fanuc 30iA, 300iA, 300is A, 31iA5, 310iA5 User Manual

...FANUC Series 30*/300*/300*s-MODEL A FANUC Series 31*/310*/310*s-MODEL A5 FANUC Series 31*/310*/310*s-MODEL A FANUC Series 32*/320*/320*s-MODEL A

Common to Lathe System/Machining Center System

USER’S MANUAL

Volume 2 of 2

B-63944EN/02

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of which are registered trademarks of respective owners. However, these names are not followed by or in the main body.

B-63944EN/02 |

TABLE OF CONTENTS |

TABLE OF CONTENTS

Volume 1 of 2 |

|

|

SAFETY PRECAUTIONS............................................................................ |

s-1 |

|

I. GENERAL |

|

|

1 GENERAL.............................................................................................................. |

3 |

|

1.1 |

NOTES ON READING THIS MANUAL.......................................................... |

8 |

1.2 |

NOTES ON VARIOUS KINDS OF DATA ...................................................... |

8 |

II. PROGRAMMING |

|

|

1 GENERAL ............................................................................................. |

11 |

|

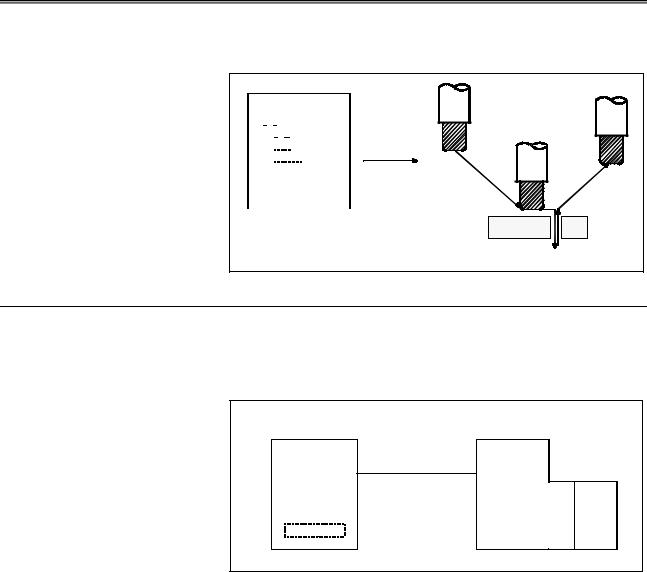

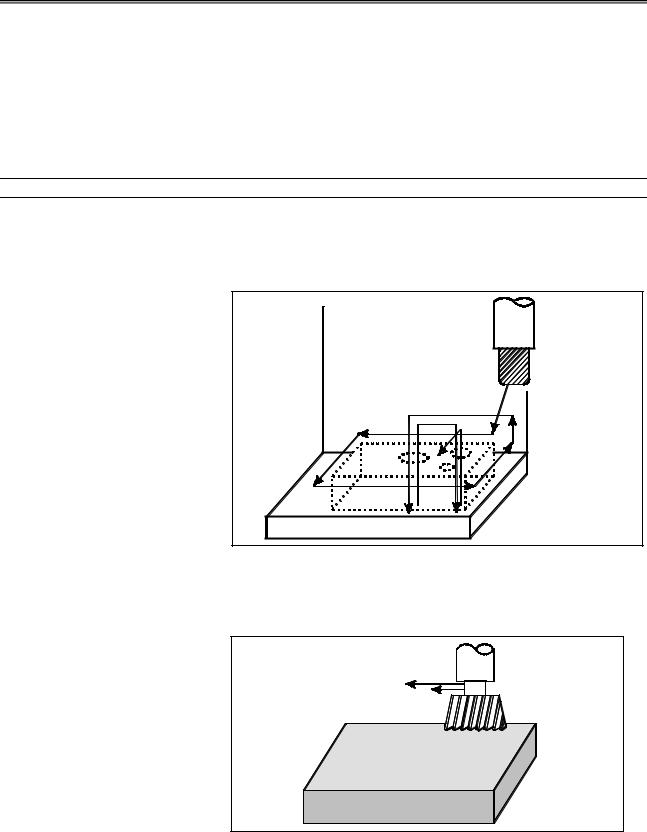

1.1TOOL MOVEMENT ALONG WORKPIECE PARTS

|

FIGURE-INTERPOLATION ......................................................................... |

12 |

1.2 |

FEED-FEED FUNCTION............................................................................. |

14 |

1.3 |

PART DRAWING AND TOOL MOVEMENT................................................ |

15 |

|

1.3.1 Reference Position (Machine-specific Position) .................................................... |

15 |

|

1.3.2 Coordinate System on Part Drawing and Coordinate System Specified by CNC - |

|

|

Coordinate System ................................................................................................. |

16 |

|

1.3.3 How to Indicate Command Dimensions for Moving the Tool (Absolute, |

|

|

Incremental Commands) ........................................................................................ |

