fanuc M900iA Maintenance Manual

FANUC > M-900iA/350

MECHANICAL UNIT

MAINTENANCE MANUAL

B-82135EN/01

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities. Therefore, matters which are not especially described as possible in this manual should be regarded as "impossible".

B-82135EN/01 |

SAFETY |

|

|

SAFETY

FANUC is not and does not represent itself as an expert in safety systems, safety equipment, or the specific safety aspects of your company and/or its work force. It is the responsibility of the owner, employer, or user to take all necessary steps to guarantee the safety of all personnel in the workplace.

The appropriate level of safety for your application and installation can best be determined by safety system professionals. FANUC therefore, recommends that each customer consult with such professionals in order to provide a workplace that allows for the safe application, use, and operation of FANUC systems.

Additionally, as the owner, employer, or user of a robotic system, it is your responsibility to arrange for the training of the operator of a robot system to recognize and respond to known hazards associated with your robotic system and to be aware of the recommended operating procedures for your particular application and robot installation.

FANUC therefore, recommends that all personnel who intend to operate, program, repair, or otherwise use the robotics system be trained in an approved FANUC training course and become familiar with the proper operation of the system. Persons responsible for programming the system-including the design, implementation, and debugging of application programs-must be familiar with the recommended programming procedures for your application and robot installation.

The following guidelines are provided to emphasize the importance of safety in the workplace.

IMPORTANT

IMPORTANT

Before operating, servicing or in any other way handling the robot, the "FANUC Robot SAFETY HANDBOOK (B-

80687EN)" must be thoroughly studied.

s-1

SAFETY |

B-82135EN/01 |

|

|

Considering safety |

Safety is essential whenever robots are used. Keep in mind the |

|

for your robot |

following factors with regard to safety: |

|

installation |

• |

The safety of people and equipment |

|

• Use of safety enhancing devices |

|

|

• Techniques for safe teaching and manual operation of the |

|

|

|

robot(s) |

|

• Techniques for safe automatic operation of the robot(s) |

|

|

• Regular scheduled inspection of the robot and workcell |

|

|

• Proper maintenance of the robot |

|

Keeping people and |

The safety of people is always of primary importance in any |

|

equipment safe |

situation. However, equipment must be kept safe, too. When |

|

|

prioritizing how to apply safety to your robotic system, consider |

|

|

the following: |

|

|

• |

People |

|

• |

External devices |

|

• |

Robot(s) |

|

• |

Tooling |

|

• |

Workpiece |

Using safety enhancing |

Always give appropriate attention to the work area that surrounds |

|

devices |

the robot. The safety of the work area can be enhanced by the |

|

|

installation of some or all of the following devices: |

|

|

• Safety fences, barriers, or chains |

|

|

• |

Light curtains |

|

• |

Interlocks |

|

• |

Pressure mats |

|

• |

Floor markings |

|

• |

Warning lights |

|

• |

Mechanical stops |

|

• |

EMERGENCY STOP buttons |

|

• |

DEADMAN switches |

Setting up a safe |

A safe workcell is essential to protect people and equipment. |

|

workcell |

Observe the following guidelines to ensure that the workcell is set |

|

|

up safely. These suggestions are intended to supplement and not |

|

|

replace existing federal, state, and local laws, regulations, and |

|

|

guidelines that pertain to safety. |

|

• Sponsor your personnel for training in approved FANUC training course(s) related to your application. Never permit untrained personnel to operate the robots.

• Install a lockout device to prevent unauthorized persons from operating the robot.

• Use anti-tie-down logic to prevent the operator from bypassing safety measures.

• Arrange the workcell so the operator faces the workcell and can see what is going on inside the cell.

s-2

B-82135EN/01 |

SAFETY |

|

|

Staying safe while teaching or manually operating the robot

•Clearly identify the work envelope of each robot in the system with floor markings, signs, and special barriers. The work envelope is the area defined by the maximum motion range of the robot, including any tooling attached to the wrist flange that extend this range.

•Position all controllers outside the robot work envelope.

•Never rely on software as the primary safety element.

•Install flashing lights and/or audible warning devices that activate whenever the robot is operating, that is, whenever power is applied to the servo drive system.

•Wherever possible, install safety fences to protect against unauthorized entry by personnel into the work envelope.

•Install special guarding that prevents the operator from reaching into restricted areas of the work envelope.

•Use interlocks.

•Use presence or proximity sensing devices such as light curtains, mats, and capacitance and vision systems to enhance safety.

