fanuc 0-TD, 0-MD, 0-GCD, 0-GSD Maintenance Manual

FANUC Series 0-TD/0-GCD

FANUC Series 0-MD/0-GSD

Maintenance Manual

B-62545EN/02

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of which are registered trademarks of respective owners. However, these names are not followed by or in the main body.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE . . . . . . . . . . . . . . . . . . . . . . . . s±2

2. WARNINGS RELATED TO CHECK OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . s±3

3. WARNINGS RELATED TO REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s±5

4. WARNINGS RELATED TO PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s±6

5. WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE . . . . . . . . . . . . . s±7

s±1

SAFETY PRECAUTIONS B±62545EN/02

1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred to as the user) and preventing damage to the machine. Precautions are classified into Warnings and Cautions according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s±2

B±62545EN/02 SAFETY PRECAUTIONS

2 WARNINGS RELATED TO CHECK OPERATION

WARNING

1.When checking the operation of the machine with the cover removed

(1)The user's clothing could become caught in the spindle or other components, thus presenting a danger of injury. When checking the operation, stand away from the machine to ensure that your clothing does not become tangled in the spindle or other components.

(2)When checking the operation, perform idle operation without workpiece. When a workpiece is mounted in the machine, a malfunction could cause the workpiece to be dropped or destroy the tool tip, possibly scattering fragments throughout the area. This presents a serious danger of injury. Therefore, stand in a safe location when checking the operation.

2.When checking the machine operation with the power magnetics cabinet door opened

(1)The power magnetics cabinet has a high±voltage section (carrying a  mark). Never touch the high±voltage section. The high±voltage section presents a severe risk of electric

mark). Never touch the high±voltage section. The high±voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on the high±voltage section. When the high±voltage section itself must be checked, note that touching a terminal presents a severe danger of electric shock.

(2)Within the power magnetics cabinet, internal units present potentially injurious corners and projections. Be careful when working inside the power magnetics cabinet.

3.Never attempt to machine a workpiece without first checking the operation of the machine. Before starting a production run, ensure that the machine is operating correctly by performing a trial run using, for example, the single block, feedrate override, or machine lock function or by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the correct operation of the machine may result in the machine behaving unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

4.Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

s±3

SAFETY PRECAUTIONS |

B±62545EN/02 |

|

|

WARNING

5.Ensure that the specified feedrate is appropriate for the intended operation. Generally, for each machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the intended operation. Refer to the manual provided with the machine to determine the maximum allowable feedrate. If a machine is run at other than the correct speed, it may behave unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

6.When using a tool compensation function, thoroughly check the direction and amount of compensation.

Operating the machine with incorrectly specified data may result in the machine behaving unexpectedly, possibly causing damage to the workpiece and/or machine itself, or injury to the user.

s±4

B±62545EN/02 SAFETY PRECAUTIONS

3 WARNINGS RELATED TO REPLACEMENT

WARNING

1.Always turn off the power to the CNC and the main power to the power magnetics cabinet. If only the power to the CNC is turned off, power may continue to be supplied to the serve section. In such a case, replacing a unit may damage the unit, while also presenting a danger of electric shock.

2.When a heavy unit is to be replaced, the task must be undertaken by two persons or more. If the replacement is attempted by only one person, the replacement unit could slip and fall, possibly causing injury.

3.After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow at least twenty minutes after turning off the power for these residual voltages to dissipate.

4.When replacing a unit, ensure that the new unit has the same parameter and other settings as the old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable machine movement could damage the workpiece or the machine itself, and present a danger of injury.

s±5

SAFETY PRECAUTIONS B±62545EN/02

4 WARNINGS RELATED TO PARAMETERS

WARNING

1.When machining a workpiece for the first time after modifying a parameter, close the machine cover. Never use the automatic operation function immediately after such a modification. Instead, confirm normal machine operation by using functions such as the single block function, feedrate override function, and machine lock function, or by operating the machine without mounting a tool and workpiece. If the machine is used before confirming that it operates normally, the machine may move unpredictably, possibly damaging the machine or workpiece, and presenting a risk of injury.

2.The CNC and PMC parameters are set to their optimal values, so that those parameters usually need not be modified. When a parameter must be modified for some reason, ensure that you fully understand the function of that parameter before attempting to modify it. If a parameter is set incorrectly, the machine may move unpredictably, possibly damaging the machine or workpiece, and presenting a risk of injury.

s±6

B±62545EN/02 SAFETY PRECAUTIONS

5 WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE

WARNING

1. Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on, and apply an emergency stop to the machine. If this work is performed with the power on and the cabinet open, only those personnel who have received approved safety and maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high±voltage circuits (marked  and fitted with an insulating cover).

and fitted with an insulating cover).

Touching the uncovered high±voltage circuits presents an extremely dangerous electric shock hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator's panel or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the contents of the CNC's memory will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

s±7

SAFETY PRECAUTIONS |

B±62545EN/02 |

|

|

WARNING

2. Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on, and apply an emergency stop to the machine. If this work is performed with the power on and the cabinet open, only those personnel who have received approved safety and maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high±voltage circuits (marked  and fitted with an insulating cover).

and fitted with an insulating cover).

Touching the uncovered high±voltage circuits presents an extremely dangerous electric shock hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator's panel or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

s±8

B±62545EN/02 |

SAFETY PRECAUTIONS |

|

|

WARNING

3. Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the blown fuse.

For this reason, only those personnel who have received approved safety and maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high±voltage circuits (marked  and fitted with an insulating cover).

and fitted with an insulating cover).

Touching an uncovered high±voltage circuit presents an extremely dangerous electric shock hazard.

s±9

B±62545EN/02 |

PREFACE |

|

|

PREFACE

Description of |

1.CRT/MDI display and operation |

this manual |

This chapter covers those items, displayed on the CRT, that are related to |

|

|

|

maintenance. A list of all supported operations is also provided at the end |

|

of this chapter. |

2.Hardware

This chapter covers hardware±related items, including the hardware configuration, connection, and NC status indicated on printed circuit boards. A list of all units is also provided as well as an explanation of how to replace each unit.