22 |

1.4 |

CUTTING SPEED - SPINDLE FUNCTION.................................................. |

25 |

1.5SELECTION OF TOOL USED FOR VARIOUS MACHINING - TOOL

|

FUNCTION .................................................................................................. |

26 |

1.6 |

COMMAND FOR MACHINE OPERATIONS - AUXILIARY FUNCTION ...... |

27 |

1.7 |

PROGRAM CONFIGURATION ................................................................... |

28 |

1.8 |

TOOL MOVEMENT RANGE - STROKE...................................................... |

31 |

2 CONTROLLED AXES ........................................................................... |

33 |

|

2.1 |

NUMBER OF CONTROLLED AXES ........................................................... |

34 |

2.2 |

NAMES OF AXES ....................................................................................... |

35 |

2.3 |

INCREMENT SYSTEM................................................................................ |

36 |

2.4 |

MAXIMUM STROKE.................................................................................... |

37 |

3 PREPARATORY FUNCTION (G FUNCTION) ...................................... |

38 |

|

3.1 |

G CODE LIST IN THE MACHINING CENTER SYSTEM ............................ |

40 |

c-1

TABLE OF CONTENTS |

B-63944EN/02 |

||

3.2 |

G CODE LIST IN THE LATHE SYSTEM .................................................... |

|

43 |

4 INTERPOLATION FUNCTIONS............................................................ |

|

47 |

|

4.1 |

POSITIONING (G00)................................................................................... |

|

48 |

4.2 |

SINGLE DIRECTION POSITIONING (G60) ................................................ |

|

50 |

4.3 |

LINEAR INTERPOLATION (G01)................................................................ |

|

53 |

4.4 |

CIRCULAR INTERPOLATION (G02, G03).................................................. |

|

56 |

4.5 |

HELICAL INTERPOLATION (G02, G03) ..................................................... |

|

62 |

4.6 |

HELICAL INTERPOLATION B (G02, G03).................................................. |

|

64 |

4.7 |

SPIRAL INTERPOLATION, CONICAL INTERPOLATION (G02, G03) |

........ 65 |

|

4.8 |

POLAR COORDINATE INTERPOLATION (G12.1, G13.1) ......................... |

|

73 |

4.9 |

CYLINDRICAL INTERPOLATION (G07.1) .................................................. |

|

82 |

4.10CUTTING POINT INTERPOLATION FOR CYLINDRICAL

|

|

INTERPOLATION (G07.1)........................................................................... |

87 |

|

4.11 |

EXPONENTIAL INTERPOLATION (G02.3, G03.3)..................................... |

99 |

|

4.12 |

SMOOTH INTERPOLATION (G05.1) ........................................................ |

107 |

|

4.13 |

NANO SMOOTHING ................................................................................. |

111 |

|

4.14 |

NURBS INTERPOLATION (G06.2) ........................................................... |

118 |

|

4.15 |

HYPOTHETICAL AXIS INTERPOLATION (G07) ...................................... |

123 |

|

4.16 |

VARIABLE LEAD THREADING (G34)....................................................... |

125 |

|

4.17 |

CIRCULAR THREADING (G35, G36) ....................................................... |

126 |

|

4.18 |

SKIP FUNCTION (G31)............................................................................. |

131 |

|

4.19 |

MULTI-STEP SKIP (G31) .......................................................................... |

133 |

|

4.20 |

HIGH-SPEED SKIP SIGNAL (G31) ........................................................... |

134 |

|

4.21 |

THREE-DIMENSIONAL CIRCULAR INTERPOLATION............................ |

135 |

5 |

FEED FUNCTIONS ............................................................................. |

140 |

|

|

5.1 |

OVERVIEW ............................................................................................... |

141 |

|

5.2 |

RAPID TRAVERSE ................................................................................... |

143 |

|

5.3 |

CUTTING FEED ........................................................................................ |

144 |

|

5.4 |

CUTTING FEEDRATE CONTROL ............................................................ |

150 |

|

|

5.4.1 Exact Stop (G09, G61), Cutting Mode (G64), Tapping Mode (G63) .................. |

151 |

|

|

5.4.2 Automatic Corner Override.................................................................................. |

152 |

|

|

5.4.2.1 Automatic override for inner corners (G62) .................................................... |

152 |

|

|

5.4.2.2 Internal circular cutting feedrate change ......................................................... |

154 |

|

5.5 |

DWELL ...................................................................................................... |

155 |

6 |

REFERENCE POSITION..................................................................... |

157 |

|

|

6.1 |

REFERENCE POSITION RETURN........................................................... |

158 |

c-2

B-63944EN/02 |

TABLE OF CONTENTS |

|

6.2 |

FLOATING REFERENCE POSITION RETURN (G30.1)........................... |

165 |

7 COORDINATE SYSTEM..................................................................... |

167 |

|

7.1 |

MACHINE COORDINATE SYSTEM.......................................................... |

168 |

7.2 |

WORKPIECE COORDINATE SYSTEM .................................................... |

170 |

|

7.2.1 Setting a Workpiece Coordinate System.............................................................. |

170 |

|

7.2.2 Selecting a Workpiece Coordinate System .......................................................... |

173 |

|

7.2.3 Changing Workpiece Coordinate System ............................................................ |

174 |

|

7.2.4 Workpiece Coordinate System Preset (G92.1)..................................................... |

178 |

|

7.2.5 Addition of Workpiece Coordinate System Pair (G54.1 or G54) ........................ |

181 |

|

7.2.6 Automatic Coordinate System Setting ................................................................. |

183 |

|

7.2.7 Workpiece Coordinate System Shift .................................................................... |

184 |

7.3 |

LOCAL COORDINATE SYSTEM .............................................................. |

186 |

7.4 |

PLANE SELECTION.................................................................................. |

188 |

8 COORDINATE VALUE AND DIMENSION ......................................... |

189 |

|

8.1 |

ABSOLUTE AND INCREMENTAL PROGRAMMING................................ |

190 |

8.2 |

INCH/METRIC CONVERSION (G20, G21) ............................................... |

192 |

8.3 |

DECIMAL POINT PROGRAMMING .......................................................... |

193 |

8.4 |

DIAMETER AND RADIUS PROGRAMMING ............................................ |

195 |

8.5 |

DIAMETER AND RADIUS SETTING SWITCHING FUNCTION................ |

196 |

9 SPINDLE SPEED FUNCTION (S FUNCTION) ................................... |

200 |

|

9.1 |

SPECIFYING THE SPINDLE SPEED WITH A CODE............................... |

201 |

9.2SPECIFYING THE SPINDLE SPEED VALUE DIRECTLY (S5-DIGIT

|

COMMAND) .............................................................................................. |

201 |

|

9.3 |

CONSTANT SURFACE SPEED CONTROL (G96, G97) .......................... |

202 |

|

9.4 |

SPINDLE POSITIONING FUNCTION ....................................................... |

207 |

|

|

9.4.1 |

Spindle Orientation............................................................................................... |

208 |

|

9.4.2 |

Spindle Positioning .............................................................................................. |

209 |

|

9.4.3 |

Canceling Spindle Positioning ............................................................................. |

211 |

9.5 |

SPINDLE SPEED FLUCTUATION DETECTION....................................... |

213 |

|

10 TOOL FUNCTION (T FUNCTION) ...................................................... |

218 |

|

10.1 |

TOOL SELECTION FUNCTION ................................................................ |

219 |

10.2 |

TOOL MANAGEMENT FUNCTION........................................................... |

221 |

10.3 |

TOOL MANAGEMENT EXTENSION FUNCTION ..................................... |

240 |

|

10.3.1 Customization of Tool Management Data Display .............................................. |

240 |

|

10.3.2 Setting of Spindle Position / Standby Position Display ....................................... |

245 |

|

10.3.3 Input of Customize Data with the Decimal Point................................................. |

247 |

|

c-3 |

|

TABLE OF CONTENTS |

B-63944EN/02 |

|||

|

|

10.3.4 Protection of Various Tool Information Items with the KEY Signal................... |

250 |

|

|

|

10.3.5 Selection of a Tool Life Count Period.................................................................. |

250 |

|

|

|

10.3.6 |

Individual Data Screen ......................................................................................... |

251 |

|

|

10.3.7 Total Life Time Display for Tools of The Same Type......................................... |

251 |

|

|

10.4 |

TOOL MANAGEMENT FUNCTION OVERSIZE TOOLS SUPPORT |

........ 252 |

|

11 |

AUXILIARY FUNCTION...................................................................... |

254 |

||

|

11.1 |

AUXILIARY FUNCTION (M FUNCTION)................................................... |

255 |

|

|

11.2 |

MULTIPLE M COMMANDS IN A SINGLE BLOCK.................................... |

256 |

|

|

11.3 |

M CODE GROUPING FUNCTION ............................................................ |

257 |

|

|

|

11.3.1 Setting an M Code Group Number Using the Setting Screen .............................. |

257 |

|

|

|

11.3.2 Setting an M Code Group Number Using a Program........................................... |

259 |

|

|

|

11.3.3 M Code Group Check Function ........................................................................... |

260 |

|

|

11.4 |

SECOND AUXILIARY FUNCTIONS (B CODES) ...................................... |

261 |

|

12 |

PROGRAM MANAGEMENT............................................................... |

264 |

||

|

12.1 |

FOLDERS.................................................................................................. |

265 |

|

|

|

12.1.1 |

Folder Configuration ............................................................................................ |