•Periodically check the safety joints or safety clutches that can be optionally installed between the robot wrist flange and tooling. If the tooling strikes an object, these devices dislodge, remove power from the system, and help to minimize damage to the tooling and robot.

•Make sure all external devices are properly filtered, grounded, shielded, and suppressed to prevent hazardous motion due to the effects of electro-magnetic interference (EMI), radio frequency interference (RFI), and electro-static discharge (ESD).

•Make provisions for power lockout/tagout at the controller.

•Eliminate pinch points. Pinch points are areas where personnel could get trapped between a moving robot and other equipment.

•Provide enough room inside the workcell to permit personnel to teach the robot and perform maintenance safely.

•Program the robot to load and unload material safely.

•If high voltage electrostatics are present, be sure to provide appropriate interlocks, warning, and beacons.

•If materials are being applied at dangerously high pressure, provide electrical interlocks for lockout of material flow and pressure.

Advise all personnel who must teach the robot or otherwise manually operate the robot to observe the following rules:

•Never wear watches, rings, neckties, scarves, or loose clothing that could get caught in moving machinery.

•Know whether or not you are using an intrinsically safe teach pendant if you are working in a hazardous environment.

•Before teaching, visually inspect the robot and work envelope to make sure that no potentially hazardous conditions exist. The work envelope is the area defined by the maximum motion

s-3

SAFETY |

B-82135EN/01 |

|

|

range of the robot. These include tooling attached to the wrist flange that extends this range.

• The area near the robot must be clean and free of oil, water, or debris. Immediately report unsafe working conditions to the supervisor or safety department.

• FANUC recommends that no one enter the work envelope of a robot that is on. However, if you must enter the work envelope, be sure all safeguards are in place, and check the teach pendant DEADMAN switch for proper operation. Take the teach pendant with you, turn it on, and be prepared to release the DEADMAN switch. Only the person with the teach pendant should be in the work envelope.

• Know the path that can be used to escape from a moving robot; make sure the escape path is never blocked.

• Isolate the robot from all remote control signals that can cause motion while data is being taught.

• Test any program being run for the first time in the following

|

manner: |

|

|

|

WARNING |

|

Stay outside the robot work envelope whenever a |

|

program is being run. Failure to do so can result in injury. |

|

- Using a low motion speed, single step the program for at least |

|

one full cycle. |

|

- Using a low motion speed, test run the program continuously for |

|

at least one full cycle. |

|

- Using the programmed speed, test run the program continuously |

|

for at least one full cycle. |

|

- Make sure all personnel are outside the work envelope before |

|

running production. |

Staying safe during |

Advise all personnel who operate the robot during production to |

production operation |

observe the following rules: |

|

• Know the entire workcell area. The workcell includes the robot |

|

and its work envelope, plus the area occupied by all external |

|

devices and other equipment with which the robot interacts. |

|

• Understand the complete task the robot is programmed to |

|

perform before initiating production operation. |

|

• Make sure all personnel are outside the work envelope before |

|

operating the robot. |

|

• Never enter or allow others to enter the work envelope during |

|

production operation of the robot. |

|

• Know the location and status of all switches, sensors, and |

|

control signals that could cause the robot to move. |

|

• Know where the EMERGENCY STOP buttons are located on |

|

both the robot control and external control devices. Be |

|

prepared to press these buttons in an emergency. |

|

• Never assume that a program is complete if the robot is not |

s-4

B-82135EN/01 |

SAFETY |

|

|

moving. The robot could be waiting for an input signal that will permit it to continue activity.