3.Data input/output

This chapter describes the input/output of data, including programs, parameters, and tool compensation data, as well as the input/output procedures for conversational data.

4.Interface between the NC and PMC

This chapter describes the PMC specifications, the system configuration, and the signals used by the PMC.

5.Digital servo

This chapter describes the servo tuning screen and how to adjust the reference position return position.

6.Trouble shooting

This chapter describes the procedures to be followed in the event of certain problems occurring, for example, if the power cannot be turned on or if manual operation cannot be performed. Countermeasures to be applied in the event of alarms being output are also described.

APPENDIX

The appendix consists of a list of all alarms, as well as a list of maintenance parts.

This manual does not provide a parameter list. If necessary, refer to the separate PARAMETER MANUAL.

This manual describes all optional functions. Refer to the manual provided by the machine tool builder for details of any options with which the installed machine tool is provided.

This manual can be used with the following models. The abbreviated names may be used.

p±1

PREFACE |

B±62545EN/02 |

|

|

Applicable models

Manuals related to Series 0±D

The models covered by this manual, and their abbreviations are :

Product name |

Abbreviations |

Series |

||

|

|

|

|

|

FANUC Series 0±TD |

0±TD |

|

T series |

|

|

|

|

||

FANUC Series 0±GCD |

0±GCD |

Series 0±D |

||

|

||||

|

|

|

||

FANUC Series 0±MD |

0±MD |

M series |

||

|

||||

|

|

|

||

FANUC Series 0±GSD |

0±GSD |

|

||

|

|

|||

|

|

|

|

|

The table below lists manuals related to the FANUC Series 0±D. In the table, this manual is marked with an asterisk (*).

Table 1 Manuals related to the FANUC Series 0±D

Manuals name |

Specification |

|

|

number |

|

||

|

|

||

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD |

B±62543EN |

|

|

CONNECTION MANUAL (HARDWARE) |

|

||

|

|

||

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD |

B±62543EN±1 |

|

|

CONNECTION MANUAL (FUNCTION) |

|

||

|

|

||

|

|

|

|

FANUC Series 0±TD/GCD OPERATOR'S MANUAL |

B±62544EN |

|

|

|

|

|

|

FANUC Series 0±MD/GSD OPERATOR'S MANUAL |

B±62574EN |

|

|

|

|

|

|

FANUC Series 0±TD/MD/GCD/GSD |

B±62545EN |

* |

|

MAINTENANCE MANUAL |

|||

|

|

||

|

|

|

|

FANUC Series 0±TD/GCD PARAMETER MANUAL |

B±62550EN |

|

|

|

|

|

|

FANUC Series 0±MD/GSD PARAMETER MANUAL |

B±62580EN |

|

|

|

|

|

p±2

B±62545EN/02 |

Table of Contents |

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

s±1 |

||

PREFACE . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

p±1 |

|

1. DISPLAY AND OPERATION OF CRT/MDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

||

1.1 |

FUNCTION KEYS AND SOFT KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

1.1.1 |

Screen Transition Triggered by The Function Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

1.2 |

POWER±ON SCREEN DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

1.3 |

DIAGNOSTIC FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.3.1 |

How to Display the Diagnosis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

1.3.2 |

Display of the CNC Internal Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

1.4 |

NC STATUS DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

1.5 |

LIST OF OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

2. HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

||

2.1 |

CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

|

|

2.1.1 |

Configuration of the Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

2.2 |

COMPLETE CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

|

|

2.2.1 |

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

2.3 |

INTER±MACHINE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

|

2.3.1 |

CRT/MDI Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

2.3.2 |

Reader/Puncher Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

2.3.3 |

Manual pulse Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

2.3.4 |

Servo Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

2.3.5 |

Serial Spindle Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

2.3.6 |

Analog Spindle Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

2.3.7 |

Position Coder Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

2.3.8 |

External Environmetal Requirements of Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

2.3.9 |

Installation Condition of CNC and Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

2.3.10 |

Power Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

2.3.11 |

Action Against Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

2.4 |

LEDS ON PRINTED±CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

2.5 |

PRINTED±CIRCUIT BOARD UNIT LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

|

|

2.5.1 |

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

|

2.5.2 |

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

2.5.3 |

Printed board unit list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

2.6 |

BATTERY REPLACEMENT METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

|

|

2.6.1 |

CNC Memory Backup Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

|

2.6.2 |

Absolute Pulse Coder Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

2.7 |

DETAILS OF POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

|

|

2.7.1 |

Details of Power Supply Unit AI (A16B±1212±0100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

64 |

|

2.7.2 |

CE Marking Correspond Details of Power Supply Unit AI (A16B±1212±0950) . . . . . . . . . . . . . . . . . |

71 |

|

2.7.3 |

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

2.8 |

MAINTENANCE OF HEAT PIPE TYPE HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

3. DATA INPUT/OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

81 |

||

3.1 |

DATA INPUT/OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

|

3.1.1 |

Locating the File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

3.1.2 |

Outputting CNC Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

|

3.1.3 |

PMC Parameter Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

|

3.1.4 |

Program Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

c±1

Table of Contents |

B±62545EN/02 |

|

|

|

3.1.5 |

Offset Value Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

3.1.6 |

CNC Parameter Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

|

3.1.7 |

PMC Parameter Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

|

3.1.8 |

Program Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

3.1.9 |

Offset Value Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

3.1.10 Parameters Related to Data Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

4. INTERFACE BETWEEN NC AND PMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

||

4.1 |

PMC SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

|

4.1.1 |

PMCLAD SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

4.2 |

SIGNAL AND SYMBOL TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

|

5. DIGITAL SERVO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

103 |

||

5.1 |

INITIAL SETTING SERVO PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

104 |

|

5.2 |

SERVO TUNING SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

|

|

5.2.1 |

Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

|

5.2.2 |

Displaying Servo Tuning Screen (Exa.: Incase of X axis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

