and departure ..... 180

6.4 Path Contours—Cartesian Coordinates ..... 182

Overview of path functions ..... 182

Programming path functions ..... 182

Straight line at rapid traverse G00

Straight line with feed rate G01 F ..... 183

Inserting a chamfer between two straight lines ..... 184

Corner rounding G25 ..... 185

Circle center I, J ..... 186

Circular path C around circle center CC ..... 187

Circular path G02/G03/G05 with defined radius ..... 188

Circular path G06 with tangential connection ..... 190

6.5 Path Contours—Polar Coordinates ..... 195

Overview ..... 195

Zero point for polar coordinates: pole I, J ..... 196

Straight line at rapid traverse G10

Straight line with feed rate G11 F ..... 196

Circular path G12/G13/G15 around pole I, J ..... 197

Circular path G16 with tangential connection ..... 198

Helical interpolation ..... 199

18

7 Programming: Subprograms and Program Section Repeats ..... 203

7.1 Labeling Subprograms and Program Section Repeats ..... 204

Labels ..... 204

7.2 Subprograms ..... 205

Operating sequence ..... 205

Programming notes ..... 205

Programming a subprogram ..... 205

Calling a subprogram ..... 205

7.3 Program Section Repeats ..... 206

Label G98 ..... 206

Operating sequence ..... 206

Programming notes ..... 206

Programming a program section repeat ..... 206

Calling a program section repeat ..... 206

7.4 Separate Program as Subprogram ..... 207

Operating sequence ..... 207

Programming notes ..... 207

Calling any program as a subprogram ..... 208

7.5 Nesting ..... 209

Types of nesting ..... 209

Nesting depth ..... 209

Subprogram within a subprogram ..... 210

Repeating program section repeats ..... 211

Repeating a subprogram ..... 212

7.6 Programming Examples ..... 213

HEIDENHAIN TNC 640 19

8 Programming: Q Parameters ..... 219

8.1 Principle and Overview ..... 220

Programming notes ..... 221

Calling Q-parameter functions ..... 222

8.2 Part Families—Q Parameters in Place of Numerical Values ..... 223

Application ..... 223

8.3 Describing Contours through Mathematical Operations ..... 224

Application ..... 224

Overview ..... 224

Programming fundamental operations ..... 225

8.4 Trigonometric Functions ..... 226

Definitions ..... 226

Programming trigonometric functions ..... 227

8.5 If-Then Decisions with Q Parameters ..... 228

Application ..... 228

Unconditional jumps ..... 228

Programming If-Then decisions ..... 228

8.6 Checking and Changing Q Parameters ..... 229

Procedure ..... 229

8.7 Additional Functions ..... 231

Overview ..... 231

D14: ERROR: Displaying error messages ..... 232

D18: Read system data ..... 236

D19 PLC: Transfer values to the PLC ..... 245

D20 WAIT FOR: NC and PLC synchronization ..... 245

D29: Transfer values to the PLC ..... 247

D37 EXPORT ..... 248

8.8 Accessing Tables with SQL Commands ..... 249

Introduction ..... 249

A Transaction ..... 250

Programming SQL commands ..... 252

Overview of the soft keys ..... 252

SQL BIND ..... 253

SQL SELECT ..... 254

SQL FETCH ..... 257

SQL UPDATE ..... 258

SQL INSERT ..... 258

SQL COMMIT ..... 259

SQL ROLLBACK ..... 259

8.9 Entering Formulas Directly ..... 260

Entering formulas ..... 260

Rules for formulas ..... 262

Programming example ..... 263

20

8.10 String Parameters ..... 264

String processing functions ..... 264

Assigning string parameters ..... 265

Chain-linking string parameters ..... 266

Converting a numerical value to a string parameter ..... 267

Copying a substring from a string parameter ..... 268

Converting a string parameter to a numerical value ..... 269

Checking a string parameter ..... 270

Finding the length of a string parameter ..... 271

Comparing alphabetic priority ..... 272

Reading machine parameters ..... 273

8.11 Preassigned Q Parameters ..... 276

Values from the PLC: Q100 to Q107 ..... 276

Active tool radius: Q108 ..... 276

Tool axis: Q109 ..... 277

Spindle status: Q110 ..... 277

Coolant on/off: Q111 ..... 277

Overlap factor: Q112 ..... 277

Unit of measurement for dimensions in the program: Q113 ..... 278

Tool length: Q114 ..... 278

Coordinates after probing during program run ..... 278

Deviation between actual value and nominal value during automatic tool measurement with the TT 130 ..... 279

Tilting the working plane with mathematical angles: rotary axis coordinates calculated by the TNC ..... 279

Measurement results from touch probe cycles (see also User’s Manual for Touch Probe Cycles) ..... 280