• If the robot is running in a pattern, do not assume it will

|

continue to run in the same pattern. |

|

• Never try to stop the robot, or break its motion, with your body. |

|

The only way to stop robot motion immediately is to press an |

|

EMERGENCY STOP button located on the controller panel, |

|

teach pendant, or emergency stop stations around the workcell. |

Staying safe during |

When inspecting the robot, be sure to: |

inspection |

• Turn off power at the controller. |

|

• Lock out and tag out the power source at the controller |

|

according to the policies of your plant. |

|

• Turn off the compressed air source and relieve the air pressure. |

|

• If robot motion is not needed for inspecting the electrical |

|

circuits, press the EMERGENCY STOP button on the operator |

|

panel. |

|

• Never wear watches, rings, neckties, scarves, or loose clothing |

|

that could get caught in moving machinery. |

|

• If power is needed to check the robot motion or electrical |

|

circuits, be prepared to press the EMERGENCY STOP button, |

|

in an emergency. |

Staying safe during |

When performing maintenance on your robot system, observe the |

maintenance |

following rules: |

|

• Never enter the work envelope while the robot or a program is |

|

in operation. |

|

• Before entering the work envelope, visually inspect the |

|

workcell to make sure no potentially hazardous conditions |

|

exist. |

|

• Never wear watches, rings, neckties, scarves, or loose clothing |

|

that could get caught in moving machinery. |

|

• Consider all or any overlapping work envelopes of adjoining |

|

robots when standing in a work envelope. |

|

• Test the teach pendant for proper operation before entering the |

|

work envelope. |

|

• If it is necessary for you to enter the robot work envelope while |

|

power is turned on, you must be sure that you are in control of |

|

the robot. Be sure to take the teach pendant with you, press the |

|

DEADMAN switch, and turn the teach pendant on. Be |

|

prepared to release the DEADMAN switch to turn off servo |

|

power to the robot immediately. |

|

• Whenever possible, perform maintenance with the power |

|

turned off. Before you open the controller front panel or enter |

|

the work envelope, turn off and lock out the 3-phase power |

s-5

SAFETY |

B-82135EN/01 |

|

|

source at the controller.

WARNING

WARNING

Lethal voltage is present in the controller WHENEVER IT IS CONNECTED to a power source. Be extremely careful to avoid electrical shock.

HIGH VOLTAGE IS PRESENT at the input side whenever the controller is connected to a power source. Turning the disconnect or circuit breaker to the OFF position removes power from the output side of the device only.

•Release or block all stored energy. Before working on the pneumatic system, shut off the system air supply and purge the air lines.

•Isolate the robot from all remote control signals. If maintenance must be done when the power is on, make sure the person inside the work envelope has sole control of the robot. The teach pendant must be held by this person.

•Make sure personnel cannot get trapped between the moving robot and other equipment. Know the path that can be used to escape from a moving robot. Make sure the escape route is never blocked.

•Use blocks, mechanical stops, and pins to prevent hazardous movement by the robot. Make sure that such devices do not create pinch points that could trap personnel.

WARNING

WARNING

Do not try to remove any mechanical component from the robot before thoroughly reading and understanding the procedures in the appropriate manual. Doing so can result in serious personal injury and component destruction.

•Be aware that when you remove a servomotor or brake, the associated axis will fall if it is not supported or resting on a hard stop.

•When replacing or installing components, make sure dirt and debris do not enter the system.

•Use only specified parts for replacement. To avoid fires and damage to parts in the controller, never use nonspecified fuses.

s-6

B-82135EN/01 |

SAFETY |

|

|

•Before restarting a robot, make sure no one is inside the work envelope; be sure that the robot and all external devices are operating normally.

•Use appropriate lighting for maintenance work. Take care that the lighting does not create new dangerous situations.

•If it is necessary to operate the robot during the inspection, pay careful attention to the robot's motion and be sure to press the EMERGENCY STOP button immediately when necessary.

•Be careful not to slip on spilled grease during maintenance.

•Do not climb on the robot.

•Some components might be hot. Take care when working on servo motors or inside the controller. Wear protective clothing (heart-resistant gloves, etc.) when working on components that are hot.

•After replacing components, be sure to tighten screws and fasteners that were loosened.

•The motor and reducer are heavy. Be careful when replacing them. If the robot collides with a mechanical hard stop, replace the mechanical hard stop even if it does not seem to be damaged.

•After replacing parts or making adjustments, be sure to test run the robot according to the following procedure.

1.Using a low motion speed, single step the program for at least one full cycle.

2.Using a low motion speed, test run the program continuously for at least one full cycle.

3.As speed is increased the path may vary slightly. Run through the program at 5-10% intervals up to 100%.

4.Using the programmed speed, test run the program continuously for at least one full cycle.

Make sure all personnel are outside the fence before test running.

•After maintenance work, clean the area around the robot of oil, water, and debris.

s-7

SAFETY |

B-82135EN/01 |

|

|

Safety procedure for |

Follow this safety procedure when entering the safeguarded space |

|

maintenance |

for maintenance. |

|

Entering safeguarded |

1. |

Stop the robot system. |

space for maintenance |

2. |

Shut off the power to the robot system, and lock the main |

|

|

breaker to prevent accidental powering on during maintenance. |

2'. If you have to enter the safeguarded space while power is available to the robot system, you must do the following prior to entering the safeguarded space:

-check the robot system to determine if any conditions exist that are likely to cause malfunctions, - check that the teach pendant works correctly, and

-if any damage or malfunction is found, complete the required corrections and perform a retest before personnel enter the safeguarded space.