5.3 |

ADJUSTING REFERENCE POSITION (DOG METHOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

|

|

5.3.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

5.4 |

DOGLESS REFERENCE POSITION SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

|

|

5.4.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

|

5.4.2 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

|

5.4.3 |

Associated Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

112 |

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

113 |

||

6.1 |

CORRECTIVE ACTION FOR FAILURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

115 |

|

|

6.1.1 |

Investigating the Conditions Under which Failure Occurred . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

115 |

6.2 |

POWER CANNOT BE SWITCHED ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

117 |

|

6.3 |

NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED . . . . . . . . |

118 |

|

6.4 |

JOG OPERATION CANNOT BE DONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

|

6.5 |

HANDLE OPERATION CANNOT BE DONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

|

6.6 |

AUTOMATIC OPERATION CANNOT BE DONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

|

6.7 |

CYCLE START LED SIGNAL HAS TURNED OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

134 |

|

6.8 |

NO DISPLAY APPEARS ON THE SCREEN WHEN THE POWER IS SWITCHED ON . . . . . . . . |

136 |

|

6.9 |

ALARM 85 TO 87 (READER/PUNCHER INTERFACE ALARM) . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

|

6.10 |

REFERENCE POSITION DEVIATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

|

6.11 |

ALARM 90 (REFERENCE POSITION RETURN IS ABNORMAL) . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

|

6.12 |

ALARM 3n0 (REQUEST FOR REFERENCE POSITION RETURN) . . . . . . . . . . . . . . . . . . . . . . . |

144 |

|

6.13 |

ALARM 3n1 TO 3n6 (ABSOLUTE PULSE CODER IS FAULTY) . . . . . . . . . . . . . . . . . . . . . . . . . . |

145 |

|

6.14 |

ALARM 3n7 TO 3n8 (ABSOLUTE PULSE CODER BATTERY IS LOW) . . . . . . . . . . . . . . . . . . . |

146 |

|

6.15 |

ALARM 3n9 (SERIAL PULSE CODER IS ABNORMAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

147 |

|

6.16 |

ALARM 400, 402 (OVERLOAD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

|

6.17 |

ALARM 401, 403 (*DRDY SIGNAL TURNED OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

150 |

|

6.18 |

ALARM 404 AND 405 (*DRDY SIGNAL TURNED ON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

151 |

|

6.19 |

ALARM 4n0 (EXCESSIVE POSITION ERROR AMOUNT DURING STOP) . . . . . . . . . . . . . . . . |

152 |

|

6.20 |

ALARM 4n1 (EXCESSIVE POSITION ERROR DURING MOVE) . . . . . . . . . . . . . . . . . . . . . . . . . |

153 |

|

6.21 |

ALARM 4n4 (DIGITAL SERVO SYSTEM IS ABNORMAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

|

c±2

B±62545EN/02 |

Table of Contents |

|

|

6.22 ALARM 4n6 (DISCONNECTION ALARM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165 6.23 ALARM 4n7 (DIGITAL SERVO SYSTEM IS ABNORMAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166 6.24 ALARM 700 (OVERHEAT AT CONTROL SIDE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167 6.25 ALARM 408 (THE SPINDLE SERIAL LINK DOES NOT START NORMALLY.) . . . . . . . . . . . . . 168 6.26 ALARM 409 (SPINDLE ALARM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169 6.27 ALARM 998 (ROM PARITY ERROR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170 6.28 ALARMS 910 TO 916 (RAM PARITY ERRORS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 6.29 ALARM 920 (WATCH DOG OR RAM PARITY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172 6.30 ALARM 941 (INCORRECTLY INSTALLED MEMORY PRINTED±CIRCUIT BOARD) . . . . . . . 173 6.31 ALARM 930 (CPU ERROR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 6.32 ALARMS 945 AND 946 (SERIAL SPINDLE COMMUNICATION ERRORS) . . . . . . . . . . . . . . . . 175 6.33 ALARM 950 (BLOWN FUSE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

APPENDIX |

|

A. ALARM LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

179 |

A.1 LIST OF ALARM CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

180 |

B. LIST OF MAINTENANCE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

199 |

B.1 MAINTENANCE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

200 |

c±3

B±62545EN/02 1. DISPLAY AND OPERATION OF CRT/MDI

1 DISPLAY AND OPERATION OF CRT/MDI

This chapter describes how to display various screens by the function keys. The screens used for maintenance are respectively displayed.