8.12 Programming Examples ..... 282

HEIDENHAIN TNC 640 21

9 Programming: Miscellaneous Functions ..... 289

9.1 Entering Miscellaneous Functions M and STOP ..... 290

Fundamentals ..... 290

9.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant ..... 291

Overview ..... 291

9.3 Miscellaneous Functions for Coordinate Data ..... 292

Programming machine-referenced coordinates: M91/M92 ..... 292

Moving to positions in a non-tilted coordinate system with a tilted working plane: M130 ..... 294

9.4 Miscellaneous Functions for Contouring Behavior ..... 295

Machining small contour steps: M97 ..... 295

Machining open contour corners: M98 ..... 297

Feed rate factor for plunging movements: M103 ..... 298

Feed rate in millimeters per spindle revolution: M136 ..... 299

Feed rate for circular arcs: M109/M110/M111 ..... 300

Calculating the radius-compensated path in advance (LOOK AHEAD): M120 ..... 301

Superimposing handwheel positioning during program run: M118 ..... 303

Retraction from the contour in the tool-axis direction: M140 ..... 304

Suppressing touch probe monitoring: M141 ..... 305

Delete basic rotation: M143 ..... 305

Automatically retract tool from the contour at an NC stop: M148 ..... 306

22

10 Programming: Special Functions ..... 307

10.1 Overview of Special Functions ..... 308

Main menu for SPEC FCT special functions ..... 308

Program defaults menu ..... 309

Functions for contour and point machining menu ..... 309

Menu of various DIN/ISO functions ..... 310

10.2 Defining DIN/ISO Functions ..... 311

Overview ..... 311

10.3 Creating Text Files ..... 312

Application ..... 312

Opening and exiting text files ..... 312

Editing texts ..... 313

Deleting and re-inserting characters, words and lines ..... 314

Editing text blocks ..... 315

Finding text sections ..... 316

HEIDENHAIN TNC 640 23

11 Programming: Multiple Axis Machining ..... 317

11.1 Functions for Multiple Axis Machining ..... 318

11.2 The PLANE Function: Tilting the Working Plane (Software Option 1) ..... 319

Introduction ..... 319

Define the PLANE function ..... 321

Position display ..... 321

Reset the PLANE function ..... 322

Defining the machining plane with spatial angles: PLANE SPATIAL ..... 323

Defining the machining plane with projection angles: PROJECTED PLANE ..... 325

Defining the machining plane with Euler angles: EULER PLANE ..... 327

Defining the working plane with two vectors: VECTOR PLANE ..... 329

Defining the working plane via three points: PLANE POINTS ..... 331

Defining the machining plane with a single, incremental spatial angle: PLANE RELATIVE ..... 333

Tilting the working plane through axis angle: PLANE AXIAL (FCL 3 function) ..... 334

Specifying the positioning behavior of the PLANE function ..... 336

11.3 Inclined-Tool Machining in a Tilted Plane (Software Option 2) ..... 341

Function ..... 341

Inclined-tool machining via incremental traverse of a rotary axis ..... 341

Inclined-tool machining via normal vectors ..... 342

11.4 Miscellaneous Functions for Rotary Axes ..... 343

Feed rate in mm/min on rotary axes A, B, C: M116 (software option 1) ..... 343

Shorter-path traverse of rotary axes: M126 ..... 344

Reducing display of a rotary axis to a value less than 360°: M94 ..... 345

Maintaining the position of the tool tip when positioning with tilted axes (TCPM):

M128 (software option 2) ..... 346

Selecting tilting axes: M138 ..... 348

Compensating the machine’s kinematics configuration for ACTUAL/NOMINAL positions at end of block: M144