3.Enter the safeguarded space (see "The Safety Sequence for fence entry" in "FANUC Robot SAFETY HANDBOOK").

4.After maintenance is complete, check that the safeguard system is effective. If it has been suspended to perform the maintenance working, return it to its original effectiveness.

s-8

B-82135EN/01 |

SAFETY |

|

|

Keeping machine |

Certain programming and mechanical measures are useful in |

tools and external |

keeping the machine tools and other external devices safe. These |

devices safe |

measures are outlined below. |

Programming safety |

Implement the following programming safety measures to prevent |

precautions |

damage to machine tools and other external devices. |

|

• Back-check limit switches in the workcell to make sure they do |

|

not fail. |

|

• Implement "failure routines" in programs that will provide |

|

appropriate robot actions if an external device or another robot |

|

in the workcell fails. |

|

• Use handshaking protocol to synchronize robot and external |

|

device operations. |

|

• Program the robot to check the condition of all external devices |

|

during an operating cycle. |

Mechanical safety |

Implement the following mechanical safety measures to prevent |

precautions |

damage to machine tools and other external devices. |

|

• Make sure the workcell is clean and free of oil, water, and |

|

debris. |

|

• Use software limits, limit switches, and mechanical hardstops |

|

to prevent undesired movement of the robot into the work area |

|

of machine tools and external devices. |

s-9

SAFETY |

B-82135EN/01 |

|

|

Keeping the robot |

Observe the following operating and programming guidelines to |

safe |

prevent damage to the robot. |

Operating safety |

The following measures are designed to prevent damage to the |

precautions |

robot during operation. |

|

• Use a low override speed to increase your control over the |

|

robot when jogging the robot. |

|

• Visualize the movement the robot will make before you press |

|

the jog keys on the teach pendant. |

|

• Make sure the work envelope is clean and free of oil, water, or |

|

debris. |

|

• Use fuses to guard against electrical overload. |

Programming safety |

The following safety measures are designed to prevent damage to |

precautions |

the robot during programming: |

|

• Establish interference zones to prevent collisions when two or |

|

more robots share a work area. |

|

• Make sure that the program ends with the robot near or at the |

|

home position. |

|

• Be aware of signals or other operations that could trigger |

|

operation of tooling resulting in personal injury or equipment |

|

damage. |

|

• In dispensing applications, be aware of all safety guidelines |

|

with respect to the dispensing materials. |

NOTE

Any deviation from the methods and safety practices described in this manual must conform to the approved standards of your company. If you have questions, see your supervisor.

s-10

B-82135EN/01 |

SAFETY |

|

|

Warning labels |

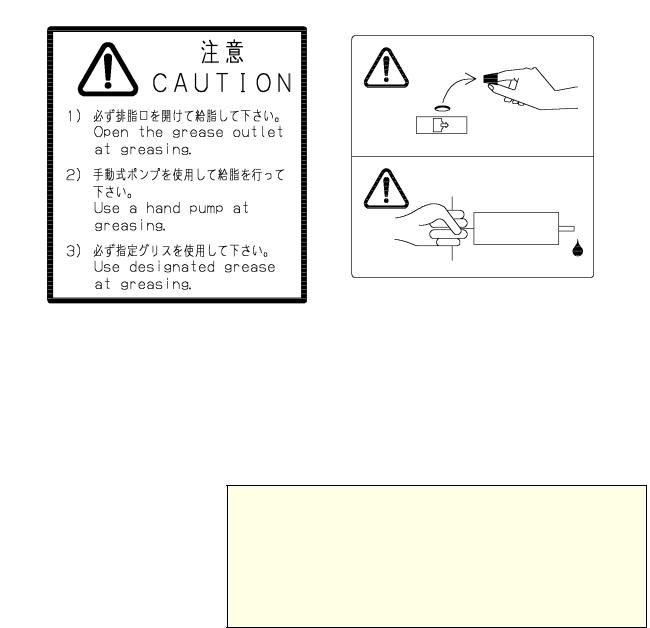

1. Greasing and degreasing label |

|

|

|

|

|

Greasing and Degreasing Label |

|

Description |

When greasing and degreasing, observe the instructions indicated |

|

|

on this label. |

|

|

1. |

When greasing, be sure to keep the grease outlet open. |

|

2. |

Use a manual pump to grease. |

|

3. |

Be sure to use a specified grease. |

NOTE

See MAINTENANCE 3.1 REPLACING GREASE OF THE

DRIVE MECHANISM for explanations about specified greases, the amount of grease to be supplied, and the locations of grease and degrease outlets for individual models.