1.1 |

FUNCTION KEYS AND SOFT KEYS . . . . . . . . . . . . |

. 2 |

1.2 |

POWER±ON SCREEN DISPLAY . . . . . . . . . . . . . . . . . |

6 |

1.3 |

DIAGNOSTIC FUNCTIONS . . . . . . . . . . . . . . . . . . . . . |

7 |

1.4 |

NC STATUS DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

1.5 |

LIST OF OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

1

1. DISPLAY AND OPERATION OF CRT/MDI |

B±62545EN/02 |

||

1.1 |

Operations and soft key display status for each function key are described |

||

FUNCTION KEYS |

below: |

|

|

|

|

|

|

AND SOFT KEYS |

|

|

|

1.1.1 |

|

|

|

ee i i |

|

|

|

i e ed e |

|

|

|

i e |

|

|

|

POSITION DISPLAY SCREEN |

|

POS |

|

|

|

ee i i i e e e f i e |

|

|

|

POS |

|

Current position screen |

|

|

|

ABS |

REL |

ALL |

|

i i i f |

i i i |

Total position dis- |

|

i e |

e i e i e |

play of each coor- |

|

e |

e |

dinate system |

|

Display of run time |

Display of run time |

Display of run time |

|

and parts count |

and parts count |

and parts count |

|

i f |

i f |

i f |

|

ee |

ee |

ee |

|

|

e i f e i e |

e i f e i e |

|

|

i e e |

i e e |

|

2

B±62545EN/02 |

1. DISPLAY AND OPERATION OF CRT/MDI |

|

|

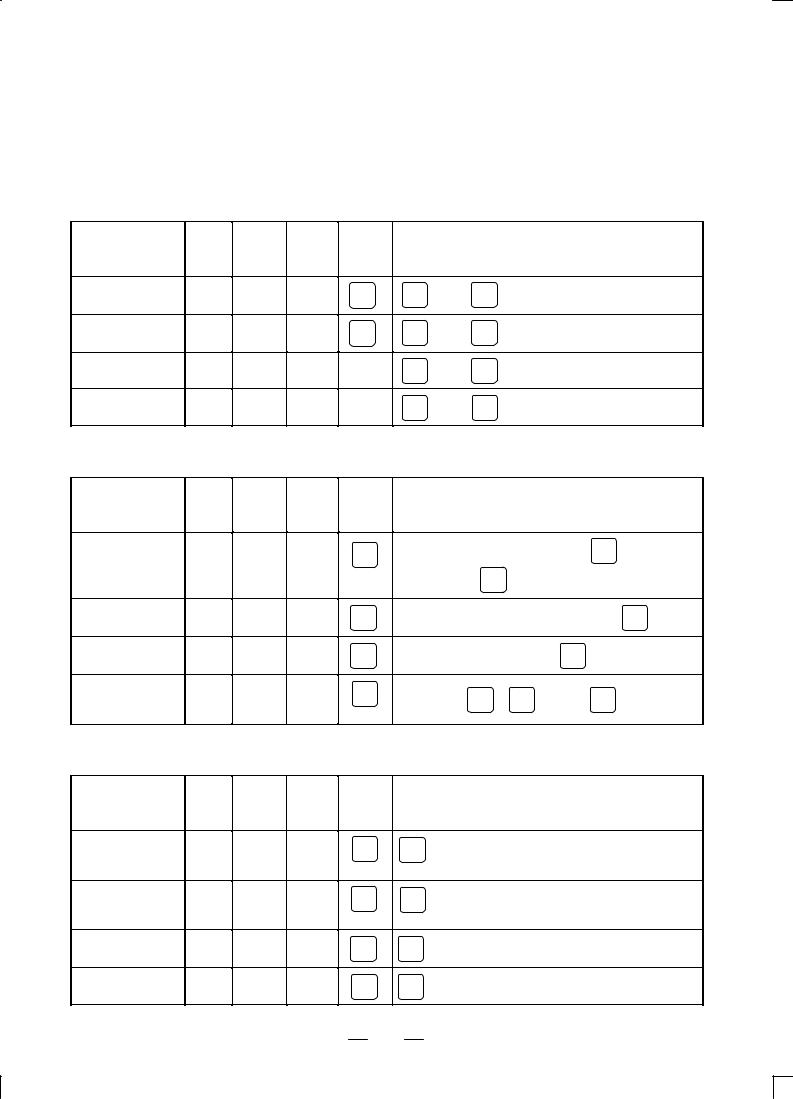

PROGRAM SCREEN

Screen transition triggered by the functionPROGkey in the AUTO or MDI mode

PROG

* : Displayed in MDI mode

Program screen

Program screen

AUTO (MDI) *

|

PRGRM |

|

|

CURRNT |

|

|

NEXT |

|

CHECK |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display of pro& gram contents

Display of program number and se& quence number

Display of current |

|

Display of current |

|

||||

block and modal |

|

block and next |

|

||||

data |

|

block |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program screen

Program being |

|

|

|

|

|

|

* |

|

Command |

||||||

executed Absolute/ |

|

|

|||||

|

for MDI operation |

|

|||||

Relative coordinate |

|

|

|||||

|

|

|

|

|

|

||

value Distance to go |

|

|

|

|

|

||

modal values |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BG±EDT

PROGRAM SCREEN

Screen transition triggered by the functionPROGkey in the EDIT mode

PROG

Program screen

Program screen

|

PRGRM |

|

|

LIB |

|

I/O |

|

EDIT |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program editing |

|

|

|

Program memory |

||

screen |

|

|

|

and program di& |

||

|

|

|

|

|

rectory |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

1. DISPLAY AND OPERATION OF CRT/MDI |

B±62545EN/02 |

|

OFFSET/SETTING SCREEN Screen transition triggered by the function SETTINGkey |

||

|

|

OFFSET |

|

|

(Machining Center) |

|

|

OFFSET |

|

|

SETTING |

Tool offset value |

|

|

OFFSET |

MACRO |

OPR |

Display of tool offset value

Setting of tool offset data

Display of macro variables

Setting macro variables

Display of workpiece coordinate system

Setting of workpiece original offset value

|

|

|

|

|

|

|

|

|

|

|

OFFSET/SETTING SCREEN |

|

|

|

|

|

|

|

|

|

Screen transition triggered by the function |

SETTINGkey |

|||||||

|

|

|

|

|

|

|

OFFSET |

|

|

|

|

|

(Lathe) |

|

|

|

|

||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFFSET

SETTING

Tool offset value

Tool offset value

WEAR |

|

GEOMETRY |

|

WORK |

|

MACRO |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display of tool offset value (Wear)

Display of tool offset value (Geometry)

Display of set Display of ting of work shift macro variables value/work

coordinate

Setting of tool offset data (Wear)

Setting of tool offset value (Geometry)