265 |

|

|

12.1.2 |

Folder Attributes ................................................................................................... |

268 |

|

|

12.1.3 |

Default Folders ..................................................................................................... |

269 |

|

12.2 |

FILES |

......................................................................................................... |

270 |

|

|

12.2.1 |

File Name ............................................................................................................. |

270 |

|

|

12.2.2 |

File Attributes ....................................................................................................... |

272 |

|

12.3 |

RELATION ....................................WITH CONVENTIONAL FUNCTIONS |

273 |

|

|

|

12.3.1 ........................................................................................... |

Relation with Folders |

273 |

|

|

12.3.2 .....................................................................................Relation with File Names |

275 |

|

|

|

12.3.3 ............................................................................................... |

Related Parameters |

277 |

13 |

PROGRAM ...........................................................CONFIGURATION |

278 |

||

|

13.1 |

PROGRAM .......COMPONENTS OTHER THAN PROGRAM SECTIONS 280 |

||

|

13.2 |

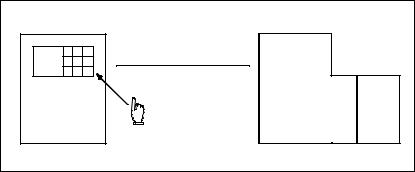

PROGRAM ................................................SECTION CONFIGURATION |

283 |

|

|

13.3 |

SUBPROGRAM .....................................................................(M98, M99) |

291 |

|

14 FUNCTIONS ...................................TO SIMPLIFY PROGRAMMING |

296 |

|||

|

14.1 |

FIGURE .................................................................COPY (G72.1, G72.2) |

297 |

|

|

14.2 |

THREE ...........................-DIMENSIONAL COORDINATE CONVERSION |

305 |

|

15 |

COMPENSATION ............................................................FUNCTION |

316 |

||

|

15.1 |

TOOL ................................LENGTH COMPENSATION (G43, G44, G49) |

317 |

|

|

|

15.1.1 .............................................................................................................. |

Overview |

317 |

|

|

|

c - 4 |

|

B-63944EN/02 |

|

TABLE OF CONTENTS |

|

|

15.1.2 G53, G28, G30, and G30.1 Commands in Tool Length Compensation Mode .... |

323 |

|

15.2 |

SCALING (G50, G51)................................................................................ |

325 |

|

15.3 |

PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) ............................... |

335 |

|

15.4 |

TOOL AXIS DIRECTION TOOL LENGTH COMPENSATION................... |

337 |

|

|

15.4.1 Control Point Compensation of Tool Length Compensation Along Tool Axis ... |

343 |

|

16 CUSTOM MACRO............................................................................... |

348 |

||

16.1 |

VARIABLES............................................................................................... |

349 |

|

16.2 |

SYSTEM VARIABLES ............................................................................... |

356 |

|

16.3 |

ARITHMETIC AND LOGIC OPERATION .................................................. |

411 |

|

16.4 |

INDIRECT AXIS ADDRESS SPECIFICATION .......................................... |

419 |

|

16.5 |

MACRO STATEMENTS AND NC STATEMENTS..................................... |

421 |

|

16.6 |

BRANCH AND REPETITION..................................................................... |

422 |

|

|

16.6.1 Unconditional Branch (GOTO Statement)........................................................... |

422 |

|

|

16.6.2 GOTO Statement Using Stored Sequence Numbers ............................................ |

423 |

|

|

16.6.3 Conditional Branch (IF Statement) ...................................................................... |

425 |

|

|

16.6.4 |

Repetition (WHILE Statement)............................................................................ |

427 |

16.7 |

MACRO CALL ........................................................................................... |

430 |

|

|

16.7.1 |

Simple Call (G65) ................................................................................................ |

431 |

|

16.7.2 Modal Call: Call After the Move Command (G66) ............................................. |

442 |

|

|

16.7.3 |

Modal Call: Each Block Call (G66.1) ................................................................. |

447 |

|

16.7.4 Macro Call Using a G Code ................................................................................. |

450 |

|

|

16.7.5 Macro Call Using a G Code (Specification of Multiple Definitions)................... |

452 |

|

16.7.6Macro Call Using a G Code with a Decimal Point (Specification of Multiple

|

|

Definitions)........................................................................................................... |

453 |

|

16.7.7 |

Macro Call Using an M Code............................................................................... |

454 |

|

16.7.8 |

Macro Call Using an M Code (Specification of Multiple Definitions)................ |

456 |

|

16.7.9 |

Subprogram Call Using an M Code ..................................................................... |

457 |

|

16.7.10 |

Subprogram Call Using an M Code (Specification of Multiple Definitions)....... |

458 |

|

16.7.11 |

Subprogram Calls Using a T Code....................................................................... |

459 |

|

16.7.12 |

Subprogram Calls Using an S Code ..................................................................... |

460 |

|

16.7.13 |

Subprogram Calls Using a Secondary Auxiliary Function .................................. |

461 |

|

16.7.14 |

Subprogram Call Using a Specific Address ......................................................... |

462 |

16.8 |

PROCESSING MACRO STATEMENTS ................................................... |

466 |

|

16.9 |

REGISTERING CUSTOM MACRO PROGRAMS ..................................... |

468 |

|

16.10 |

CODES AND RESERVED WORDS USED IN CUSTOM MACROS ......... |

469 |

|

16.11 |

EXTERNAL OUTPUT COMMANDS.......................................................... |

471 |

|

16.12 |

RESTRICTIONS........................................................................................ |

475 |

|

c-5

TABLE OF CONTENTS |

|

B-63944EN/02 |

||

16.13 INTERRUPTION TYPE CUSTOM MACRO............................................... |

477 |

|||

|

16.13.1 |

Specification Method ........................................................................................... |

478 |

|

|

16.13.2 |

Details of Functions.............................................................................................. |

479 |

|

17 REAL-TIME CUSTOM MACRO .......................................................... |

489 |

|||

17.1 |

TYPES OF REAL TIME MACRO COMMANDS......................................... |

493 |

||

|

17.1.1 |

Modal Real Time Macro Command / One-shot Real Time Macro Command.....493 |

||

17.2 |

VARIABLES............................................................................................... |

|

500 |

|

|

17.2.1 Variables Dedicated To Real Time Custom Macros ............................................ |

501 |

||

|

|

17.2.1.1 |

System variables .............................................................................................. |

501 |

|

|

17.2.1.2 |

Real time macro variables (RTM variables) ................................................... |

503 |

|

17.2.2 |

Custom Macro Variables...................................................................................... |

505 |

|

|

|

17.2.2.1 |

System variables .............................................................................................. |