s-11

SAFETY |

B-82135EN/01 |

|

|

2. Step-on prohibitive label

|

Step-on prohibitive label |

Description |

Do not step on or climb the robot as it may adversely affect the |

|

robot and you may get hurt if you lose your footing as well. |

s-12

B-82135EN/01 |

SAFETY |

|

|

3. High-temperature warning label

|

High-temperature warning label |

Description |

Be cautious about a section where this label is affixed, as the |

|

section generates heat. If you have to inevitably touch such a |

|

section when it is hot, use a protective provision such as heat- |

|

resistant gloves. |

s-13

SAFETY |

B-82135EN/01 |

|

|

4. Transportation label

|

|

Transportation label |

Description |

When transporting the robot, observe the instructions indicated on |

|

|

this label. |

|

|

1. |

Using a forklift |

|

|

• Use a forklift having a load capacity of |

|

|

3,000 kg or greater. |

|

|

• Keep the total weight of the robot to be |

|

|

transported to within 2,800 kg, because the |

|

|

withstand load of the forklift bracket |

|

|

(option) is 13,720 kgN (1,400 kg) |

|

2. |

Using a crane |

|

|

• Use a crane having a load capacity of 3,000 |

|

|

kg or greater. |

• Use at least four slings each having a withstand load of 9,800 N (1,000 kgf) or greater.

• Use at least four eyebolts each having a withstand load of 6,174 N (630 kgf) or greater.

s-14

B-82135EN/01 |

SAFETY |

|

|

NOTE

See CONNECTION 3.1 TRANSPORTATION for explanations about the posture a specific model should take when it is transported.

s-15

PREFACE |

B-82135EN/01 |

|

|

PREFACE

This manual explains the maintenance and connection procedures for the following robots:

Model name |

Mechanical unit |

Maximum load |

|

specification No. |

|||

|

|

||

|

|

|

|

|

|

|

|

FANUC Robot M- |

A05B-1327-B201 |

350kg |

|

900iA/350 |

|

|

|

|

|

|

The label stating the mechanical unit specification number is affixed in the position shown below. Before reading this manual, determine the specification number of the mechanical unit.