Setting of work shift value/work coordinate

Setting of macro variable

4

B±62545EN/02 |

1. DISPLAY AND OPERATION OF CRT/MDI |

|

|

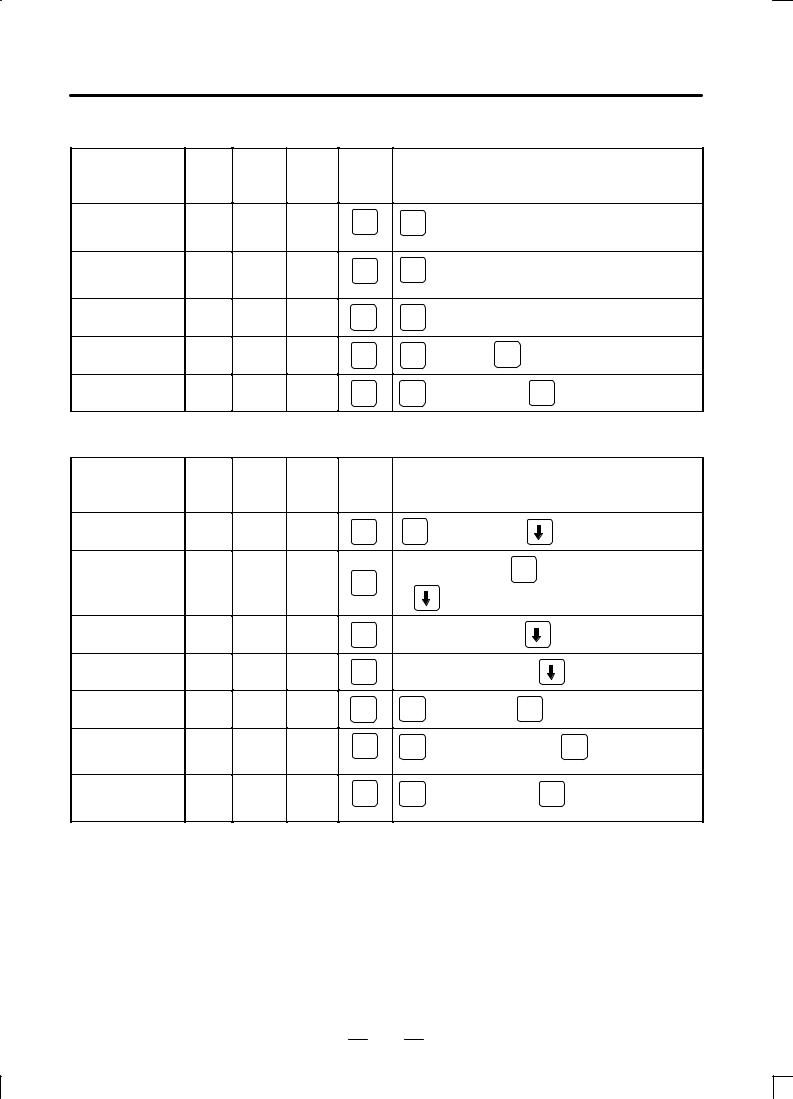

PARAMETER/DIAGNOSIS SCREEN

DGNOS

Screen transition triggered by the functionPARAMkey

(Lathe)

DGNOS

PARAM

Parameter screen

Parameter screen

*

PARAM |

|

DGNOS |

|

|

|

SV±PRM |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

isplay of |

isplay of |

parameter |

diagnosis |

screen |

screen |

Setting of parameter

Setting of pitch error compensation data

Setting of setting data

Display of servo setting screen

Display of servo adjusting screen

* :Setting parameter (No.0389#0).

Servo setting/adjusting screen are not displaied.

|

|

|

|

|

|

|

|

|

|

ALARM SCREEN |

|

Screen transition triggered by the function key |

ALARM |

||||

|

|

|

|

|

|

|

OPR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPR |

|

|

ALARM |

Alarm screen |

|

|

ALARM |

OPR |

MESSAGE |

Display of |

Display of soft- |

Display of |

alarm screen |

ware opera- |

operator mes- |

|

tor's panel |

sage |

|

Setting of soft- |

|

|

ware operator's |

|

|

panel |

|

5

1. DISPLAY AND OPERATION OF CRT/MDI |

B±62545EN/02 |

1.2

POWER±ON SCREEN DISPLAY

D Slot state screen

±The CRT screen displays differ slightly between the M and T systems.

±The screen displays shown below are for reference purposes only. Some of these displays may not appear depending on the installed options and actual system configuration.

0 4 7 1 ± 0 5

NOT READY

Automatically switched

0 4 7 1 ± 0 5

PMC: XXXX ± XX

NOT READY

CNC software edition and version displays, which also appear also on the program list screen

CNC software edition and version displays, which also appear also on the program list screen

Indicates that the servo system is not ready to operate, that is, it is inoperable.

Type of other software in use

PMC : Sequence programs created by the machine tool builder

±This display does not appear if no other software is available.

±The displays shown above remain on the screen if the machine is brought to an emer gency stop.

An ordinary position display is restored when the machine is released from an emergency stop state.

6

B±62545EN/02 1. DISPLAY AND OPERATION OF CRT/MDI

1.3

DIAGNOSTIC FUNCTIONS

1.3.1

How to Display the |

|

|

|

(1) Press the |

PARAMDGNOS |

|

key several times, or the [Diagnosis] soft key. |

||||||||||||

Diagnosis Screen |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1.3.2 |

|

|

|

If the CNC does not respond to a command, it is possible to determine the |

|||||||||||||||

Display of the CNC |

|

|

|

status of the CNC. |

|

|

|

|

|

|

|

|

|||||||

Internal Status |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#7 |

#6 |

|

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

|

||||||

DGN |

|

0700 |

|

|

|

|

CSCT |

|

CITL |

COVZ |

CINP |

CDWL |

CMTN |

CFIN |

|

||||

#6 CSCT |

The CNC is waiting for the spindle speed reached signal (SAR) to be |

||||||||||||||||||

|

|

|

|

turned on after cutting feed begins or an S command is read. |

|

|

|||||||||||||

|

|

|

|

#7 |

#6 |

|

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

|

||||||

DGN |

|

0120 |

|

|

|

|

|

|

|

|

|

SAR |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

SAR |

0 The spindle speed has not reached the specified speed. |

|

|

|||||||||||||||

|

|

|

|

#7 |

#6 |

|

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

|

||||||

PRM |

|

0024 |

|

|

|

|

|

|

|

|

|

|

|

SCTO |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

SCTO |

1 : The spindle speed reached signal will be checked. |

|

|

|

|||||||||||||||

|

|

|

|

0 : The spindle speed reached signal will not be checked. |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

||||||||||||

PRM |

|

0110 |

|

|

Delay timer for checking the spindle speed reached signal [ms] |

|

|

||||||||||||

#5 CITL |

An interlock (disable axis movement) signal has been input. |

|

|

||||||||||||||||

[0±MD and 0±GSD]