505 |

|

|

17.2.2.2 |

Local variables................................................................................................. |

506 |

17.3 |

ARITHMETIC AND LOGICAL OPERATION.............................................. |

507 |

||

17.4 |

CONTROL ON REAL TIME MACRO COMMANDS .................................. |

509 |

||

|

17.4.1 |

Conditional Branch (ZONCE Statement)............................................................. |

510 |

|

|

17.4.2 |

Condition Transition (ZEDGE Statement)........................................................... |

511 |

|

|

17.4.3 |

Repetition (ZWHILE Statement) ......................................................................... |

512 |

|

|

17.4.4 |

Multi-statement (ZDO...ZEND Statement) .......................................................... |

513 |

|

17.5 |

MACRO CALL ........................................................................................... |

|

516 |

|

17.6 |

OTHERS.................................................................................................... |

|

518 |

|

17.7 |

AXIS CONTROL COMMAND .................................................................... |

519 |

||

17.8 |

NOTES |

...................................................................................................... |

|

532 |

17.9 |

LIMITATION .............................................................................................. |

|

534 |

|

18 PROGRAMMABLE PARAMETER INPUT (G10)................................ |

536 |

|||

19 HIGH-SPEED CUTTING FUNCTIONS................................................ |

539 |

|||

19.1AI CONTOUR CONTROL FUNCTION I AND AI CONTOUR CONTROL

|

FUNCTION II (G05.1) ................................................................................ |

540 |

19.2 |

JERK CONTROL....................................................................................... |

557 |

|

19.2.1 Speed Control with Change of Acceleration on Each Axis.................................. |

557 |

|

19.2.2 Look-Ahead Smooth Bell-Shaped Acceleration/Deceleration before |

|

|

Interpolation ......................................................................................................... |

560 |

19.3 |

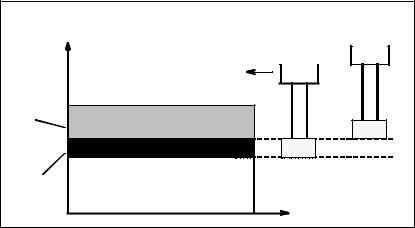

OPTIMUM TORQUE ACCELERATION/DECELERATION........................ |

562 |

20 AXIS CONTROL FUNCTIONS............................................................ |

574 |

|

20.1 |

AXIS SYNCHRONOUS CONTROL........................................................... |

575 |

|

20.1.1 Axis Configuration for Axis Synchronous Control.............................................. |

576 |

|

c-6 |

|

B-63944EN/02 |

|

|

TABLE OF CONTENTS |

|

|

20.1.2 |

Synchronous Error Compensation........................................................................ |

579 |

|

|

20.1.3 |

Synchronous Establishment ................................................................................. |

581 |

|

|

20.1.4 Automatic Setting for Grid Position Matching .................................................... |

585 |

||

|

20.1.5 |

Synchronous Error Check .................................................................................... |

586 |

|

|

20.1.6 Methods of Alarm Recovery by Synchronous Error Check................................. |

588 |

||

|

20.1.7 Axis Synchronous Control Torque Difference Alarm.......................................... |

590 |

||

20.2 |

POLYGON TURNING (G50.2, G51.2)....................................................... |

593 |

||

20.3 |

ROTARY AXIS ROLL-OVER..................................................................... |

599 |

||

|

20.3.1 |

Rotary Axis Roll-over .......................................................................................... |

599 |

|

|

20.3.2 |

Rotary Axis Control ............................................................................................. |

600 |

|

20.4 |

ANGULAR AXIS CONTROL...................................................................... |

601 |

||

20.5 |

TOOL RETRACT AND RECOVER............................................................ |

611 |

||

20.6 |

ELECTRIC GEAR BOX ............................................................................. |

616 |

||

|

20.6.1 |

Electric Gear Box ................................................................................................. |

616 |

|

|

20.6.2 Electronic Gear Box Automatic Phase Synchronization...................................... |

625 |

||

|

20.6.3 Skip Function for EGB Axis ................................................................................ |

630 |

||

|

20.6.4 Electronic Gear Box 2 Pair................................................................................... |

632 |

||

|

|

20.6.4.1 Specification method (G80.5, G81.5).............................................................. |

632 |

|

|

|

20.6.4.2 Description of commands compatible with those for a hobbing machine |

|

|

|

|

|

(G80, G81)....................................................................................................... |

635 |

|

|

20.6.4.3 Controlled axis configuration example............................................................ |

639 |

|

|

|

20.6.4.4 |

Sample programs ............................................................................................. |

640 |

|

|

20.6.4.5 Synchronization ratio specification range........................................................ |

645 |

|

|

|

20.6.4.6 |

Retract function ............................................................................................... |

649 |

21 5-AXIS MACHINING FUNCTION........................................................ |

650 |

|||

21.1 |

TOOL CENTER POINT CONTROL FOR 5-AXIS MACHINING................. |

651 |

||

21.2 |

TILTED WORKING PLANE COMMAND ................................................... |

705 |

||

21.3 |

INCLINED ROTARY AXIS CONTROL ...................................................... |

731 |

||

21.4 |

CUTTER COMPENSATION FOR 5-AXIS MACHINING............................ |

735 |

||

|

21.4.1 Cutter Compensation in Tool Rotation Type Machine ........................................ |

738 |

||

|

|

21.4.1.1 |

Tool side offset ................................................................................................ |

739 |

|

|

21.4.1.2 |

Leading edge offset ......................................................................................... |

759 |

|

|

21.4.1.3 Tool tip position (cutting point) command ...................................................... |

765 |

|

|

21.4.2 Cutter Compensation in Table Rotation Type Machine....................................... |

769 |

||

|

21.4.3 Cutter Compensation in Mixed-Type Machine.................................................... |

777 |

||

|

21.4.4 Interference Check and Interference Avoidance .................................................. |

784 |

||

|

21.4.5 |

Restrictions........................................................................................................... |

788 |

|

|

|

21.4.5.1 Restrictions common to machine configurations............................................. |

788 |

|

|

|

21.4.5.2 Restriction on tool rotation type ...................................................................... |

791 |

|

|

|

|

c-7 |

|

TABLE OF CONTENTS |

B-63944EN/02 |

|

|

21.4.5.3 Restriction on machine configurations having table rotation axes (table |

|

|

rotation type and mixed-type).......................................................................... |

792 |

|

21.4.6 Examples .............................................................................................................. |

796 |

22 MUITI-PATH CONTROL FUNCTION.................................................. |

801 |

|

22.1 |

OVERVIEW ............................................................................................... |

802 |

22.2 |

WAITING FUNCTION FOR PATHS .......................................................... |

804 |

22.3 |

COMMON MEMORY BETWEEN EACH PATH......................................... |

810 |

22.4 |

SPINDLE CONTROL BETWEEN EACH PATH......................................... |

812 |

22.5SYNCHRONOUS CONTROL, MIXTURE CONTROL, AND

|

|

SUPERPOSITION CONTROL................................................................... |

813 |

|

|

|

|

||

Volume 2 of 2 |

|

|

||

III. OPERATION |

|

|||

1 |

GENERAL |

........................................................................................... |