TABLE 1

No. |

(1) |

(2) |

(3) |

(4) |

(5) |

|

|

|

|

|

|

CONTENTS |

|

TYPE |

No. |

DATE |

WEIGHT |

|

|

|

|

|

(Without |

|

|

|

|

|

controller) |

|

|

|

|

|

|

LETTERS |

FANUC Robot |

A05B-1327-B201 |

1720kg |

||

|

M-900iA/350 |

|

SERIAL NO. |

PRODUCTION |

|

|

|

|

|

YEAR AND MONTH |

|

|

|

|

|

|

|

Position of label indicating mechanical unit specification number

p-1

B-82135EN/01 |

PREFACE |

|

|

|

Specifications |

|

|

|

|

ITEM |

M-900iA/350 |

|

|

|

|

|

|

|

Type |

Articulated Type |

|

|

|

|

Controlled axes |

6 axes (J1, J2, J3, J4, J5, J6) |

|

|

|

|

Installation (NOTE) |

Floor mount, Upside-down (Angle mount) |

|

|

|

|

Motion range J1-axis |

360° (6.28rad) |

|

|

|

|

Motion range J2-axis |

150° (2.62rad) |

|

|

|

|

Motion range J3-axis |

223.4° (3.90rad) |

|

|

|

|

Motion range J4-axis |

720° (12.57rad) |

|

|

|

|

Motion range J5-axis |

250° (4.36rad) |

|

|

|

|

Motion range J6-axis |

720° (12.57rad) |

|

|

|

|

Max. Motion speed J1-axis |

100°/s (1.75rad/s) |

|

|

|

|

Max. Motion speed J2-axis |

95°/s (1.66rad/s) |

|

|

|

|

Max. Motion speed J3-axis |

95°/s (1.66rad/s) |

|

|

|

|

Max. Motion speed J4-axis |

105°/s (1.83rad/s) |

|

|

|

|

Max. Motion speed J5-axis |

105°/s (1.83rad/s) |

|

|

|

|

Max. Motion speed J6-axis |

170°/s (2.97rad/s) |

|

|

|

|

Max. load capacity at wrist |

350kg |

|

|

|

|

Max. load capacity at J3 arm |

|

25kg |

|

|

|

Max. load capacity at J2 arm |

550kg |

|

|

|

|

Allowable load moment at wrist J4-axis |

1960N m (200kgf m) |

|

|

|

|

Allowable load moment at wrist J5-axis |

1960N m (200kgf m) |

|

|

|

|

Allowable load moment at wrist J6-axis |

891.8N m (91kgf m) |

|

|

|

|

Allowable load inertia at wrist J4-axis |

235.2kg m2 |

(2400kgf cm s2) |

Allowable load inertia at wrist J5-axis |

235.2kg m2 |

(2400kgf cm s2) |

Allowable load inertia at wrist J6-axis |

156.8kg m2 |

(1600kgf cm s2) |

Drive method |

Electric servo drive by AC servo motor |

|

|

|

|

Repeatability |

+/- 0.3mm |

|

|

|

|

Weight |

Approx. 1720kg |

|

|

|

|

Installation enviroment |

Ambient temperature : 0 - 45°C |

|

|

Ambient humidity |

|

|

Normally : 75%RH or less No dew, nor frost allowed. |

|

|

Short time (within one month) : Max 95%RH |

|

|

Height : |

|

|

Up to 1,000 meters above the sea level requires, no particular provision for |

|

|

attitude. |

|

|

Vibration : 0.5 (4.9m/s2) or less |

|

p-2

PREFACE |

B-82135EN/01 |

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

The operation range of the J1-axis and J2-axis are limited |

|

||

|

|

|

|

to the installation condition. |

|

||

RELATED MANUALS |

|

For the FANUC Robot series, the following manuals are |

|

||||

|

|

|

|

available: |

|

|

|

|

|

|

|

|

|

|

|

Safety handbook |

|

|

|

|

Intended readers : |

|

|

B-80687EN |

|

|

|

|

All persons who use FANUC Robot, system |

|

|

|

|

|

|

|

|

designer |

|

All persons who use the FANUC Robot and |

|

Topics : |

|

||||

system designer must read and understand |

|

Safety items for robot system design, operation, |

|

||||

thoroughly this handbook |

|

|

|

maintenance |

|

||

|

|

|

|

|

|

||

R-J3iB |

Setup and Operations |

|

Intended readers : |

|

|||

controller |

manual |

|

|

|

Operator, programmer, maintenance person, |

|

|

|

|

SPOT TOOL |

|

|

|

system designer |

|

|

|

B-81464EN-1 |

|

Topics : |

|

||

|

|

|

|

|

|

Robot functions, operations, programming, |

|

|

|

HANDLING TOOL |

|

setup, interfaces, alarms |

|

||

|

|

B-81464EN-2 |

|

Use : |

|

||

|

|

SEALING TOOL |

|

Robot operation, teaching, system design |

|

||

|

|

|

|

|

|||

|

|

B-81464EN-4 |

|

|

|

||

|

|

|

|

|

|

||

R-J3iB |

Maintenance manual |

|

Intended readers : |

|

|||

controller |

B-81465EN |

|

Maintenance person, system designer |

|

|||

|

|

|

|

|

|

Topics : |

|

|

|

B-81465EN-1 |

|

Installation, connection to peripheral equipment, |

|

||

|

|

(European |

specification) |

|

maintenance |

|

|

|

|

|

|

|

|

Use : |

|

|

|

|

|

|

|

Installation, start-up, connection, maintenance |

|

|

|

|

|

|

|

||

Mechanical unit |

Maintenance manual |

|

Intended readers : |

|

|||

|

|

|

|

|

|

Maintenance person, system designer |

|

|

|

|

|

|

|

Topics : |

|

|

|

|

|

|

|

Installation, connection to the controller, |

|

|

|

|

|

|

|

maintenance |

|

|

|

|

|

|

|

Use : |

|

|

|

|

|

|

|

installation, start-up, connection, maintenance |

|

|

|

|

|

|

|

||

|

|

FANUC Robot M-900iA/350 |

|

|

|||

|

|

B-82135EN |

|

|

|

|

|

|

|

- Spot welding, general-purpose large robot |

|

||||

|

|

|

|

|

|

|

|

p-3

B-82135EN/01 |

Table of Contents |

|

|

|

TABLE OF CONTENTS |

|

SAFETY |

............................................................................................. |