PRM |

PRM |

PRM |

PRM |

Signal name |

DGN number |

|

49#0 |

08#7 |

15#2 |

12#1 |

|||

|

|

|||||

|

|

|

|

|

|

|

1 |

Ð |

Ð |

Ð |

* MITX, Y, Z |

142.0 to 7 |

|

|

|

|

|

|

|

|

Ð |

1 |

Ð |

Ð |

*ITX, Y, Z, 4 |

128.0 to 3 |

|

|

|

|

|

|

|

|

Ð |

0 |

0 |

0 |

*ILK (all axes) |

117.0 |

|

|

|

|

|

|

||

Ð |

0 |

0 |

1 |

*ILK (Z±axis only) |

||

|

||||||

|

|

|

|

|

|

|

Ð |

0 |

1 |

0 |

*RILK (all axes) |

008.5 |

|

|

|

|

|

|

||

Ð |

0 |

1 |

1 |

*RILK (Z±axis only) |

||

|

||||||

|

|

|

|

|

|

7

1. DISPLAY AND OPERATION OF CRT/MDI B±62545EN/02

[0±TD and 0±GCD]

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

||

DGN |

0120 |

|

|

|

|

|

|

|

STLK |

|

|

|

|

|

|

|

|

|

|

|

|

STLK 1 : The start lock is in effect.

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

||

DGN |

0128 |

|

|

|

|

|

IT4 |

IT3 |

ITZ |

ITX |

|

|

|

|

|

|

|

|

|

|

|

IT 1 : The start lock for the corresponding start lock is in effect.

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

||

DGN |

0008 |

|

|

|

±MIT2 |

+MIT2 |

±MIT1 |

+MIT1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

*PRM Valid only when bit 7 (EDILK) of PRM 024 = 1.

#4 COVZ The override signal is 0%.

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

||

DGN |

0121 |

|

|

|

|

|

*OV8 |

*OV4 |

*OV2 |

*OV1 |

Override 0% |

When bit 4 of PRM 003=0 |

1 |

1 |

1 |

1 |

|

|

|

|

|

|

|

When bit 4 of PRM 003=1 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

#3 CINP A position check is being performed.

DGN 800 to Positional deviation > PRM 500 to Effective area

± Probable causes include errors in the servo circuit or machine load.

#2 CDWL |

A dwell command (G04) is being executed. |

|

|

|

|

||||||||

#1 CMTN |

An axis move command is being executed automatically. |

|

|

||||||||||

#0 |

CFIN |

The M, S, T, or B function is being executed (has not been completed). |

|||||||||||

|

|

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

|

#1 |

#0 |

PRM |

|

0045 |

|

HSIF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HSIF The M, S, T, and B code processing uses either of the following interfaces. 1 : High±speed interface

0 : Ordinary interface

8

B±62545EN/02 |

1. DISPLAY AND OPERATION OF CRT/MDI |

|

|

[Ordinary interface]

DOperation sequence of auxiliary functions

DGN |

700.0=1 |

|

Read auxiliary |

To the next block |

|

|

||

function |

S and T |

|

Auxiliary function code |

||

functions |

||

(BCD) |

M function |

|

Strobe (MF, SF,..) |

|

|

Operation of function |

|

|

Completion (FIN) |

|

|

#7 |

|

#6 |

#5 |

#4 |

#3 |

|

#2 |

#1 |

#0 |

|||

DGN |

0150 |

|

|

|

|

|

|

TF |

|

SF |

|

MF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Strobe signals |

|

|

|

|

|

|

|

|

|||

|

#7 |

|

#6 |

#5 |

#4 |

#3 |

|

#2 |

#1 |

#0 |

|||

DGN |

|

0157 |

|

|

|

|

MF3 |

MF2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

MF2, MF3 Strobe signal for multiple M functions per block |

|

|

|

||||||||||

|

#7 |

|

#6 |

#5 |

#4 |

#3 |

|

#2 |

#1 |

#0 |

|||

DGN |

0120 |

|

|

|

|

|

|

FIN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[M function]

DGN

DGN

FIN Auxiliary function completion (common to M, S, T and B)

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

|

0151 |

|

M28 |

M24 |

M22 |

M21 |

M18 |

M14 |

M12 |

M11 |

|

|

|

|

|

|

|

|

|

|

0157 |

|

|

|

|

|

M38 |

M34 |

M32 |

M31 |

|

|

|

|

|

|

|

|

|

|

±M31 to M38 are the BCD code corresponding to the third digit with the 3±digit M function.

[2±digit S function only]

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0152 |

|

S28 |

S24 |

S22 |

S21 |

S18 |

S14 |

S12 |

S11 |

|

|

|

|

|

|

|

|

|

|

|

[T function]

DGN

DGN

± This signal is not used for the 4±digit S function.

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

0153 |

|

T28 |

T24 |

T22 |

T21 |

T18 |

T14 |

T12 |

T11 |

|

|

|

|

|

|

|

|

|

|

0156 |

|

T48 |

T44 |

T42 |

T41 |

T38 |

T34 |

T32 |

T31 |

|

|

|

|

|

|

|

|

|

|

±T31 to T48 are the BCD code corresponding to the fourth and third digits with the 4±digit T function.