819 |

|

|

1.1 |

MANUAL OPERATION.............................................................................. |

820 |

|

|

1.2 |

TOOL MOVEMENT BY PROGRAMING - AUTOMATIC OPERATION ..... |

822 |

|

|

1.3 |

AUTOMATIC .......................................................................OPERATION |

824 |

|

|

1.4 |

TESTING ............................................................................A PROGRAM |

826 |

|

|

|

1.4.1 ...........................................................................Check by Running the Machine |

826 |

|

|

|

1.4.2 .........How to View the Position Display Change without Running the Machine |

828 |

|

|

1.5 |

EDITING .............................................................................A PROGRAM |

829 |

|

|

1.6 |

DISPLAYING ..........................................................AND SETTING DATA |

830 |

|

|

1.7 |

DISPLAY ................................................................................................... |

833 |

|

|

|

1.7.1 ................................................................................................... |

Program Display |

833 |

|

|

1.7.2 ...................................................................................... |

Current Position Display |

834 |

|

|

1.7.3 ...................................................................................................... |

Alarm Display |

835 |

|

|

1.7.4 ..............................................................Parts Count Display, Run Time Display |

835 |

|

2 |

OPERATIONAL ..................................................................DEVICES |

836 |

||

|

2.1 |

SETTING ............................................................AND DEISPLAY UNITS |

837 |

|

|

|

2.1.1 ..............................................................................7.2" LCD CNC Display Panel |

838 |

|

|

|

2.1.2 ..............................................................................8.4" LCD CNC Display Panel |

838 |

|

|

|

2.1.3 ............................................................................10.4" LCD CNC Display Panel |

839 |

|

|

|

2.1.4 ............................................................................12.1" LCD CNC Display Panel |

840 |

|

|

|

2.1.5 ...............................................................................15" LCD CNC Display Panel |

840 |

|

|

|

2.1.6 ...........................................................................Standard MDI Unit (ONG Key) |

841 |

|

|

|

2.1.7 ...................................................................Standard MDI Unit (QWERTY Key) |

842 |

|

|

|

|

c - 8 |

|

B-63944EN/02 |

|

|

TABLE OF CONTENTS |

|

2.1.8 Small MDI Unit (ONG Key)................................................................................ |

843 |

|

2.2 |

OPERATIONAL DEVICES......................................................................... |

844 |

|

2.3 |

FUNCTION KEYS AND SOFT KEYS ........................................................ |

847 |

|

|

2.3.1 |

General Screen Operations................................................................................... |

848 |

|

2.3.2 |

Function Keys ...................................................................................................... |

850 |

|

2.3.3 |

Soft Keys .............................................................................................................. |

851 |

|

2.3.4 Key Input and Input Buffer .................................................................................. |

861 |

|

|

2.3.5 |

Warning Messages ............................................................................................... |

862 |

2.4 |

EXTERNAL I/O DEVICES ......................................................................... |

863 |

|

2.5 |

POWER ON/OFF....................................................................................... |

865 |

|

|

2.5.1 Turning on the Power........................................................................................... |

865 |

|

|

2.5.2 |

Power Disconnection............................................................................................ |

866 |

3 MANUAL OPERATION....................................................................... |

867 |

||

3.1 |

MANUAL REFERENCE POSITION RETURN........................................... |

868 |

|

3.2 |

JOG FEED (JOG)...................................................................................... |

870 |

|

3.3 |

INCREMENTAL FEED .............................................................................. |

872 |

|

3.4 |

MANUAL HANDLE FEED.......................................................................... |

874 |

|

3.5 |

MANUAL ABSOLUTE ON AND OFF......................................................... |

877 |

|

3.6 |

RIGID TAPPING BY MANUAL HANDLE................................................... |

883 |

|

3.7 |

MANUAL NUMERICAL COMMAND.......................................................... |

886 |

|

3.8 |

MANUAL FEED FOR 5-AXIS MACHINING............................................... |

895 |

|

3.8.1Tool Axis Direction Handle Feed / Tool Axis Direction JOG Feed / Tool Axis

|

Direction Incremental Feed .................................................................................. |

896 |

3.8.2 |

Tool Axis Right-Angle Direction Handle Feed / Tool Axis Right-Angle |

|

|

Direction JOG Feed / Tool Axis Right-Angle Direction Incremental Feed......... |

898 |

3.8.3Tool Tip Center Rotation Handle Feed / Tool Tip Center Rotation JOG Feed /

Tool Tip Center Rotation Incremental Feed......................................................... |

903 |

3.8.4Table Vertical Direction Handle Feed / Table Vertical Direction JOG Feed /

Table Vertical Direction Incremental Feed .......................................................... |

906 |

3.8.5Table Horizontal Direction Handle Feed / Table Horizontal Direction JOG Feed /

|

|

Table Horizontal Direction Incremental Feed ...................................................... |

908 |

3.9 |

DISTANCE CODED LINEAR SCALE INTERFACE................................... |

912 |

|

|

3.9.1 Procedure for Reference Position Establishment ................................................. |

912 |

|

|

3.9.2 |

Reference Position Return.................................................................................... |

914 |

|

3.9.3 Distance Coded Rotary Encoder .......................................................................... |

914 |

|

|

3.9.4 |

Axis Synchronization Control .............................................................................. |

915 |

|

3.9.5 Axis Control by PMC........................................................................................... |

916 |

|

|

|

c-9 |

|

TABLE OF CONTENTS |

B - 63944EN/02 |

|

3.9.6 |

Angular Axis Control |

...........................................................................................917 |

3.9.7 |

Note .................................................................................................................... |

917 |

3.10LINEAR SCALE WITH DISTANCE-CODED REFERENCE MARKS

|

|

(SERIAL) ................................................................................................... |

919 |

|

4 |

AUTOMATIC OPERATION................................................................. |

925 |

||

|

4.1 |

MEMORY OPERATION ............................................................................ |

926 |

|

|

4.2 |

MDI OPERATION...................................................................................... |

929 |

|

|

4.3 |

DNC OPERATION..................................................................................... |

934 |

|

|

4.4 |

EXTERNAL SUBPROGRAM CALL (M198)............................................... |

936 |

|

|

4.5 |

MANUAL HANDLE INTERRUPTION ........................................................ |

939 |

|

|

4.6 |

MIRROR IMAGE........................................................................................ |

946 |

|

|

4.7 |

PROGRAM RESTART .............................................................................. |

948 |

|

|

4.8 |

TOOL RETRACT AND RECOVER............................................................ |

962 |

|

|

|

4.8.1 |

Retract .................................................................................................................. |

966 |

|

|

4.8.2 |

Withdrawal ........................................................................................................... |

967 |

|

|

4.8.3 |

Return ................................................................................................................... |