s-1 |

PREFACE .......................................................................................... |

p-1 |

|

I. MAINTENANCE |

|

|

1. CONFIGURATION ............................................................................ |

3 |

|

1.1 |

J1-AXIS DRIVE MECHANISM........................................................................ |

4 |

1.2 |

J2/J3-AXIS DRIVE MECHANISM................................................................... |

5 |

1.3 |

J4-AXIS DRIVE MECHANISM........................................................................ |

6 |

1.4 |

J5/J6-AXIS DRIVE MECHANISM................................................................... |

7 |

1.5 |

MAJOR COMPONENT SPECIFICATIONS .................................................... |

8 |

2. PREVENTIVE MAINTENANCE ........................................................ |

9 |

|

2.1 |

DAILY CHECKS ............................................................................................. |

10 |

2.2 |

3-MONTH CHECKS........................................................................................ |

12 |

2.3 |

1-YEAR CHECKS............................................................................................ |

13 |

2.4 |

1.5-YEAR CHECKS......................................................................................... |

14 |

2.5 |

3-YEAR CHECKS............................................................................................ |

15 |

2.6 |

MAINTENANCE TOOLS ............................................................................... |

16 |

3. PERIODIC MAINTENANCE............................................................ |

21 |

|

3.1 |

REPLACING GREASE OF THE DRIVE MECHANISM.............................. |

22 |

|

3.1.1 Grease Replacement Procedure for the J1-Axis/J2-Axis/J3-Axis and J4-Axis Gear Box22 |

|

|

3.1.2 Grease Replacement Procedure for the Wrist ................................................................... |

22 |

|

3.1.3 Attitude for Greasing......................................................................................................... |

23 |

3.2 |

GREASING POINTS ....................................................................................... |

26 |

3.3 |

REPLACING THE BATTERIES..................................................................... |

27 |

4. TROUBLESHOOTING .................................................................... |

28 |

|

4.1 |

OVERVIEW ..................................................................................................... |

29 |

4.2 |

FAILURE AND CAUSE.................................................................................. |

30 |

4.3 |

BACKLASH MEASUREMENT...................................................................... |

38 |

5. ADJUSTMENTS.............................................................................. |

41 |

|

5.1 |

AXIS LIMITS SETUP...................................................................................... |

42 |

|

5.1.1 Zero Point Position and Motion Limit .............................................................................. |

43 |

|

5.1.2 Software Setting ................................................................................................................ |

48 |

|

5.1.3 Hard Stopper and Limit Switch Setting ............................................................................ |

50 |

5.2 |

ADJUSTING LIMIT SWITCH (OPTION)...................................................... |

55 |

5.3 |

MASTERING ................................................................................................... |

58 |

c-1

Table of Contents |

B-82135EN/01 |

|

|

5.3.1 |

General ............................................................................................................................. |

58 |

5.3.2 Resetting Alarms and Preparing for Mastering................................................................ |

59 |

|

5.3.3 Mastering to a Fixture (Master Position Master) ............................................................. |

60 |

|

5.3.4 |

Zero Degree Mastering..................................................................................................... |

65 |

5.3.5 |

Quick Mastering ............................................................................................................... |

68 |

5.3.6 |

Single Axis Mastering ...................................................................................................... |

69 |

5.3.7 |

Mastering Data Entry ....................................................................................................... |

72 |

6. REPLACING PARTS....................................................................... |

75 |

|

6.1 |

NOTE FOR PART REPLACEMENT ............................................................. |

76 |

6.2 |

REPLACING J1-AXIS MOTOR (M1) AND REDUCER .............................. |

78 |

6.3 |

REPLACING J2-AXIS MOTOR (M2) AND REDUCER .............................. |

85 |

6.4 |

REPLACING J3-AXIS MOTOR (M3) AND REDUCER .............................. |

90 |

6.5 |

REPLACING THE WRIST AXIS MOTORS (M4, M5, AND M6), |

|

|

WRIST UNIT AND J4 AXIS REDUCER95 |

|

6.6 |

SEALANT APPLICATION............................................................................. |

99 |

6.7 |

REPLACING MOTOR COVERS (OPTION) ............................................... |

100 |

7. PIPING AND WIRING.................................................................... |

101 |

|

7.1 |

PIPING DIAGRAM ....................................................................................... |

102 |

7.2 |

WIRING DIAGRAM ..................................................................................... |

103 |

8. REPLACING CABLES .................................................................. |

106 |

|

8.1 |

CABLE FORMING ....................................................................................... |

108 |

8.2 |

CABLE REPLACEMENT............................................................................. |

111 |

8.3 |

LIMIT SWITCH REPLACEMENT (OPTION) ............................................ |

122 |

II. CONNECTION

1. ROBOT INTERFERENCE AREA .................................................. |

129 |

|

1.1 |

External Dimensions ...................................................................................... |