(software option 2) ..... 349

11.5 TCPM FUNCTION (Software Option 2) ..... 350

Function ..... 350

Defining the TCPM FUNCTION ..... 351

Mode of action of the programmed feed rate ..... 351

Interpretation of the programmed rotary axis coordinates ..... 352

Type of interpolation between the starting and end position ..... 353

Resetting the TCPM FUNCTION ..... 354

11.6 Peripheral milling: 3-D radius compensation with TCPM and radius compensation (G41/G42) ..... 355

Application ..... 355

24

12 Programming: Pallet Editor ..... 357

12.1 Pallet Editor ..... 358

Application ..... 358

Selecting a pallet table ..... 360

Exiting the pallet file ..... 360

Executing the pallet file ..... 361

HEIDENHAIN TNC 640 25

13 Manual Operation and Setup ..... 363

13.1 Switch-On, Switch-Off ..... 364

Switch-on ..... 364

Switch-off ..... 366

13.2 Moving the Machine Axes ..... 367

Note ..... 367

Moving the axis using the machine axis direction buttons ..... 367

Incremental jog positioning ..... 368

Traversing with the HR 410 electronic handwheel ..... 369

13.3 Spindle Speed S, Feed Rate F and Miscellaneous Functions M ..... 370

Application ..... 370

Entering values ..... 370

Changing the spindle speed and feed rate ..... 371

Activating feed-rate limitation ..... 372

13.4 Datum Setting without a 3-D Touch Probe ..... 373

Note ..... 373

Preparation ..... 373

Workpiece presetting with axis keys ..... 374

Datum management with the preset table ..... 375

13.5 Using the 3-D Touch Probe ..... 381

Overview ..... 381

Selecting touch probe cycles ..... 381

Writing the measured values from touch probe cycles in datum tables ..... 382

Writing the measured values from touch probe cycles in the preset table ..... 382

13.6 Calibrating a 3-D Touch Probe ..... 383

Introduction ..... 383

Calibrating the effective length ..... 384

Calibrating the effective radius and compensating center misalignment ..... 385

Displaying calibration values ..... 386

13.7 Compensating Workpiece Misalignment with a 3-D Touch Probe ..... 387

Introduction ..... 387

Measuring a basic rotation ..... 388

Saving a basic rotation in the preset table ..... 388

Displaying a basic rotation ..... 388

Canceling a basic rotation ..... 388

26

13.8 Datum Setting with a 3-D Touch Probe ..... 389

Overview ..... 389

Datum setting in any axis ..... 389

Corner as datum ..... 390

Circle center as datum ..... 391

Measuring workpieces with a 3-D touch probe ..... 392

Using touch probe functions with mechanical probes or dial gauges ..... 395

13.9 Tilting the Working Plane (Software Option 1) ..... 396

Application, function ..... 396

Traversing reference points in tilted axes ..... 398

Position display in a tilted system ..... 398

Limitations on working with the tilting function ..... 398

Activating manual tilting ..... 399

Setting the current tool-axis direction as the active machining direction ..... 400

Setting the datum in a tilted coordinate system ..... 401

HEIDENHAIN TNC 640 27

14 Positioning with Manual Data Input ..... 403

14.1 Programming and Executing Simple Machining Operations ..... 404

Positioning with Manual Data Input (MDI) ..... 404

Protecting and erasing programs in $MDI ..... 407

28

15 Test Run and Program Run ..... 409

15.1 Graphics ..... 410

Application ..... 410

Setting the speed of the test run ..... 411

Overview of display modes ..... 412

Plan view ..... 412

Projection in 3 planes ..... 413

3-D view ..... 414

Magnifying details ..... 416

Repeating graphic simulation ..... 417

Displaying the tool ..... 417

Measuring the machining time ..... 418

3-D line graphics ..... 419

15.2 Showing the Blank in the Working Space ..... 421

Application ..... 421

15.3 Functions for Program Display ..... 422

Overview ..... 422

15.4 Test Run ..... 423

Application ..... 423

15.5 Program run ..... 425

Application ..... 425

Running a part program ..... 426

Interrupting machining ..... 427

Moving the machine axes during an interruption ..... 428

Resuming program run after an interruption ..... 429

Mid-program startup (block scan) ..... 430

Returning to the contour ..... 432

15.6 Automatic Program Start ..... 433

Application ..... 433

15.7 Optional block skip ..... 434

Application ..... 434

Inserting the "/" character ..... 434

Erasing the "/" character ..... 434

15.8 Optional Program-Run Interruption ..... 435

Application ..... 435

HEIDENHAIN TNC 640 29

16 MOD Functions ..... 437

16.1 Selecting MOD Functions ..... 438

Selecting the MOD functions ..... 438

Changing the settings ..... 438

Exiting the MOD functions ..... 438

Overview of MOD functions ..... 439

16.2 Software Numbers ..... 440

Application ..... 440

16.3 Entering Code Numbers ..... 441

Application ..... 441

16.4 Setting the Data Interfaces ..... 442

Serial interfaces on the TNC 640 ..... 442

Application ..... 442

Setting the RS-232 interface ..... 442

Setting the baud rate (baudRate) ..... 442

Setting the protocol (protocol) ..... 442

Setting the data bits (dataBits) ..... 443

Parity check (parity) ..... 443

Setting the stop bits (stopBits) ..... 443

Setting the handshake (flowControl) ..... 443

Settings for data transfer with the TNCserver PC software ..... 444

Setting the operating mode of the external device (fileSystem) ..... 444

Software for data transfer ..... 445

16.5 Ethernet Interface ..... 447

Introduction ..... 447

Connection possibilities ..... 447

Configuring the TNC ..... 448

16.6 Position Display Types ..... 454

Application ..... 454

16.7 Unit of Measurement ..... 455

Application ..... 455

16.8 Displaying Operating Times ..... 456

Application ..... 456

30

Loading...

Loading...