967 |

|

|

4.8.4 |

Repositioning ....................................................................................................... |

968 |

|

|

4.8.5 Tool Retract and Return for Threading ................................................................ |

969 |

|

|

|

4.8.6 Operation Procedure for a Canned Cycle for Drilling.......................................... |

972 |

|

5 |

TEST OPERATION ............................................................................. |

974 |

||

|

5.1 |

MACHINE LOCK AND AUXILIARY FUNCTION LOCK ............................. |

975 |

|

|

5.2 |

FEEDRATE OVERRIDE............................................................................ |

977 |

|

|

5.3 |

RAPID TRAVERSE OVERRIDE................................................................ |

978 |

|

|

5.4 |

DRY RUN .................................................................................................. |

979 |

|

|

5.5 |

SINGLE BLOCK ........................................................................................ |

980 |

|

6 |

SAFETY FUNCTIONS......................................................................... |

982 |

||

|

6.1 |

EMERGENCY STOP................................................................................. |

983 |

|

|

6.2 |

OVERTRAVEL........................................................................................... |

984 |

|

|

6.3 |

STORED STROKE CHECK....................................................................... |

986 |

|

|

6.4 |

STROKE LIMIT CHECK BEFORE MOVE ................................................. |

991 |

|

|

6.5 |

WRONG OPERATION PREVENTION FUNCTIONS ................................ |

994 |

|

|

|

6.5.1 Functions that are Used When Data is Set ........................................................... |

995 |

|

|

|

|

6.5.1.1 Input data range check..................................................................................... |

996 |

|

|

|

6.5.1.2 Confirmation of incremental input .................................................................. |

998 |

|

|

|

6.5.1.3 Prohibition of the absolute input by the soft key ............................................. |

999 |

|

|

|

6.5.1.4 Confirmation of the deletion of the program ................................................. |

1000 |

|

|

|

6.5.1.5 Confirmation of the deletion of all data......................................................... |

1001 |

|

|

|

c-10 |

|

B-63944EN/02 |

|

|

TABLE OF CONTENTS |

||

|

|

|

6.5.1.6 Confirmation of a data update during the data setting process...................... |

1002 |

|

|

|

6.5.2 |

Functions that are Used when the Program is Executed .................................... |

1003 |

|

|

|

|

6.5.2.1 Display of updated modal information .......................................................... |

1004 |

|

|

|

|

6.5.2.2 |

Start check signal........................................................................................... |

1005 |

|

|

|

6.5.2.3 |

Axis status display ......................................................................................... |

1006 |

|

|

|

6.5.2.4 Confirmation of the start from a middle block .............................................. |

1007 |

|

|

|

|

6.5.2.5 |

Data range check ........................................................................................... |

1008 |

|

|

|

6.5.2.6 Maximum incremental value check ............................................................... |

1009 |

|

|

|

6.5.3 |

Setting Screen..................................................................................................... |

1010 |

|

|

|

|

6.5.3.1 Operation confirmation function setting screen............................................. |

1011 |

|

|

|

|

6.5.3.2 Tool offset range setting screen..................................................................... |

1013 |

|

|

|

|

6.5.3.3 Workpiece origin offset range setting screen ................................................ |

1018 |

|

|

|

|

6.5.3.4 Y-axis tool offset range setting screen........................................................... |

1020 |

|

|

|

|

6.5.3.5 Workpiece shift range setting screen............................................................. |

1022 |

|

7 |

ALARM AND SELF-DIAGNOSIS FUNCTIONS................................ |

1024 |

|||

|

7.1 |

ALARM DISPLAY .................................................................................... |

1025 |

||

|

7.2 |

ALARM HISTORY DISPLAY ................................................................... |

1027 |

||

|

7.3 |

CHECKING BY SELF-DIAGNOSIS SCREEN ......................................... |

1028 |

||

8 |

DATA INPUT/OUTPUT ..................................................................... |

1029 |

|||

|

8.1 |

INPUT/OUTPUT ON EACH SCREEN ..................................................... |

1030 |

||

|

|

8.1.1 |

Inputting and Outputting a Program................................................................... |

1031 |

|

|

|

|

8.1.1.1 |

Inputting a program ....................................................................................... |

1031 |

|

|

|

8.1.1.2 |

Outputting a program..................................................................................... |

1032 |

|

|

8.1.2 |

Inputting and Outputting Parameters.................................................................. |

1033 |

|

|

|

|

8.1.2.1 |

Inputting parameters ...................................................................................... |

1033 |

|

|

|

8.1.2.2 |

Outputting parameters ................................................................................... |

1034 |

|

|

8.1.3 |

Inputting and Outputting Offset Data................................................................. |

1035 |

|

|

|

|

8.1.3.1 |

Inputting offset data....................................................................................... |

1035 |

|

|

|

8.1.3.2 |

Outputting offset data .................................................................................... |

1036 |

|

|

8.1.4 |

Inputting and Outputting Pitch Error Compensation Data ................................. |

1041 |

|

|

|

|

8.1.4.1 Inputting pitch error compensation data ........................................................ |

1041 |

|

|

|

|

8.1.4.2 Outputting pitch error compensation data ..................................................... |

1042 |

|

|

|

|

8.1.4.3 Input/output format of pitch error compensation data ................................... |

1043 |

|

|

|

8.1.5 |

Inputting and Outputting Three-dimensional Error Compensation Data ........... |

1044 |

|

|

|

|

8.1.5.1 Inputting three-dimensional error compensation data ................................... |

1044 |

|

|

|

|

8.1.5.2 Outputting three-dimensional error compensation data................................. |

1045 |

|

|

|

|

8.1.5.3 Input/output format of three-dimensional error compensation data .............. |

1046 |

|

|

|

8.1.6 |

Inputting and Outputting Custom Macro Common Variables ........................... |

1048 |

|

|

|

|

8.1.6.1 Inputting custom macro common variables................................................... |

1048 |

|

|

|

|

8.1.6.2 Outputting custom macro common variables ................................................ |

1049 |

|

|

|

8.1.7 |

Inputting and Outputting Workpiece Coordinates System Data ........................ |

1051 |

|

c-11

TABLE OF CONTENTS |

|

B-63944EN/02 |

|

|

8.1.7.1 |

Inputting workpiece coordinate system data.................................................. |

1051 |

|

8.1.7.2 |

Outputting workpiece coordinate system data............................................... |

1052 |

8.1.8 |

Inputting and Outputting Operation History Data.............................................. |

1053 |

|

|

8.1.8.1 |

Outputting operation history data .................................................................. |

1053 |

8.1.9 |

Inputting and Outputting Tool Management Data ............................................. |

1054 |

|

|

8.1.9.1 |

Inputting tool management data .................................................................... |

1054 |

|

8.1.9.2 |

Outputting tool management data.................................................................. |

1055 |

|

8.1.9.3 |

Inputting magazine data................................................................................. |

1056 |

|

8.1.9.4 |

Outputting magazine data .............................................................................. |

1057 |

|

8.1.9.5 |

Inputting tool life status name data................................................................ |