130 |

1.2 |

Operation Area ............................................................................................... |

131 |

2. MECHANICAL COUPLING TO THE ROBOT............................... |

133 |

|

2.1 |

WRIST LOAD CONDITIONS ...................................................................... |

134 |

2.2 |

LOAD CONDITIONS ON J2-AXIS BASE AND J3-AXIS ARM ............... |

135 |

2.3 |

MECHANICAL COUPLING OF END EFFECTOR TO WRIST ................ |

136 |

2.4 |

EQUIPMENT MOUNTING FACE............................................................... |

137 |

2.5SETTING SYSTEM VARIABLES FOR MINIMUM CYCLE CONTROL 138

2.6 |

AIR SUPPLY (OPTION)............................................................................... |

141 |

2.7 |

INTERFACE FOR OPTION CABLE (OPTION) ......................................... |

142 |

3. TRANSPORTATION AND INSTALLATION.................................. |

154 |

|

3.1 |

TRANSPORTATION .................................................................................... |

155 |

3.2 |

INSTALLATION........................................................................................... |

160 |

c-2

B-82135EN/01 |

Table of Contents |

|

|

3.3 |

MAINTENANCE AREA ............................................................................... |

164 |

3.4 |

AIR PIPING (OPTION) ................................................................................. |

165 |

3.5 |

INSTALLATION SPECIFICATIONS........................................................... |

167 |

3.6 |

STORAGE ...................................................................................................... |

168 |

APPENDIX |

|

|

A. SPARE PARTS LIST ................................................................... |

171 |

|

B. CONNECTION DIAGRAM............................................................ |

175 |

|

C. PERIODIC MAINTENANCE TABLE ............................................ |

179 |

|

D. BOLT TIGHTENING TORQUE TABLE........................................ |

182 |

|

c-3

Table of Contents |

B-82135EN/01 |

|

|

I. MAINTENANCE

B-82135EN/01 |

MAINTENANCE |

1. CONFIGURATION |

|

|

|

1 CONFIGURATION

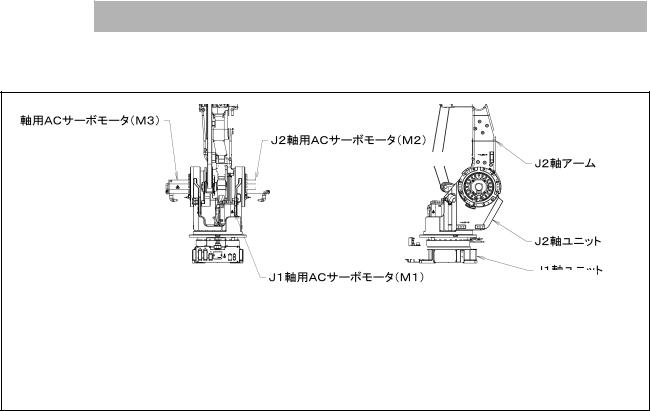

The configuration of the mechanical unit is shown in Fig. 1.

AC SERVO MOTOR (M6) |

|

END EFFECTOR |

|||

FOR J6-AXIS |

|

|

|||

|

|

MOUNTING FACE |

|||

|

AC SERVO MOTOR (M4) |

|

|||

|

|

|

|

||

|

FOR J4-AXIS |

|

|

||

|

J3-AXIS CASING |

WRIST UNIT |

|

||

|

|

|

|||

AC SERVO MOTOR (M5)

FOR J5-AXIS

AC SERVO MOTOR (M3)

FOR J3-AXIS AC SERVO MOTOR (M2)

FOR J2-AXIS

J2 AXIS ARM

|

|

J2 AXIS UNIT |

AC SERVO MOTOR (M1) |

|

J1 AXIS UNIT |

FOR J1-AXIS |

|

|

|

|

Fig. 1 Mechanical unit configuration

—— 3 ——

1. CONFIGURATION |

MAINTENANCE |

B-82135EN/01 |

|

|

|

1.1J1-AXIS DRIVE MECHANISM

Fig. 1.1 shows the J1-axis drive mechanism.

The rotation of the J1-axis motor (M1) fastened to the table is input to the reducer through the center gear, and the output rotates the table.

Motor (M1) for J1-axis

|

Center gear |

|

Pipe |

||

|

Pinion gear

Table

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J1-axis reducer |

|

|||

J1-axis base |

|

|

||||

|

|

|

|

|

||

(Hollow shaft) |

||||||

|

|

|||||

Fig. 1.1 J1-axis drive mechanism

—— 4 ——

Loading...

Loading...