9

1. DISPLAY AND OPERATION OF CRT/MDI B±62545EN/02

[3±/6±digit B function]

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0150 |

|

BF1 |

BF2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BF1 |

Strobe signal for the 3 low±order digits of the B code |

|

|

||||||||

|

BF2 |

Strobe signal for the 3 high±order digits of the B code |

|

|

||||||||

|

|

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

|

0154 |

|

|

|

|

|

B38 |

B34 |

B32 |

B31 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DGN |

|

0155 |

|

B28 |

B24 |

B22 |

B21 |

B18 |

B14 |

B12 |

B11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

± For the 6±digit B function, code signals are output for every three digits.

[High±speed interface]

DAuxiliary±function operation sequences

DGN 700.0=1 |

|

|

|

DGN 700.0=1 |

|

To the next block |

|

|

To the next block |

||

Read auxiliary function

Auxiliary function code (BCD)

Strobe (MF, SF,..)

Behavior of function

Completion (MFIN,...)

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0150 |

|

BF1 |

BF2 |

|

|

TF |

SF |

|

MF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DGN |

0115 |

|

BFIN1 |

BFIN2 |

|

|

TFIN |

SFIN |

|

MFIN |

|

|

|

|

|

|

|

|

|

|

|

MFIN, SFIN, TFIN Function completion signals |

|

|

|

|

|

|||||

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0701 |

|

|

|

CRST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#5 CRST The emergency stop signal (*ESP), external reset signal (ERS), reset & rewind signal (RRW), or MDI reset button is on.

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0021 |

|

|

|

|

*ESP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DGN |

0121 |

|

ERS |

|

|

*ESP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DGN |

0104 |

|

|

RRW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*ESP 0 : The emergency stop signal is on.

ERS 1 : The external reset signal is on.

RRW 1 : The reset & rewind signal is on.

± There is no DGNOS display for the MDI reset button.

10

B±62545EN/02 |

|

|

|

|

|

|

|

|

|

|

|

1. DISPLAY AND OPERATION OF CRT/MDI |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#7 |

|

#6 |

|

#5 |

|

#4 |

|

#3 |

#2 |

|

#1 |

|

#0 |

||||

DGN |

0712 |

|

STP |

REST |

EMS |

RRW |

|

RSTB |

|

|

|

|

CSU |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

This diagnosis information is valid only if automatic operation is |

||||||||||||||||||||

|

|

terminated when it should not be. The information indicates the reason |

||||||||||||||||||||

|

|

why the cycle start lamp (STL) is off. |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

#7 |

#6 |

|

#5 |

#4 |

|

#3 |

#2 |

|

#1 |

#0 |

|

|

|

|

Reason |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

1 |

|

1 |

|

1 |

0 |

|

0 |

0 |

|

0 |

1 |

|

The emergency stop signal (*ESP) was input. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

*(1) |

1 |

|

1 |

|

0 |

0 |

|

0 |

0 |

|

0 |

0 |

|

The external reset (ERS) signal was input. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

*(2) |

1 |

|

1 |

|

0 |

1 |

|

0 |

0 |

|

0 |

0 |

|

The reset & rewind (RRW) signal was input. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

1 |

|

1 |

|

0 |

0 |

|

1 |

0 |

|

0 |

0 |

|

The MDI reset button was pressed. |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

1 |

|

0 |

|

0 |

0 |

|

0 |

0 |

|

0 |

1 |

|

A servo alarm occurred. |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

1 |

|

0 |

|

0 |

0 |

|

0 |

0 |

|

0 |

0 |

|

The feed hold (*SP) signal was input, or |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

another manual mode was selected. |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

0 |

|

0 |

|

0 |

0 |

|

0 |

0 |

|

0 |

0 |

|

The machine stopped in a single±function |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

block. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. All these bits are cleared to 0 when the power is switched on.

|

|

|

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

#0 |

DGN |

0021 |

|

|

|

|

*ESP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DGN |

0121 |

|

ERS |

|

*SP |

*ESP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*ESP 0 The emergency stop signal is on.

ERS 1 The external reset signal is on.

*SP 0 The feed hold signal is on.

|

#7 |

#6 |

#5 |

|

#4 |

|

|

#3 |

#2 |

#1 |

#0 |

||||||

DGN |

|

|

0104 |

|

|

RRW |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

RRW 1 The reset & rewind signal is on. |

|

|

|

|

|||||||||||||

|

#7 |

#6 |

#5 |

|

#4 |

|

|

#3 |

#2 |

#1 |

#0 |

||||||

DGN |

|

0116 |

|

|

|

|

|

|

|

|

|

|

|

|

SBK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

SBK 1 : The single block signal is on. |

|

|

|

|

||||||||||||

|

#7 |

#6 |

#5 |

|

#4 |

|

|

#3 |

#2 |

#1 |

#0 |

||||||

DGN |

|

0122 |

|

|

|

|

|

|

|

|

|

|

|

MD4 |

MD2 |

MD1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

Automatic operation (AUTO) |

0 |

0 |

1 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

Manual data input (MDI) |

|

0 |

0 |

0 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

±If the program ends with M02 or M03, the machine may enter state 1 or 2 in the above table depending on the processing adopted by the machine tool builder.

11

1. DISPLAY AND OPERATION OF CRT/MDI |

B±62545EN/02 |

1.4

NC STATUS

ACTUAL POSITION (ABSOLUTE)