1058 |

|

8.1.9.6 |

Outputting tool life status name data ............................................................. |

1059 |

|

8.1.9.7 |

Inputting name data of customize data .......................................................... |

1060 |

|

8.1.9.8 |

Outputting name data of customize data........................................................ |

1061 |

|

8.1.9.9 |

Inputting customize data displayed as tool management data ....................... |

1062 |

|

8.1.9.10 |

Outputting customize data displayed as tool management data..................... |

1063 |

|

8.1.9.11 |

Inputting spindle waiting position name data ................................................ |

1064 |

|

8.1.9.12 |

Outputting spindle waiting position name data ............................................. |

1065 |

|

8.1.9.13 |

Inputting decimal point position data of customize data ............................... |

1066 |

|

8.1.9.14 |

Outputting decimal point position data of customize data............................. |

1067 |

|

8.1.9.15 |

Inputting tool geometry data.......................................................................... |

1068 |

|

8.1.9.16 |

Outputting tool geometry data ....................................................................... |

1069 |

|

8.2 |

INPUT/OUTPUT ON THE ALL IO SCREEN............................................ |

1070 |

|

|

8.2.1 Inputting/Outputting a Program ......................................................................... |

1071 |

|

|

8.2.2 Inputting and Outputting Parameters.................................................................. |

1072 |

|

|

8.2.3 Inputting and Outputting Offset Data................................................................. |

1073 |

|

|

8.2.4 Inputting/Outputting Pitch Error Compensation Data........................................ |

1074 |

|

|

8.2.5 Inputting/Outputting Custom Macro Common Variables .................................. |

1076 |

|

|

8.2.6 Inputting and Outputting Workpiece Coordinates System Data ........................ |

1077 |

|

|

8.2.7 Inputting and Outputting Operation History Data.............................................. |

1078 |

|

|

8.2.8 Inputting and Outputting Tool Management Data ............................................. |

1079 |

|

|

8.2.9 File Format and Error Messages......................................................................... |

1083 |

|

8.3 |

EMBEDDED ETHERNET OPERATIONS................................................ |

1084 |

|

|

8.3.1 FTP File Transfer Function ................................................................................ |

1084 |

9 |

CREATING PROGRAMS.................................................................. |

1088 |

|

|

9.1 |

CREATING PROGRAMS USING THE MDI PANEL................................ |

1089 |

|

9.2 |

AUTOMATIC INSERTION OF SEQUENCE NUMBERS ......................... |

1090 |

|

9.3 |

CREATING PROGRAMS IN TEACH IN MODE (PLAYBACK) ................ |

1092 |

10 |

EDITING PROGRAMS ...................................................................... |

1095 |

|

|

10.1 |

EDIT DISABLE ATTRIBUTE.................................................................... |

1096 |

c-12

B-63944EN/02 |

|

|

TABLE OF CONTENTS |

10.2 |

INSERTING, ALTERING AND DELETING A WORD |

.............................. 1097 |

|

|

10.2.1 |

Word Search....................................................................................................... |

1098 |

|

10.2.2 |

Heading a Program............................................................................................. |

1100 |

|

10.2.3 |

Inserting a Word................................................................................................. |

1101 |

|

10.2.4 |

Altering a Word.................................................................................................. |

1102 |

|

10.2.5 |

Deleting a Word ................................................................................................. |

1103 |

10.3 |

DELETING BLOCKS ............................................................................... |

1104 |

|

|

10.3.1 |

Deleting a Block................................................................................................. |

1104 |

|

10.3.2 |

Deleting Multiple Blocks ................................................................................... |

1105 |

10.4 |

PROGRAM SEARCH .............................................................................. |

1106 |

|

10.5 |

SEQUENCE NUMBER SEARCH ............................................................ |

1107 |

|

10.6 |

DELETING PROGRAMS......................................................................... |

1109 |

|

|

10.6.1 |

Deleting One Program........................................................................................ |

1109 |

|

10.6.2 |

Deleting All Programs........................................................................................ |

1109 |

10.7 |

EDITING OF CUSTOM MACROS........................................................... |

1110 |

|

10.8 |

PASSWORD FUNCTION ........................................................................ |

1111 |

|

10.9 |

EDITING PROGRAM CHARACTERS ..................................................... |

1114 |

|

|

10.9.1 |

Available Keys ................................................................................................... |

1118 |

|

10.9.2 |

Input Mode ......................................................................................................... |

1119 |

|

10.9.3 |

Line Number Display ......................................................................................... |

1119 |

|

10.9.4 |

Search ................................................................................................................. |

1120 |

|

10.9.5 |

Replacement ....................................................................................................... |

1121 |

|

10.9.6 |

Reversing Edit Operations (Undo Function)...................................................... |

1122 |

|

10.9.7 |

Selection ............................................................................................................. |

1122 |

|

10.9.8 |

Copy .................................................................................................................. |

1123 |

|

10.9.9 |

Deletion .............................................................................................................. |

1123 |

|

10.9.10 |

Paste 1123 |

|

|

10.9.11 |

Saving................................................................................................................. |

1123 |

|

10.9.12 |

Creation .............................................................................................................. |

1124 |

|

10.9.13 |

Line Number Search........................................................................................... |

1124 |

10.10 |

PROGRAM COPY FUNCTION................................................................ |

1125 |

|

10.11 KEYS AND PROGRAM ENCRYPTION................................................... |

1127 |

||

11 PROGRAM MANAGEMENT............................................................. |

1131 |

||

11.1 |

SELECTING A DEVICE........................................................................... |

1132 |

|

|

11.1.1 |

Selecting a Memory Card Program as a Device................................................. |

1133 |

11.2 |

CREATING A FOLDER ........................................................................... |

1139 |

|

11.3 |

RENAMING A FOLDER .......................................................................... |

1140 |

|

c-13

TABLE OF CONTENTS |

B-63944EN/02 |

||

11.4 |

CHANGING FOLDER ATTRIBUTES....................................................... |

1141 |

|

11.5 |

DELETING A FOLDER............................................................................ |

1142 |

|

11.6 |

SELECTING A DEFAULT FOLDER ........................................................ |

1143 |

|

11.7 |

RENAMING A FILE ................................................................................. |

1144 |

|

11.8 |

DELETING A FILE................................................................................... |

1145 |

|

11.9 |

CHANGING FILE ATTRIBUTES.............................................................. |

1146 |

|

11.10 |

SELECTING A MAIN PROGRAM............................................................ |

1147 |

|

11.11 |

MAKING A PROGRAM COMPACT......................................................... |

1148 |

|

12 SETTING AND DISPLAYING DATA................................................. |

1149 |

||

12.1 |

SCREENS DISPLAYED BY FUNCTION KEY ....................................... |

1157 |

|

|

12.1.1 Position Display in the Workpiece Coordinate System ..................................... |

1158 |

|

|

12.1.2 Position Display in the Relative Coordinate System.......................................... |

1160 |

|

|

12.1.3 |

Overall Position Display .................................................................................... |

1163 |

|

12.1.4 Workpiece Coordinate System Preset ................................................................ |

1165 |

|

|

12.1.5 |

Actual Feedrate Display ..................................................................................... |

1166 |

|

12.1.6 Display of Run Time and Parts Count................................................................ |

1168 |

|

|

12.1.7 Setting the Floating Reference Position ............................................................. |

1170 |

|

|

12.1.8 |

Operating Monitor Display ................................................................................ |

1171 |

12.1.9Display of Manual Feed for 5-axis Machining (Tool Tip Coordinates, Number

|

of Pulses, Machine Axis Move Amount) ........................................................... |

1174 |

12.2 SCREENS DISPLAYED BY FUNCTION KEY ....................................... |

1178 |

|

12.2.1 |

Program Contents Display.................................................................................. |

1179 |

12.2.2 |

Editing a Program............................................................................................... |

1180 |

12.2.3 Program Screen for MDI Operation ................................................................... |

1182 |

|

12.2.4 |

Program Folder Screen....................................................................................... |

1183 |

12.2.5 Next Block Display Screen ................................................................................ |

1184 |

|

12.2.6 |

Program Check Screen ....................................................................................... |

1185 |

12.2.7 |

Background Editing............................................................................................ |

1186 |

12.2.8 Stamping the Machining Time ........................................................................... |

1192 |

|

12.3 SCREENS DISPLAYED BY FUNCTION KEY ....................................... |

1202 |

|

12.3.1 Displaying and Entering Setting Data ................................................................ |

1203 |

|

12.3.2 Sequence Number Comparison and Stop ........................................................... |

1206 |

|

12.3.3 Displaying and Setting Run Time, Parts Count, and Time ................................ |

1208 |

|

12.3.4 Displaying and Setting the Workpiece Origin Offset Value .............................. |

1211 |

|

12.3.5 Direct Input of Workpiece Origin Offset value measured ................................. |

1212 |

|

12.3.6 Displaying and Setting Custom Macro Common Variables .............................. |

1214 |

|

12.3.7 Displaying and Setting Real Time Custom Macro Data .................................... |

1216 |

|

|

c-14 |

|

B-63944EN/02 |

|

|

TABLE OF CONTENTS |

|

|

12.3.8 |

Displaying and Setting the Software Operator's Panel....................................... |

1218 |

|

|

12.3.9 Setting and Displaying Tool Management Data ................................................ |

1221 |

||

|

|

12.3.9.1 |

Displaying and setting magazine screen ........................................................ |

1221 |

|

|

12.3.9.2 |

Displaying and setting tool management screen............................................ |

1223 |

|

|

12.3.9.3 |

Each tool data screen ..................................................................................... |

1230 |

|

|

12.3.9.4 |

Displaying the total life of tools of the same type ......................................... |

1233 |

|

|

12.3.9.5 |

Tool geometry data screen............................................................................. |

1238 |

|

12.3.10 Displaying and Switching the Display Language .............................................. |

1243 |

||

|

12.3.11 Protection of Data at Eight Levels...................................................................... |

1245 |

||

|

|

12.3.11.1 |

Operation level setting................................................................................... |

1245 |

|

|

12.3.11.2 |

Password modification................................................................................... |

1247 |

|

|

12.3.11.3 |

Protection level setting .................................................................................. |

1249 |

|

|

12.3.11.4 |

Setting the change protection level and output protection level of a |

|

|

|

|

program.......................................................................................................... |

1253 |

|

12.3.12 |

Precision Level Selection ................................................................................... |

1255 |

|

12.4 |

SCREENS DISPLAYED BY FUNCTION KEY ....................................... |

1256 |

||

|

12.4.1 |

Displaying and Setting Parameters..................................................................... |

1257 |

|

|

12.4.2 |

Displaying and Setting Pitch Error Compensation Data .................................... |

1260 |

|

|

12.4.3 |

Displaying and Setting Three-Dimensional Error Compensation Data ............. |

1263 |

|

|

12.4.4 |

Servo Parameters................................................................................................ |

1267 |

|

|

12.4.5 |

Servo Tuning ...................................................................................................... |

1268 |

|

|

12.4.6 |

Spindle Setting ................................................................................................... |

1269 |

|

|

12.4.7 |

Spindle Tuning ................................................................................................... |

1270 |

|

|

12.4.8 |

Spindle Monitor.................................................................................................. |

1271 |

|

|

12.4.9 |

Color Setting Screen........................................................................................... |

1272 |

|

|

12.4.10 |

Machining Parameter Tuning............................................................................. |

1275 |

|

|

12.4.11 |

Displaying Memory Data ................................................................................... |

1283 |

|

|

12.4.12 |

Parameter Tuning Screen ................................................................................... |

1285 |

|

|

|

12.4.12.1 |

Displaying the menu screen and selecting a menu item ................................ |

1285 |

|

|

12.4.12.2 |

Parameter tuning screen (system setting) ...................................................... |

1289 |

|

|

12.4.12.3 |

Parameter tuning screen (axis setting) ........................................................... |

1291 |

|

|

12.4.12.4 |

Displaying and setting the FSSB amplifier setting screen............................. |

1292 |

|

|

12.4.12.5 |

Displaying and setting the FSSB axis setting screen ..................................... |

1293 |

|

|

12.4.12.6 |

Displaying and setting the servo setting screen ............................................. |

1294 |

|

|

12.4.12.7 |

Parameter tuning screen (spindle setting)...................................................... |

1295 |

|

|

12.4.12.8 |

Parameter tuning screen (miscellaneous settings) ......................................... |

1296 |

|

|

12.4.12.9 |

Displaying and setting the servo tuning screen ............................................. |

1297 |

|

12.4.12.10 Displaying and setting the spindle tuning screen............................................. |

1298 |

||

|

12.4.12.11 Displaying and setting the machining parameter tuning screen ...................... |

1299 |

||

12.5 |

SCREENS DISPLAYED BY FUNCTION KEY ....................................... |

1304 |

||

c-15

TABLE OF CONTENTS |

B-63944EN/02 |

12.6DISPLAYING THE PROGRAM NUMBER, SEQUENCE NUMBER, AND STATUS, AND WARNING MESSAGES FOR DATA SETTING OR

INPUT/OUTPUT OPERATION ................................................................ |

1305 |

|

12.6.1 |

Displaying the Program Number and Sequence Number................................... |

1305 |

12.6.2 |

Displaying the Status and Warning for Data Setting or Input/Output |

|

|

Operation............................................................................................................ |

1307 |

13 |

GRAPHIC FUNCTION....................................................................... |

1310 |

|

|

13.1 |

GRAPHIC DISPLAY ................................................................................ |

1311 |

IV. MAINTENANCE |

|

||

1 |

ROUTINE MAINTENANCE ............................................................... |

1327 |

|

|

1.1 |

ACTION TO BE TAKEN WHEN A PROBLEM OCCURRED ................... |

1328 |

|

1.2 |