DISPLAYS

O0010 N0000

X123.456

Y363.233

Z0.000

ACT.F |

3000 MM/M |

S |

0 T |

|

||

NOT READY |

ALM |

BAT |

BUF AUTO |

|

|

|

[ ABS |

] [ |

REL |

] [ |

ALL ] [ HNDL ] [ |

] |

|

|

|

|

|

|

|

|

(1)Current mode |

MDI |

: |

Manual data input |

|

|

AUTO |

: |

Automatic operation (memory± or tape±based operation) |

|

|

EDIT |

: |

Memory editing |

|

|

HNDL |

: |

Manual handle feed |

|

|

JOG |

: |

Jog feed |

|

|

TJOG |

: |

Teach±in jog feed |

|

|

THND |

: |

Teach±in handle feed |

|

|

STEP |

: |

Manual incremental feed |

|

|

ZRN |

: |

Manual reference position return |

|

(2)Alarm conditions |

Alarm |

: |

Indicates the current alarm. |

|

|

BAT |

: |

Indicates that the battery voltage is dropping. |

|

(3)Other status displays |

Input |

|

: Indicates that data is being input. |

|

|

Output |

|

: Indicates that data is being output. |

|

|

Search |

|

: Indicates that a search is being carried out. |

|

|

Editing |

|

: Indicates that some other miscellaneous editing operation |

|

|

|

|

|

(such as insertion or modification) is under way. |

|

Collation |

: Indicates that a program is being collated. |

||

|

LSK |

|

: Indicates the state of label skipping during data input. |

|

|

BUF |

|

: Indicates that the next block to be executed has been read. |

|

|

NOT READY |

: Indicates that the machine is in the emergency stop |

||

|

|

|

|

state. |

12

B±62545EN/02 |

1. DISPLAY AND OPERATION OF CRT/MDI |

|

|

1.5

LIST OF OPERATIONS

Reset

|

Data |

Param- |

|

Func- |

|

|

|

|

Function |

protec- |

Mode |

|

|

Operation |

|

||

tion |

eter |

tion |

|

|

|

|||

|

write=1 |

|

button |

|

|

|

|

|

|

key |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Resetting run hour |

|

|

± |

POS |

R |

→ |

CAN |

|

|

|

|

|

|||||

Resetting no. of |

|

|

± |

POS |

P |

→ |

CAN |

|

machined parts |

|

|

|

|||||

Resetting OT alarm |

|

|

At Pow- |

± |

P |

and |

CAN |

|

|

|

|

er ON |

|

||||

|

|

|

|

|

|

|

|

|

Resetting alarm 100 |

|

|

± |

± |

CAN |

and |

RESET |

|

|

|

|

|

|||||

Registration from MDI |

|

|

|

|

|

|

|

|

|

Data |

Param- |

|

Func- |

|

|

|

|

Function |

protec- |

Mode |

|

|

Operation |

|

||

tion |

eter |

tion |

|

|

|

|||

|

write=1 |

|

button |

|

|

|

|

|

|

key |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Inputting |

|

|

MDI |

SYSTEM |

Parameter no.→ [NO.SRH]→ Data→ |

INPUT |

||

|

f |

|

|

|

|

|

||

parameters |

|

|

→ PWE =0 → |

|

|

|||

|

|

|

|

RESET |

|

|||

|

|

|

|

(PARAM) |

|

|||

|

|

|

|

|

|

|

|

|

Inputting offset |

|

|

± |

OFFSET |

Offset number→ [NO.SRH]→ Offset value→ INPUT |

|||

values |

|

|

||||||

|

|

|

|

|

|

|

|

|

Inputting setting |

|

|

MDI |

OFFSET |

Setting no.→ [NO.SRH]Data→ INPUT |

|

||

data |

|

|

SETTING |

|

||||

|

|

|

|

|

|

|

|

|

Input of PMC |

f |

f |

MDI |

SYSTEM |

Setting no.→ DGNOS → INPUT→ Data→ |

INPUT |

||

parameters |

|

|||||||

|

|

|

|

|

|

PARAM |

|

|

|

|

|

|

(DGNOS) |

|

|

|

|

Registration from tape |

|

|

|

|

|

|

|

|

|

Data |

Param- |

|

Func- |

|

|

|

|

Function |

protec- |

Mode |

|

|

Operation |

|

||

tion |

eter |

tion |

|

|

|

|||

|

write=1 |

|

button |

|

|

|

|

|

|

key |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Inputting |

|

|

|

SYSTEM |

INPUT |

|

|

|

parameters |

|

f |

EDIT |

|

|

|

||

|

|

|

|

|

|

|||

(tape→ memory) |

|

|

|

(DGNOS) |

|

|

|

|

Input of PMC |

f |

f |

EDIT |

SYSTEM |

INPUT |

|

|

|

parameter |

|

|

|

|

|

|||

|

|

|

(DGNOS) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inputting offset |

|

|

EDIT |

OFFSET |

INPUT |

|

|

|

values |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Registration of |

f |

|

EDIT/ |

PRGRM |

INPUT |

|

|

|

program |

|

AUTO |

|

|

|

|||

|

|

|

|

|

|

|

||

13

1. DISPLAY AND OPERATION OF CRT/MDI B±62545EN/02

Punch out

|

Data |

Param- |

|

Func- |

|

|

|

|

Function |

protec- |

Mode |

|

|

Operation |

|||

tion |

eter |

tion |

|

|

||||

|

write=1 |

|

button |

|

|

|

|

|

|

key |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Punch of parameter |

|

|

EDIT |

SYSTEM |

OUTPUT |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

(PARAM) |

|

|

|

|

Punch of PMC |

|

|

EDIT |

SYSTEM |

OUTPUT |

|

|

|

parameter |

|

|

|

|

|

|

|

|

|

|

|

(DGNOS) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Punch of offset |

|

|

EDIT |

SETTING |

|

|

|

|

|

|

|

|

OFFSET |

OUTPUT |

|

|

|

Punch of all |

|

|

EDIT |

PROG |

O |

→ ±999 → OUTPUT |

|

|

programs |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Punch of one |

|

|

EDIT |

PROG |

O |

→ Program no.→ |

OUTPUT |

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Search |

|

|

|

|

|

|

|

|

|

Data |

Param- |

|

Func- |

|

|

|

|

Function |

protec- |

Mode |

|

|

Operation |

|||

tion |

eter |

tion |

|

|

||||

|

write=1 |

|

button |

|

|

|

|

|

|

key |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Searching a |

|

|

EDIT/ |

PROG |

O → Program no.→ |

|

(cursor key) |

|

program number |

|

|

AUTO |

|

||||

|

|

|

|

|

|

|

||